Patents

Literature

35results about How to "Control heat dissipation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Purification method of ultra-pure aluminum

The invention relates to a purification method of ultra-pure aluminum, comprising the following steps: cleaning and drying raw refined aluminum, wherein the purity of the selected refined aluminum is at least 4N6, Mg is less than 6ppm, Ti is less than 0.2ppm and Zr is less than 0.2ppm; loading the selected raw refined aluminum into a purification furnace, sealing and vacuumizing the furnace, and heating to 680-750 DEG C by using a gas furnace to melt the solid raw refined aluminum to form liquid; moving the purification furnace heated to 680-750 DEG C to a crystal growing furnace which is kept at 660 DEG C inside by a crystal growing furnace heater, rotating the aluminum liquid of the purification furnace in the crystal growing furnace heater, and enabling the aluminum liquid inside the purification furnace to self-keep the crystallization speed at 5-10 cm / h by controlling the heat dissipating capacity of the crystal growing furnace and finishing the crystallization after 4-6 hours; cooling the crystallized purification furnace, taking out a crystallization ingot, removing 25-35 percent relative to the mass of the crystallization from the tail part of the crystallization ingot and obtaining a first purified aluminum ingot; placing the first purified aluminum ingot into the purification furnace again, and repeating purification until the aluminum ingot reaching the required precision is obtained.

Owner:CHANGSHA ZHONGDA TIMES ELECTRONICS TECH DEV

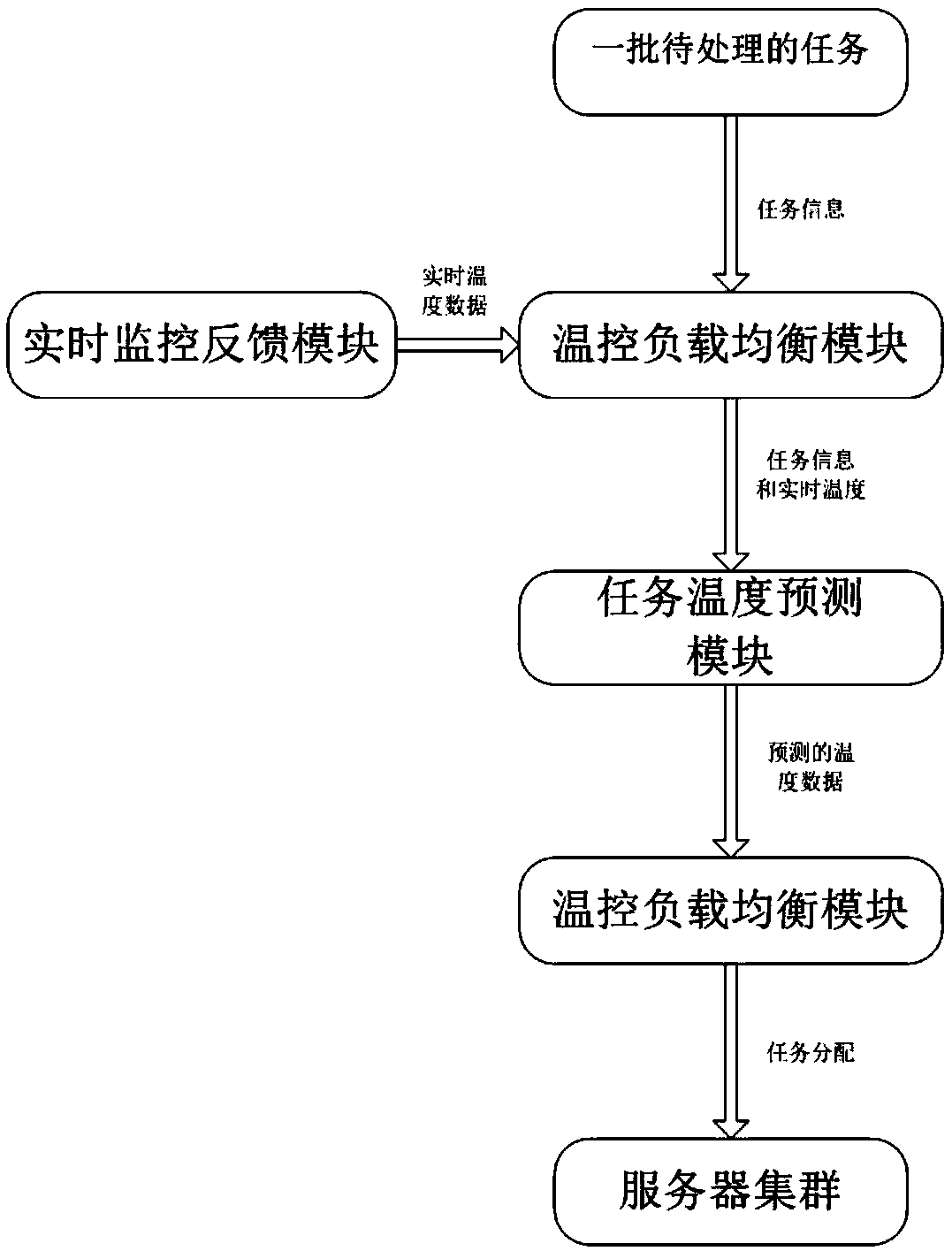

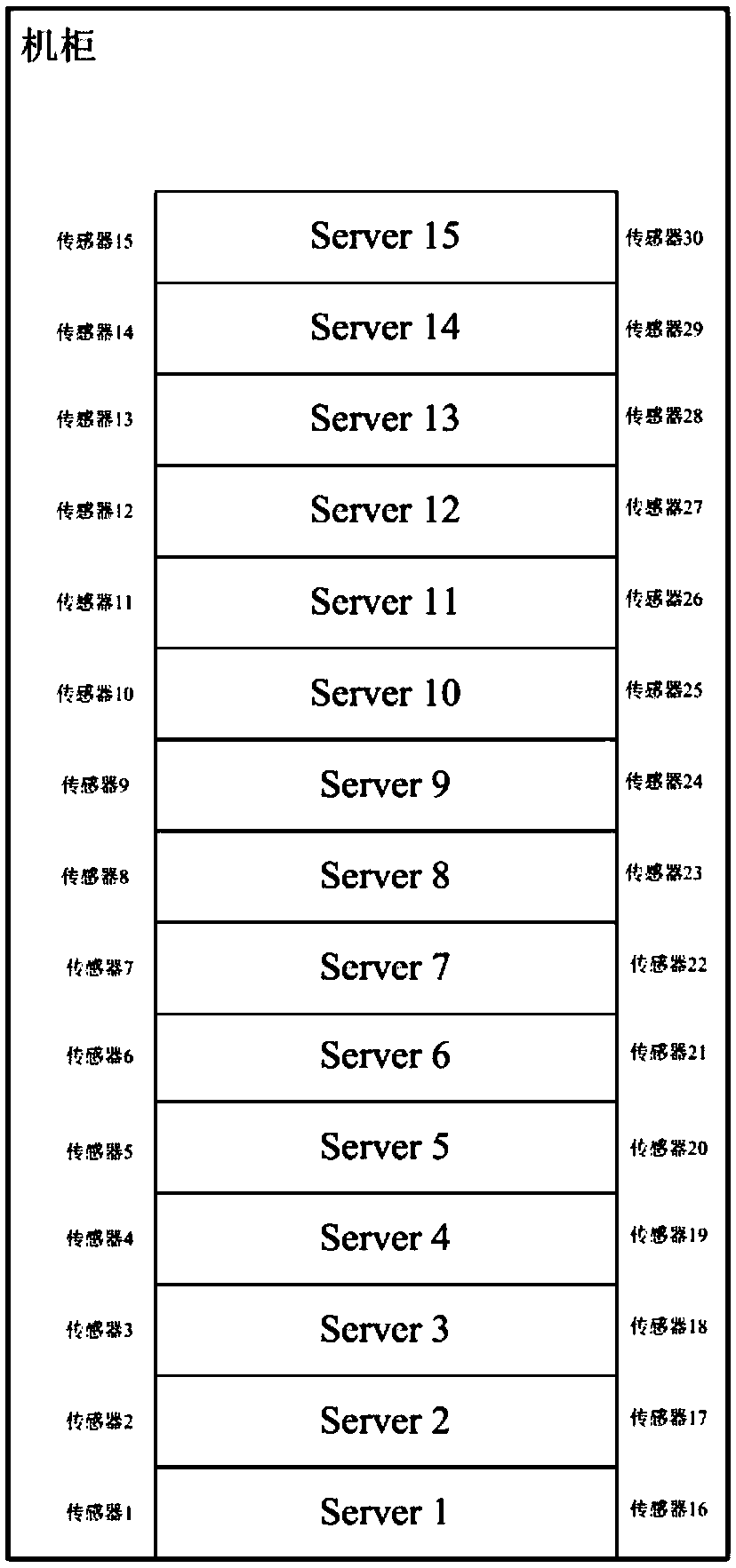

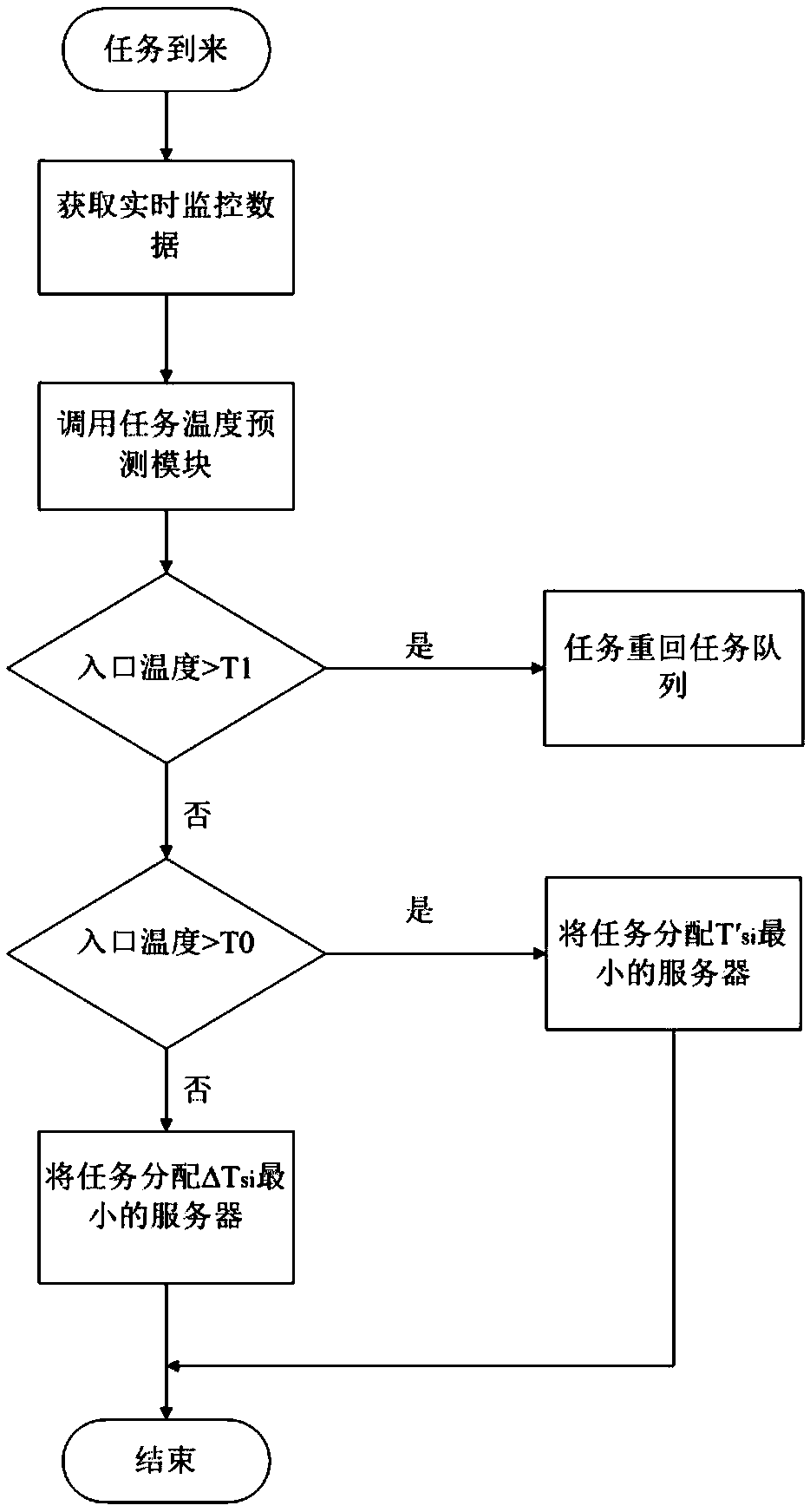

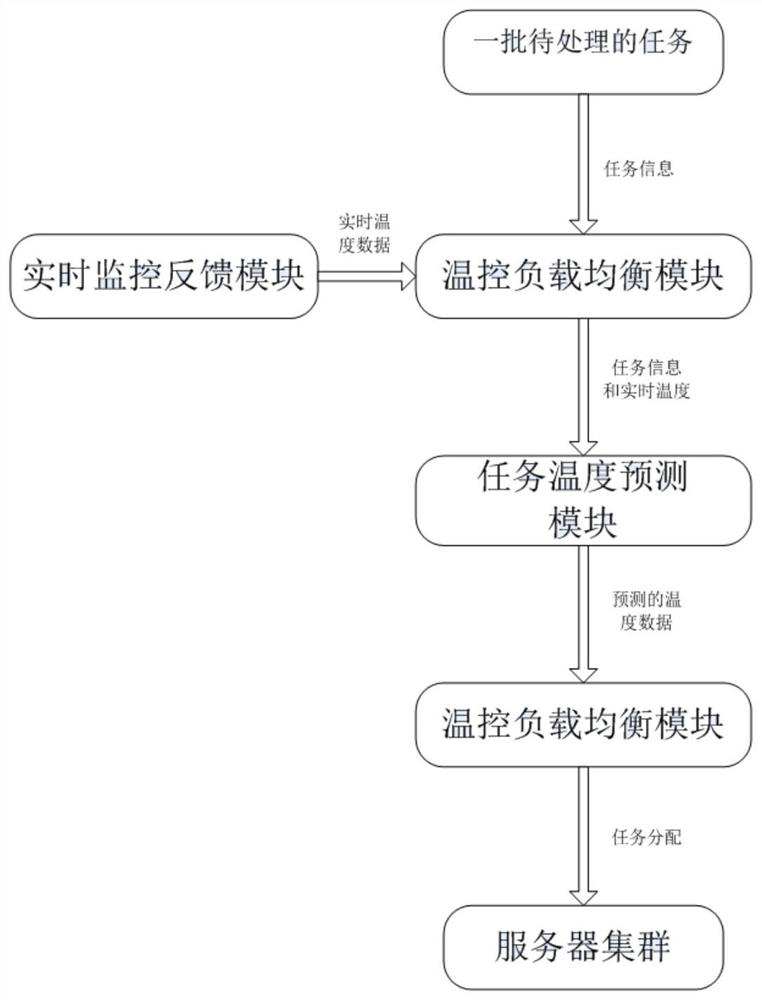

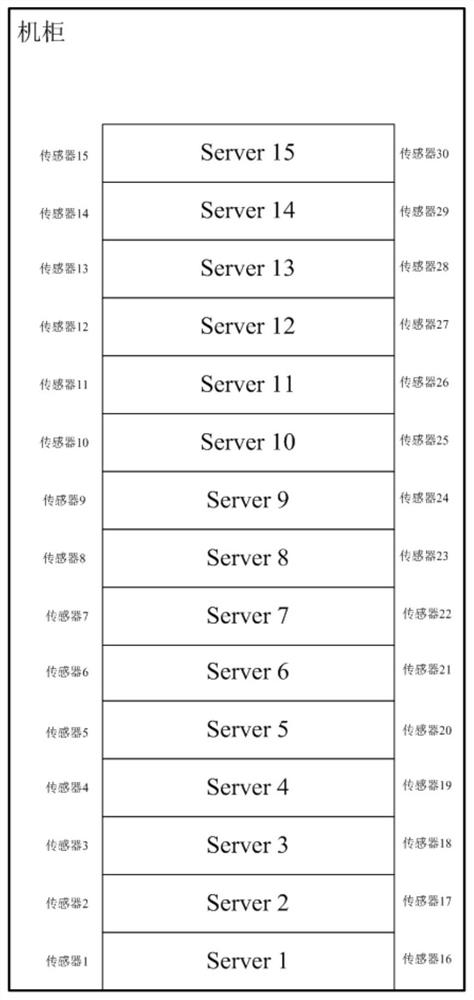

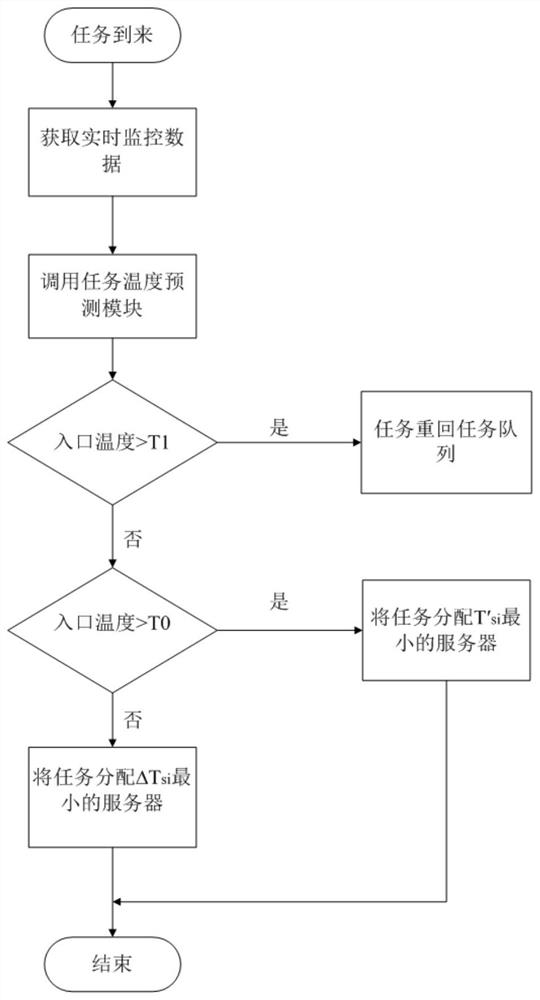

Data center task temperature prediction and scheduling method based on RBF neural network

ActiveCN109375994AReduce the temperatureReduce energy consumptionProgram initiation/switchingDigital data processing detailsTemperature controlData center

The invention discloses a data center task temperature prediction and scheduling method based on an RBF neural network, which includes adopting the RBF neural network to establish a task temperature prediction model; establishing a temperature-controlled load balancing module, determining a safe temperature and an alert temperature of the server, and judging and selecting with any server Si; the monitoring feedback module real-time monitors and feeds server operating temperature back to the temperature control load balancing module, the temperature control load balancing module is used for scheduling control. The invention carries out task scheduling through active temperature prediction, and has better flexibility than the method of determining task scheduling only based on feedback temperature. By setting two active scheduling strategies in different temperature ranges, the energy consumption can be reduced and the safe operation of the data center can be ensured.

