Patents

Literature

43results about How to "Precise heating temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

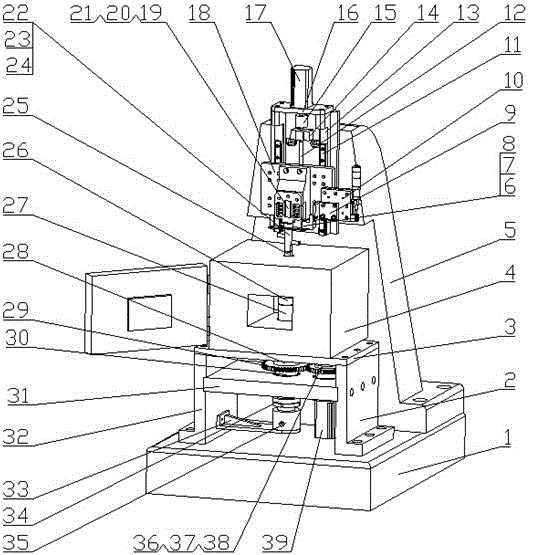

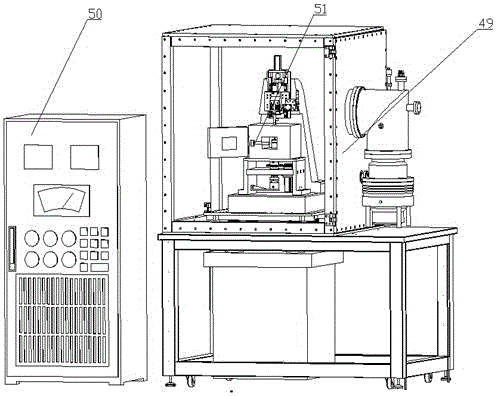

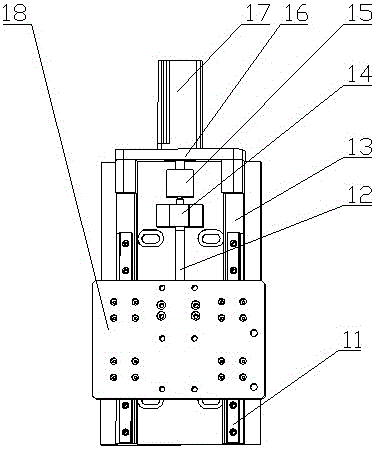

High-temperature micro-nano press mark test device and method in vacuum environment

PendingCN106404574AReduce the impact of collectionAvoid entanglementInvestigating material hardnessTest theoryMaterial hardness

The invention relates to a high-temperature micro-nano press mark test device and method in vacuum environment, and belongs to the field of mechanical and electronic integration precise instrument. The device can be used in vacuum environment; the oxidization caused by high-temperature environment on a press head and a test specimen can be prevented; the influence of air flowing on the test specimen heating is weakened; the stable heating temperature of the test specimen is ensured; further, the test analysis on the test specimen micro mechanical properties can be started; the characteristics parameters and the like of material hardness, elasticity modulus, creep properties and thermo-mechanical coupling effects are obtained so as to study the influence rule of variable-temperature and high-temperature environment on the material micro mechanical behaviors, deformation damage mechanisms and micro tissue structure evolution; the material and product design manufacturing, service prediction and reliability evaluation are guided. The structure of the device is compact; the measurement precision is high; the application range is wide; the wide application prospects are realized in the fields of material science, equipment manufacturing, ferrous metallurgy, national defense and military, aerospace and the like. According to the test method provided by the invention, the rich material micro mechanical property test theories and technical systems are combined.

Owner:JILIN UNIV

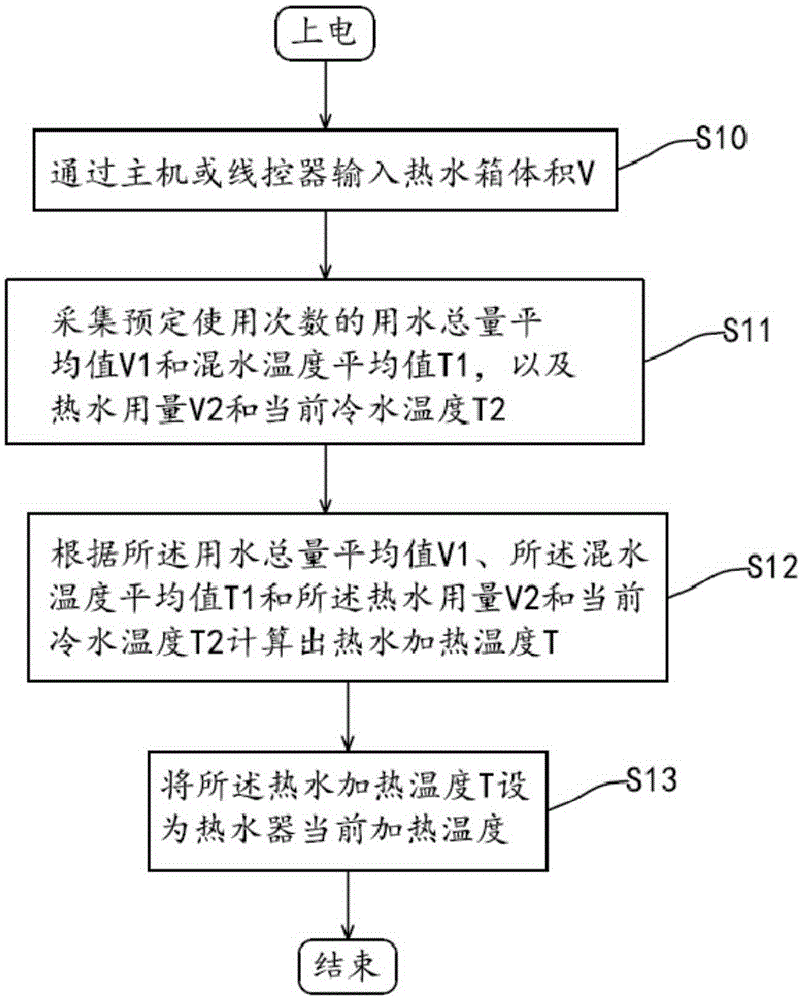

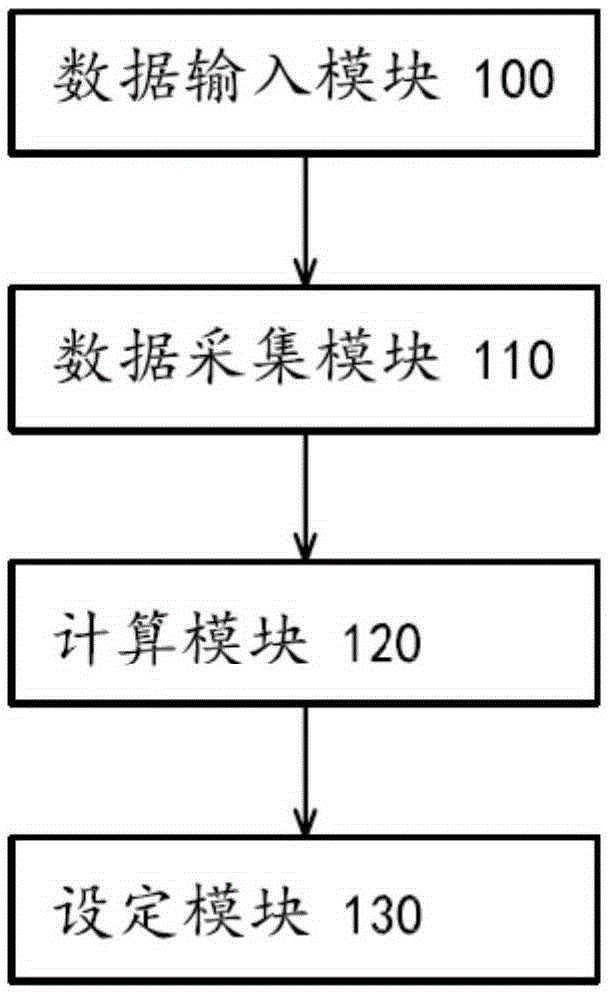

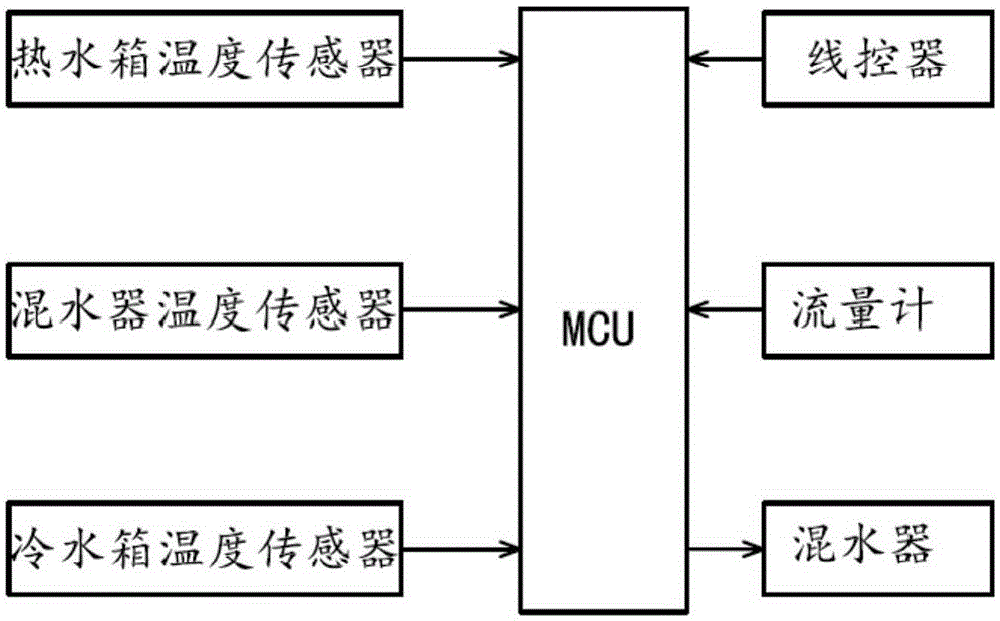

Control method and control system for automatically adjusting heating temperature of water

ActiveCN105352189AMeeting water needsPrecise heating temperatureFluid heatersEngineeringThermal water

The invention relates to a control method for automatically adjusting the heating temperature of water. The control method comprises the following steps that S11, a total water consumption average value V1 and a mixture water temperature average value T1 as well as hot water consumption V2 and a current cold water temperature T2 of a water heater within predetermined using times are collected; S12, a hot water heating temperature T is figured out according to the total water consumption average value V1, the mixture water temperature average value T1, the hot water consumption V2 and the current cold water temperature T2; and S13, the hot water heating temperature T is set as the current heating temperature of the water heater. According to the control method for automatically adjusting the heating temperature of the water, the hot water heating temperature T is figured out according to the total water consumption average value V1, the mixture water temperature average value T1, the hot water consumption V2 and the current cold water temperature T2; the habitual water consumption and set temperature of a user are fully reflected, so that the water consuming demand of the user is met, and the waste of hot water is avoided.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

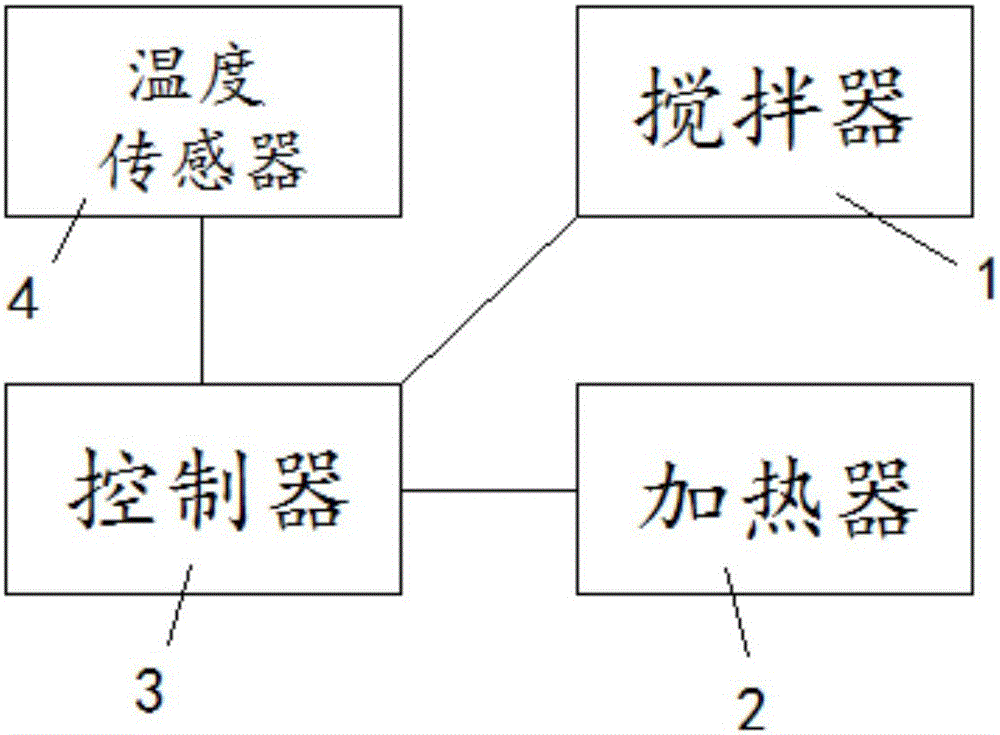

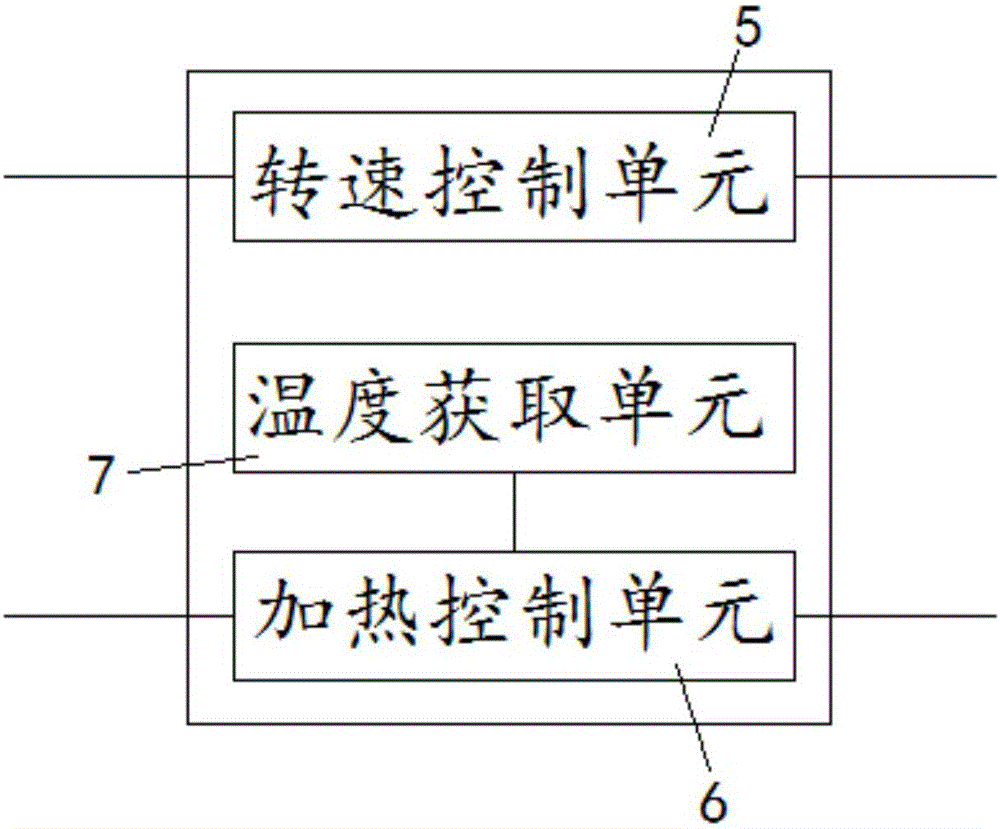

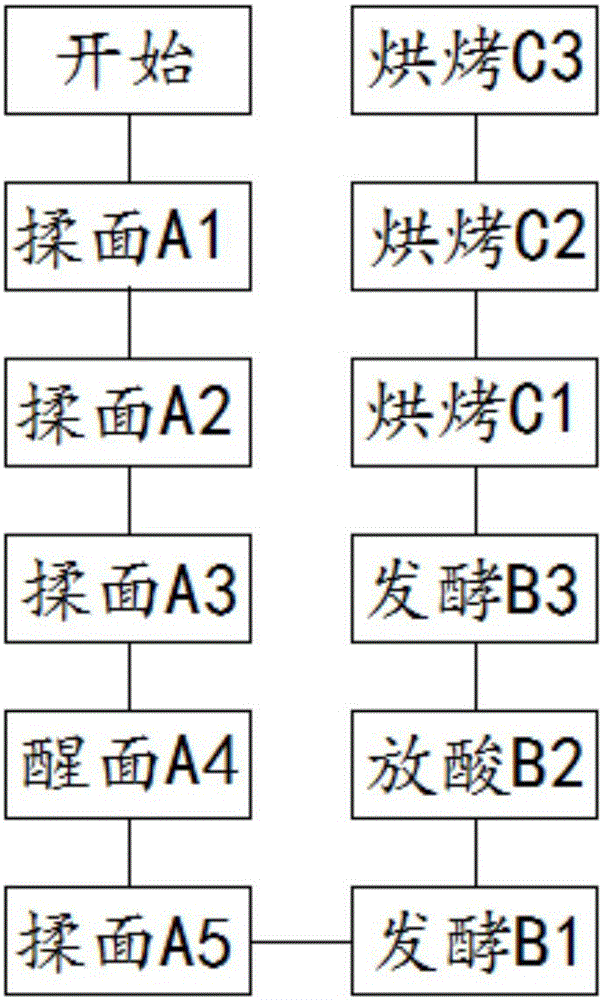

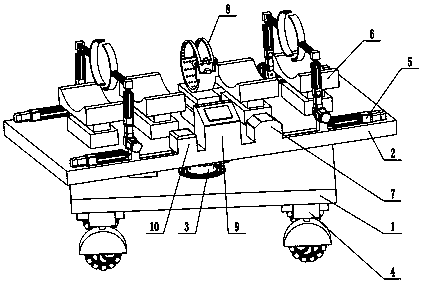

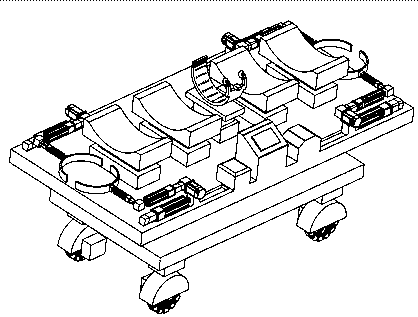

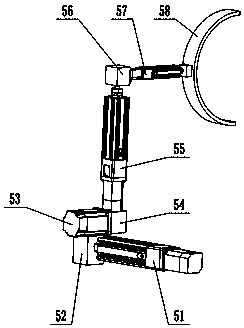

Bread maker control system, device and method

InactiveCN106308566AImprove production efficiencyImprove qualityBread-toastersCooking & bakingControl system

The invention relates to a bread maker controller system, device and method. By means of variable-speed control over stirring rotation speed and duration and precise control over heating temperature and duration in different stage of bread making, combined dough kneading is conducted at different rotation speeds and durations, the manual dough kneading process is simulated, quick film output can be achieved, dough quality is high, time for fermentation and baking in later stages is greatly shortened, and bread making time is greatly shortened. After bread is cut, the bread is uniform in bread pore density, and the bread sends out strong wheat aroma, can be tore into slices and is better in taste.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

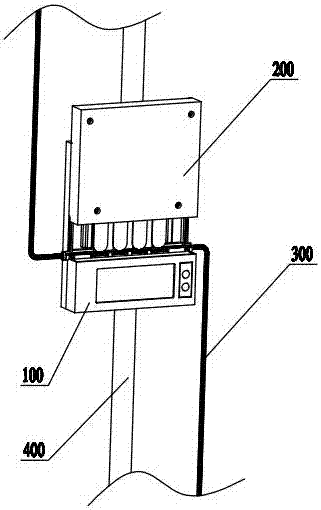

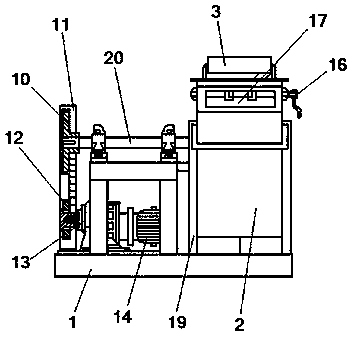

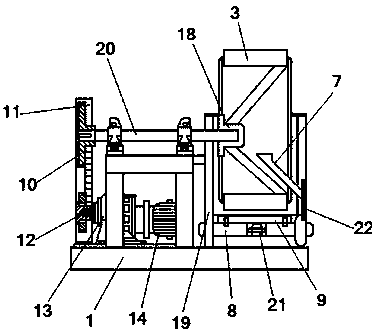

Automatic hot melting welding machine and welding method

ActiveCN110315763AHigh degree of visualizationEasy to operatePipe connection arrangementsComputer moduleEngineering

The invention provides an automatic hot melting welding machine. The automatic hot melting welding machine comprises an upper bottom plate, a clamping unit, a supporting unit and a fixing devic, wherein the clamping unit is arranged on the upper bottom plate, the supporting unit is arranged on the upper bottom plate, the fixing device is arranged on the upper bottom plate and is positioned in themiddle of the supporting unit, a hot melting welding machine body and a console are arranged on the upper bottom plate, a controller is arranged in the console, a hot melting sleeve is attached to a pipeline to be welded through the fixing device, the hot melting welding machine is controlled to heat the hot melting sleeve through the console, the controller comprises an SSR, an SCR, a PLC and anAD acquisition module, and voltage and current signals are correspondingly collected, converted, displayed and heated and controlled through the SSR, the SCR, the PLC and the AD acquisition module. According to the automatic hot melting welding machine, a motor which is internally arranged in an upper arc plate is used for driving a gear C to rotate so as to drive the upper arc plate to slide in asliding groove A of a lower arc plate, and then the hot melting sleeve is driven to carry out complete sleeving on the pipeline to be welded.

