Purification method of ultra-pure aluminum

A purification method and pure aluminum technology, which is applied in the field of ultra-high-purity aluminum purification, can solve problems such as unstable quality, unsatisfactory quality, and unqualified products, and achieve short heating and melting time, strong heat explosion, and energy saving costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

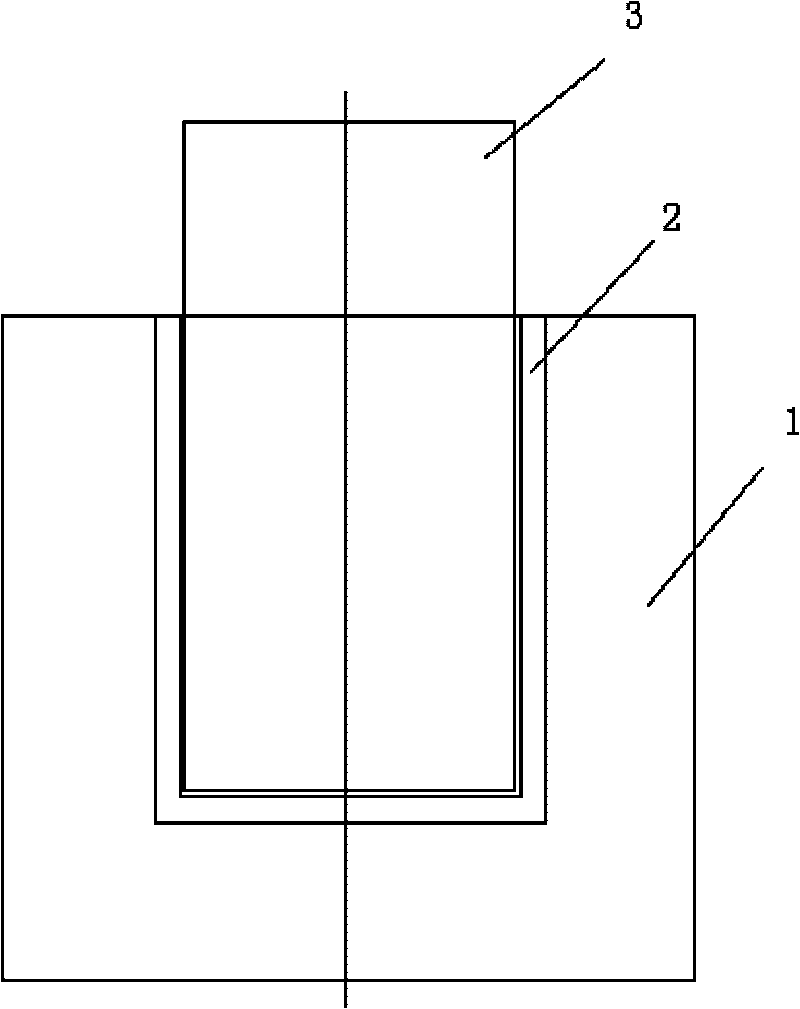

Image

Examples

Embodiment 1

[0021] Embodiment 1: Select 30 kg raw material refined aluminum whose purity is at least 4N6, and wherein Mg-3 ; Then put the refining furnace containing the raw material refined aluminum into the gas furnace and heat it to 680°C, so that the raw material refined aluminum in the refining furnace will be melted from solid to liquid; then move the refining furnace heated to 680°C from the gas furnace Crystallization furnace, make the molten aluminum in the purification furnace rotate in the heater of the crystallization furnace, the heater of the crystallization furnace is kept at 660°C, by controlling the temperature of the cooling water and making the purification furnace spiral out at a speed of 5cm / h Crystallization furnace, so that the aluminum liquid in the purification furnace maintains a crystallization speed of 5cm / h, and the crystallization ends after 6 hours; the purification furnace after crystallization is cooled, the crystallization ingot is taken out, and 25% of the...

Embodiment 2

[0022] Embodiment 2: Select 30 kg raw material refined aluminum whose purity is at least 4N6, and wherein Mg-3 ; Then put the refining furnace containing the raw material refined aluminum into a gas furnace and heat it to 715°C, so that the raw material refined aluminum in the refining furnace will be melted from solid to liquid; then move the refining furnace heated to 715°C from the gas furnace Crystallization furnace, make the molten aluminum in the purification furnace rotate in the heater of the crystallization furnace, the heater of the crystallization furnace is kept at 660°C, by controlling the temperature of the cooling water and making the purification furnace spirally extend out of the crystallization furnace, so that the aluminum liquid in the purification furnace maintains a crystallization speed of 7.5cm / h, and the crystallization ends after 5 hours; the purification furnace after crystallization is cooled, and the crystallization ingot is taken out, and the weight...

Embodiment 3

[0023] Embodiment 3: Select 30 kg raw material refined aluminum whose purity is at least 4N6, and wherein Mg-3 ; Then put the refining furnace containing the raw material refined aluminum into the gas furnace and heat it to 750°C, so that the raw material refined aluminum in the refining furnace is melted from solid to liquid; then the refining furnace heated to 750°C is moved from the gas furnace Crystallization furnace, make the molten aluminum in the purification furnace rotate in the heater of the crystallization furnace, the heater of the crystallization furnace is kept at 660°C, by controlling the temperature of the cooling water and making the purification furnace spiral out at a speed of 10cm / h Crystallization furnace, so that the molten aluminum in the purification furnace maintains a crystallization speed of 10cm / h, and the crystallization ends after 4 hours; after the purification furnace is cooled after crystallization, take out the crystallization ingot, and remove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com