Owner:XI AN JIAOTONG UNIV

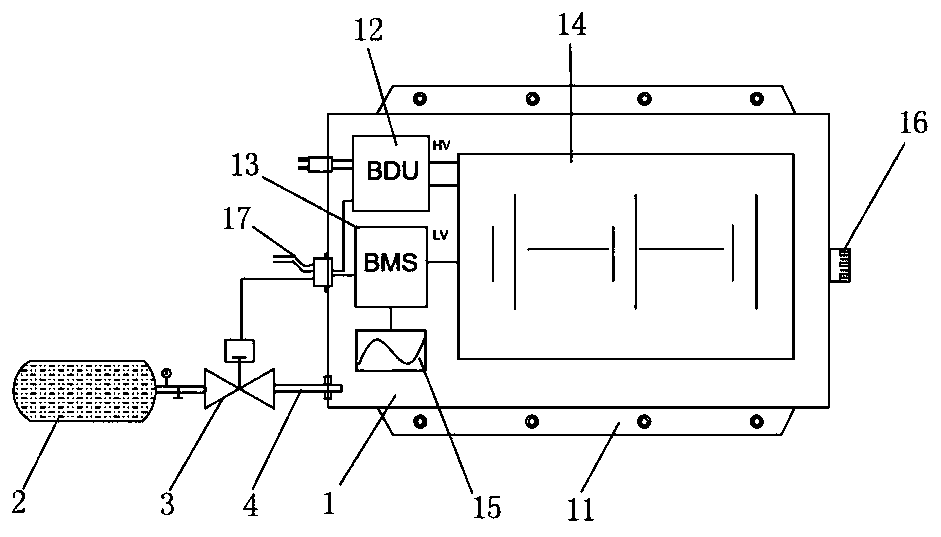

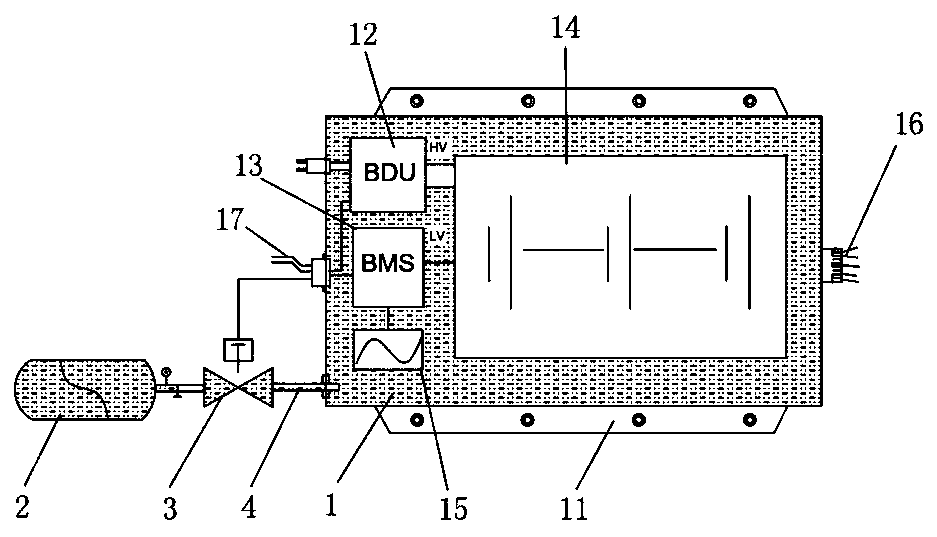

Thermal runaway control system for lithium ion battery pack for new energy electric vehicle and running method

PendingCN110838600AControl thermal runawayControl heat dissipationBatteries circuit arrangementsSecondary cells servicing/maintenanceThermal runawayAutomotive engineering

The invention discloses a thermal runaway control system for a lithium ion battery pack for a new energy electric vehicle, which comprises a battery pack body and an inert gas tank, wherein a batterymodule, a BMS module and a BDU module are arranged in a box body of the battery pack body; the BMS module and the BDU module are used for monitoring the state of the battery module; a thermal runawaymonitor electrically connected with the BMS module is further arranged in the box body; an outlet of the inert gas tank communicates with the interior of the box body of the battery pack body througha gas conveying pipeline; an electromagnetic valve controlled by the BMS module is installed on the gas conveying pipeline; and a balance ventilation valve is further arranged at one end of the box body. The thermal runaway control system disclosed in the invention is simple and convenient in component integration, safe, reliable, high in detection precision, high in response timeliness rate, highin restraining effectiveness, adjustable in component fixity, good in universality and practicability and capable of effectively monitoring and restraining thermal runaway while thermal runaway is prevented, and therefore thermal runaway can be effectively and controllably achieved.

Owner:江西优特汽车技术有限公司

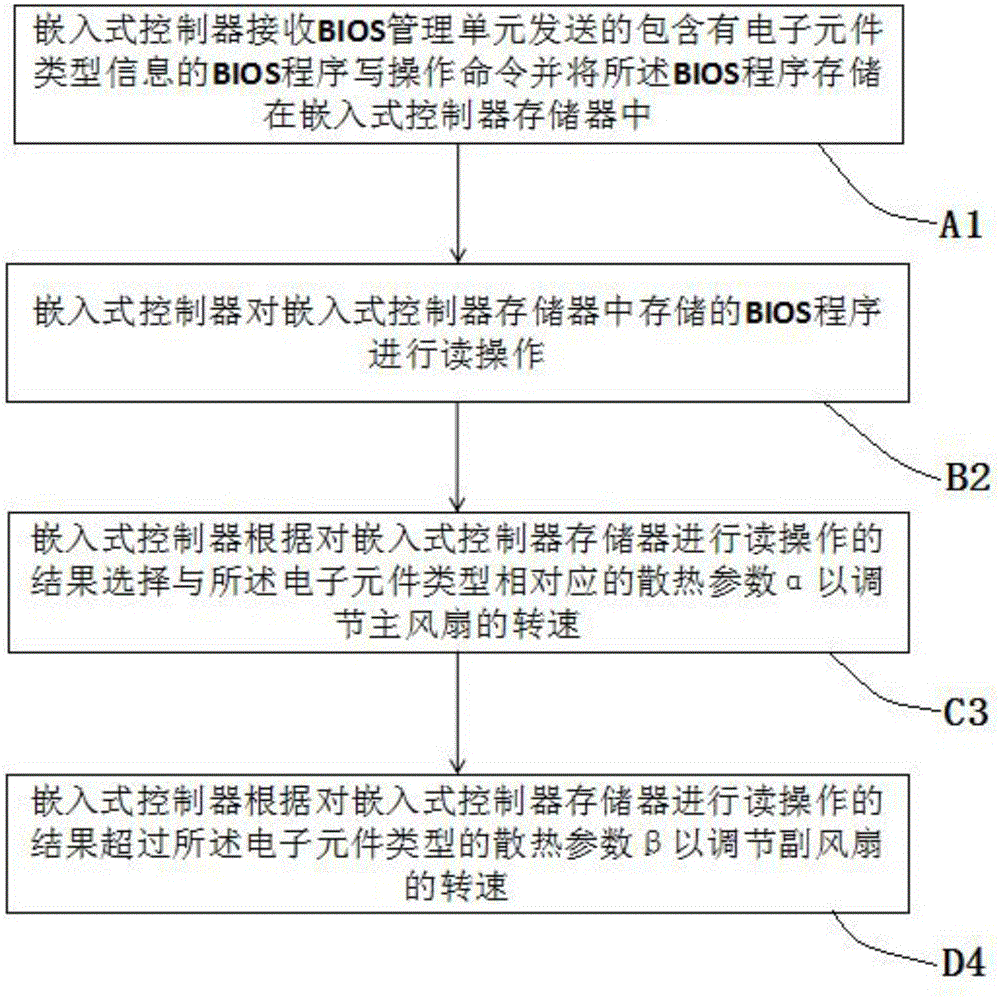

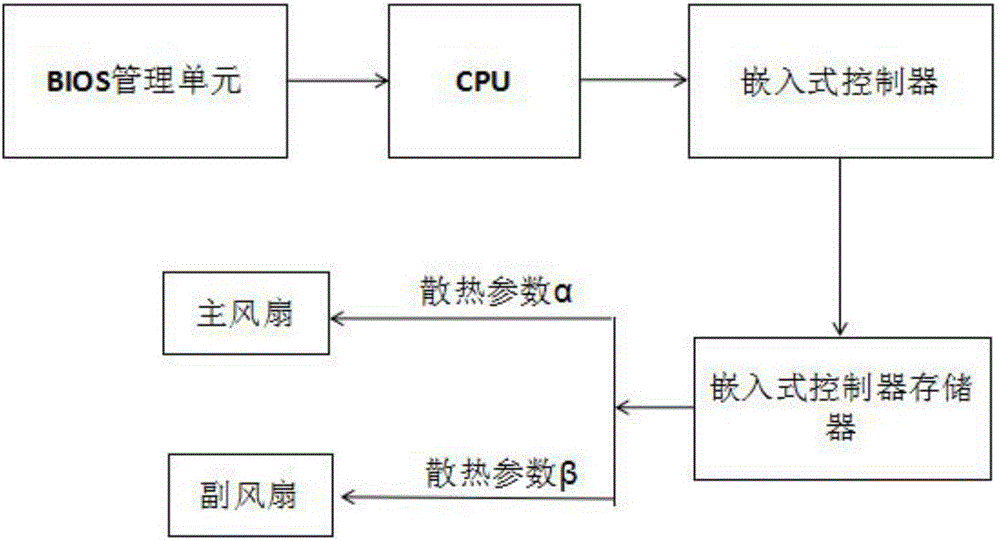

Intelligent adjusting method and controlling system of computer fan revolving speed

InactiveCN106445027ANoise controlControl heat dissipationDigital data processing detailsDetecting faulty computer hardwareEmbedded systemControl bus

The invention discloses an intelligent adjusting method and a controlling system of a computer fan revolving speed. The controlling system comprises a BIOS managing unit, a CPU and an embedded controller which are all connected with a control bus, the controlling system also comprises an embedded controller storage connected with the embedded controller. Through the embedded controller, the controlling system receives a BIOS program write command containing electronic component type information sent by the BIOS managing unit, and then the controlling system stores the BIOS program in the embedded controller storage. According to the intelligent adjusting method and the controlling system of the computer fan revolving speed, the types of electric components are detected after starting up the computer, then the types of the electric components are sent to the embedded controller, and then according to the types of the electric components, the embedded controller selects a heat dissipation parameter corresponding to the type of the electric component so as to control the fan. In this way, CPU heat dissipation can be adjusted by controlling a main fan and an assistant fan, and heat dissipation temperature can be controlled according to operating power of the CPU, thus a suitable operation environment for the CPU is guaranteed when the CPU is in a high temperature environment or in a high-burden operation.

Owner:安徽爱她有果电子商务有限公司

Novel electrical cabinet

InactiveCN107666789APrevent infiltrationPromote circulationCasings/cabinets/drawers detailsCooling/ventilation/heating modificationsElectric machineryEngineering