Owner:TIANJIN JINENG PIPE

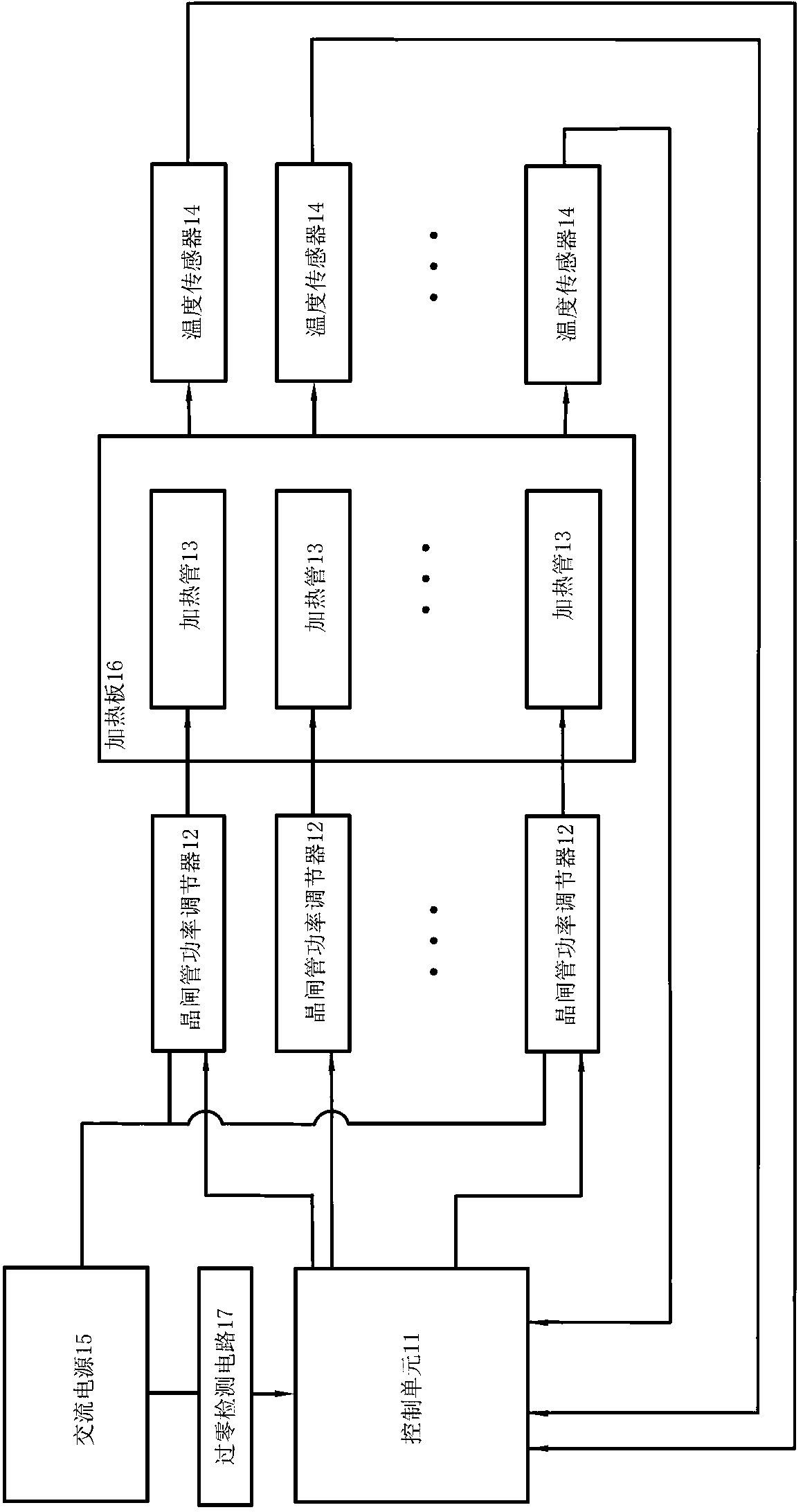

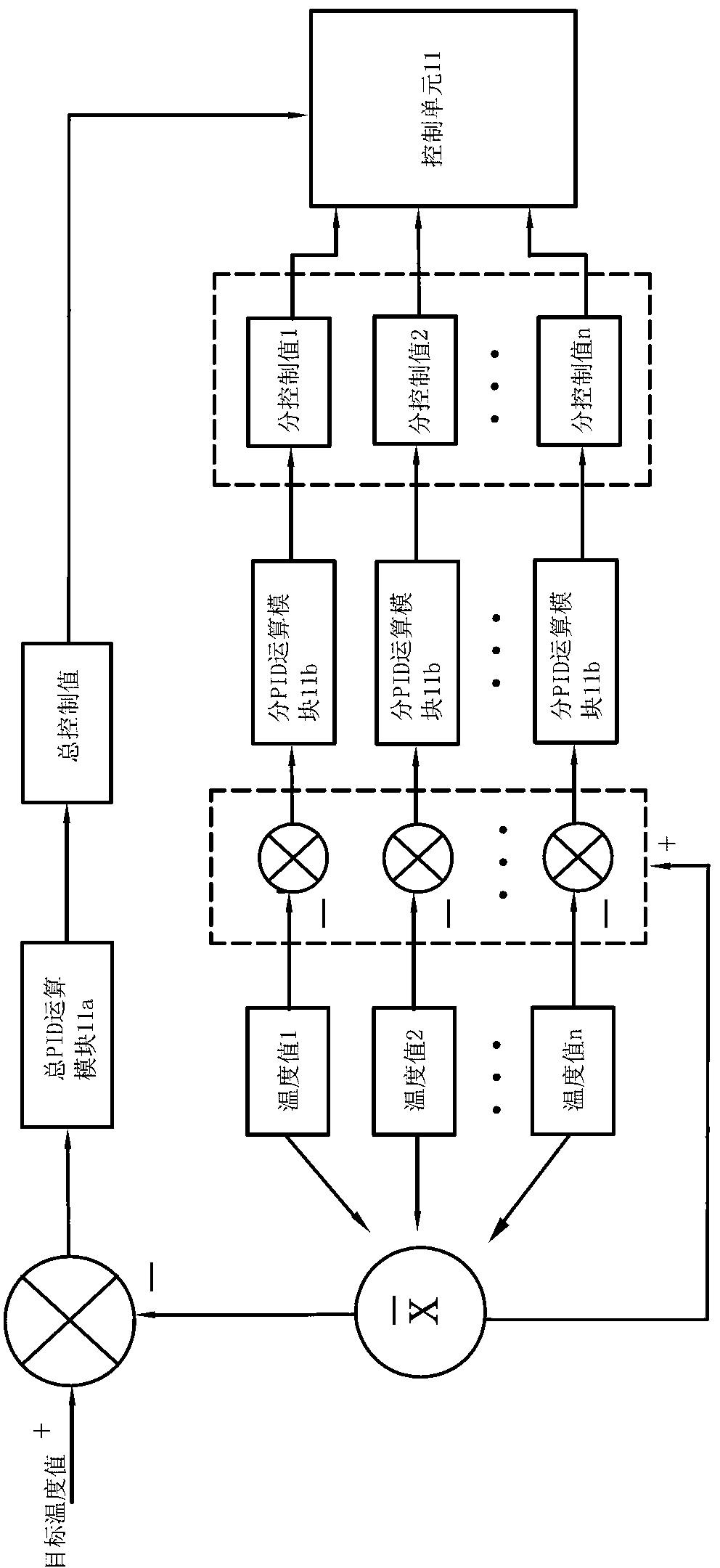

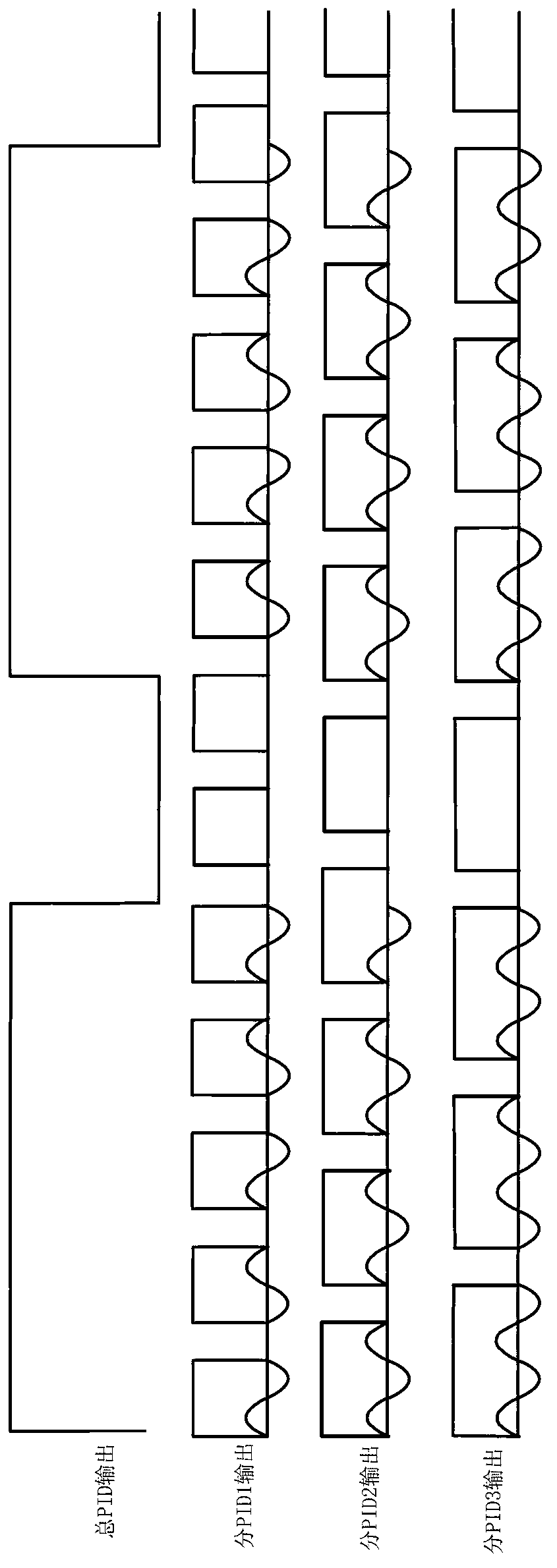

Multi-way PID (proportion integration differentiation) temperature control device and control method thereof

The invention provides a multi-way PID temperature control device and a control method thereof, and belongs to the technical field of automatic control. The multi-way PID temperature control device solves the problem that the dynamic temperature of all positions of a heating plate can not be balanced in the prior art. The multi-way PID temperature control device comprises a control unit, an alternating current power supply, a plurality of temperature sensors, a plurality of thyristor power regulators and a plurality of heating tubes, wherein each heating tube corresponds to one temperature sensor and one thyristor power regulator; each temperature sensor is connected with the input terminal of the control unit; each thyristor power regulator is connected with the output terminal of the control unit; the alternating current power supply and the heating tubes are respectively connected with the thyristor power regulators. The control device and the control method ensure that the dynamic temperature balance of a mold temperature controller heating plate keeps identical, the dynamic accuracy is high, and a die is uniformly heated.

Owner:ZHEJIANG SAIHAO IND CO LTD

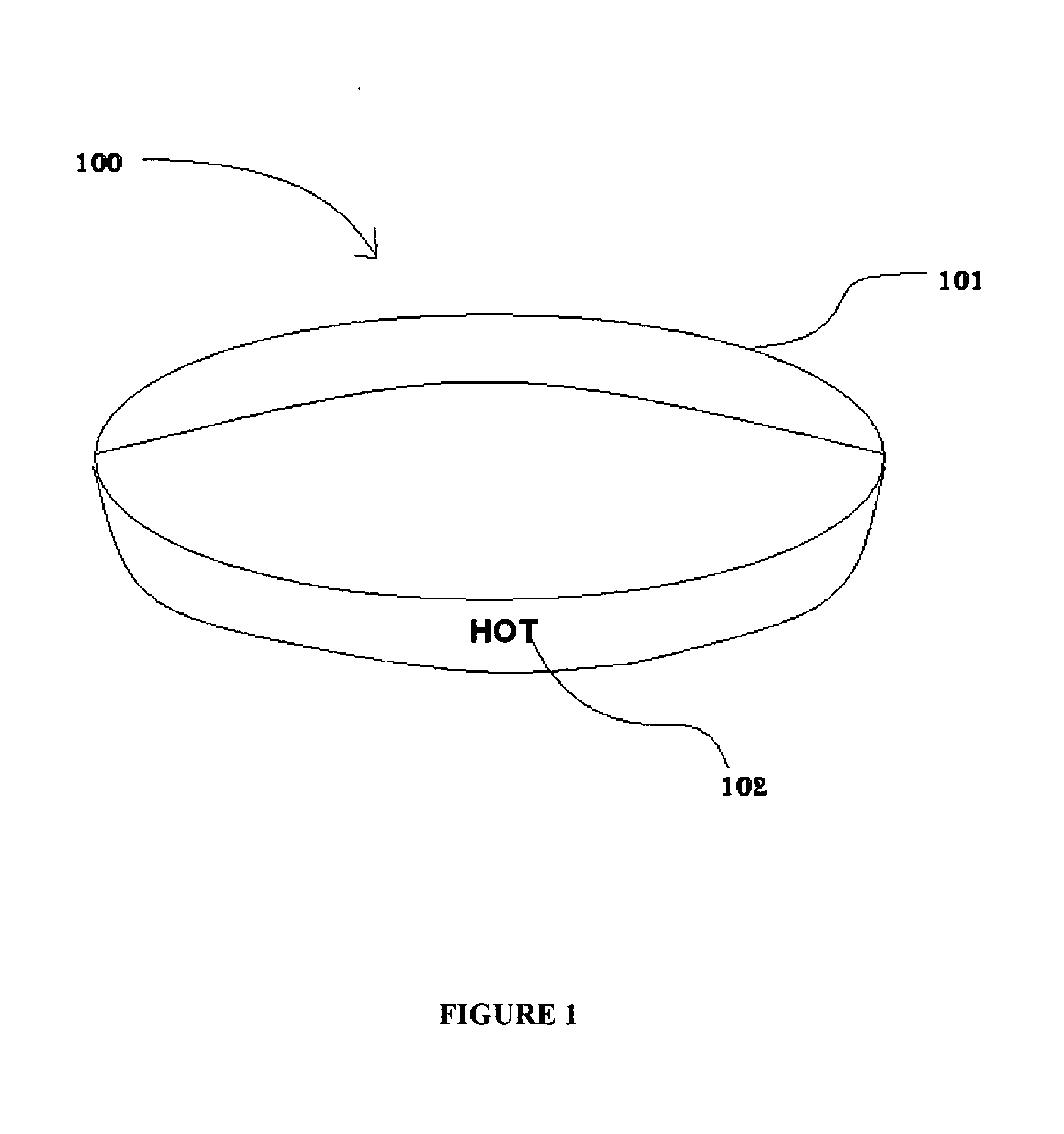

Method and device for preparation of a container containing a heated liquid of proper temperature

InactiveUS20090084692A1Precise heating temperatureEffective and convenient and safeThermometer detailsTemperature measurement in household appliancesChange colorEngineering

The present invention relates generally to the field of methods, devices, and kits for preparation of a baby bottle, cup, mug, or the like containing a heated liquid having a proper temperature for infants, and particularly to methods and devices including a thermochromatic ink that changes color above the comfort zone of the infant. The present invention is particularly adaptable as an addition to any baby bottle of evaluation of the temperature of the heated liquid inside the baby bottle before feeding the infant.

Owner:FERNANDEZ MELISSA J

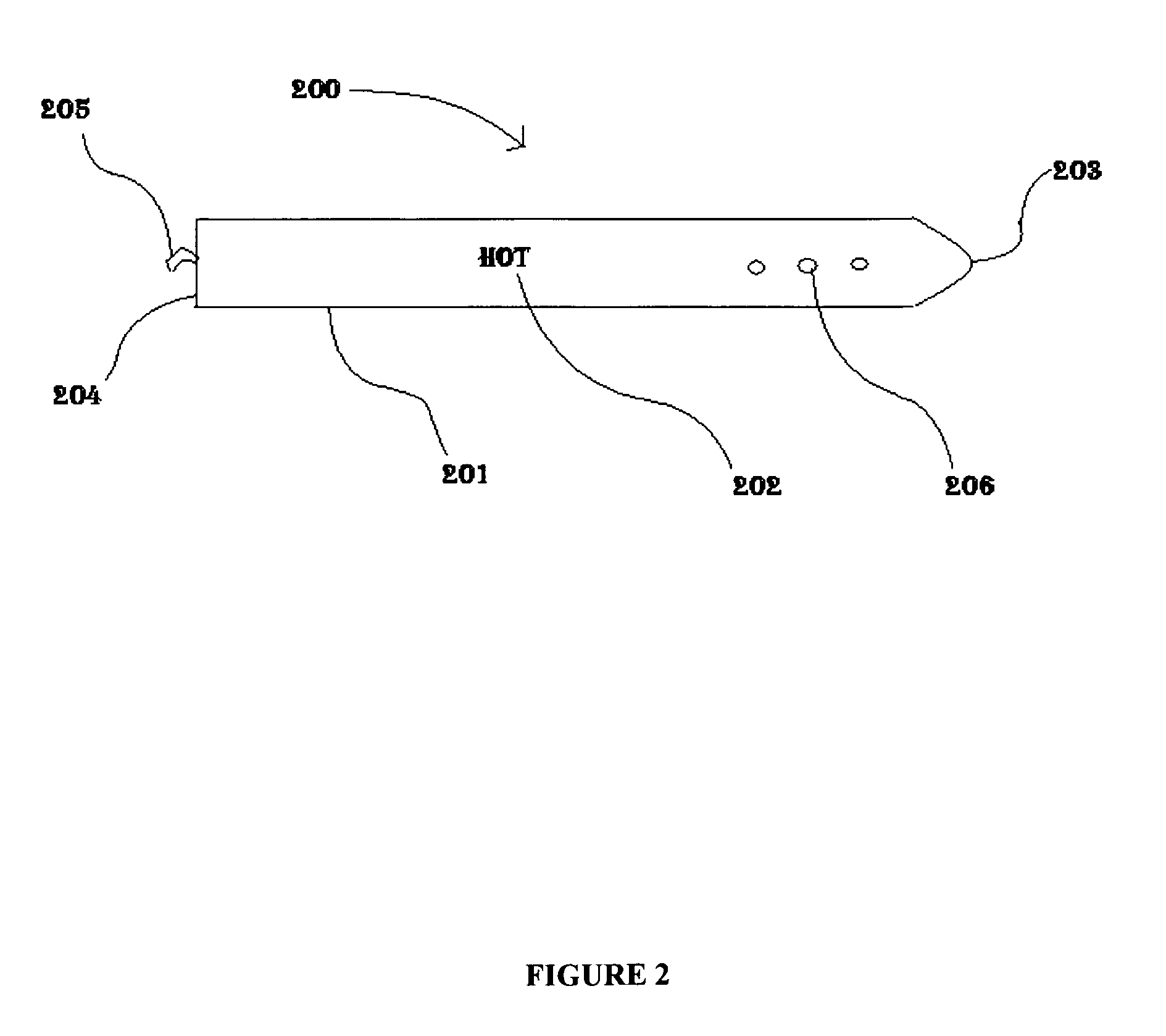

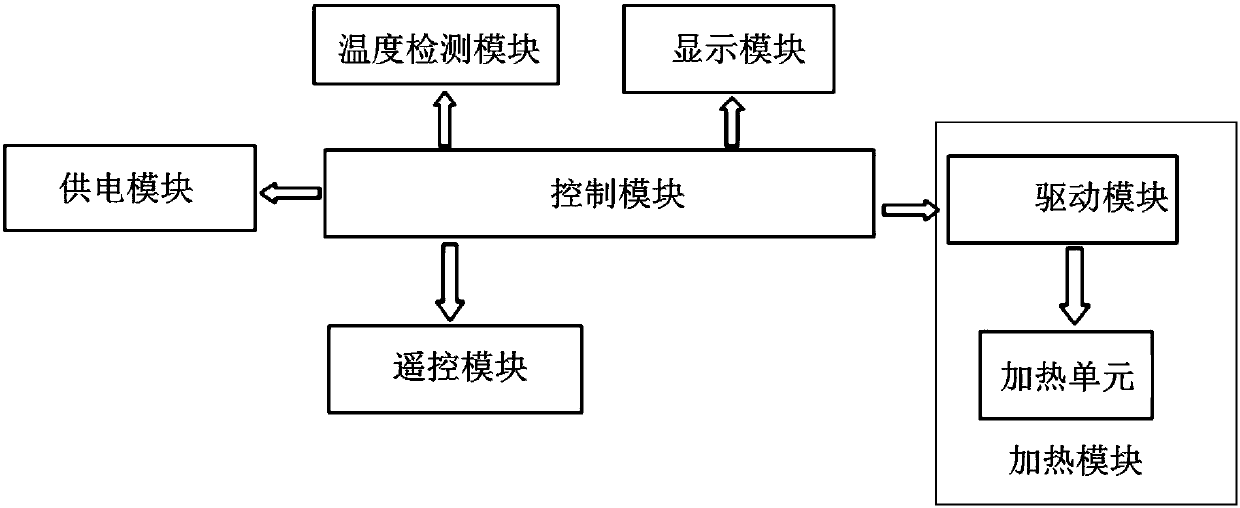

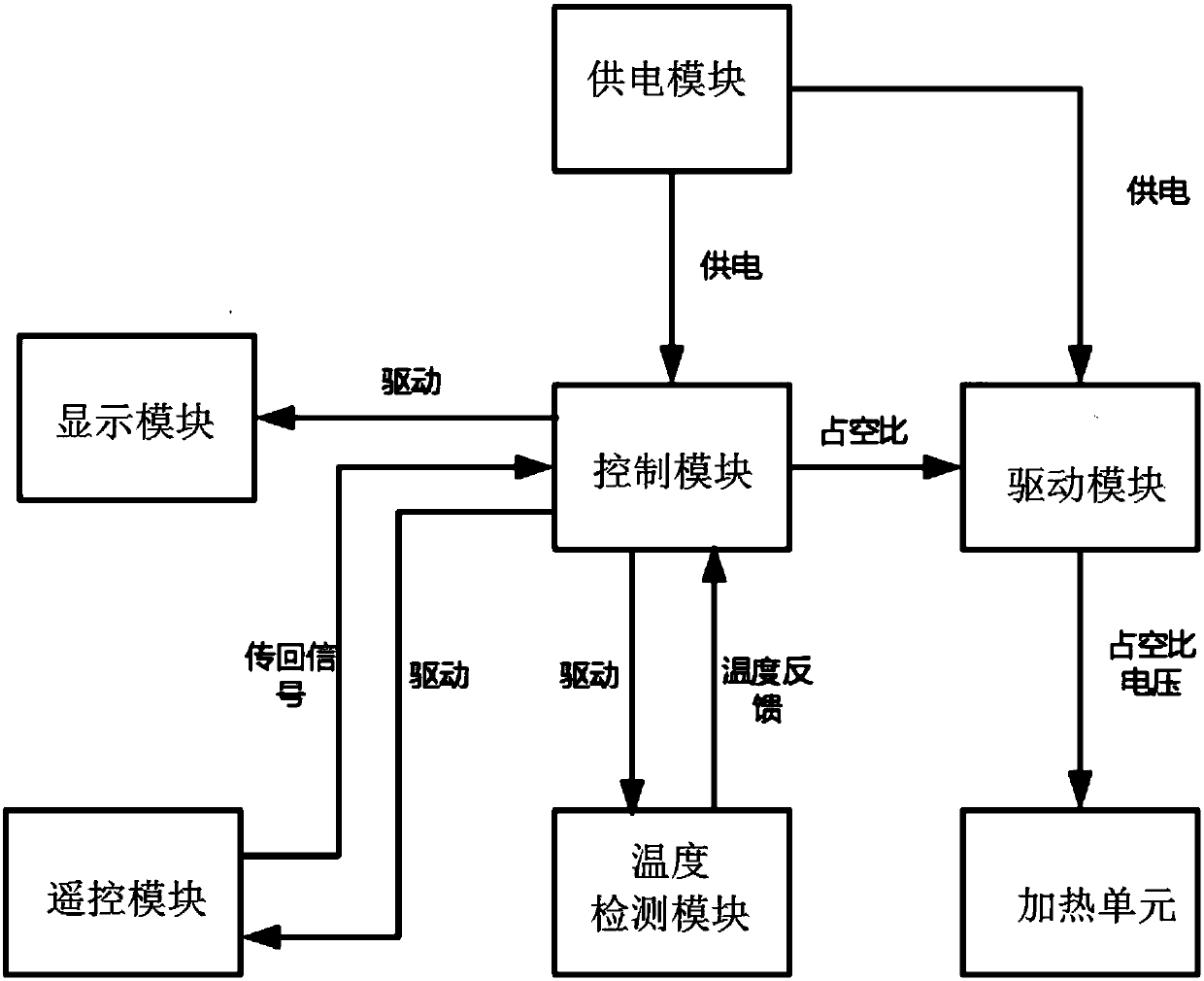

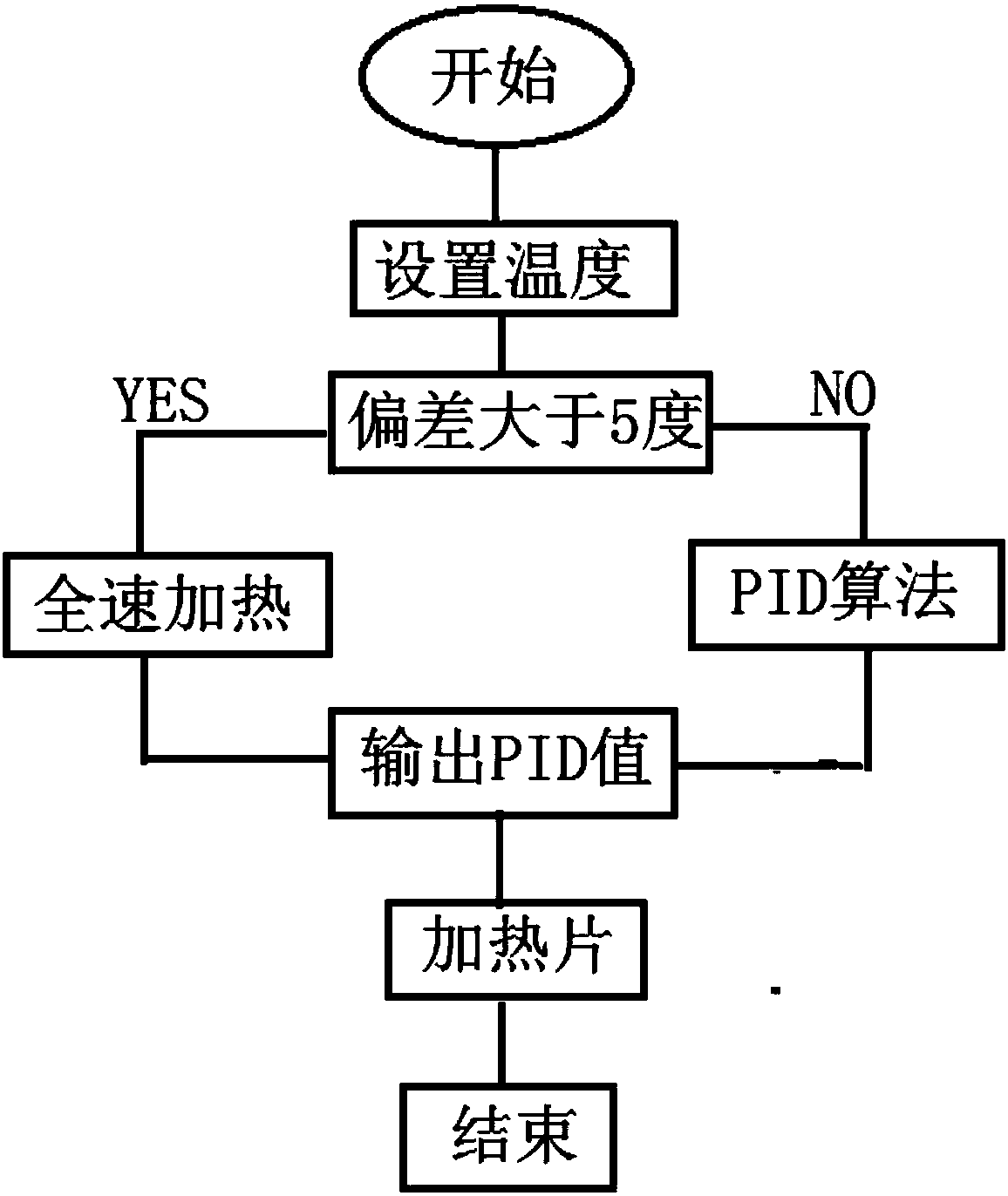

Broiling physical therapy appliance

PendingCN107550720APrecise heating temperatureAccurate temperature readingsDevices for heating/cooling reflex pointsHuman bodyEngineering

The invention relates to a broiling physical therapy appliance which aims at solving the technical problem that temperature is difficult to control as drilled wood becomes red and cannot be heated uniformly. The appliance comprises a shell in which a control module is arranged, and a heating module, a display module, a driver module, a temperature detection module and a power supply module which are connected with the control module; the control module is used for presetting temperature and controlling the heating module according to preset temperature; a heat conduction mechanism for contacting with a human body is arranged at the heating module; the power supply module is further connected with the heating module, and used for supplying power for the broiling physical therapy appliance;the driver module is used for controlling the voltage of a heating piece; the temperature detection module is used for detecting the real-time temperature of the heating module and feeds the temperature back to the control module; and the technical scheme that the display module is used for displaying the preset temperature and real-time temperature solves the problem relatively well, and the broiling physical therapy appliance can be applied to the broiling physical therapy in traditional Chinese medicine.

