Method and application of dyeing and finishing of pure cotton fabrics

A processing method and fabric technology, applied in the direction of dyeing method, improved handle fiber, dry-cleaning fiber products, etc., can solve the problems of poor fabric feel, high cost, low efficiency of sand washing process, etc., and achieve good alkali resistance and soft feel , Improve the effect of color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

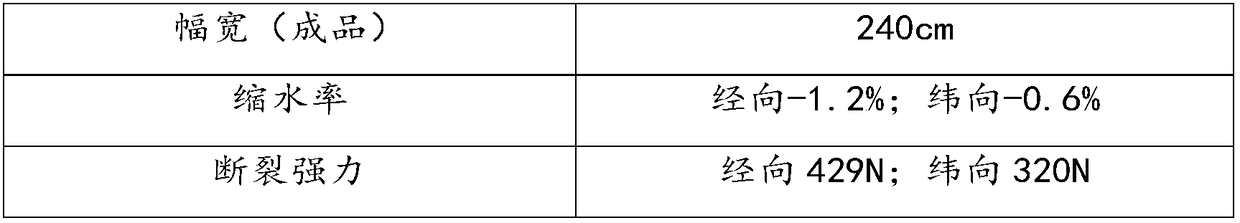

Embodiment 1

[0083] Gray fabric: pure cotton 40s / 110×90 non-mercerized semi-finished product

[0084] The above-mentioned gray cloth after the pretreatment is processed through the following steps in turn:

[0085] Dyeing (jig dyeing): the reactive dye used is reactive blue 198 (two monochloro-s-triazine reactive dyes), the concentration is 0.4% owf; the number of dyeing passes is 4, and each pass runs for 20 minutes. Carry out dyeing promotion, the number of channels for promoting dyeing is 4, each channel runs for 20 minutes, add alkali to fix the color, the number of channels for color fixing is 4;

[0086] Sand washing: the dyed fabrics enter the overflow machine for sand washing, add a mixture of 20g / L sodium metasilicate and 20g / L sodium bicarbonate as sand washing aids, first raise the temperature to 98°C, keep warm for 20min, and then Then cool down to 40°C, keep warm for 30 minutes, and drain;

[0087] Water washing: first wash with hot water at 80°C for 10 minutes twice; then e...

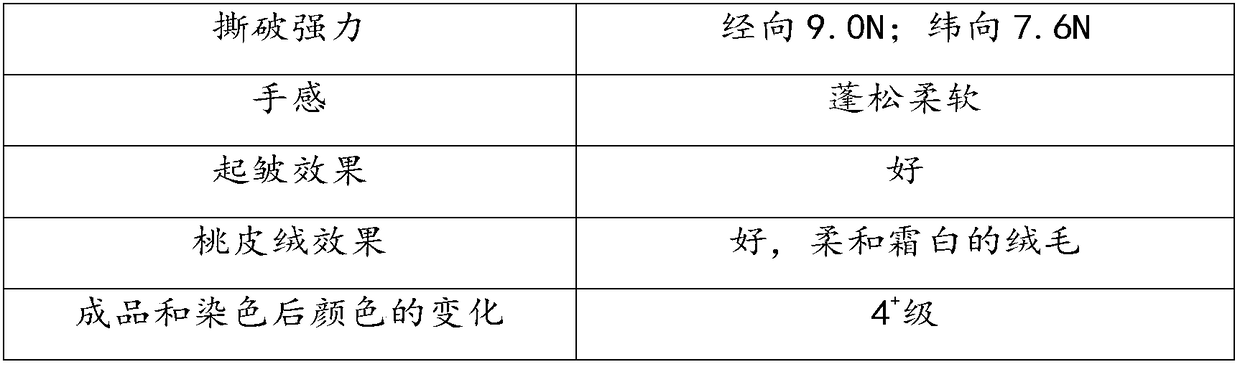

Embodiment 2

[0128] Gray fabric: pure cotton 40s / 110×90 non-mercerized semi-finished product

[0129] The above-mentioned gray cloth after the pretreatment is processed through the following steps in turn:

