Friction device and friction method for orientation film

A technology of friction device and alignment film, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of uneven friction effect of alignment film and achieve uniform friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

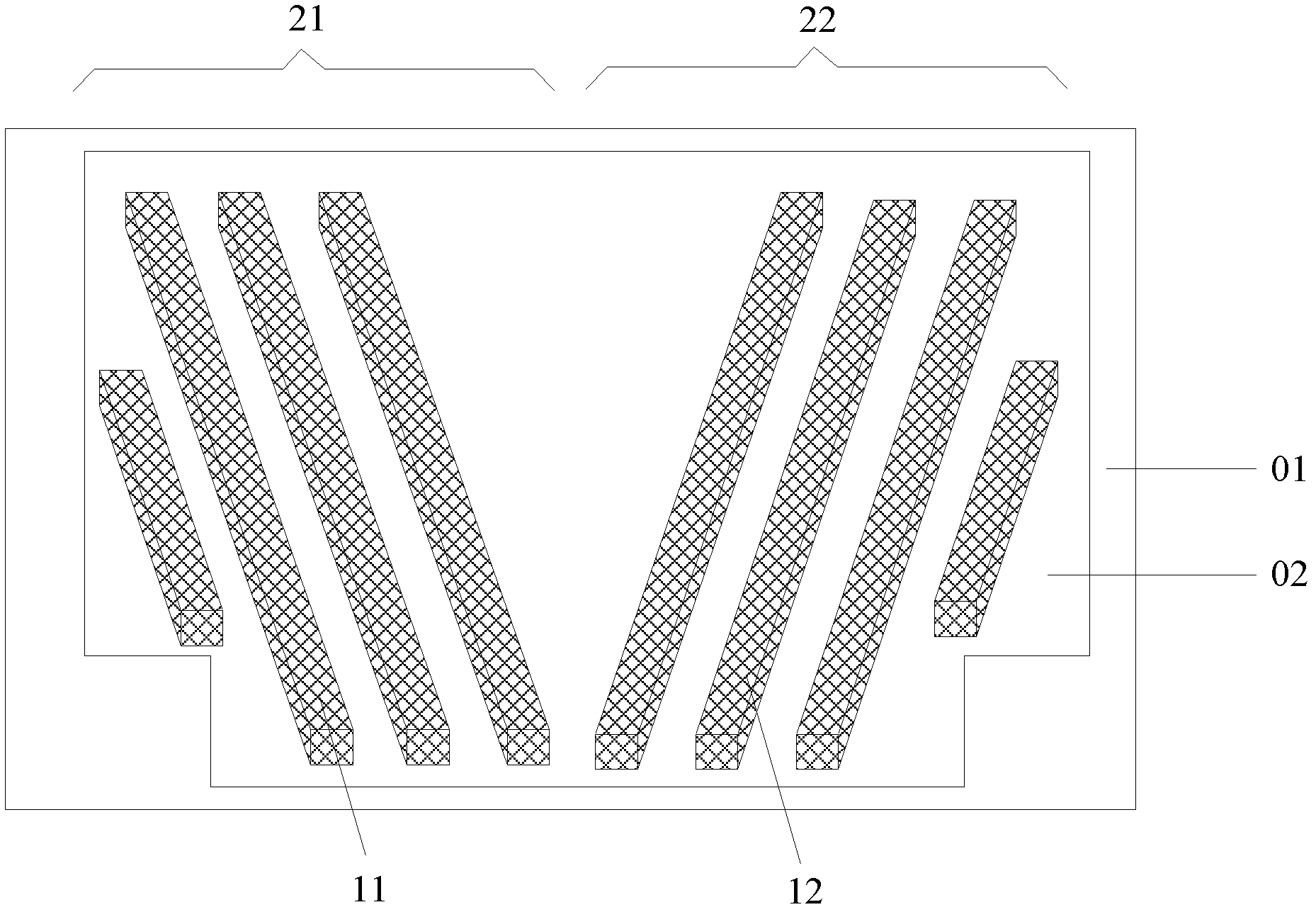

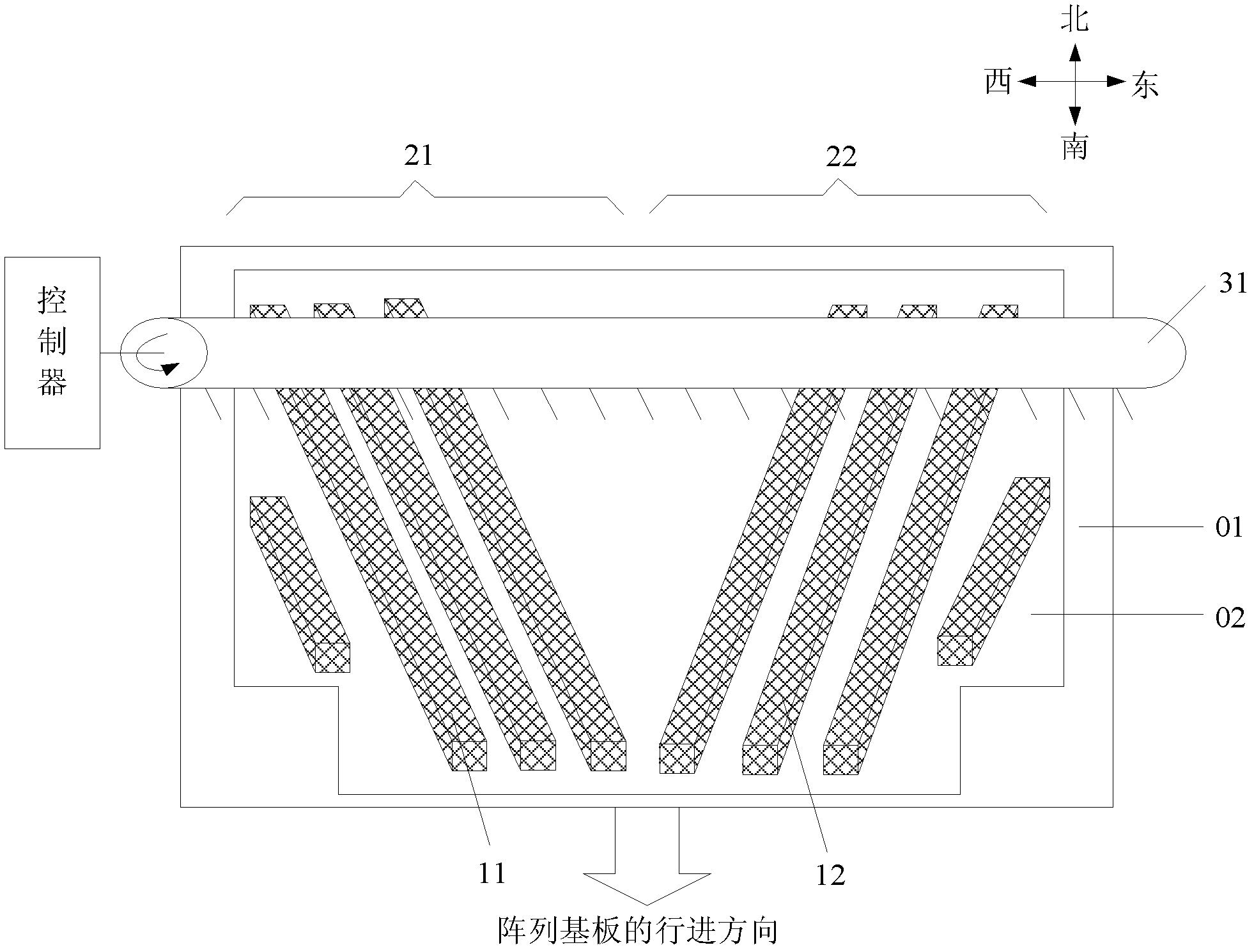

[0038] The above-mentioned alignment film rubbing device will be described in detail below for specific situations. The specific circumstances are as figure 2 As shown, the alignment film rubbing device includes a rubbing roller 31, and the rubbing roller 31 rubs the alignment film 02 of the array substrate 01 provided with two pixel electrodes arranged in different directions. In the embodiment of the present invention, the array substrate is provided with two pixel electrodes arranged in different directions, that is, the first pixel electrode 11 and the second pixel electrode 12 .

[0039] Such as figure 2 In the schematic diagram of rubbing the alignment film shown, the rubbing device for the alignment film includes: a rubbing roller 31, on which a rubbing cloth is attached; friction.

[0040] For one of the pixel electrodes on the array substrate, the inclination direction of the fluff of the rubbing cloth on the rubbing roller is consistent with the arrangement direct...