Owner:JIANGYIN BAOLONG ELECTRONICS

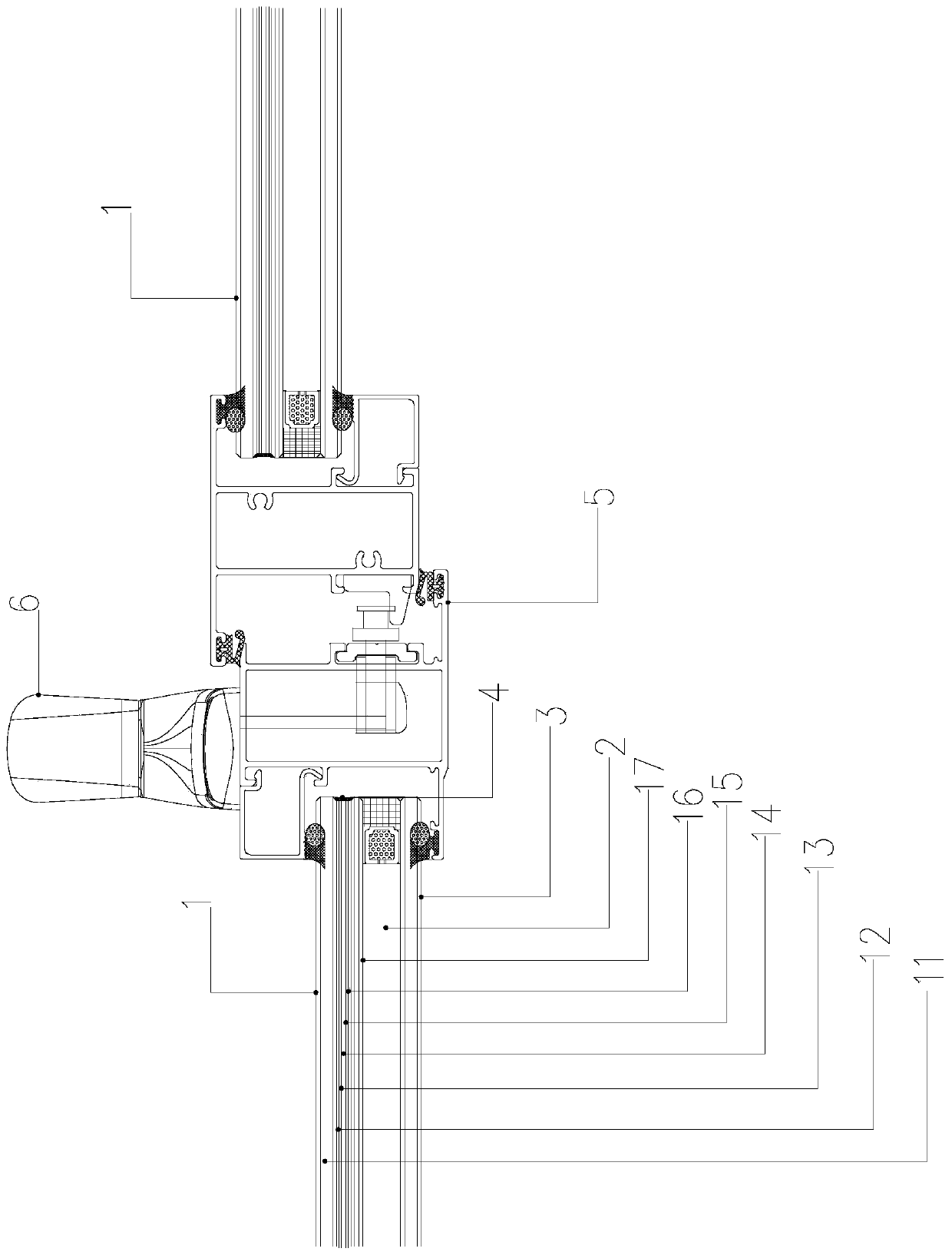

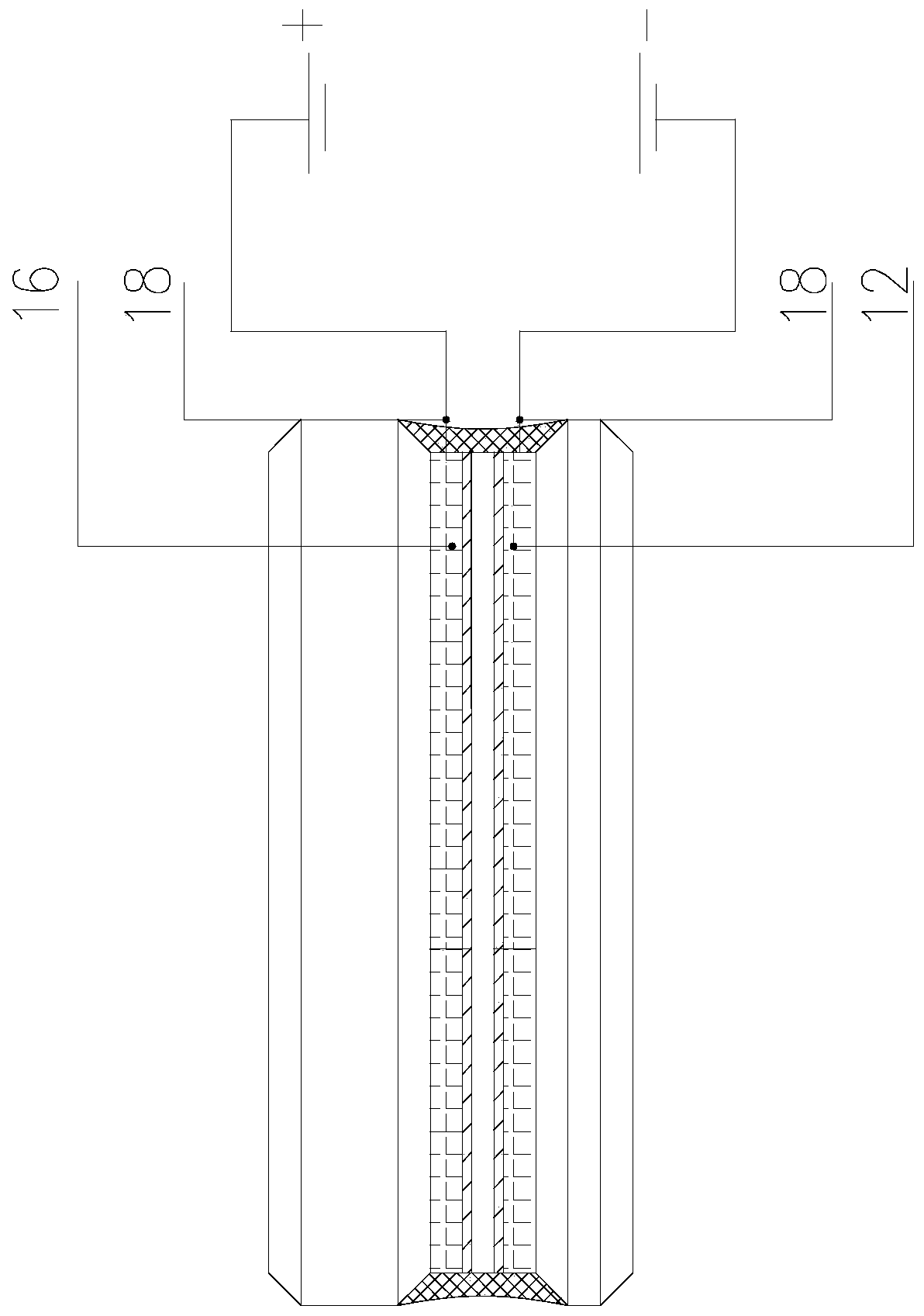

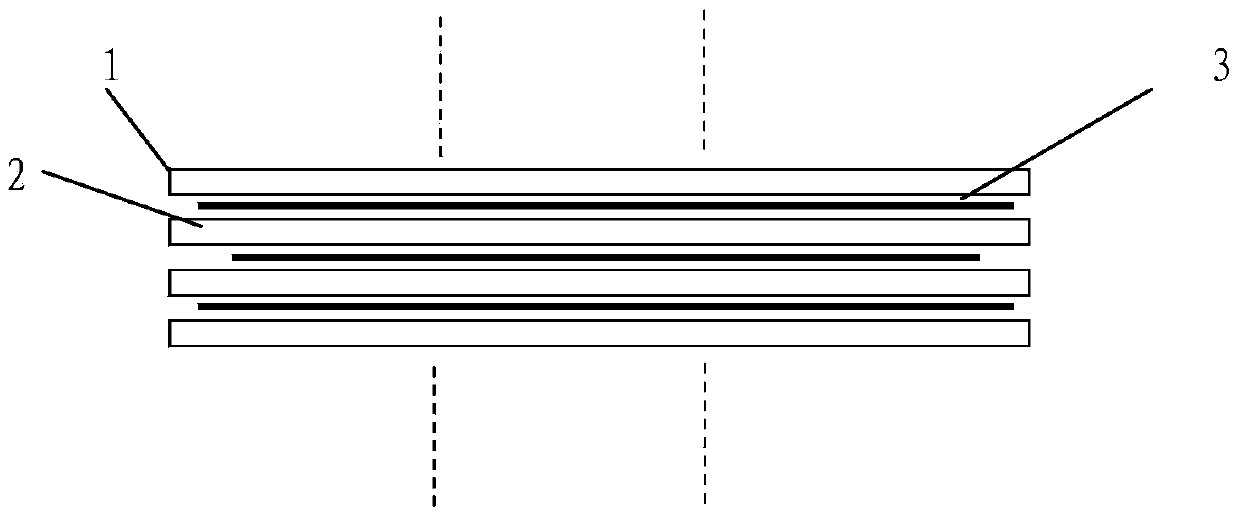

Electrochromic glass dimming window assembly

PendingCN111562705ARealize the functionalization of the structureSolve light pollutionFireproof doorsNoise insulation doors/windowsLight pollutionPhysical chemistry

The invention discloses an electrochromic glass dimming window assembly. The electrochromic glass dimming window assembly includes electrochromic glass, the electrochromic glass comprises first tempered glass, a first transparent conducting layer arranged on the first toughened glass, a first tungsten trioxide electrochromic layer arranged on the first transparent conducting layer, an electrolytelayer arranged on the first tungsten trioxide electrochromic layer, a second tungsten trioxide electrochromic layer arranged on the electrolyte layer, a second transparent conducting layer arranged onthe second tungsten trioxide electrochromic layer, and a second tempered glass layer arranged on the second transparent conducting layer. By adoption of the structure, light and temperature can be adjusted according to the magnitude of current, so that indoor light is soft, comfortable and pleasant, and the light-transmitting effect is not lost; a large amount of energy which has to be consumed when buildings like office buildings and residential buildings keep cool in summer and keep warm in winter is reduced, meanwhile, the purposes of improving the natural illumination degree and preventing peeping are achieved, and the problem of urban light pollution which is worsened constantly in modern times is solved.

Owner:广东省雅众幕墙科技有限公司

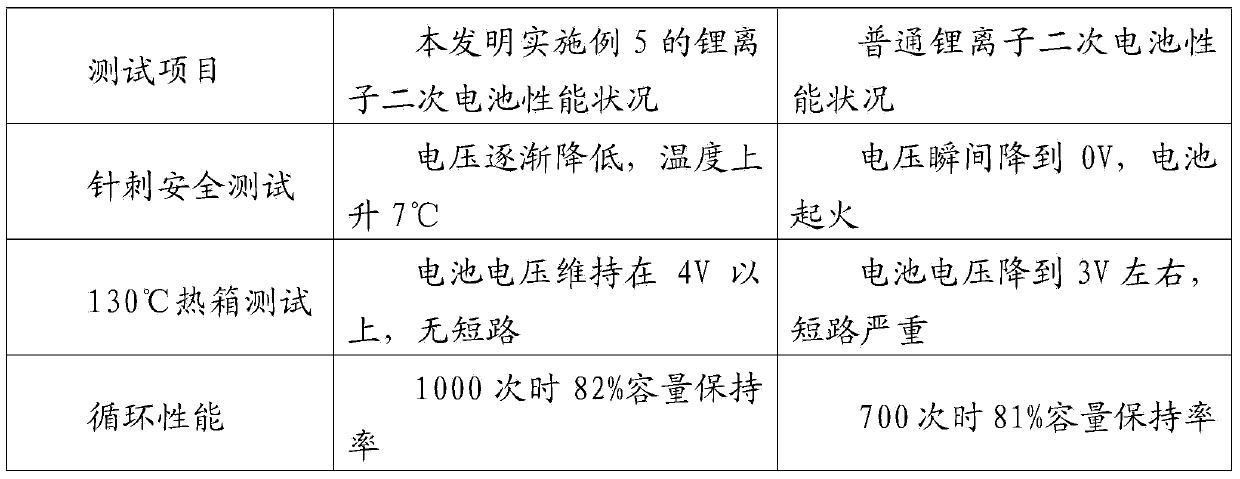

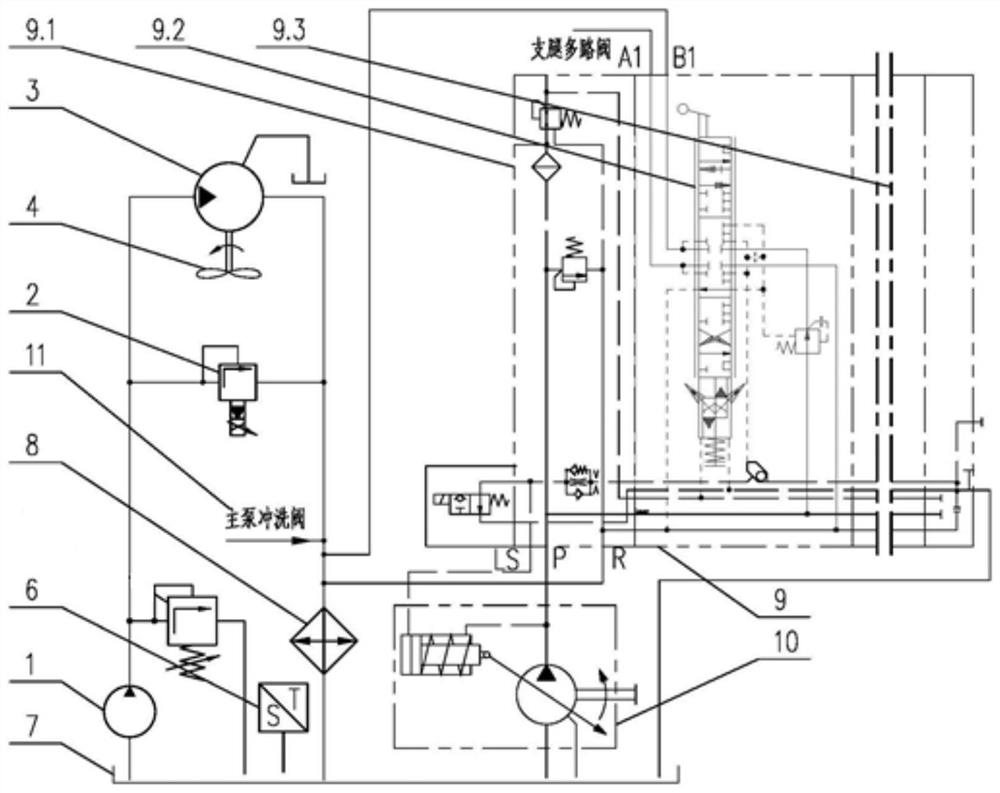

Glass fiber baffle plate and lithium ion battery adopting glass fiber buffer plate

InactiveCN103700799AImprove toughnessReduce thicknessSecondary cellsCell component detailsPorosityGlass fiber

The invention discloses a glass fiber buffer plate which comprises 80-97% of glass fiber by mass and 3-20% of adhesive glue by mass. The invention further discloses a production method of the glass fiber buffer plate and a lithium ion battery having the glass fiber buffer plate; compared with the general glass fiber buffer plate with the same specification, the strength of the glass fiber buffer plate disclosed by the invention is improved more than 500%; the toughness of the glass fiber buffer plate is reinforced; the glass fiber buffer plate is reduced to be as the thickness of a lithium ion buffer plate. The glass fiber porosity is generally above 80%, and is far higher than the porosity of a high-molecular polymer buffer plate; meanwhile, the high-temperature resistance of the glass fiber buffer plate is prominent, the high-temperature short circuit can be effectively prevented when the glass fiber buffer plate is used as the lithium ion battery buffer plate; the internal short-circuit resistant capacity is prominent; the heat diffusion in the internal short circuit can be effectively controlled; the overall battery safety performance is improved.

Owner:杭州万好万家动力电池有限公司

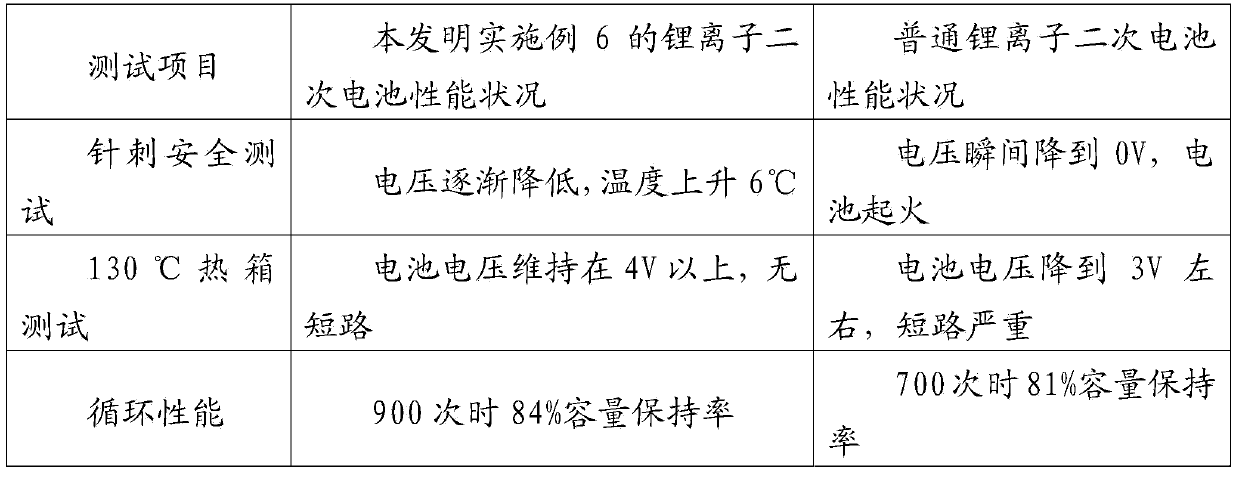

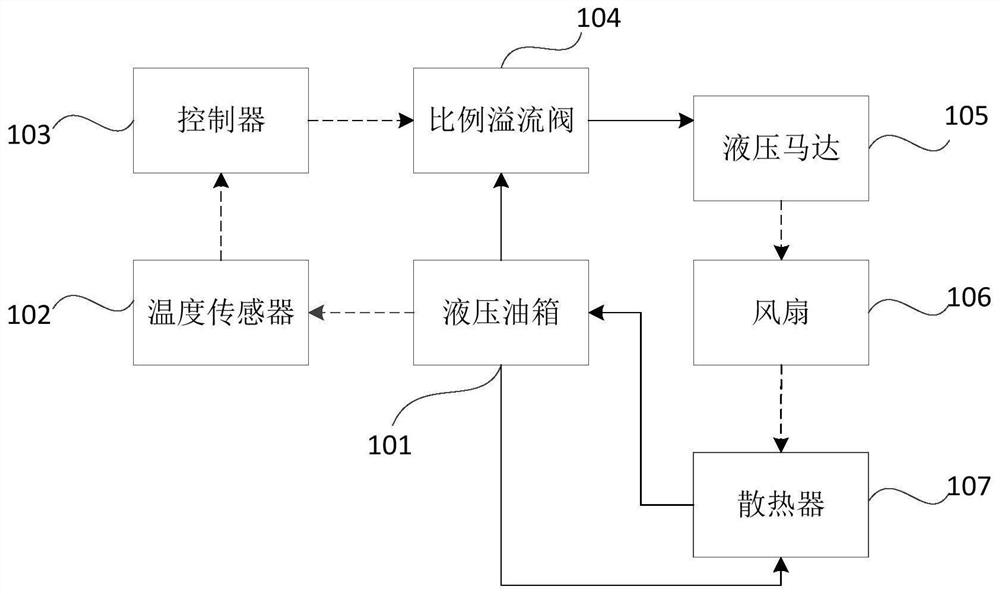

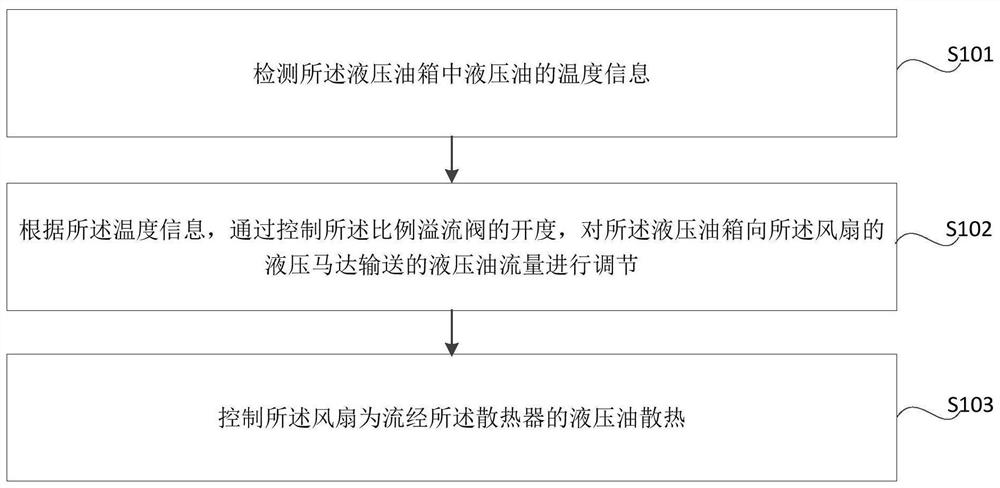

Hydraulic oil temperature control system, hydraulic oil temperature control method and pump truck

PendingCN112814974AControl heat dissipationImprove cooling effectFluid-pressure actuator componentsTruckControl system

The invention relates to a hydraulic oil temperature control system, a hydraulic oil temperature control method and a pump truck, and aims to control the heat dissipating capacity of hydraulic oil in a radiator by adjusting the rotating speed of a fan. The system comprises a temperature sensor, the fan, the radiator, a proportional overflow valve and a controller, wherein the proportional overflow valve is arranged on a pipeline through which a hydraulic oil tank conveys hydraulic oil to a hydraulic motor of the fan, and the controller is connected with the temperature sensor and the proportional overflow valve, wherein the temperature sensor is used for detecting temperature information of the hydraulic oil in the hydraulic oil tank; the controller is used for adjusting the flow of the hydraulic oil conveyed to the hydraulic motor of the fan by the hydraulic oil tank by controlling the opening degree of the proportional overflow valve according to the temperature information detected by the temperature sensor, and the flow of the hydraulic oil conveyed to the hydraulic motor is in positive correlation with the temperature of the hydraulic oil; and the fan is used for dissipating heat of the hydraulic oil flowing through the radiator.

