Patents

Literature

119results about How to "Even friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

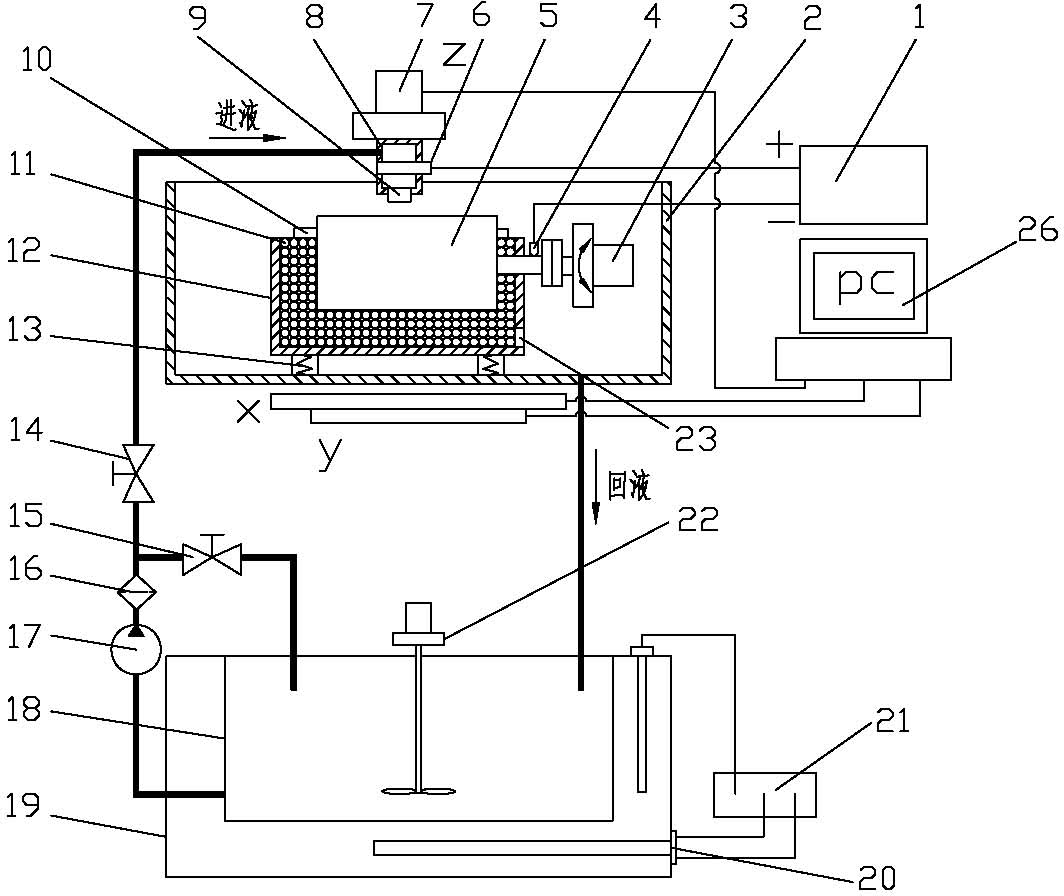

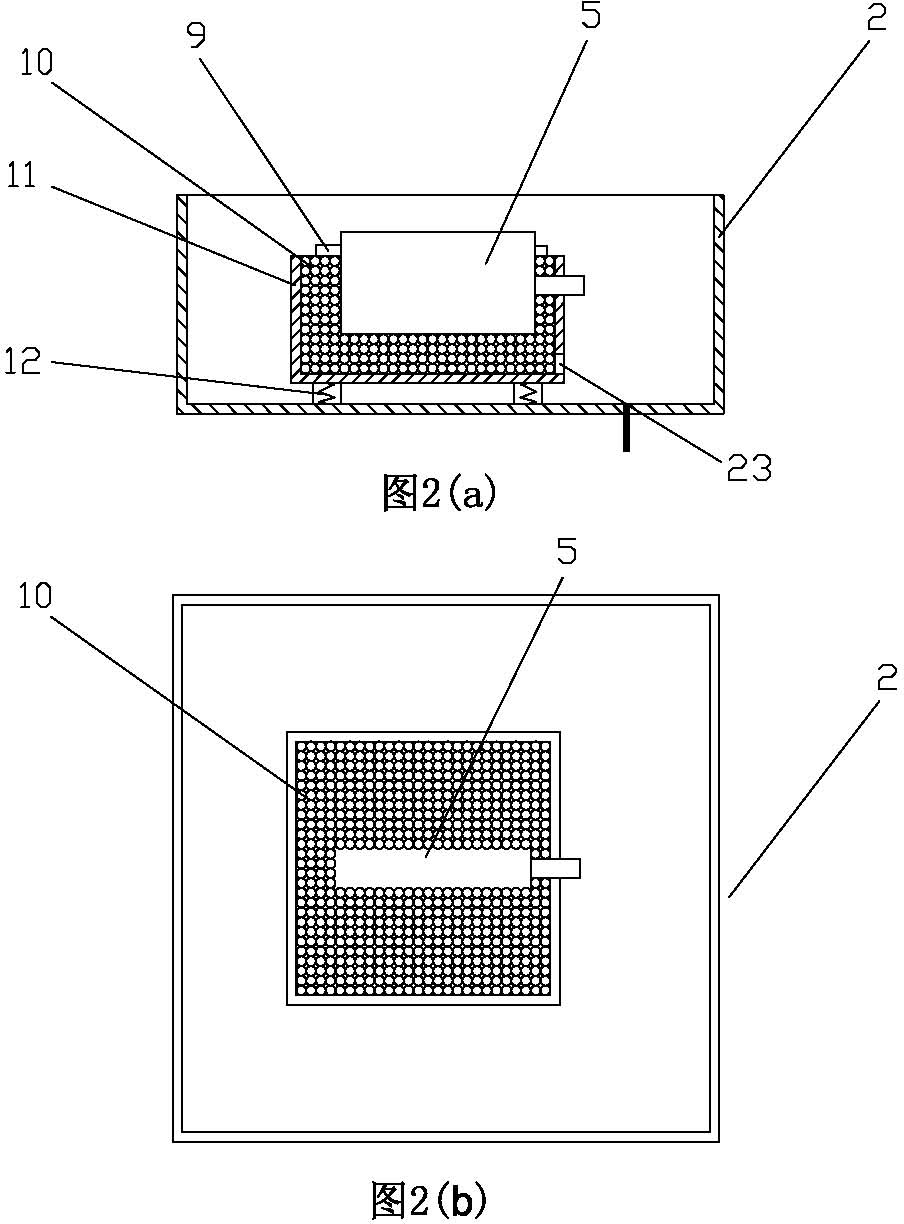

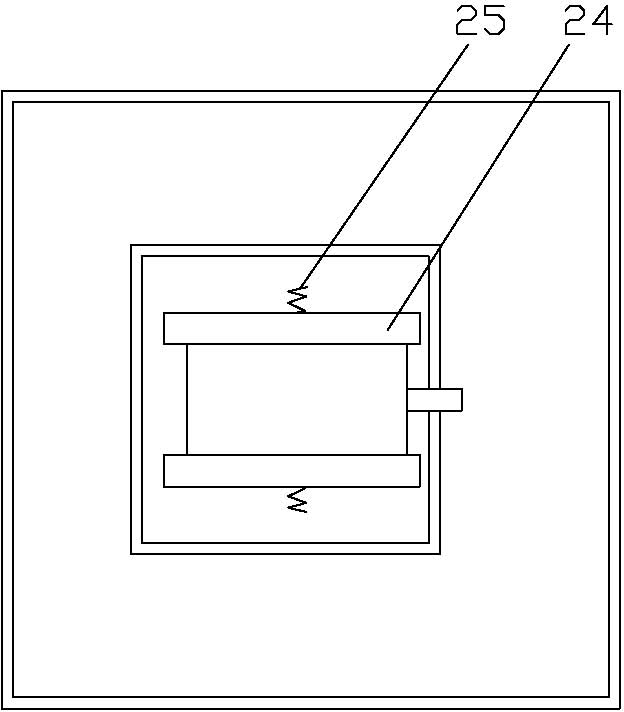

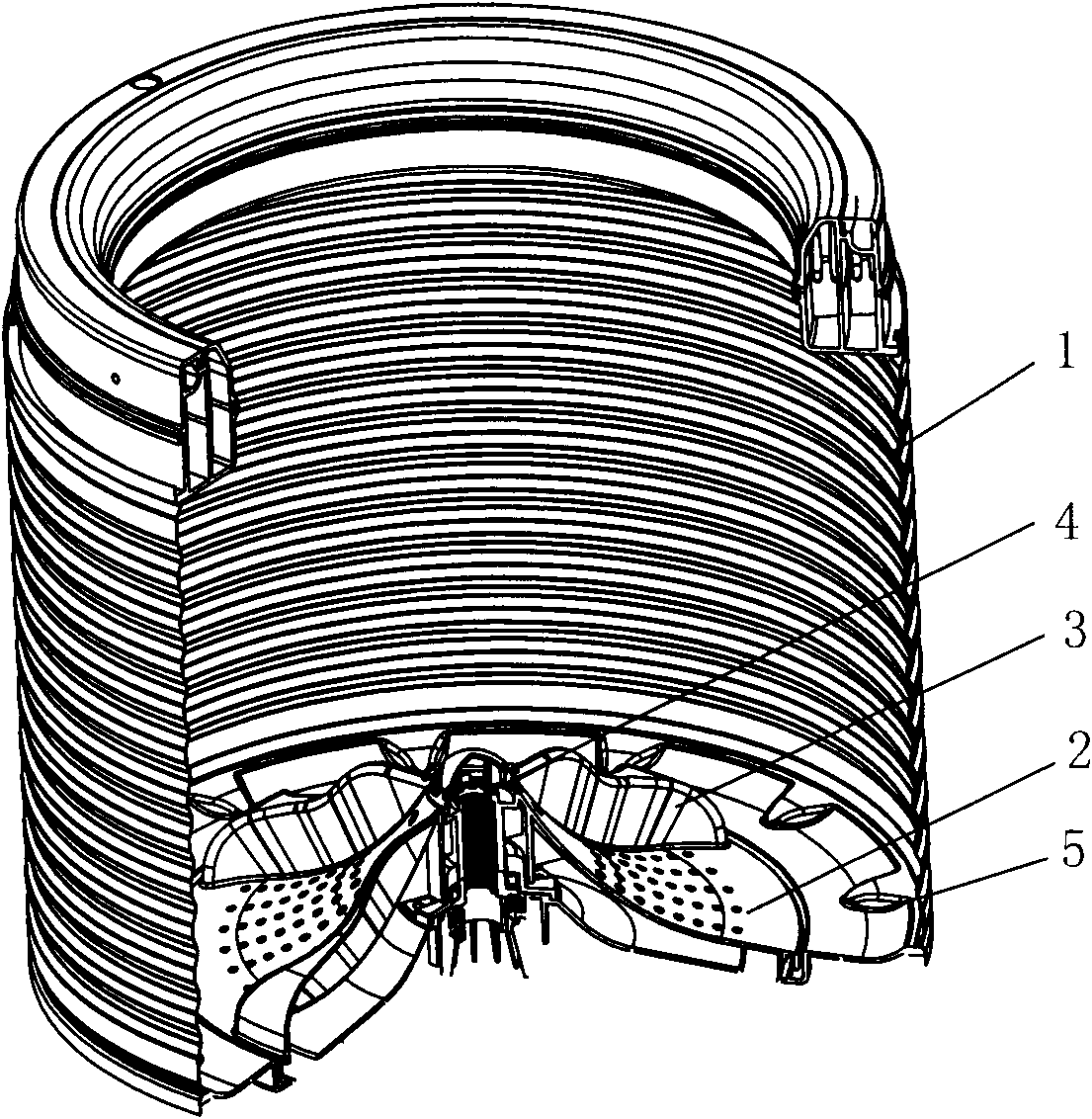

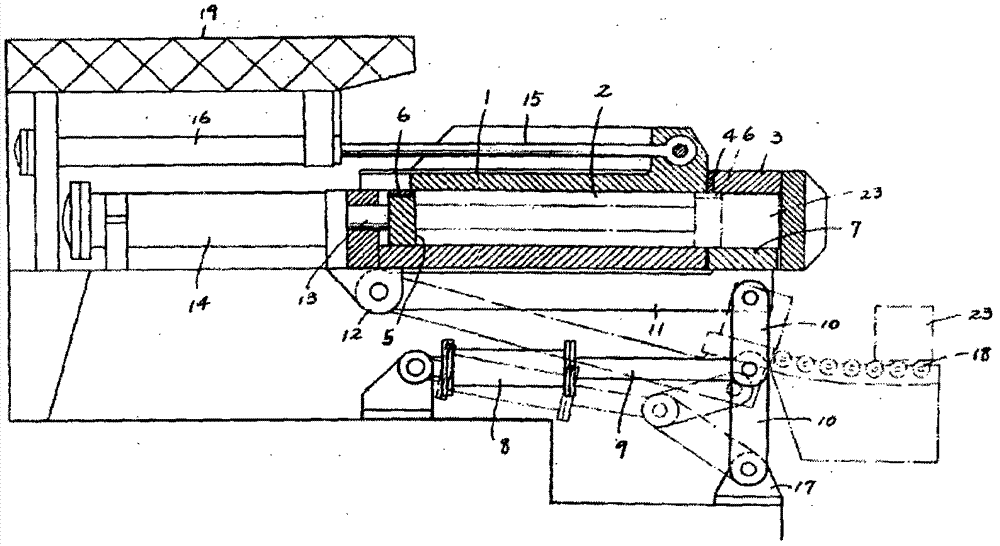

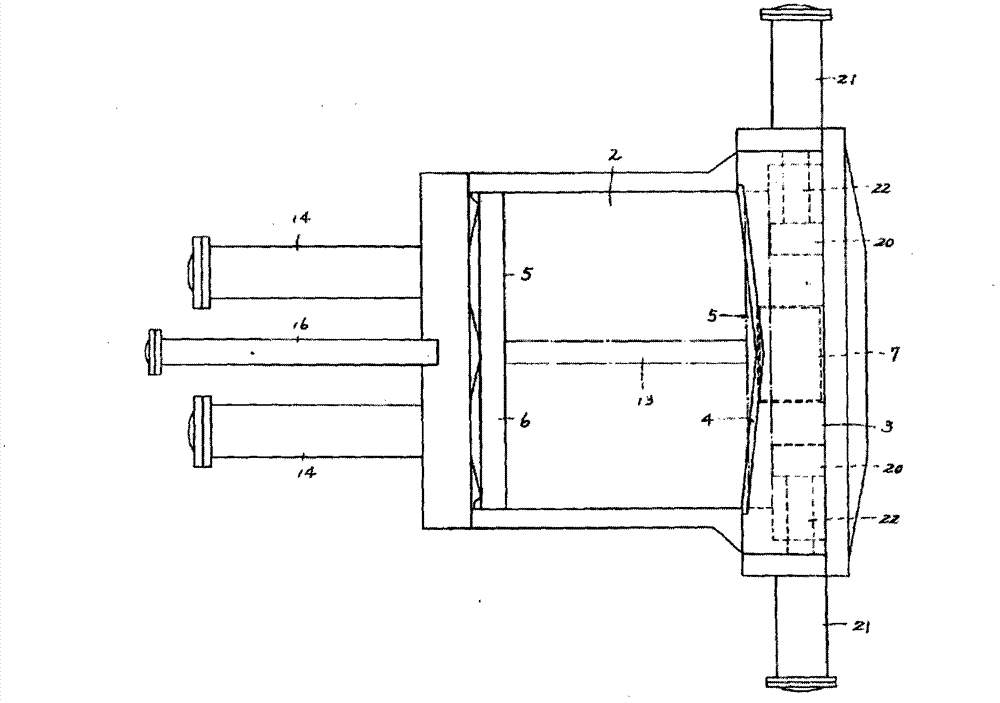

Method and device for processing revolving parts by high-speed jet injection electroforming

InactiveCN101994137AReduce thicknessOvercome timeElectroforming processesTemperature controlControl system

The invention provides a method and device for processing revolving parts by high-speed jet injection electroforming. The method is characterized in that an electroforming core mould is partially buried in an electroforming groove which is filled with hard particles or is in direct contact with a plated negative pole surface through a friction piece, so that the defects of accumulated tumors, burrs and the like on a deposition surface can be effectively removed by the friction of the hard particles or the friction piece on an electroforming layer; and a computer is used for controlling a jet nozzle to scan along with a certain track and cooperates with the rotary motion of the electroforming core mould at the same time, so that the exposed electroforming core mould surface is subjected to selective scanning electroforming so as to pile up the required parts layer by layer. The device of the invention mainly comprises a table movement mechanism, a negative pole rotation drive device, a control system, a temperature control device, an electroforming liquid circulating filter system and the like. The method and device for processing the revolving parts by high-speed jet injection electroforming of the invention are adopted, thus not only effectively removing the defects of hard spots, air holes, accumulated tumors and the like on the electroforming layer surface and manufacturing the electroforming layer with compact and even texture at higher deposition speed, but also abandoning the complicated negative pole female die of the traditional electroforming and rapidly and efficiently forming the revolving parts with different shapes and wall thicknesses by one step.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

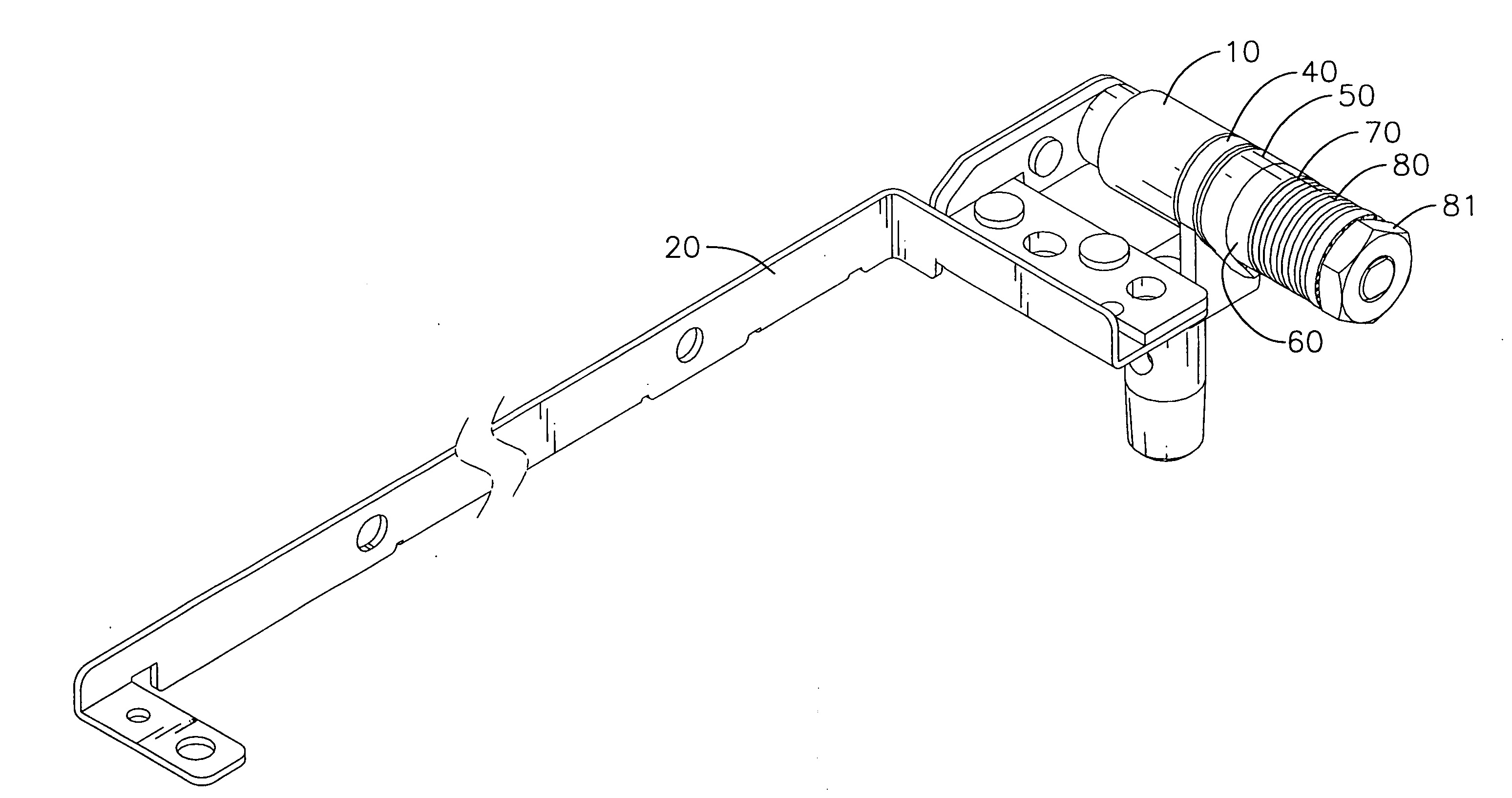

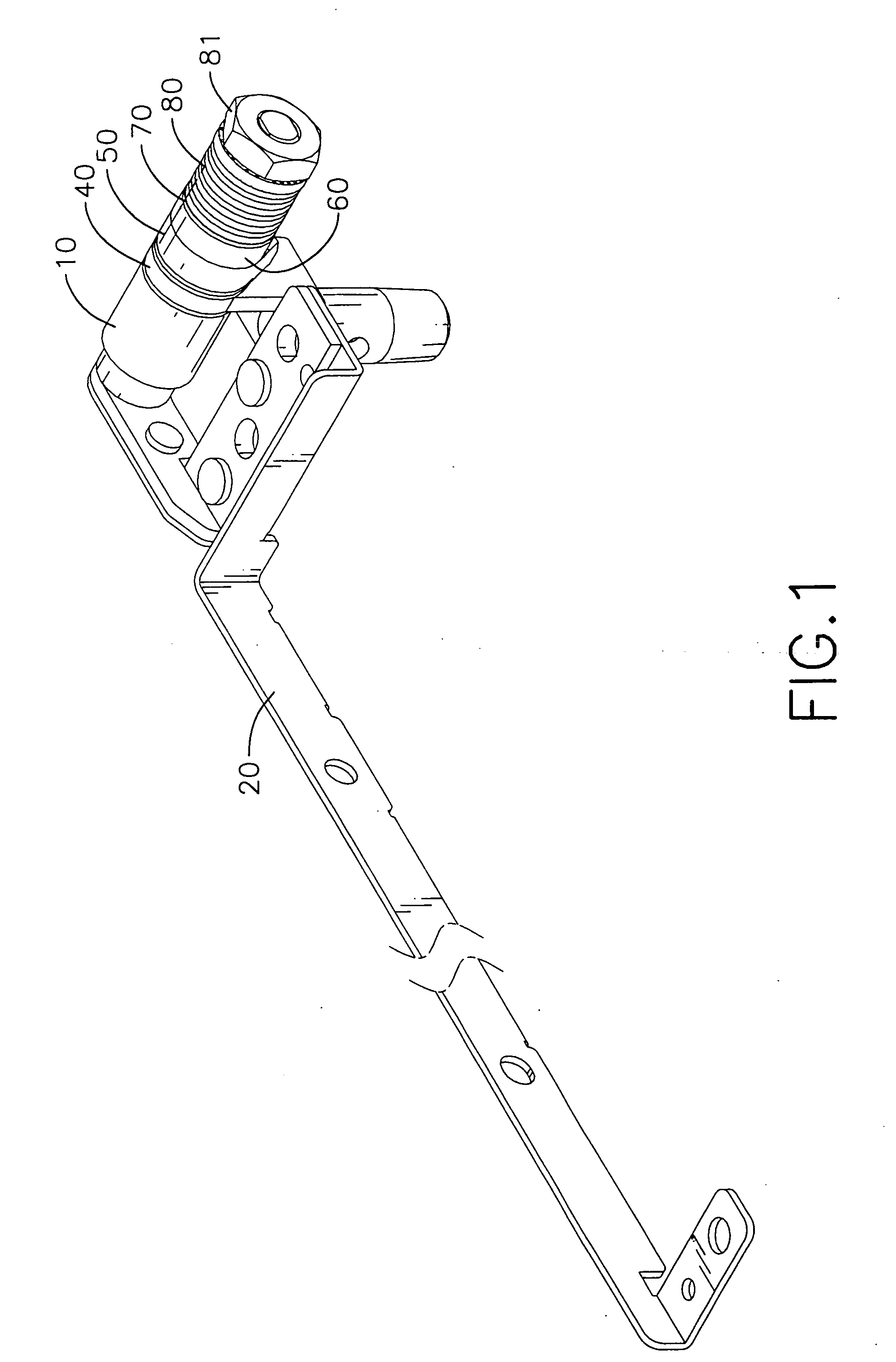

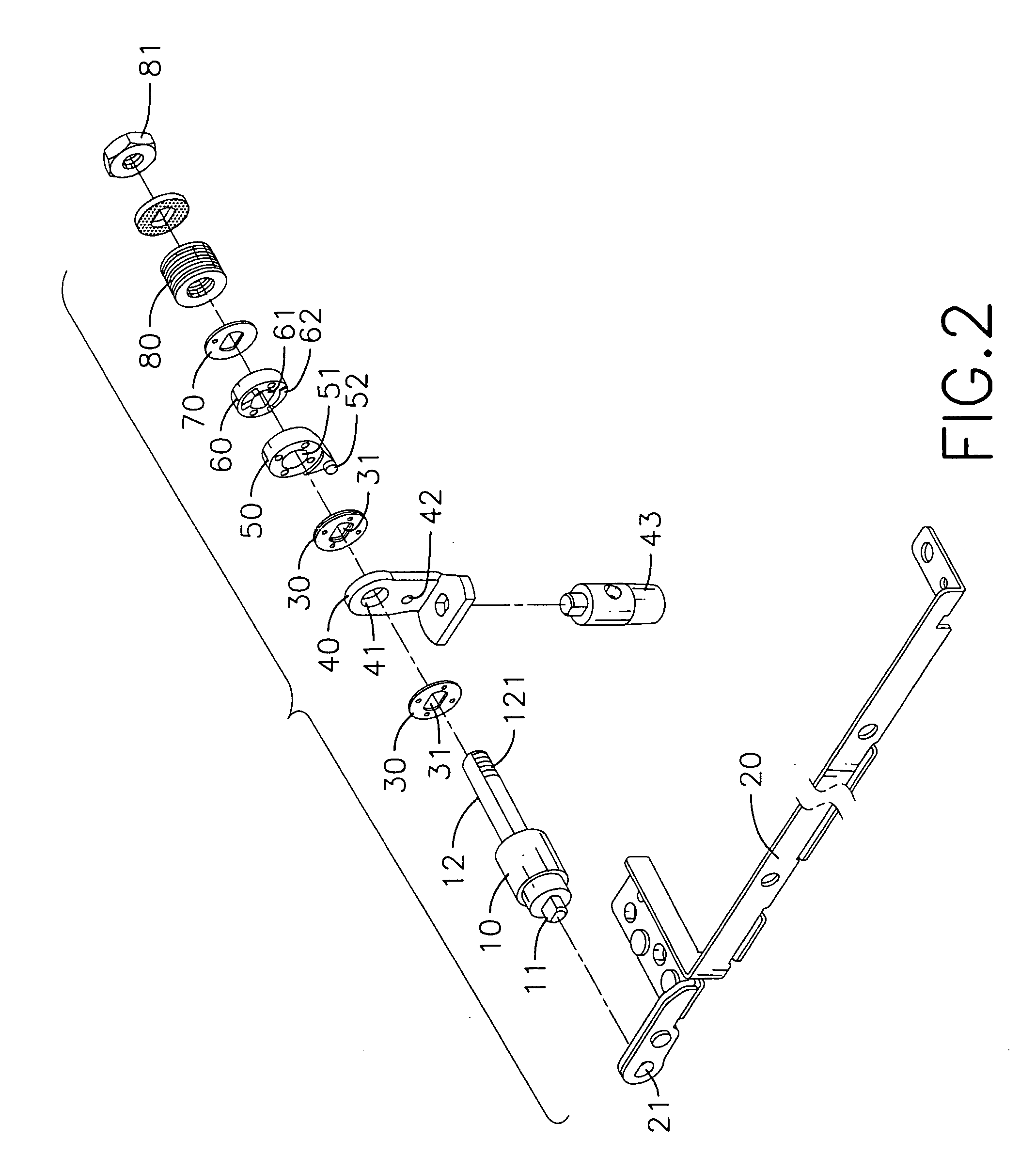

Hinge with less noise

InactiveUS20070199179A1Less noiseSecurely mountedBuilding braking devicesWing fastenersEngineeringGasket

A hinge pivotally connects to a cover and a base of an electrical appliance and has a stationary-positioning element, a rotating-positioning element and a buffering spacer. The stationary-positioning element is mounted securely in the base and has at least one positioning protrusion. The rotating-positioning element is mounted securely in the cover and has at least one positioning detent corresponding to the positioning protrusion when the cover is closed. The buffering spacer is attached to the rotating-positioning element to let the stationary-positioning element and the rotating-positioning element in constant contact, which results in friction between the stationary-positioning element and the rotating-positioning element being uniform. Therefore, the hinge as described makes less noise.

