Continuous proportioning system and method for refractory synthesis material

A raw material and refractory technology, applied in the field of refractory materials, can solve the problem of difficulty in guaranteeing the composition of the grinding materials, and achieve the effect of realizing large-scale production, ensuring stability and uniformity, and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

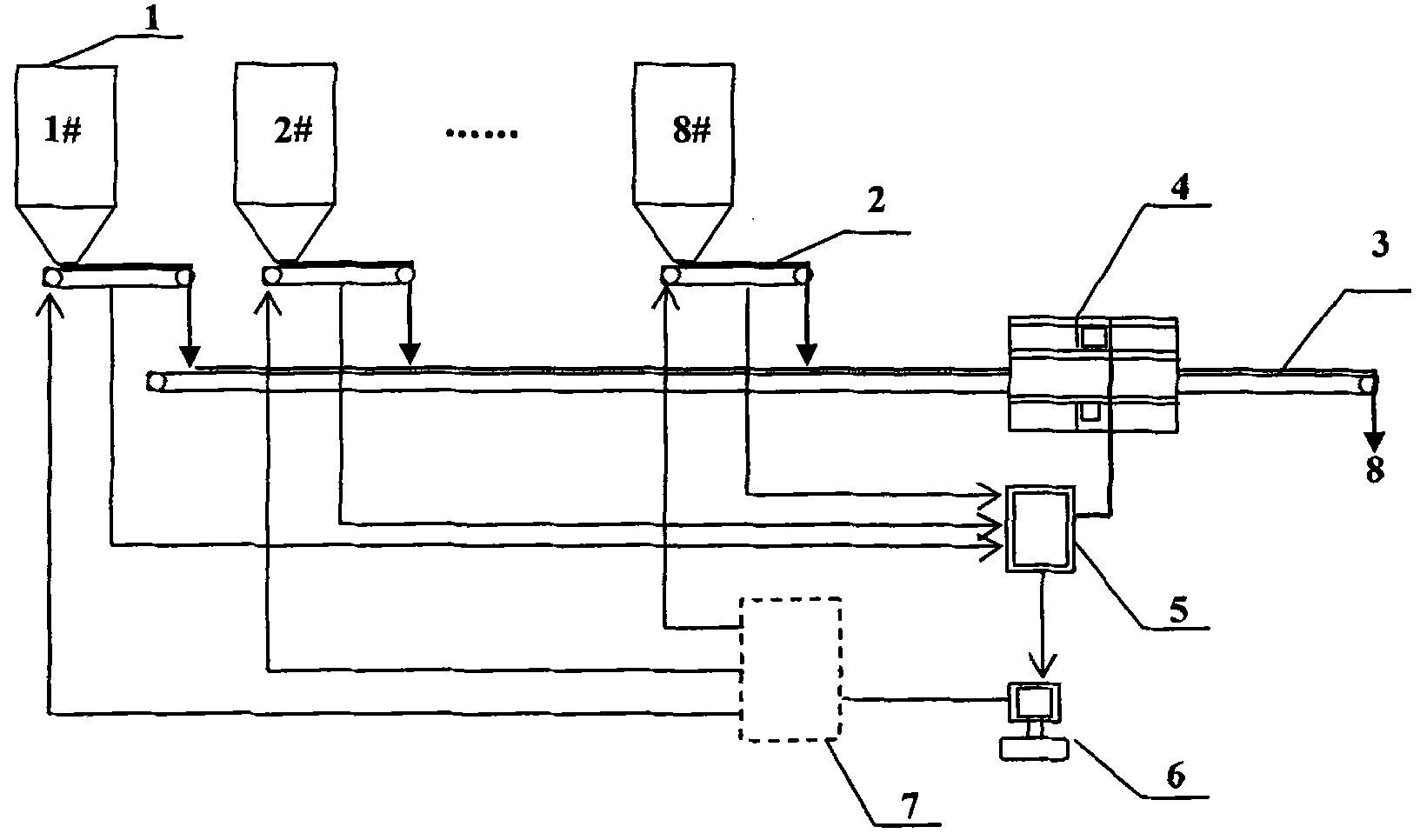

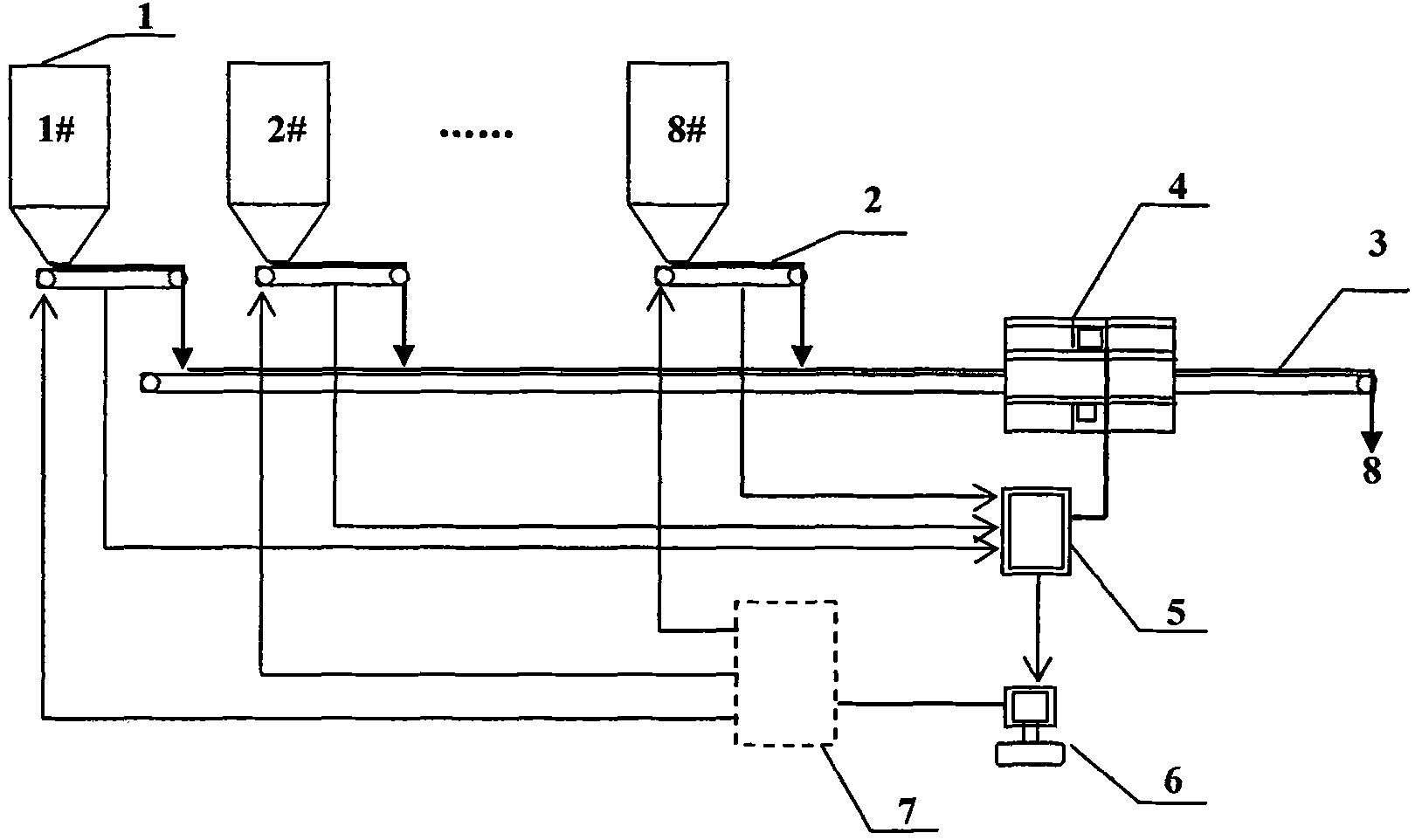

[0026] like figure 1 As shown, the system of the present invention includes a batching bin 1, a belt scale 2, a belt conveyor 3, an on-line element analyzer 4, an information data processing device 5, an operation console 6, a batching software to control the feeding ratio 7, and a grinding 8. The batching bins are respectively equipped with different grades of bauxite and additives, and belt scales with different ranges are installed under the batching bins. The obtained data is processed to obtain the composition of the material, and then the batching software is used to control the feeding ratio of the raw material according to the formula requirements, so as to realize the automatic control of batching.

[0027] Using the continuous batching system of the online elemental analyzer to produce a refractory synthetic raw material, the daily output reaches about 500 tons.

[0028] The 8 batching bins are respectively equipped with different grades of bauxite and additives. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com