Owner:GUILIN UNIV OF ELECTRONIC TECH

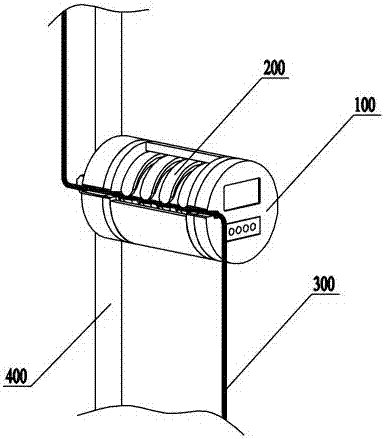

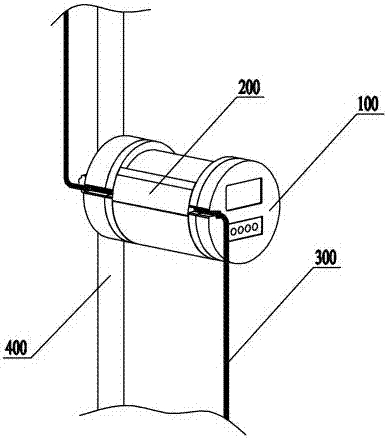

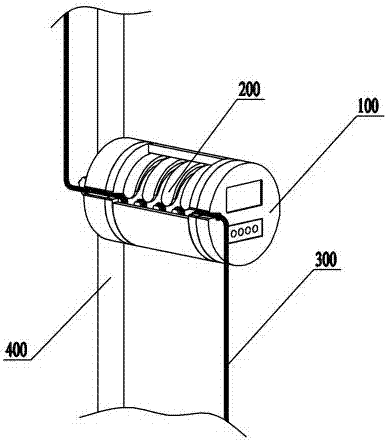

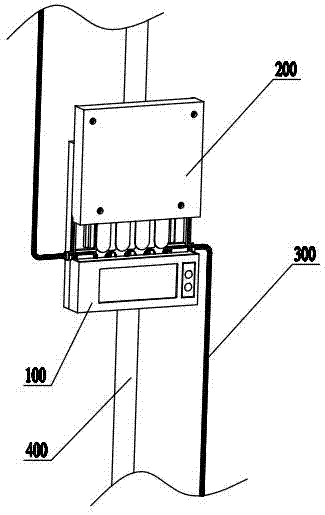

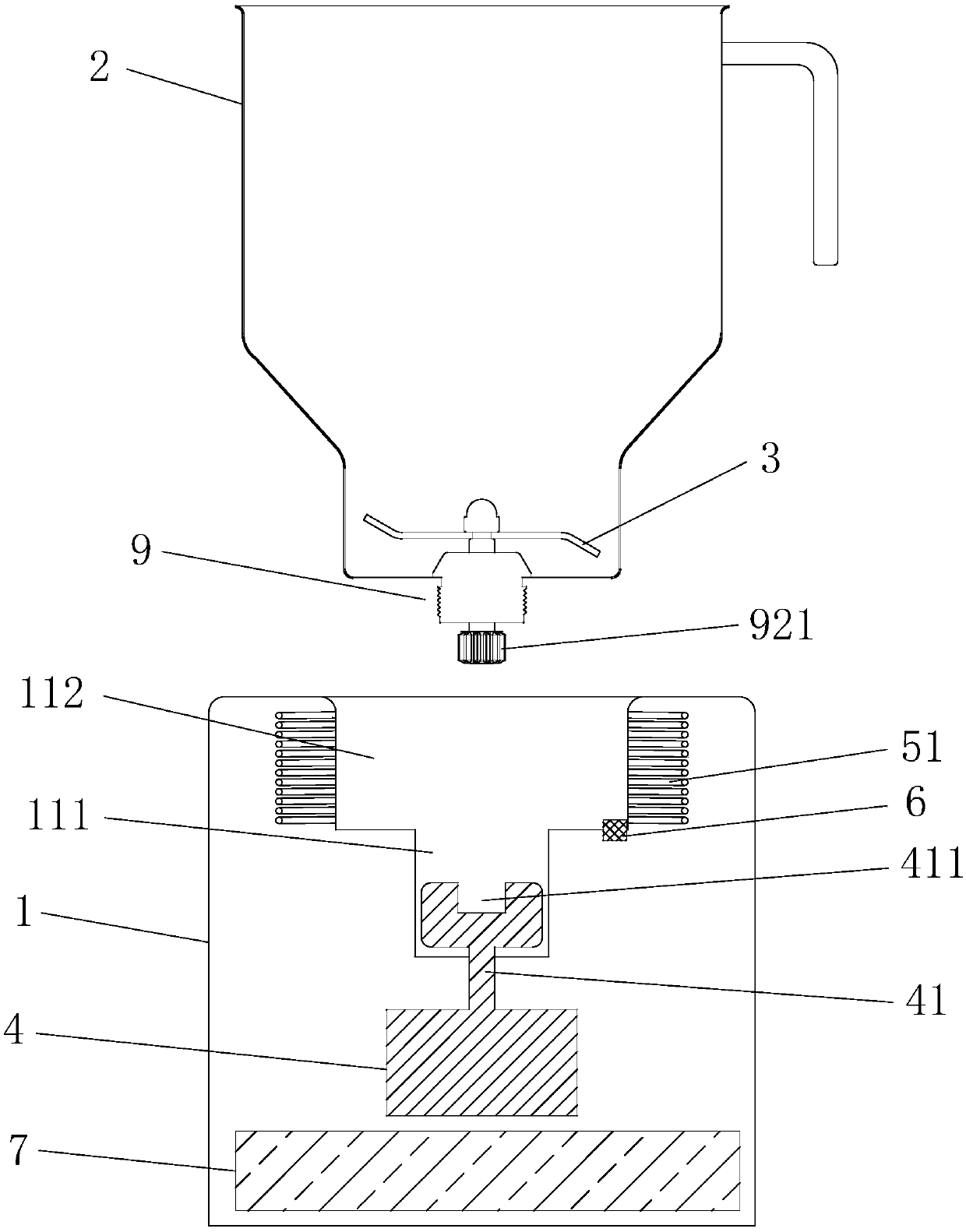

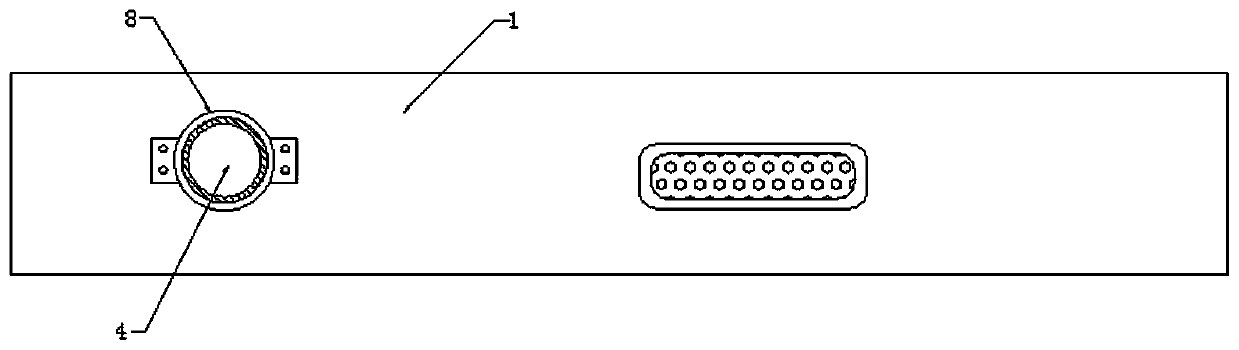

Infusion heating device

ActiveCN106890385AEasy to fold and bendFully heatedInfusion devicesMedical devicesEngineeringHeating element

The invention provides an infusion heating device. The infusion heating device comprises a fixed part and a rotary part, wherein the rotary part rotates relative to the fixed part; the fixed part comprises a transmission device, a fixed base and a fixed cover; the rotary part comprises a rotary heating part; the fixed base comprises a fixed base end cover and a fixed base toothed part; the fixed base end cover is connected or integrated with the fixed base toothed part; the transmission device is mounted on one side of the fixed base end cover; the fixed cover is mounted at one end, away from the fixed base end cover, of the fixed base toothed part; the rotary heating part is mounted between the fixed base end cover and the fixed cover; the transmission device drives the rotary heating part to rotate; at least one heating element is arranged in the heating part; the fixed base toothed part and the rotary heating part form an accommodating cavity for accommodating an infusion tube. The infusion heating device has the advantages that the infusion tube can be folded and bent conveniently, heating sources are arranged around the infusion tube during heating, and sufficient and even heating is achieved.

Owner:东营昱辰技术有限公司

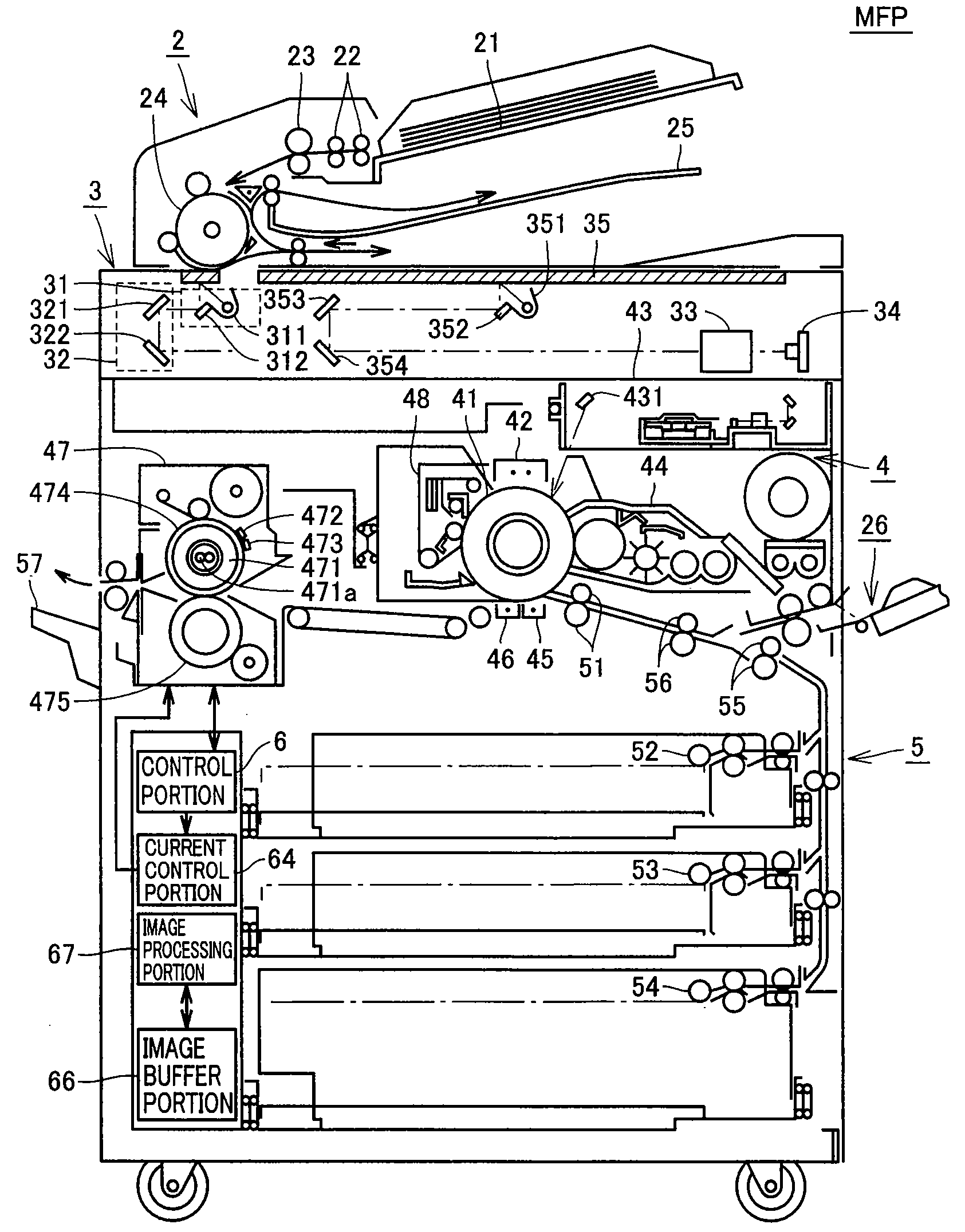

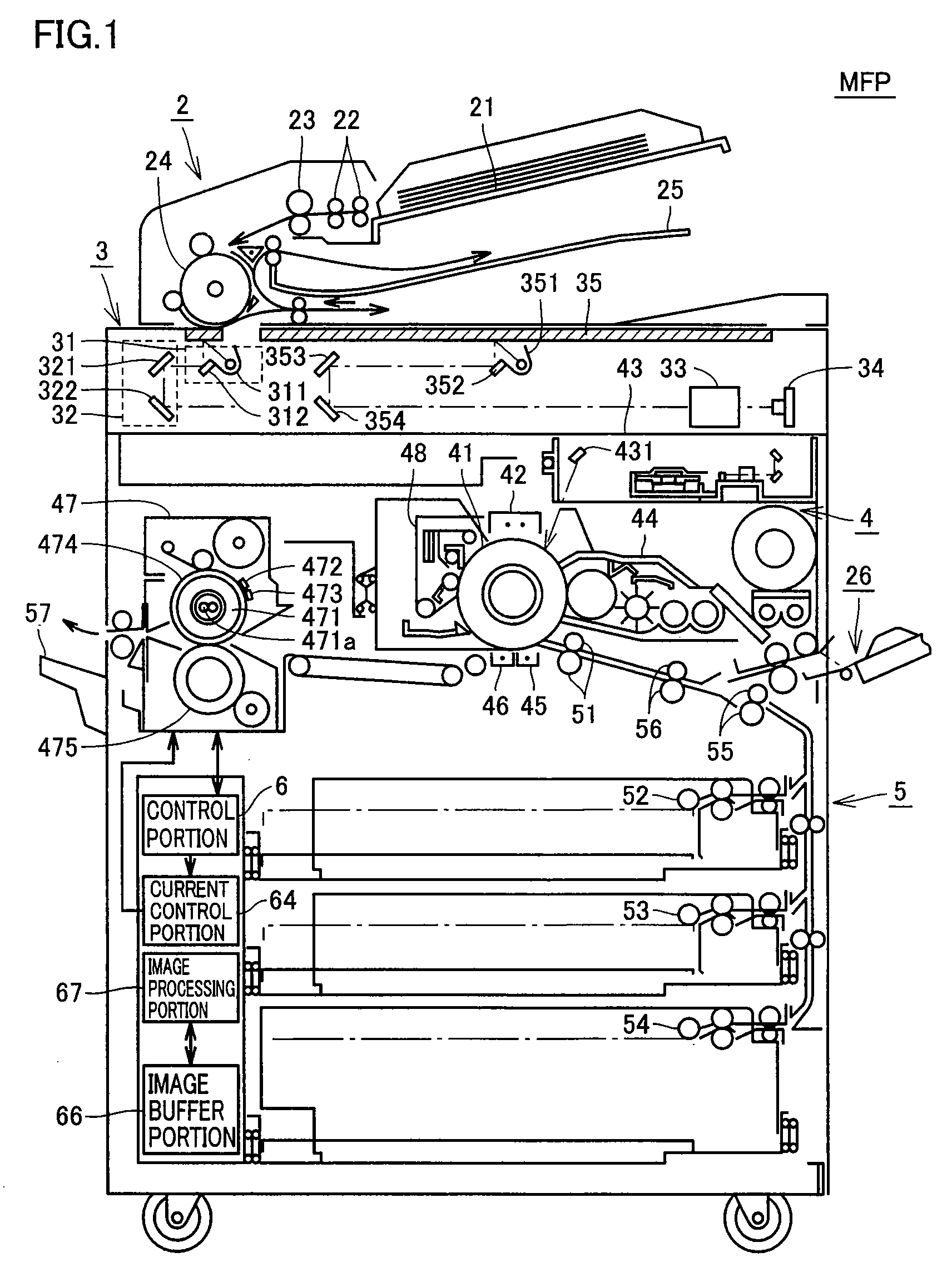

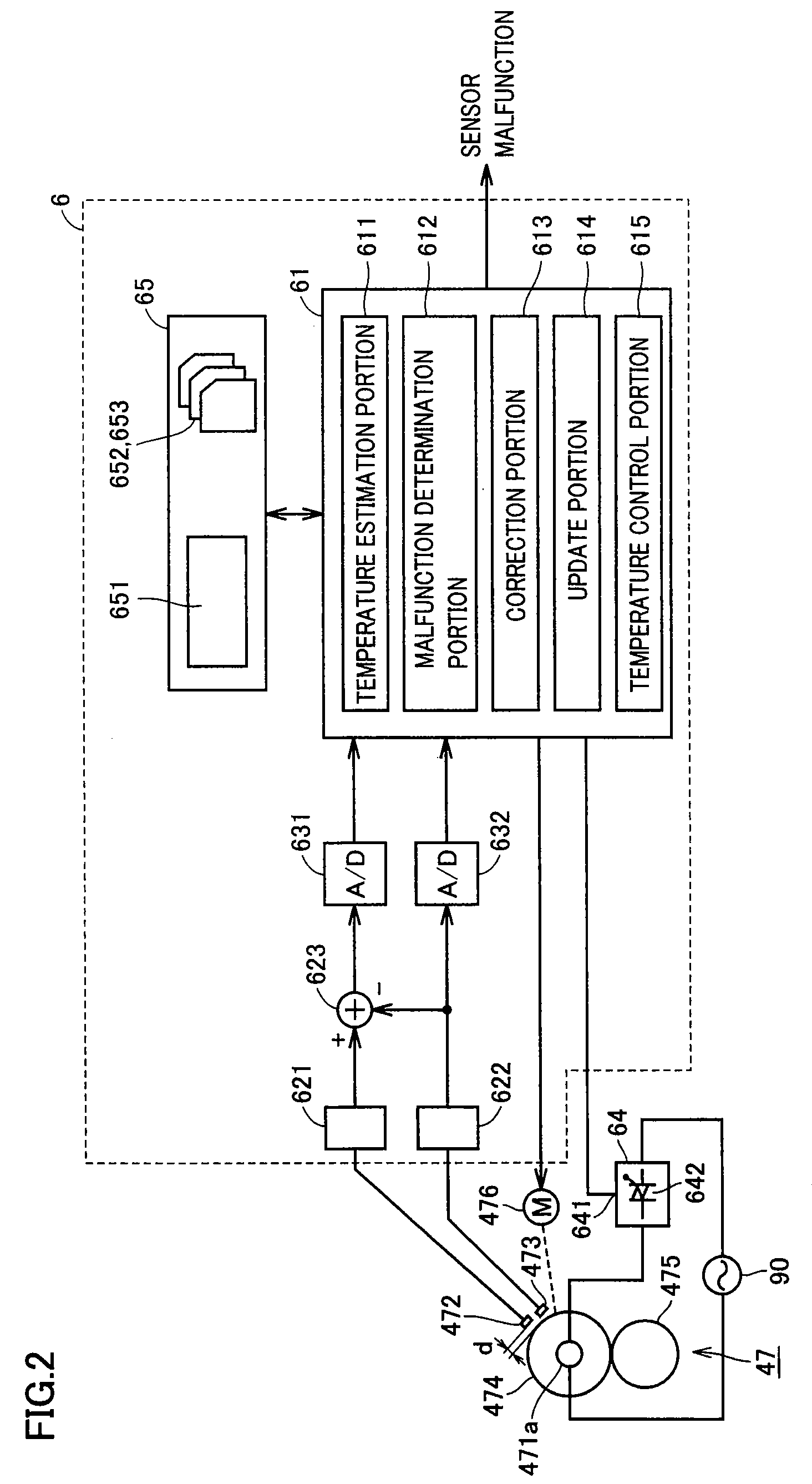

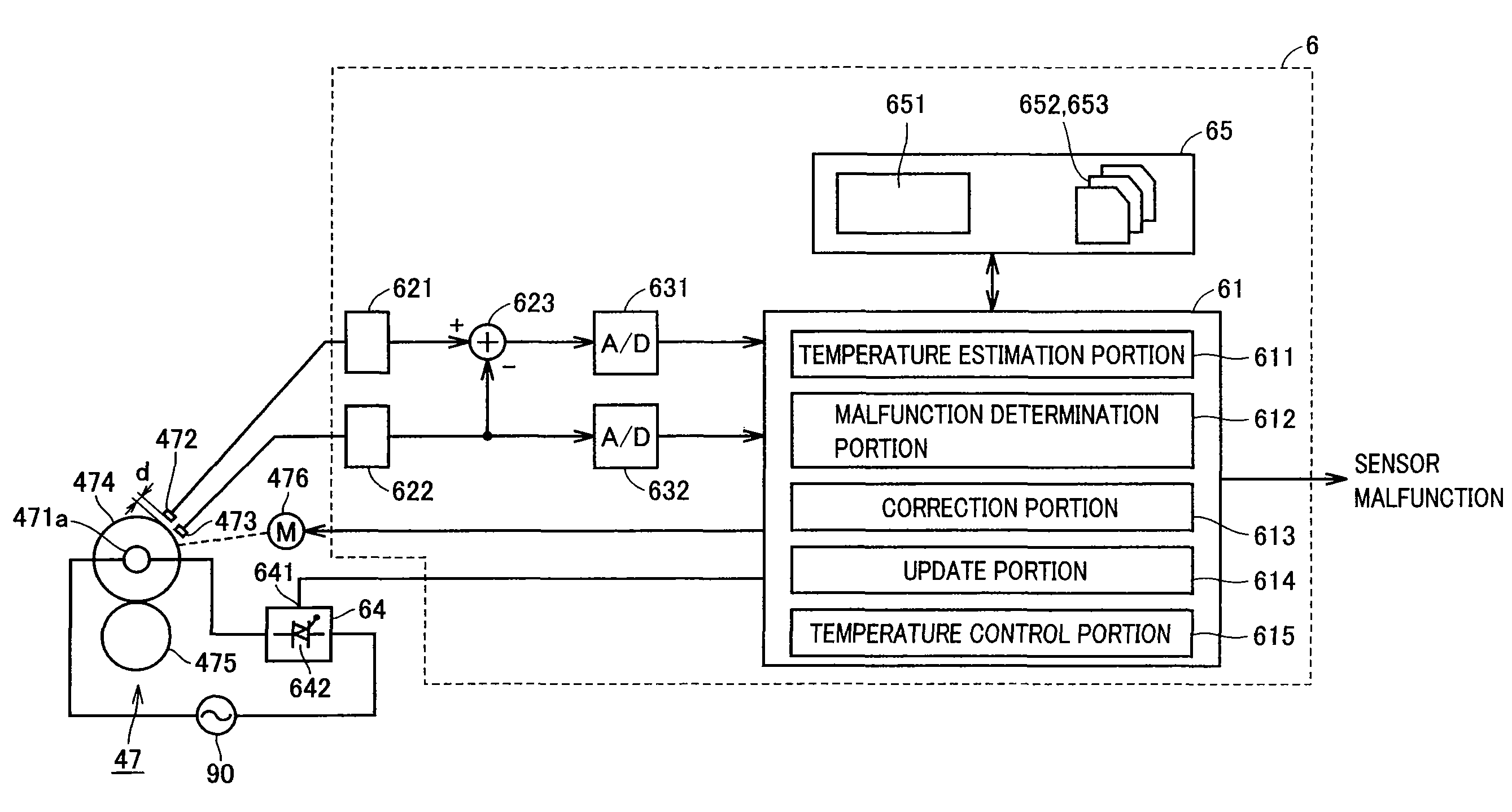

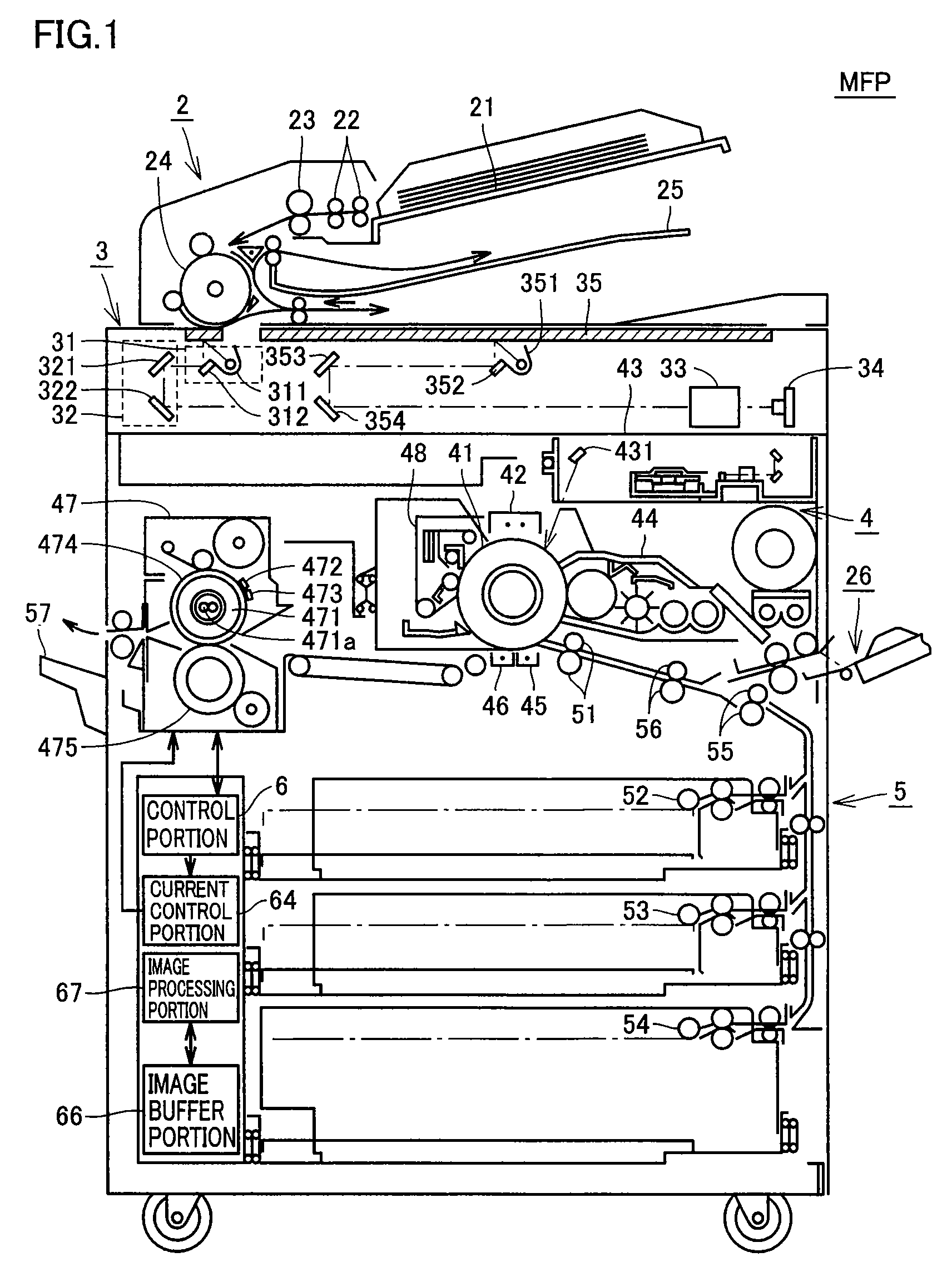

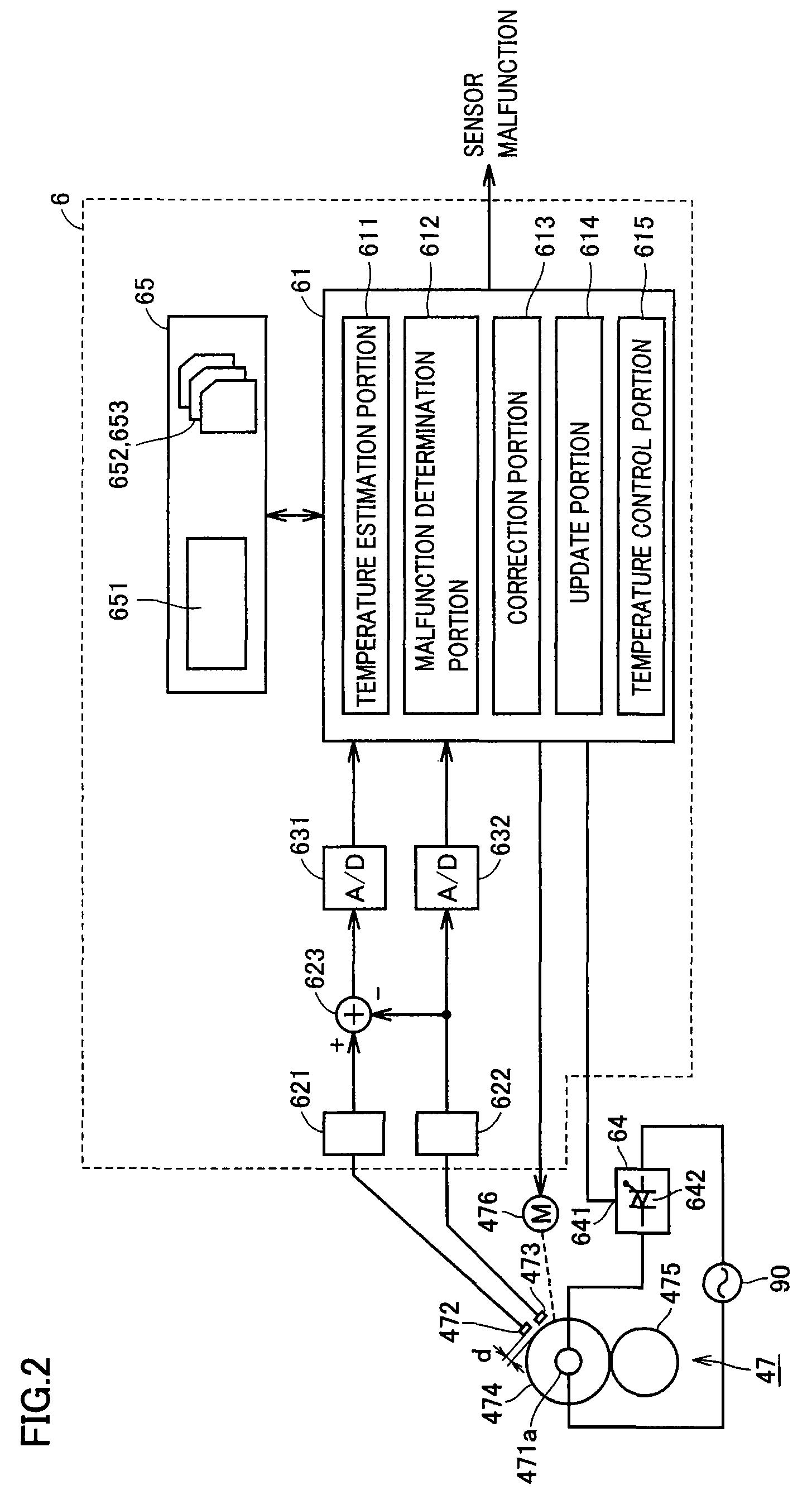

Image formation apparatus including hot-roll type fixing device and method for determining malfunction of temperature sensor in the same