Owner:河北雷萨重型工程机械有限责任公司

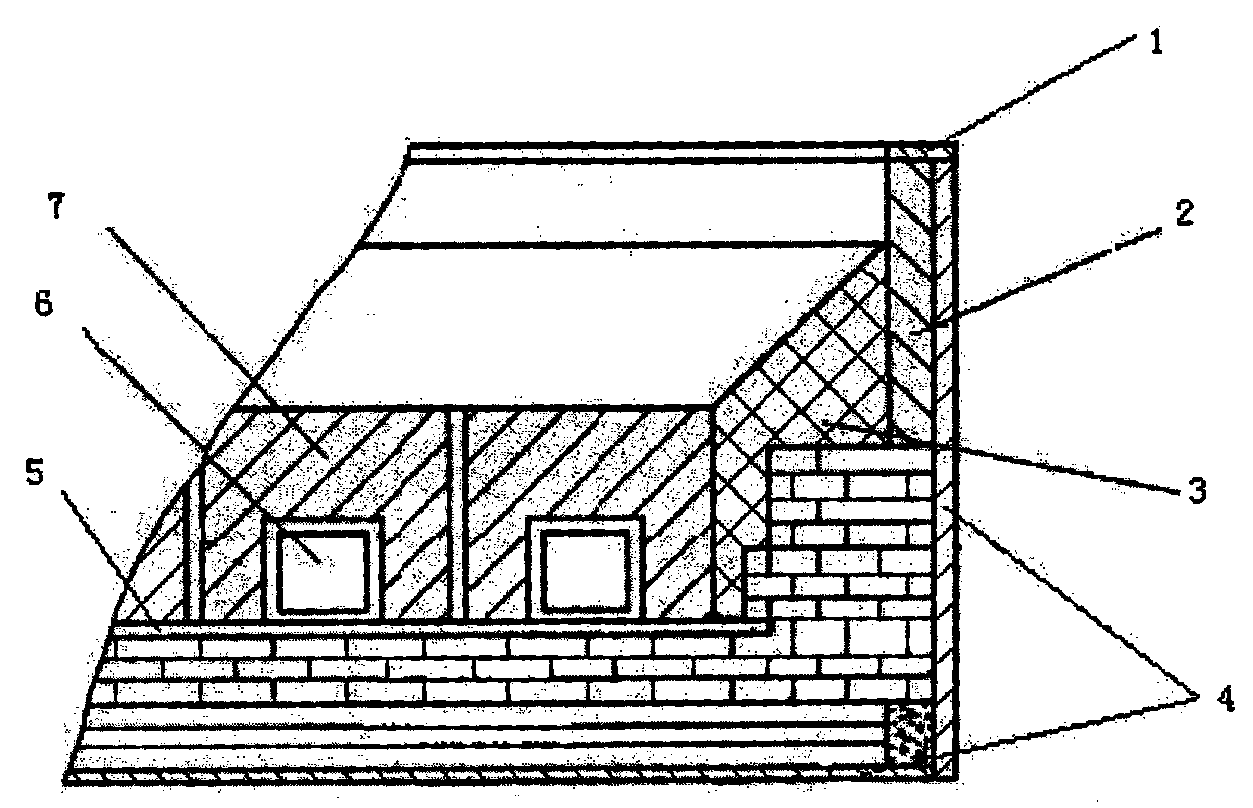

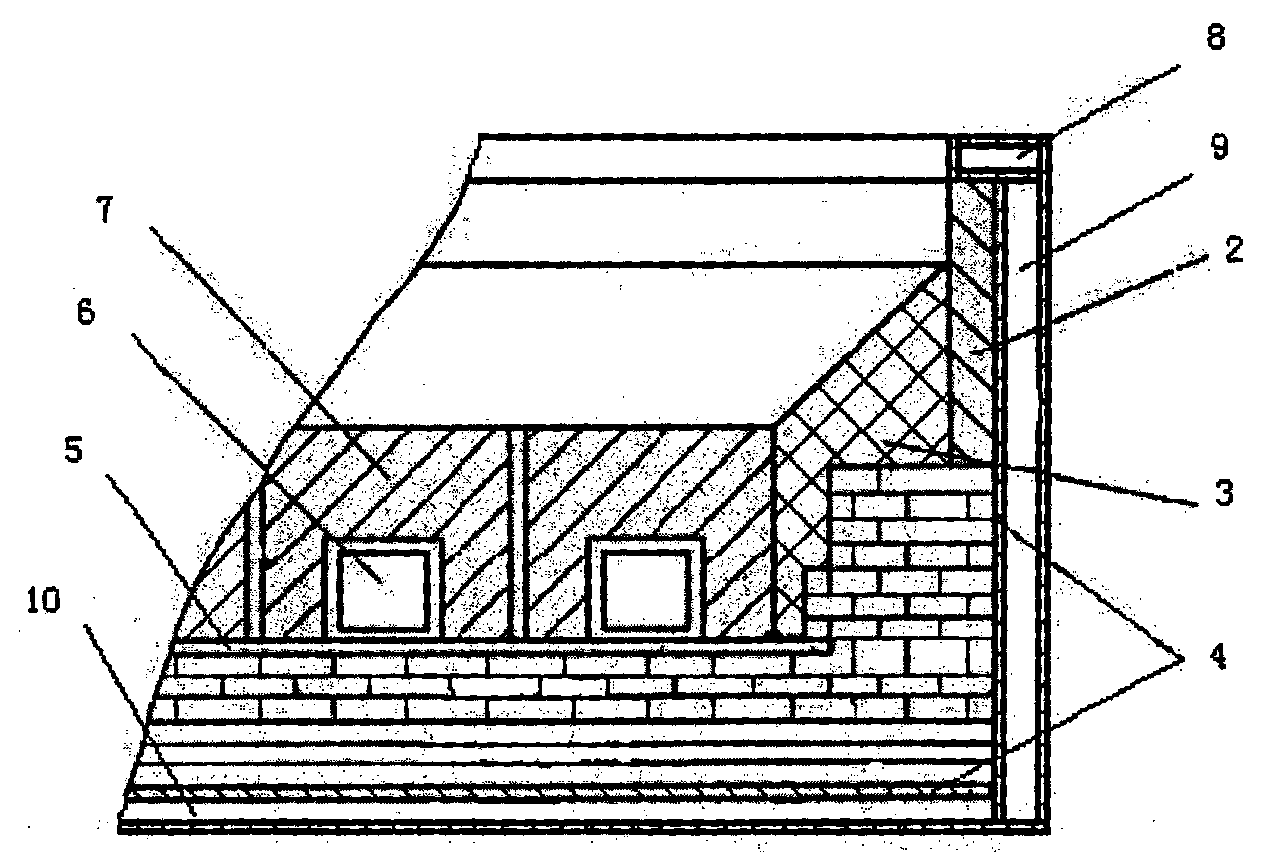

Forced heat transferring type aluminum electrolyzing groove

InactiveCN103469253ARecovery of waste heat resourcesIncreased current efficiency and cell lifeEngineeringPower flow

A forced heat transferring type aluminum electrolyzing groove comprises an electrolyzing groove body. The forced heat transferring type aluminum electrolyzing groove is characterized in that a heat exchanger with heat transferring oil as a heat transferring medium is arranged outside an outer shell of the electrolyzing groove body. The inlet oil temperature, the outlet oil temperature and the flow of the heat transferring oil of the heat exchanger are controlled, the heat dissipating capacity of the electrolyzing groove is controlled, and therefore the heat balance of the electrolyzing groove can be controlled, the electrolyzing groove can operate under the stable heat balanced conditions all the time, the residual heat resources are effectively recovered, meanwhile, a good and stable electrolyzing groove inner shape can be formed, the current efficiency is improved, and the service life of the electrolyzing groove is prolonged.

Owner:ZHENGZHOU UNIV

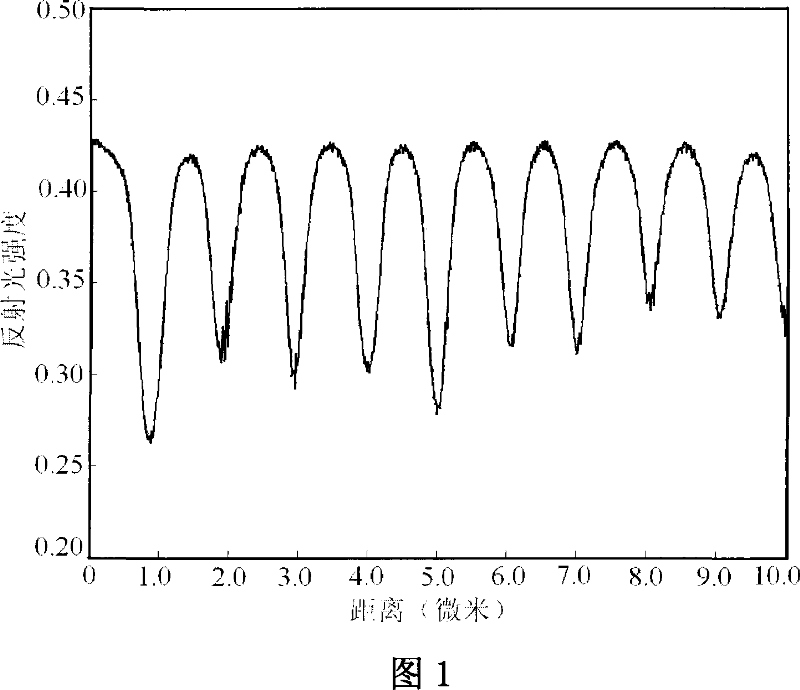

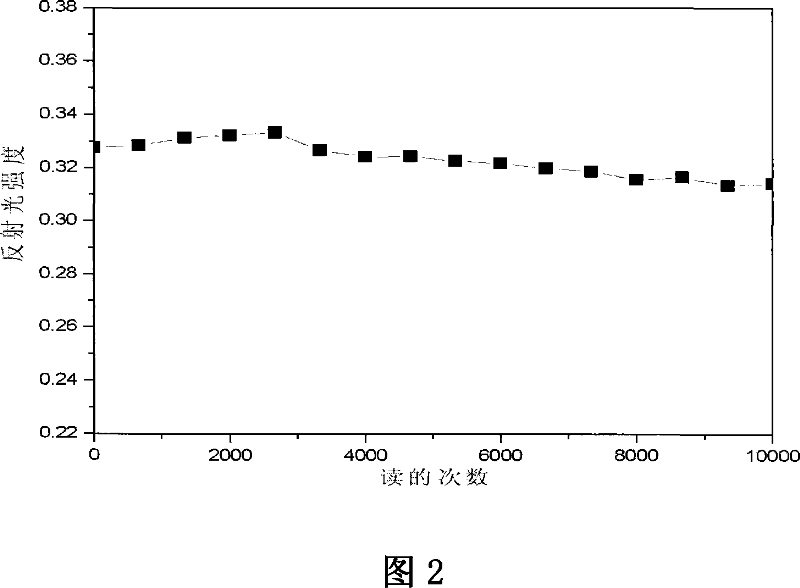

One time write-in-type blue light storing inorganic medium and method for making same

