Cleaning Wiper for Glass

a wiper and glass technology, applied in the direction of carpet cleaners, cleaning equipment, cleaning machines, etc., can solve the problems of inability to wipe an eyeglass, difficult cleaning,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015]Hereinafter, a preferred exemplary embodiment of the present invention will be described in detail with reference to the accompanying drawings.

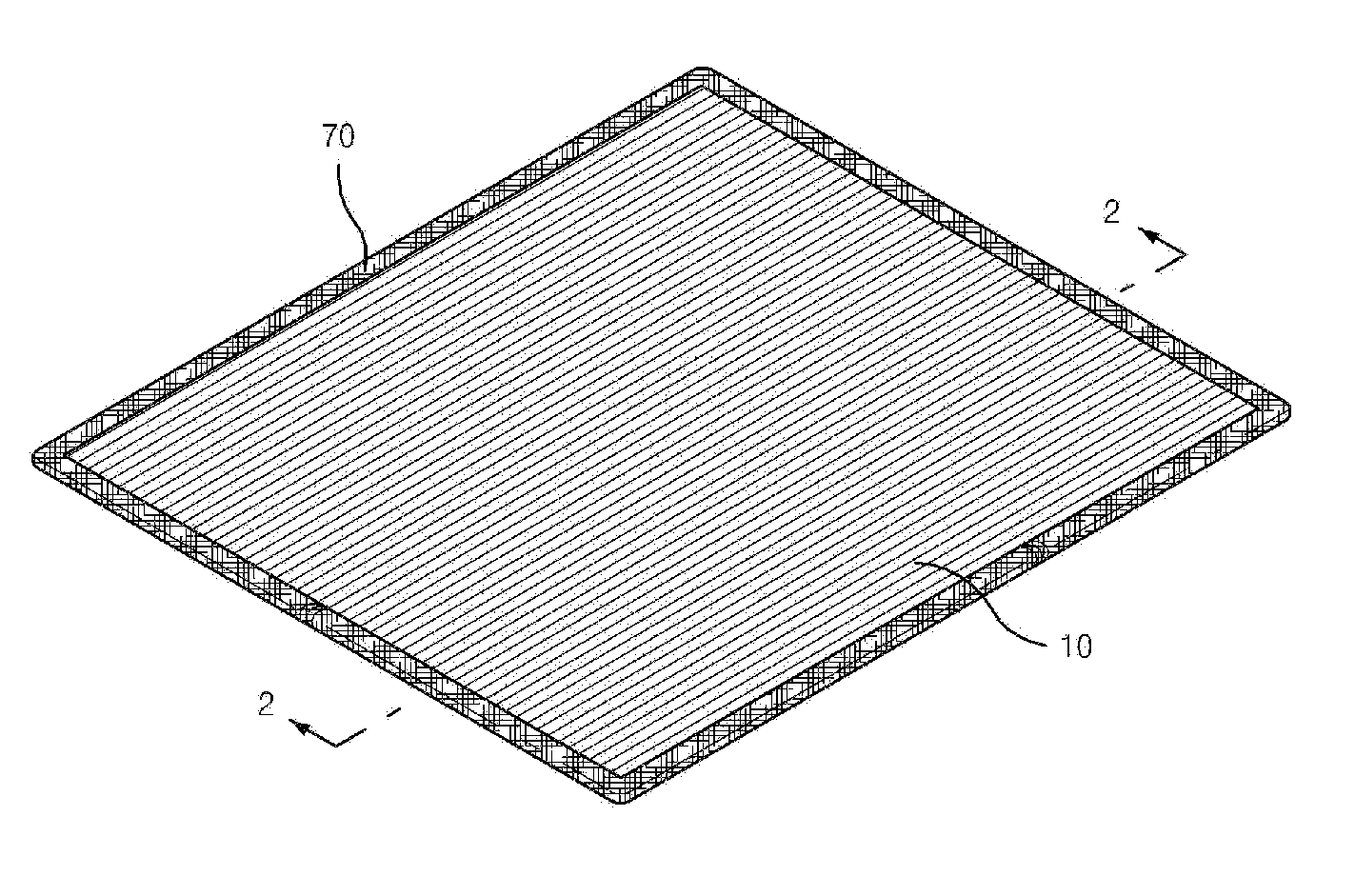