ActiveUS20090080928A1Accurately determinePrecise heating temperatureElectrographic process apparatusImage formationEngineering

Owner:KONICA MINOLTA BUSINESS TECH INC

Image formation apparatus including hot-roll type fixing device and method for determining malfunction of temperature sensor in the same

ActiveUS8218983B2Accurately determinePrecise heating temperatureElectrographic process apparatusImage formationEngineering

Owner:KONICA MINOLTA BUSINESS TECH INC

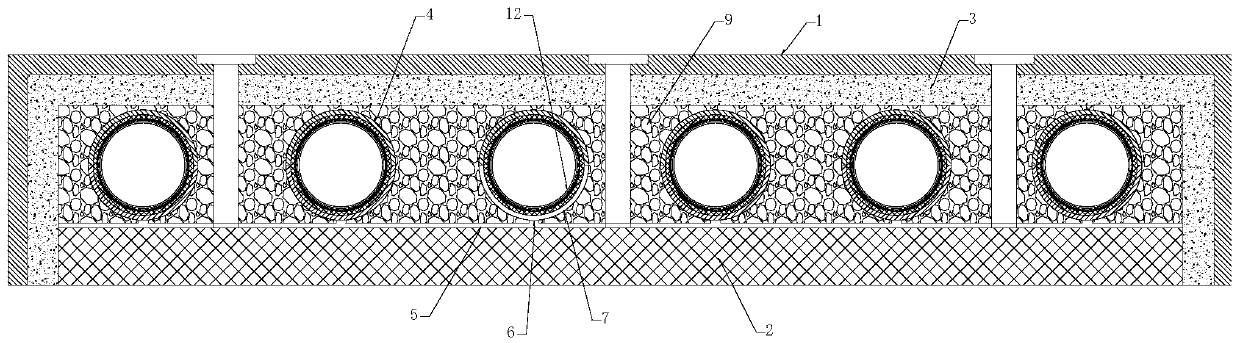

Heating device used for transfusion

ActiveCN106964032AEasy to fold and bendFully heatedMedical devicesIntravenous devicesEngineeringHeating element

The invention provides a heating device used for transfusion. The heating device used for transfusion includes a fixed part and a sliding part; the sliding part does translational movement relative to the fixed part, the fixed part includes a rear cover, a motor, a fixed base and a first gear; the rear cover is fixedly connected with the fixed base, the motor is fixedly installed on the rear cover or the fixed base, and the first gear is connected with the motor; the sliding part includes a movable base, the movable base is in sliding connection with the fixed base, and a first rack is arranged on the movable base and meshed with the first gear; the fixed base includes a fixed base heating part, the movable base includes a movable base heating part, heating elements are arranged in the fixed base heating part and the movable base heating part, and after the fixed base heating part and the movable base heating part are closed, a containing cavity for containing a transfusion pipe is formed. By means of the heating device used for the transfusion, heating is more sufficiently and uniformly conducted.

Owner:西安合创易联电子科技有限公司

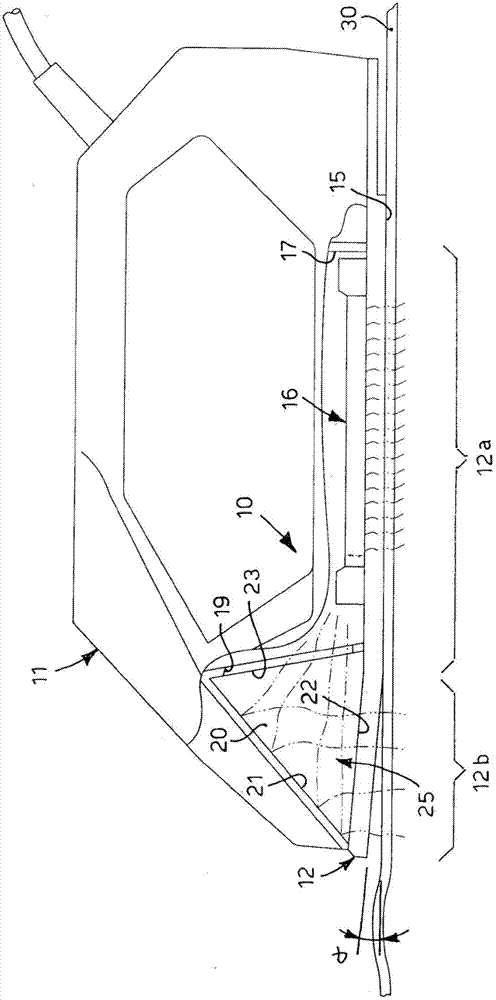

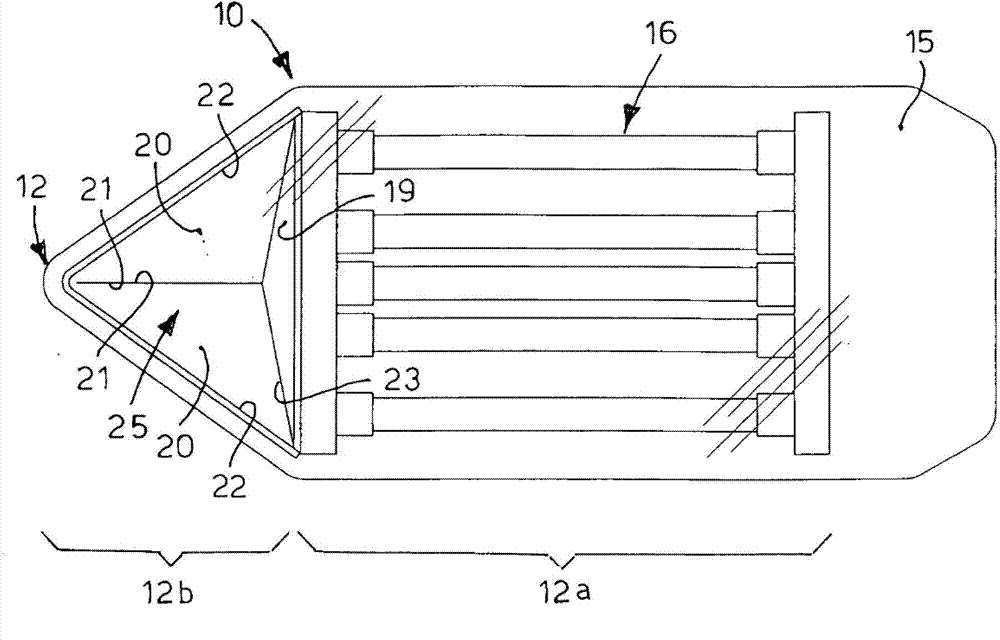

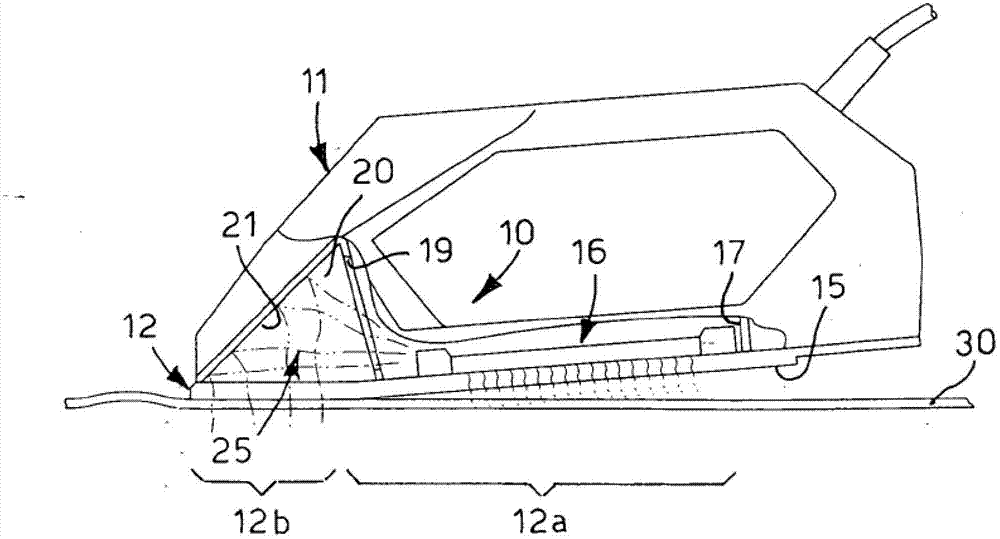

Heating device in an iron and relative iron

ActiveCN103119213AUniform coverageEffective ironingHand ironTextiles and paperEngineeringOptical communication

Heating device for an iron (11) provided with an ironing plate (12), comprising at least a plurality of irradiation lamps (16), which are disposed in cooperation with a first portion (12a) of the ironing plate (12), in order to irradiate a luminous radiation toward a fabric (30) in correspondence with the first portion (12a) of the ironing plate (12). The heating device comprises localized heating means (20) of the reflection type disposed in optical communication with the irradiation lamps (16) through a radiation window (19), and oriented so as to direct at least part of the radiations emitted by the irradiation lamps (16) toward a second portion (12b) of the ironing plate (12), different from the first portion (12a).

Owner:DELONGHI APPLIANCES S R L CON UNICO SOCIO

Washing machine

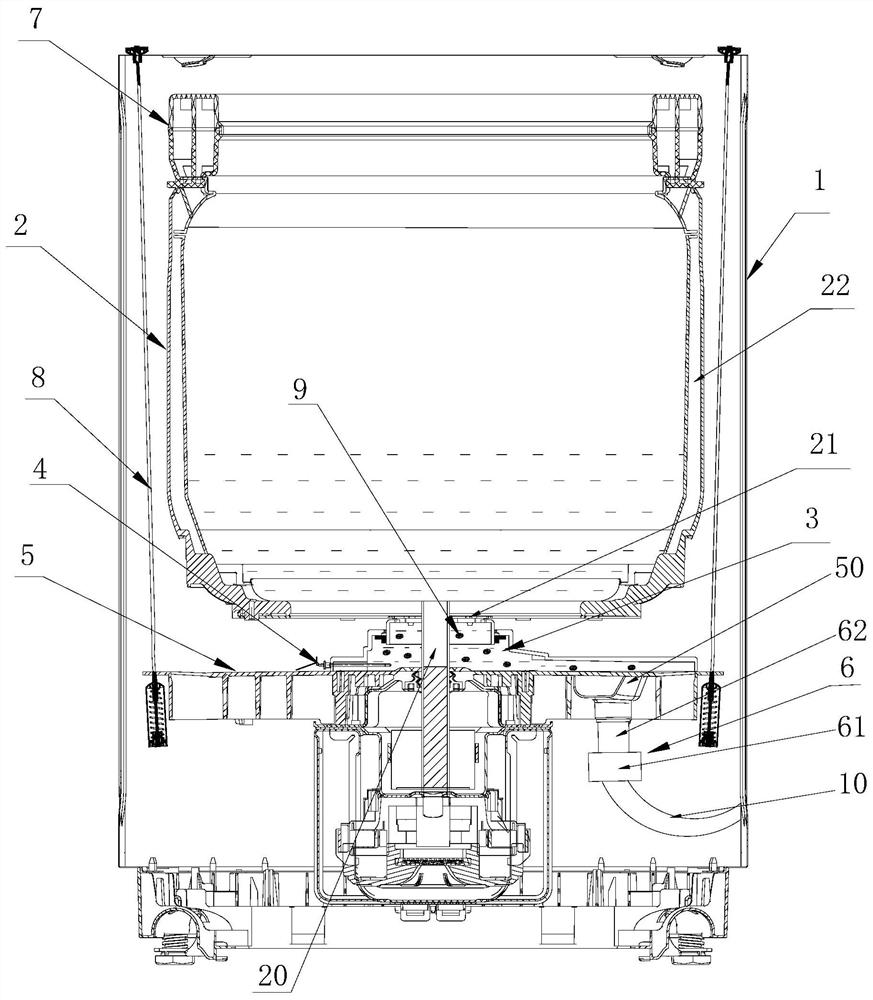

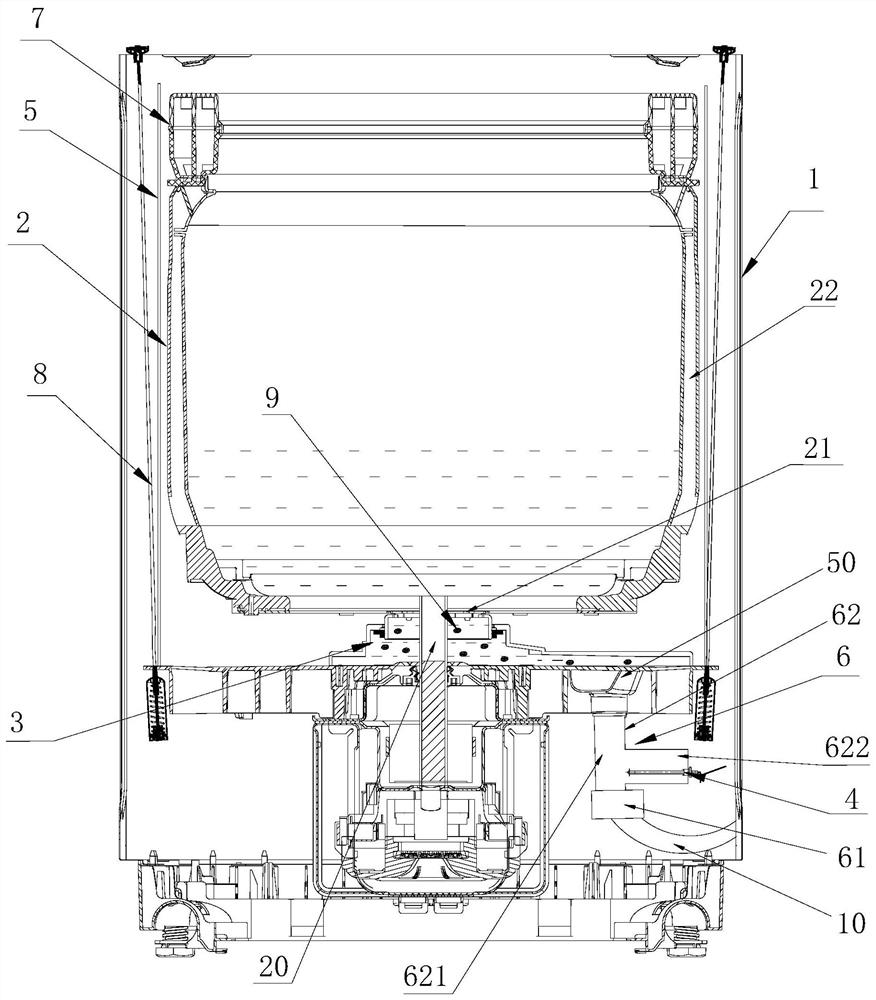

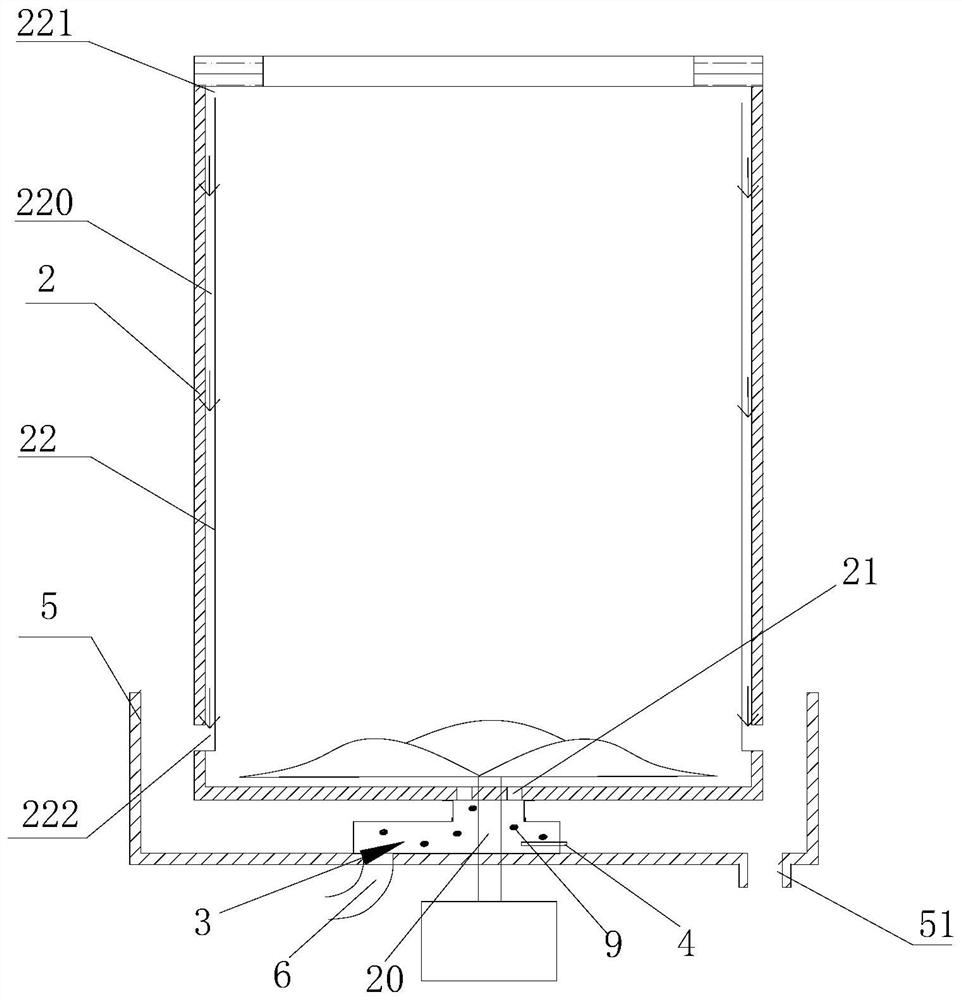

PendingCN111719285ARealize self-cleaningSimple structureOther washing machinesTextiles and paperLaundry washing machineWater flow

The invention discloses a washing machine. The washing machine comprises an outer shell, a wash bucket rotatably arranged in the outer shell, and a drainage chamber arranged below the wash bucket andcommunicating with the interior of the wash bucket, wherein the wash bucket is of a water-containing bucket structure; and the interior of the drainage chamber is provided with cleaning particles usedfor cleaning the inner wall of the chamber. The washing machine further comprises a water catcher for supporting the wash bucket. The water catcher is arranged outside the wash bucket. At least one part of the water catcher is arranged below the wash bucket. The water catcher is further provided with a draining component. The bucket bottom of the wash bucket is provided with a first drain outlet.The first drain outlet communicates with the draining component through the drainage chamber. The cleaning particles can move freely in the drainage chamber along with water flow. During the washingand / or rinsing stages, the water flow drives the cleaning particles to impact and rub the inner wall of the drainage chamber to clean the inner wall. The washing machine provided by the invention is simple in structure and low in cost and has the characteristic of self-cleaning.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