Embodiment 2

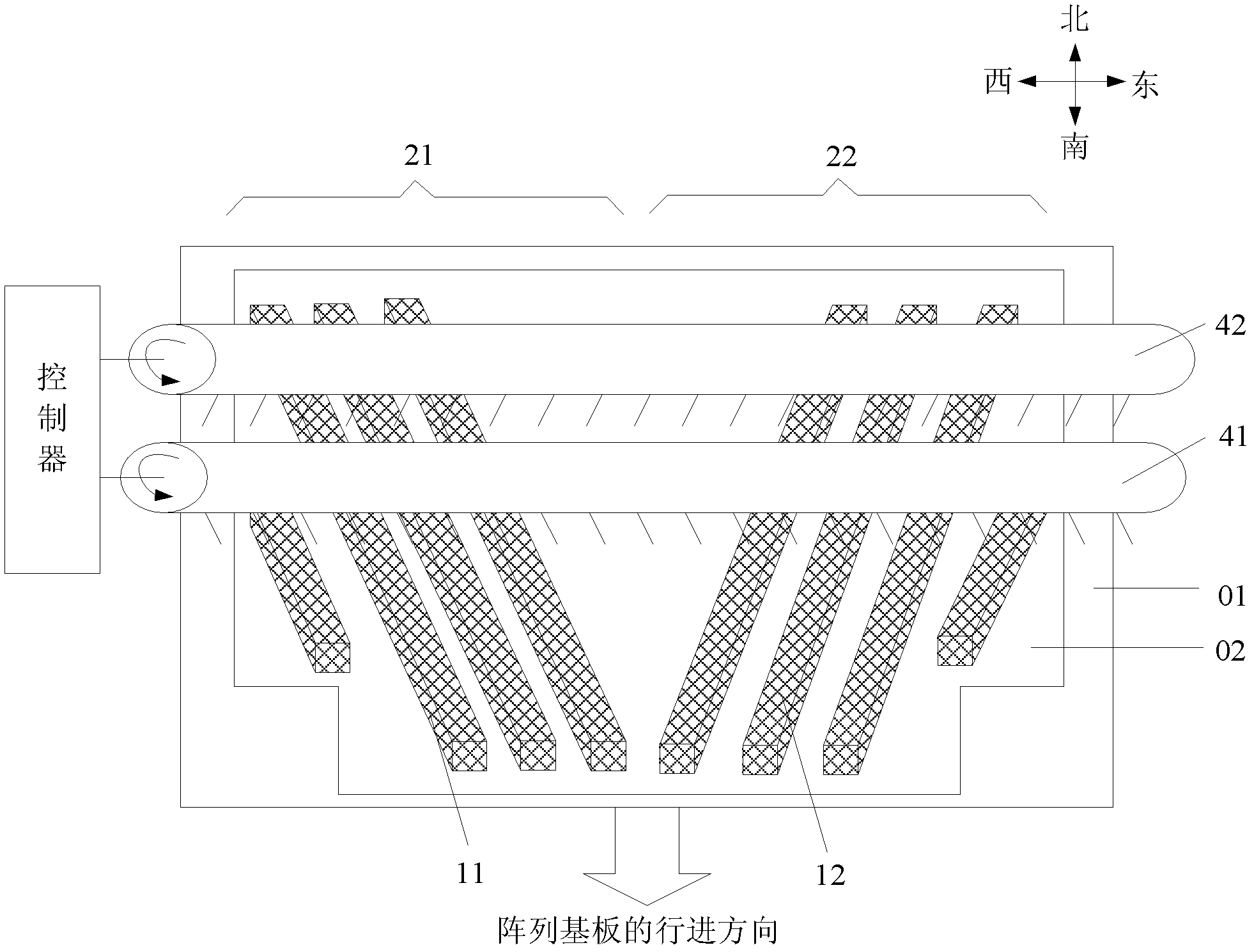

[0054] Embodiments of the present invention provide another alignment film rubbing device and rubbing method. Such as image 3 As shown, the alignment film rubbing device includes two rubbing rollers, namely a first rubbing roller 41 and a second rubbing roller 42; the rubbing rollers 41, 42 are paired with an array substrate 01 with two pixel electrodes arranged in different directions. The alignment film 02 is rubbed. In the embodiment of the present invention, the array substrate is provided with two pixel electrodes arranged in different directions, that is, the first pixel electrode 11 and the second pixel electrode 12 .

[0055] Such as image 3 In the shown orientation film rubbing diagram, the alignment film rubbing device includes: two rubbing rollers 41, 42, on which rubbing cloth is attached; the two rubbing rollers 41, 42 are used to align the array The alignment film 02 of the substrate 01 is rubbed twice.

[0056] Wherein, the two rubbing rollers 41 and 42 ar...

Embodiment 3

[0067] Embodiments of the present invention provide another alignment film rubbing device and rubbing method. Such as Figure 4 As shown, the alignment film rubbing device includes two rubbing rollers, namely a first rubbing roller 51 and a second rubbing roller 52; Make a rub. In the embodiment of the present invention, the array substrate is provided with two pixel electrodes arranged in different directions, that is, the first pixel electrode 11 and the second pixel electrode 12 .

[0068] Such as Figure 4 In the shown orientation film rubbing diagram, the alignment film rubbing device includes: two rubbing rollers 51, 52, on which rubbing cloth is attached; the two rubbing rollers 51, 52 are used to align the array The alignment film 02 of the substrate 01 is rubbed twice.

[0069] Wherein, the two rubbing rollers are used to rub the alignment film 02 of the array substrate 01 twice, which means that the first rubbing roller 51 rubs the alignment film 02 of the array ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com