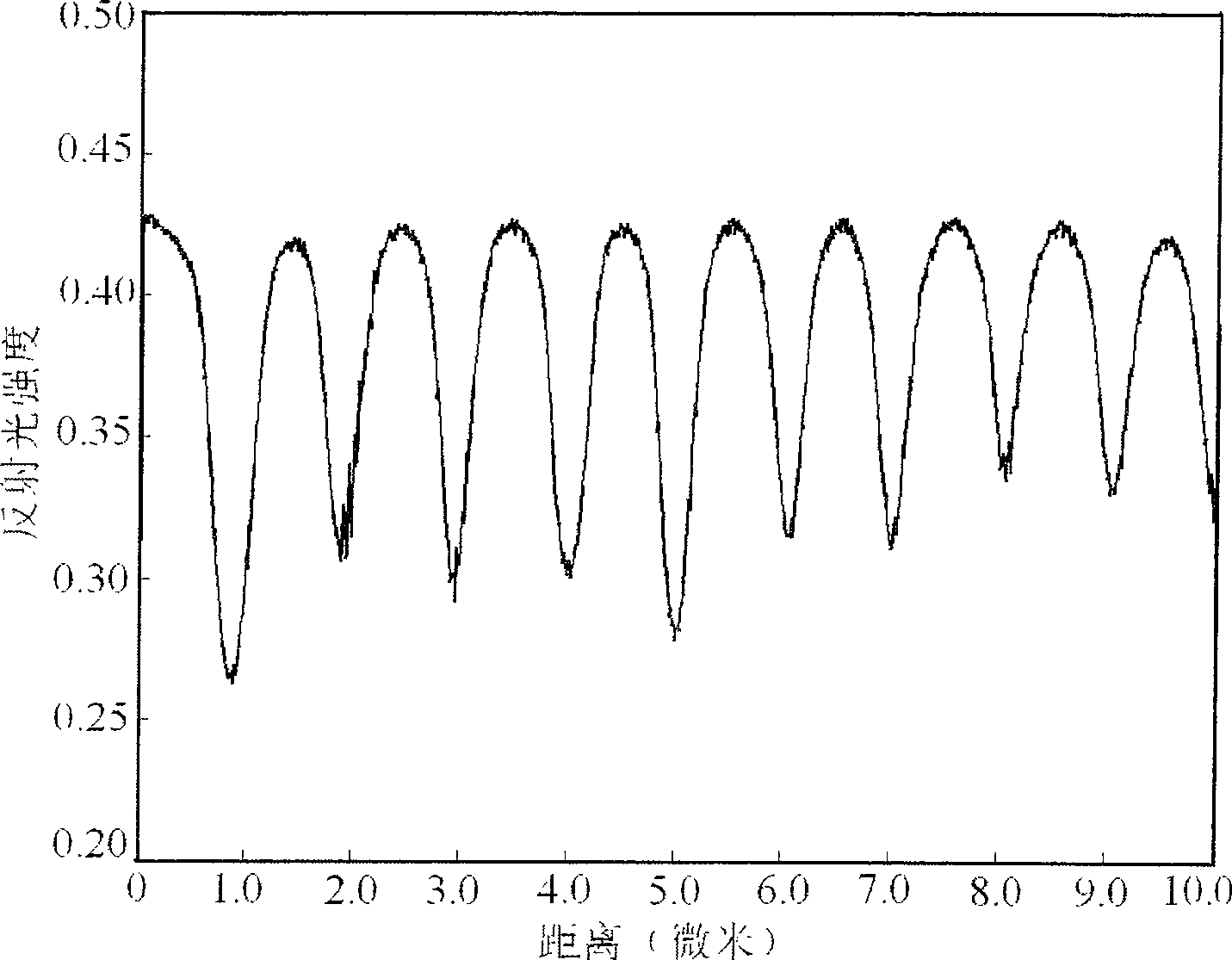

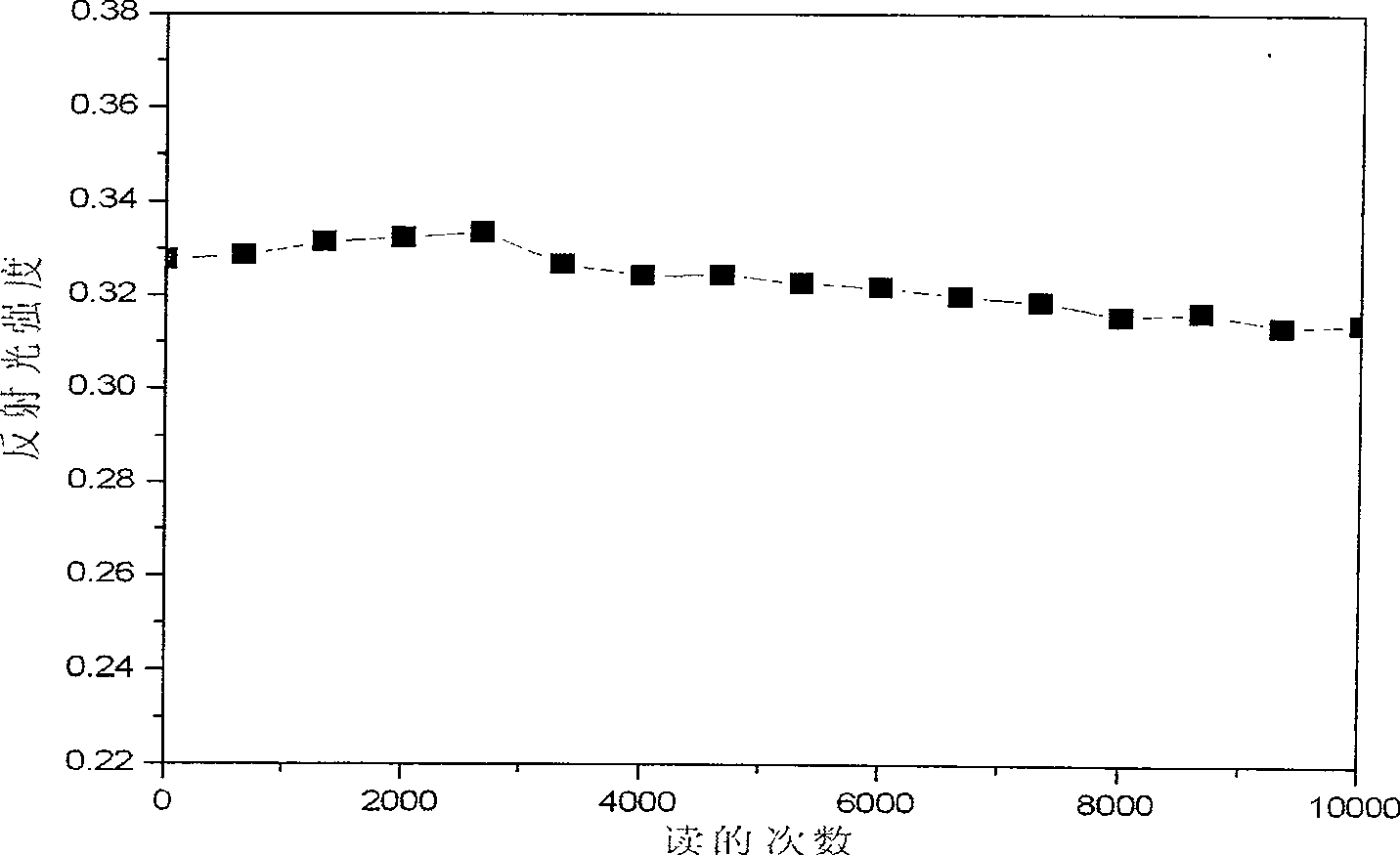

InactiveCN101038767AHigh optical contrastImprove stabilityRecord information storageRecord carrier materialsComposite filmOptical contrast

A one-off blue-light storage inorganic medium and a manufacturing method thereof are provided. The one-off blue-light storage inorganic medium is a Sb-Sb2O3-SiO2 composite thin film which is prepared on a substrate by stibium Sb and silicon Si through a reactive magnetron sputtering method, and which comprises three components of Sb, Sb2O3 and SiO2, wherein the mol percent of Sb is 10%-70%, the mol percent of Sb2O3 is 10%-40%, the mol percent of SiO2 is 20%-80%. The blue-light storage inorganic medium of the invention prepared by the reactive magnetron sputtering method has a high optical contrast and stability before and after layer action.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

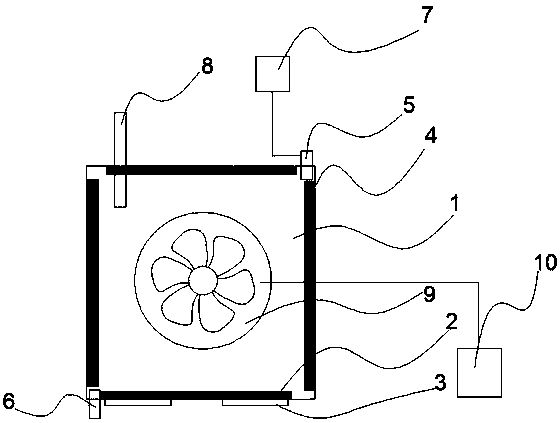

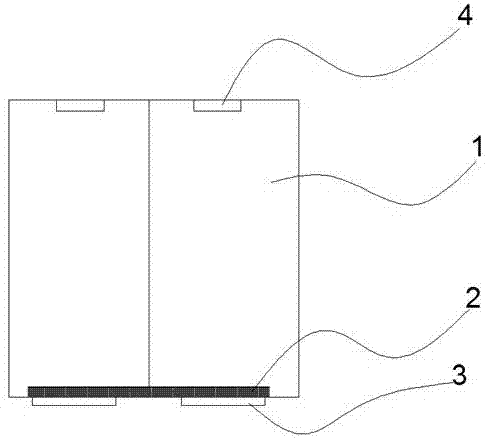

Heat dissipation electrical cabinet

InactiveCN107453225ATemperature controlPrevent infiltrationSubstation/switching arrangement cooling/ventilationCasings/cabinets/drawers detailsEngineeringAir convection

The invention discloses a heat dissipation electrical cabinet, which comprises an electrical cabinet body (1), a support frame (3) is provided at the bottom of the electrical cabinet body (1), and a layer of filter screen (2) is provided at the bottom of the electrical cabinet body (1). ), the electrical cabinet body (1) is designed with a fan (4) on the top. The beneficial effects of the invention are: when the electrical components are working, the heat dissipation of the electrical cabinet can be controlled by means of the temperature-expandable support frame in the electrical cabinet, and the support frame can be raised when the temperature is high. The filter screen in the electrical cabinet is set at the bottom to prevent the infiltration of rainwater in rainy days and other weather, and secondly to better circulate the air in the electrical cabinet, using the connectivity between the fan and the filter screen so that the temperature will not continue to increase. The temperature in the electrical cabinet is strictly controlled to protect the electrical components.

Owner:JIANGYIN HENGTONG ELECTRICAL EQUIP CO LTD

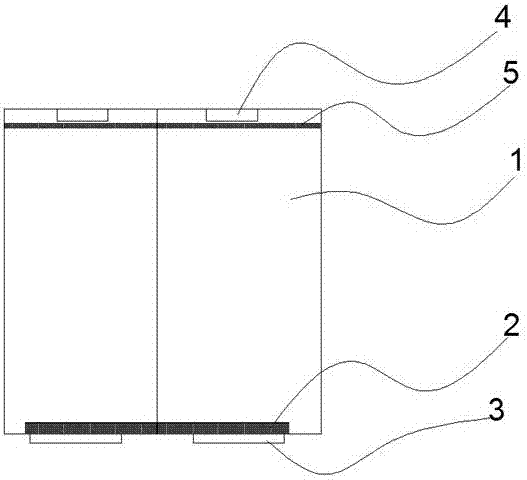

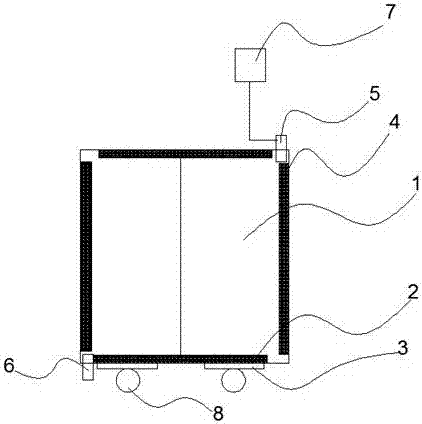

Heat dissipation electrical cabinet

InactiveCN107453217ATemperature controlControl heat dissipationSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsAir convectionElectrical equipment

The invention discloses a heat dissipation electrical cabinet, which comprises an electrical cabinet body (1), a support frame (3) is provided at the bottom of the electrical cabinet body (1), and a layer of filter screen (2) is provided at the bottom of the electrical cabinet body (1). ), a fan (4) is designed on the top of the electrical cabinet body (1), and a dust-proof filter (5) is designed under the fan (4). The beneficial effects of the invention are: when the electrical components are working, the heat dissipation of the electrical cabinet can be controlled by means of the temperature-expandable support frame in the electrical cabinet, and the support frame can be raised when the temperature is high. The filter screen in the electrical cabinet is set at the bottom to prevent the infiltration of rainwater in rainy days and other weather, and secondly to better circulate the air in the electrical cabinet, using the connectivity between the fan and the filter screen so that the temperature will not continue to increase. Strictly control the temperature in the electrical cabinet, and at the same time, install a dust-proof filter under the fan to more effectively separate the dust in the air, play a dust-proof role, and protect the electrical components.

Owner:JIANGYIN HENGTONG ELECTRICAL EQUIP CO LTD

Method for covering tea plant

InactiveCN101300932APromote growthPromote early germinationPlant protective coveringsAgroforestryTea tree

Owner:谭建

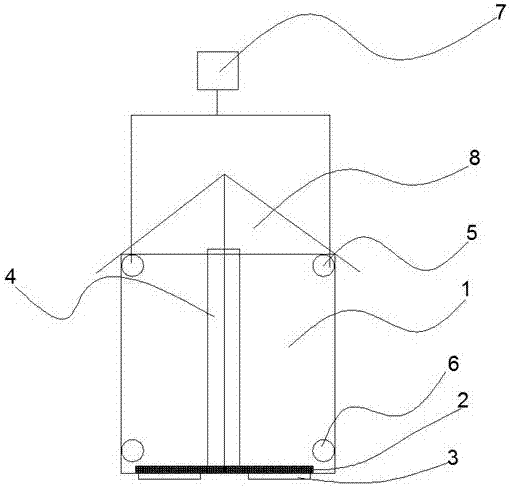

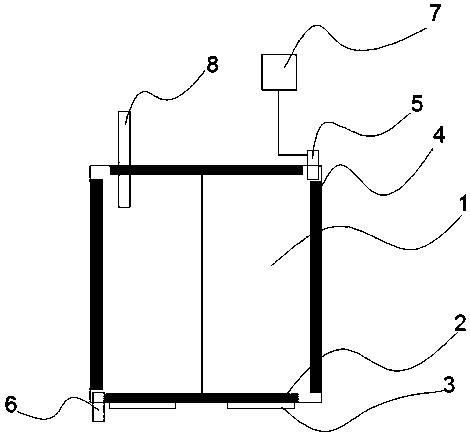

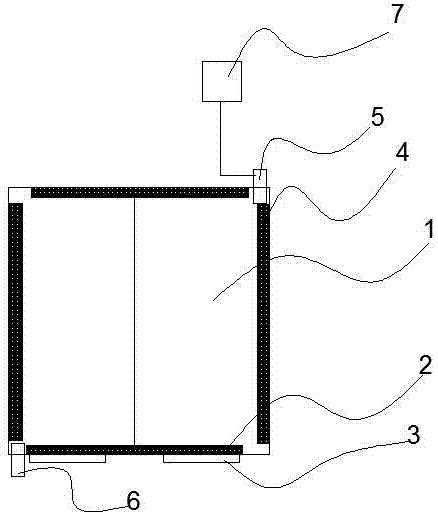

Heat dissipation electrical cabinet

InactiveCN107454771AImprove protectionTemperature controlCasings/cabinets/drawers detailsCooling/ventilation/heating modificationsWorking temperatureEngineering

The invention discloses a heat dissipation electrical cabinet. The heat dissipation electrical cabinet comprises an electrical cabinet body (1); supporting frames (3) are arranged at the bottom of the electrical cabinet body (1); a layer of filtering net (2) is arranged at the bottom layer of the electrical cabinet body (1); a rainproof plate (4) is arranged on an electrical cabinet door; two air inlet fans (5) are arranged on the top of the electrical cabinet body (1); two air outlet fans (6) are arranged at the bottom of the electrical cabinet body (1); the two air inlet fans (5) are connected with a motor (7); and a triangular shielding cover (8) is arranged on the upper part of the electrical cabinet body (1). The heat dissipation electrical cabinet has the beneficial effects as follows: the supporting frames can be elevated when the working temperature of electric appliance elements is high, so that heat dissipation performance of the electrical cabinet can be controlled; the filtering net in the electrical cabinet is arranged at the bottom, so that rainwater permeation in rainy days and the like can be prevented; by virtue of the rainproof plate, rainwater permeation and the like can be prevented; and by virtue of matching of the air inlet fans and the air outlet fans, gas in the electrical cabinet can be in full exchange with the outside, so that electric appliance elements can be protected.

Owner:JIANGYIN HENGTONG ELECTRICAL EQUIP CO LTD

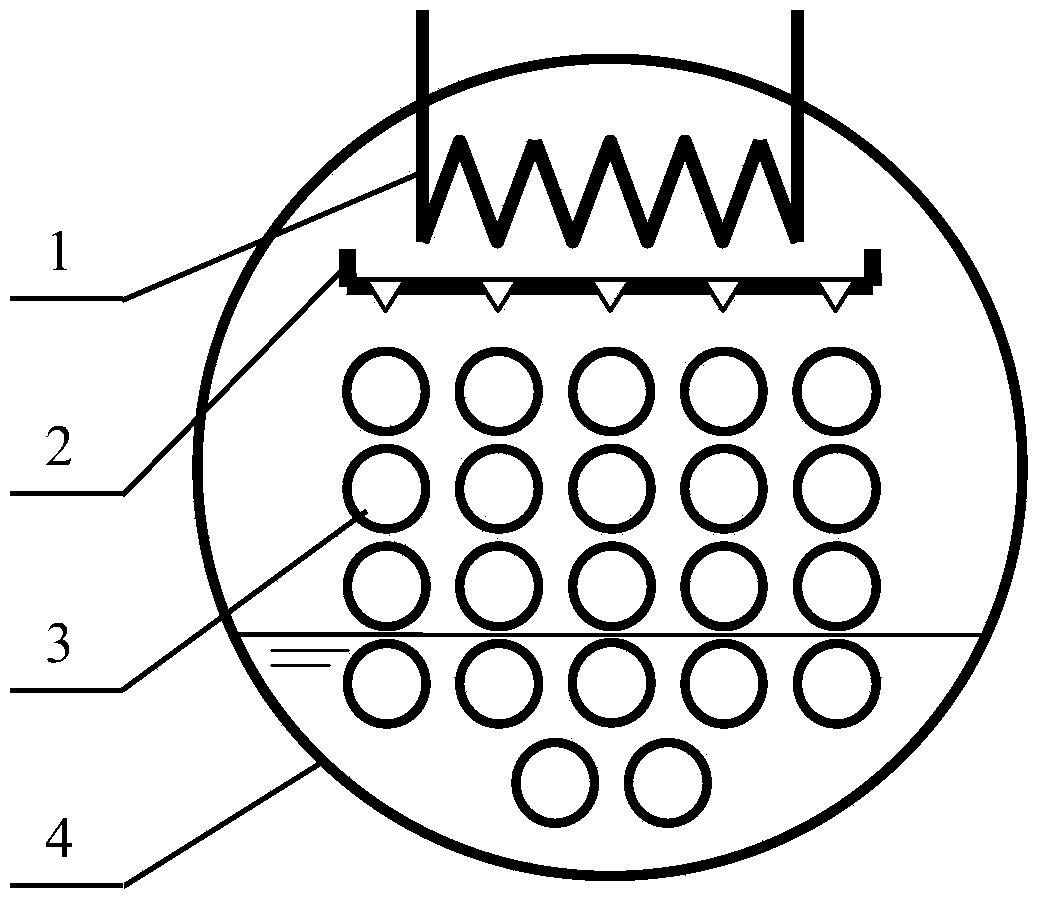

Falling-film evaporation device

InactiveCN104006580AAchieve flooded evaporationOil return is simpleEvaporators/condensersEvaporationEngineering

The invention discloses a falling-film evaporation device. According to the falling-film evaporation device, heat exchange is achieved through evaporation and condensation of saturated liquid. A barrel is horizontally arranged. A plurality of heat exchange tubes are horizontally arranged on the lower middle portion inside the barrel in parallel. An evaporation coil is arranged on the upper portion of the barrel. A liquid distributor is installed between the evaporation coil and the topmost heat exchange tube. The several bottommost heat exchange tubes are immersed in the saturated liquid. The space, outside the saturated liquid, in the barrel is filled with saturated gas. The heat exchange tubes are filled with flowing secondary refrigerant. The evaporation coil servers as an evaporator of a refrigeration system and is filled with flowing refrigerant. The refrigerant is evaporated in the evaporation coil, lubricating oil directly flows back to a compressor along with the evaporated refrigerant, the saturated liquid does not contain the lubricating oil, no oil film is attached to the heat tubes, and therefore the heat transfer coefficient is increased. Meanwhile, no oil return device is needed, and therefore oil return of refrigeration system is simple.