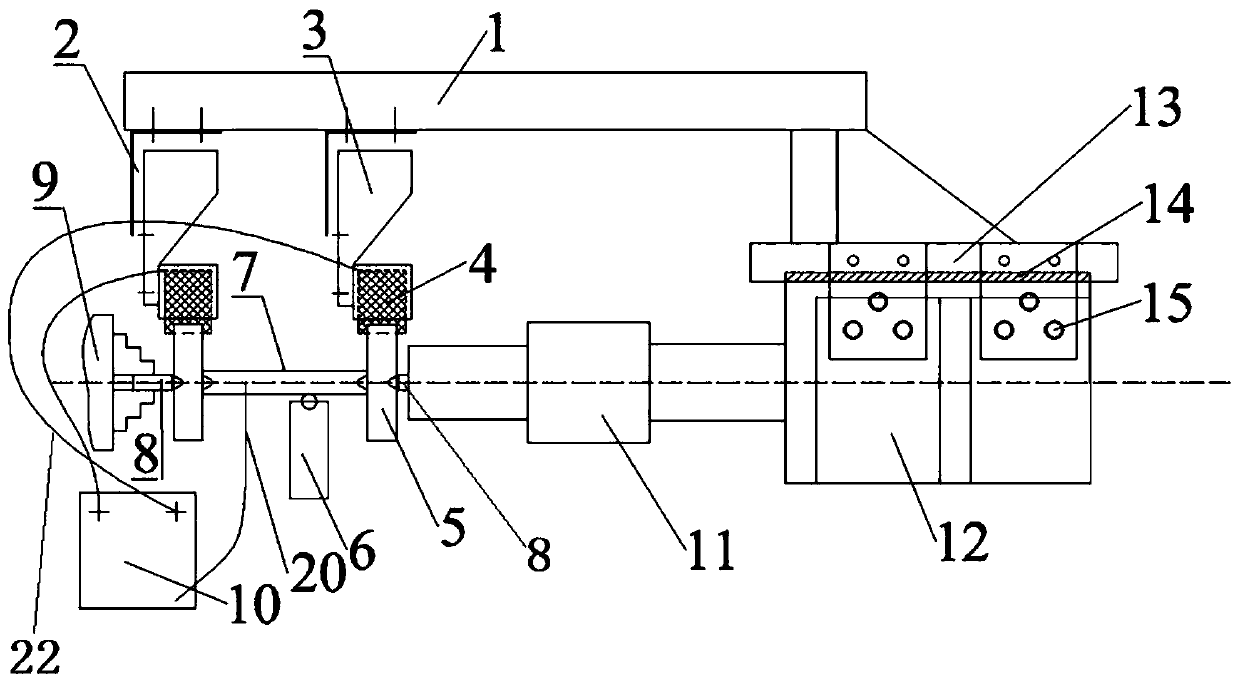

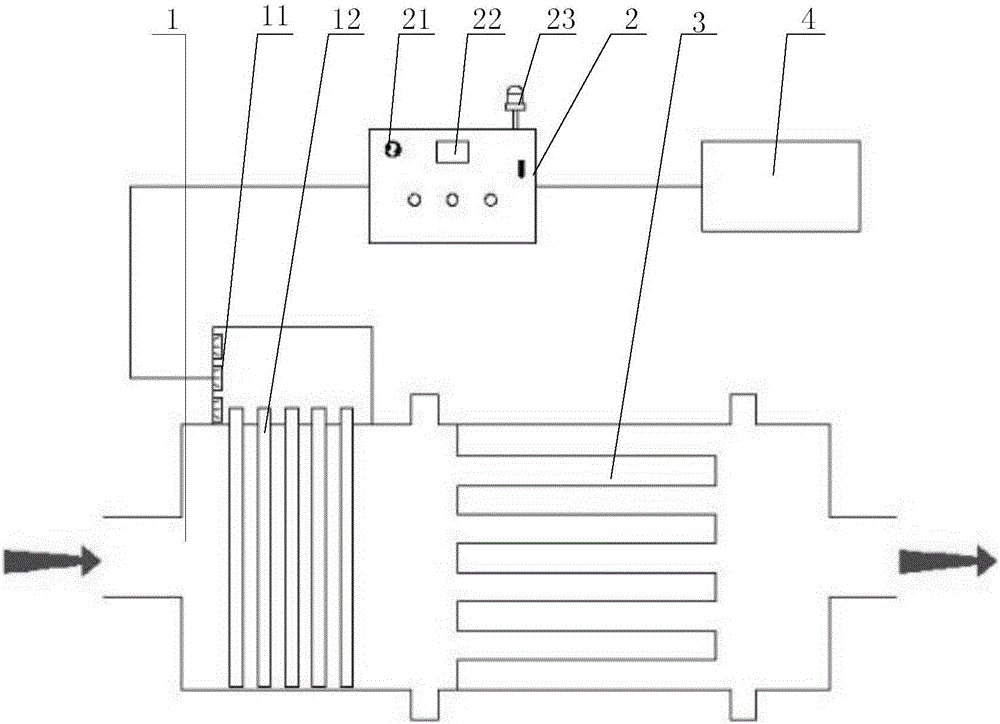

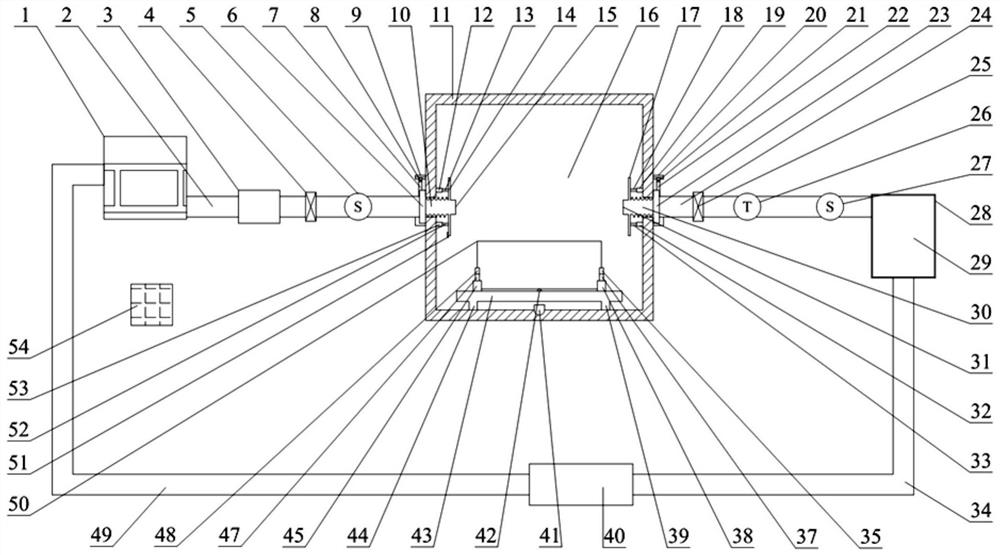

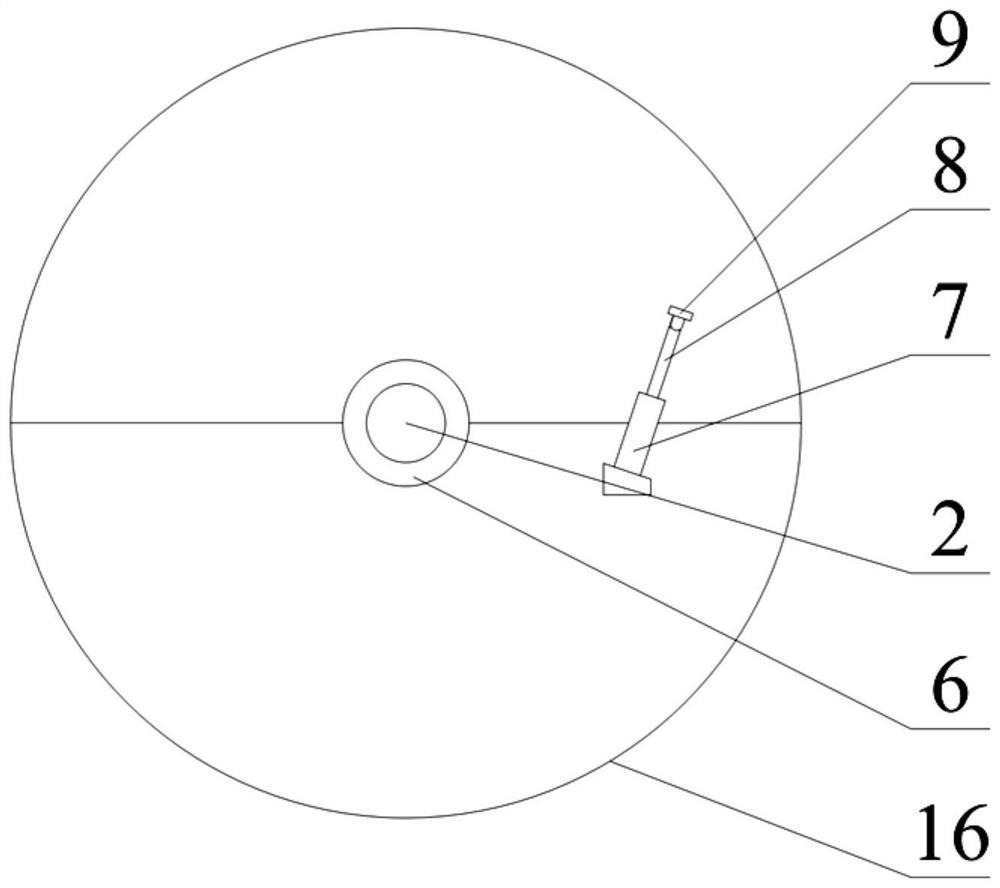

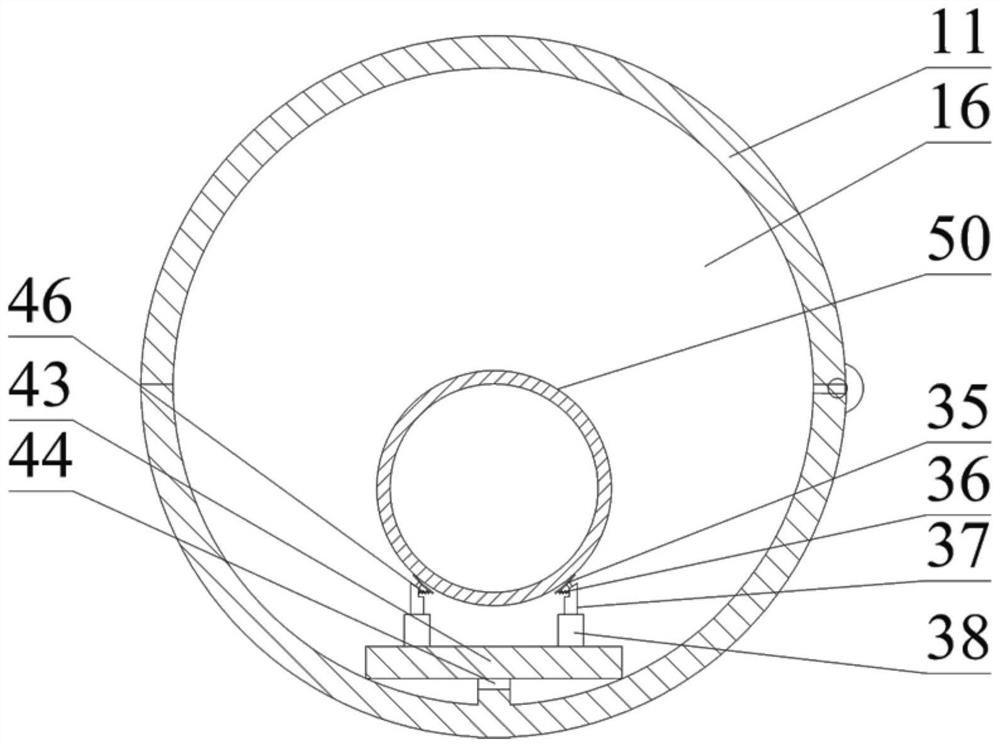

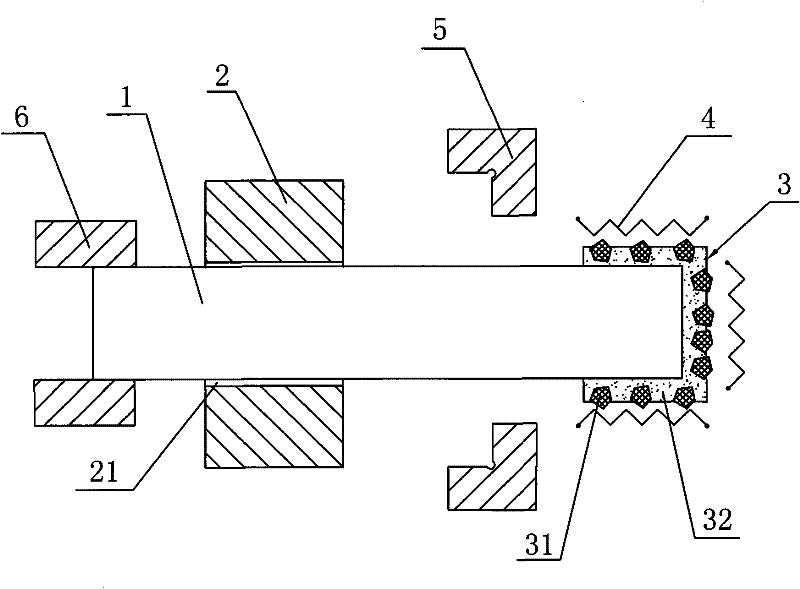

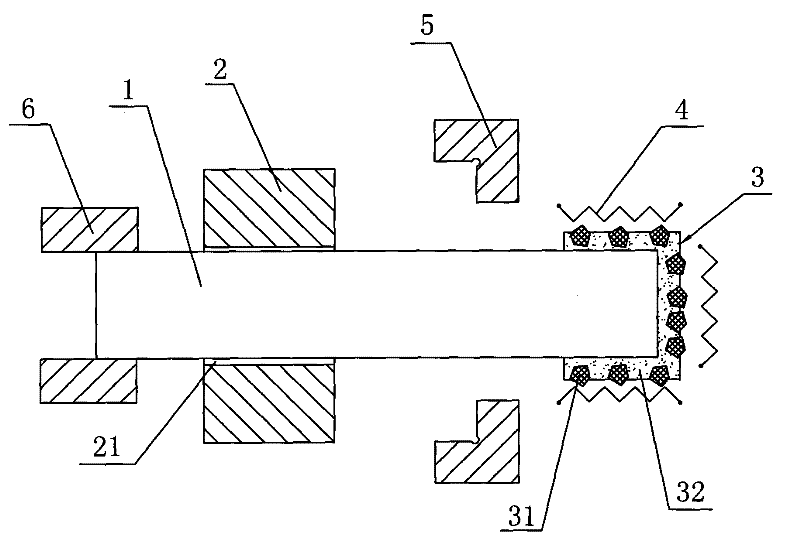

A high-frequency direct current heating auxiliary rolling processing device and processing method thereof

ActiveCN108406224BReduce deformation resistanceRolling processing effect is obviousMetal working apparatusClosed loopCopper electrode

The invention relates to a high-frequency direct-current heating auxiliary rolling device added on a machine tool. The high-frequency direct-current heating auxiliary rolling device comprises a rolling device, a heating component and a loading component; the rolling device is fixedly mounted on a cutter frame of the machine tool; and a rolling head is towards parts to be machined. The heating component comprises a high-frequency direct-current power supply, two copper electrodes and two electric brushes; and the high-frequency direct-current power supply, the two electric brushes, the two copper electrodes and the parts to be machined are connected through leads to form a closed loop. The loading component comprises an electric brush frame, two insulation fixed thimbles and an insulation revolving thimble; and in the horizontal direction of the machine tool, a machine tool tail base, the insulation revolving thimble, the first insulation fixed thimble, the first copper electrode, the parts to be machined, the second copper electrode, the second insulation fixed thimble and a power tool power chuck are coaxially clamped in sequence. The invention further relates to a machining method of the high-frequency direct-current heating auxiliary rolling device. The device is simple in structure, convenient to operate and high in practicability, and belongs to the field of metal machining equipment.

Owner:SOUTH CHINA UNIV OF TECH

Electric heating DPF control device

InactiveCN106523078ASimple structureReduce volumeExhaust apparatusSilencing apparatusPower gridDisplay device

The invention discloses an electric heating DPF control device and relates to the technical field of diesel tail gas treatment. The electric heating DPF control device comprises a heating cavity, a control cabinet and a diesel particulate filter. A heating tube and a temperature sensor are mounted in the heating cavity. A controller, an indicator lamp and a display device are mounted in the control cabinet. A power grid supplies power to the control cabinet and the heating tube. The temperature sensor is connected with the controller through a signal line. The gas outlet end of the heating cavity is connected with the diesel particulate filter. The electric heating DPF control device is simple in structure, small in size and capable of being mounted on special non-road vehicles such as small forklifts. The control device is uniform and precise in heating temperature, the corresponding calibration can be conducted according to the actual vehicle conditions, and the applicability and stability of a DPF regeneration system can be enhanced.

Owner:ANHUI ACT BLUE ENVIRONMENTAL PROTECTION CO LTD

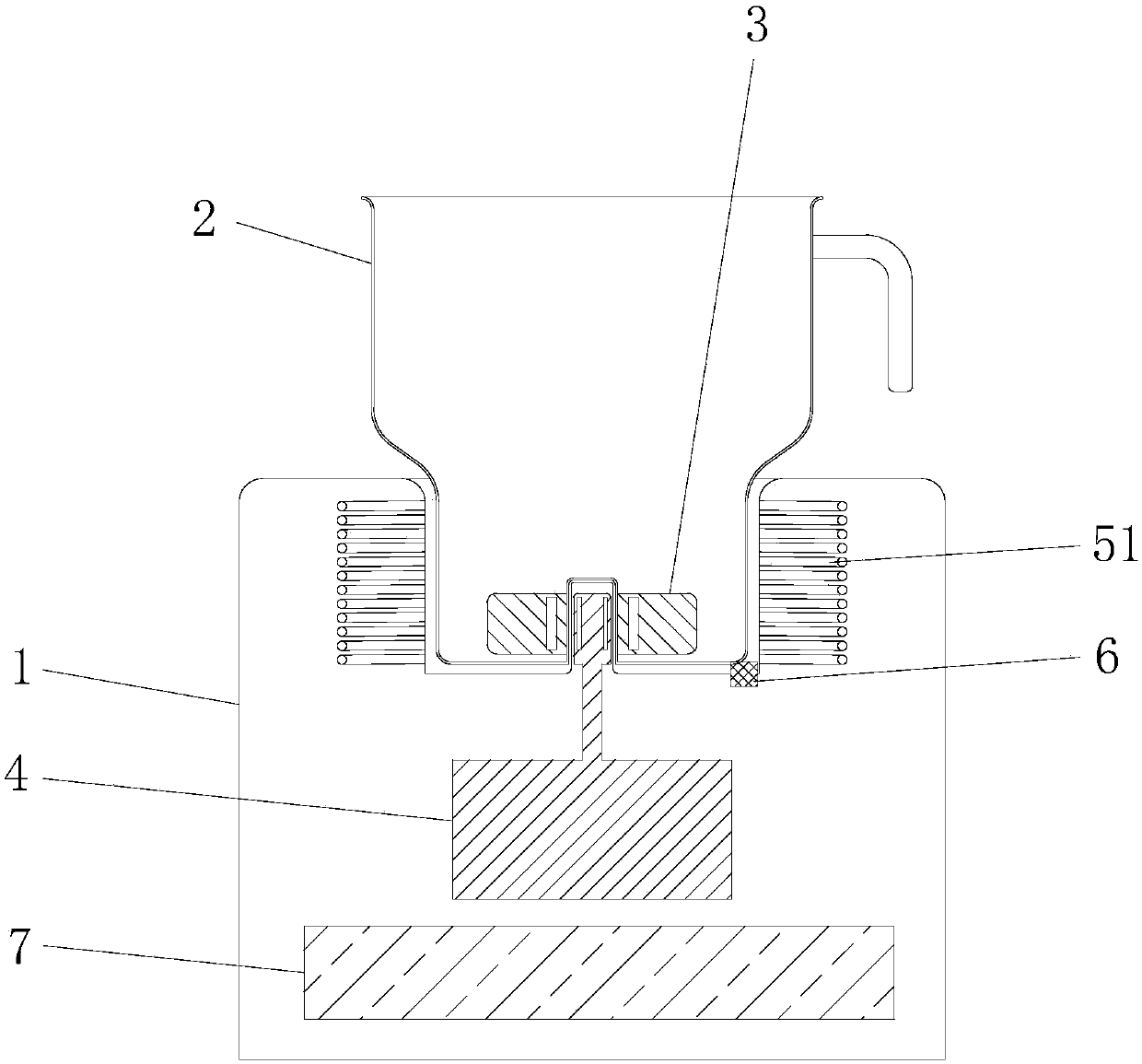

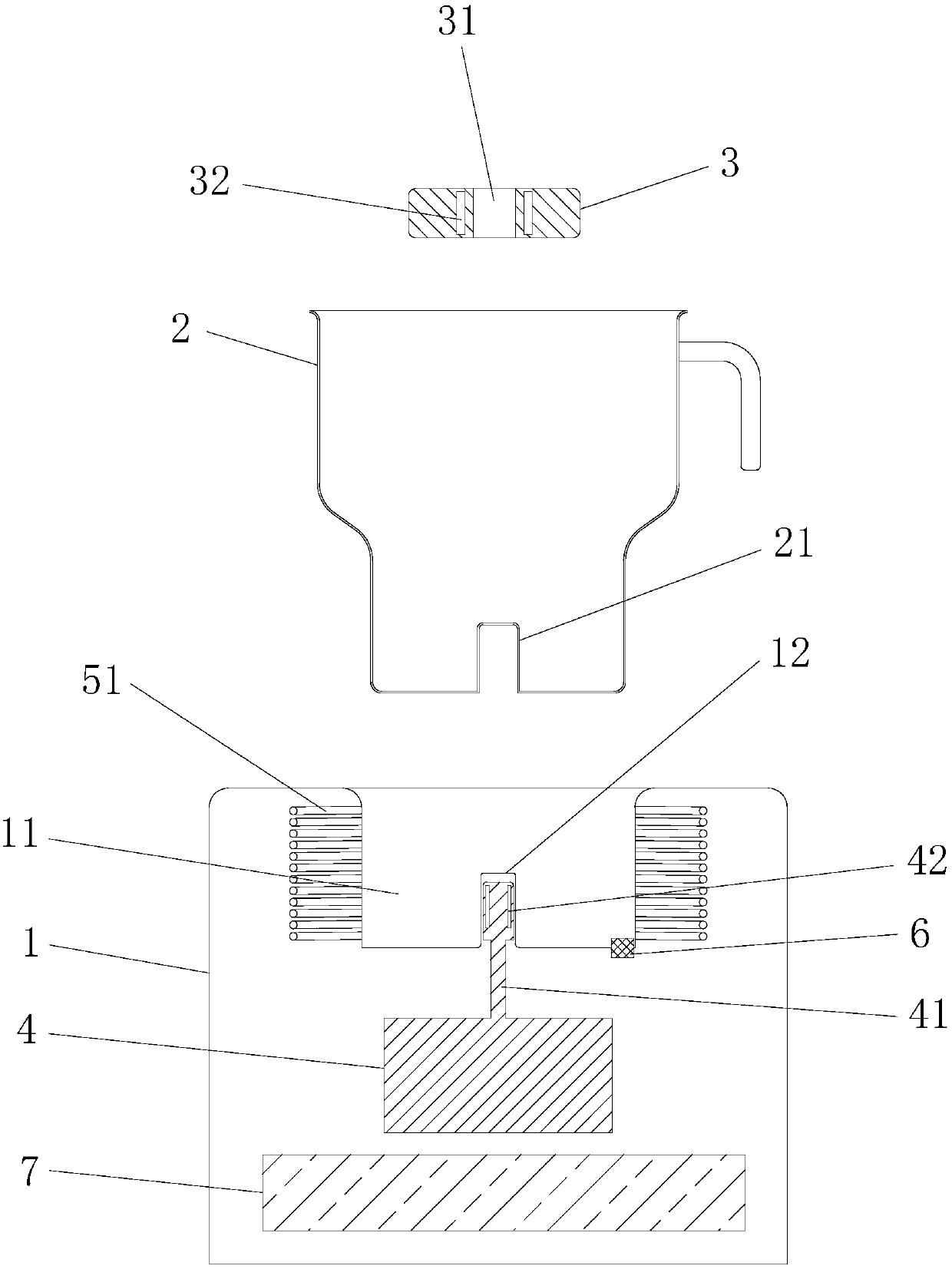

Stirring and heating device

The invention discloses a stirring heating device which comprises a base and a cup body. A rotating piece is arranged inside the cup body. The base is provided with a motor. The cup body is a stainless steel cup body capable of achieving electromagnetic heating. Compared with the prior art, the side wall of the stainless steel cup body is electromagnetically heated through a side wall induction coil, and the bottom pasting phenomenon cannot easily appear during heating, so that the phenomenon that cancerogenic substances are generated due to burnt materials is avoided, and the food health and safety are ensured; due to the adoption of the electromagnetic heating mode, heating is stopped immediately when power is off, and waste heat generated by an electric heating disc or pipe does not exist; accordingly, accuracy of heating temperature is ensured, and nutrition, taste and the like of food are prevented from being damaged; a wireless temperature measurement system is adopted, the cup body and the base are connected in a non-conductive mode, the conductive connection of the stirring heating device is simple in structure, the cup body can be washed with water and cleaned even when soaked into water, and cleaning is quite convenient.

Owner:东莞市沃森实业有限公司

Heating furnace for processing aromatic hydrocarbon oils from heavy components of petroleum

ActiveCN103062888AReduce coking problemsAvoid cokingThermal non-catalytic crackingRefining by heating/coolingFluePetroleum

The invention discloses a heating furnace for processing aromatic hydrocarbon oils from heavy components of petroleum. The heating furnace comprises a furnace body, a flue and a gas nozzle, wherein the upper end of the furnace body is provided with a raw material pipe inlet and a steam pipe inlet in parallel, the lower end of the furnace body is provided with a raw material pipe outlet, and the steam pipe outlet is arranged on the middle of the furnace body. By means of staring the heating process by entering a convection section and ending the heating in a radiation section, the problem of coking can be reduce; heating temperature in the radiation section is more accurate, compared with a convection section; the heating temperature and temperature fluctuations can be well controlled, and the coking can be effectively reduced and avoided.

Owner:武汉保华石化新材料开发股份有限公司

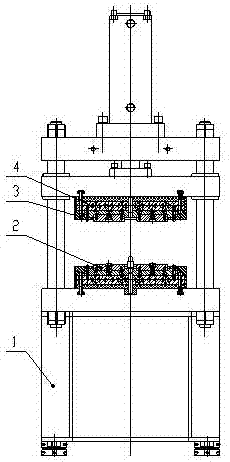

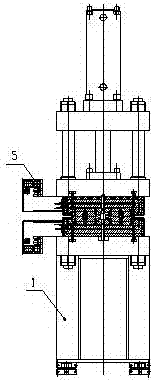

Clutch damping disc tempering and trimming machine

InactiveCN107541592AGuarantee product qualityIncrease productivityFurnace typesHeat treatment furnacesClutchElectrical control

The invention discloses a clutch damping disc tempering forming machine, which comprises a press assembly, a mold assembly, a thermal insulation layer, a heating system and an electric control system, the press assembly is installed at the bottom, and the mold assembly The mold assembly is located above the press assembly, a heating system is provided inside the mold assembly, and an insulating layer is provided on the surface of the mold assembly. An electric heating plate is arranged in the mold assembly, and is heated by the electric control system. The thermal insulation layer consists of a thermal insulation cover plate, a thermal insulation cover and a thermal insulation backing plate, which plays a role of thermal insulation for the device. The electric control system is arranged on the side of the mold assembly and connected with the electric heating plate circuit.

