Novel batch heating machine for silica sand

A heating machine and silica sand technology, which is applied in the direction of silicon oxide and silicon dioxide, can solve the problems of inaccurate heating temperature, unstable production quality of silica sand, and uneven heating efficiency, so as to achieve accurate heating temperature and improve the stability of production quality , the effect of uniform heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

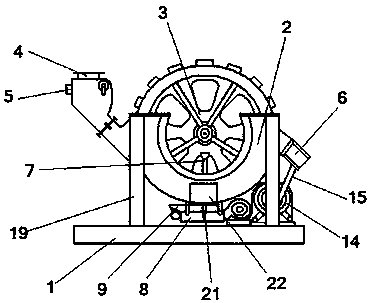

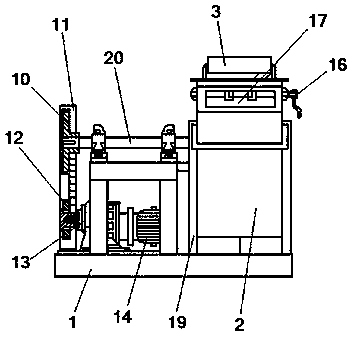

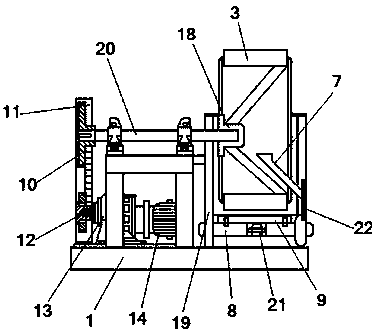

[0017] In order to make those skilled in the art better understand the technical solution of the present invention, the following in conjunction with the attached Figure 1-3 The present invention is further analyzed.

[0018] Such as figure 1 As shown, a new type of batch heating machine for silica sand, including: base 1, casing 2, runner assembly 3, feed port 4, rear cover 5, cylinder 6, sampling port 7, crank rod 8, discharge Door 9, large sprocket 10, protective cover 11, small sprocket 12, small sprocket flange 13, gear motor 14, transmission shaft 15, handle 16, flap gate 17, spoke 18, support body 19, drive shaft 20 , cotter pin 21 and temperature measuring thermocouple 22; casing 2 is arranged on the top side of base 1 through support body 19; inside casing 2 is vertically provided with runner assembly 3, and runner assembly 3 can be around drive shaft 20 rotates in the casing 2; the feeding port 4 is connected to one side of the casing 2; the side of the feeding po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com