Deformation-controllable bionic joint based on friction effect, and preparation method and application of deformation-controllable bionic joint

A technology of bionic joints and friction effects, applied in the field of structural bionics, can solve problems such as complex structures, poor compatibility of human body structures, and inability to meet the needs of multi-stage deformation, and achieve the effect of low cost, simple materials, and high forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

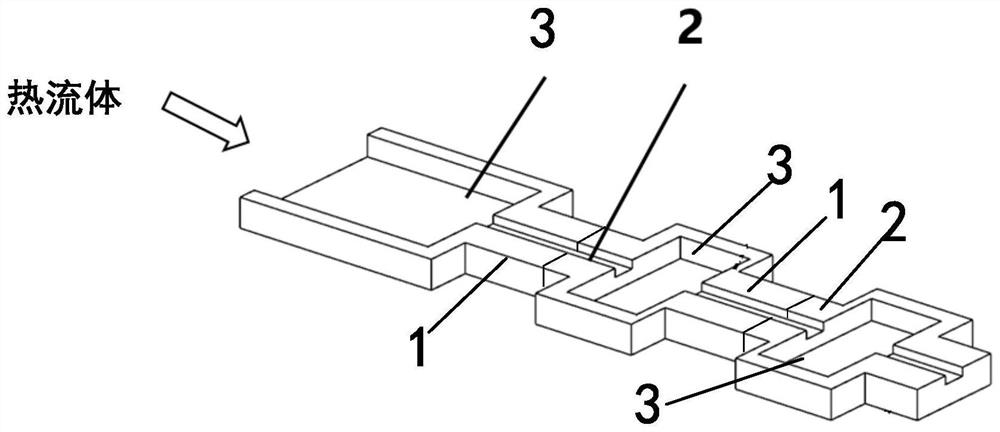

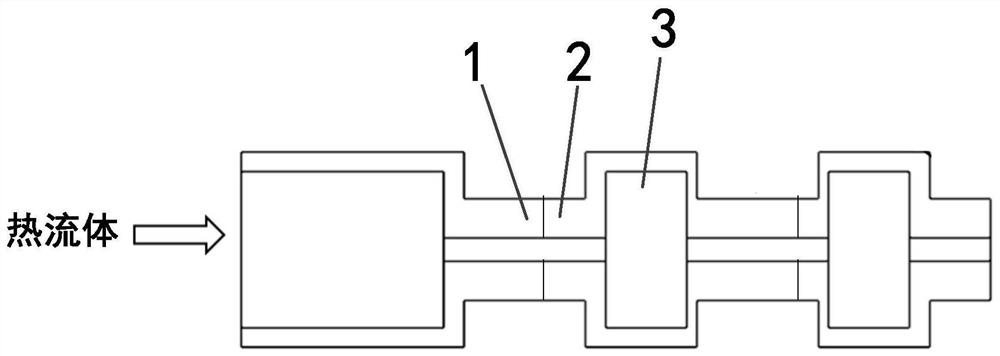

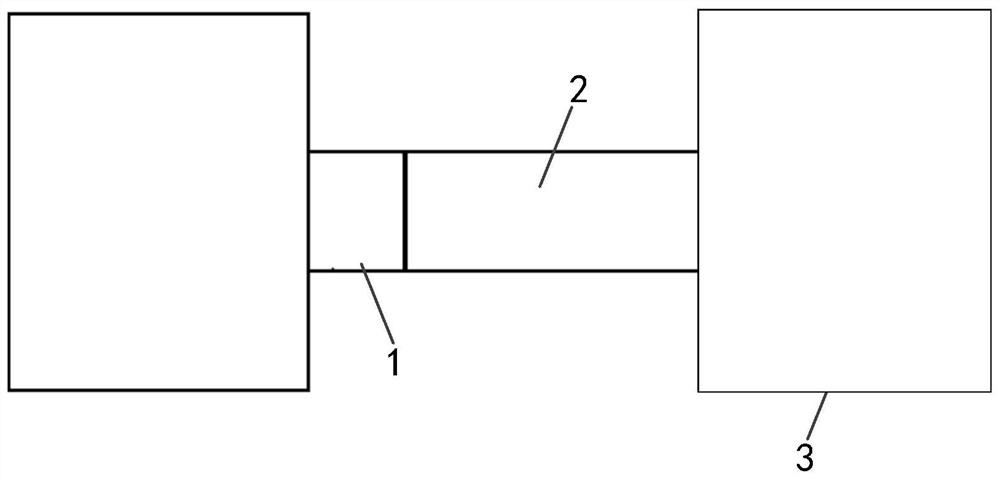

[0041] The embodiment of the present disclosure is the bionic of the elbow joint of the arm. Since the elbow joint is a straight section connected to a curved section and then connected to a straight section, a set of heating section, deformation section and cooling section can be used. The length of the heating section is the length of the forearm of the arm, and the length of the cooling section is the length of the forearm of the arm. The internal fluid is water, and the material of the deformation section is NiTi shape memory alloy. Since the phase transition temperature of NiTi shape memory alloy varies greatly with the composition ratio and process parameters, the deformation critical temperature of the material is taken as 80°C (specifically The value is determined by the composition ratio and process parameters). Comprehensively consider the influence of the pipe diameter on the unit temperature rise and the initial water temperature, for example, the pipe diameter is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com