Washing machine with clothes being overturned at constant speed and washing mode

A technology of clothes turning and washing method, which is applied to the washing machine and washing method with uniform turning and turning of clothes, changing the washing and turning path of clothes, and can solve the problems of single movement form, high washing cost, and entangled clothes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

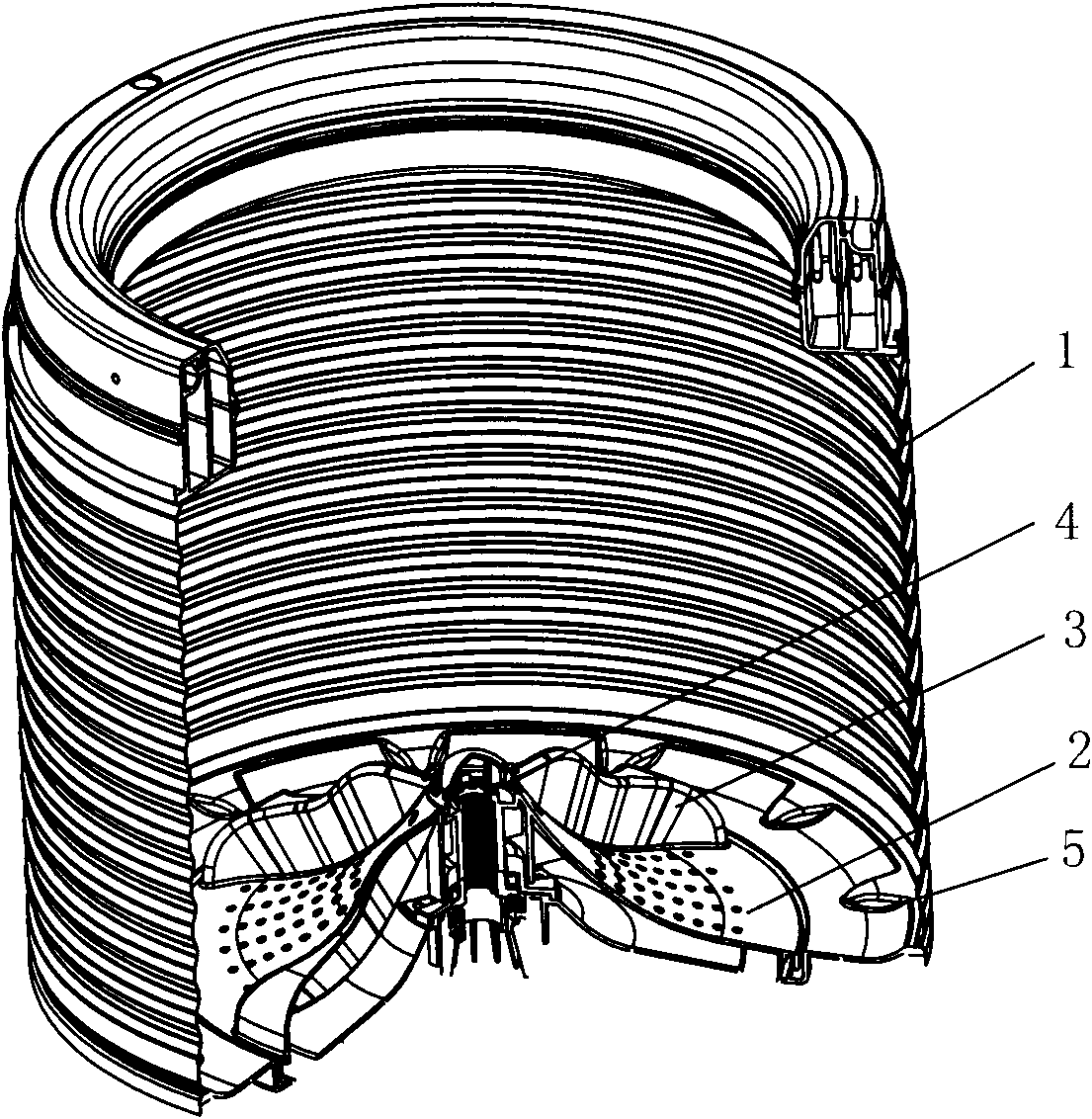

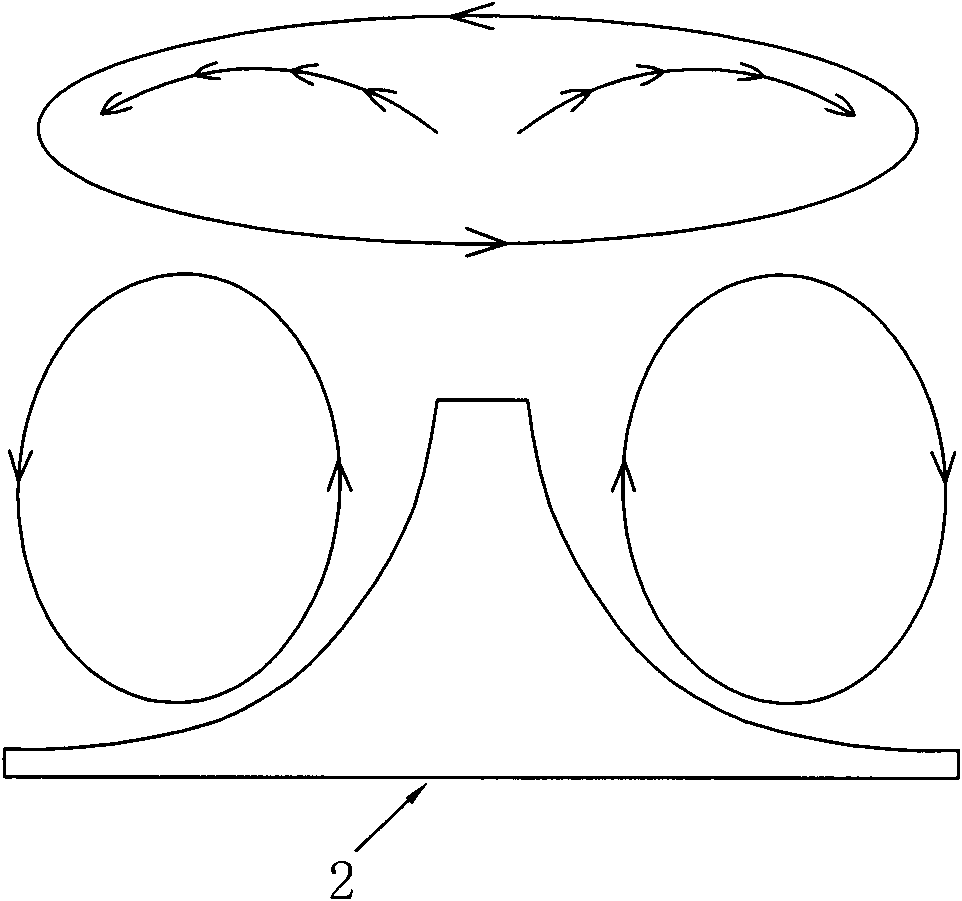

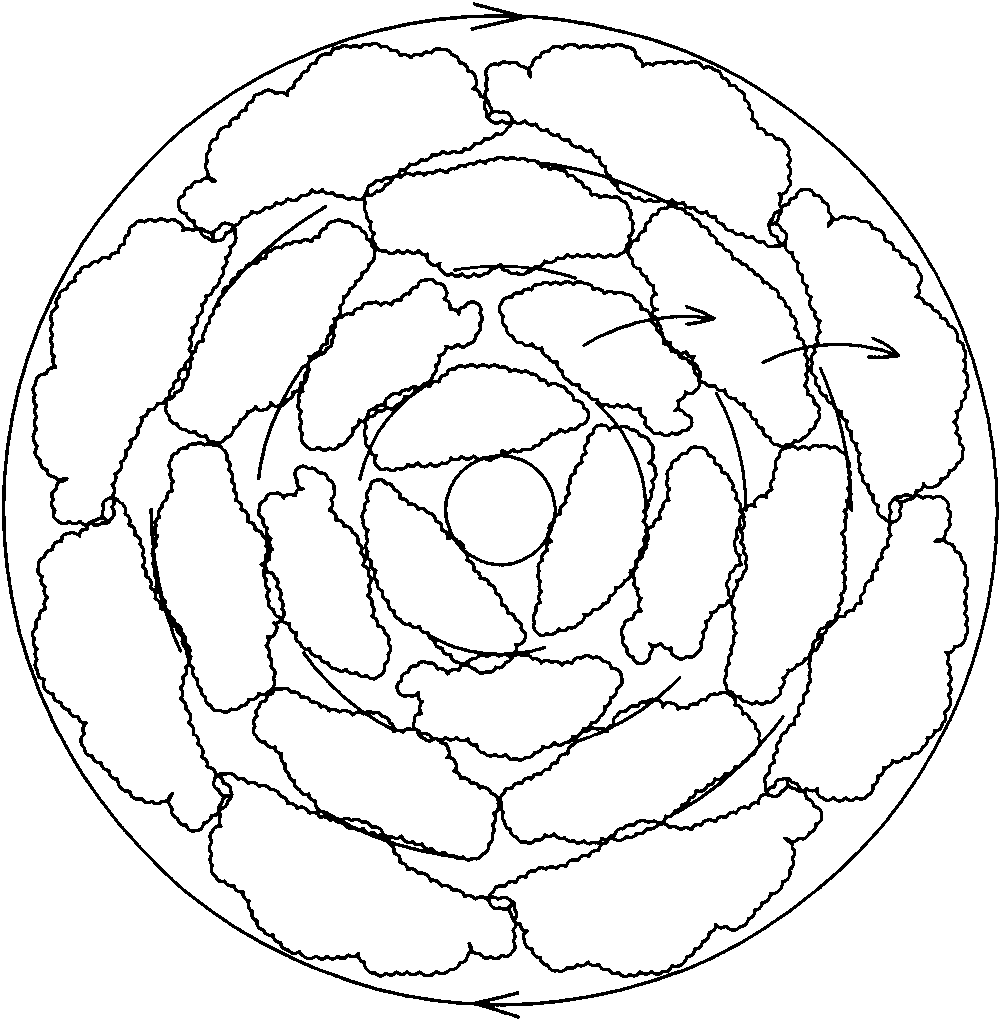

[0036] The washing machine of the present invention comprises an outer tub for holding water, an inner tub 1 for placing clothes in the outer tub, a rotatable pulsator 2 and a driving device for controlling the rotation of the inner tub and the pulsator, such as figure 1 and figure 2 As shown, the pulsator 2 is provided with a protrusion 3 that can guide the clothes to move to the center. After the clothes move to the center of the pulsator 4 and reach the apex, they roll to the outer periphery in a layered and everted manner and fall to the bottom of the inner barrel along the inner barrel wall. The protrusions 3 are distributed radially outward from the center of the pulsator 4, and the upper surface of the protrusions 3 extends outwards in a tangential manner from the bulge of the center 4 of the pulsator, and finally intersects the lower part of the pulsator in an arc shape. The distance L of the outer edge of the pulsator is 3mm-10mm (see Figure 7 ). The circumference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com