Creping adhesive and process for creping tissue paper

A technology of dispersion liquid and cationic starch, which is applied in the direction of creping adhesive addition, adhesive type, textile and paper making, and can solve the problems of not being able to provide blade rate "rewetability" and degree of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

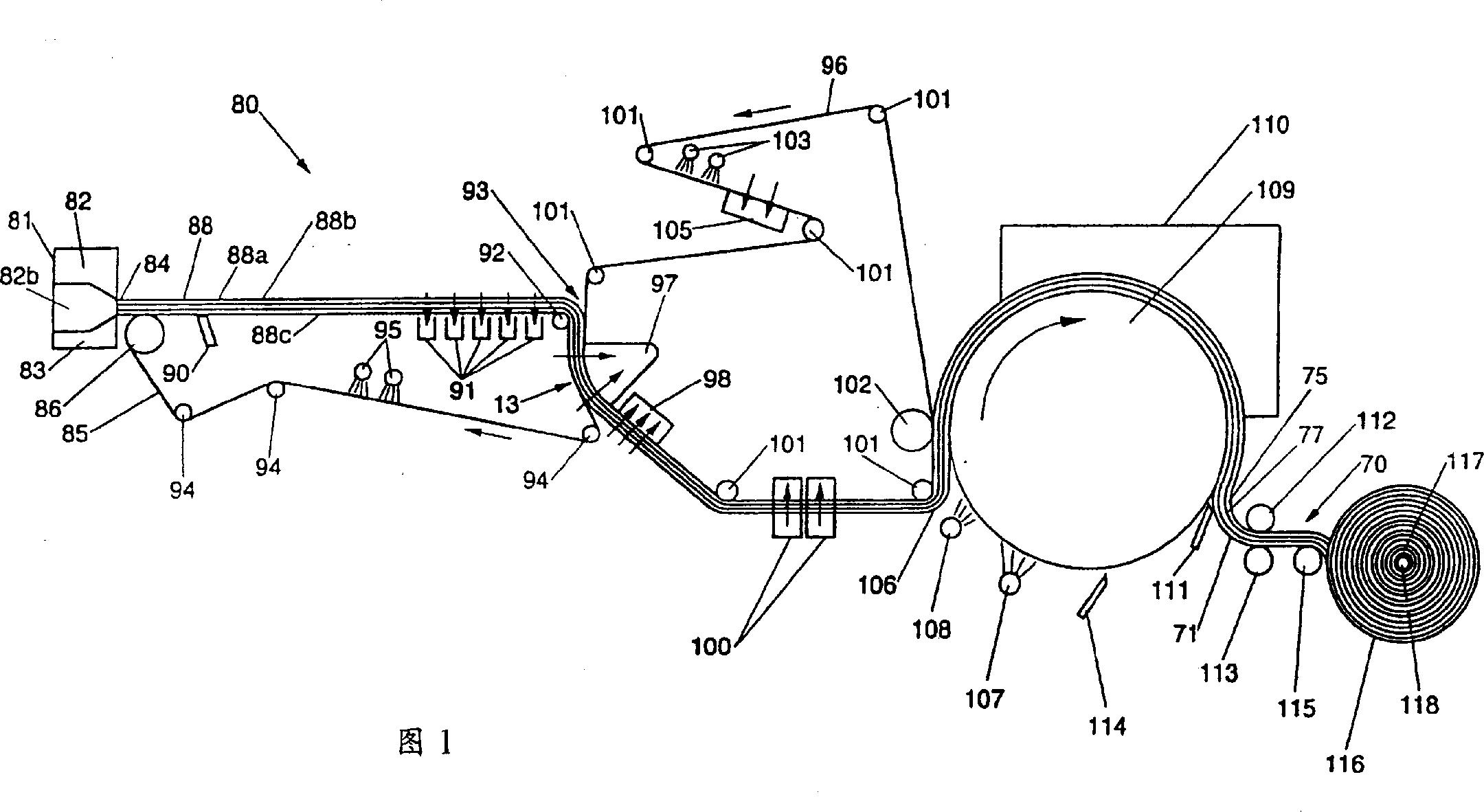

Image

Examples

Embodiment Construction

[0184] The following examples are provided to illustrate how to practice the invention. These examples are provided to help illustrate the present invention and should not be construed as limiting the scope of the present invention. The scope of the invention is limited only by the claims.

[0185] First, an aqueous slurry of northern softwood pulp (NSK) with a consistency of about 3% was prepared using a conventional pulper and fed into the headbox of the Fourdrinier paper machine through the raw material pipeline.

[0186] To impart temporary wet strength to finished products, Co-BOND 1000 is prepared 1% dispersion and it is sufficient to deliver 1% Co-BOND 1000 based on NSK fiber dry weight The rate is added to the NSK feedstock tube. The adsorption capacity of the temporary wet strength resin is increased by passing the treated slurry through an in-line mixer.

[0187] The NSK slurry was diluted with white water in a fan pump to a concentration of about 0.2%.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com