Owner:HUANGSHI UNIVERSE AUTO EQUIP

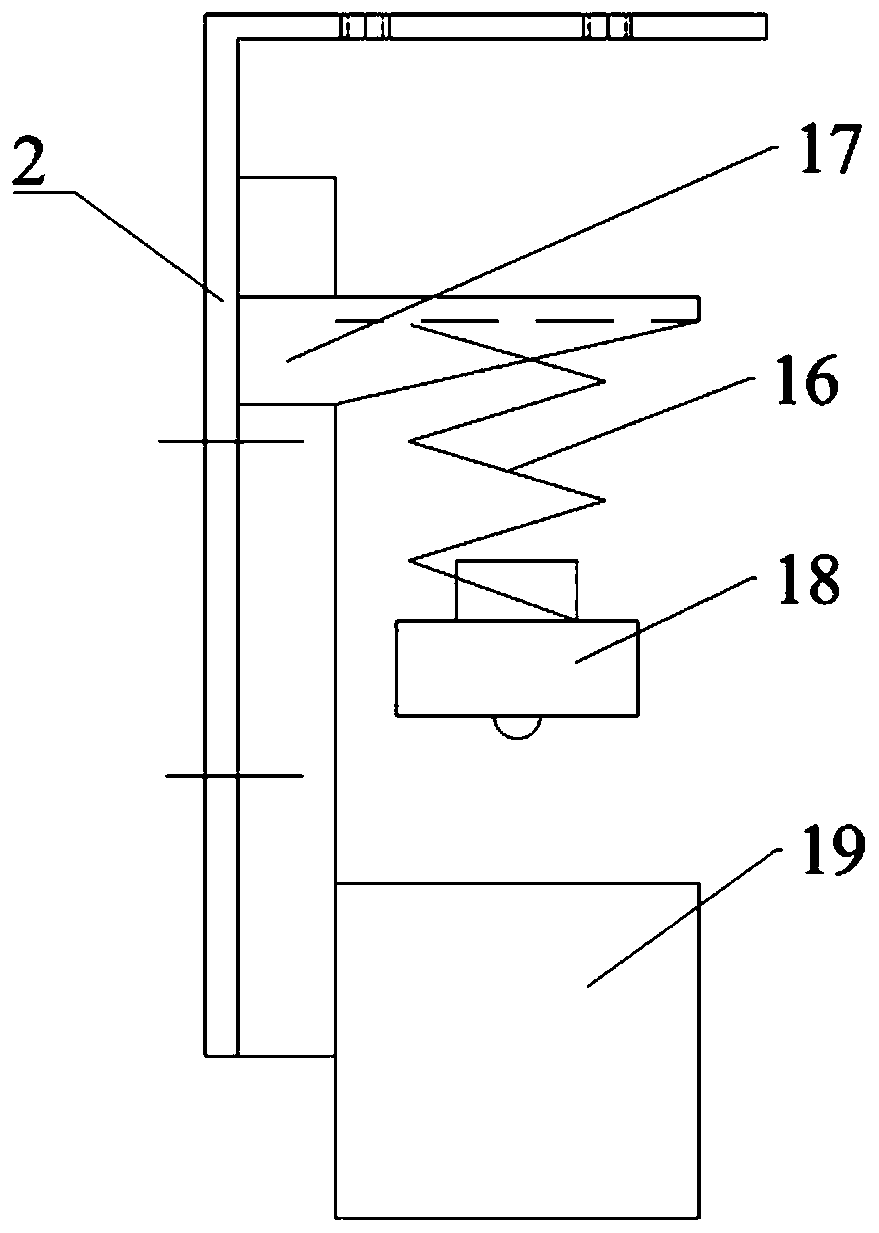

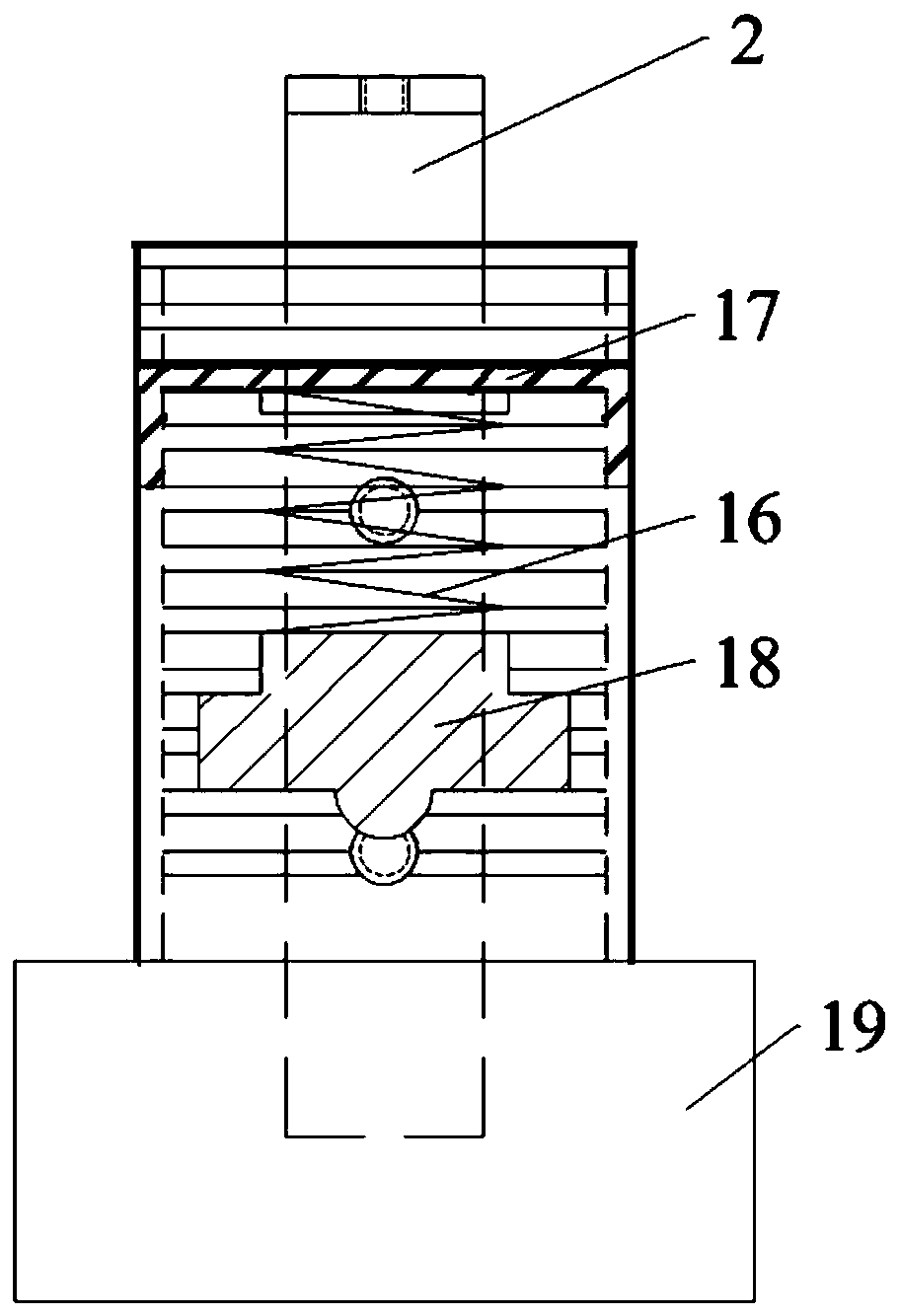

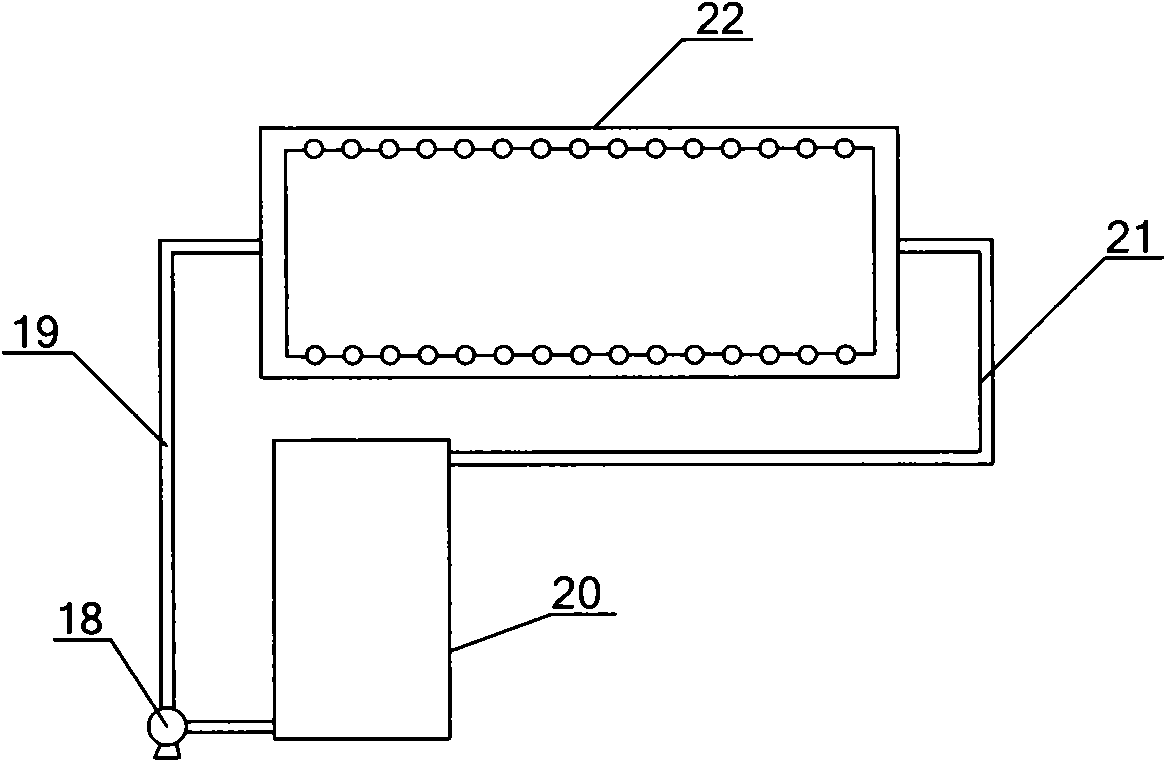

Intelligent control high-temperature rock-low-temperature water heat exchange device and using method

PendingCN114705557APrecise temperature controlPrecise control of flow rateMaterial strength using tensile/compressive forcesSimultaneous control of multiple variablesWater storageTemperature control

The invention discloses an intelligent control high-temperature rock-low-temperature water heat exchange device and a use method. The intelligent control high-temperature rock-low-temperature water heat exchange device mainly comprises a water temperature controller, a constant-speed water pump, an annular rock sample heater, a high-temperature rock sample placement cabin, a water storage cabin, a water return pump, an intelligent analysis operation table and other auxiliary devices. And a temperature control system is arranged in the water temperature controller. And a flow speed controller is arranged in the constant-speed water pump. And a heating system is arranged in the annular rock sample heater. And intelligent cabin door switching devices are arranged on two sides of the high-temperature rock sample placing cabin. A water pipe external connector is arranged outside the water storage bin. And an intelligent sensor is arranged in the water return pump. The system is simple in structure, the rock temperature, the water temperature and the flow speed are efficiently, safely and innovatively adjusted through an intelligent analysis control system, and the safety of workers is guaranteed while the labor cost and the engineering operation time are saved; water can be recycled through cooperation of the mechanisms, the purpose of saving water is achieved, and the requirement for heat exchange accuracy of low-temperature water passing through a high-temperature rock sample is met.

Owner:HENAN POLYTECHNIC UNIV

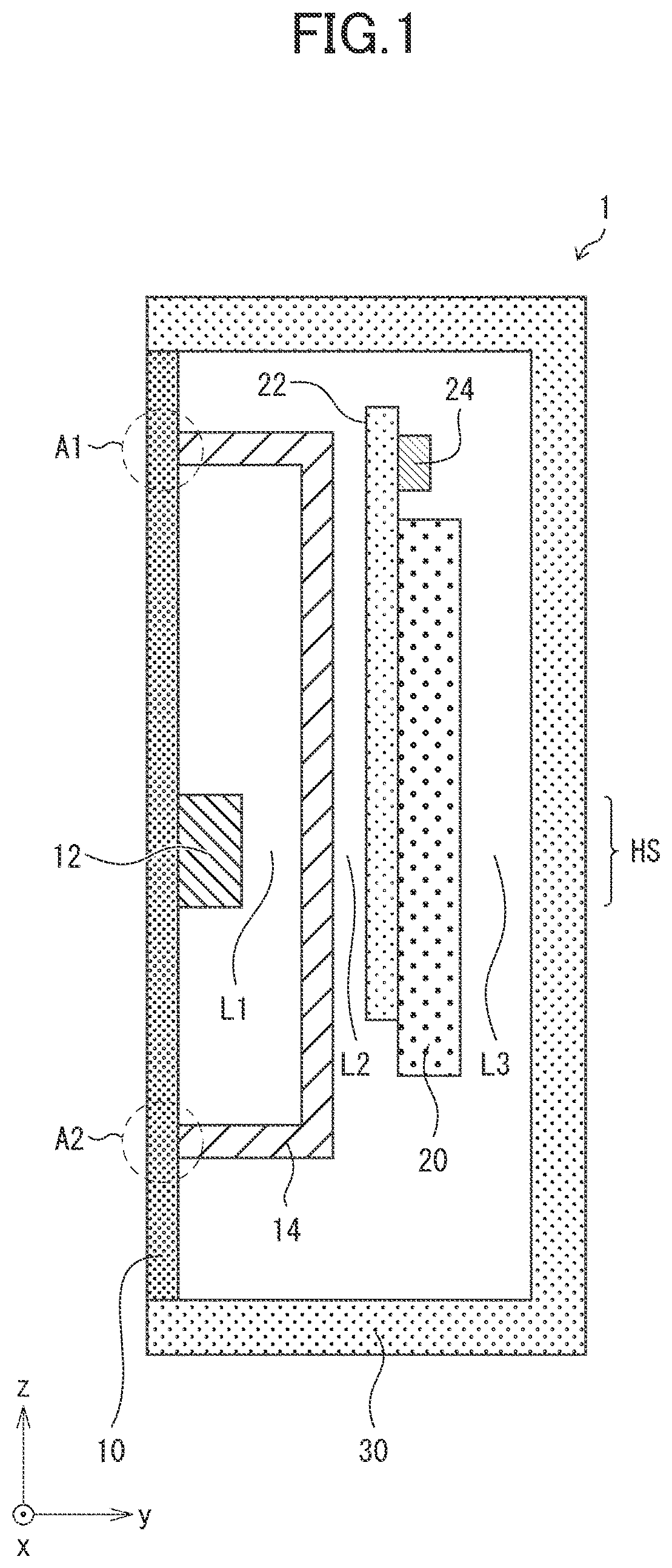

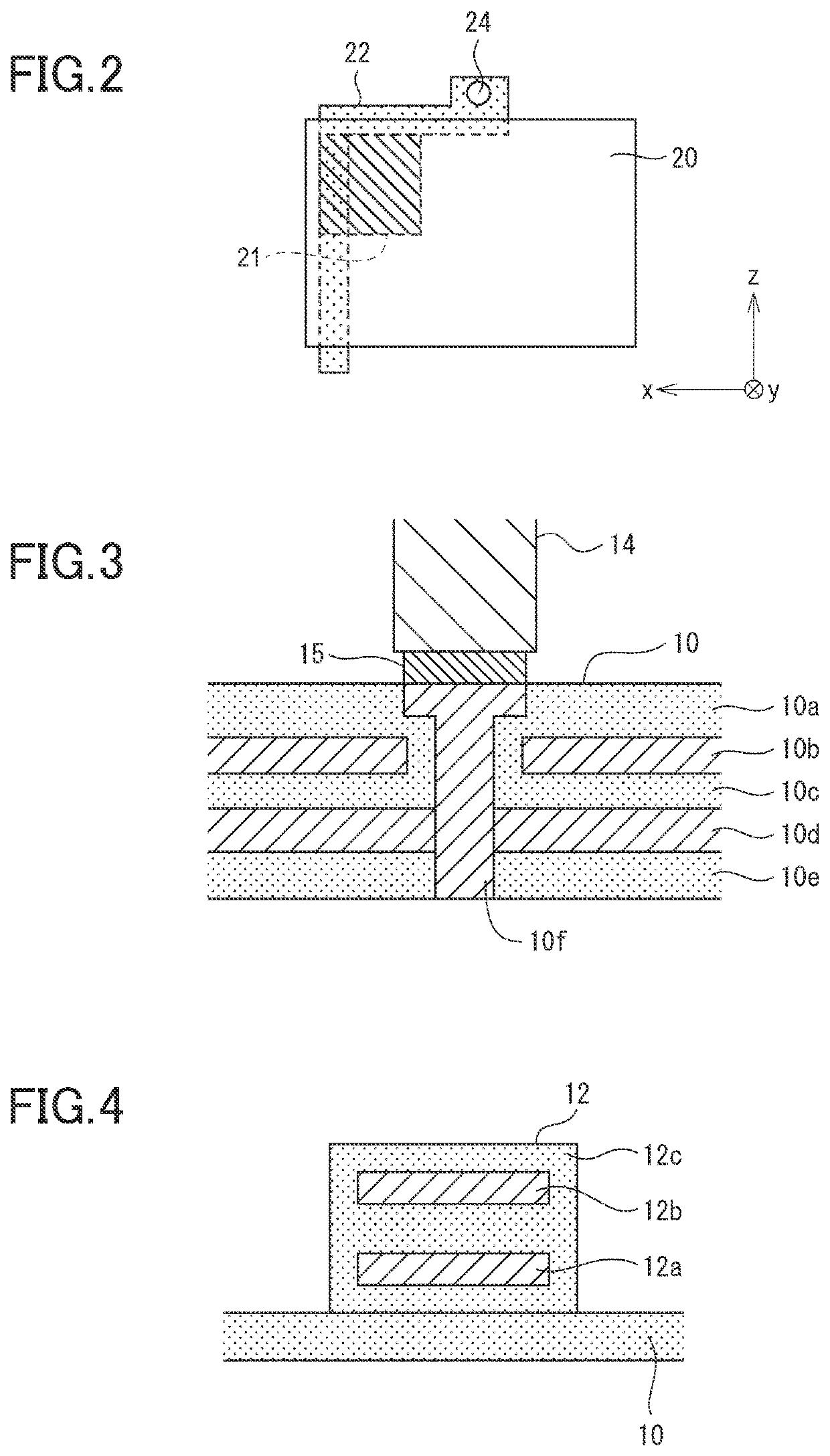

Electronic device

InactiveUS20210259137A1Precise heating temperatureThermometer detailsTemperature control using plurality of sensorsThermodynamicsInsulation layer

An electronic device comprises an electronic component serving as a heat source; a first substrate on which the electronic component is disposed; a heat dissipation member that covers, with a first heat insulation layer in between, an area including a region of the first substrate, at which the electronic component is disposed, and being on a front side or a rear side of the first substrate; a housing that accommodates at least the first substrate and the heat dissipation member; a second substrate that faces the heat dissipation member across a second heat insulation layer in the housing; and a thermistor disposed on the second substrate.

Owner:SHARP KK

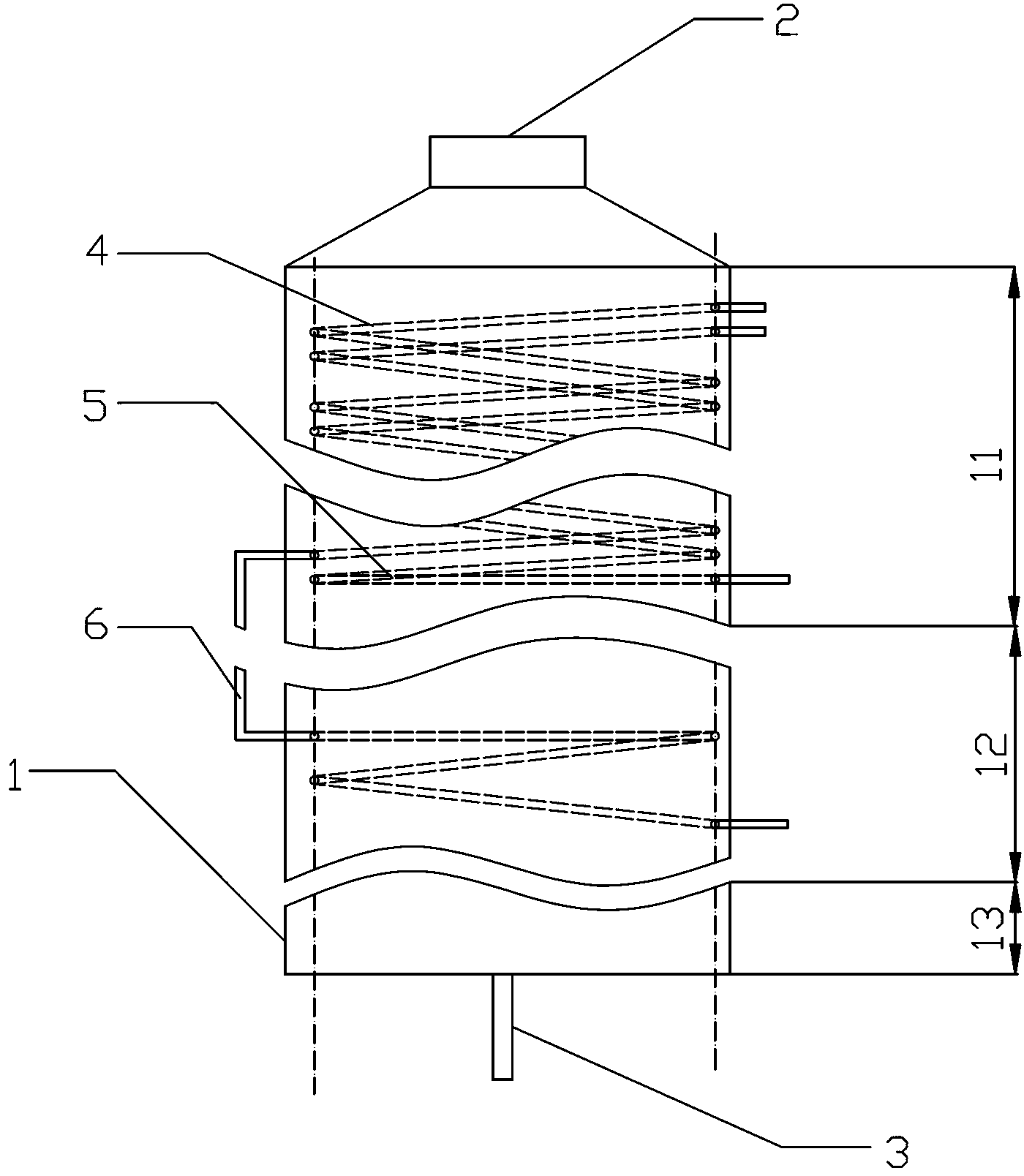

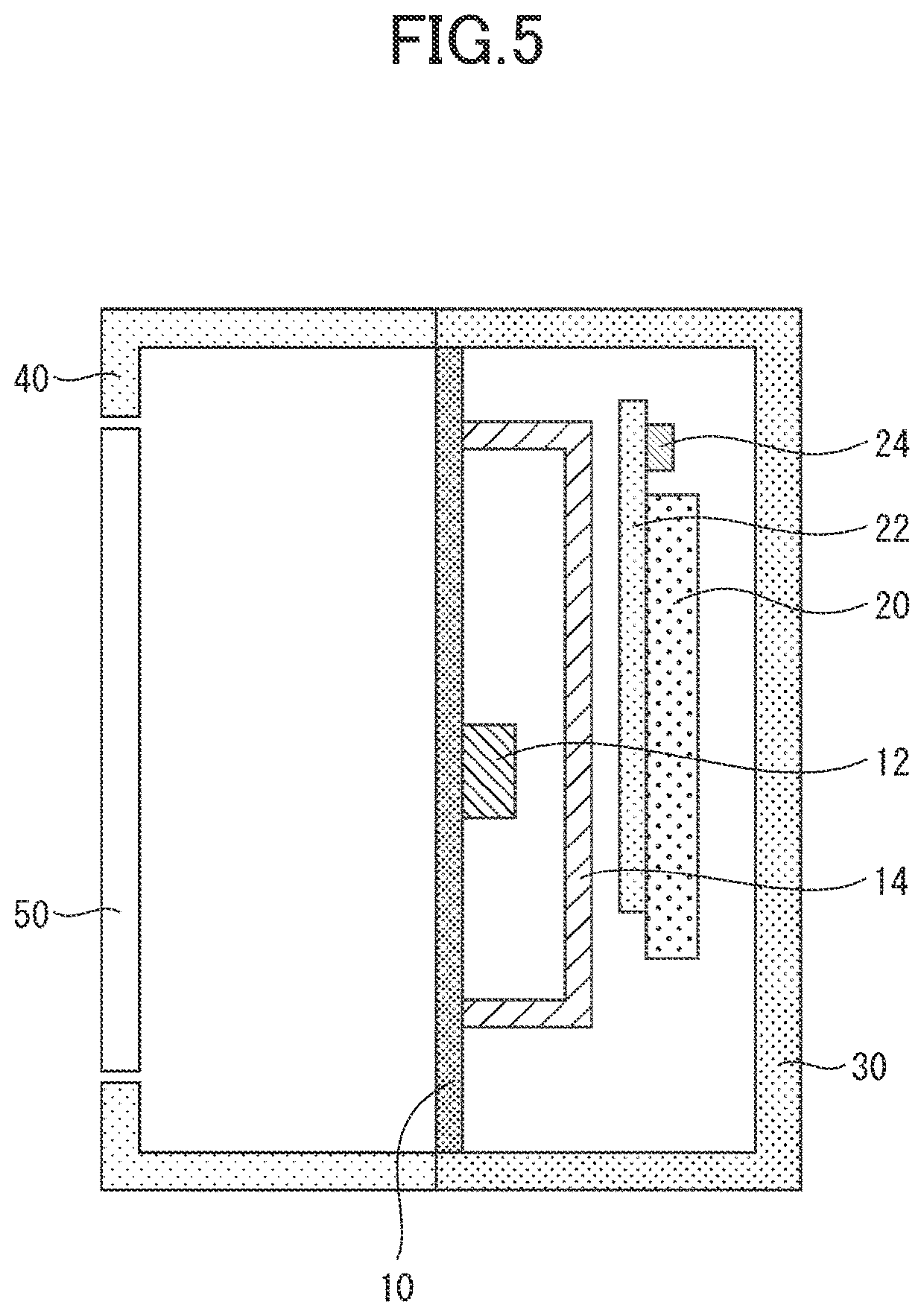

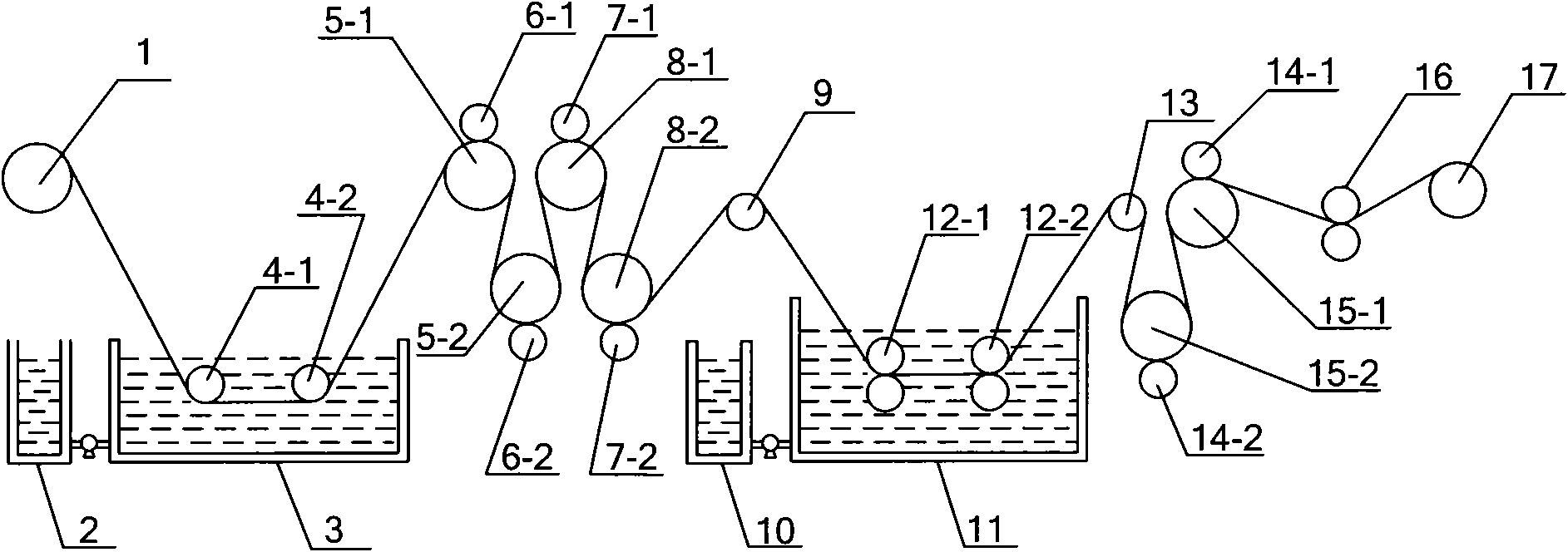

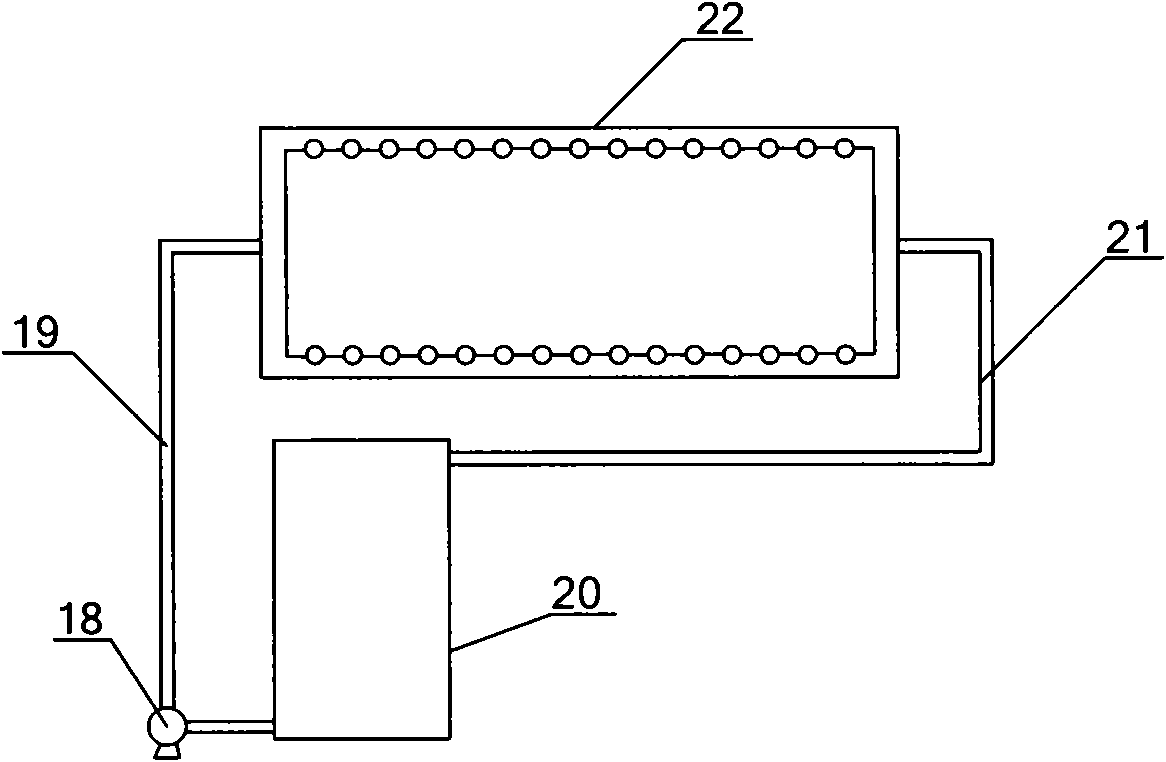

Production device of broad width PVA polarized light film

InactiveCN101672942AThickness is easy to controlSimple structurePolarising elementsLiquid storage tankOptoelectronics

The invention relates to a production device of a broad width PVA polarized light film. The prior processes and devices can not produce broad width PVA polarized light films. The production device ofthe broad width PVA polarized light film comprises a film fabrication device and a post treatment device; the film fabrication device comprises a stirring kettle, a liquid storage tank and a buffer slot which are connected in series through pipelines; a stainless steel conveyer belt of a track conveying device is arranged by penetrating an oven, and the rear part thereof is provided with a film fabrication heating roller group, a film fabrication setting roller group, a film fabrication traction device and a winding device; and the post treatment device comprises a primary solution tank, a post treatment heating roller group, a secondary solution tank, a post treatment setting roller group, a post treatment traction device and a winding device which are sequentially arranged; and two positioning rollers are arranged in the primary solution tank, and two stretching rollers are arranged in the secondary solution tank. In the production device of the broad width PVA polarized light film,the heating roller group, the setting roller group and the stretching rollers are heated by adopting oil medium; and the production device of the broad width PVA polarized light film has simple structure, accurate heating temperature and easy control of film thickness, and can realize the industrialization production and produce the broad width PVA polarized light films.