Owner:SHIN ZU SHING

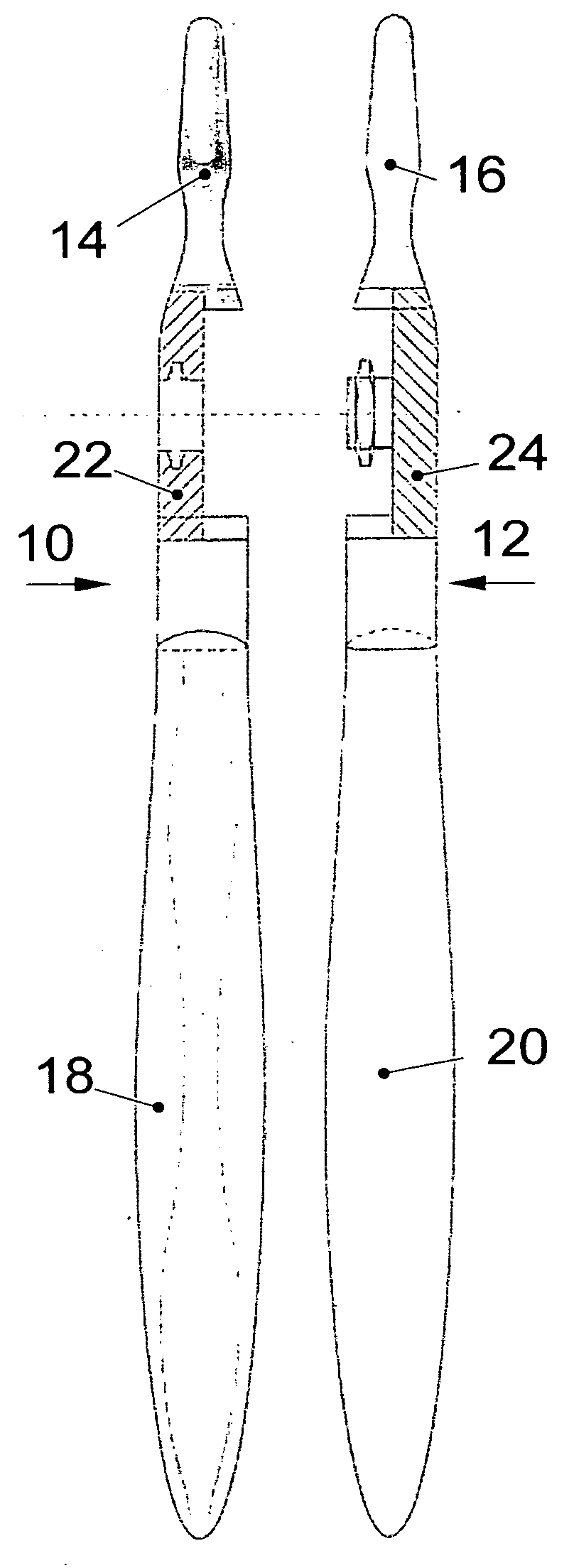

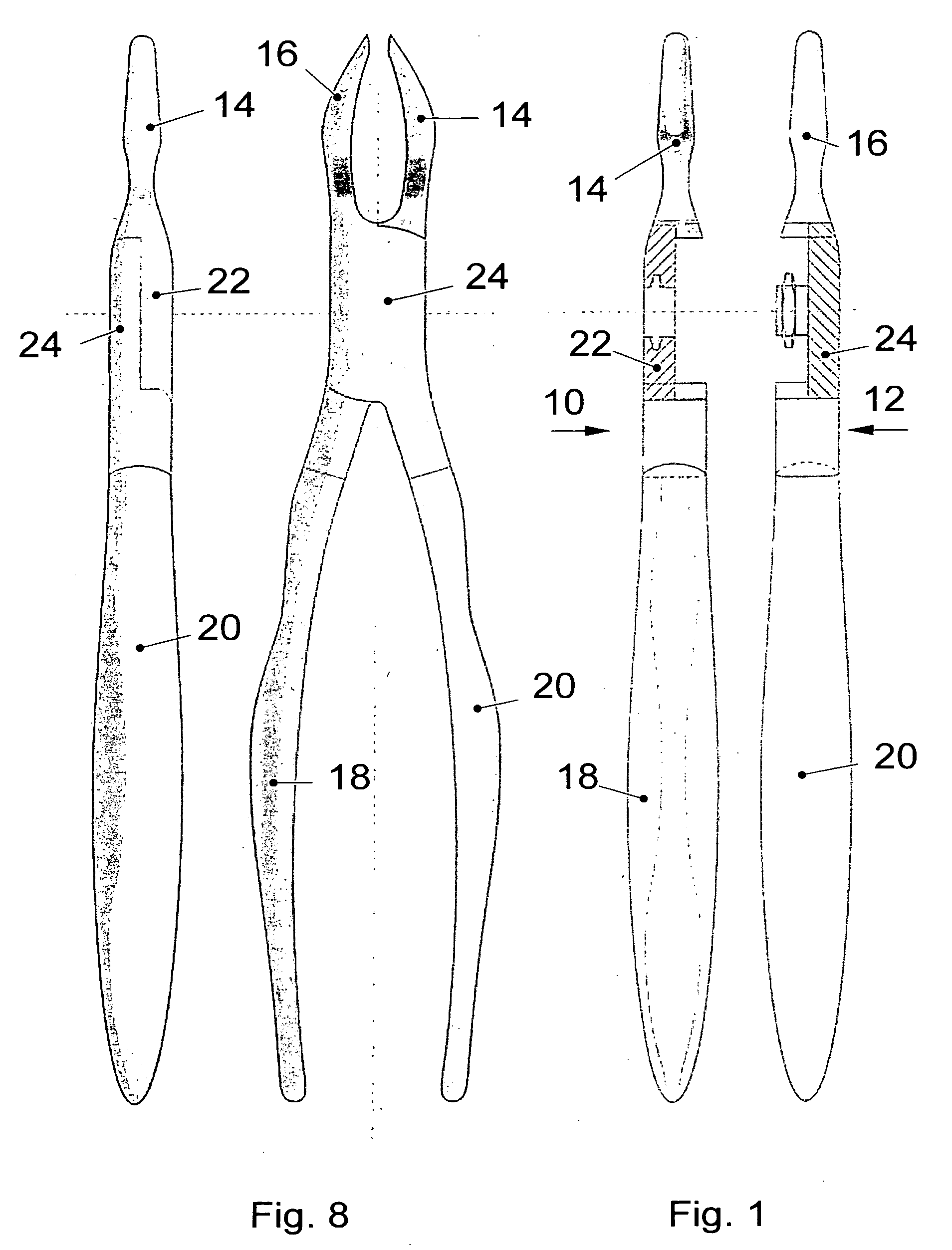

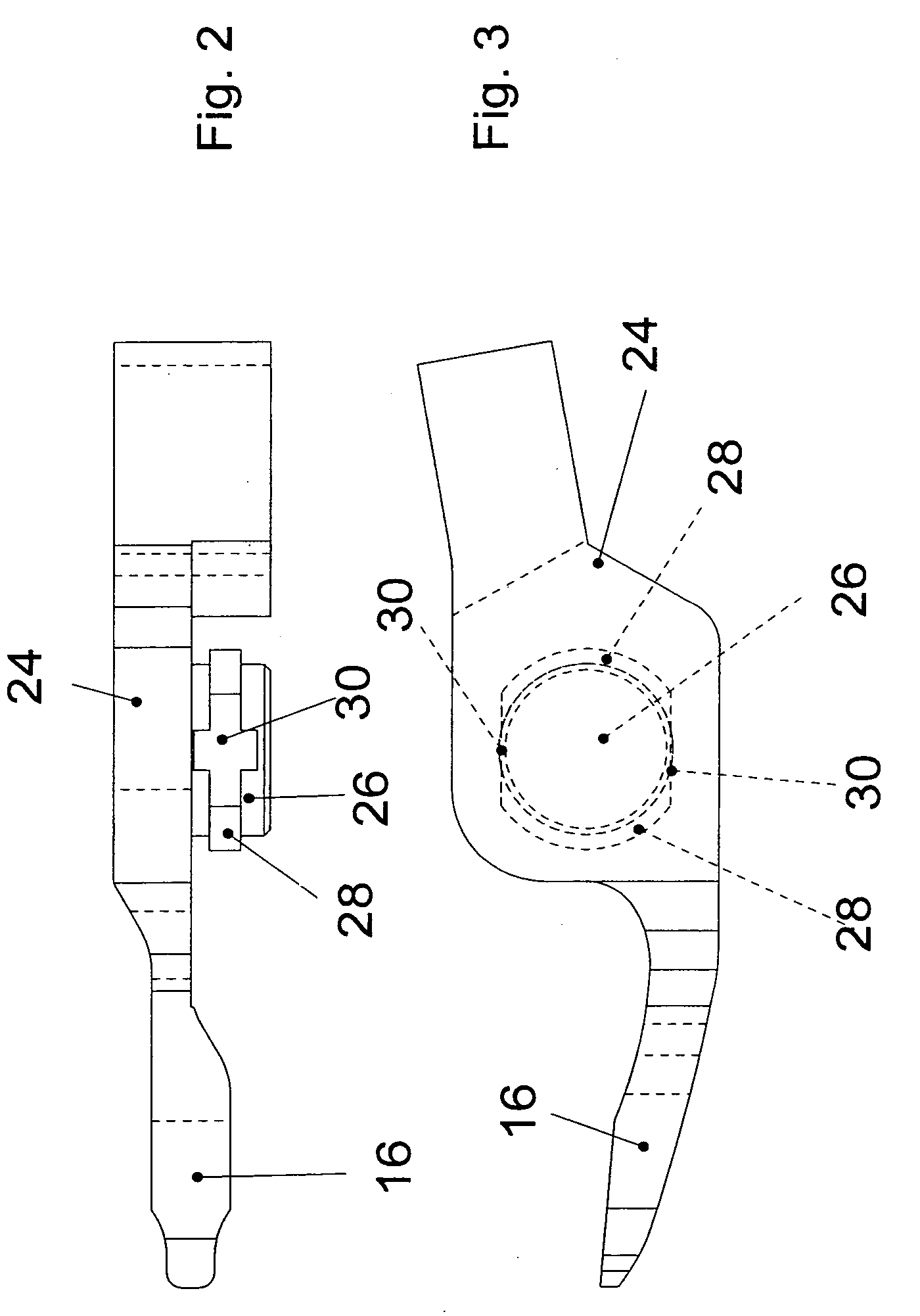

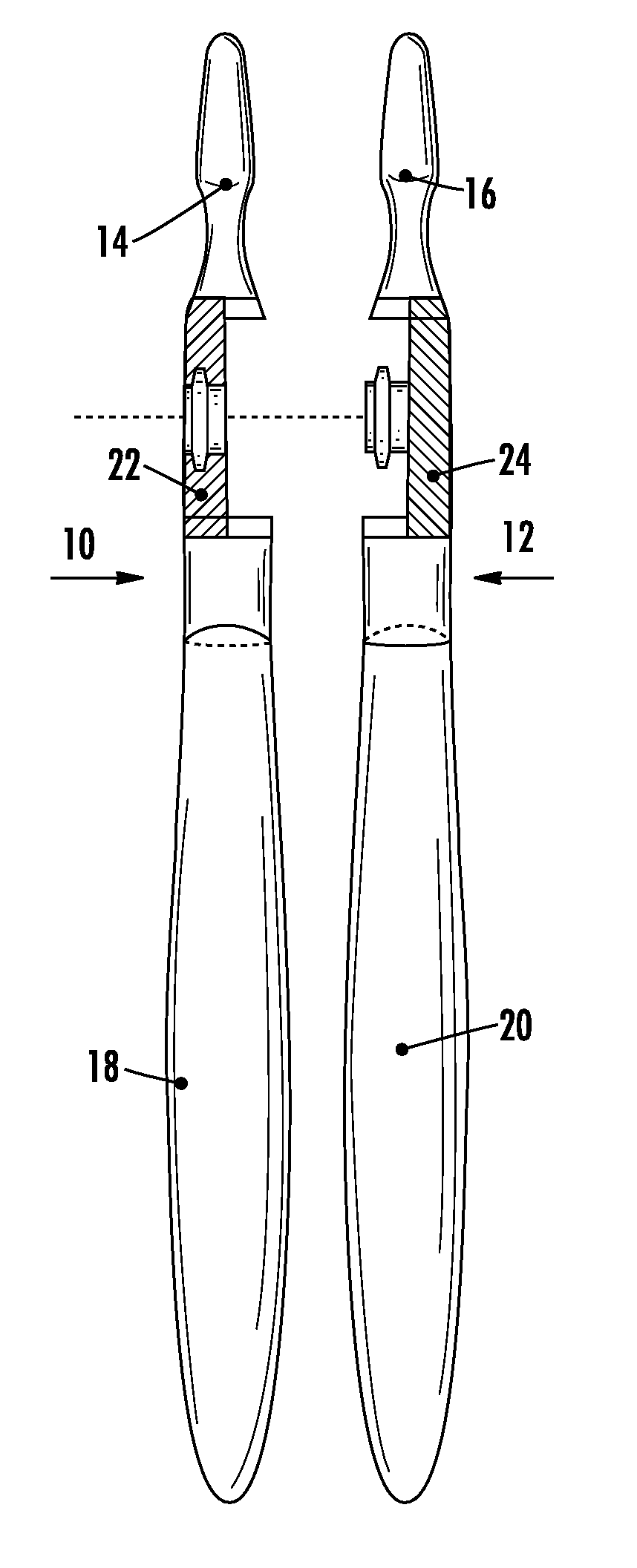

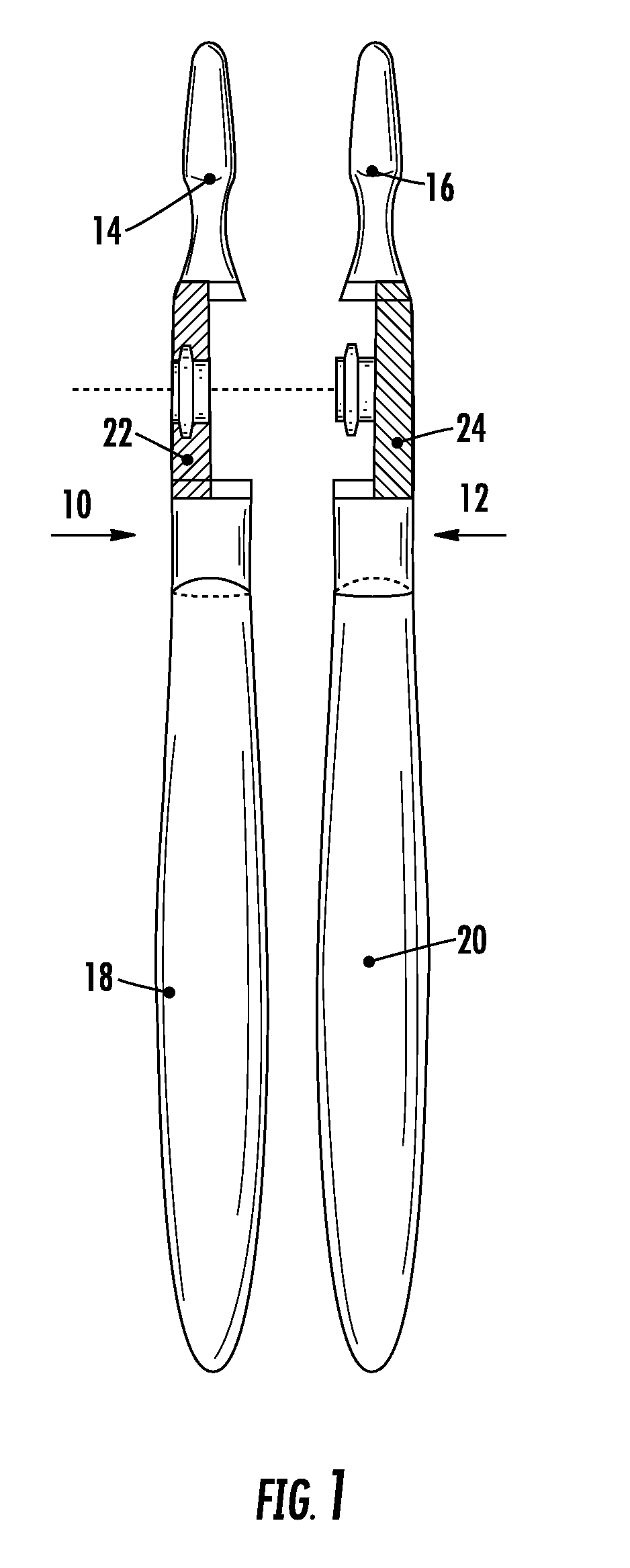

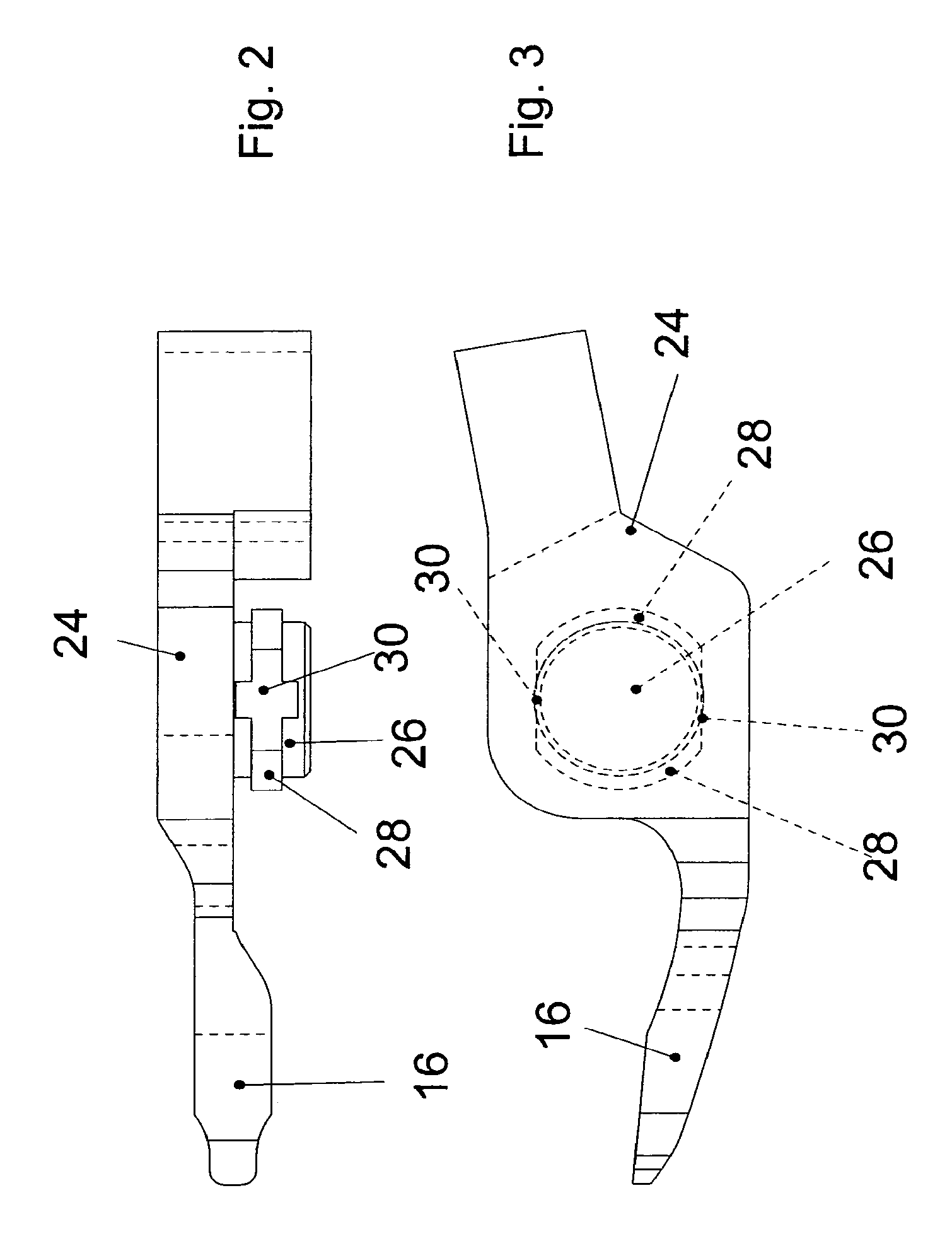

Dental pliers

InactiveUS20050186536A1Reduce manufacturing costReduce material costsDentist forcepsDiagnosticsEngineeringLinkage concept

Dental pliers with two pliers parts, each respectively comprising one jaw of a pliers mouth and one lever arm of a pliers grip, the pliers parts pivotably connected with each other via a linkage. The linkage includes a cylindrical journal (26) on the first pliers part (12) coaxial to the pivot axis, which engages in a cylindrical bore (32) on the other pliers part (10) coaxial to the pivot axis having the same diameter, and is rotatable in this bore (32) about the pivot axis. The journal (26) and the bore (32) are axially located form-fittingly via at least one circumferential tab (28) and one circumferential groove (34). The at least one circumferential tab (28) extends only over a partial angular area of the circumference. At least one entry segment (36) corresponding to the cross-sectional shape of the circumferential tab (28) leads axially to the circumferential groove (34). The at least one circumferential tab (28) and the at least one entry segment (36) are so oriented in their angular orientation in the respective linkage area (22) or as the case may be (24), that these come into registry with each other in the open or spread position of the pliers parts (10, 12), and the at least one circumferential tab (28) can be introduced into the circumferential groove (34) through the entry segment (36) or as the case may be removed therefrom, while in the other spread positions of the pliers parts (10, 12) the at least one circumferential tab (28) engages in the circumferential groove (34) and is held form-fittingly axially therein.

Owner:INTEGRA YORK PA

Method for processing rectangular-tooth spline sleeve using 42CrMoE high-quality alloy steel as material

InactiveCN102534374AImprove wear resistanceImprove bending abilityCouplings for rigid shaftsPhosphorylationThermal treatment

The invention discloses a method for processing a rectangular-tooth spline sleeve using 42CrMoE high-quality alloy steel as a material, belonging to the technical field of thermal treatment. The method comprises the steps of: free forging of a blank, normalizing treatment, rough turning, hardening and tempering thermal treatment, finish turning, spline drawing, drilling, burr gripping, carburization treatment, surface deposition treatment, phosphorylation treatment, electroplating, drying and detection. In the invention, due to the new material and new technology, the wear resistance of the produced rectangular-tooth spline sleeve is greatly enhanced, the phenomenon of crack of the rectangular-tooth spline sleeve is avoided, the surface is smooth, the friction is low, the heat dissipation is good, and the service life is prolonged, thus the processing technology is widely applied.

Owner:无锡市万邦机械制造厂

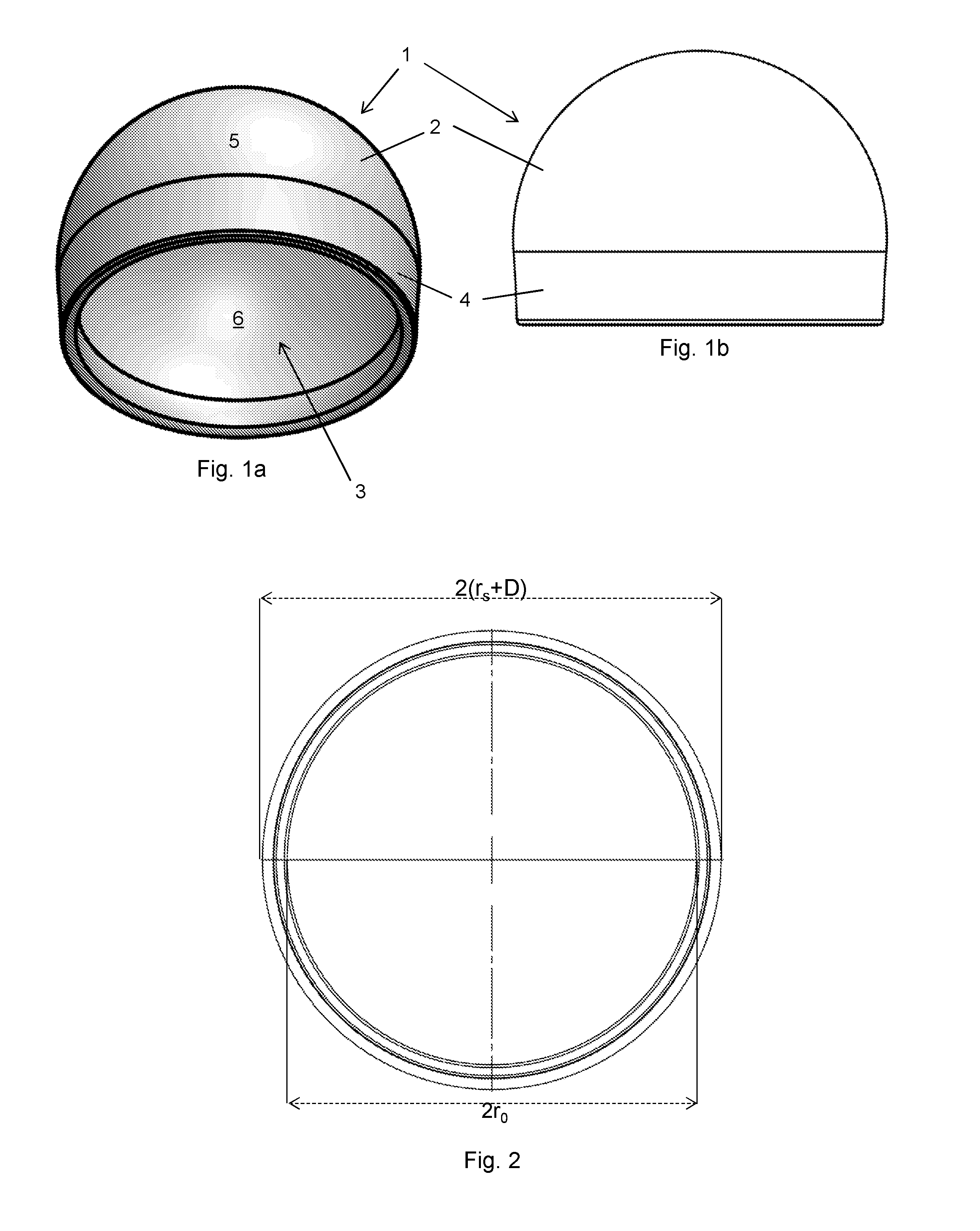

Medical Implant for Reducing Pain in Diseased Joints

ActiveUS20150335437A1Reduce interventionExpense can be limitedSurgeryJoint implantsDiseaseJoint pain

The present invention relates to a medical implant for reducing pain in diseased joints such as synovial joints, in particular ball and socket joints such as the hip joint and the shoulder joint. One embodiment relates to a medical implant for attachment to and at least partly covering the femoral head, said medical implant comprising a dome shaped shell with an orifice, said shell having a height h1, an equatorial shell radius rs and an orifice radius ro wherein the shell radius rs>ro, and h1>rs, and the orifice is defined by a circumferential rounded edge.