[0130] Dyeing (jig dyeing): the reactive dye used is reactive blue 268 (two-fluoro-s-triazine group reactive dye), the concentration is 0.3% owf; the number of dyeing passes is 4, and each pass runs for 20 minutes, adding sodium sulfate Carry out dyeing promotion, the number of channels for promoting dyeing is 4, each channel runs for 20 minutes, add alkali to fix the color, the number of channels for color fixing is 4;

[0131] Sand washing: the dyed fabrics enter the overflow machine for sand washing, add a mixture of 20g / L sodium metasilicate and 20g / L sodium bicarbonate as sand washing aids, first raise the temperature to 98°C, keep warm for 20min, and then Then cool down to 40°C, keep warm for 30min, and drain;

[0132] Water washing: first wash with hot water at 80°C for 10 min...

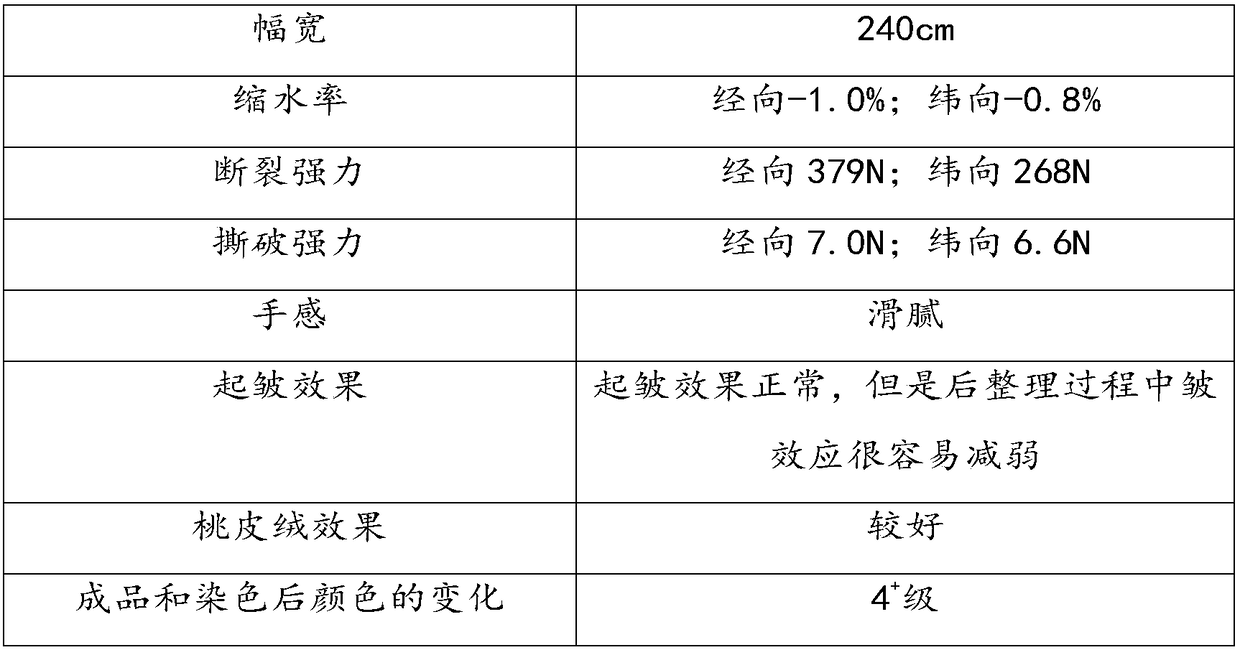

Embodiment 3

[0139] Gray fabric: pure cotton 40s / 110×90 non-mercerized semi-finished product

[0140] The above-mentioned gray cloth after the pretreatment is processed through the following steps in turn:

[0141] Dyeing (jig dyeing): the reactive dye used is reactive blue 198 (two monochloro-s-triazine group reactive dyes), the concentration is 0.5% owf; the number of dyeing passes is 2, and each pass runs for 20 minutes, adding sodium sulfate Carry out dyeing promotion, the number of channels for promoting dyeing is 2, each channel runs for 20 minutes, add alkali to fix the color, and the number of channels for color fixing is 4;

[0142] All the other are identical with embodiment 1.

[0143] The finished product obtained in Example 3 was tested, and the test results are shown in Table 7.

[0144] The detection result of table 7 embodiment 3

[0145]

[0146]

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com