A heating plate assembly

A heating plate and component technology, applied in the field of heating plate components, can solve the problems of uncontrollable heat dissipation, precise control of heat dissipation, unable to meet social production needs, etc., to reduce work intensity, accurate heating temperature, and reduce sealing pressure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

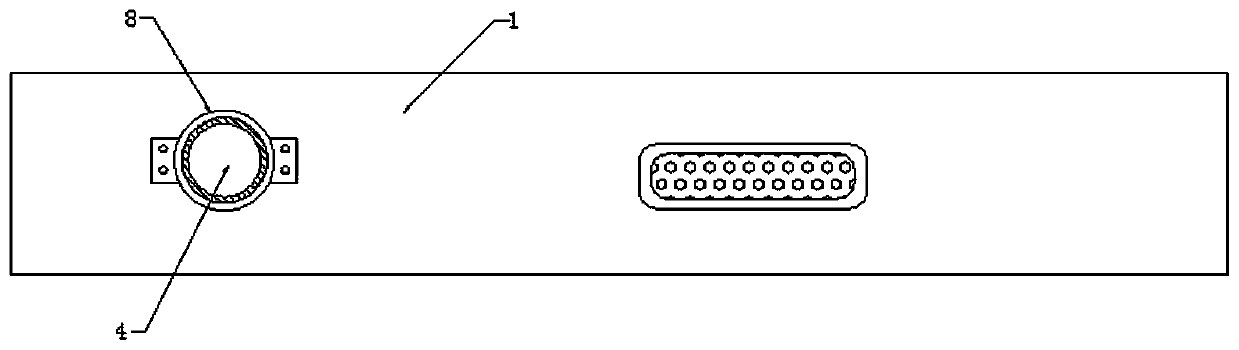

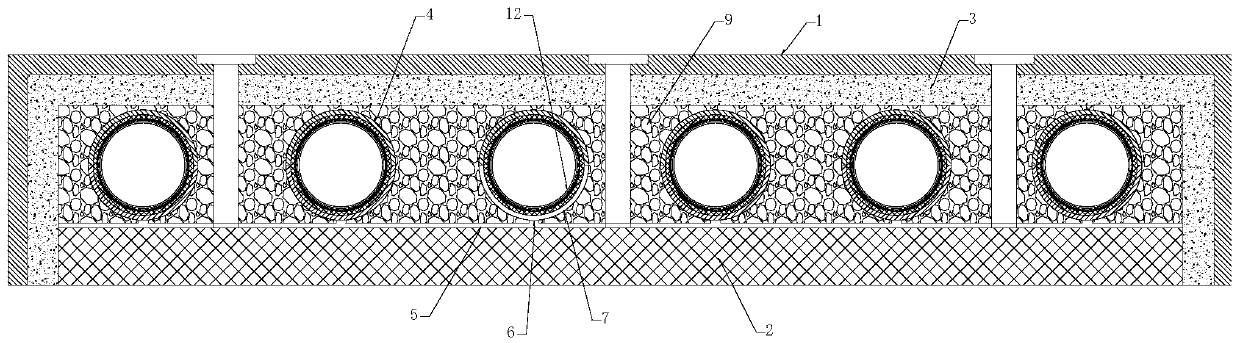

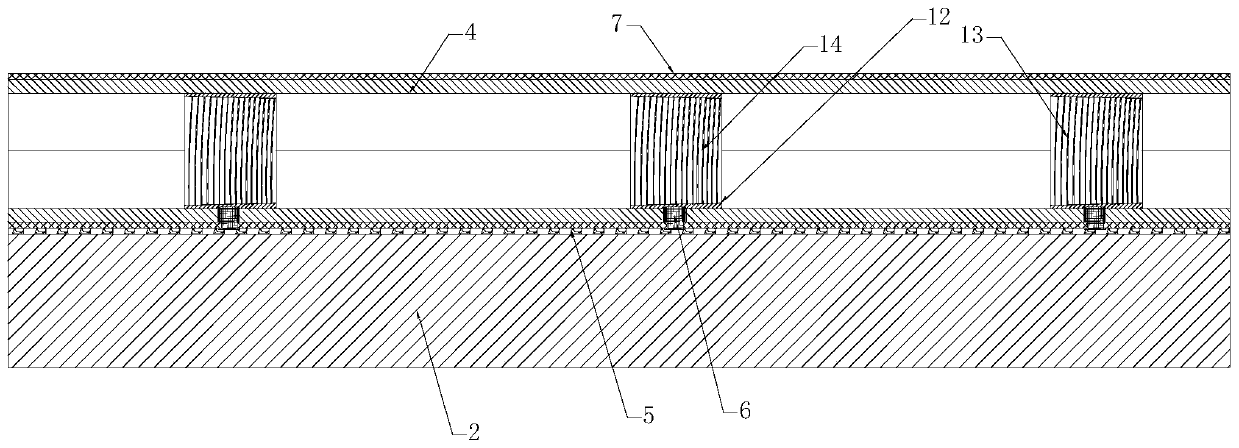

[0024] Please refer to the accompanying drawings, a heating plate assembly, including a shell 1, a heating plate 2 and a heat shield 3, the shell 1 is provided with an opening at the bottom, and the inside of the shell 1 is installed with a heat shield 3 and a heating plate in sequence from the inside to the outside 2. The heating plate 2 is the main component that generates heat. Generally, the heat produced by the heating plate 2 is constant. The heating plate assembly also includes the infusion tube 4, the heat conducting layer 5, the heat conducting component 6 and the heat insulating sheath 7, and the heat conducting layer 5 is made of high-temperature-resistant heat-conducting material mixed with carbon nanotubes. The heat-conducting layer 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com