Owner:BISPEBJERG HOSPITAL

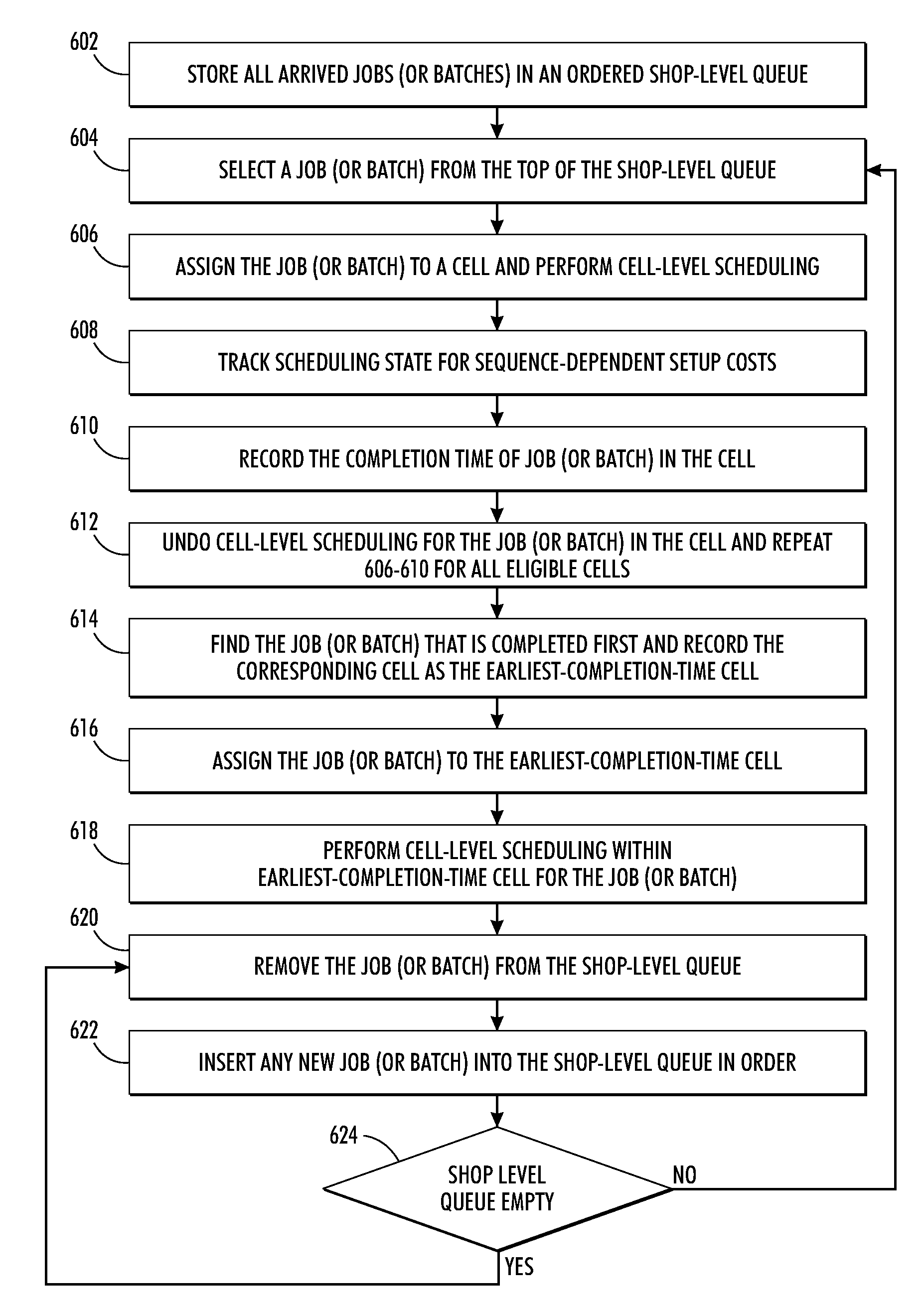

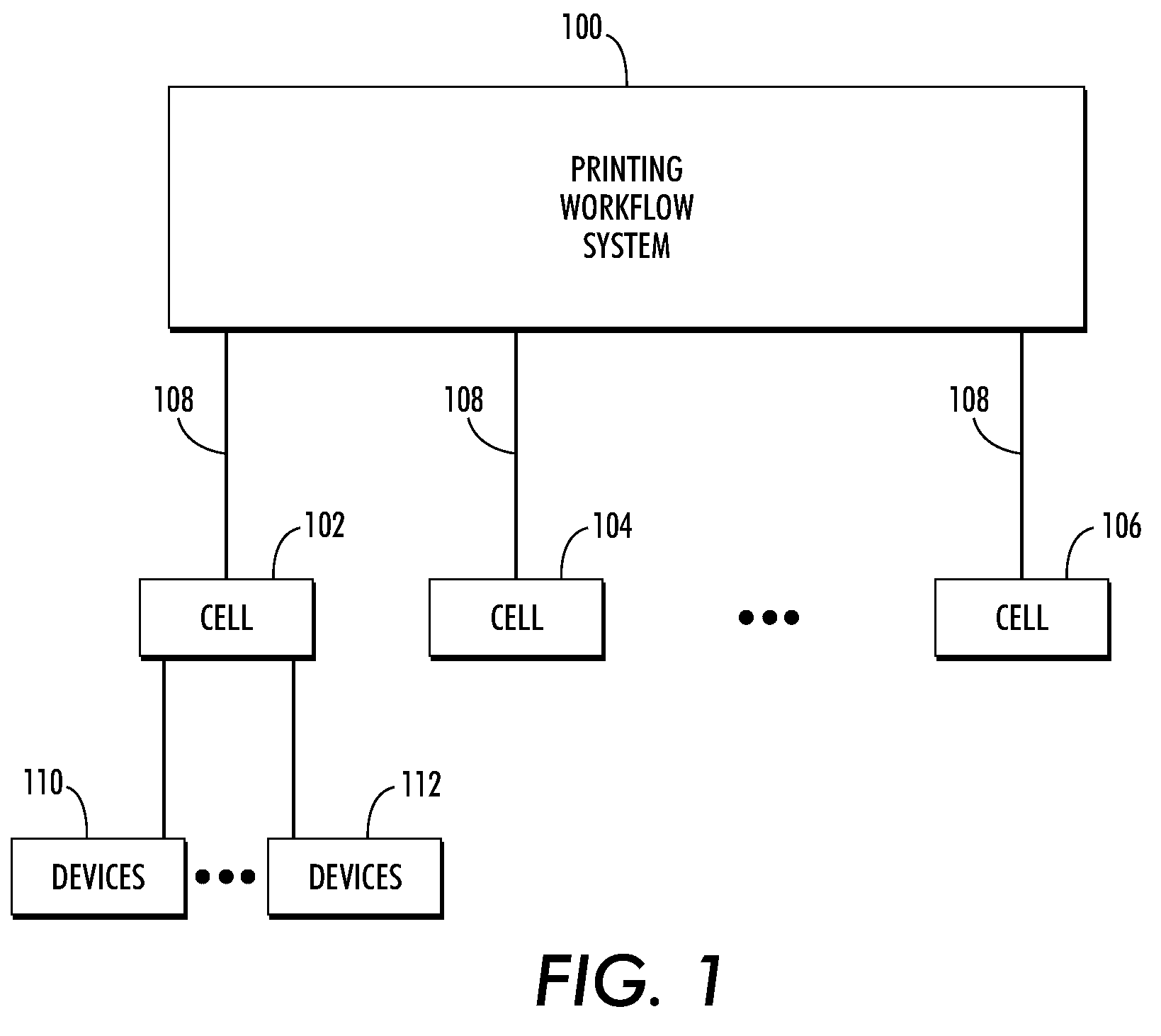

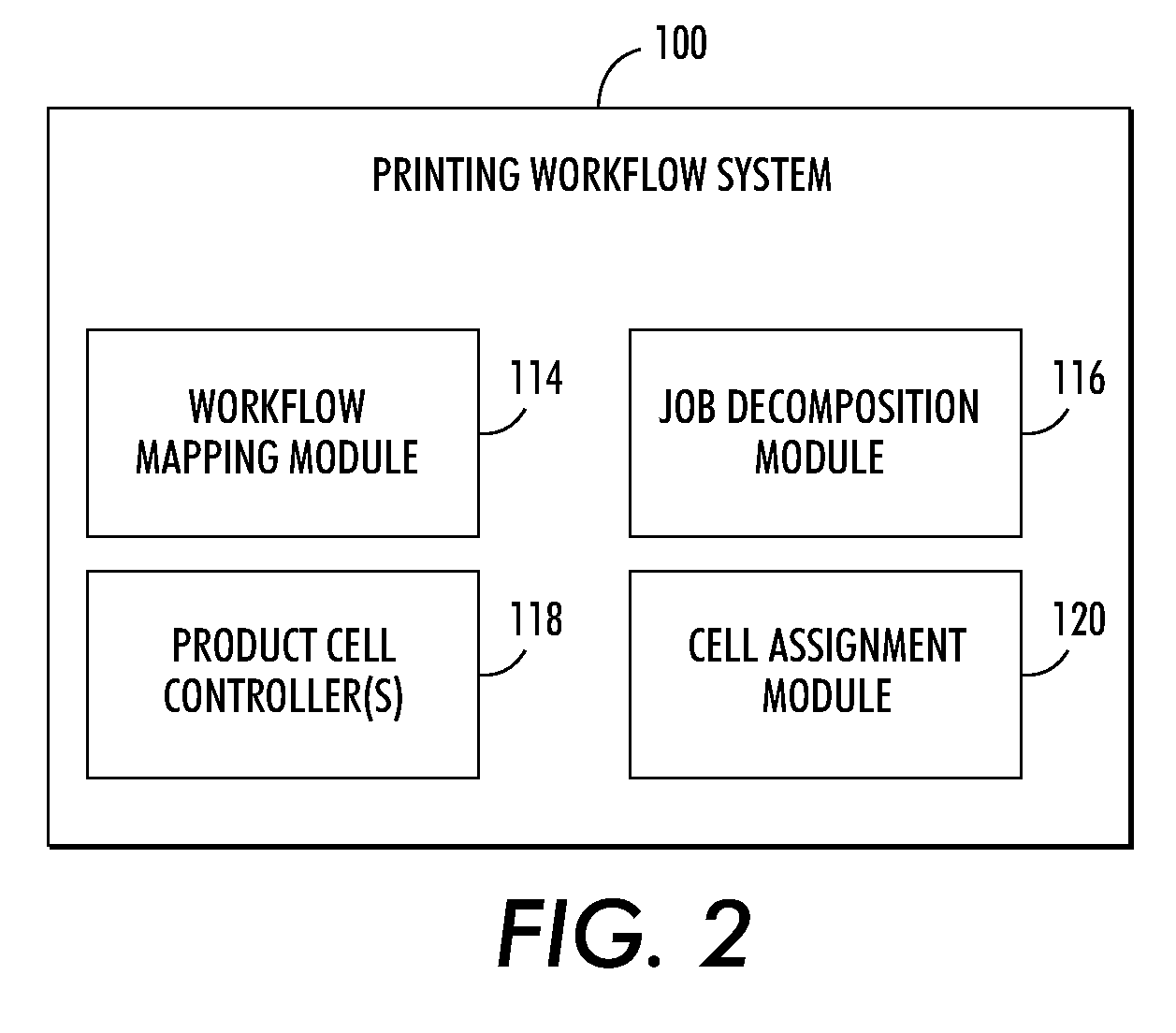

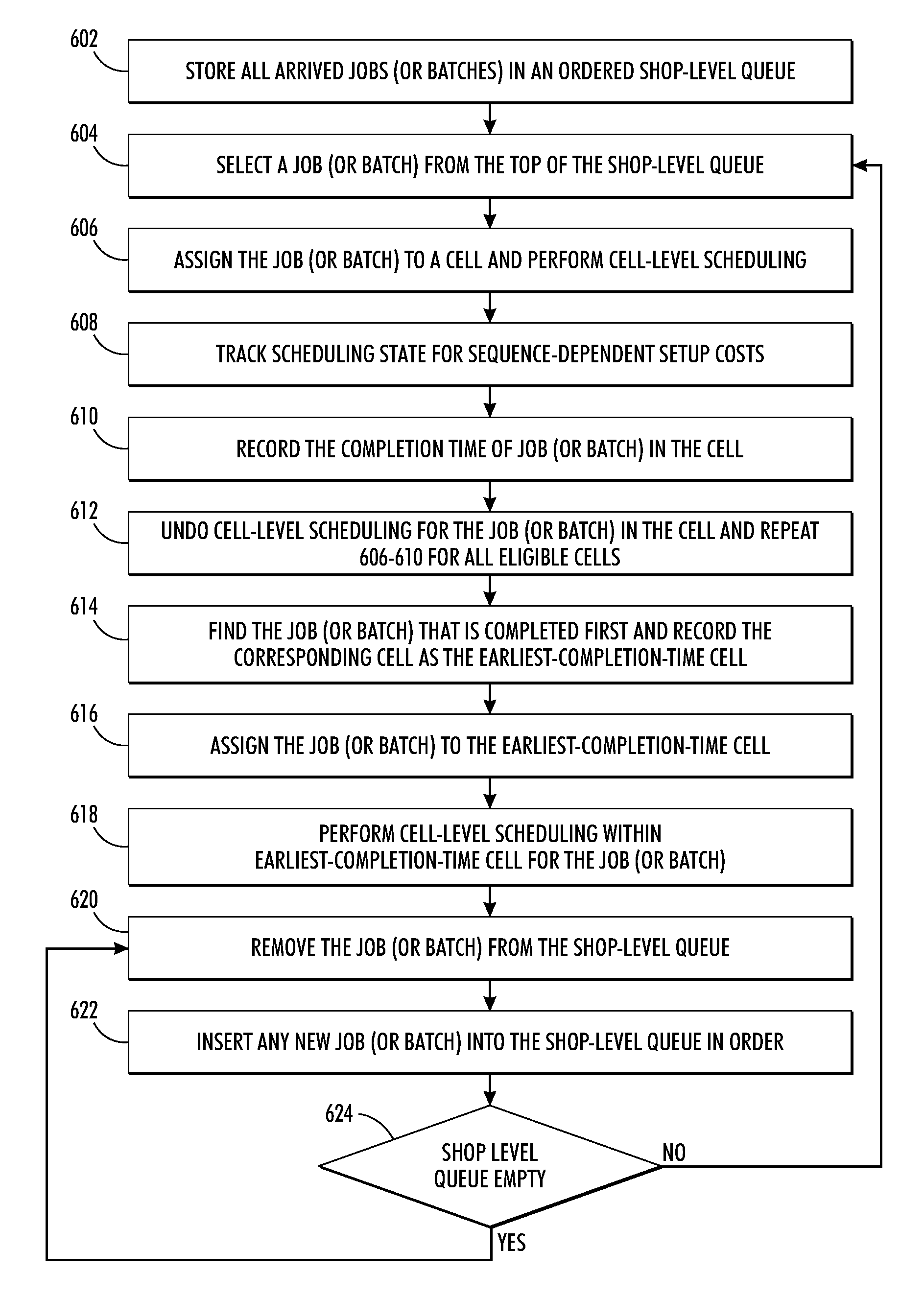

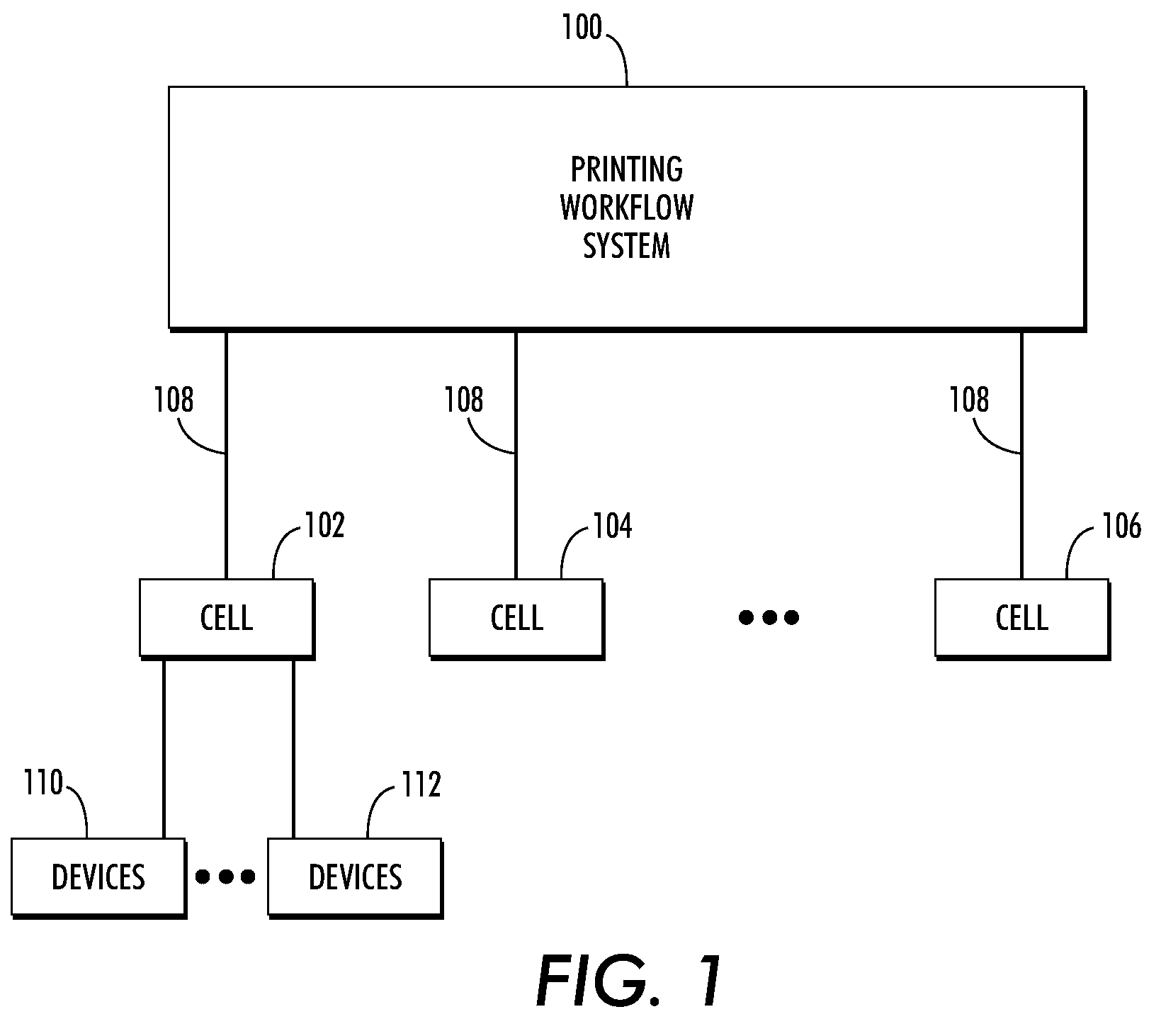

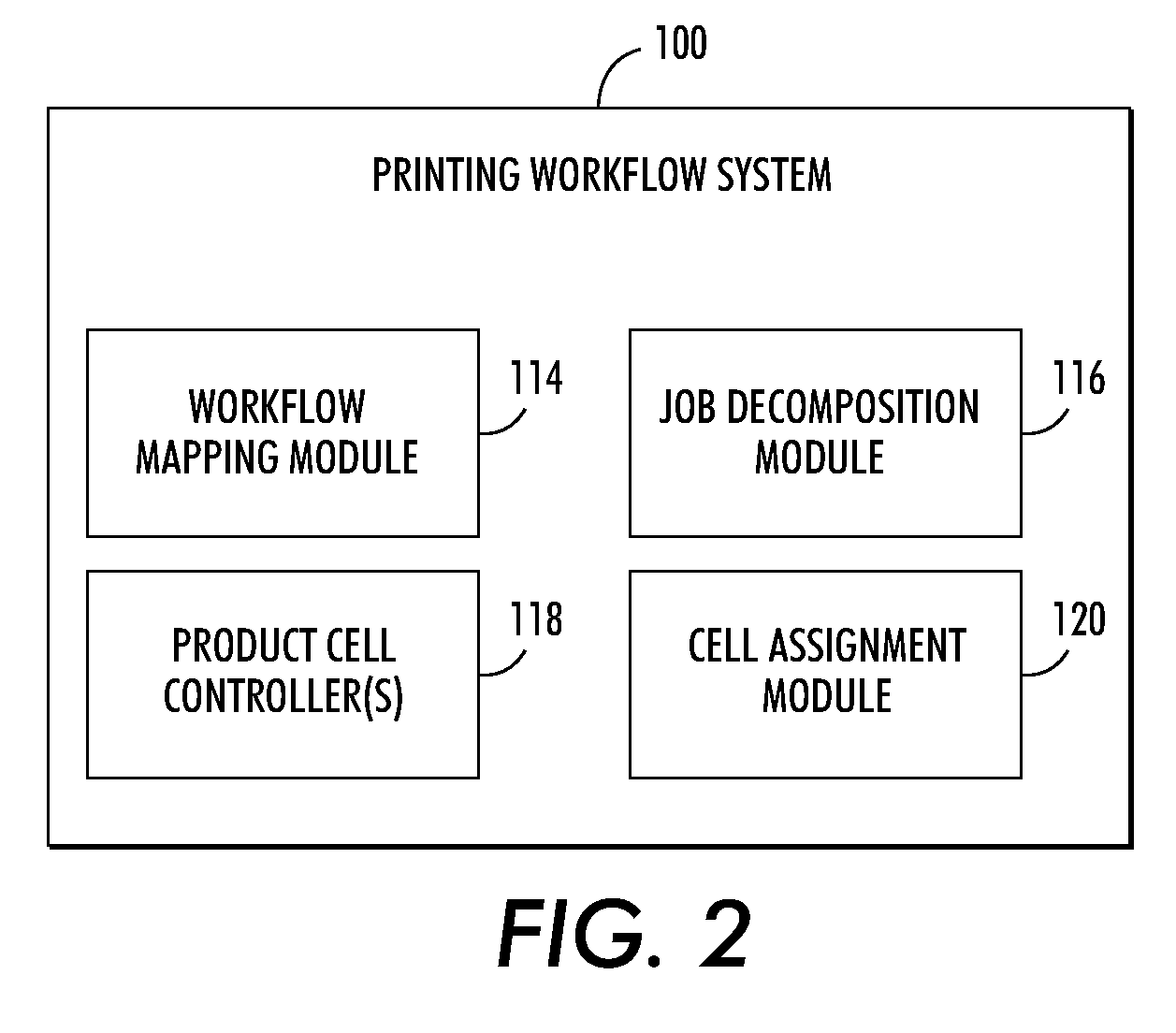

System and methods for dynamic scheduling in cellular manufacturing with batch-splitting

ActiveUS20110066269A1Increase productionImprove efficiencyProgramme controlMultiprogramming arrangementsCompletion timeBatch processing

The present application a new and improved system and method of enhanced Lean Document Production (LDP), which applies cellular manufacturing to document printing operations. The LDP process incorporates process friendly cells and, a push model to order to improve efficiency, reduce work in progress and smooth out the “frictions” in production environments. The current application presents an earliest-completion-time strategy for assigning jobs to cells and a dynamic-priority-based-batch-scheduling algorithm.

Owner:PALO ALTO RES CENT INC +1

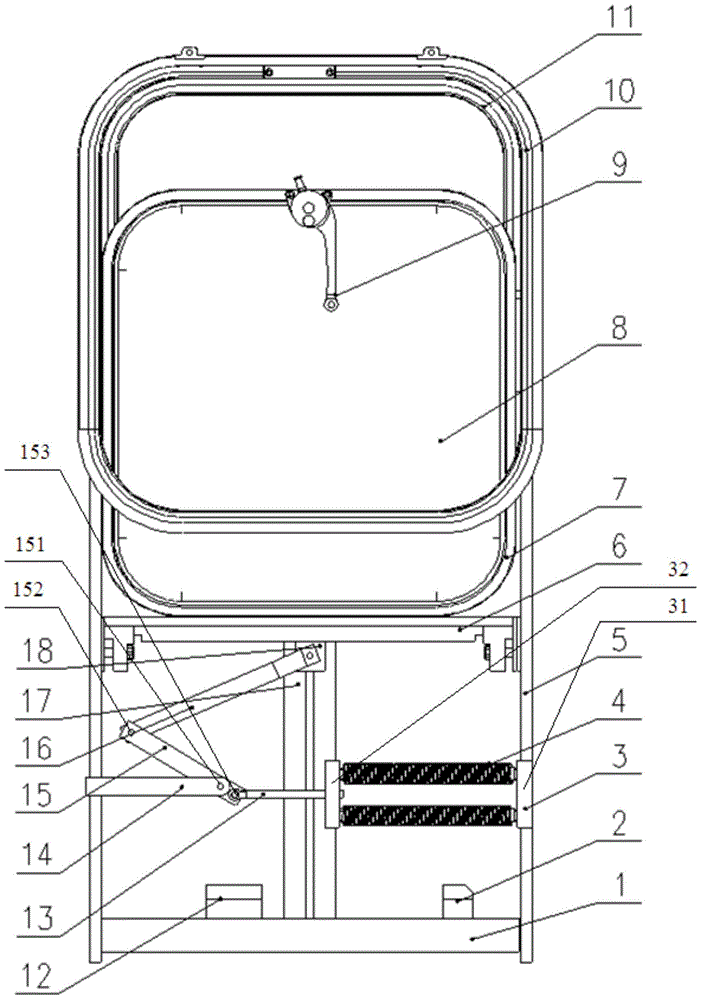

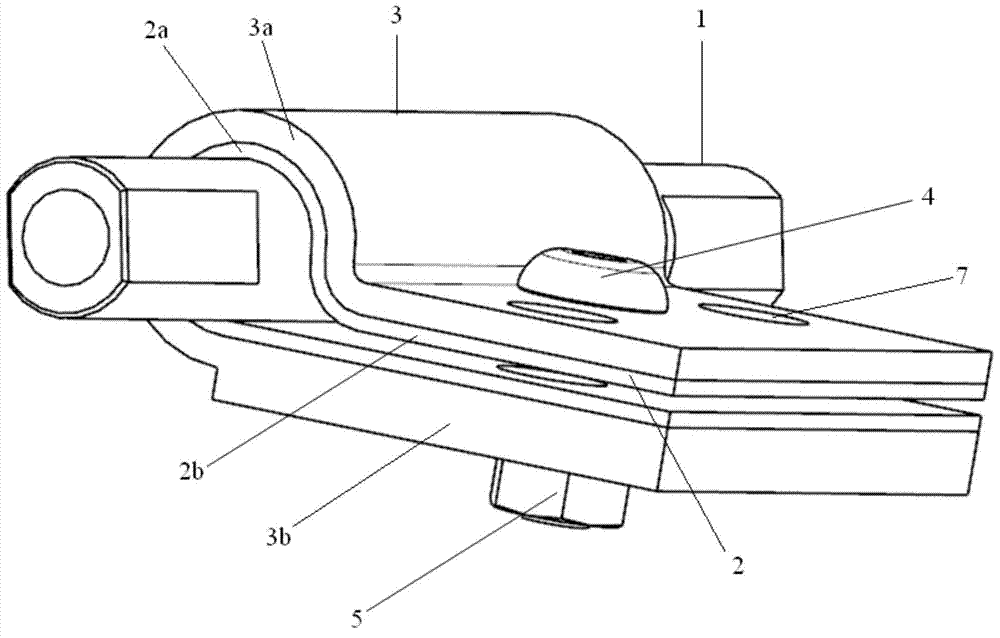

Cab side window for rail transit locomotive

ActiveCN104963591AEven by forceExtended service lifeWing arrangementsWing suspension devicesEngineeringBlock match

The invention provides a cab side window for a rail transit locomotive. The cab side window comprises a bottom cross beam, a side window fixing frame, a glass supporting beam, a glass fixing frame, side window glass, a crank-connecting rod-sliding block mechanism and sliding rails. The length direction of the sliding rails is vertically arranged, the sliding rails are located in the center of the side window fixing frame in the width direction, the bottom ends of the sliding rails are fixedly connected to the bottom cross beam, and the top ends of the sliding rails are directly or indirectly connected to the side wall of a locomotive cab fixedly. A sliding block matched with the sliding rails is connected with the glass supporting beam. One end of a crank-connecting rod assembly is fixedly connected to the side window fixing frame, and the other end of the crank-connecting rod assembly and the sliding block are connected to form the crank-connecting rod-sliding block mechanism so as to support the sliding block to vertically move up and down in the sliding rails along with the side window glass. An existing crank-connecting rod mechanism which is eccentrically stressed is replaced with the crank-connecting rod-sliding block mechanism which is centrally stressed, the improved side window is balanced in stress, abrasion to an aluminum alloy window frame is reduced in the opening and closing processes of the side window, and the normal service life of the side window is prolonged.