Owner:SERVICE CENT OF COMMLIZATION OF RES FINDINGS HAIAN COUNTY

Energy-efficient sulfonation reaction device and method for naphthalene water reducers

PendingCN109382063AImprove efficiencyLow costChemical/physical/physico-chemical stationary reactorsFusionHot runnerHeat conducting

The invention discloses an energy-efficient sulfonation reaction device and method for naphthalene water reducers. The energy-efficient sulfonation reaction device comprises a sulfonation reactor, wherein a waste gas outlet is formed in the top of the sulfonation reactor; a jacket is arranged on the out wall of the sulfonation reactor, a heat conducting oil inlet is formed in the lower part of thejacket, a heat conducting oil outlet is formed in the top of the jacket; the device further comprises a naphthalene melting kettle; a heating runner is arranged on the outer wall of the naphthalene melting kettle; the exhaust gas outlet in the top of the sulfonation reactor is communicated with the hot runner of the naphthalene melting kettle through an exhaust fan. According to the method, the device is used, the sulfonation reactor is heated by heat conducting oil, the heating temperature is stable and accurate, and production efficiency of the naphthalene water reducers is improved; high-temperature gas of sulfonation reaction is directly used as a heat source for melting industrial naphthalene, and melting of industrial naphthalene is simultaneously performed in the sulfonation reaction process, so that the period of the whole process is greatly shortened, and production efficiency is improved.

