Creping methods using ph-modified creping adhesive compositions

一种粘合剂、组合物的技术,应用在皱纹纸的制造领域,能够解决粘合剂聚集等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

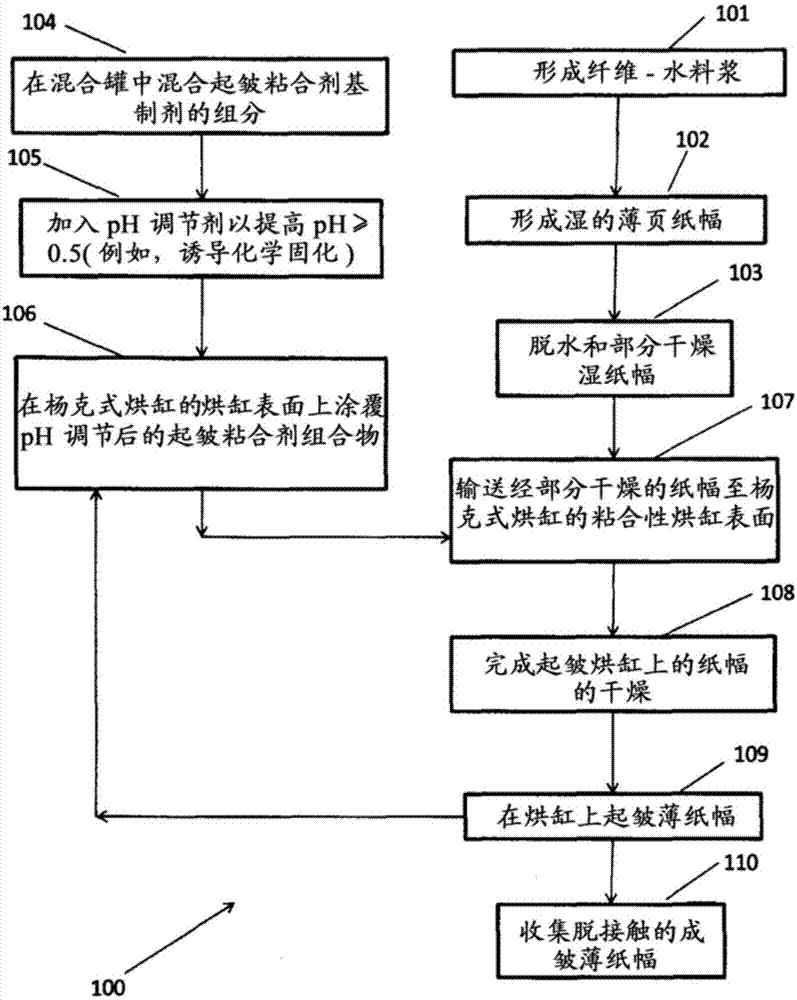

Method used

Image

Examples

Embodiment 1

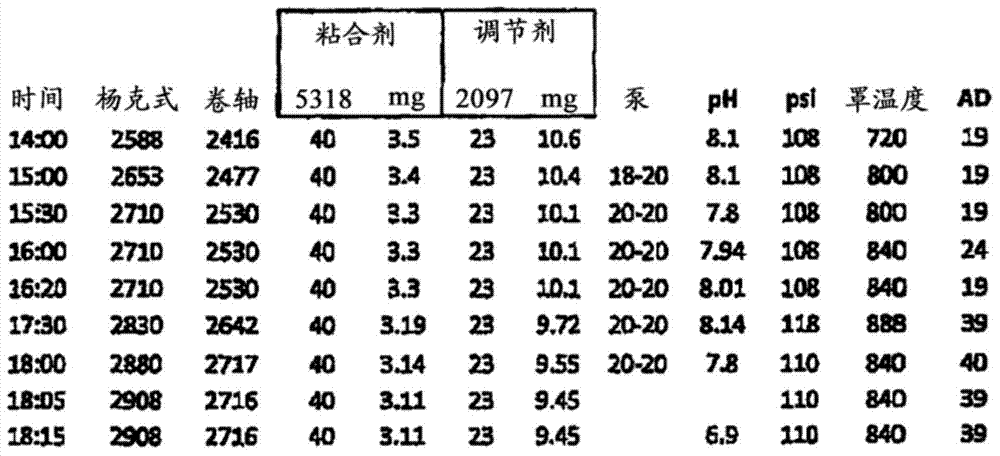

[0109] In this example, an adhesive base formulation was prepared comprising a polymer in an aqueous dispersion containing 5318 (commercial PAE creping adhesive (Hercules Inc.)) and 2097 (Beckman Laboratories International, Inc.) composition of mold release agents. The towel fiber sheet was creped using an 8 foot diameter Yankee dryer with a suction pressure roll. The pressure at the nozzle was about 108-110 psi, and the operating speed was adjusted from about 2600 feet per minute to about 2900 feet per minute (FPM). The machine is a semi-wet creping design with flat formers. The fiber sheet when transferred to the Yankee dryer has a moisture content of about 60-70% by weight and when the creped product is removed from the dryer the moisture content is about 15-20% by weight. Yankee dryer and mandrel speeds in feet per minute (FPM), pump settings, and dryer hood temperatures in degrees Fahrenheit (°F) were used in this study at image 3 indicated in the table. at about ...

Embodiment 2

[0111] A separate study was conducted on a 10 inch diameter Yankee dryer for creping napkin grade paper webs with a residence time of 22.5 milliseconds. A 10% by weight NaOH solution was fed into the mixing tank. Add about 10 ml / min of caustic. A similar composition of adhesive and release agent as used in Example 1 was also used in this example. The fiber sheet has a moisture content of about 60-70% by weight when transferred to the Yankee dryer and about 8-10% by weight when the creped product is removed from the dryer. Yankee dryer and reel speeds in feet per minute, pump settings, and Yankee temperature of 56°F were used in this study at Figure 4 indicated in the table. The initial pH was 5.9, then caustic was added to raise the pH to about 7.6. The coverage rate of 5318 adhesive can range from 3.1mg / m 2 Reduced to 2.4mg / m 2 (approximately 20% reduction) without streaks or chatter marks, and makes the release agent ( 2097) at 15.7mg / m 2 . An experienced technic...

Embodiment 3

[0113] A separate study was conducted on an 18-foot diameter Yankee dryer processing 12# tissue grade sheet with a moisture content of 12-14% by weight. A 10% by weight NaOH solution was added directly to the clean water in order to compensate for the concentration in the mixing tank. Add about 15-35 ml / min of caustic. In this example, an adhesive base formulation was prepared comprising a polymer comprising a composition of: in an aqueous dispersion, a commercially conditioned polyamine-type creping adhesive 2624 (Beckman Laboratories International) and release agent 2097. The fibrous sheet has a moisture content of about 65-70% by weight when transferred to the Yankee dryer and a moisture content of about 5-10% by weight when the creped product is removed from the dryer. The Yankee dryer speed is 4500-5500FPM, while the reel speed is 4000-4500FPM. The Yankee temperature is 180-210°F and the pressure is 90-110 psi. The initial pH is 5-6.5, and caustic is added to raise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com