Owner:HUNAN LIANCHENG TRACK EQUIP CO LTD

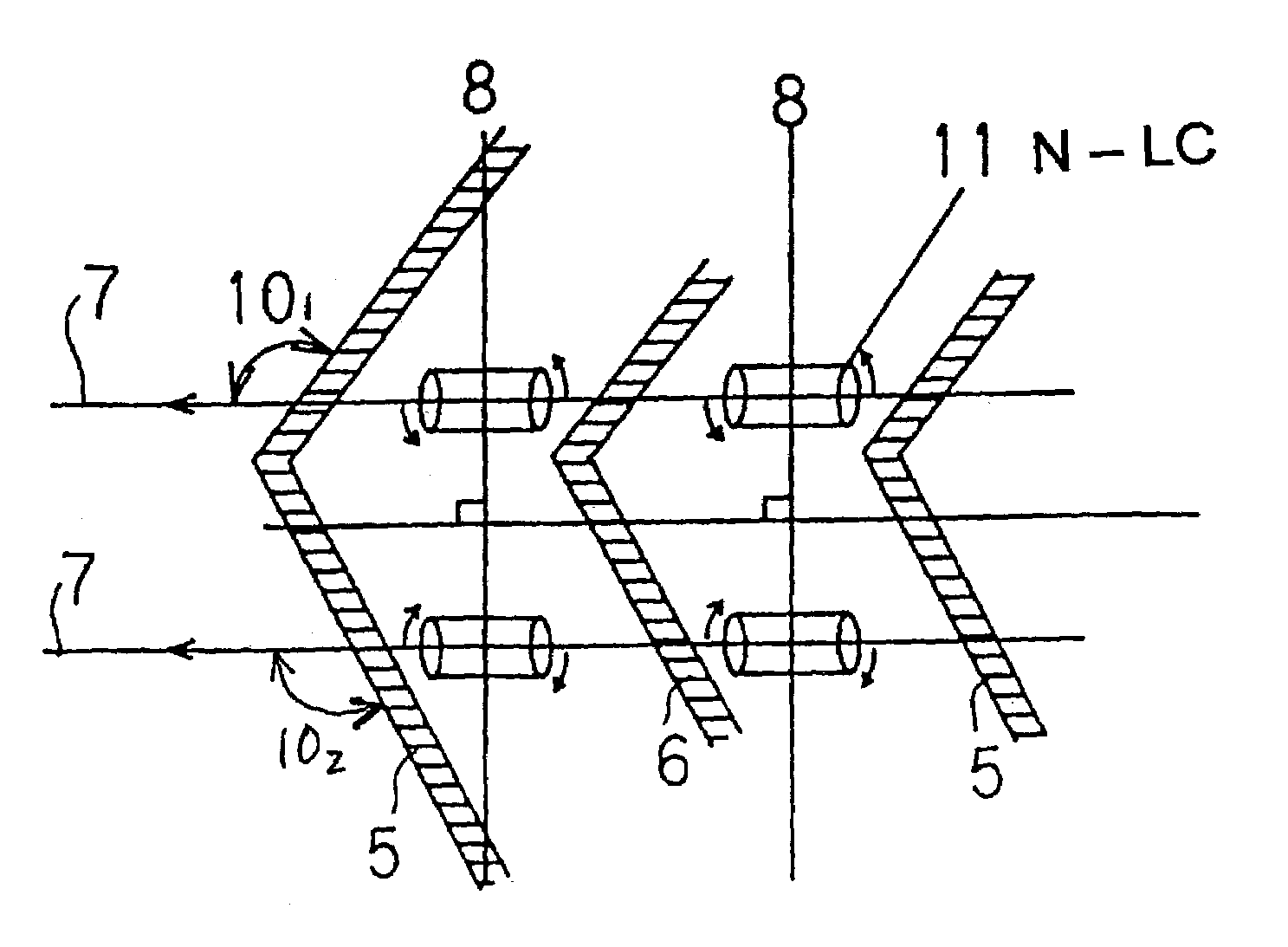

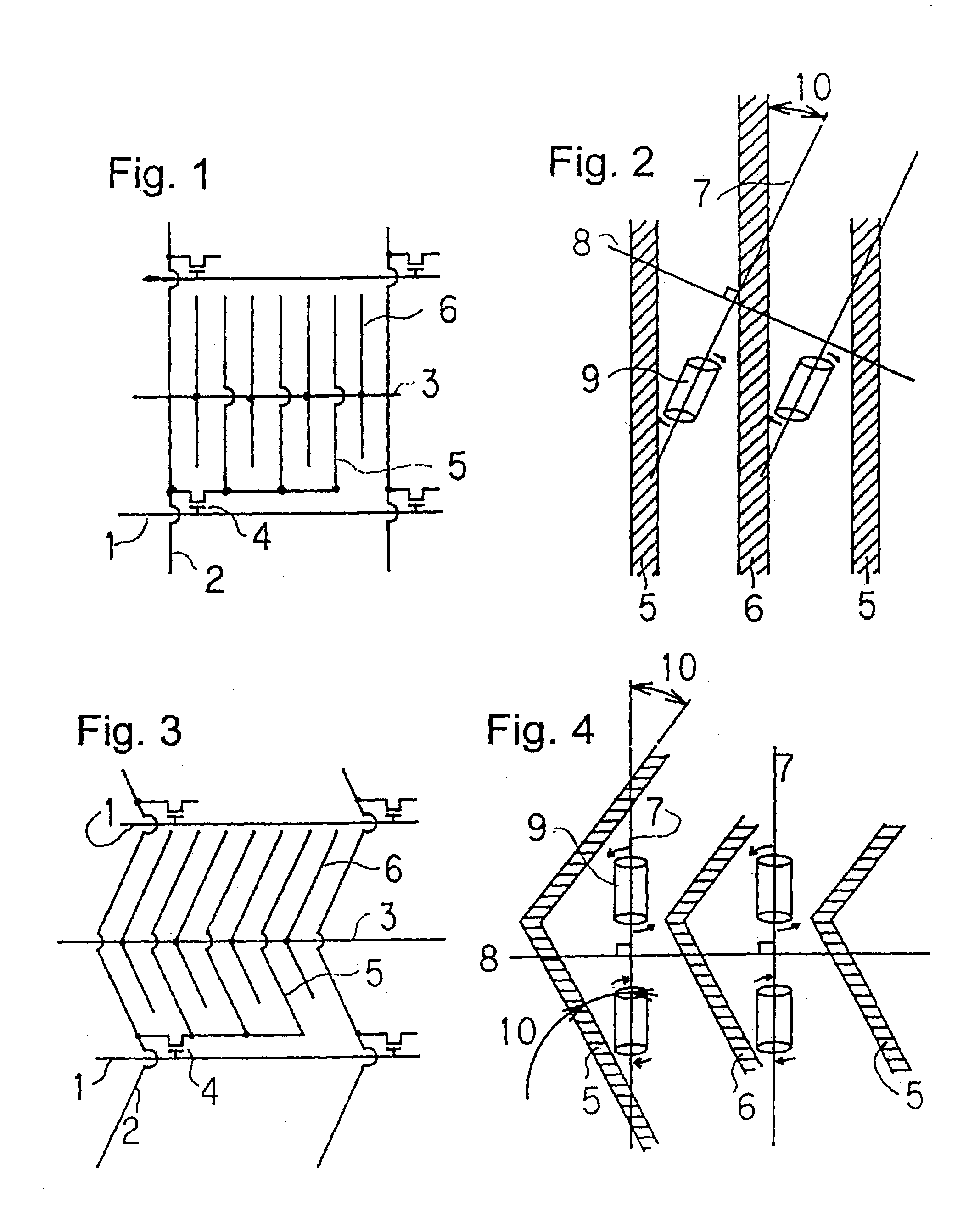

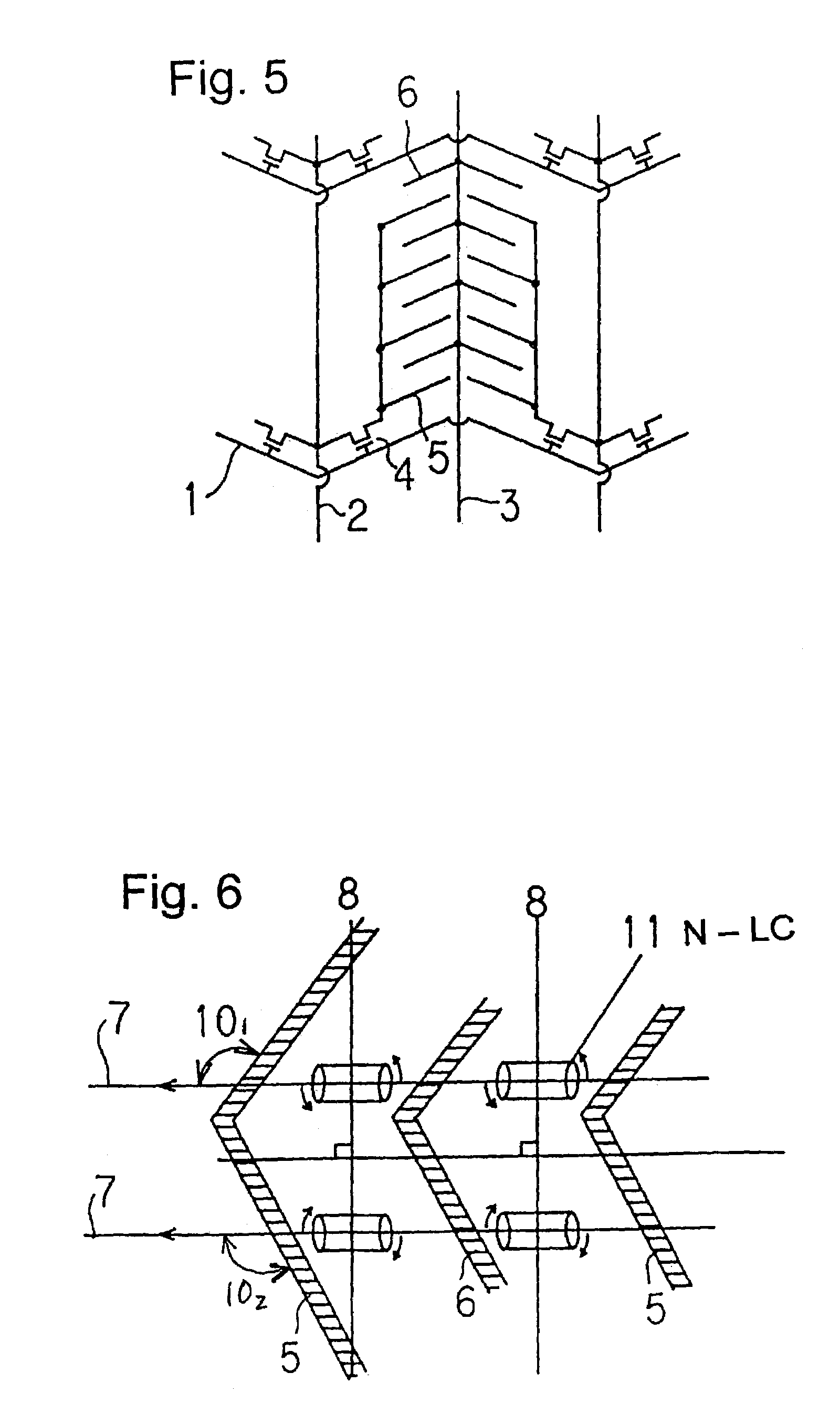

Liquid crystal display device comprising pixel and common electrodes inclined in first and second directions to form a zigzag shape which is symmetrical relative to alignment direction of liquid crystal

InactiveUS7098980B2Inferior residual imageProductivity will not decreaseNon-linear opticsVisual field lossElectric field

An active matrix type liquid crystal display device where display pixels are constituted on a substrate by scanning signal lines, video signal lines, pixel electrodes, common electrodes and active elements in order to obtain an image having good visual field angle characteristics and a high display quality with less residual image. The substrate is opposed to another substrate having a color filter forming a liquid crystal alignment film, and the liquid crystal layer is held by the two substrates. The electrodes and the active elements are so constituted that an electric field can be applied to the liquid crystal layer substantially in parallel with the substrate. The video signal lines, the common electrodes and the pixel electrodes are bent within a range of 60 to 120 degrees relative to the direction of liquid crystal alignment.

Owner:LG DISPLAY CO LTD

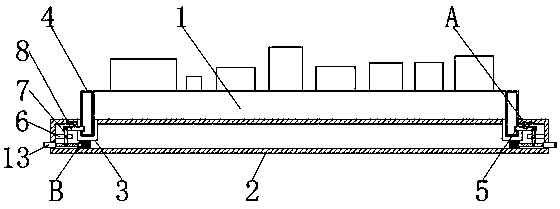

Computer mainboard mounting structure

InactiveCN107831861ASolve the cumbersome operationFast installationDigital processing power distributionMotherboardComputer engineering

Owner:湖南新融创科技有限公司

Dental pliers

InactiveUS7318725B2Easy to assembleEasy to operateDentist forcepsDiagnosticsAngular orientationEngineering

Dental pliers with two pliers parts, each respectively comprising one jaw of a pliers mouth and one lever arm of a pliers grip, the pliers parts pivotably connected with each other via a linkage. The linkage includes a cylindrical journal (26) on the first pliers part (12) coaxial to the pivot axis, which engages in a cylindrical bore (32) on the other pliers part (10) coaxial to the pivot axis having the same diameter, and is rotatable in this bore (32) about the pivot axis. The journal (26) and the bore (32) are axially located form-fittingly via at least one circumferential tab (28) and one circumferential groove (34). The at least one circumferential tab (28) extends only over a partial angular area of the circumference. At least one entry segment (36) corresponding to the cross-sectional shape of the circumferential tab (28) leads axially to the circumferential groove (34). The at least one circumferential tab (28) and the at least one entry segment (36) are so oriented in their angular orientation in the respective linkage area (22) or as the case may be (24), that these come into registry with each other in the open or spread position of the pliers parts (10, 12), and the at least one circumferential tab (28) can be introduced into the circumferential groove (34) through the entry segment (36) or as the case may be removed therefrom, while in the other spread positions of the pliers parts (10, 12) the at least one circumferential tab (28) engages in the circumferential groove (34) and is held form-fittingly axially therein.