Owner:TIANJIN UNIV OF COMMERCE

Data Center Task Temperature Prediction and Scheduling Method Based on RBF Neural Network

ActiveCN109375994BControl heat dissipationAvoid hot spotsProgram initiation/switchingDigital data processing detailsTemperature controlData center

The invention discloses a data center task temperature prediction and scheduling method based on RBF neural network. The RBF neural network is used to establish a task temperature prediction model; a temperature control load balancing module is established to determine the safety temperature and warning temperature of the server and communicate with any server Si Make judgment and selection; monitor and feed back the operating temperature of the server to the temperature control load balancing module in real time through the monitoring feedback module, and the temperature control load balancing module performs scheduling control. The present invention performs task scheduling through active temperature prediction, which has better flexibility than the method of determining task scheduling based only on feedback temperature. By setting two active scheduling strategies in different temperature ranges, the purpose of reducing energy consumption and ensuring the safe operation of the data center is achieved.

Owner:XI AN JIAOTONG UNIV

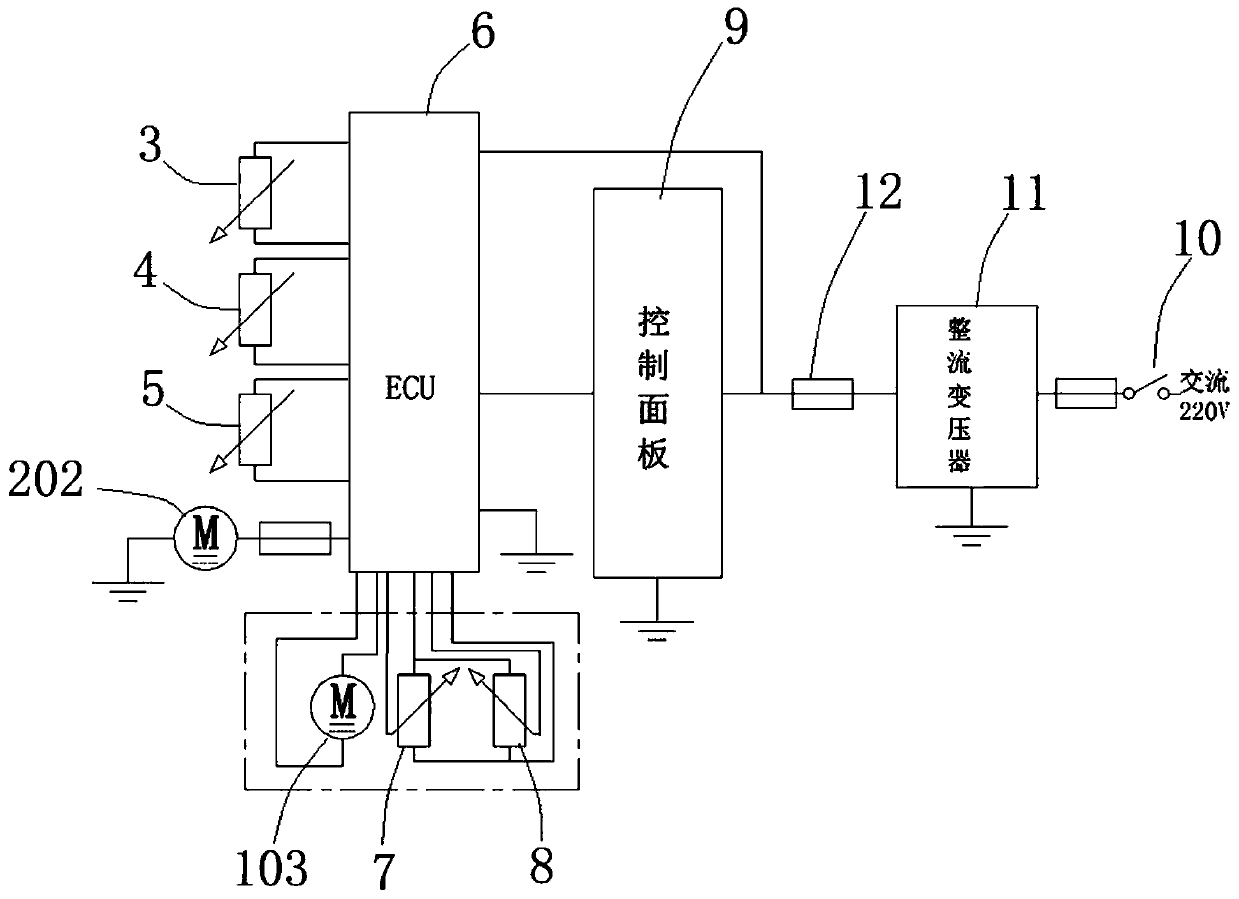

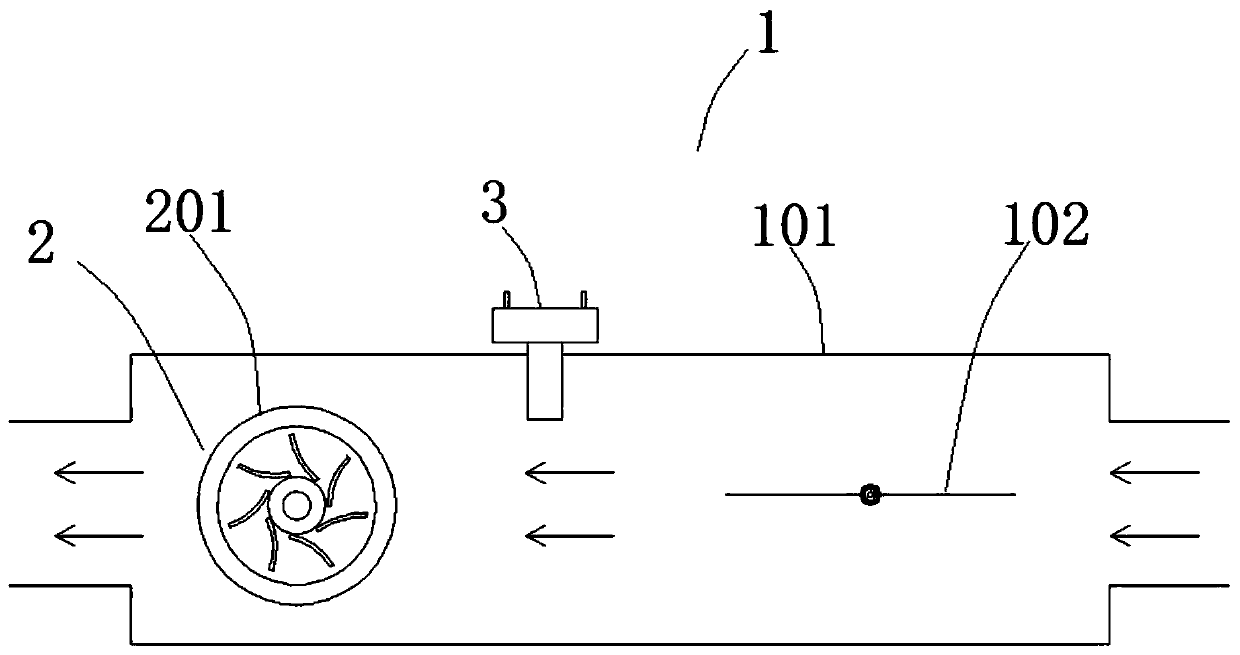

Intelligent control device for hot-water heating

InactiveCN111288540AImprove the level of intelligent controlReal-time monitoring of water temperatureLighting and heating apparatusSpace heating and ventilation detailsTemperature controlWater saving

An embodiment of the invention discloses an intelligent control device for hot-water heating, and belongs to the technical field of heating control. The intelligent control device is arranged on a hot-water heating device. The hot-water heating device is provided with a heating pipeline and a radiator. The intelligent control device comprises a water throttle valve body mechanism arranged on the heating pipeline, a water pumping mechanism arranged on the water throttle valve body mechanism, a first temperature sensor arranged on the water throttle valve body mechanism and used for monitoring the water temperature in the heating pipeline, a second temperature sensor arranged on the surface of the radiator and used for monitoring the temperature of the surface of the radiator, and a third temperature sensor arranged on the outer part of a case of the water throttle valve body mechanism and used for monitoring the indoor air temperature. The intelligent control device also comprises an ECU, wherein the ECU is separately and electrically connected to the first temperature sensor, the second temperature sensor and the third temperature sensor; and the ECU is electrically connected to the water throttle valve body mechanism and the water pumping mechanism. The intelligent control device for hot-water heating is ingenious in principle design, and has the characteristics of simplicityin operation, safety, energy conservation and universality. The intelligent control device for hot-water heating is high in intelligent level, and improves indoor temperature control efficiency.

Owner:SHANDONG HUAYU UNIV OF TECH

Heat dissipation electrical cabinet

InactiveCN107453223AProtect electrical componentsEasy to move and handleSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsAirflowElectrical equipment

The invention discloses a heat dissipation electric cabinet, which comprises an electric cabinet body (1), a support frame (3) is arranged at the bottom of the electric cabinet body (1), and a layer of filter screen is arranged at the bottom and top layers of the electric cabinet body (1) (2), there are ventilation nets (4) on the left and right sides of the electrical cabinet body (1), the upper right corner of the electrical cabinet body (1) is equipped with an air inlet (5), the lower left corner is equipped with an air outlet (6), and the air inlet (5) Connect the motor (7), and set the roller (8) under the support frame (3). The beneficial effects of the invention are: when the electrical components are working, the heat dissipation of the electrical cabinet can be controlled by means of the temperature-expandable support frame in the electrical cabinet, and the support frame can be raised when the temperature is high. The filter screens in the electrical cabinet are set at the bottom and top to prevent the infiltration of rainwater in rainy days and other weather. The setting of the ventilation screens on the left and right sides is more conducive to the exchange of air flow and prevents infiltration. The cooperation of the air inlet and the air outlet prevents the temperature from continuously increasing. , to protect the electrical components.

Owner:JIANGYIN HENGTONG ELECTRICAL EQUIP CO LTD

Novel electrical cabinet

InactiveCN107666788APrevent infiltrationPromote circulationCasings/cabinets/drawers detailsModifications using gaseous coolantsEngineeringElectrical equipment

Owner:JIANGYIN BAOLONG ELECTRONICS

One time write-in-type blue light storing inorganic medium and method for making same

InactiveCN100514465CInertLow thermal conductivityRecord information storageRecord carrier materialsComposite filmOptical contrast

A one-off blue-light storage inorganic medium and a manufacturing method thereof are provided. The one-off blue-light storage inorganic medium is a Sb-Sb2O3-SiO2 composite thin film which is prepared on a substrate by stibium Sb and silicon Si through a reactive magnetron sputtering method, and which comprises three components of Sb, Sb2O3 and SiO2, wherein the mol percent of Sb is 10%-70%, the mol percent of Sb2O3 is 10%-40%, the mol percent of SiO2 is 20%-80%. The blue-light storage inorganic medium of the invention prepared by the reactive magnetron sputtering method has a high optical contrast and stability before and after layer action.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

