Dryer cylinder coating establishing device and controlling method thereof

A control method and coating technology, applied in the field of papermaking, to achieve the best wrinkle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

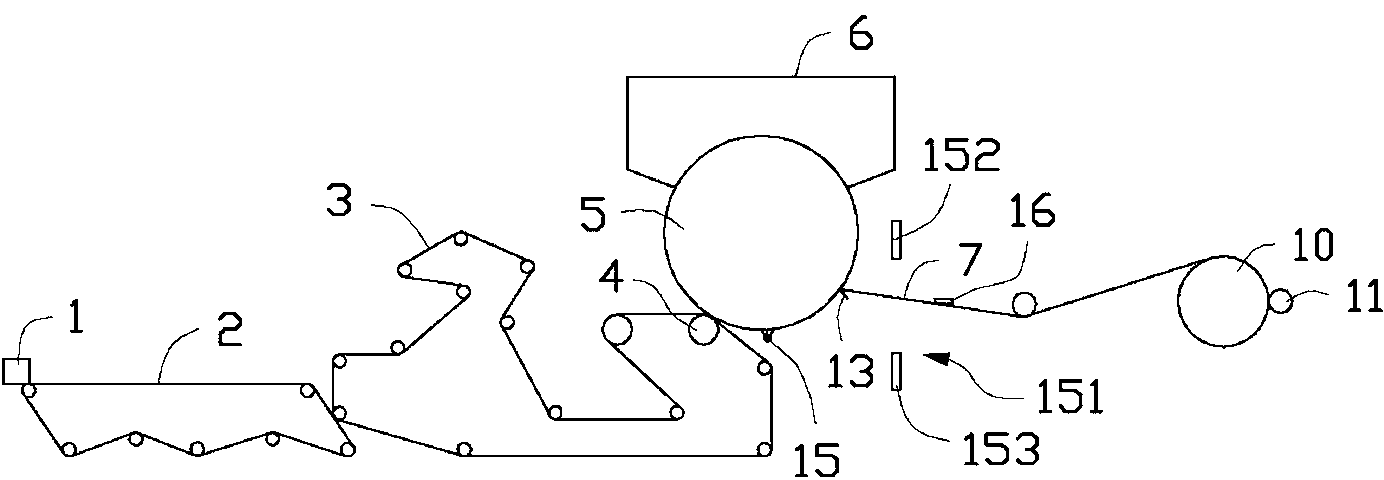

[0045] Please refer to figure 2 , the papermaking raw material slurry enters the paper machine head box 1 with a certain concentration, and the slurry forms paper 7 on the wire part 2, controls the dehydration amount of the paper machine wire part 2, felt part 3 and press part 4, and then transfers to the drying cylinder 5 to dry. Generally speaking, when the drying cylinder 5 is wrinkled after drying, the water content of the paper 7 is in the range of 1-20%. In this embodiment, the water content of the paper 7 is controlled at 3% when it is wrinkled.