Owner:INTEGRA YORK PA

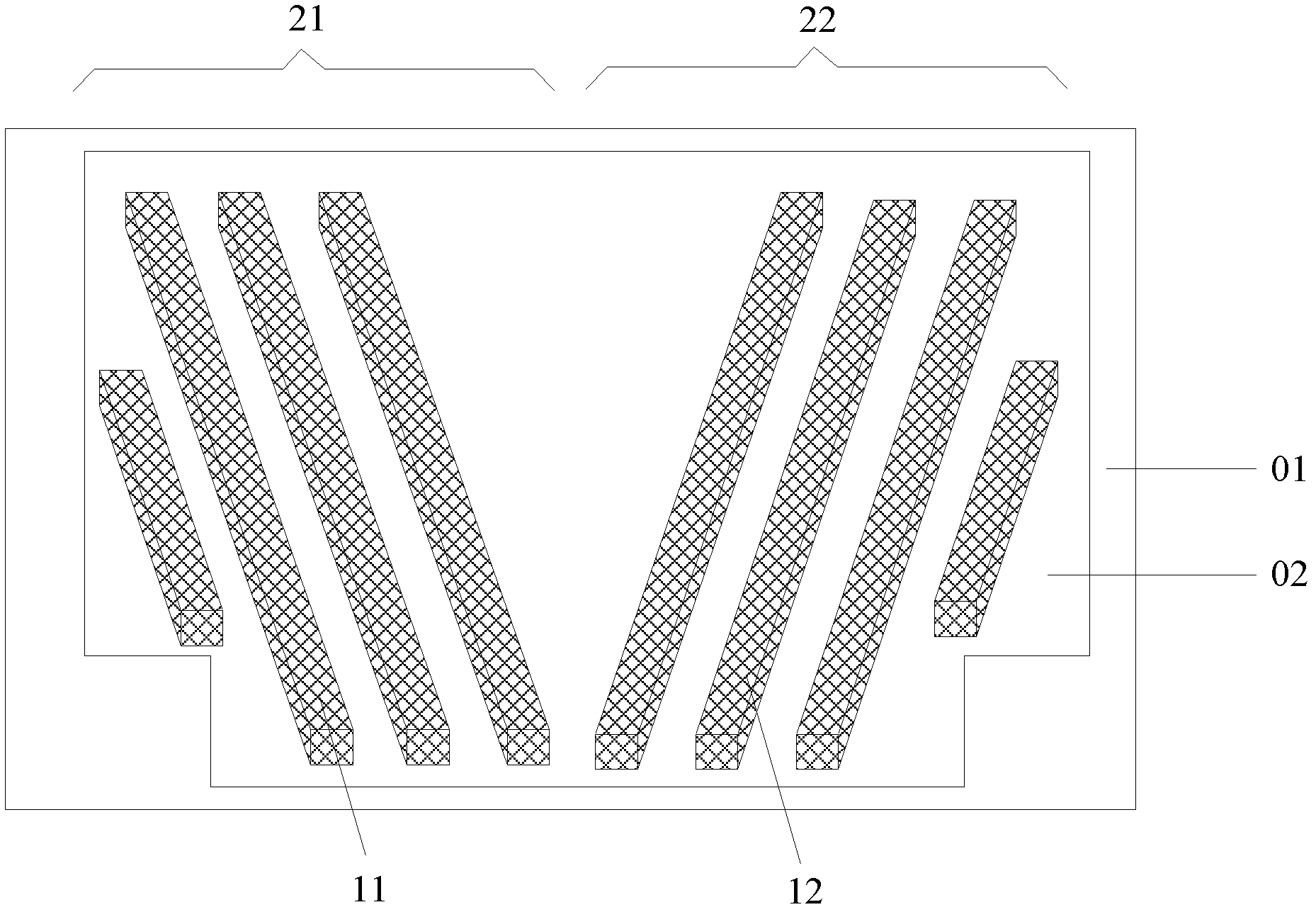

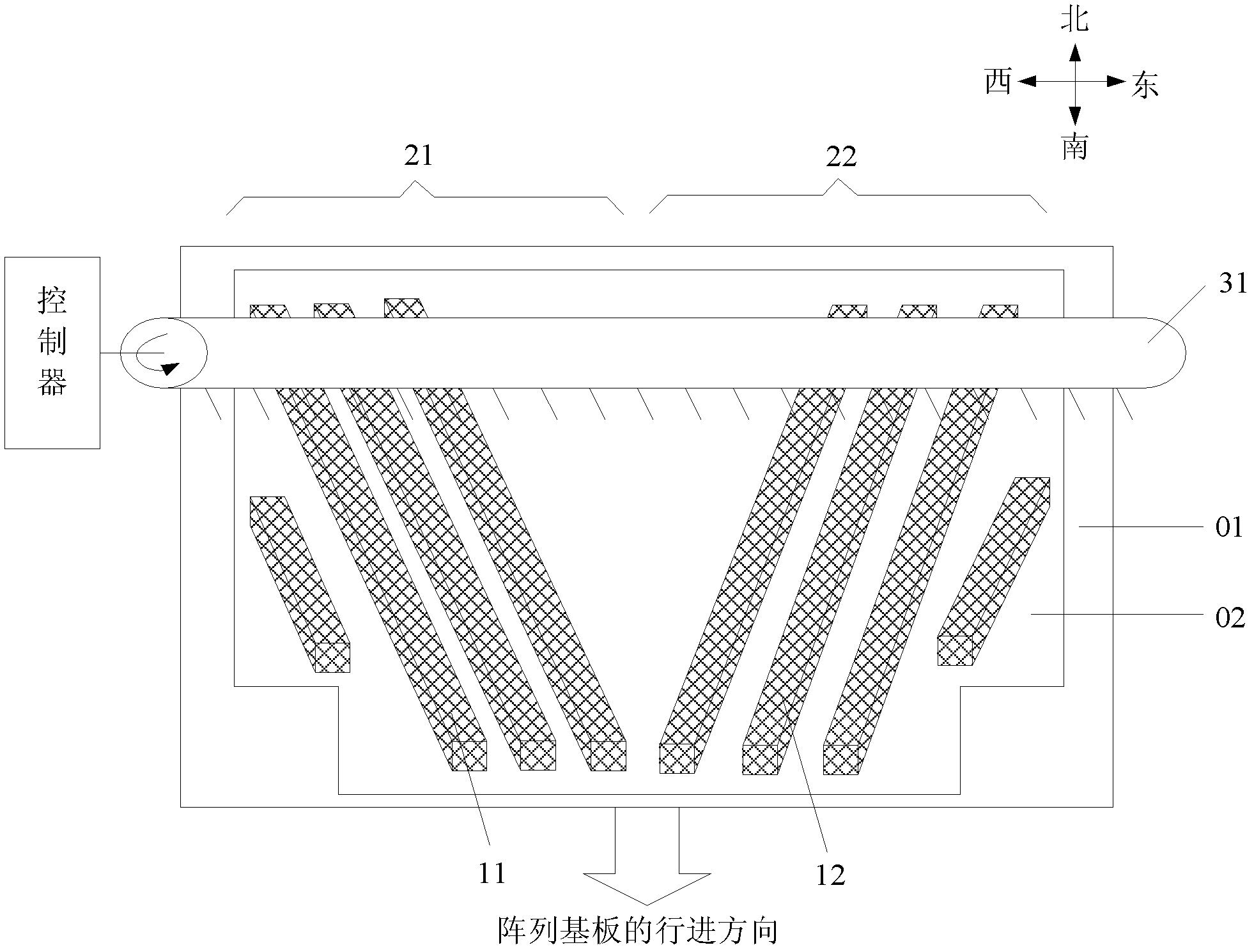

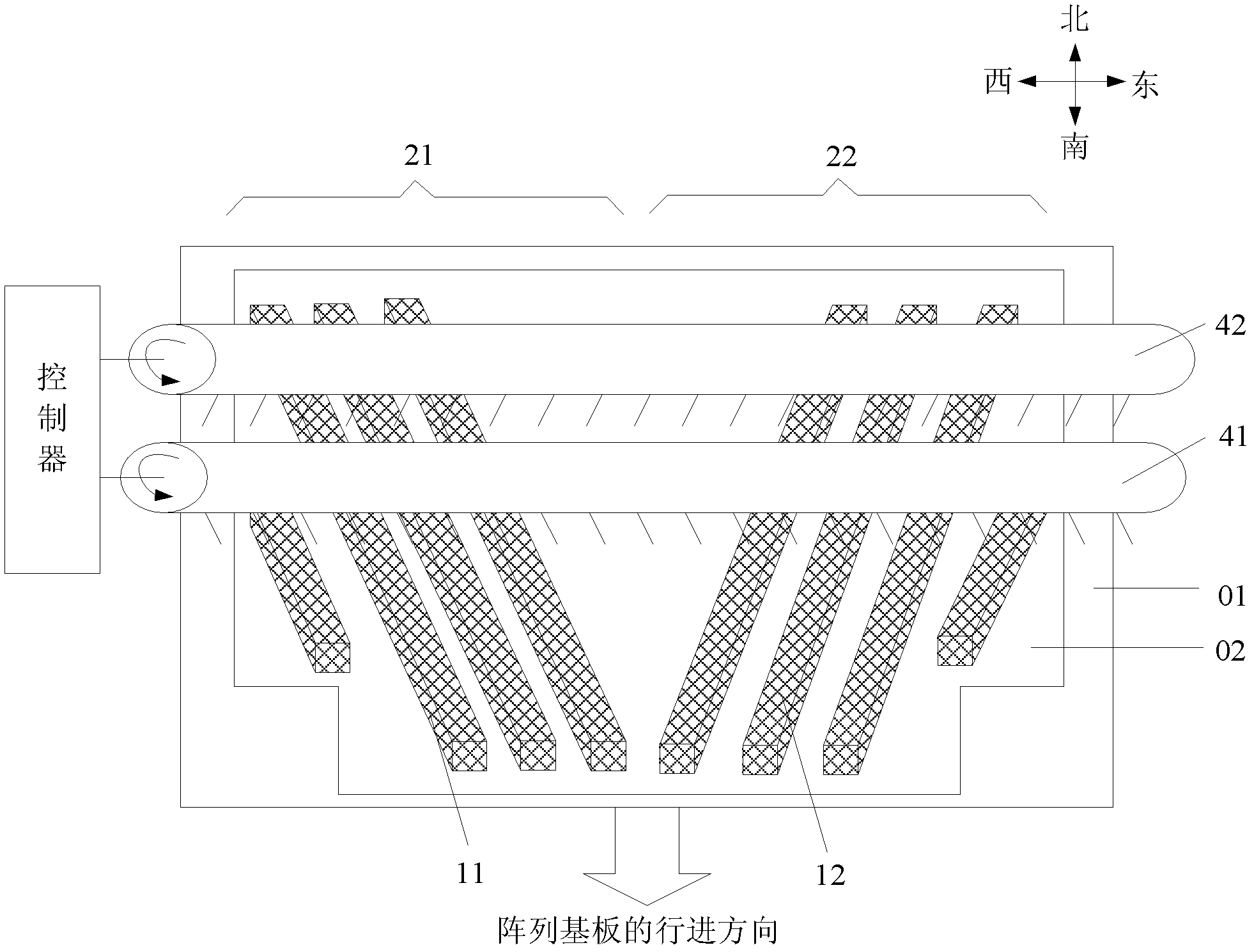

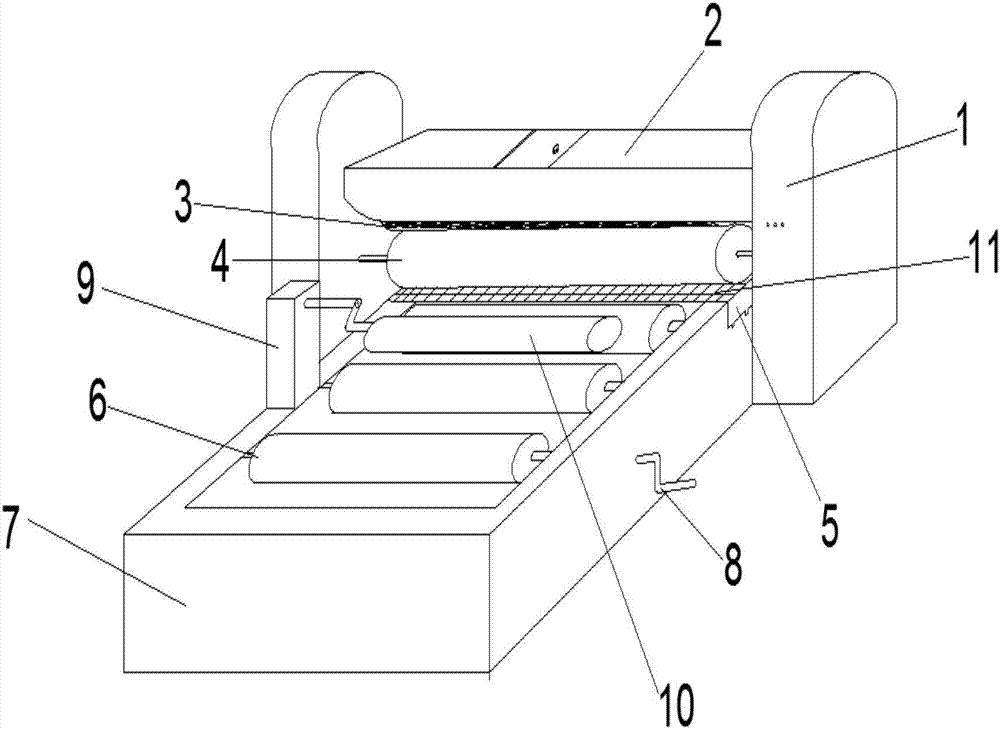

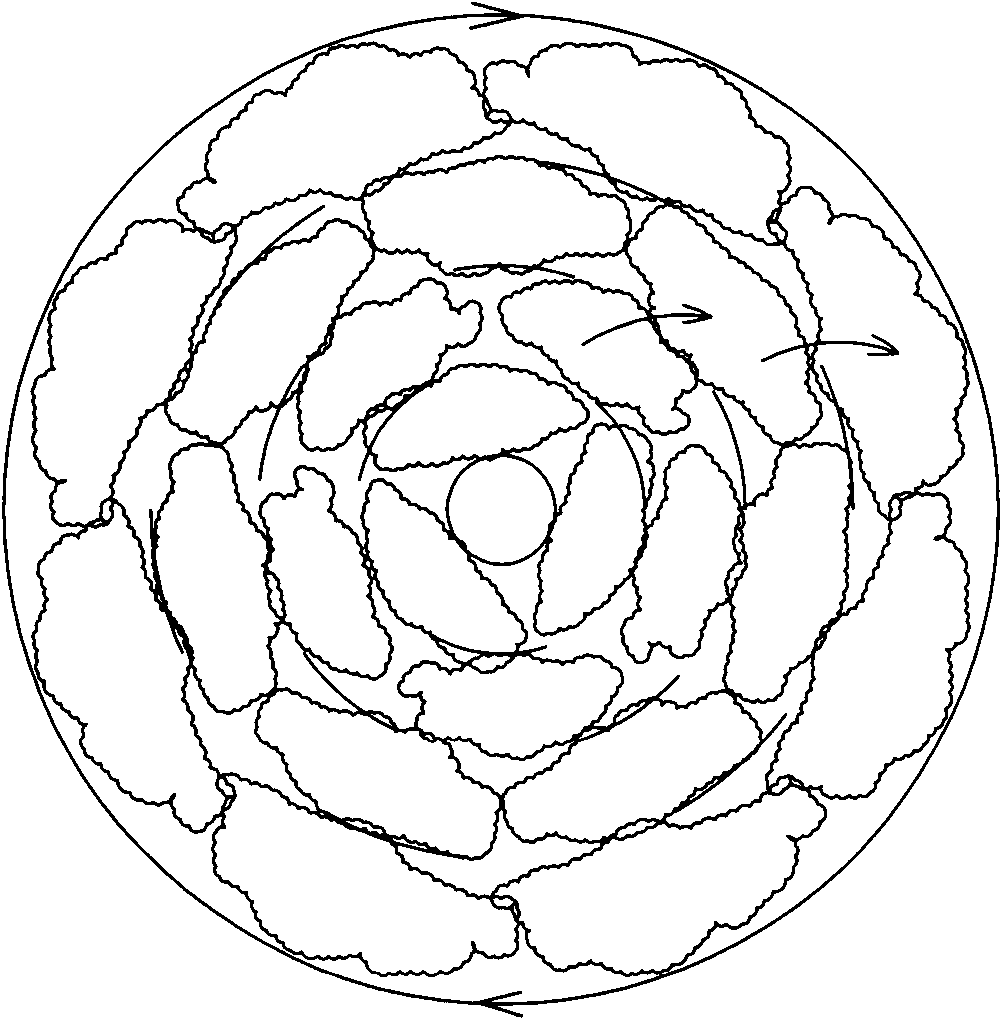

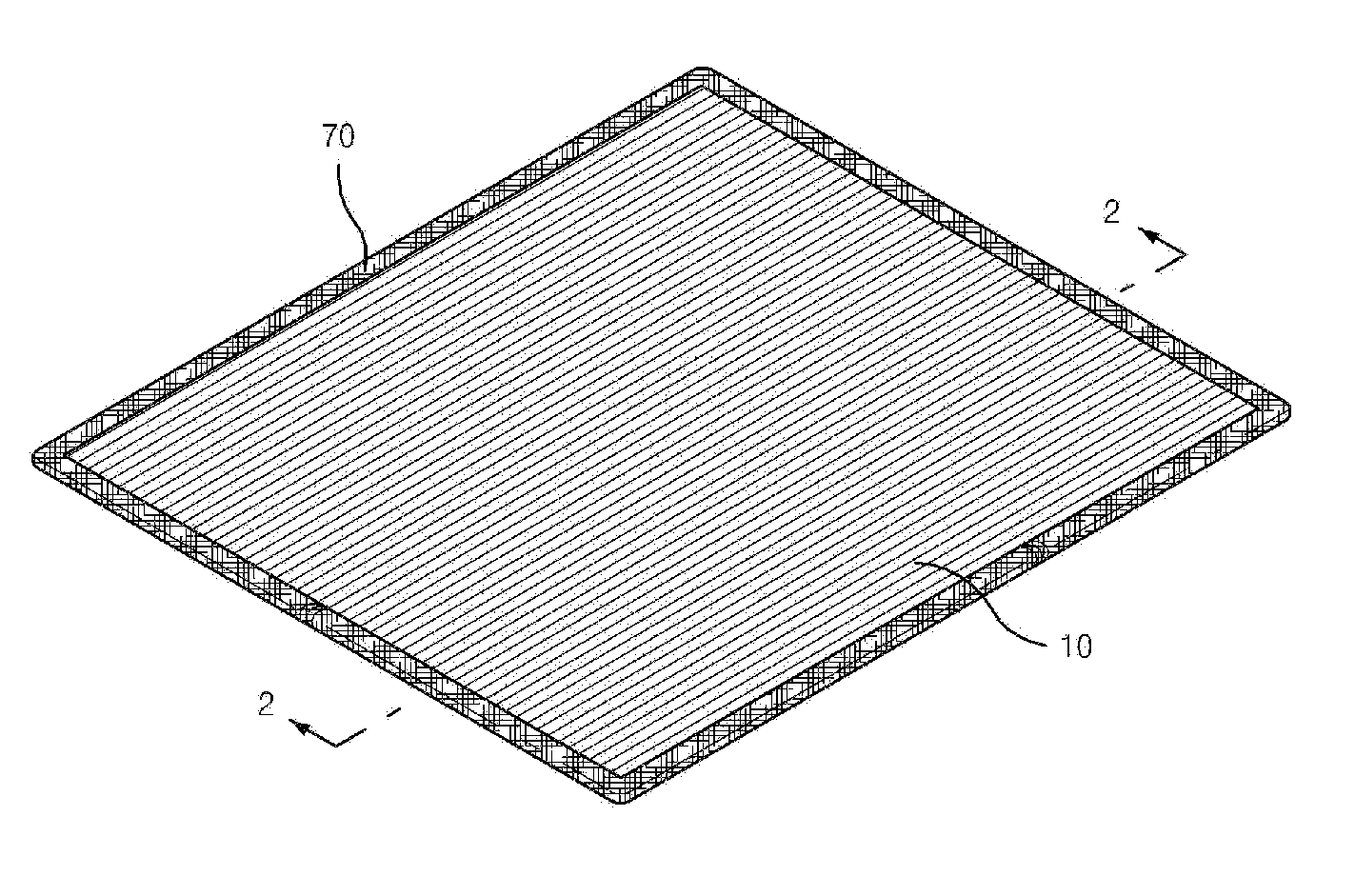

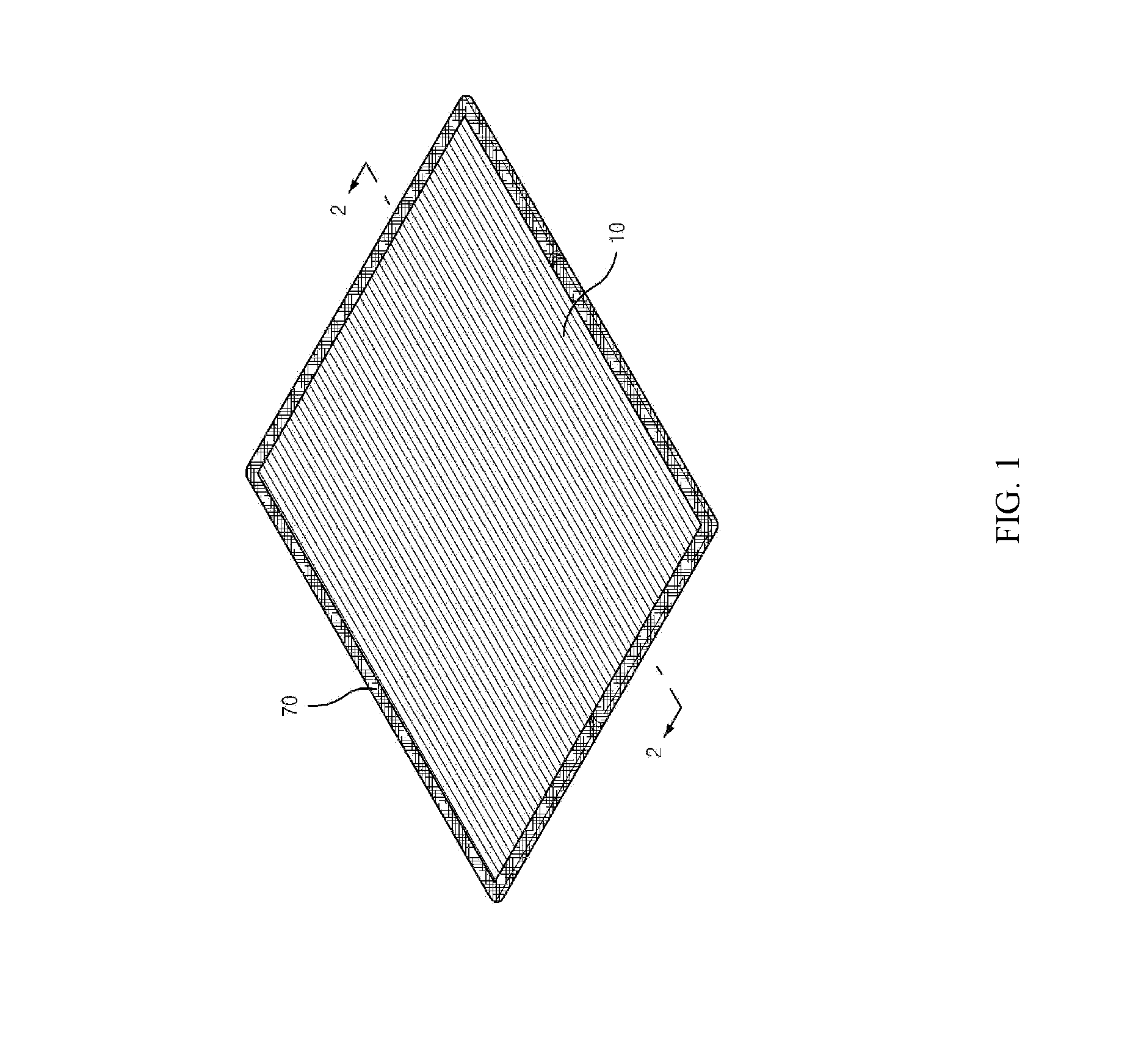

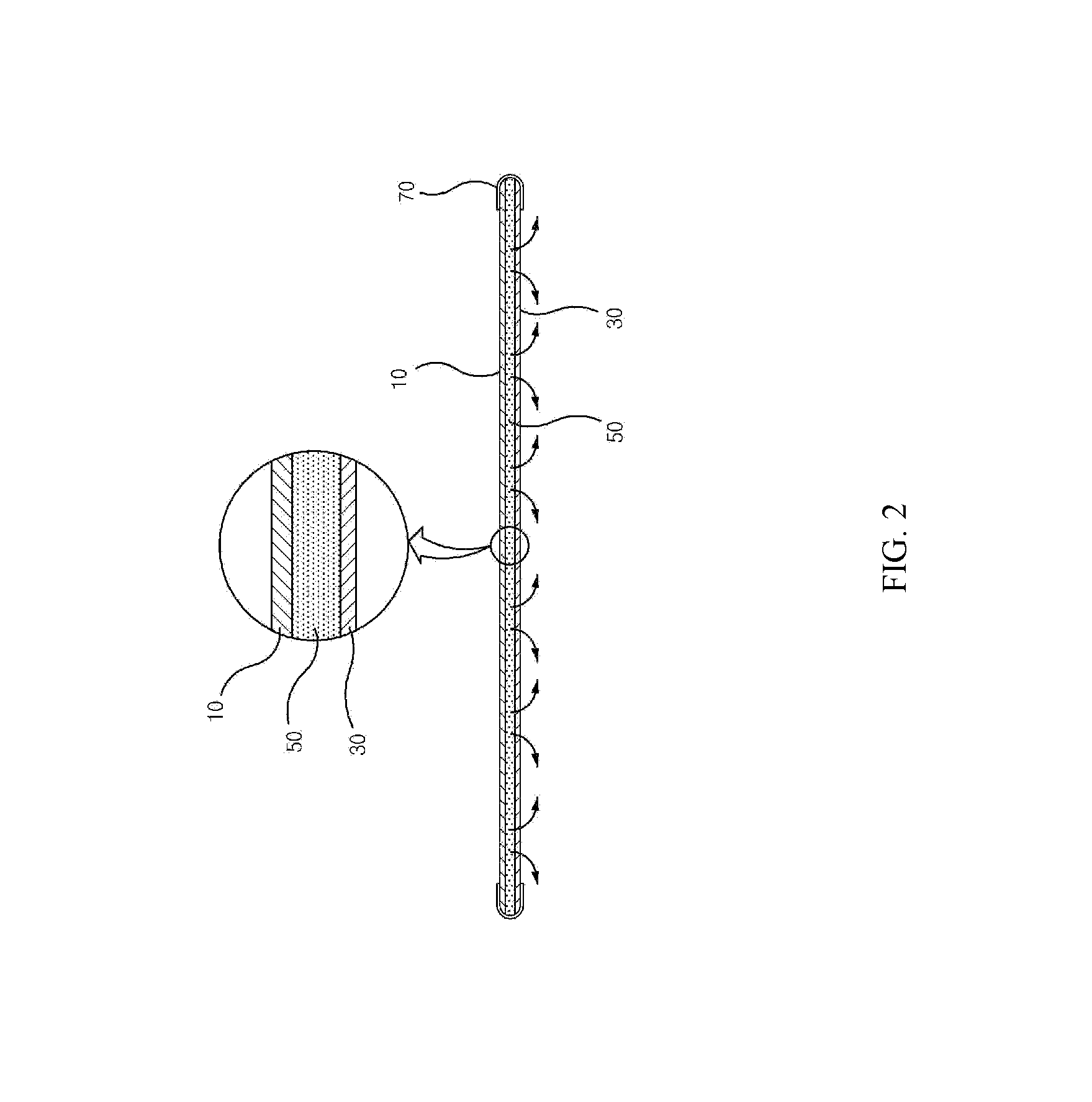

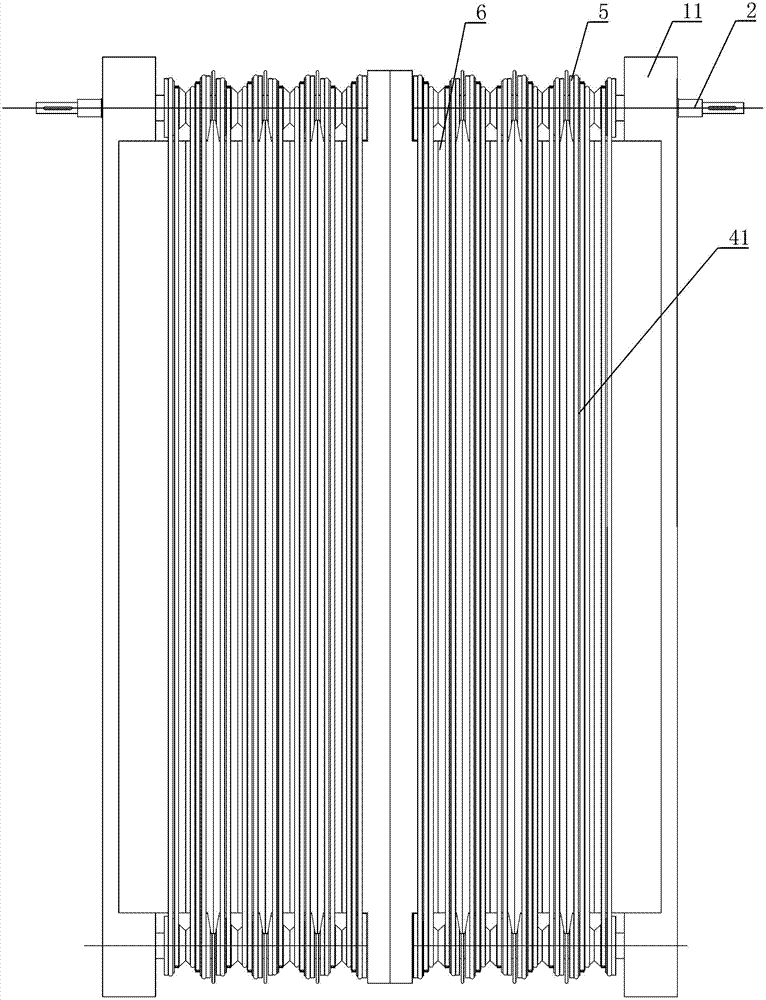

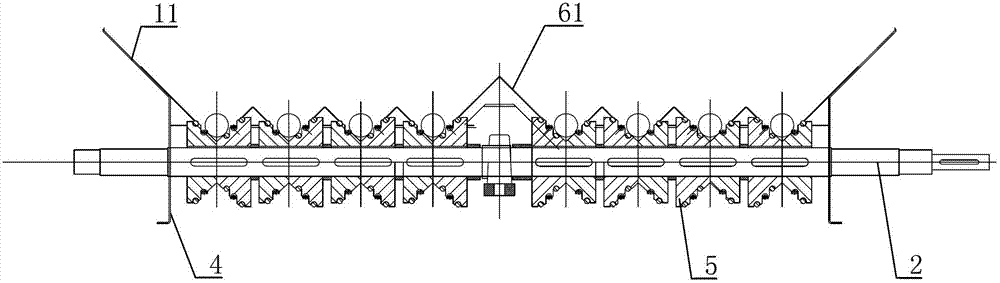

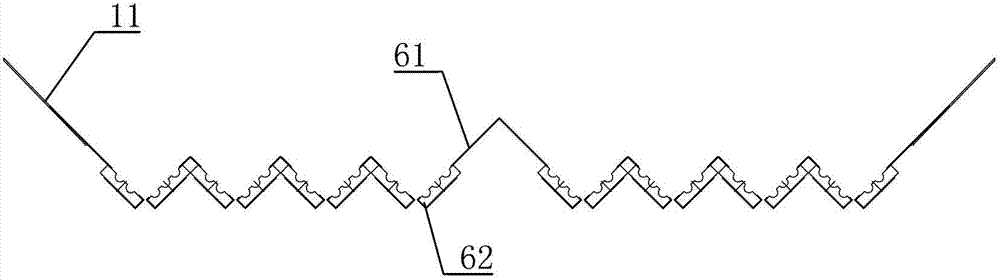

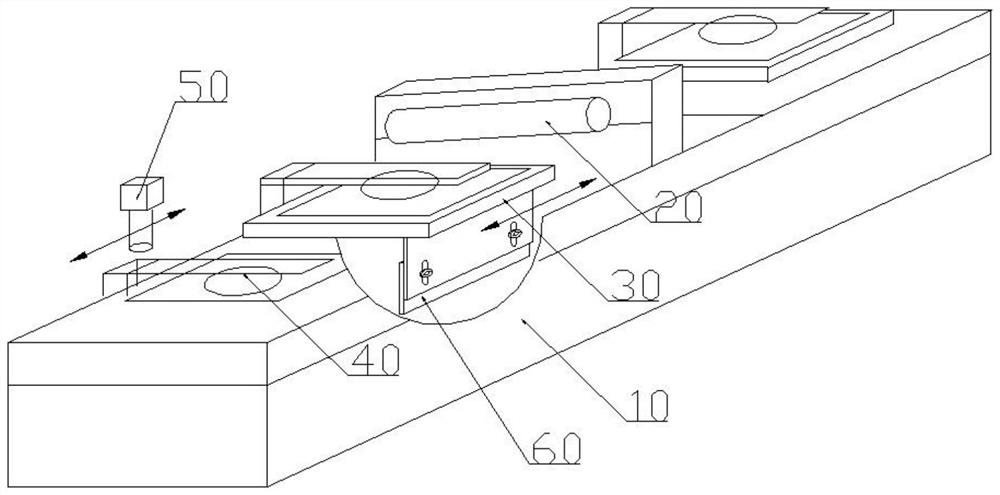

Friction device and friction method for orientation film

InactiveCN102629026AUniform friction effectEven frictionNon-linear opticsFriction effectLiquid-crystal display

An embodiment of the invention discloses a friction device and a friction method for an orientation film, which relate to the field of liquid crystal display and are used for solving the problems that a friction effect for the orientation film is not even if the orientation film is provided with an array substrate with pixel electrodes in at least two different directions. The friction method for the orientation film includes that at least one friction roller is used for conducting at least two times of friction on the orientation film of the array substrate, and at least two groove marks are left on the orientation film of the array substrate. Friction cloth is arranged on the friction roller, the pixel electrodes in at least two different arrangement directions are arranged on the array substrate. The directions of the at least two groove marks correspond to arrangement directions of the pixel electrode in at least two different arrangement directions one by one, and two corresponding directions are the same. The scheme is applicable to friction process of the orientation film in a production process of a liquid crystal display panel.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

Novel damping structure and construction method thereof

ActiveCN104265831AHigh hardnessLow densityRotating vibration suppressionPassenger spaceEngineeringHardness

The invention provides a novel damping structure and a construction method thereof. The novel damping structure comprises an axially extending shaft sleeve, a friction plate and a ferrule, the friction plate and the ferrule sequentially sleeve the shaft sleeve, the friction plate comprises a first C-shaped portion and a first extension portion, the first C-shaped portion is matched with the shaft sleeve, the first extension portion extends out from the edge of the first C-shaped portion, the ferrule is an aluminum alloy or copper alloy extrusion part and comprises a second C-shaped portion and a second extension portion, the second C-shaped portion is matched with the friction plate, the second extension portion extends out from the edge of the second C-shaped portion, pressing force between the friction plate and the ferrule is adjusted by a fastener penetrating the first extension portion and the second extension portion, friction force between the friction plate and the shaft sleeve is further adjusted, and a friction surface is formed between the shaft sleeve and the friction plate. The ferrule is creatively formed from aluminum alloy or copper alloy by an extrusion process, high stability and high precision of the extrusion process are reserved, high hardness and low density of the aluminum alloy or copper alloy are reserved, internal plastic deformation stress of the ferrule is released, and the damping structure has remarkable superiority.