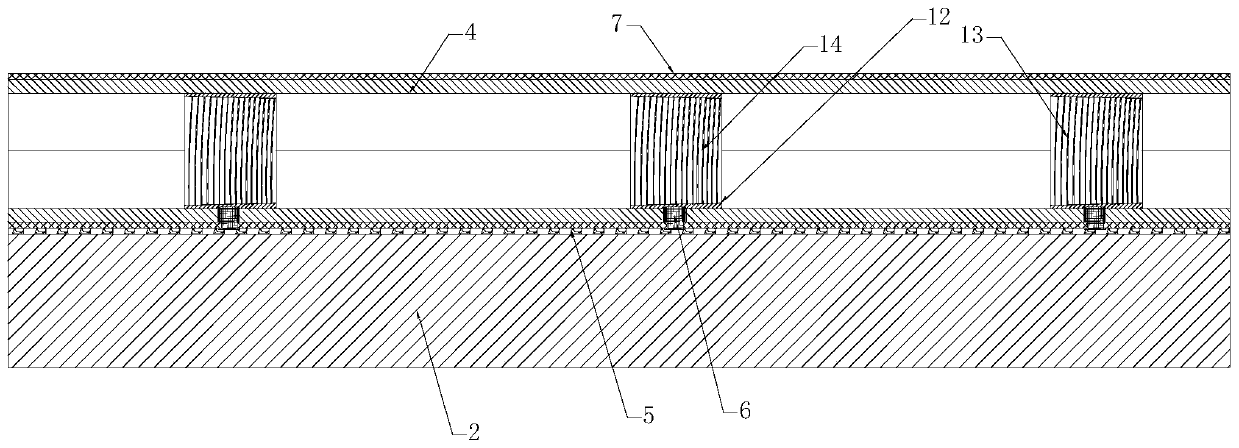

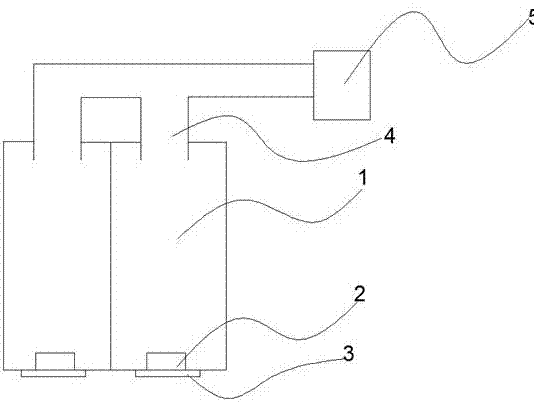

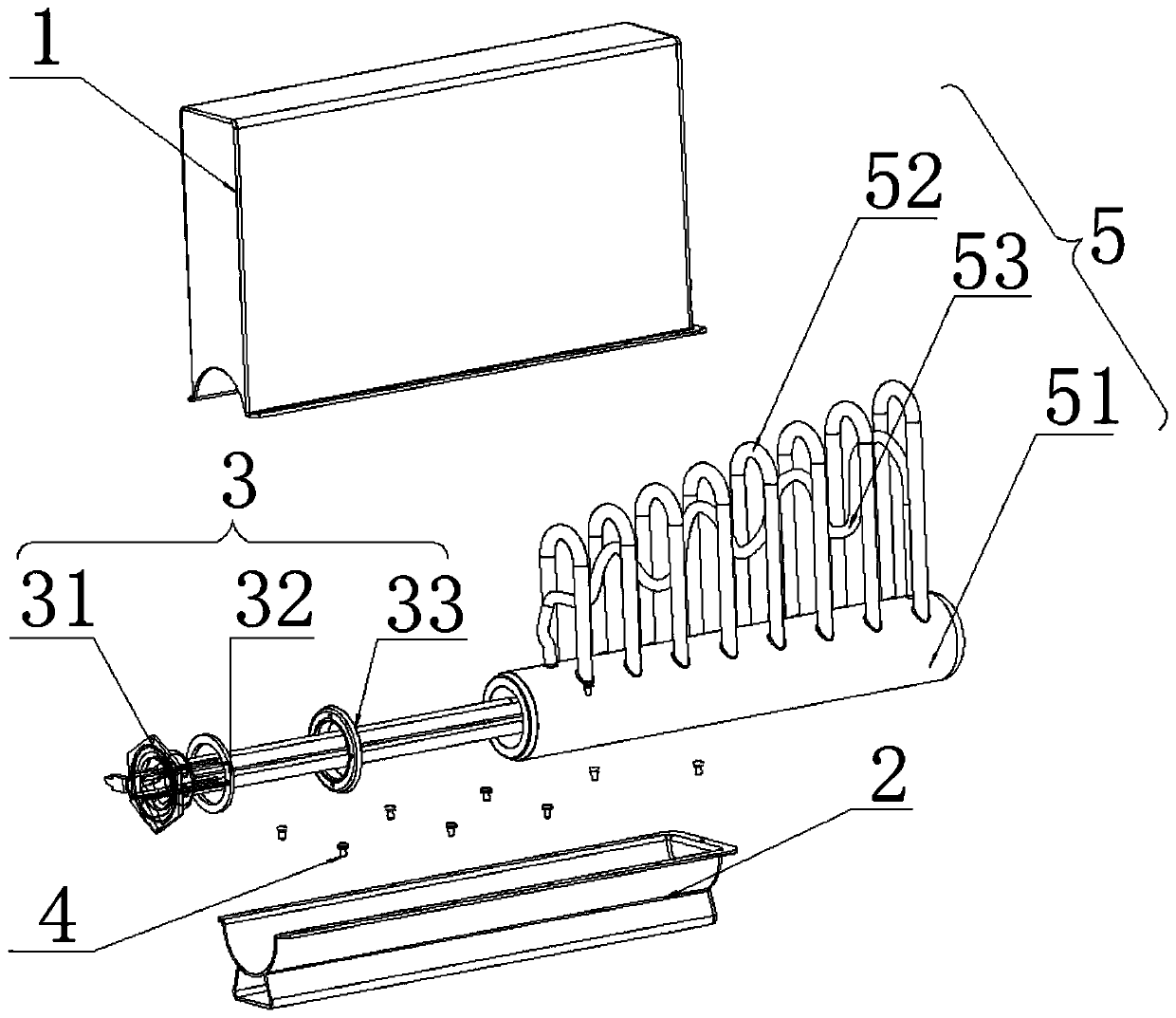

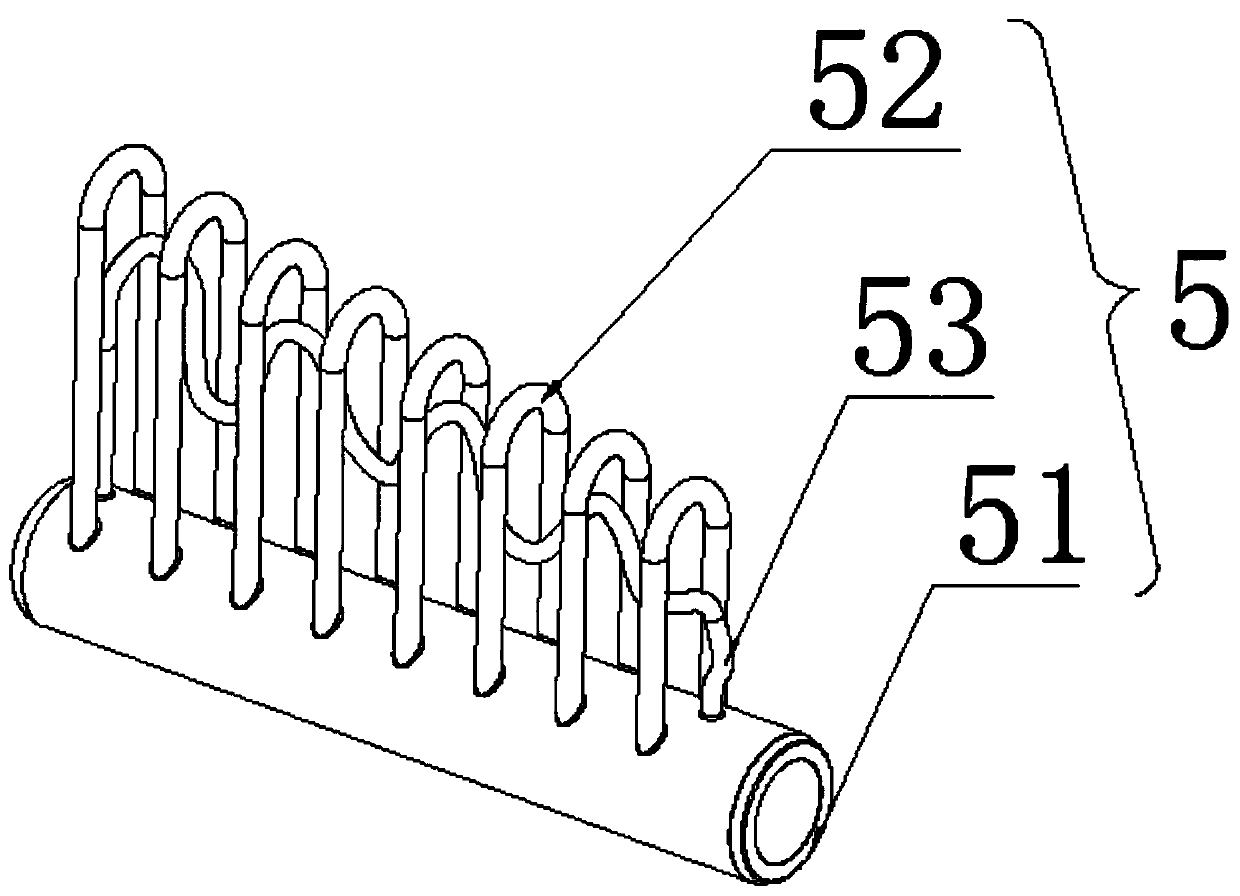

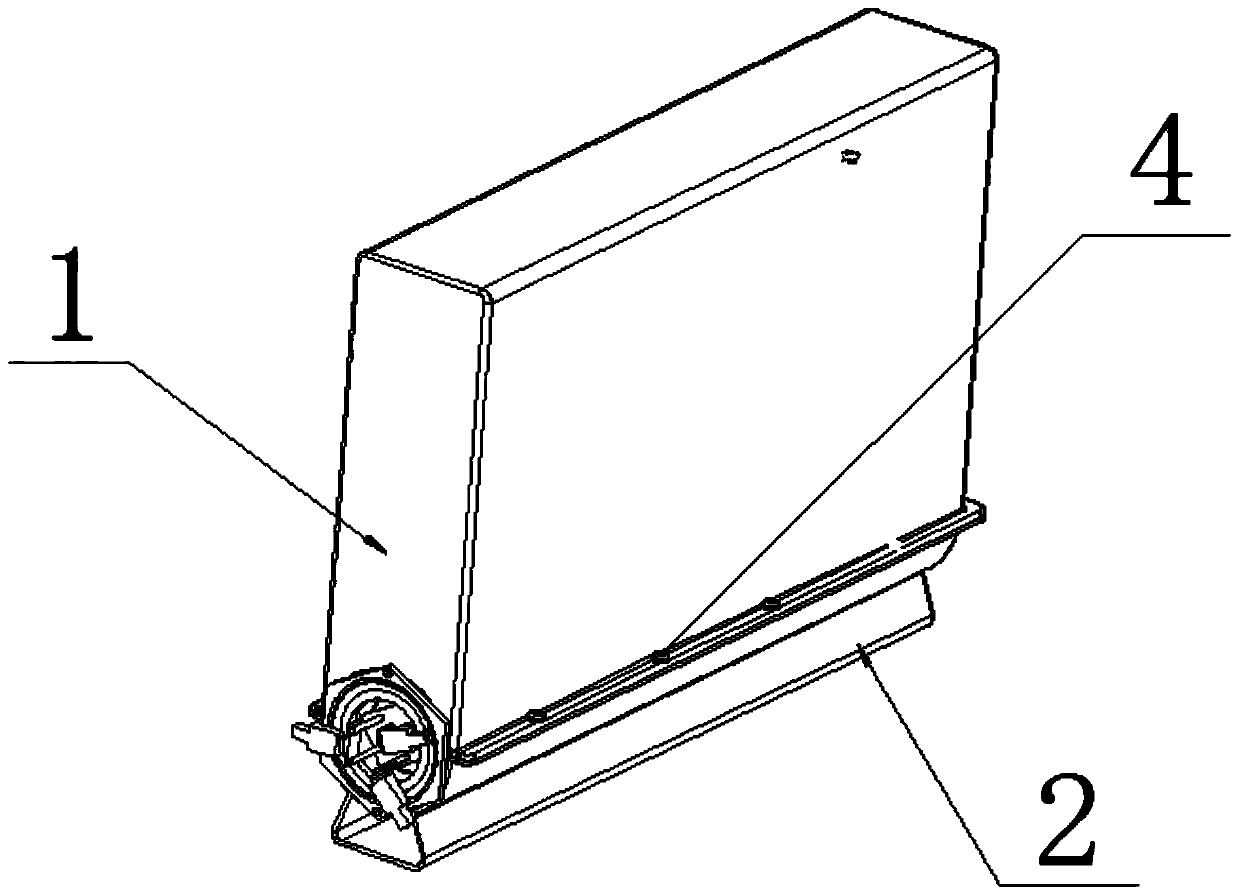

A heating plate assembly

The invention discloses a heating plate assembly, which comprises a shell, a heating plate and a heat insulation plate. The bottom of the shell is provided with an opening. layer, heat-conducting parts and heat-insulating sheath, the heat-conducting layer is made of high-temperature heat-resistant heat-conducting material mixed with carbon nanotubes, the heat-conducting layer is fixedly installed on the end surface of the heating plate, the outer side of the infusion tube is equipped with a heat-insulating sheath, and the infusion tube is coiled The infusion tube is clamped between the heat conduction layer and the heat insulation plate, and the periphery of the infusion tube is filled with high temperature resistant heat insulation material. The heat conduction parts are fixedly installed on the heat conduction layer, and one end extends into the In the infusion tube, heat is delivered to the infusion tube. The invention can control the heat dissipation of the heating plate and improves the process.

Owner:ANHUI SIYUAN SANQING INTELLIGENT MFG CO LTD

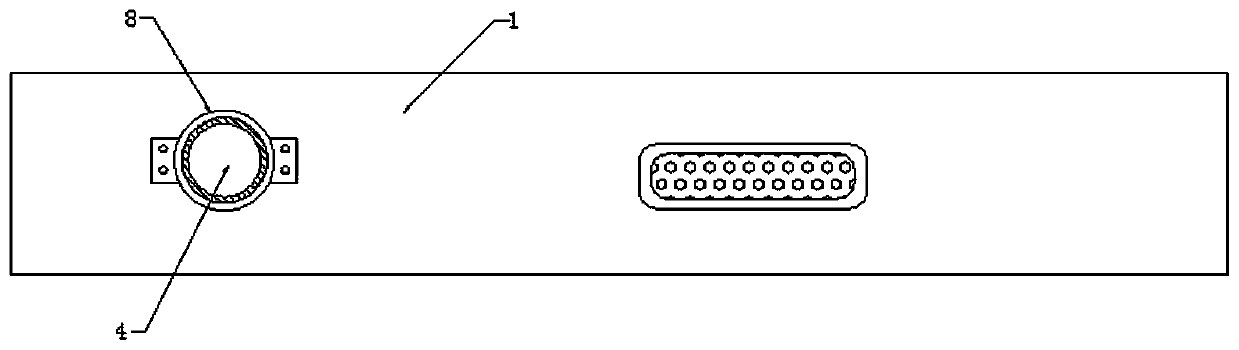

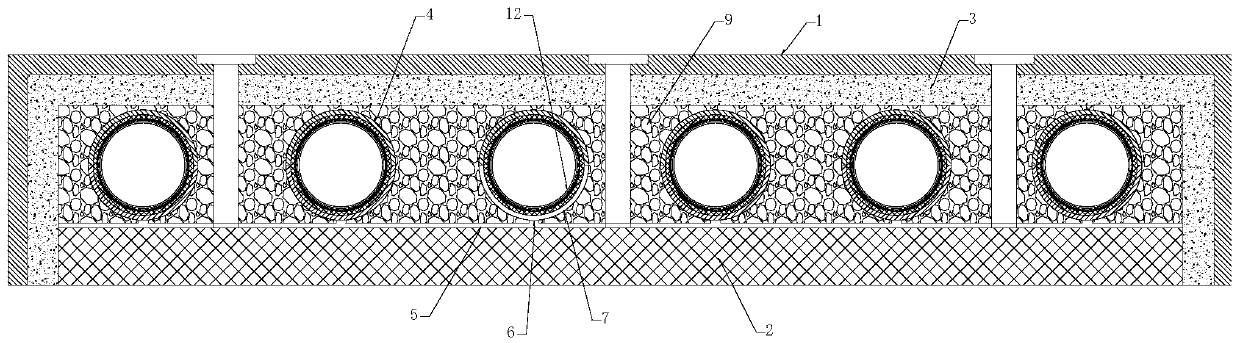

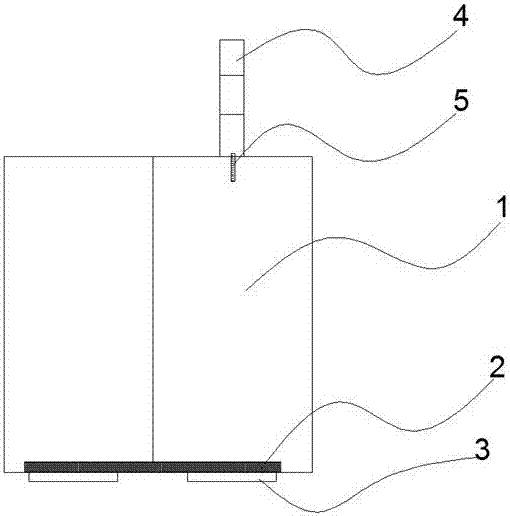

Heat dissipation electrical cabinet

InactiveCN107454776AControl heat dissipationReduce the temperatureCasings/cabinets/drawers detailsCooling/ventilation/heating modificationsEngineeringElectrical equipment

The invention discloses a heat dissipation electrical cabinet, which comprises an electrical cabinet body (1), a support frame (3) is provided at the bottom of the electrical cabinet body (1), and an air outlet (2) is provided at the bottom of the electrical cabinet body (1). , An air inlet (4) is provided on the top of the electrical cabinet body (1), and the air inlet (4) is connected to the motor (5) through a pipe. The beneficial effects of the invention are: when the electrical components are working, the heat dissipation of the electrical cabinet can be controlled by means of the temperature-expandable support frame in the electrical cabinet, and the support frame can be raised when the temperature is high. The cooperation of the air inlet and air outlet in the electrical cabinet can fully flow the fluid in the electrical cabinet, communicate with the outside air, reduce the temperature, prevent accidents, and protect electrical components.

Owner:JIANGYIN HENGTONG ELECTRICAL EQUIP CO LTD

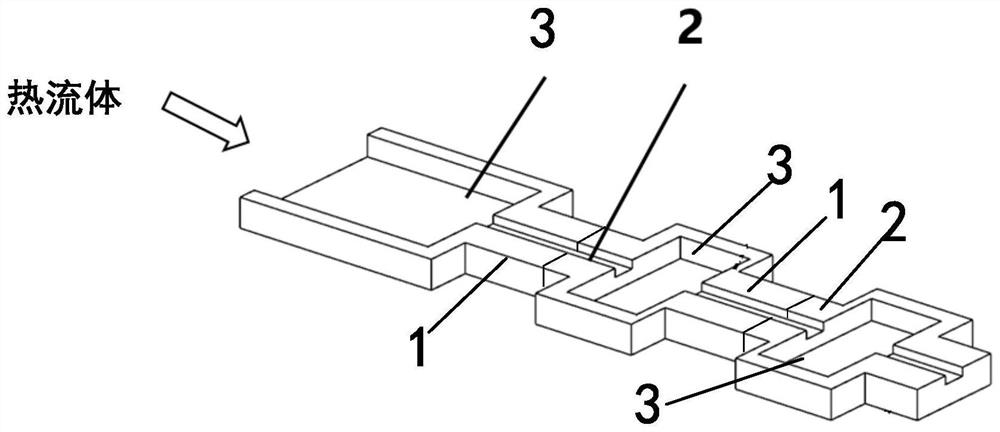

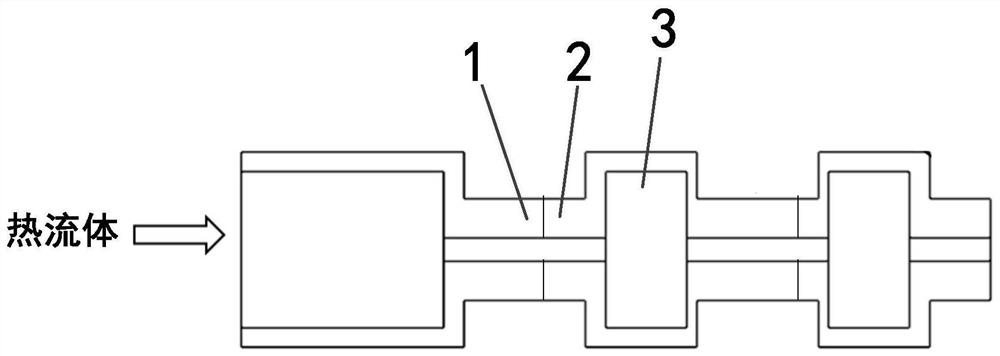

Deformation-controllable bionic joint based on friction effect, and preparation method and application of deformation-controllable bionic joint

ActiveCN112451177AControl heat dissipationAdjustable lengthFinger jointsAnkle jointsFriction effectThermal insulation

The invention belongs to the structural bionics related technology field, and discloses a deformation-controllable bionic joint based on a friction effect, and a preparation method and application ofthe deformation-controllable bionic joint. The bionic joint comprises at least one group of temperature rise segments, deformation segments and cooling segments, wherein the temperature rise segments,the deformation segments and the cooling segments are in through connection in sequence; the material of each deformation segment is shape memory alloy; the inner wall of each temperature rise segment is made of thermal insulation materials; the material of each cooling segment is a heat conduction material; and when a fluid flows through each temperature rise segment, due to a friction effect, the temperature rises to the deformation temperature of each deformation segment to enable each deformation segment to deform when the fluid flows through each deformation segment, and the fluid whichflows out of each deformation segment is subjected to heat dissipation and cooling through each cooling segment. By use of the deformation-controllable bionic joint disclosed by the invention, a deformation requirement of multiple deformation segments in a bionic structure is realized, and the bionic structure can be actively controlled.