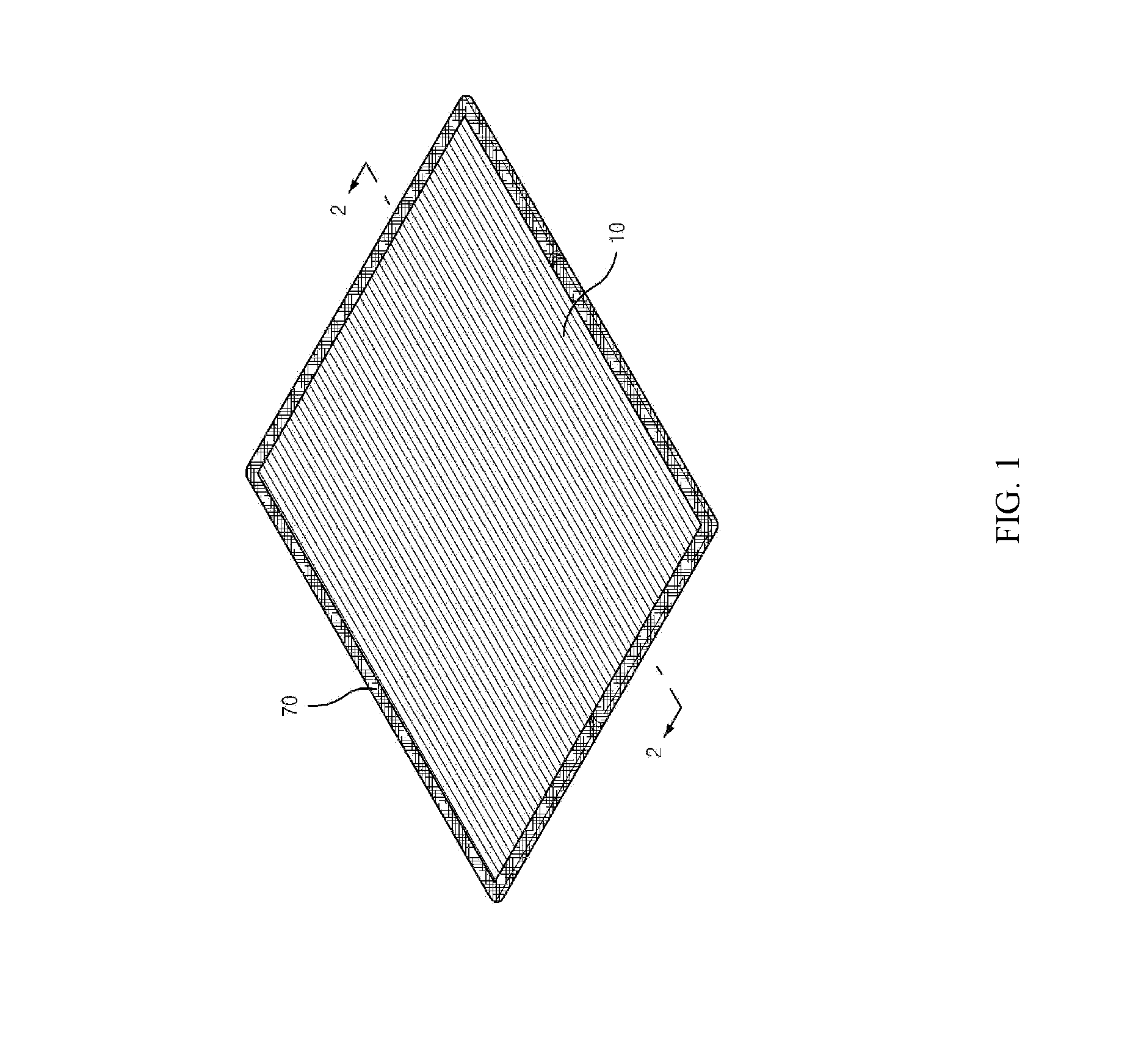

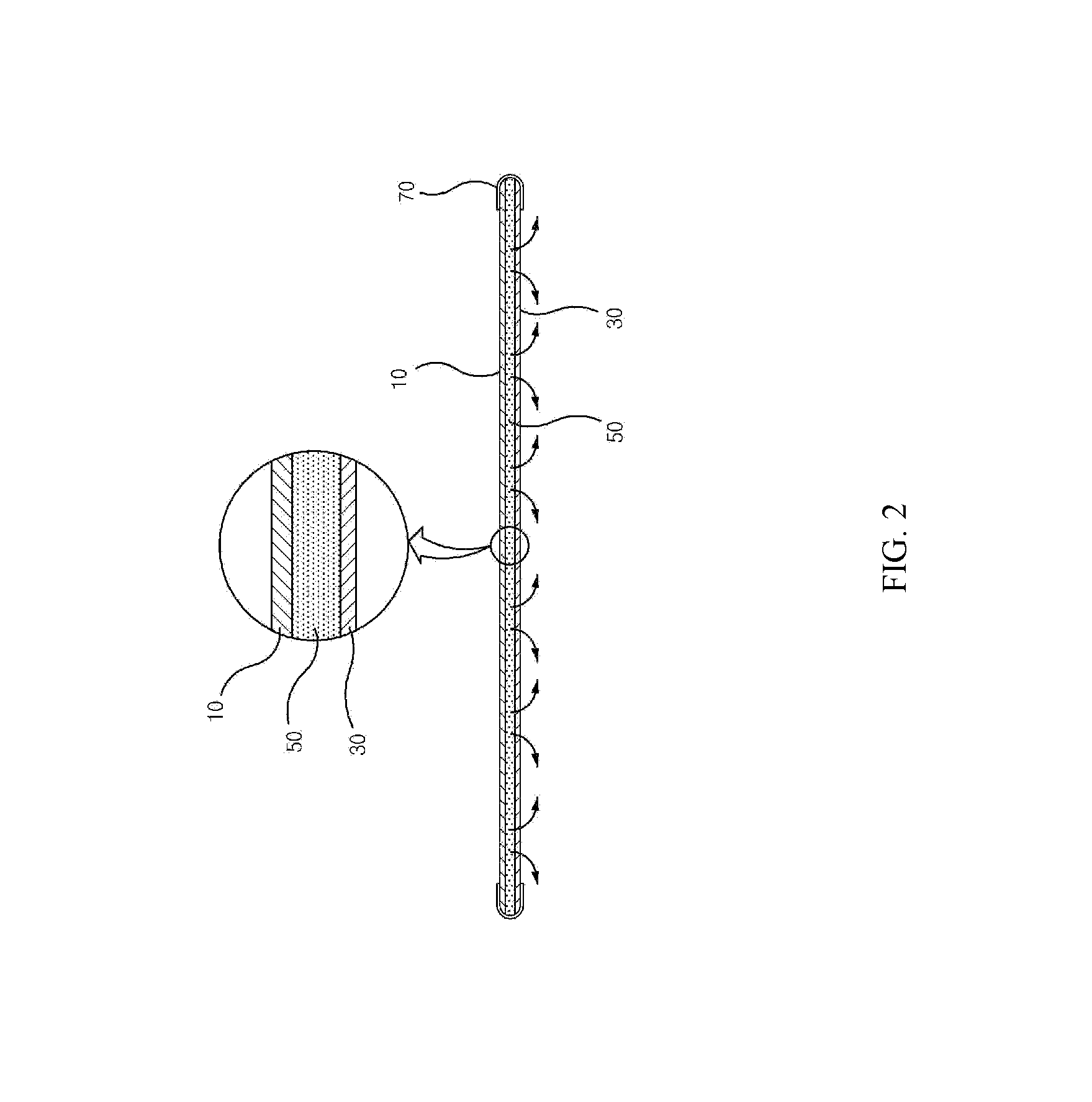

[0016]FIG. 1 is a prospective view illustrating a cleaning cloth for glass according to a preferred exemplary embodiment of the present invention, and FIG. 2 is a cross-sectional view along the line 2-2 in FIG. 1.

[0017]As illustrated in FIGS. 1 to 2, a cleaning cloth for glass according to an exemplary embodiment of the present invention includes: a first microfiber cloth 10; a second microfiber cloth 30; and an intervening layer 50 which is interposed between said first microfiber cloth 10 and said second microfiber cloth 30.

[0018]It is advantageous in that especially the first microfiber cloth 10 and the second microfiber cloth 30 are made of tricot woven fabrics weaved by single warp conjugated yarns made of polyester and nylon.

[0019]Since the tricot fabrics are weaved by warp yarns having multiple rows comprised of uneven surfaces, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com