Owner:SHANGHAIK YANFENG JINQIAO AUTOMOTIVE TRIM SYSTEMS CO LTD

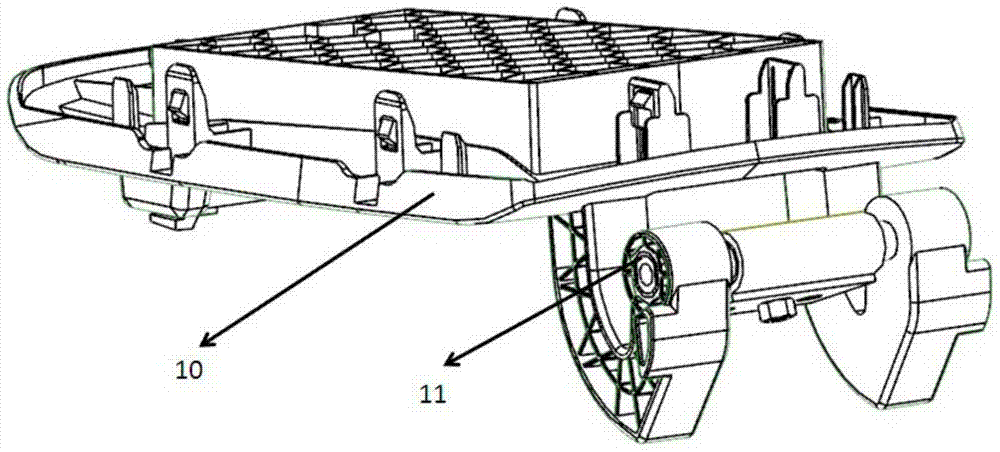

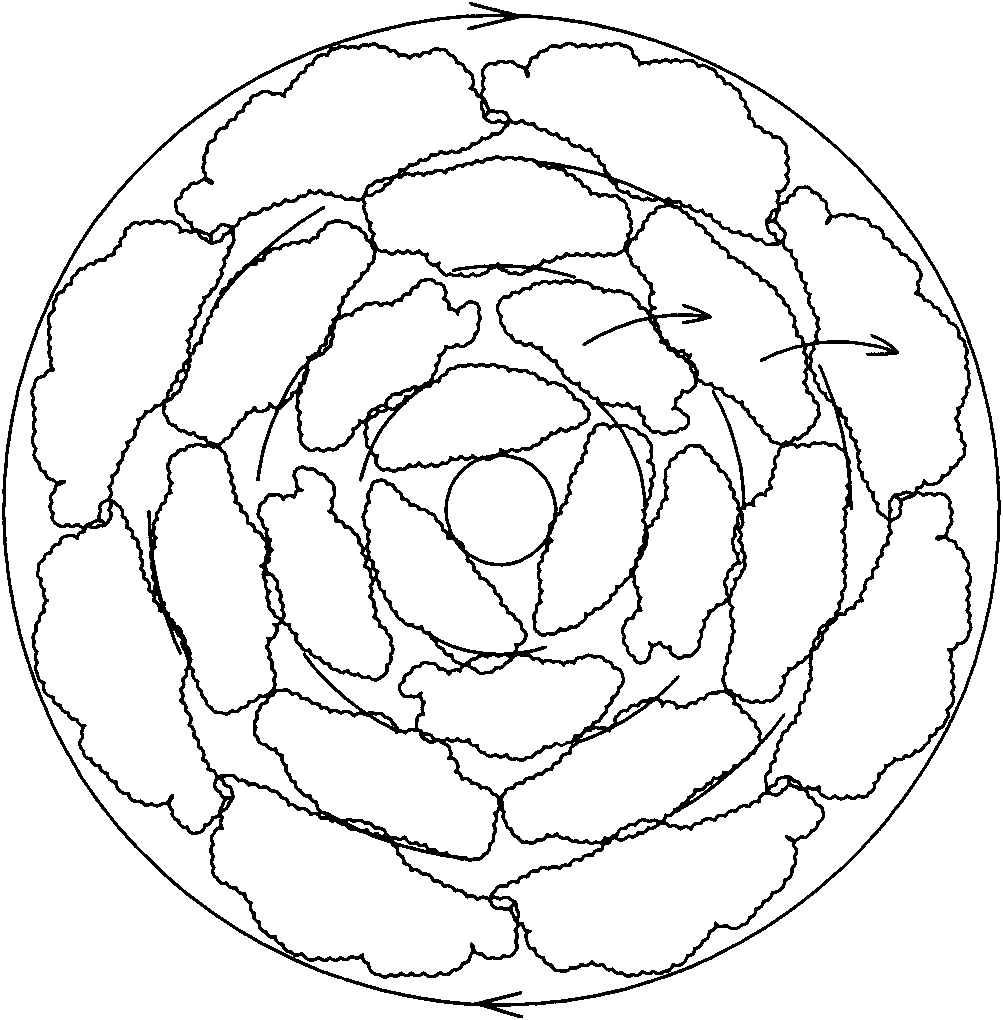

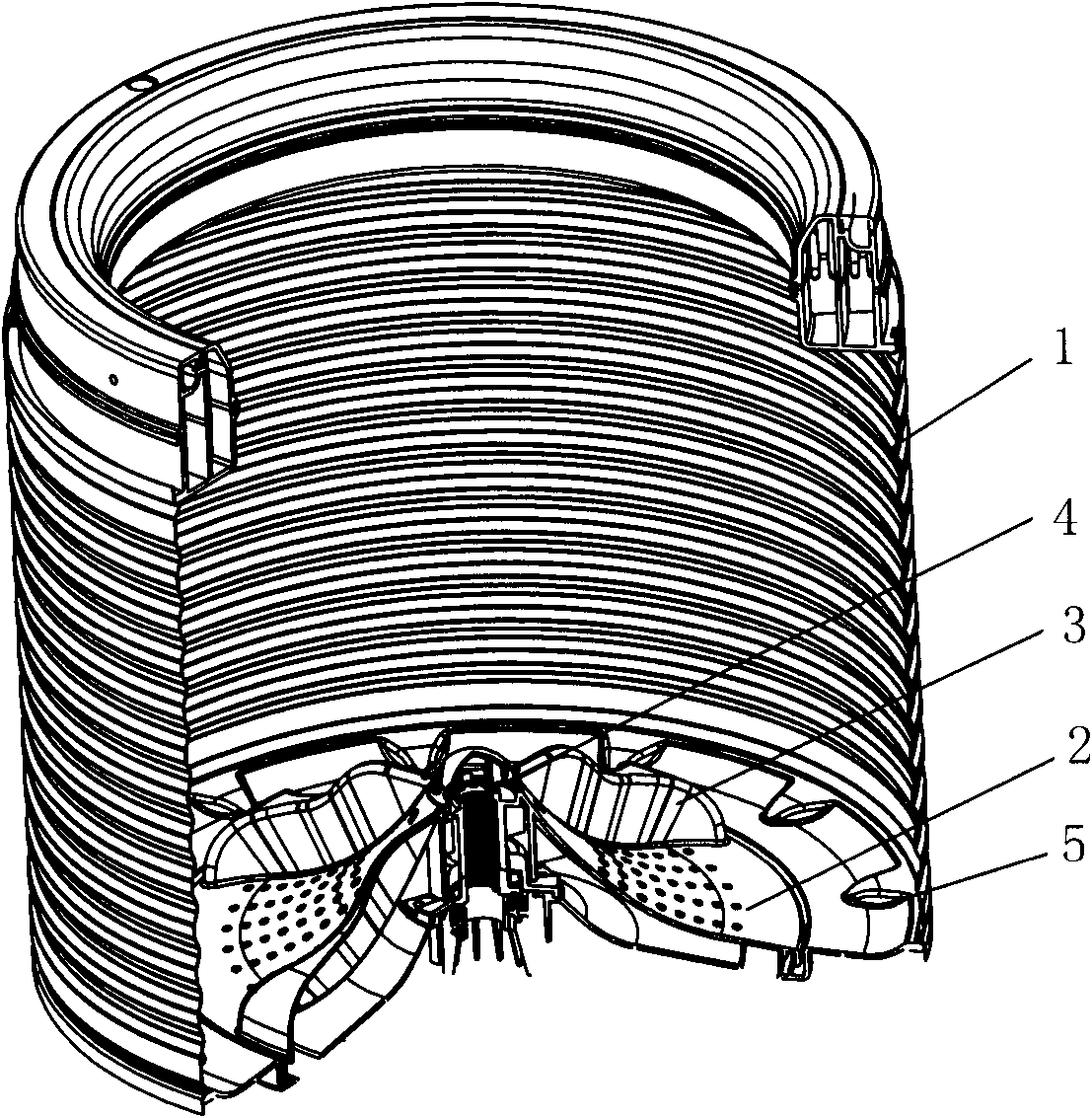

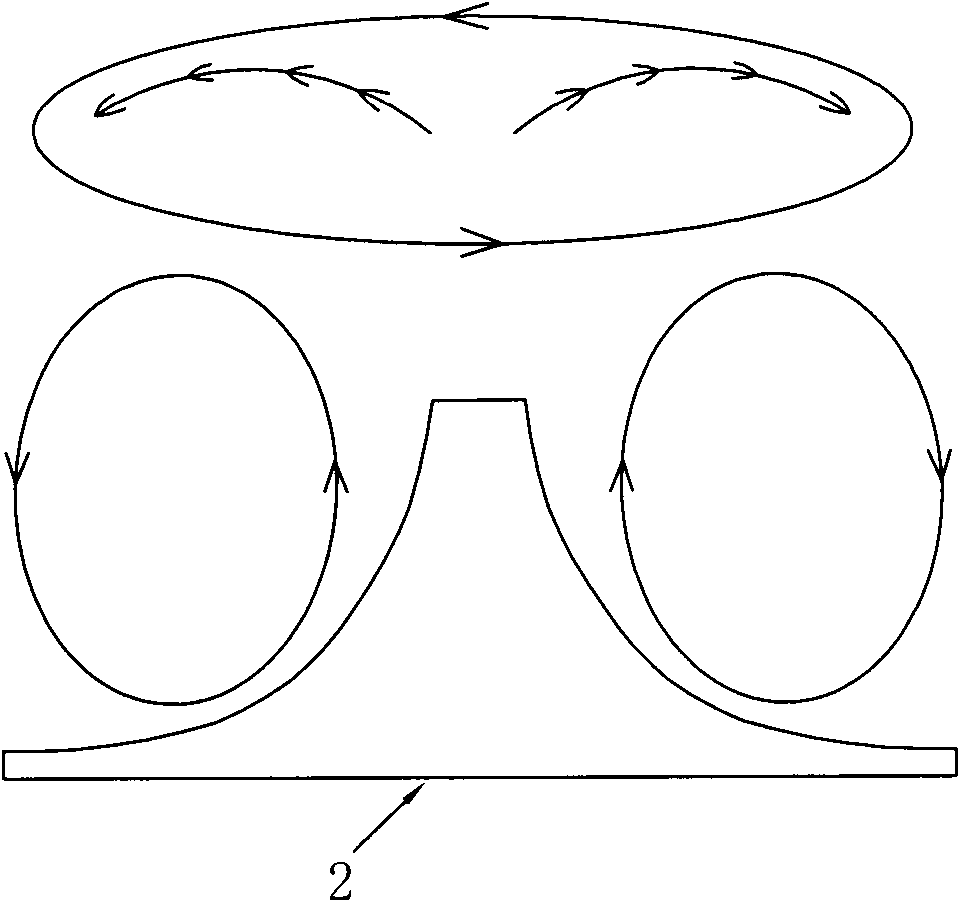

Washing machine with clothes being overturned at constant speed and washing mode

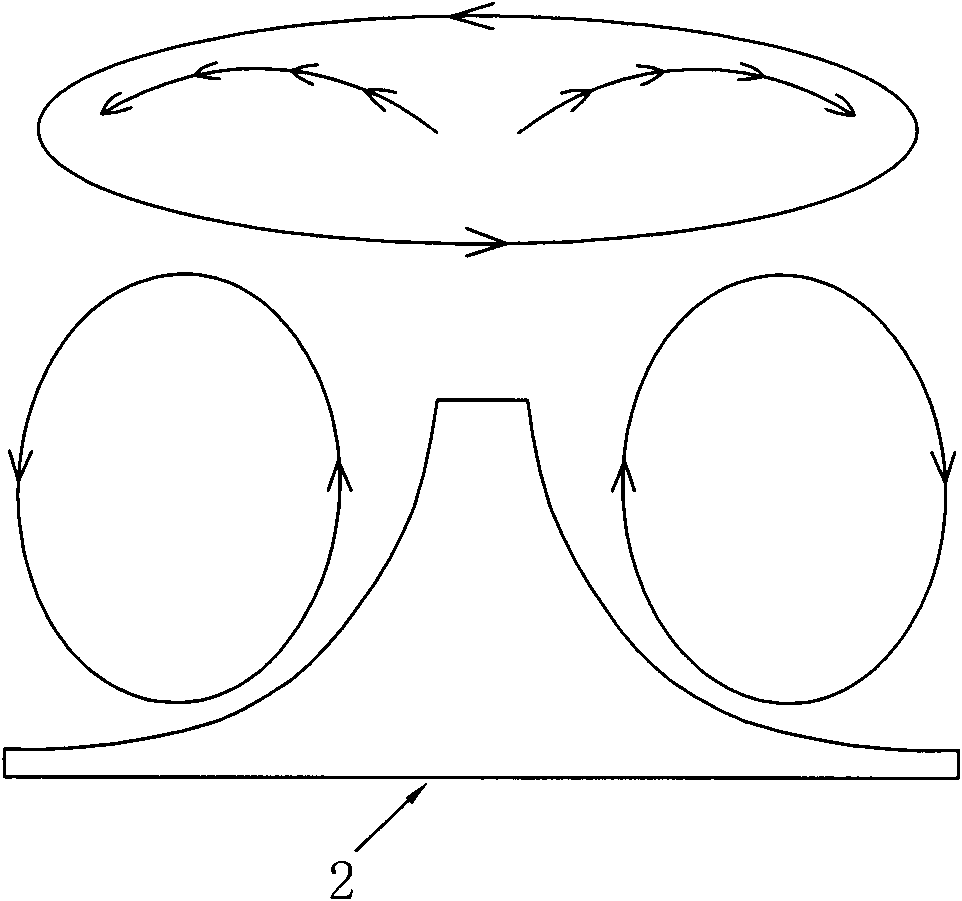

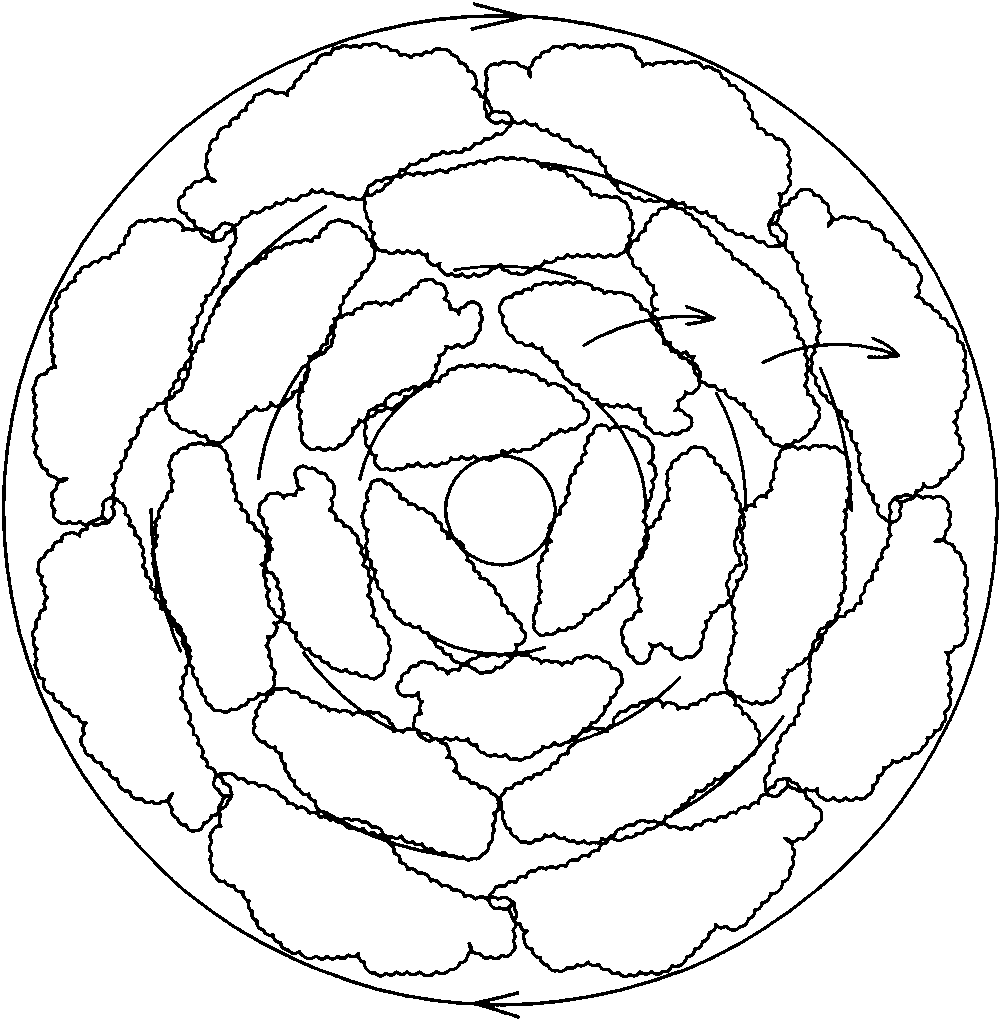

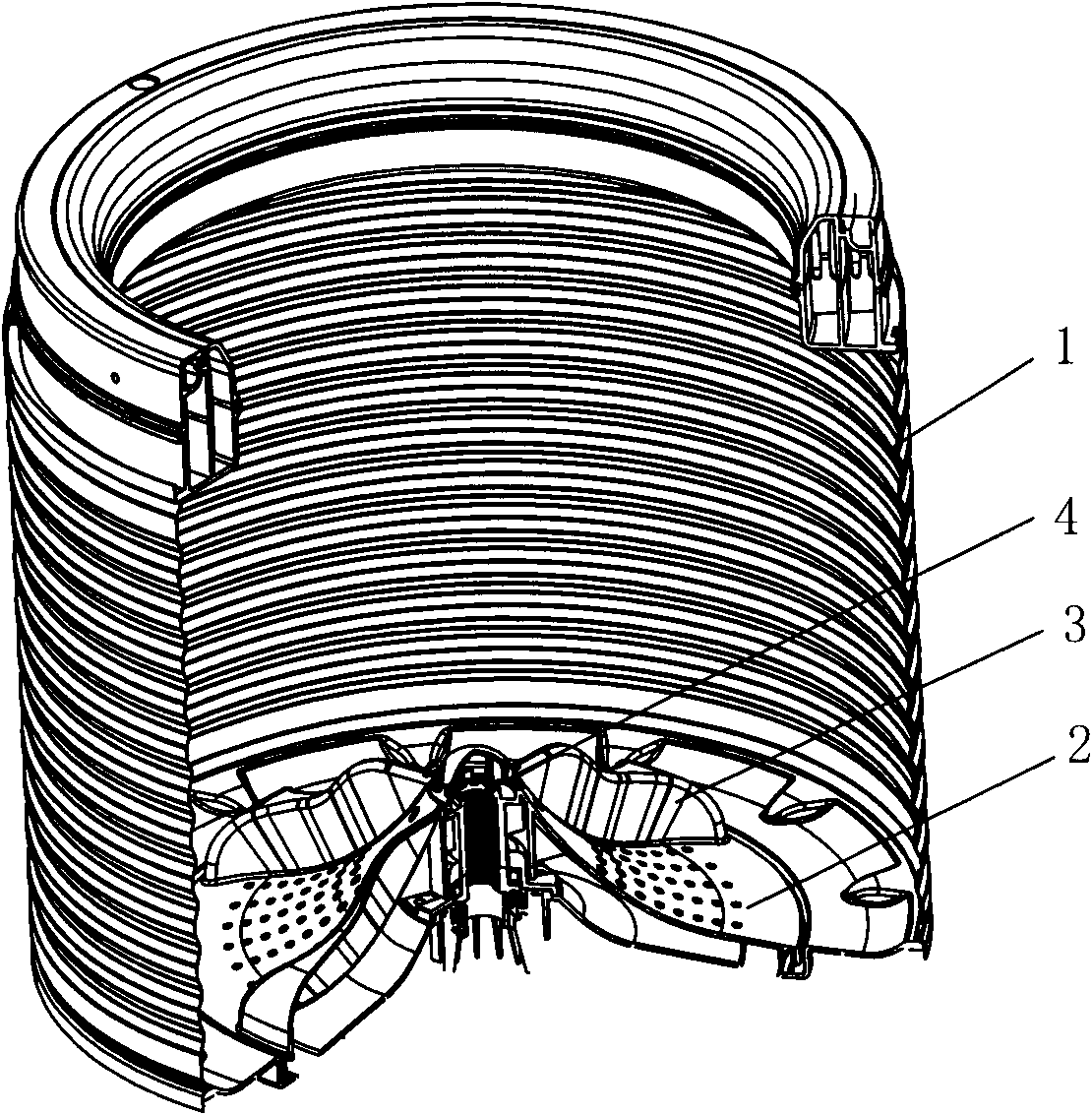

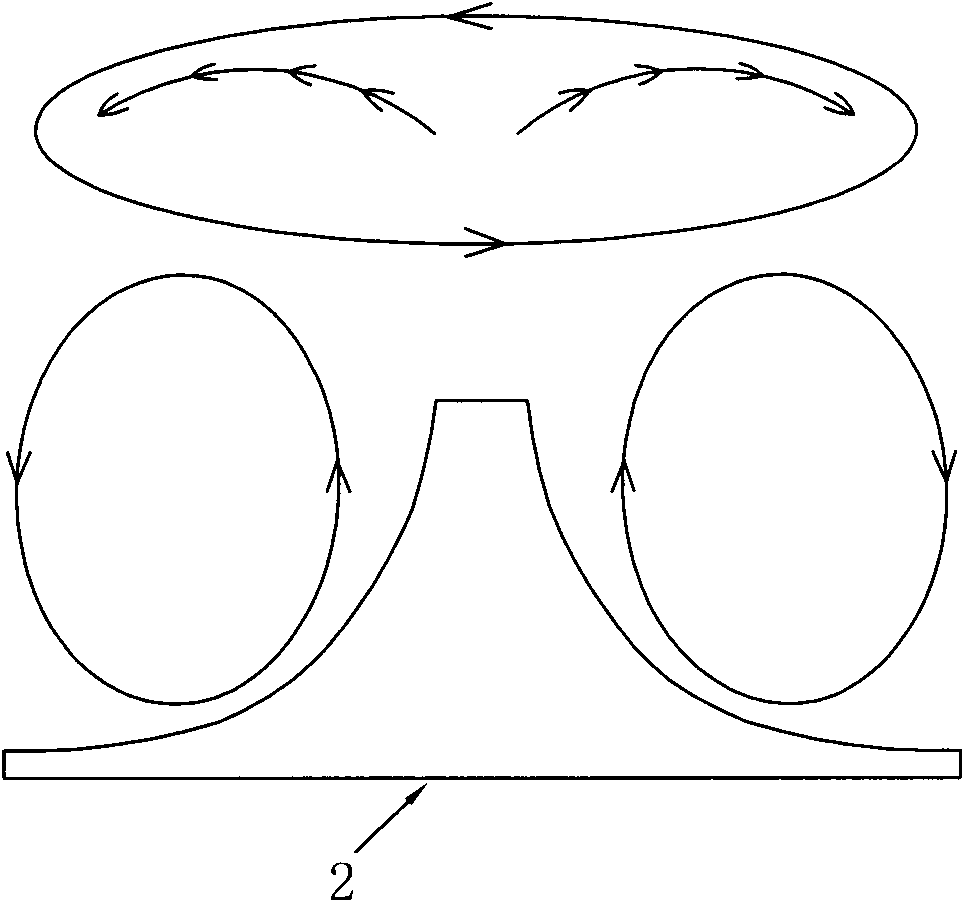

ActiveCN102140748AImprove buffering effectToggle cycle continuousOther washing machinesWashing machine with receptaclesDiameter ratioEngineering

The invention discloses a washing machine with clothes being overturned at constant speed and a washing mode. The washing machine comprises an outer barrel, an inner barrel, a rotatable wave wheel and a driving device, wherein the outer barrel is used for containing water; the inner barrel is arranged in the outer barrel and used for placing clothes; and the driving device is used for controlling the inner barrel and the wave wheel to rotate. Bulges capable of guiding the clothes to move to the center are arranged on the wave wheel, the clothes roll to the periphery in a stacked outward-turning mode and fall into the bottom of the inner barrel along the wall of the inner barrel after moving to the center of the wave wheel and then upwards to a peak, the bulges are radially distributed from the center of the wave wheel to the outside along the radial direction, the upper surfaces of the bulges outwards step down and extend in a tangent mode from the bump part at center of the wave wheel, a plurality of lugs capable of preventing the clothes from fully rotating along with the wave wheel to change the moving direction of the clothes are uniformly distributed on the circumference of the bottom wall of the inner barrel, and the diameter ratio of the wave wheel to the inner barrel is 0.6-0.8. The washing machine improves clothes cleanliness ratio and washing uniformity and saves washing water.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Uniform power washing method and washing machine

ActiveCN102140747AEven frictionReduce dependenceWashing machine with receptaclesTextiles and paperImpellerWater flow

The invention discloses a uniform power washing method and a washing machine. The washing machine comprises an outer barrel for accommodating water, an inner barrel which is arranged in the outer barrel and is used for accommodating clothes, a rotatable impeller, and a driving device for controlling the inner barrel and the impeller to rotate, wherein uniform power is that clothes are influenced by combined force of the centrifugal force of the impeller, applied force between the clothes and the impeller, applied force between the clothes and water flow, and applied force among the clothes in the washing process of the washing machine, move to the center of the impeller along the impeller at the bottom of the inner barrel upwards and arrive at the top while rotating with the impeller, are turned towards the periphery, fall down to the bottom of the inner barrel along the wall of the inner barrel, and are pushed outwards one circle by one circle from the center at a certain frequency and uniformly vibrated and turned layer by layer in the turning process, time for turning once is shorter than 1 minute when a load is less than 60 percent of rated load, time for turning once is 1 to 3 minutes when the load is more than 60 percent of the rated load and less than a full load, and time for turning once is 4 to 5 minutes under the full load condition. The washing machine improves the cleaning ratio and washing uniformity of the clothes.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

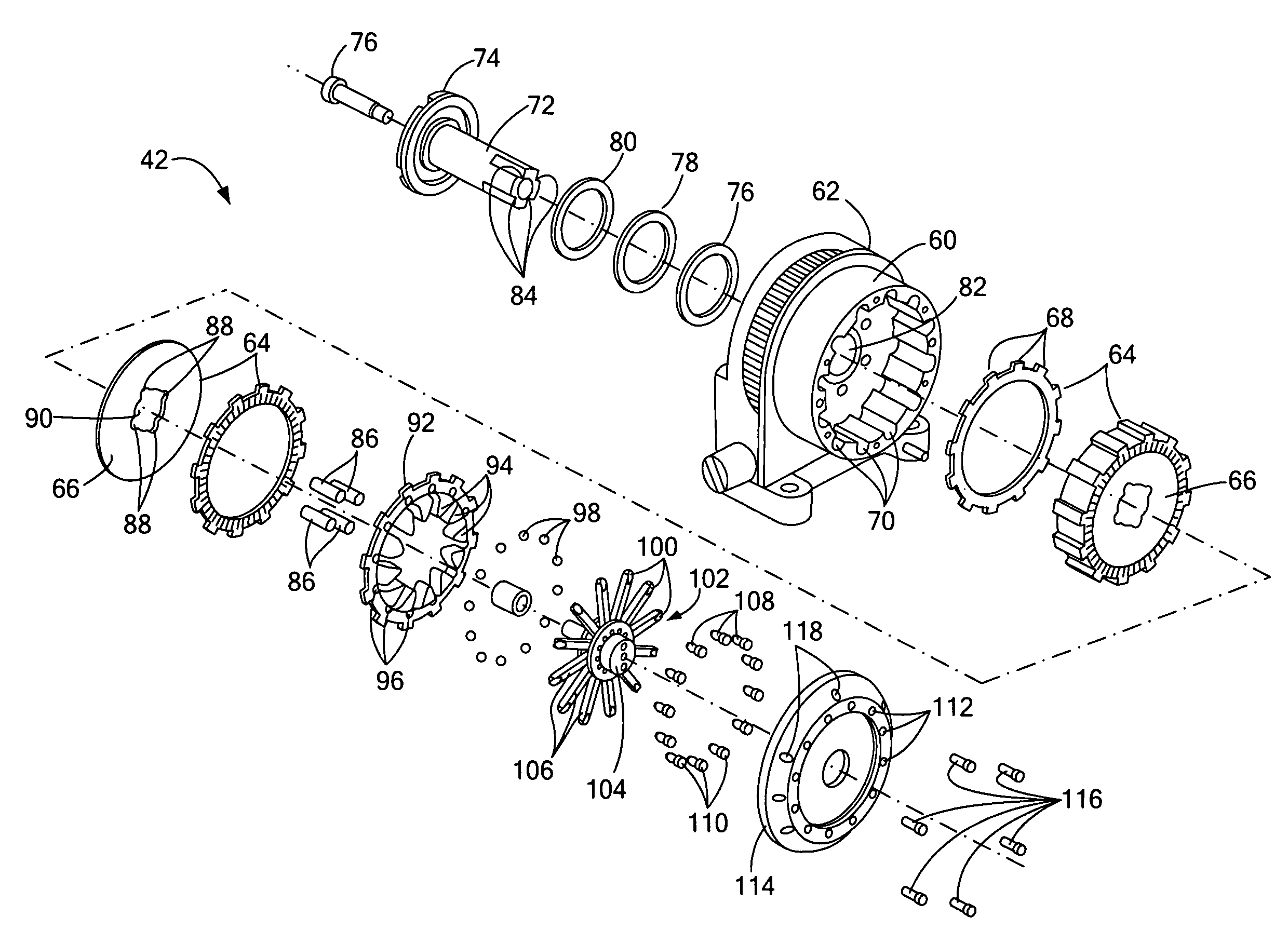

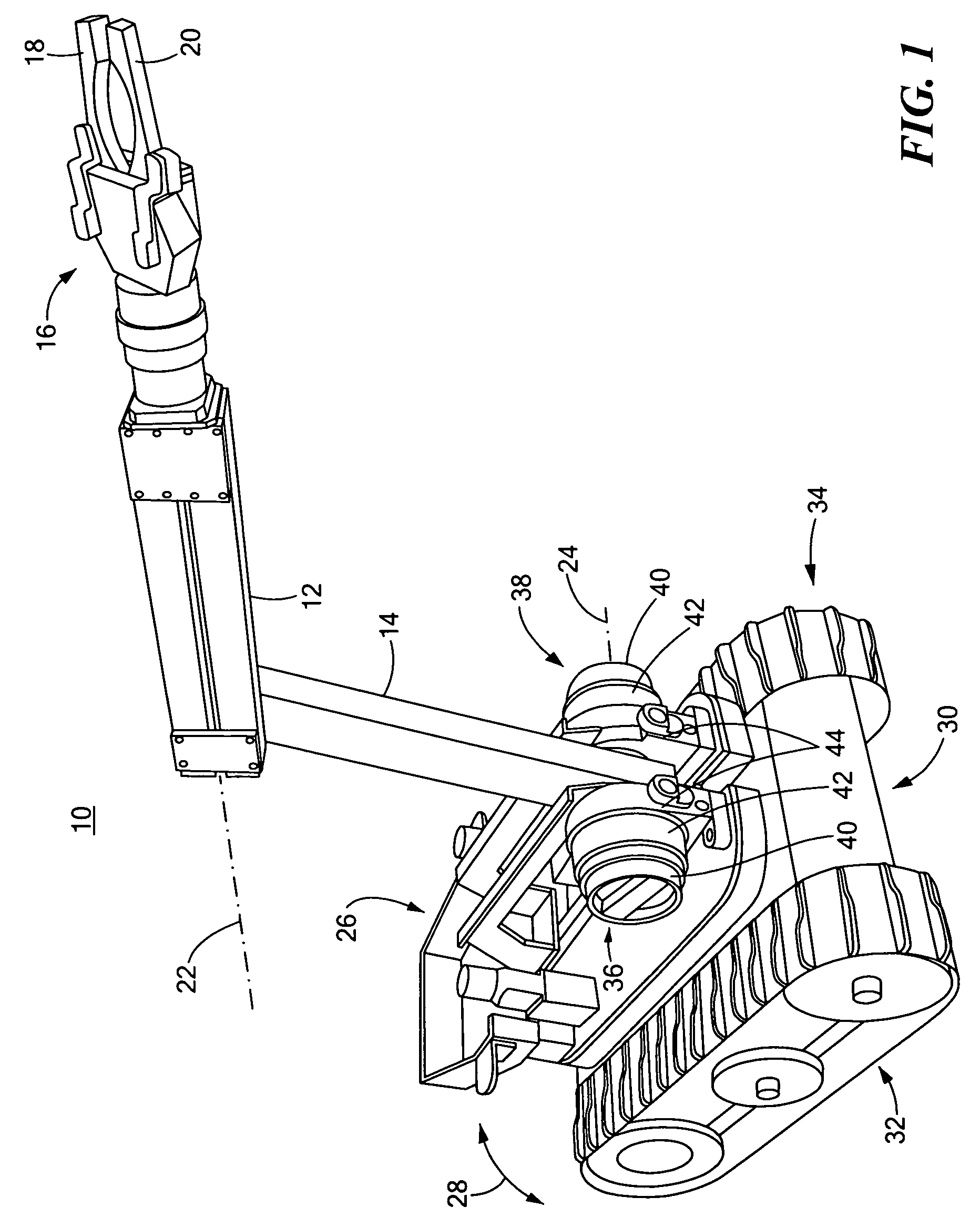

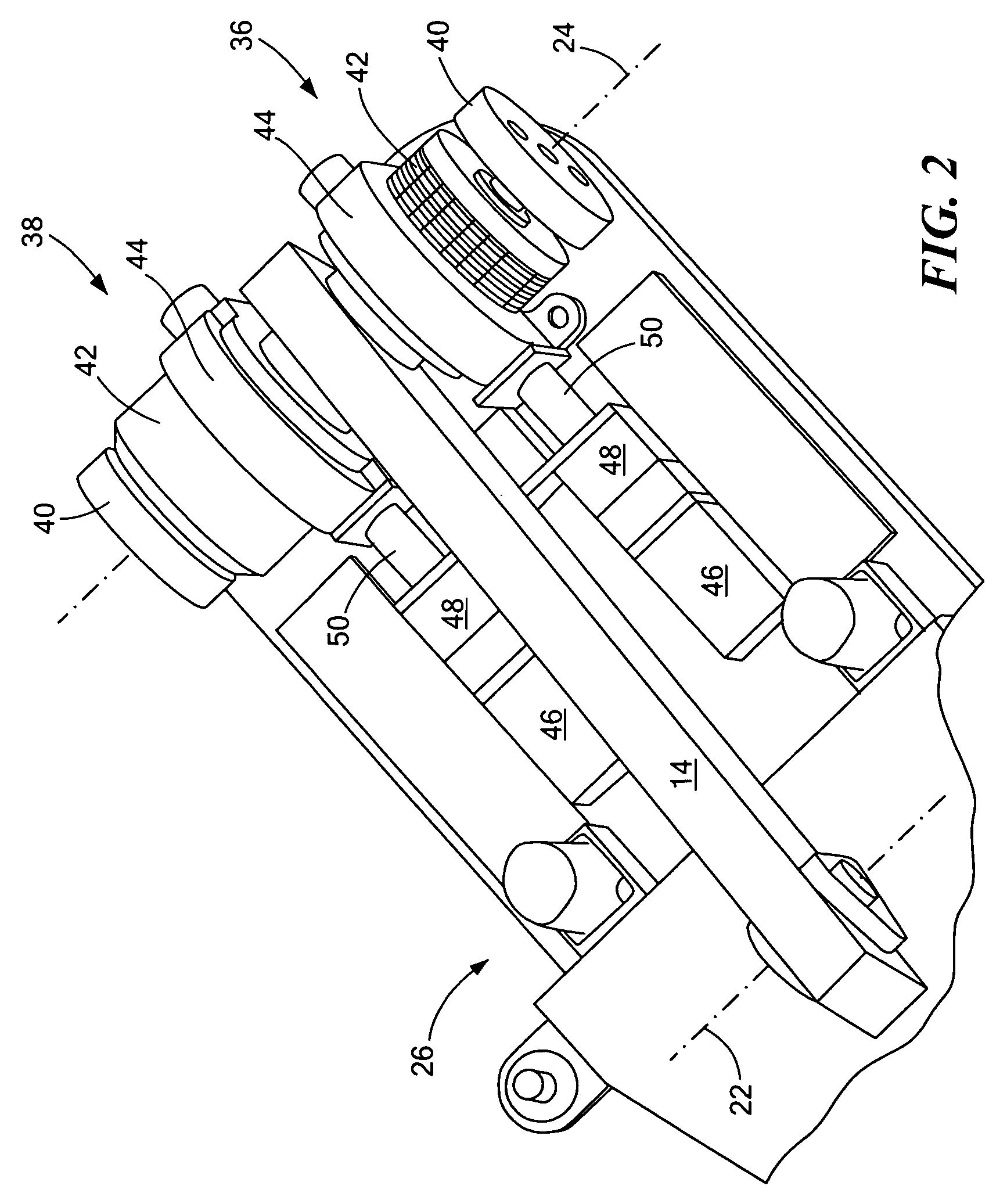

Drive system for mobile robot arm

ActiveUS8776977B2Quick and easy manipulationQuickly and easily accomplishedSlip couplingEngineering safety devicesDrive motorControl theory

A drive system for each arm of a mobile robot, each drive system including a drive motor and an adjustable clutch system interconnected between its associated arm and the drive motor and having a high friction locked position for enabling direct drive of the arm by the drive motor and a reduced friction slip position for enabling manual movement of the associated arm without back-driving the drive motor.

Owner:FOSTER-MILLER

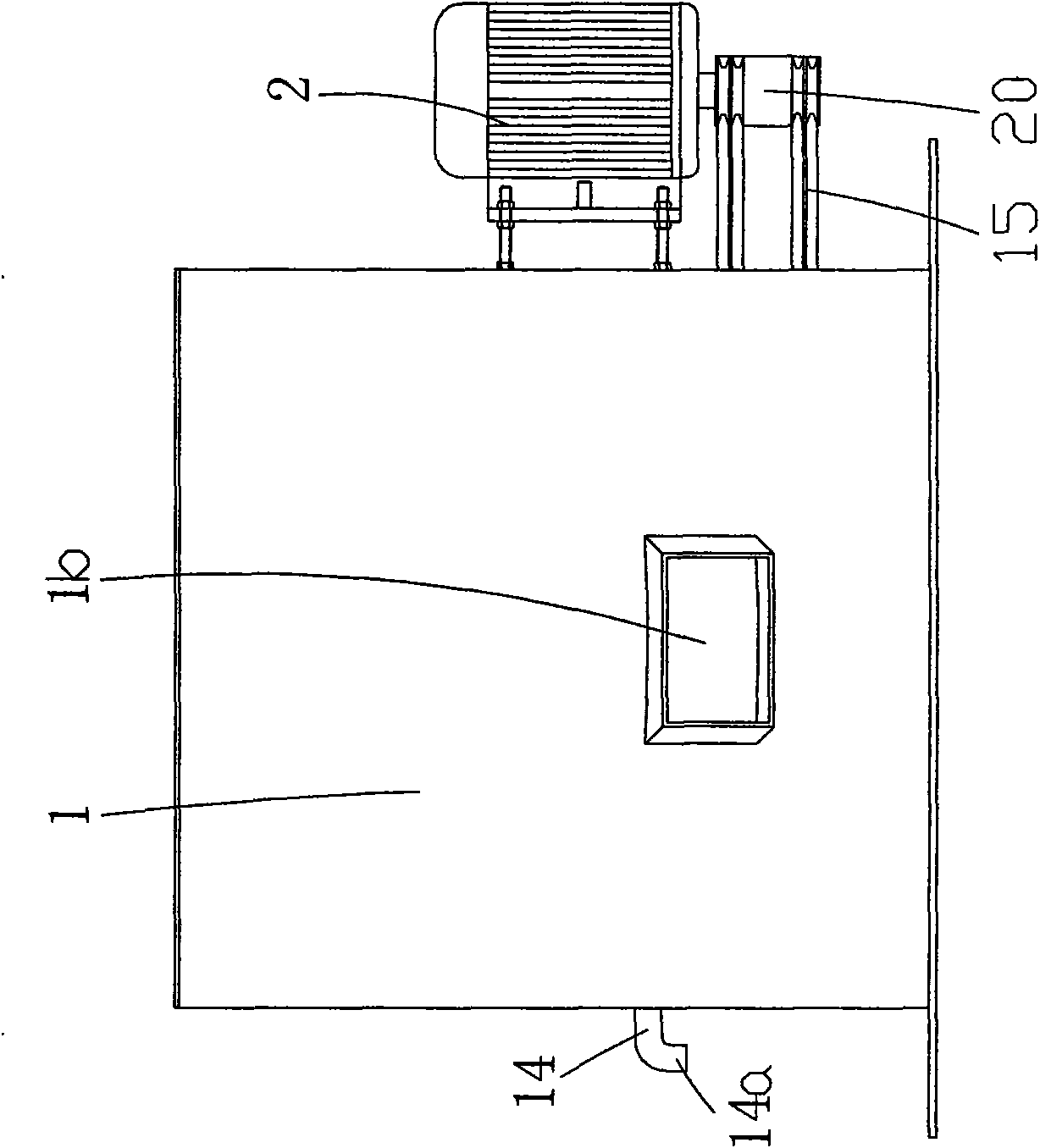

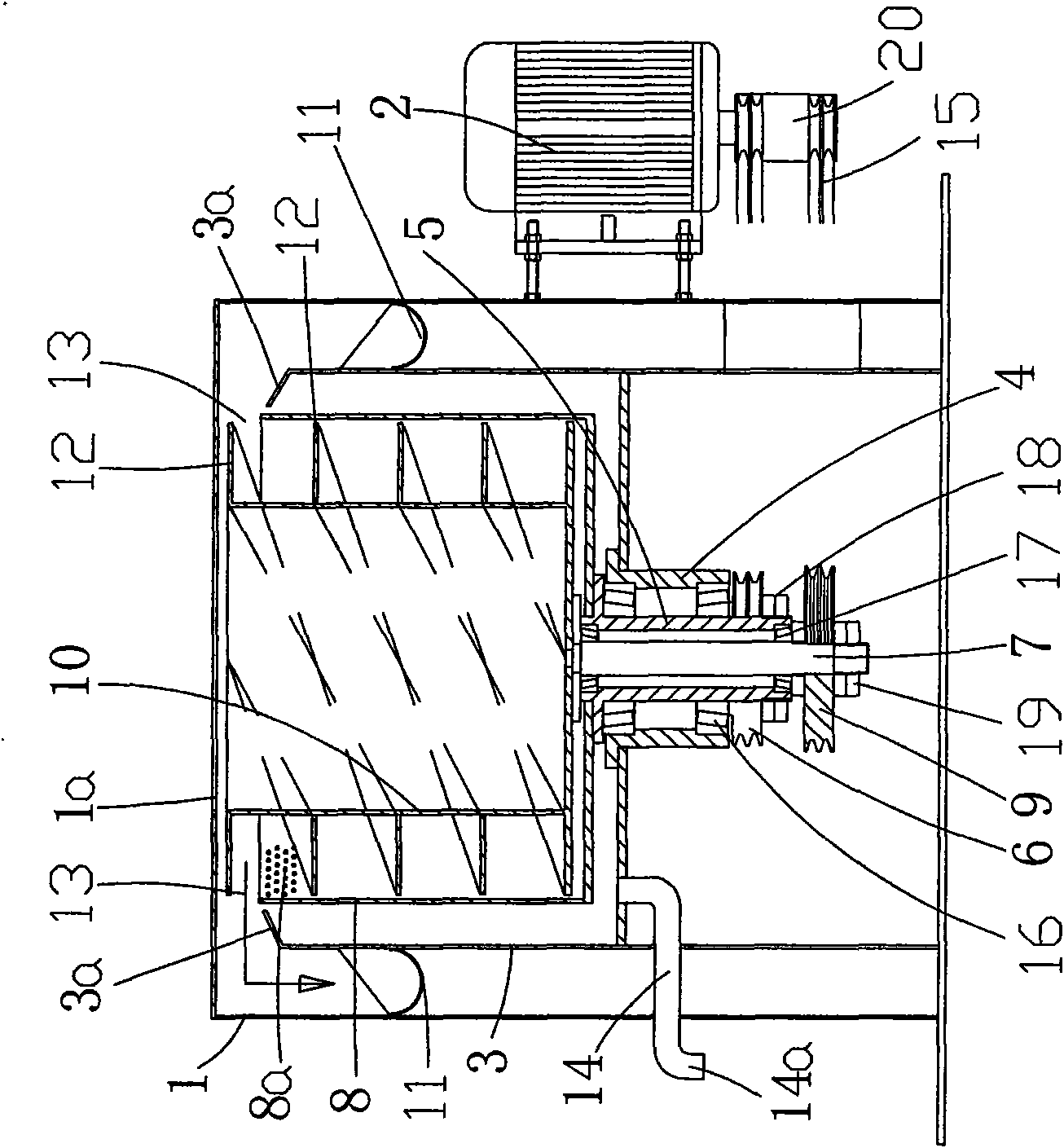

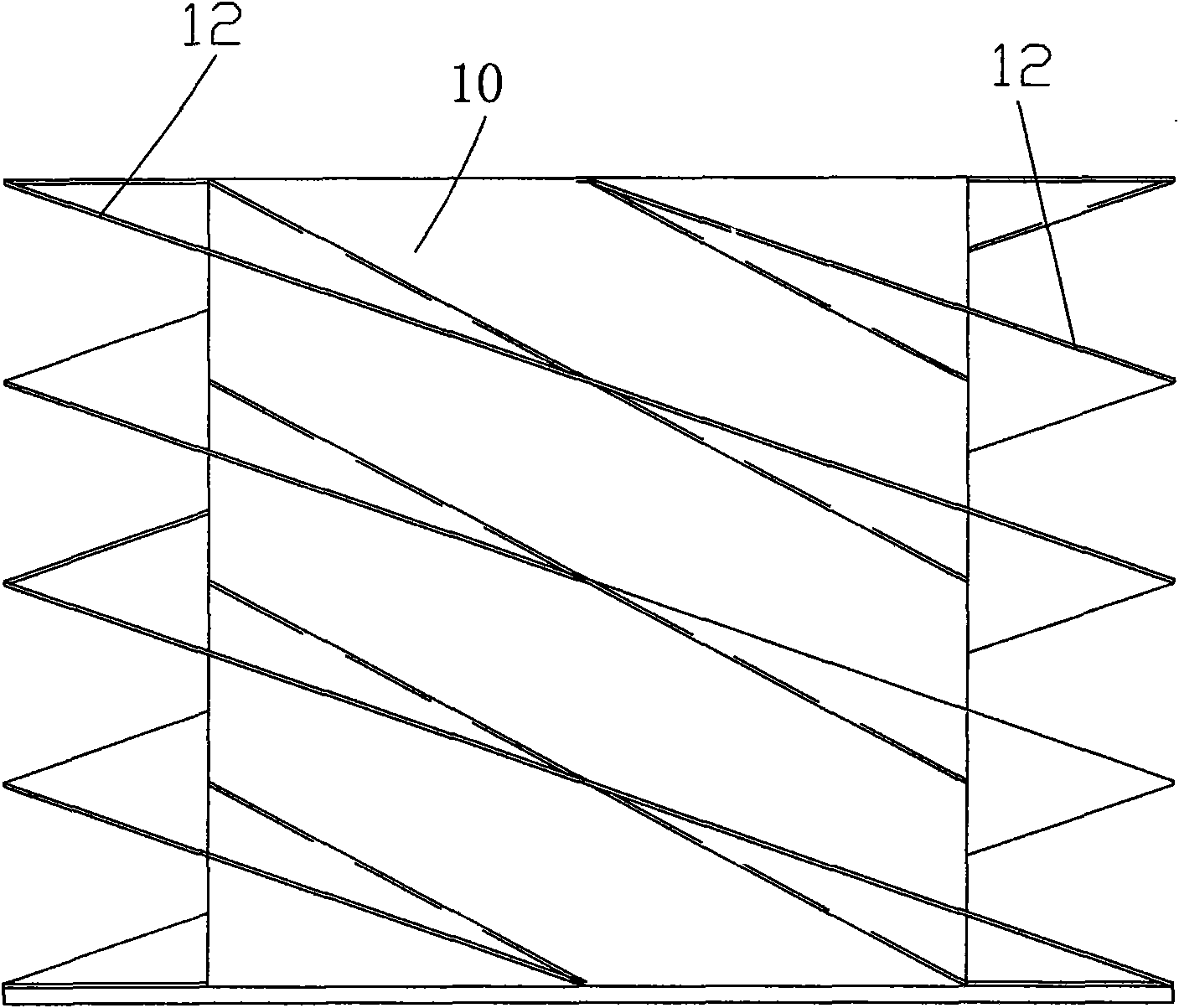

Double-speed automatic degreasing centrifuge

InactiveCN101653750ARealize the highest point limitAchieve automatic separationRotary centrifugesEngineeringCentrifuge