Owner:HUAZHONG UNIV OF SCI & TECH

Oil heater assembly of separated oil circuit and electric heater

PendingCN111197795ASave volume and spaceGood experienceHeating fuelLighting and heating apparatusPhysicsOil storage

The invention discloses an oil heater assembly of a separated oil circuit. The oil heater assembly of the separated oil circuit comprises a shell, an oil storage assembly arranged in the inner cavityof the shell and a heating assembly arranged in the oil storage assembly; the oil storage assembly comprises oil storage tubes and an oil cylinder provided with the heating assembly, the outer side wall of the oil cylinder is connected with the multiple oil storage tubes in a penetrating mode, and thus the oil storage tubes are separated from the inner part of the oil cylinder; and the invention further discloses an electric heater, which comprises the oil heater assembly of the separated oil circuit. The design mainly solves the problem that a traditional oil heater oil circuit and a tablet are mixed together and cannot be separated; and by separating the oil storage tubes in the oil storage assembly, size space of the oil heater can be greatly saved, and at the same time, the structure trend of the oil circuit can be arranged more freely, so as to achieve the purpose of arrangement of the internal heat distribution in an oil heater body.

Owner:GREE ELECTRIC APPLIANCES INC

Preparation method and application of fluorescent composite glass film

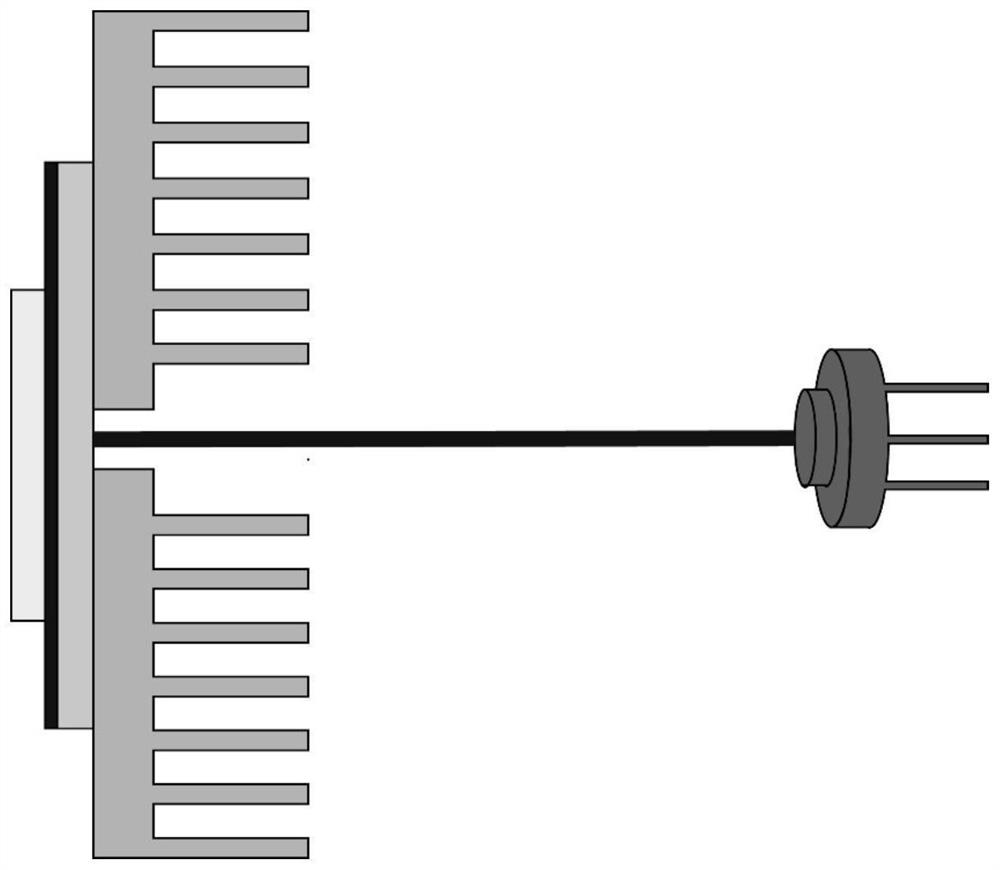

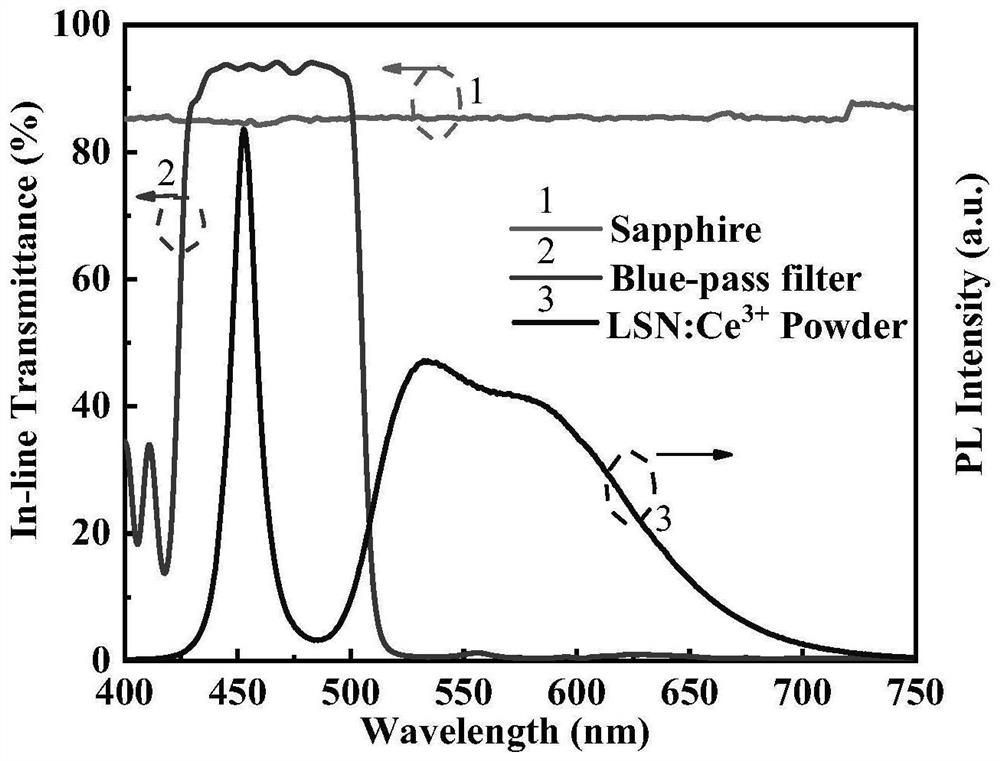

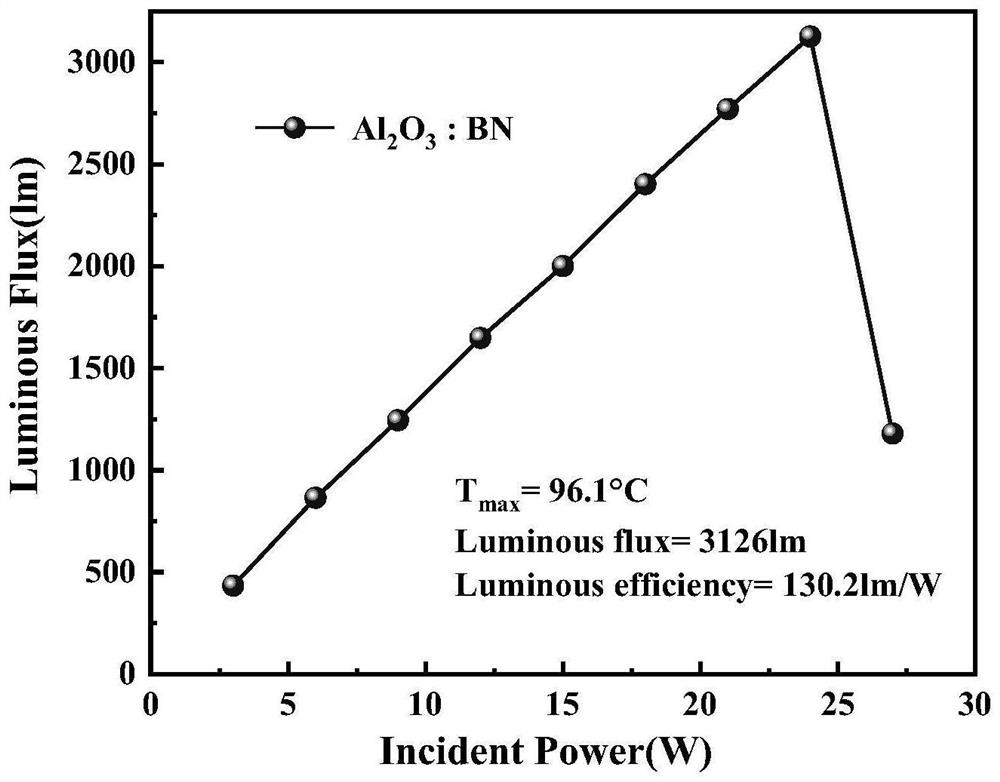

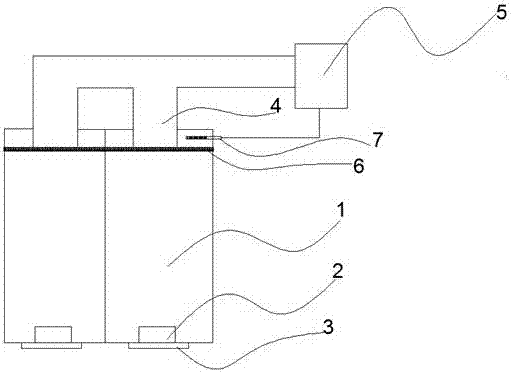

PendingCN114836195AHigh thermal conductivityLittle change in light effectHeat-exchange elementsEnergy efficient lightingFluorescenceLaser illumination

The invention discloses a preparation method and application of a fluorescent composite glass film. The fluorescent composite glass film comprises a blue laser diode, a composite fluorescent glass film, a blue light transmitting film, a sapphire substrate and a heat dissipation plate. In the composite fluorescent glass film, fluorescent powder, glass powder and heat-conducting filler are mixed according to the mass fraction ratio of 3: 2: 5; the heat-conducting filler is formed by mixing two to three of three heat-conducting materials, namely Al2O3, AlN and BN; blue light generated by the blue laser diode excites the composite fluorescent glass film to generate yellow light, and the yellow light is mixed with blue laser to form uniform white light. According to the high-thermal-conductivity composite fluorescent glass film disclosed by the invention, the thermal effect generated by the film layer during laser excitation can be greatly reduced, and the heat dissipation requirement of laser illumination can be well met.

Owner:CHINA JILIANG UNIV

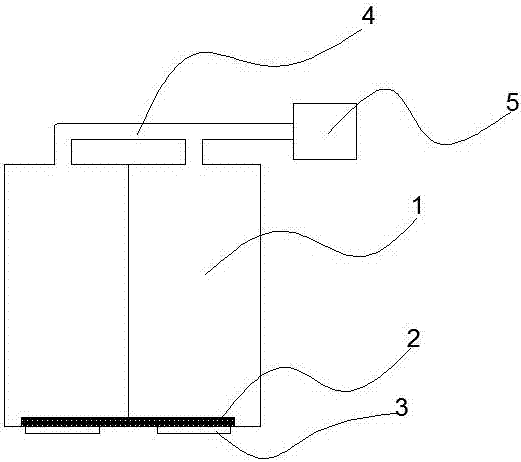

Heat dissipation electrical cabinet

InactiveCN107453224AReduce the temperaturePrevent accidentsSubstation/switching arrangement cooling/ventilationCasings/cabinets/drawers detailsTemperature measurementImpurity

The invention discloses a heat dissipation electrical cabinet, which comprises an electrical cabinet body (1), a support frame (3) is provided at the bottom of the electrical cabinet body (1), and an air outlet (2) is provided at the bottom of the electrical cabinet body (1). , There is an air inlet (4) on the top of the electrical cabinet body (1), the air inlet (4) is connected to the motor (5) through a pipe, and a dust-proof net (6) is installed under the air inlet (4). (1) A temperature measuring machine (7) is set on the top. The beneficial effects of the invention are: when the electrical components are working, the heat dissipation of the electrical cabinet can be controlled by means of the temperature-expandable support frame in the electrical cabinet, and the support frame can be raised when the temperature is high. The cooperation of the air inlet and the air outlet in the electrical cabinet can fully flow the fluid in the electrical cabinet, communicate with the outside air, reduce the temperature, and prevent accidents. Filter out, prevent in advance, and protect electrical components. The setting of the temperature measuring machine is to lock the temperature more accurately to control whether the motor is working, which greatly saves costs and achieves high efficiency and stability.

Owner:JIANGYIN HENGTONG ELECTRICAL EQUIP CO LTD

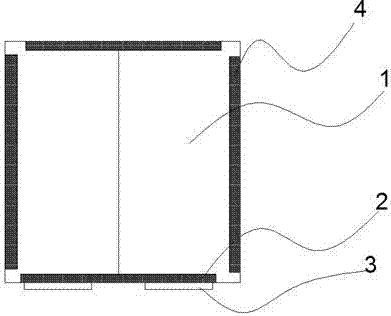

Heat dissipation electrical cabinet

InactiveCN107454774AGood for exchanging airIncrease temperatureCasings/cabinets/drawers detailsAirflowEngineering

The invention discloses a heat dissipation electric cabinet, which comprises an electric cabinet body (1), a support frame (3) is arranged at the bottom of the electric cabinet body (1), and a layer of filter screen is arranged at the bottom and top layers of the electric cabinet body (1) (2), there are ventilation nets (4) on the left and right sides of the electrical cabinet body (1). The beneficial effects of the invention are: when the electrical components are working, the heat dissipation of the electrical cabinet can be controlled by means of the temperature-expandable support frame in the electrical cabinet, and the support frame can be raised when the temperature is high. The filter screens in the electrical cabinet are set at the bottom and top to prevent the infiltration of rainwater in rainy days and other weather. The ventilation screens on the left and right sides are more conducive to the exchange of air flow and prevent penetration. The temperature will not continue to increase, which protects the electrical components.

Owner:JIANGYIN HENGTONG ELECTRICAL EQUIP CO LTD

Heat dissipation electrical cabinet

InactiveCN107454777AIncrease temperatureTemperature understandingCasings/cabinets/drawers detailsEngineeringAir convection

The invention discloses a heat dissipation electrical cabinet, which comprises an electrical cabinet body (1), a support frame (3) is provided at the bottom of the electrical cabinet body (1), and a layer of filter screen (2) is provided at the bottom of the electrical cabinet body (1). ), a temperature alarm (4) is provided on the top of the electrical cabinet body (1), and a thermometer (5) is connected under the temperature alarm (4). The beneficial effects of the invention are: when the electrical components are working, the heat dissipation of the electrical cabinet can be controlled by means of the temperature-expandable support frame in the electrical cabinet, and the support frame can be raised when the temperature is high. The filter screen in the electrical cabinet is set at the bottom to prevent the infiltration of rainwater in rainy days and other weather, and secondly to better circulate the air in the electrical cabinet so that the temperature will not continue to increase. The temperature alarm can be used to understand the electrical cabinet in a timely and effective manner. temperature, prevent accidents, and protect electrical components.

Owner:JIANGYIN HENGTONG ELECTRICAL EQUIP CO LTD

Heat dissipation electrical cabinet

InactiveCN107454768ATemperature controlPrevent infiltrationCasings/cabinets/drawers detailsInlet valveAir exchange

The invention discloses a heat dissipation electrical cabinet. The heat dissipation electrical cabinet comprises an electrical cabinet body (1), wherein support racks (3) are arranged at the bottom of the electrical cabinet body (1), a layer of filtering net (2) is arranged at a bottom layer of the electrical cabinet body (1), and an air inlet valve (4) is arranged at the top of the electrical cabinet body (1) and is externally connected with a motor. The heat dissipation electrical cabinet has the beneficial effects that the temperature telescopic support racks in the electrical cabinet can be employed when an electrical component works, and the heat dissipation performance of the electrical cabinet is controlled by lifting the support racks when the temperature is raised; the filtering net in the electrical cabinet is arranged at the bottom and is used for preventing rainwater from permeating in weather such as a rainy day, and air in the electrical cabinet is circulated better; and by matching with the air inlet valve, external air constantly enters the electrical cabinet and flows out of the filtering net, the internal temperature of the electrical cabinet is controlled better by such circulated air exchange, and the electrical component is protected

Owner:JIANGYIN HENGTONG ELECTRICAL EQUIP CO LTD

Heat dissipation electrical cabinet

InactiveCN107454773AControl heat dissipationPrevent infiltrationCasings/cabinets/drawers detailsCooling/ventilation/heating modificationsPermeationElectrical equipment

The invention discloses a heat dissipation electric cabinet, which comprises an electric cabinet body (1), a support frame (3) is arranged at the bottom of the electric cabinet body (1), and a layer of filter screen is arranged at the bottom and top layers of the electric cabinet body (1) (2), there are ventilation nets (4) on the left and right sides of the electrical cabinet body (1), the upper right corner of the electrical cabinet body (1) is equipped with an air inlet (5), the lower left corner is equipped with an air outlet (6), and the air inlet (5) Connect the motor (7). The beneficial effects of the invention are: when the electrical components are working, the heat dissipation of the electrical cabinet can be controlled by means of the temperature-expandable support frame in the electrical cabinet, and the support frame can be raised when the temperature is high. The filter screens in the electrical cabinet are set at the bottom and top to prevent the infiltration of rainwater in rainy days. The cooperation of the air outlet and the air outlet prevents the temperature from continuously increasing and protects the electrical components.

Owner:JIANGYIN HENGTONG ELECTRICAL EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com