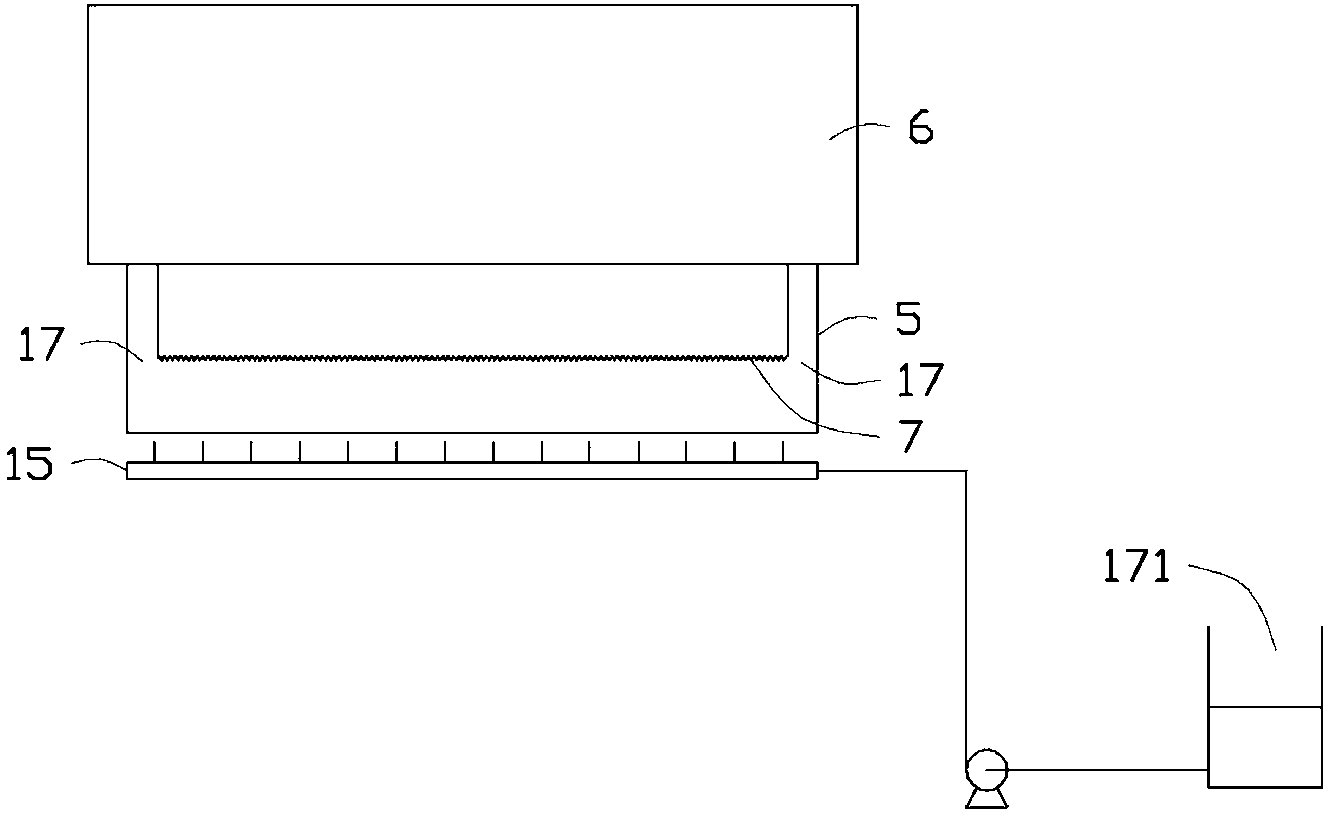

[0046] Please also refer to figure 1 , the coating 17 is established on the surface of the drying cylinder 5 by means of the coating material supply device 171 and the spraying device 15 . In this embodiment, two kinds of cylinder sticking agents are selected, and the hardness of the two kinds of cylinder sticking agents is different, and one oily peeling agent is selected. In addition, MAP (Mono ammonia phosphate) is sele...

specific Embodiment 2

[0049] Please refer to figure 2 , the papermaking raw material slurry enters the paper machine head box 1 with a certain concentration, and the slurry forms paper 7 on the wire part 2, controls the dehydration amount of the paper machine wire part 2, felt part 3 and press part 4, and then transfers to the drying cylinder 5 to dry. In this embodiment, the moisture content of the paper 7 during creping is controlled at 10%.

[0050] Please also refer to figure 1, the coating 17 is established on the surface of the drying cylinder 5 by means of the coating material supply device 171 and the spraying device 15 . In this embodiment, two kinds of cylinder sticking agents are selected, and the hardness of the two kinds of cylinder sticking agents is different, and one plastic release agent is selected. In addition, DAP (di ammonia phosphate) is selected as the protective agent for the drying cylinder 5 to protect the drying cylinder 5 from corrosion caused by the wet end. Contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com