The invention relates to a double-speed automatic degreasing centrifuge which comprises a hollow centrifuge jacket, wherein a motor is fixed on the outer wall surface of the centrifuge jacket; an oilcontaining bucket is embedded and fixed in an inner cavity of the centrifuge jacket; the top end of a lifting shaft is provided with a lifting rack which can receive a product, and the lifting rack isembedded in and matched with an inner middle cavity of an isolating bucket; a material outlet channel is arranged between the outer wall surface of the oil containing bucket and the inner wall surface of the centrifuge jacket; the circumference of the lifting rack is provided with a lifting plate with a helical structure; the peripheral wall of the isolating bucket is uniformly provided with netholes, and oil liquid generated by the centrifugal rotation of a product is directly thrown into an inner cavity on the upper part of the oil containing bucket through the net holes. The lifting platewith a high-end configuration is adopted, thereby realizing the automatic separation during the lifting of the product. The lifting rack is provided with the lifting plate with the helical structure,thus the product can be easily lifted, and the integral effect is excellent. The lifting rack and the isolating bucket are simultaneously operated at double speed, thus, while the product is thrown to clear greasy dirt, the thrown greasy dirt can be drained outwards, furthermore, the problem of high labor intensity is saved and the mechanized operation degree is improved.

Owner:蔡体勇

Sponge gluing machine

ActiveCN106944303AIncrease profitAvoid contactLiquid surface applicatorsCoatingsMetal gridMechanical equipment

The invention provides a sponge gluing machine, and relates to the field of gluing mechanical equipment. The sponge gluing machine comprises a gluing device, a conveying device and a pressure roller device; the gluing device includes stands, a glue storer, a glue outlet roller and a glue loading roller; the left and right ends of the glue storer are fixedly connected with the stands on the left and right sides; the glue outlet roller is arranged in the glue storer; a glue outlet is formed in the bottom of the glue storer; the bottom of the glue outlet roller penetrates through the glue outlet to contact with the glue loading roller; the conveying device includes a base, a conveying motor and a conveying roller; the conveying motor is positioned in the base; the conveying roller is connected with the base through a rotating shaft; the rotating shaft is connected with the conveying motor through a chain; a metal grid is arranged on the base, and is positioned below the glue loading roller; and a glue collecting box is arranged below the metal grid. The sponge gluing machine has the advantages of simple structure, high automation degree, high working efficiency and good coating effect.

Owner:湖北世丰新材料有限公司

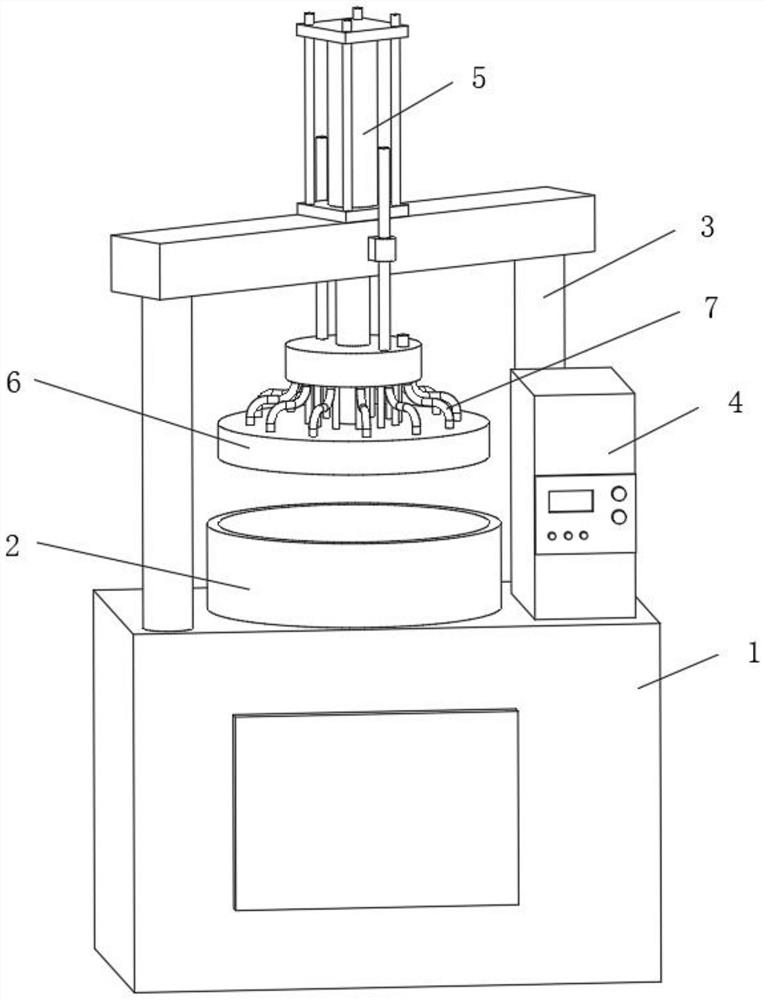

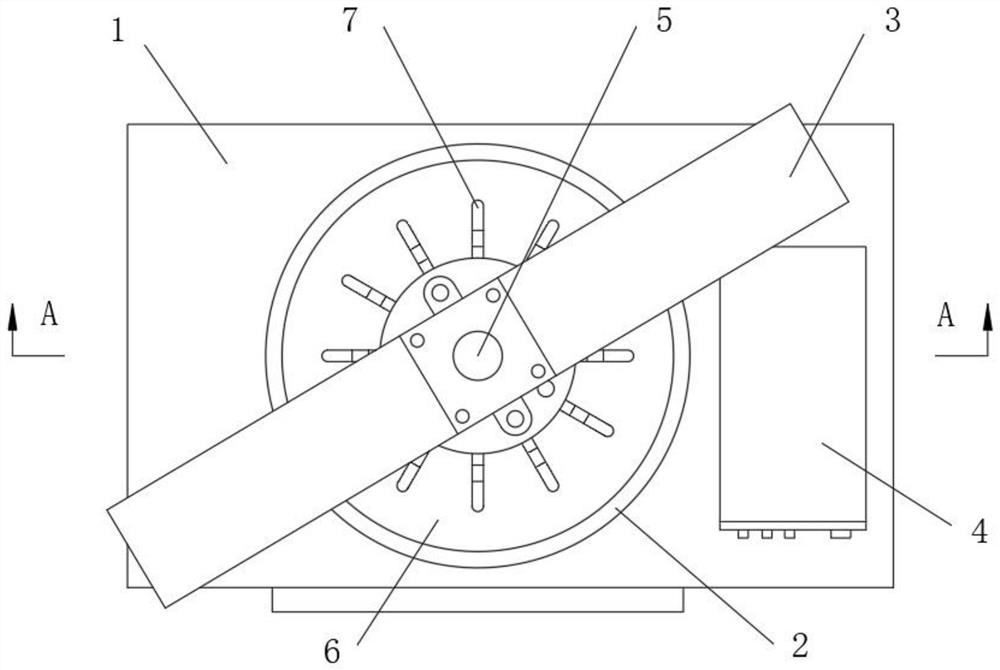

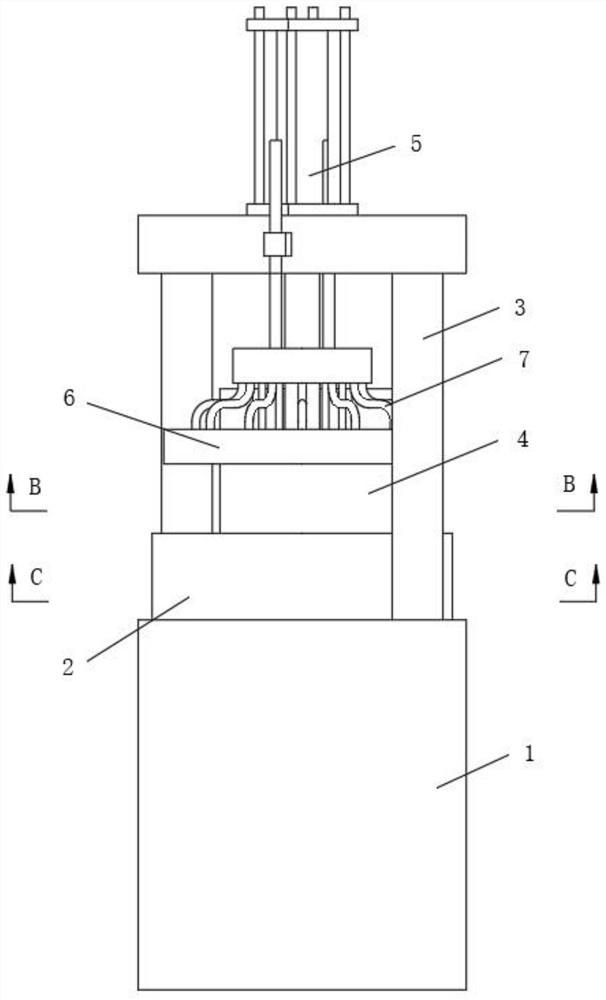

Precision bearing width grinding device and grinding method thereof

ActiveCN112108949AEven frictionGuaranteed service lifeRevolution surface grinding machinesGrinding drivesGear wheelEngineering

The invention relates to the technical field of machining equipment and discloses a precision bearing width grinding device which comprises a machine base. A supporting frame is fixedly installed at the diagonal position of the top face of the machine base, an upper grinding disc is movably installed at the bottom of the supporting frame, liquid outlet grooves are evenly formed in the bottom of the upper grinding disc, and a lower grinding cylinder is fixedly installed in the middle of the top face of the machine base. Rotary grinding discs are annularly and movably installed at the bottom inthe lower grinding cylinder, planetary wheels externally engaged with a rotary gear column gear are movably installed at the tops of the rotary grinding discs, and a slag discharging device is fixedlyinstalled at the position, located between each rotary grinding disc and a rotary gear column, in the lower grinding cylinder. A grinding disc mounting hole is formed in the position, located at thebottom of the center of each rotary grinding disc, of the lower grinding cylinder, and a liquid collecting cavity is formed in the bottom end of the lower grinding cylinder. The device has the beneficial effects of being high in grinding precision and long in service life by designing the multiple rotary grinding discs and the rotary tooth column for engagement rotation and the slag discharging devices.

Owner:丽水市奥佳自动化有限公司

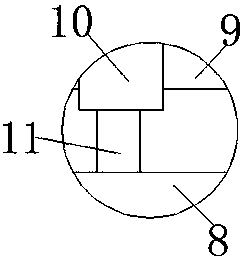

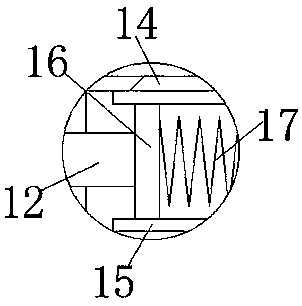

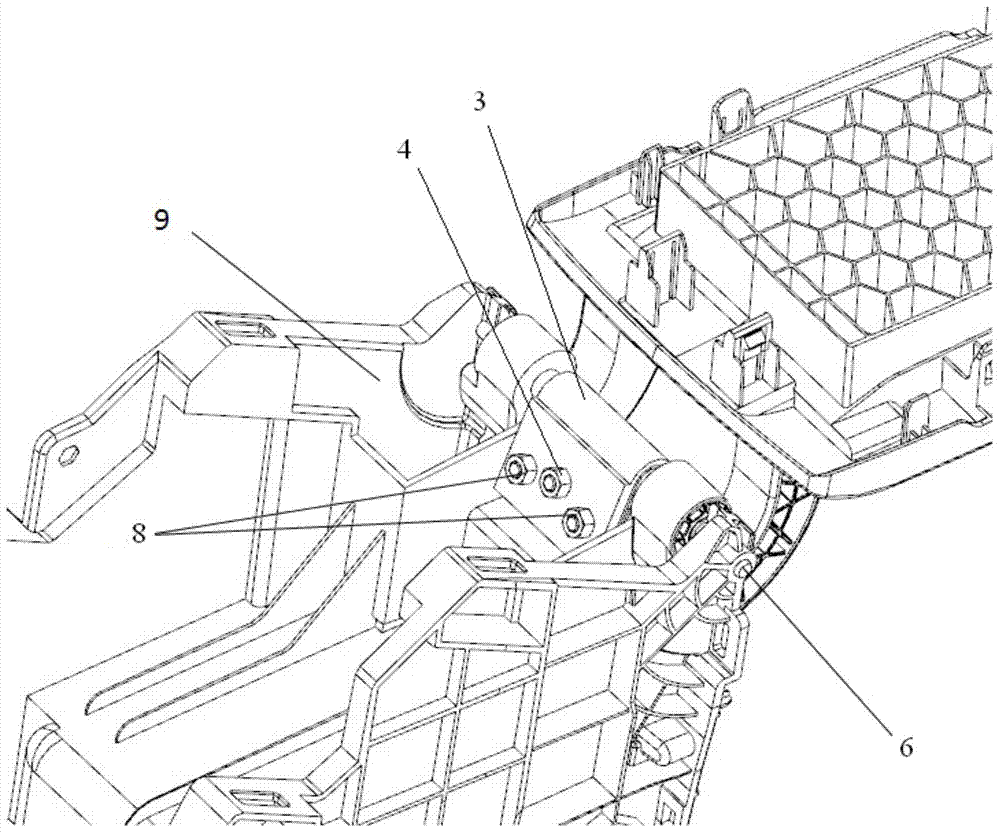

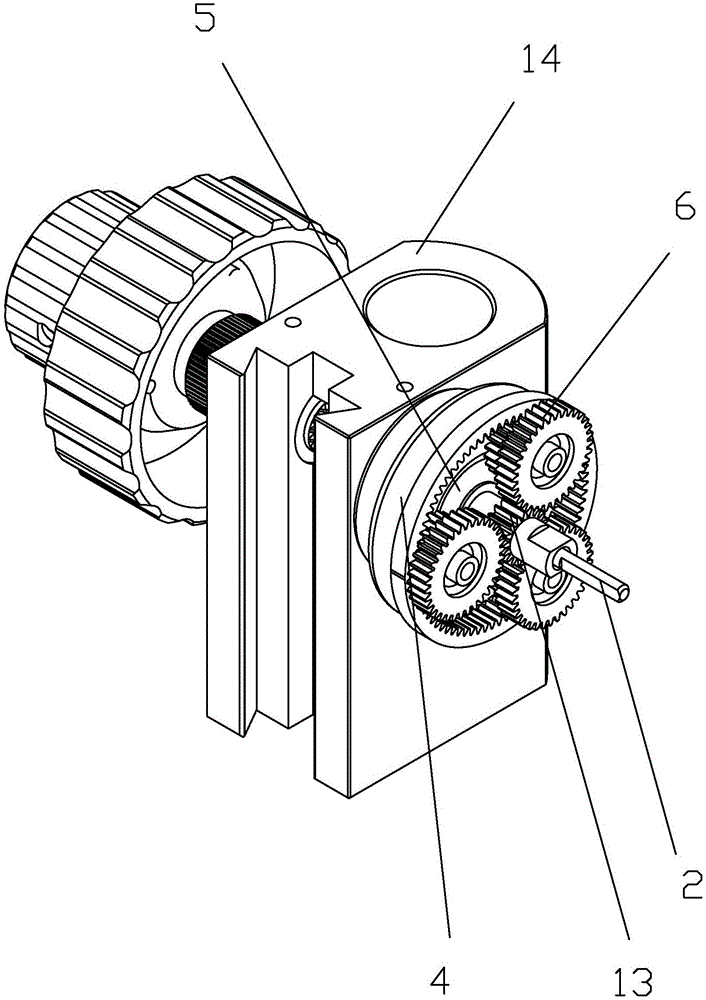

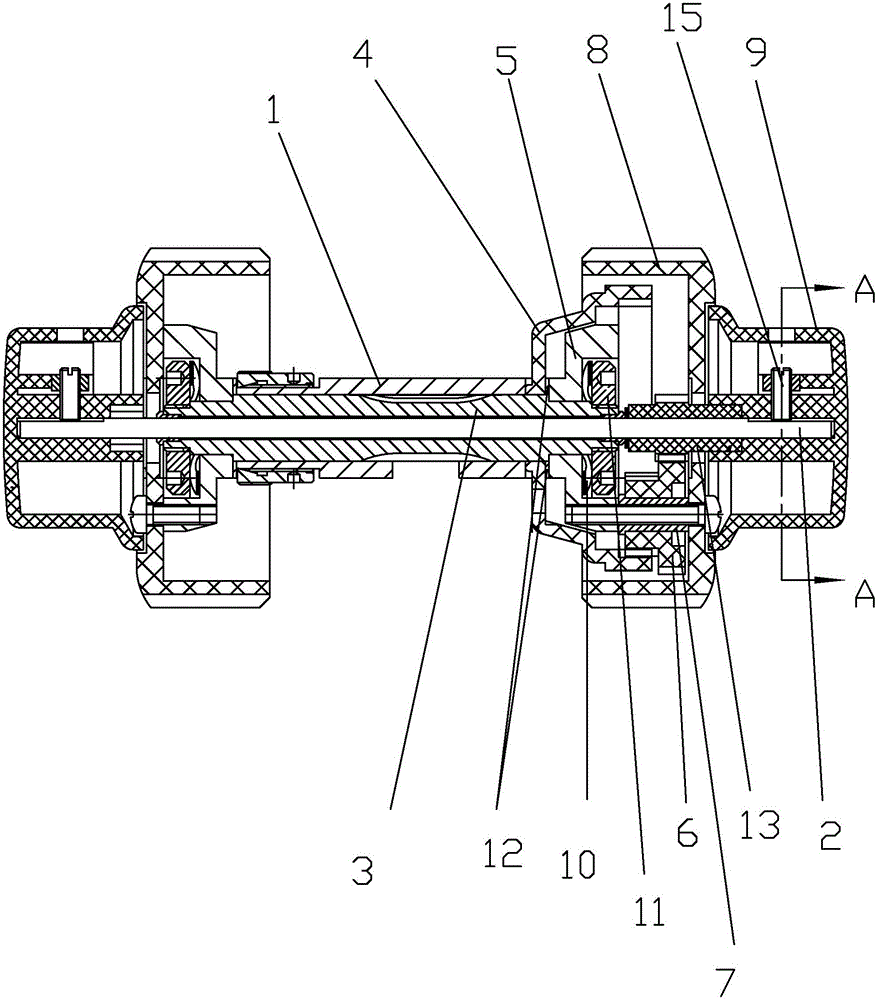

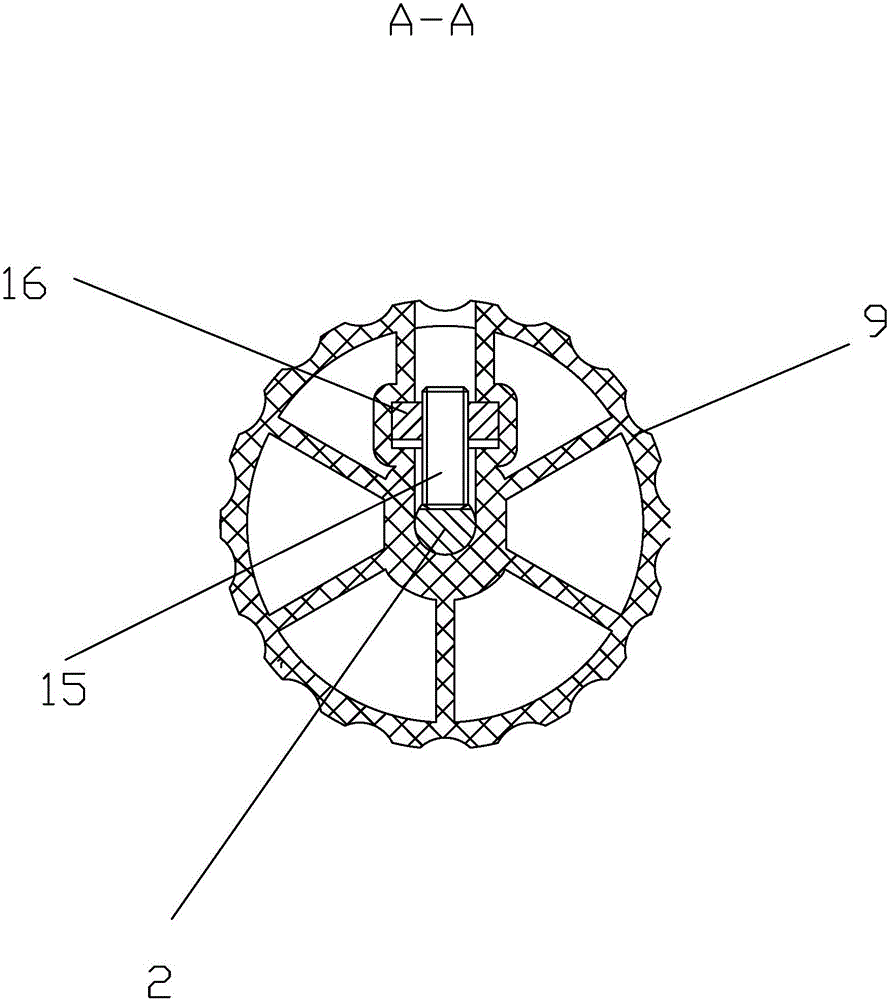

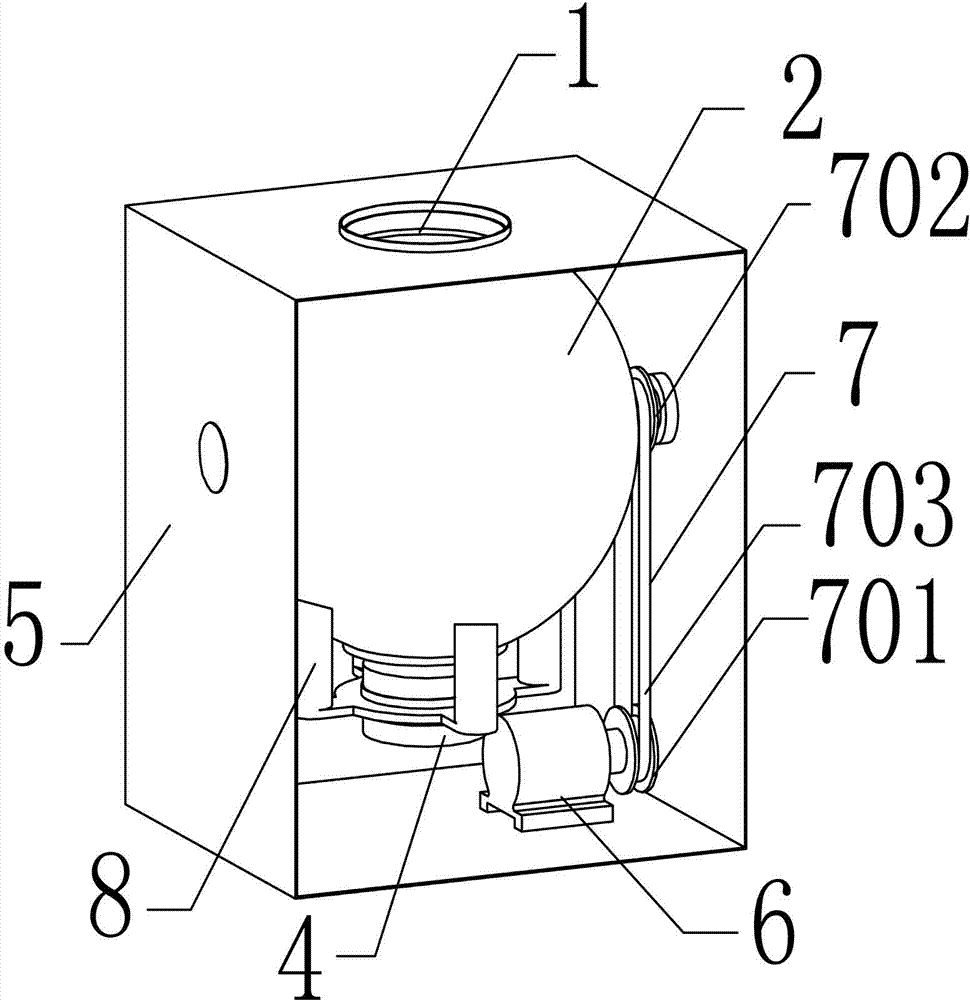

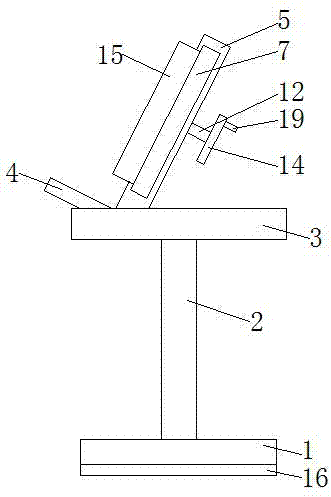

Focusing structure of coarse-fine-tuning coaxial microscope

The invention relates to a focusing structure of a coarse-fine-adjustment coaxial microscope. The focusing structure comprises a coarse tuning gear wheel (3), a fine tuning shaft (2), a tooth bar sleeve (1), a coarse tuning hand wheel (8), and a fine tuning hand wheel (9), wherein the tooth bar sleeve (1), the coarse tuning hand wheel (8), and the fine tuning hand wheel (9) are installed on a microscope body (14) axially. A fixed center wheel (4) is fixedly connected to one end of the tooth bar sleeve (1) between the tooth bar sleeve (1) and the coarse tuning hand wheel (8); and a connecting sleeve (5) sleeves the outer wall of one end, arranged inside the cavity of the fixed center wheel (4), of the coarse tuning gear wheel (3). A transmission mechanism includes a wave-shaped spring washer (10) and a fixed nut (11); the fixed nut (11) cooperates with a thread formed at the outer side of the end portion of the coarse tuning gear wheel (3); and the wave-shaped spring washer (10) is arranged between the inner wall of the connecting sleeve (5) and the fixed nut (11). A gear wheel is arranged at the outer wall of one end of the fixed center wheel (4); a center wheel (13) is arranged at the outer wall of the fine tuning shaft (2); and the fine tuning hand wheel (9) is fixedly connected with the end portion of the fine tuning shaft (2).