Owner:山东万山化工有限公司

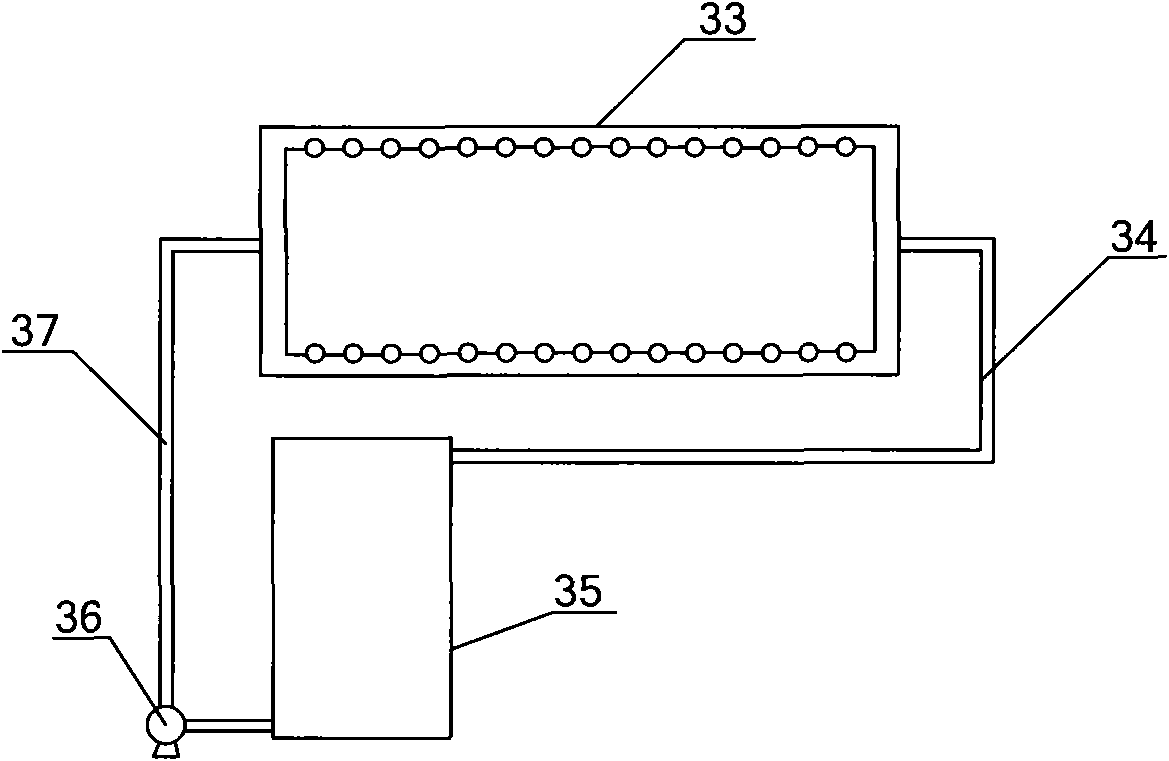

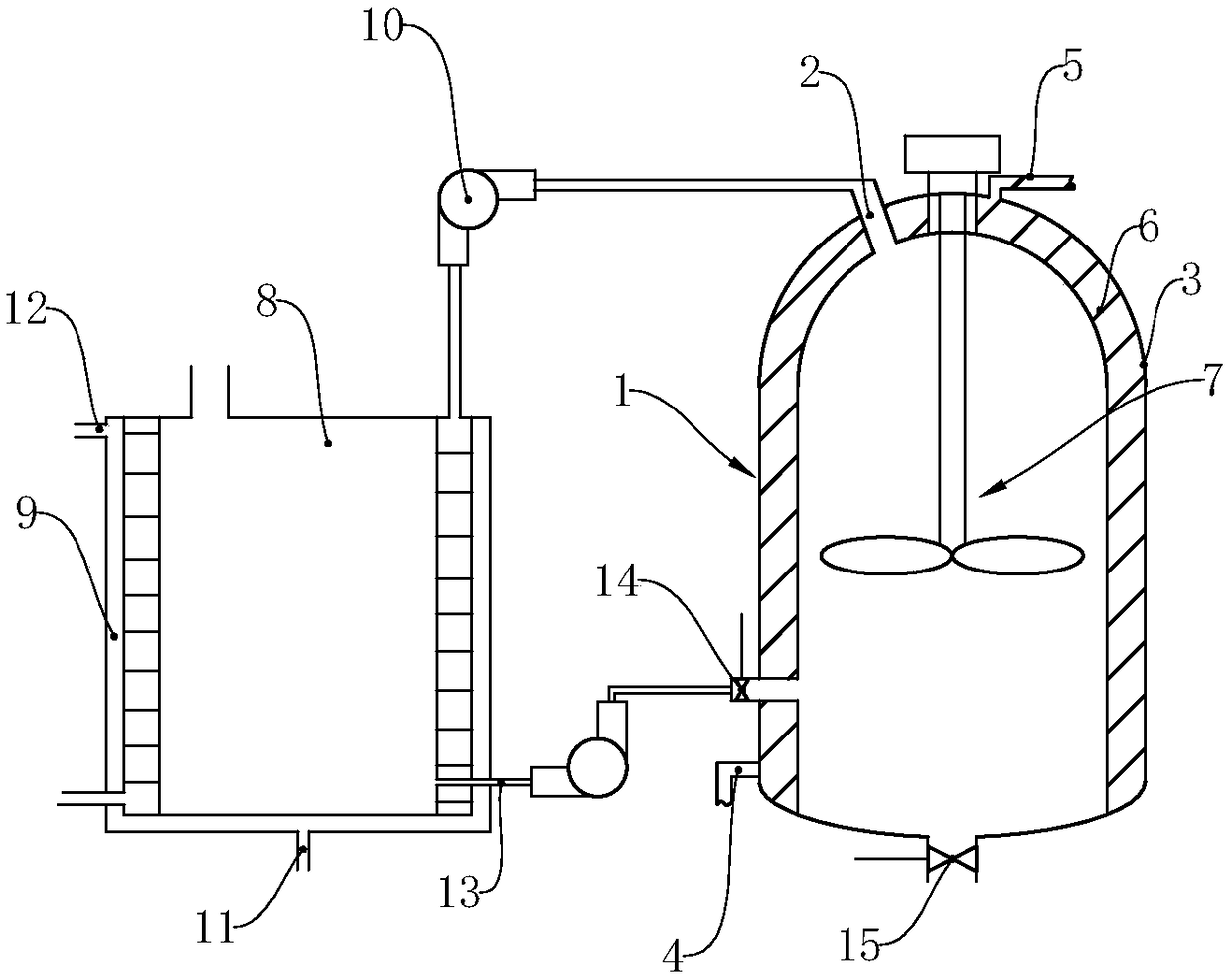

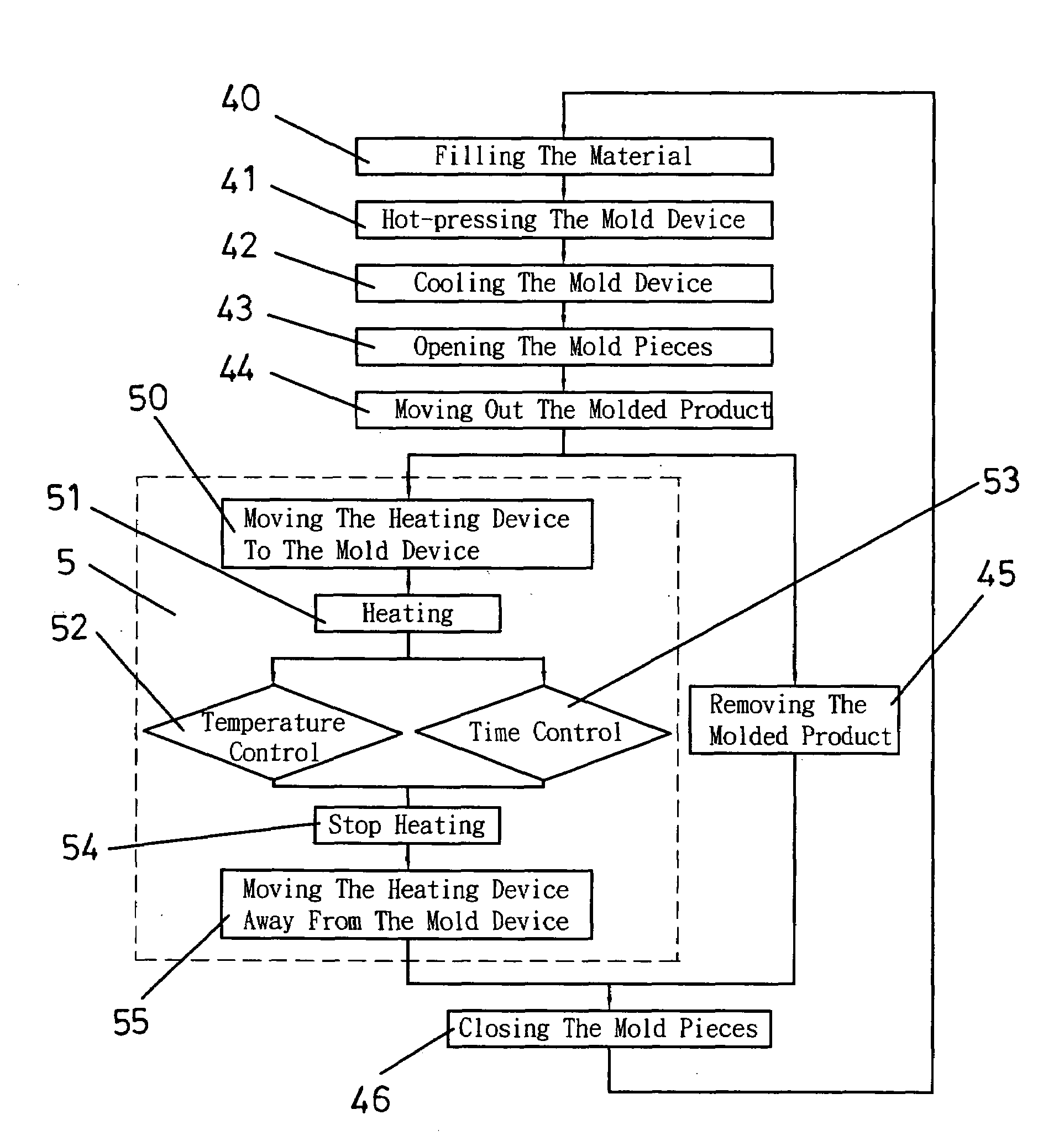

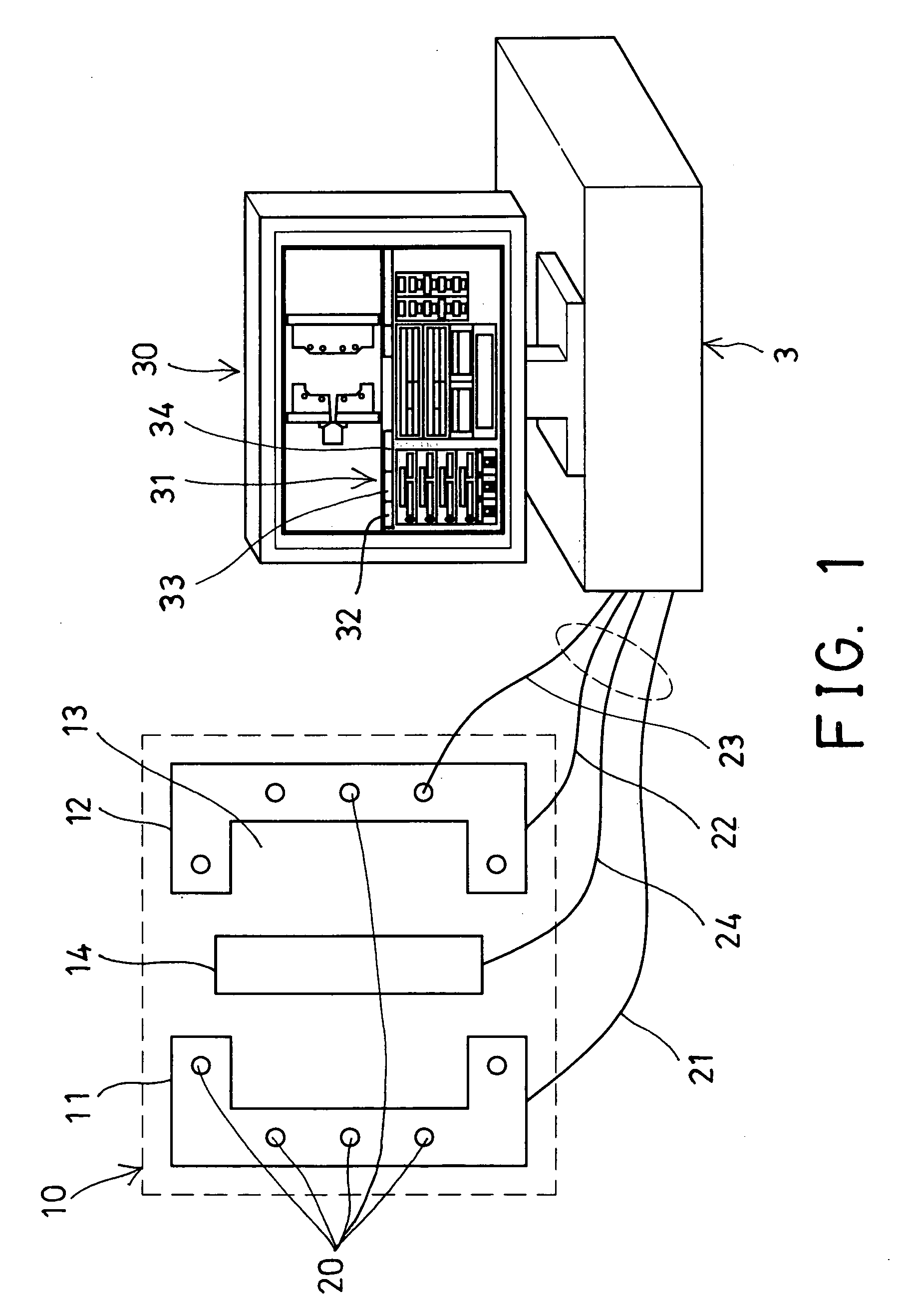

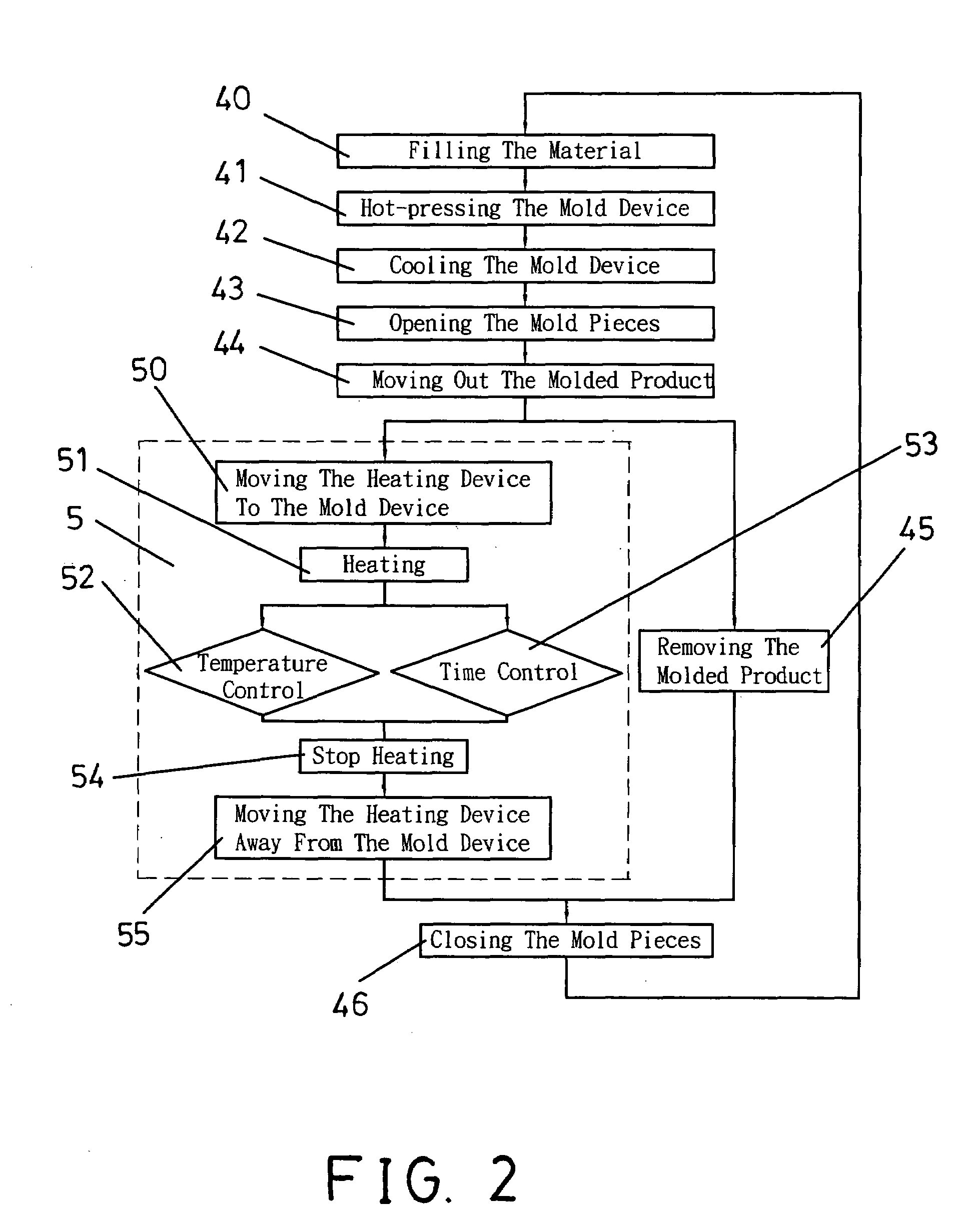

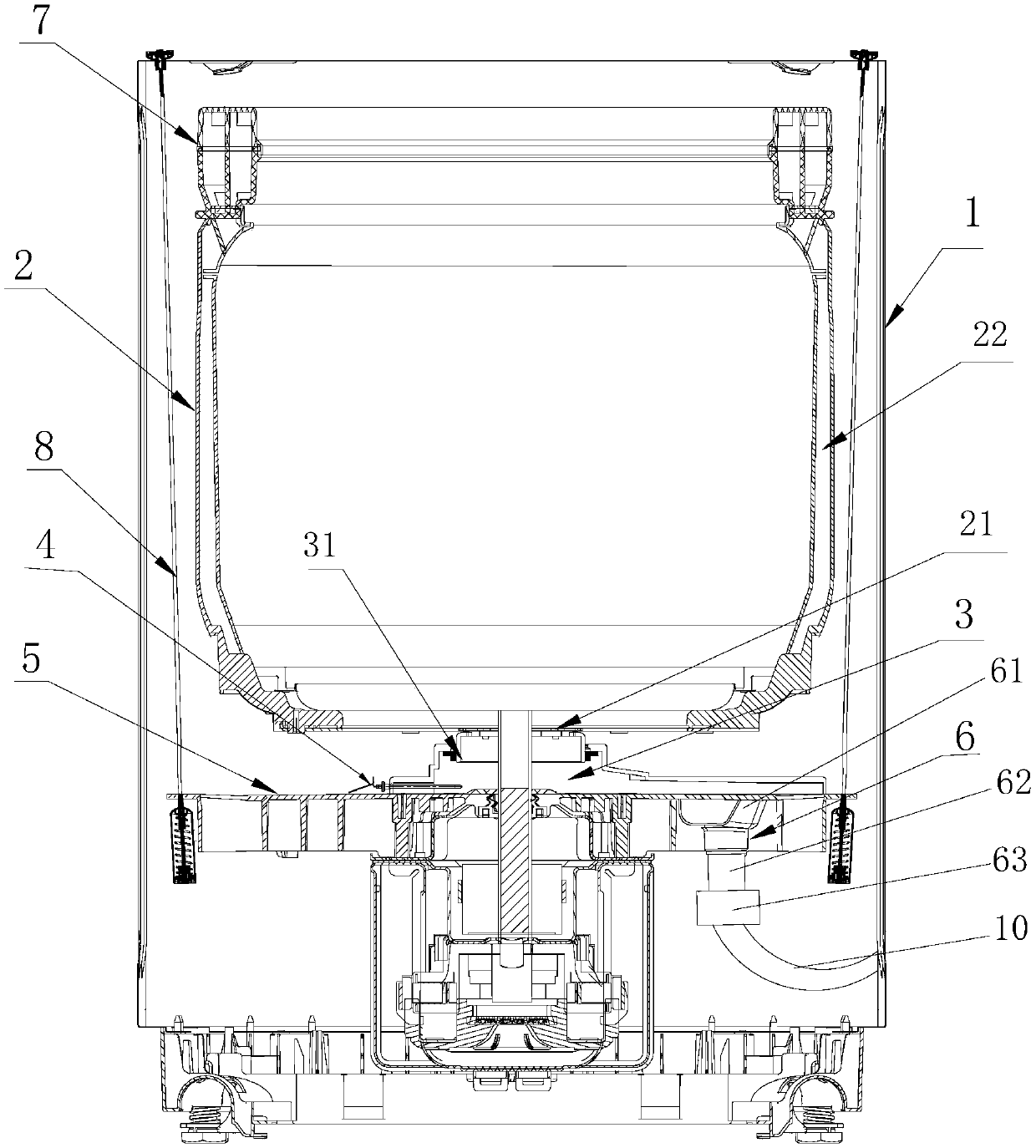

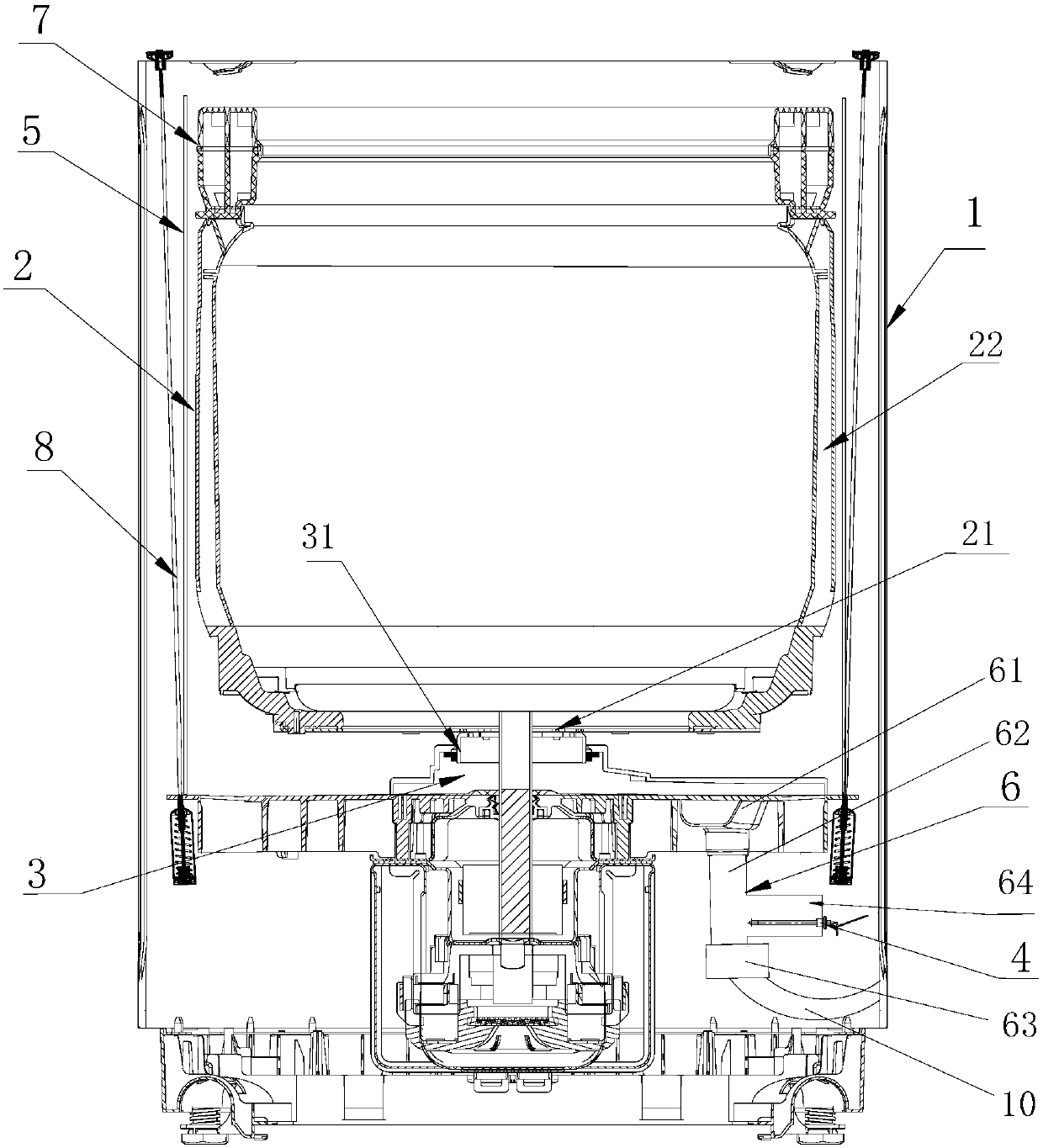

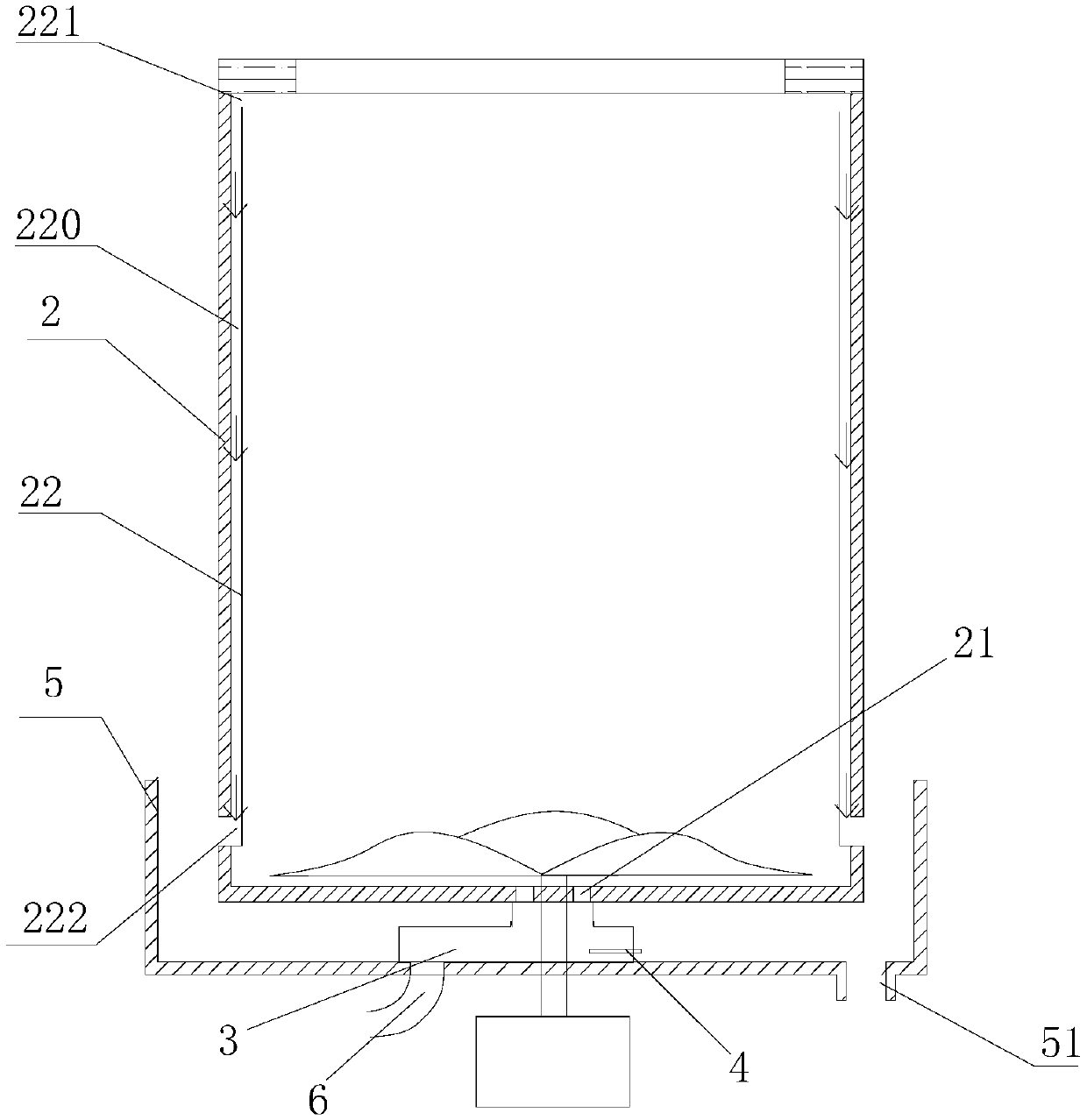

Temperature control system for molding facility

InactiveUS20090166909A1Efficient fillingPrecise heating temperatureAuxillary shaping apparatusTemperature controlControl system

A temperature control system includes a mold device having a mold cavity formed between two or more mold pieces for receiving a filling material, a number of detecting devices attached to the mold pieces for detecting the temperature of the mold pieces, a heating device for heating the mold pieces to a desired temperature, and a control module coupled to the mold pieces for closing and opening the mold cavity of the mold device, and for receiving the detected temperature signals from the detecting devices, and for controlling the heating device, such as for moving the heating device relative to the mold pieces of the mold device and for suitably pre-heating the mold pieces of the mold device.

Owner:CHUNG YUAN CHRISTIAN UNIVERSITY

Washing machine

PendingCN111379135AAchieve heatingSimple structureOther washing machinesWashing machine with receptaclesTemperature controlLaundry washing machine

The invention discloses a washing machine. The washing machine comprises a housing, a washing barrel and a heating chamber, and further comprises a water receiving slot, wherein the washing barrel canbe rotatably arranged in the housing and is in a water container structure;the heating chamber is arranged below the washing barrel, and communicates with the inner part of the washing barrel; a heating unit is arranged in the heating chamber for heating water in the chamber and the washing barrel; the water receiving slot is used for supporting the washing barrel, is formed outside the washing barrel, and is at least partially formed below the washing barrel; the water receiving slot is further provided with a water drainage part; a first water drainage hole is formed in the barrel bottom ofthe washing barrel; the first water drainage hole communicates with the water drainage part through a first water drainage channel; and the heating unit is arranged in the first water drainage channel and / or the water drainage part. The washing machine is simple in structure, is low in cost, is high in heating efficiency, can control heating temperatures at different gears according to differentfunctions, can heat washing water, also has the heat sterilization function, and is precise in temperature control.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

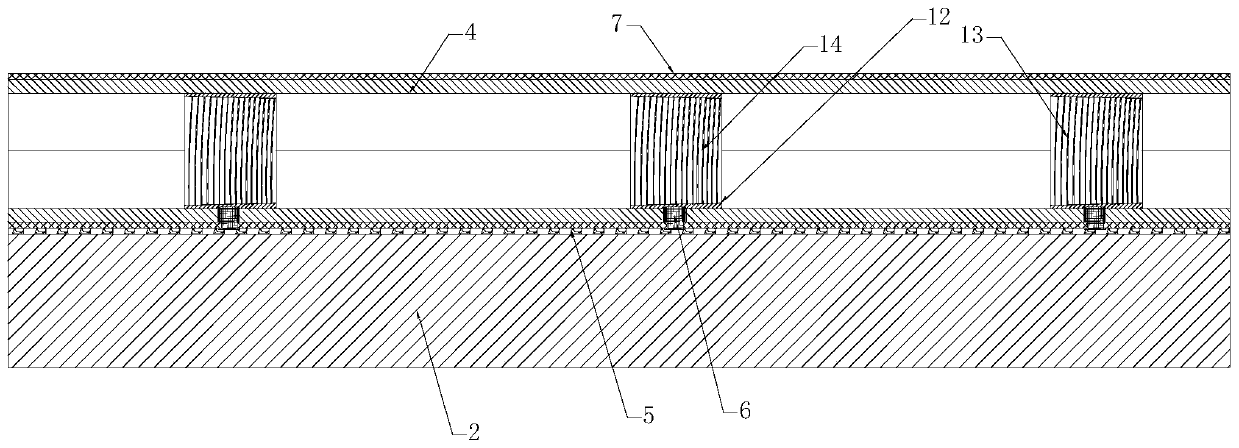

A heating plate assembly

The invention discloses a heating plate assembly, which comprises a shell, a heating plate and a heat insulation plate. The bottom of the shell is provided with an opening. layer, heat-conducting parts and heat-insulating sheath, the heat-conducting layer is made of high-temperature heat-resistant heat-conducting material mixed with carbon nanotubes, the heat-conducting layer is fixedly installed on the end surface of the heating plate, the outer side of the infusion tube is equipped with a heat-insulating sheath, and the infusion tube is coiled The infusion tube is clamped between the heat conduction layer and the heat insulation plate, and the periphery of the infusion tube is filled with high temperature resistant heat insulation material. The heat conduction parts are fixedly installed on the heat conduction layer, and one end extends into the In the infusion tube, heat is delivered to the infusion tube. The invention can control the heat dissipation of the heating plate and improves the process.

Owner:ANHUI SIYUAN SANQING INTELLIGENT MFG CO LTD

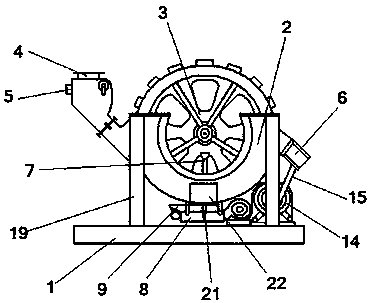

Novel batch heating machine for silica sand

PendingCN109354027AImprove product quality stabilityUniform heating efficiencySilicaSplit pinDrive shaft

The invention relates to a novel batch heating machine for silica sand. The novel batch heating machine is characterized in that a casing is arranged on one side of the top of a base through a supportbody; a rotating wheel assembly is vertically arranged in the casing; a feed inlet is connected to one side of the casing; a rear cover is arranged on one side of the feed inlet; a discharge door isarranged directly below the casing; a split pin is arranged in the discharge door, and is connected with a speed reducing motor through a curved rod; the speed reducing motor is connected with an aircylinder through a drive shaft; the air cylinder is connected to one side of the rotating wheel assembly; one end of the speed reducing motor is connected to a small sprocket through a small sprocketflange; a large sprocket is connected to the upper side of the small sprocket and connected with the drive shaft; a spoke is fixedly arranged on one inner side of the rotating wheel assembly; the drive shaft is connected to the rotating wheel assembly through the spoke; a flap gate is arranged on one side of the casing; a sampling port is obliquely arranged on one side of the casing; a temperaturemeasuring thermocouple is arranged at the tail end of the sampling port. The novel batch heating machine has the advantages that batched heating is conducted, and accordingly, the heating efficiencyis uniform; through real-time monitoring, the heating temperature is accurate; the production quality stability of the silica sand is effectively improved.

Owner:江门市新会区金昌矽砂有限公司

Method for separating grinding material layer and basal body of electroplated diamond grinding head

InactiveCN101648199BEnable recyclingEasy to separateSolid waste disposalSurface oxidationHeating temperature

The invention discloses a method for separating a grinding material layer and a basal body of an electroplated diamond grinding head, which is characterized by comprising the following steps: generating a tiny clearance between the grinding material layer and the basal body of the diamond grinding head by an induction heating method and then thoroughly separating the grinding material layer and the basal body by torsion and pull. The invention has the advantages that because the grinding material layer is heated by the induction heating method, the grinding material layer is heated and expanded and generates the tiny clearance with the basal body; then the end part of the grinding material layer is clamped by a second jig to keep the grinding material layer fixed, the basal body is alternately twisted by a first jig in the clockwise and anticlockwise directions, and the grinding material layer and the basal body are loosened so as to further promote the separation of the grinding material layer and the basal body; the whole heating and separating process has high speed and efficiency and less surface oxidation of the basal body and the grinding material layer and saves energy resources, and the induction heating method has precise heating depth and temperature and is easy to control the whole heating process.

Owner:NINGBO UNIV

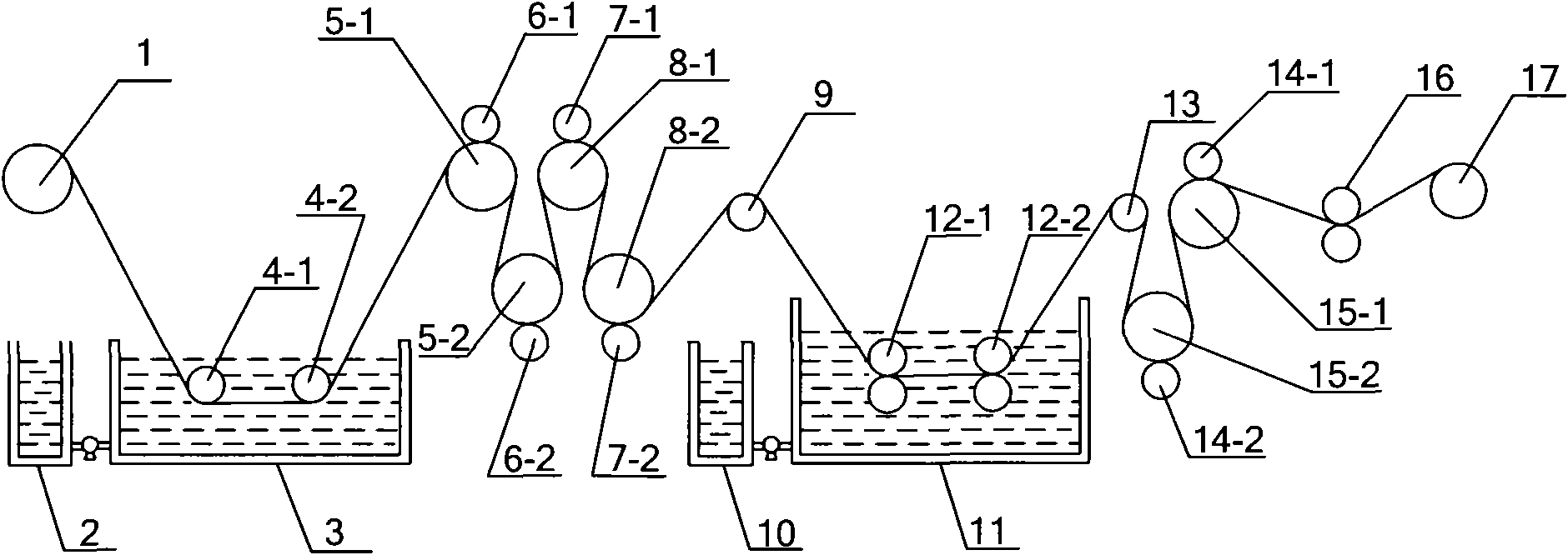

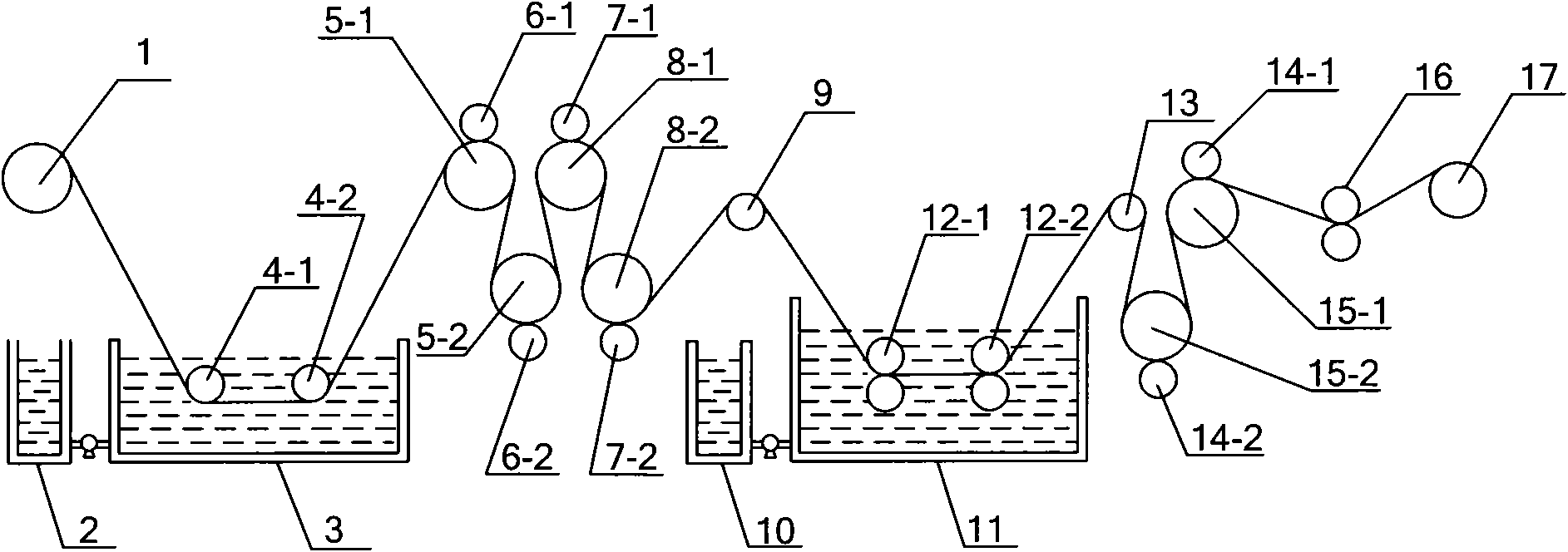

Production method of a broad PVA polarized light film

InactiveCN101672943BThickness is easy to controlSimple processPolarising elementsBoric acidRejection rate

The invention relates to a production method of a broad PVA polarized light film. The broad PVA polarized light film can not be produced in the prior art. The broad PVA polarized light film production method comprises the following steps: firstly soaking a PVA film into saturated solution of KI and KI2 with the weight ratio of 2-8:1 at the normal temperature; then heating two sides of the PVA film twice; putting the PVA film into a boric acid saturated solution with the temperature of 55-65 DEG C, and stretching the PVA film by 1-9 times in the boric acid saturated solution; respectively and thermally setting both sides of the PVA film through two heat setting rollers at the heat setting temperature of 65-75 DEG C; and drawing the thermal set PVA film and winding into a drum. The method has the advantages of simple process, accurate heating temperature, easy control of film thickness and low rejection rate, and realizes the industrialization production of the broad PVA polarized lightfilms.

Owner:SERVICE CENT OF COMMLIZATION OF RES FINDINGS HAIAN COUNTY

Production method of a broad PVA polarized light film

InactiveCN101672943AThickness is easy to controlSimple processPolarising elementsBoric acidRejection rate

The invention relates to a production method of a broad PVA polarized light film. The broad PVA polarized light film can not be produced in the prior art. The broad PVA polarized light film productionmethod comprises the following steps: firstly soaking a PVA film into saturated solution of KI and KI2 with the weight ratio of 2-8:1 at the normal temperature; then heating two sides of the PVA filmtwice; putting the PVA film into a boric acid saturated solution with the temperature of 55-65 DEG C, and stretching the PVA film by 1-9 times in the boric acid saturated solution; respectively and thermally setting both sides of the PVA film through two heat setting rollers at the heat setting temperature of 65-75 DEG C; and drawing the thermal set PVA film and winding into a drum. The method has the advantages of simple process, accurate heating temperature, easy control of film thickness and low rejection rate, and realizes the industrialization production of the broad PVA polarized lightfilms.

Owner:SERVICE CENT OF COMMLIZATION OF RES FINDINGS HAIAN COUNTY

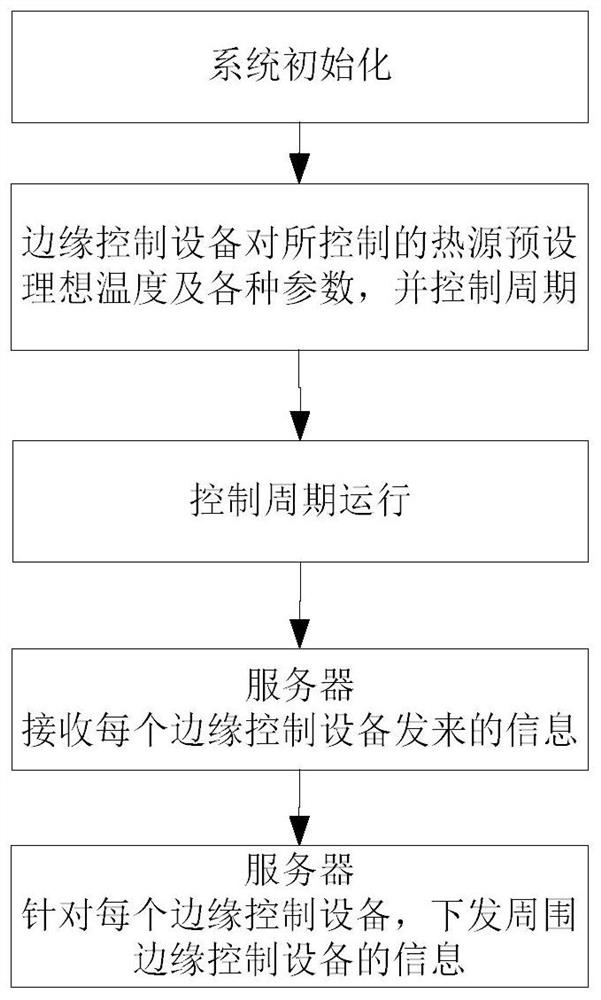

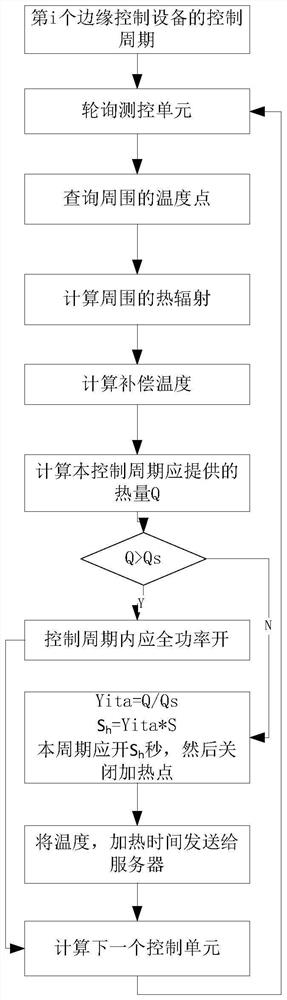

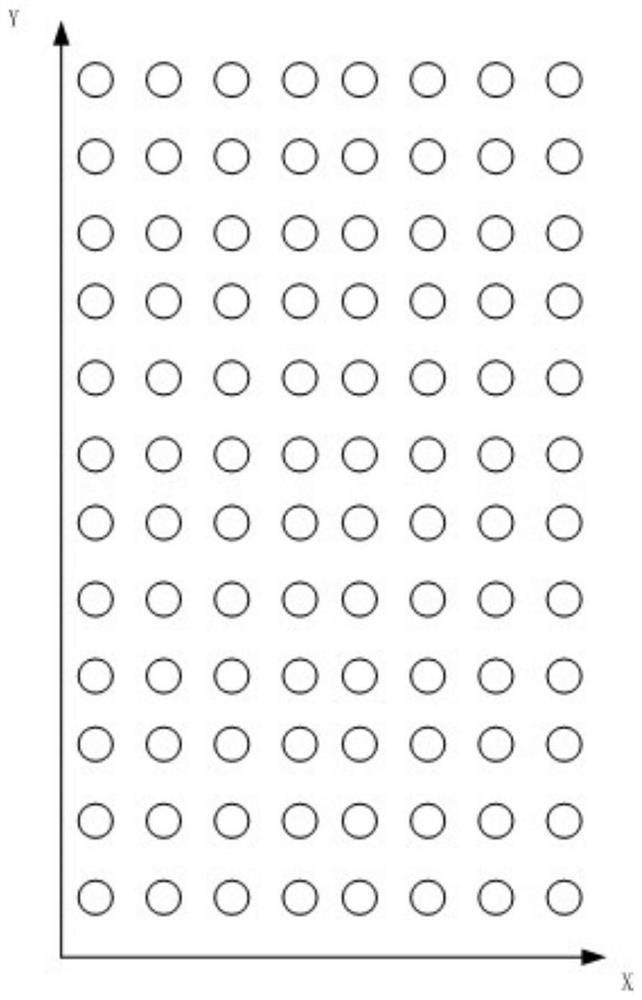

Distributed controllable heat source temperature field design method and system

InactiveCN111752318APrecise heating temperatureFlexible heating temperatureTemperatue controlCycle controlControl engineering

The invention discloses a distributed controllable heat source temperature field design method and system. The method comprises the steps of initializing each numerical value of a heat source system,presetting an ideal temperature for a controlled heat source through edge control equipment, and controlling a period; collecting information uploaded by the edge control equipment in the control cycle operation process; enabling a server to issue information detected by the peripheral edge control equipment according to the information uploaded by each piece of edge control equipment; and enabling the server to receive the information uploaded by each piece of edge control equipment, generate different temperature data and send the temperature data to each piece of edge control equipment, anda lot of edge control equipment being communicated with the server through the Ethernet. According to the invention, distributed heat source control adopted by a traditional temperature field is improved, so that the temperature field distribution is more reasonable; and the edge control equipment completes on-site calculation, so that the pressure of the server is reduced. The server can collectthe temperature of each temperature test point, and can count the time of each control point.

Owner:南京朝焱智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com