Owner:NINGBO HUAGUANG PRECISION INSTR

Uniform power washing method and uniform power washing machine

ActiveCN102146626AEven frictionReduce dependenceWashing machine with receptaclesTextiles and paperLaundry washing machineControl theory

The invention discloses a uniform power washing method and a uniform power washing machine. The uniform power washing machine comprises an outer barrel for accommodating water, an inner barrel arranged in the outer barrel and used for placing clothes, a rotatable wave wheel and a driving device for controlling rotation of the inner barrel and the wave wheel; the uniform powder means that: after the clothes move to the center of the wave wheel at the bottom of the inner barrel along the wave wheel and upwards reach a vertex while following the wave wheel to rotate in the clothes washing process of the washing machine, the clothes roll to the periphery and falls to the bottom of the inner barrel along the wall of the inner barrel, the clothes are uniformly shaken and turned layer by layer from center to outside in a form of one circle of push and one circle of superposition in the turnover process, the size of the swing angle of the wave wheel is determined according to the load of the clothes so that the stress directions of the clothes correspond to the moving directions of the turnover locus respectively, and the swing angle of the low-load clothes wave wheel is 150 to 200 degrees; the swing angle of the medium-load clothes wave wheel is 200 to 250 degrees; and the swing angle of the heavy-load clothes wave wheel is 250 to 300 degrees. The washing machine has the characteristics of improving the washing ratio and the washing uniformity of the clothes.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Spinning oil for fine-denier melt-spun spandex fiber

The invention discloses spinning oil for a fine-denier melt-spun spandex fiber. The oil comprises the following components by weight percentage: 30-60% of dimethyl silicon oil, 30-50% of modified silicone oil, 0-10% of nonionic surfactant and the balance of other additive, wherein the modified silicone oil is amino modified silicone oil or polyether modified silicone oil; polysiloxane chain segments m and n in the amino modified silicone oil are equal to 30-120; an adduct number b of polyoxyethylene chain segments in the polyether modified silicone oil is equal to 0-10; an adduct number a of polyoxypropylene chain segments is equal to 0-10; the nonionic surfactant is fatty alcohol polyoxyethylene ether, fatty alcohol polypropylene oxide ether or fatty alcohol polyoxyethylene polyoxypropylene ether; and other additive is phosphate potassium salt of alkyl alcohol polyoxyethylene ether.

Owner:TIANJIN POLYTECHNIC UNIV +1

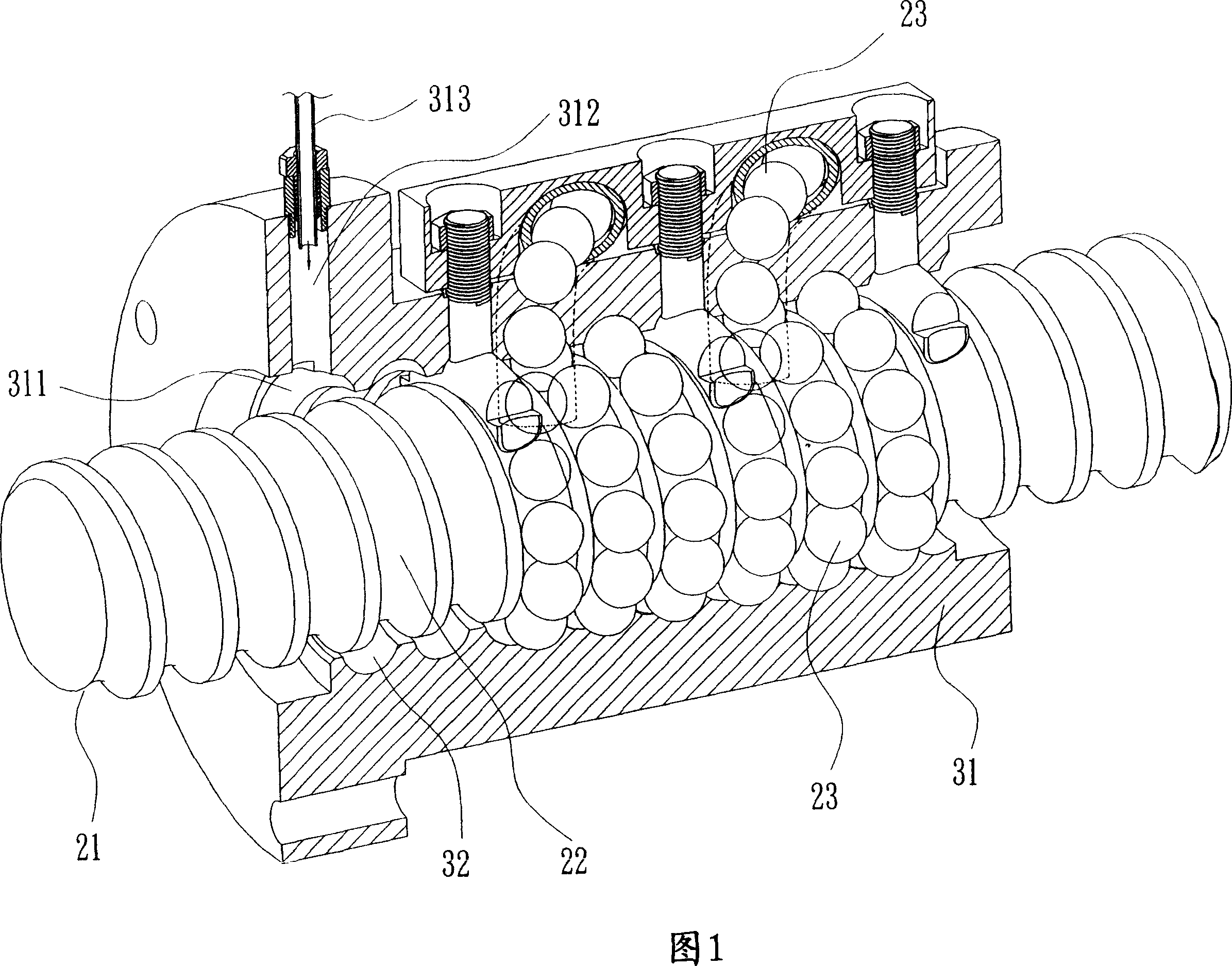

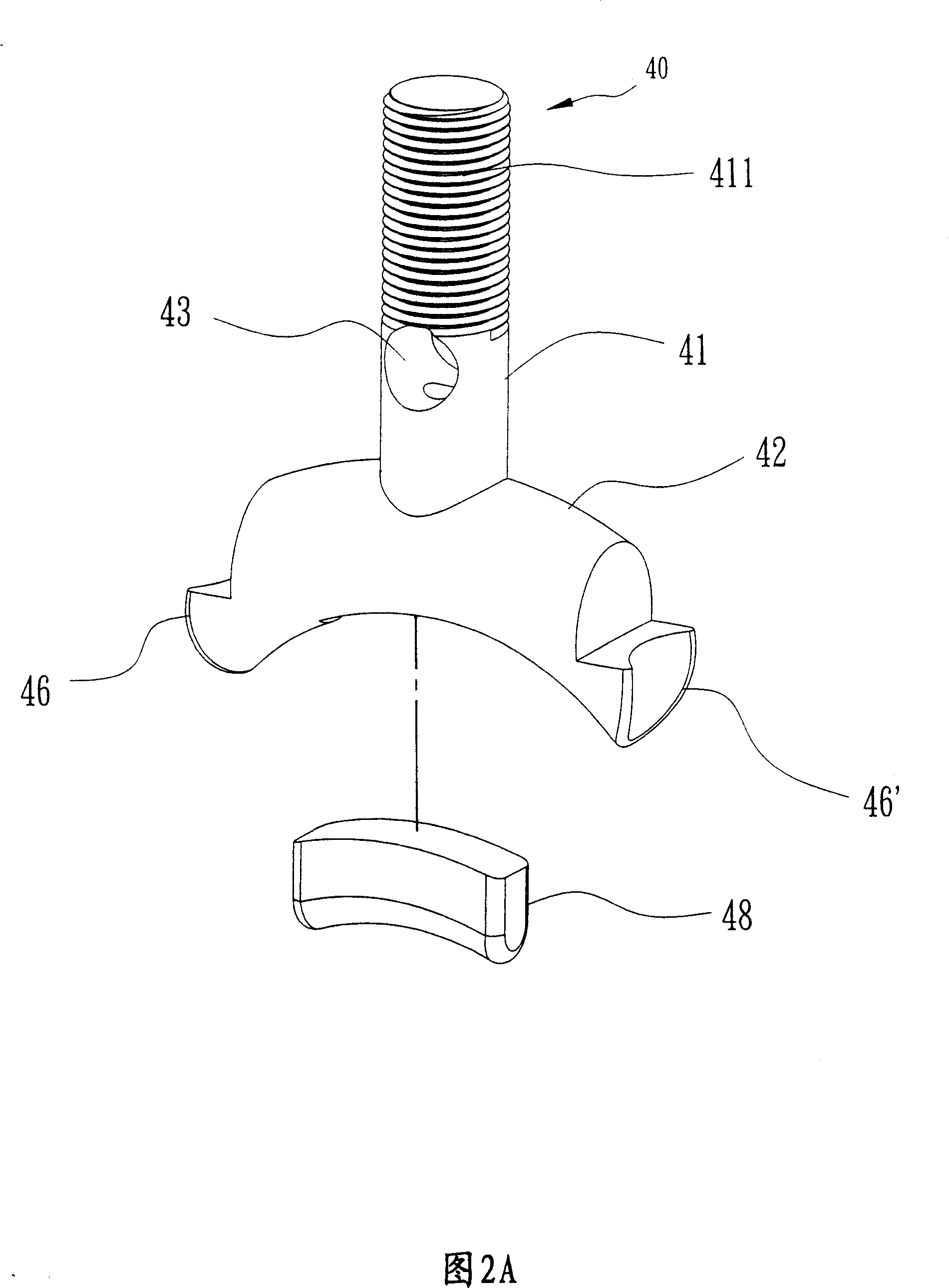

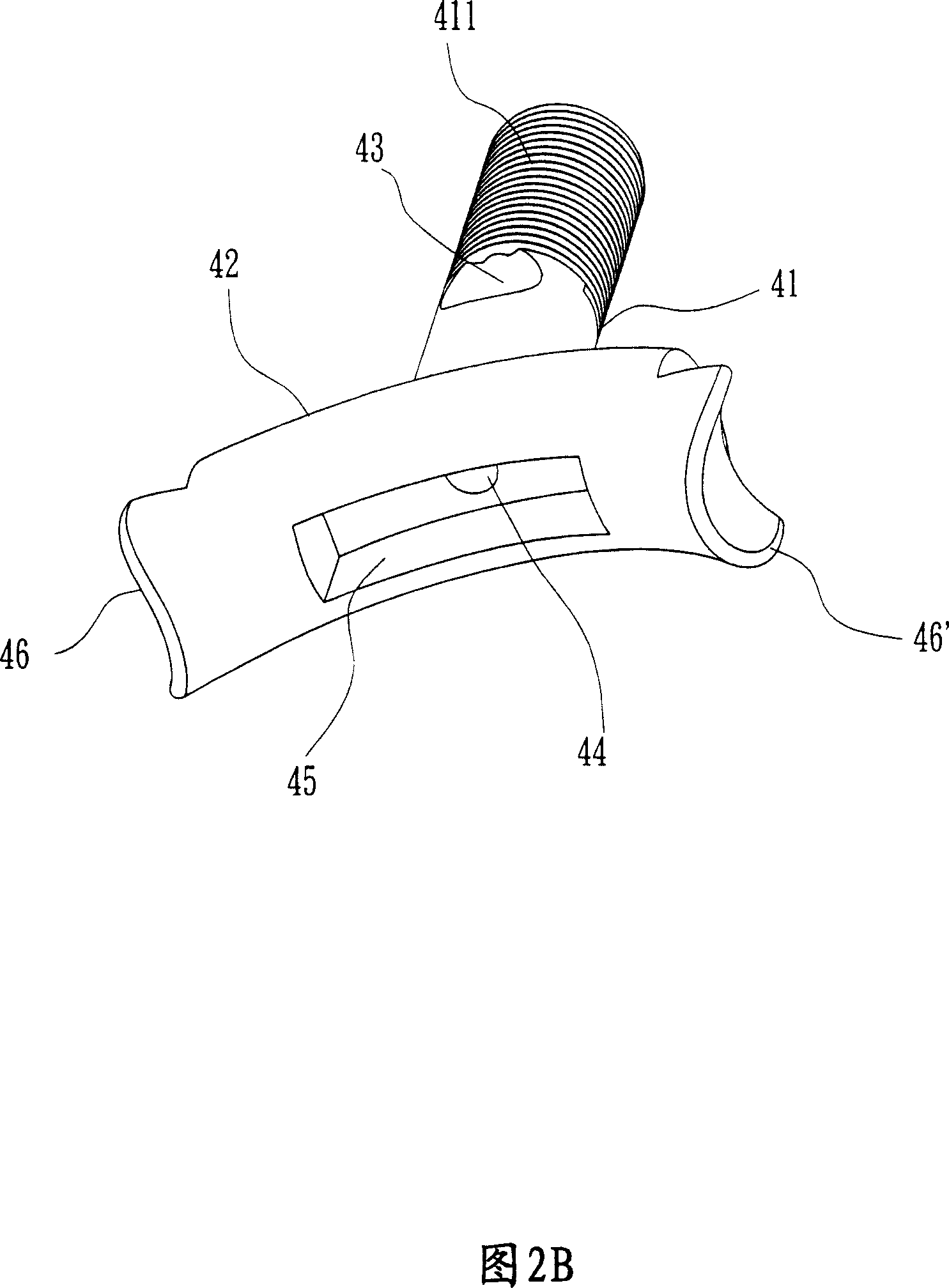

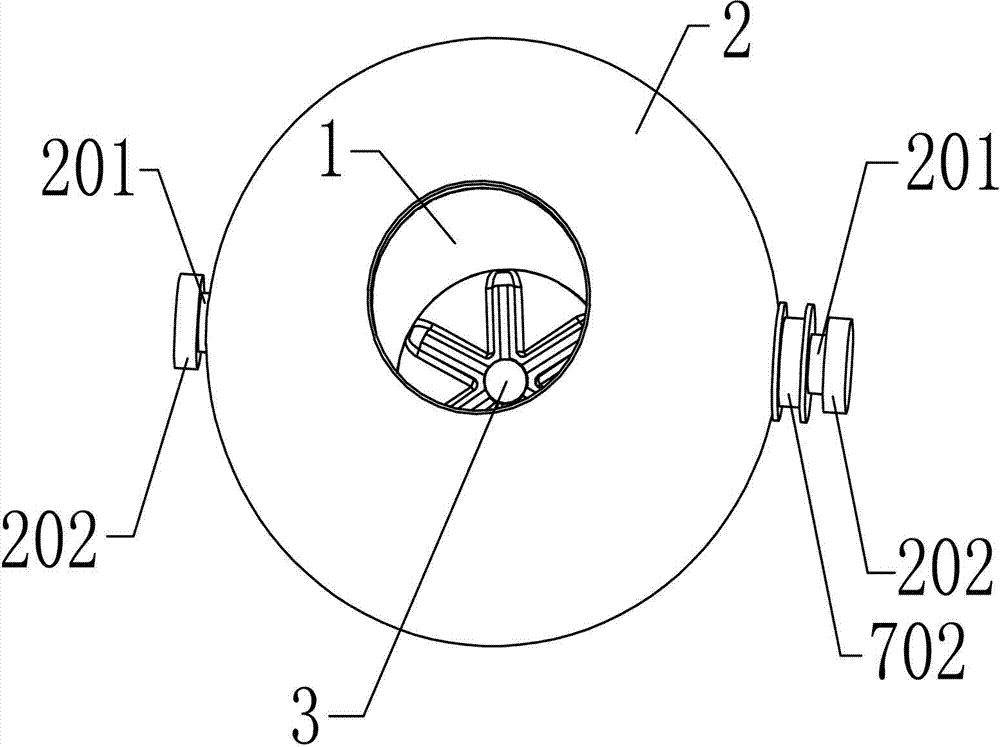

Self-lubricator of ball leading lever

ActiveCN1940351AImprove the lubrication effectSmooth transmissionGearingGear lubrication/coolingEngineeringBall screw

There is disclosed a ball-screw self-lubricator and at the bottom of the self-lubricator is disposed an oil-sucking element standing on the ball track of the screw, so as to lubricate the ball track in different positions. On each side of the self-lubricator is disposed a steering part capable of leading the ball rolling in the screw ball track into a return pipe and then into another ball track position of the screw. Both sides of the oil-sucking element protruded from the corresponding steering parts can contact with the return ball and the ball is lubricated by the oil-sucking element. The oil-sucking element can store the lubricating oil, so it can lubricate the screw ball track continuously during the driving of the ball-screw.

Owner:HIWIN TECH

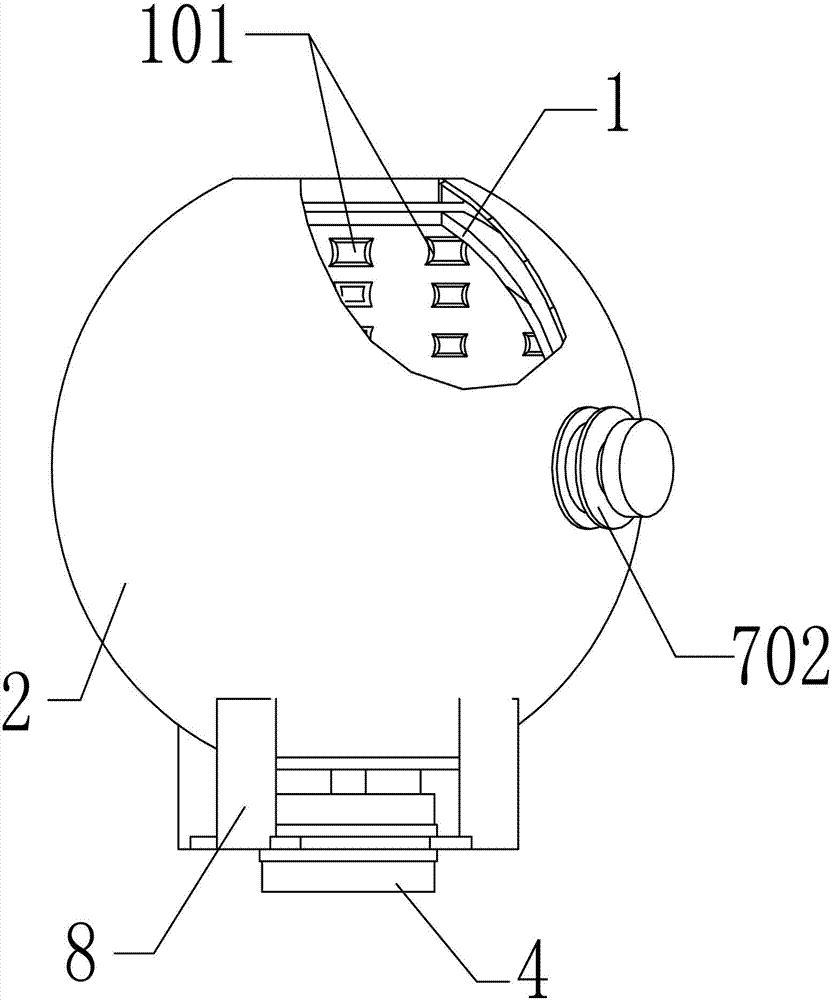

Two-degree-of-freedom spherical barrel washer

InactiveCN104746277AImprove wash flipping effectWash evenlyOther washing machinesWashing machine with receptaclesImpellerLaundry washing machine

The invention relates to the field of washing equipment, in particular to a two-degree-of-freedom spherical barrel washer. The washer comprises an inner barrel, an outer barrel, an impeller, an impeller motor, a box, a barrel motor and a transmission, wherein the inner barrel, the outer barrel, the impeller and the impeller motor are all arranged in the box, the inner barrel and the outer barrel are of concentric spherical shapes, openings are formed above the inner barrel and the outer barrel and are communicated with an opening above the box; the inner barrel is arranged in the outer barrel, the inner surface is provided with a plurality of protuberances, and the two sides of the outer barrel are provided with rotating shafts which are respectively hinged with the box through bearings; the impeller is arranged at the inner bottom part of the inner barrel, the impeller motor is fixedly arranged at the bottom of the outer barrel through a motor seat, and a rotating shaft of the impeller motor is fixedly connected with the impeller; the barrel motor is fixed at the inside bottom of the box, the input end of the transmission is connected with the rotating shaft of the barrel motor, and the output end of the transmission is connected with the rotating shaft arranged on the outer wall of the outer barrel. According to the washer provided by the invention, the washing and overturning effect of clothes can be improved, the washing ratio can be improved, and the washer has the functions of the impeller washer and parts of functions of the barrel washer.

Owner:王涛

Method for manufacturing a metal scrap compression material

The present invention relates to a method for manufacturing a metal scrap compression material. According to the method for manufacturing the metal scrap compression material, a through-hole is not punched after compressing the metal scrap compression material, but rather a through-hole is formed during the process of manufacturing the metal scrap compression material. Thus, even though the through-hole is formed in the metal scrap compression material which is compressed and formed so as to be highly dense, friction and stress applied to a core may be minimized to minimize the damage of the core and a failure occurrence rate.

Owner:DAEJONG IND +1

Dynamic scheduling of jobs/batches using earliest completion time algorithm in cellular manufacturing with batch-splitting of jobs above certain size

ActiveUS8464268B2Increase productionImprove efficiencyProgramme controlMultiprogramming arrangementsCompletion timeEarliest finish time

The present application a new and improved system and method of enhanced Lean Document Production (LDP), which applies cellular manufacturing to document printing operations. The LDP process incorporates process friendly cells and, a push model to order to improve efficiency, reduce work in progress and smooth out the “frictions” in production environments. The current application presents an earliest-completion-time strategy for assigning jobs to cells and a dynamic-priority-based-batch-scheduling algorithm.

Owner:XEROX CORP

Cleaning Wiper for Glass

InactiveUS20150067975A1Even frictionSatisfactory flowBoard cleaning devicesCarpet cleanersEngineeringMoisture

This invention relates to a cleaning cloth for glass which is convenient in wiping water moistures, stubborn stains, watermarks, hand stains, fat, and the like of the glass products (hereinafter refer to as ‘glass surfaces’) such as liquid crystal device or glass and the like.

Owner:CLEMBON

Tank tidying device for continuous sterilization machine

ActiveCN102730242AEasy to handleSmooth and straighten outPackage sterilisationConveyor partsDrive shaftControl engineering

The invention discloses a tank tidying device for a continuous sterilization machine. The tank tidying device comprises a support, a driving shaft and a driven shaft are rotatablely arranged on the support; mutually corresponding conveyor belt wheels are arranged on the driving shaft and the driven shaft respectively; V-shaped ring grooves are formed on the outer peripheral surfaces of the conveyor belt wheels; tank tidying conveyor belts are in transmission connection between the corresponding conveyor belt wheels on the driving shaft and the driven shaft; V-shaped conveyor troughs matched with the ring grooves are arranged between the corresponding conveyor belt wheels on the driving shaft and the driven shaft; the tank tidying conveyor belts pass through the conveyor troughs and are sleeved on the inner side walls of the ring grooves; and the driving shaft is in transmission connection with a tank tidying power device. The tan tidying device is reasonable in structure, the tank body processing capacity is strong, and the tidying and conveying of a tank body are performed smoothly, so that the tank tidying device can meet requirements on continuous and mass production.

Owner:山东鼎泰盛机械科技有限公司

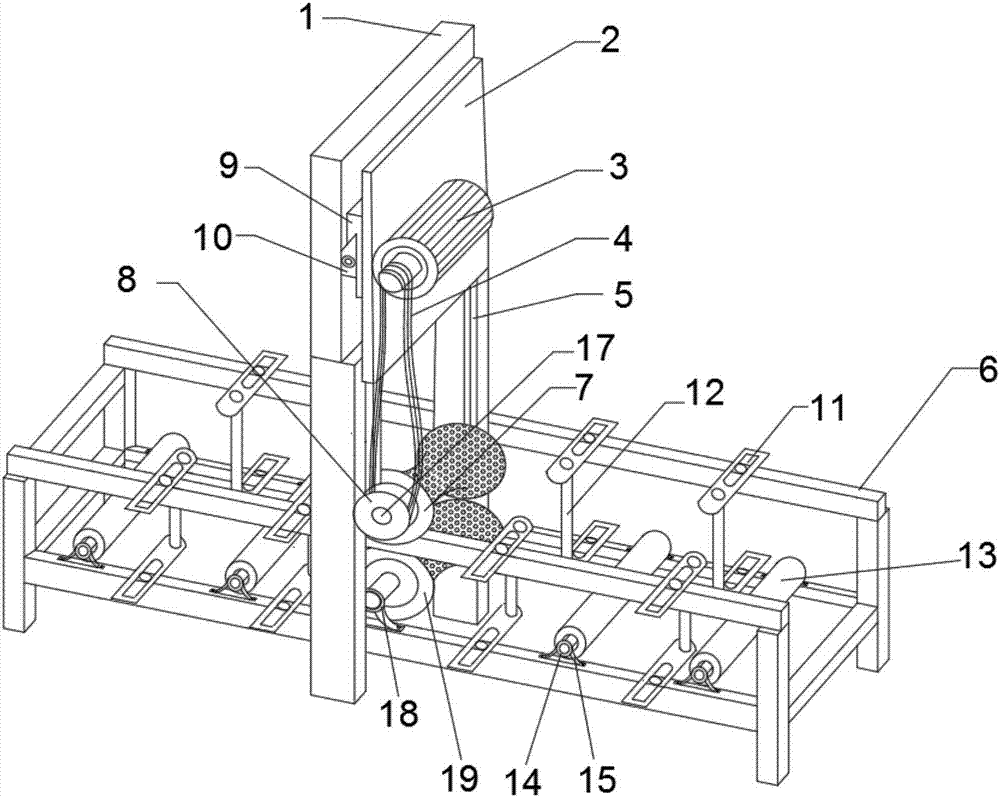

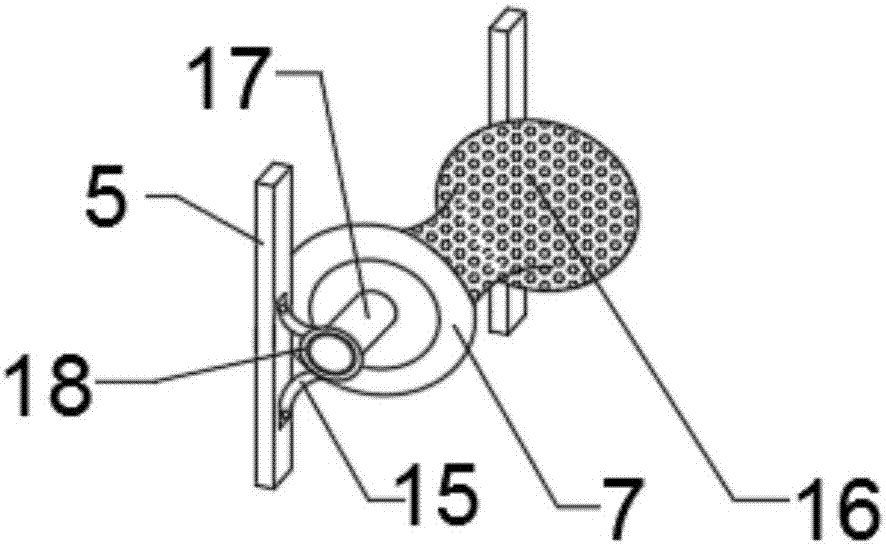

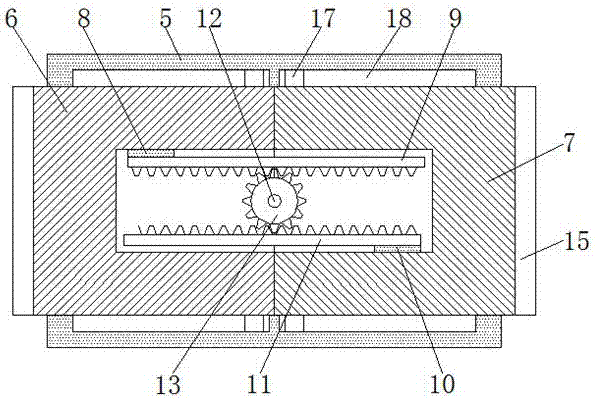

Friction machine

The invention discloses a friction machine for rubbing a glass substrate. The friction machine comprises a rack, a friction roller, a working platform, a first manipulator and a visual image recognition device, wherein the friction roller and the working platform are arranged on the rack; the first manipulator is arranged on one side of the working platform; and the first manipulator is used for rotating the glass substrate by a preset angle and placing the workpiece on the working platform according to the preset angle. When the working platform and the friction roller work, a workpiece is kept fixed, the rigidity of the system is improved, and therefore friction is ensured to be evenly conducted in the same direction during friction.

Owner:深圳市晶向科技有限公司

Cylinder fender arc face grinding device

ActiveCN107160247AImprove standardsEven frictionGrinding carriagesGrinding drivesFenderElectric machinery

The invention belongs to the technical field of mechanical equipment, and particularly relates to a cylinder fender arc face grinding device. A motor is used for driving a grinding wheel to rotate so that a cylinder solid foam plastic raw material can be ground into a cylinder fender with the smooth appearance. A body structure of the cylinder fender arc face grinding device comprises a motor, a conveying belt, a fixing frame, an upper transverse grinding wheel, a lower transverse grinding wheel, a conveying wheel, a sliding rail, a vertical roller, a transverse roller, grinding sand and the like. A raw material is pushed to the part between the upper transverse grinding wheel and the lower transverse grinding wheel, the upper transverse grinding wheel is tightly pressed on the raw material, a power source is turned on, the motor works, the transverse grinding wheel is driven to rotate at a high speed, the surface grinding sand is used for grinding the raw material, the upper transverse grinding wheel and the lower transverse grinding wheel grind the raw material at the same time, the motor works, repeated grinding is conducted till the size requirement is met, and a finished cylinder fender is obtained. The cylinder fender arc face grinding device is low in cost, simple in structure, convenient to operate, wide in application, high in grinding efficiency, low in noise, friendly in using environment and easy to popularize and use.

Owner:青岛鲁航气囊护舷有限公司

Shelf for music score

The invention discloses a shelf for musical scores, which comprises a base, the top of the base is fixedly connected with a support column, the top of the support column is fixedly connected with a connecting plate, and the left side of the top of the connecting plate is fixedly connected with a slanting plate , the top of the connecting plate is obliquely and fixedly connected to the main board, and the main board is located on the right side of the slanting board, and the back and front of the main board are respectively provided with a first movable board and a second movable board. In the present invention, a base, a support column, a connecting plate, an inclined plate, a main plate, a first movable plate, a second movable plate, a first fixed block, a first toothed plate, a second fixed block, a second toothed plate, a movable column, The combined use of gears, turntables and baffles solves the problem that the use area of the existing music score racks is fixed, and mismatched music scores and racks easily cause the score to fall off. The music score rack has the ability to adjust the use area The advantages are convenient for users to use.

Owner:纪芳丽

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com