Patents

Literature

121results about How to "Stable heating temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

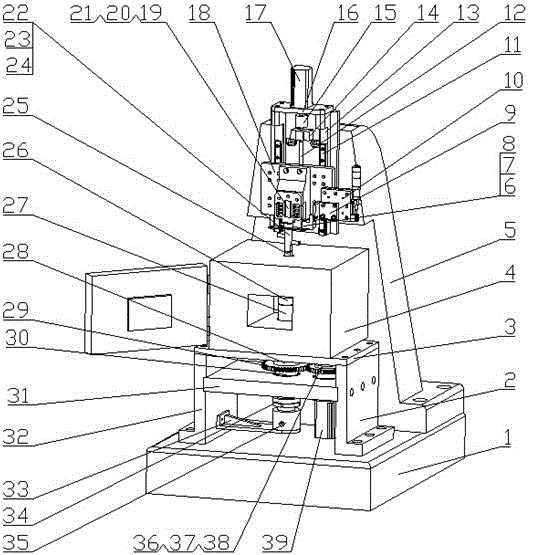

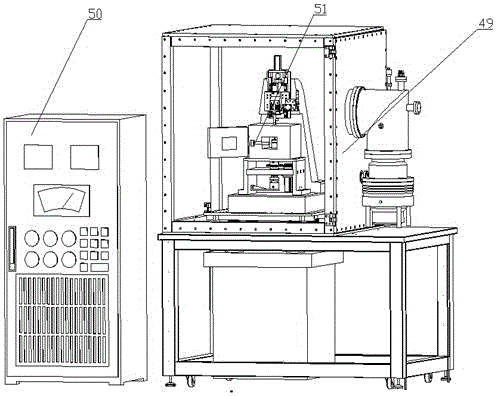

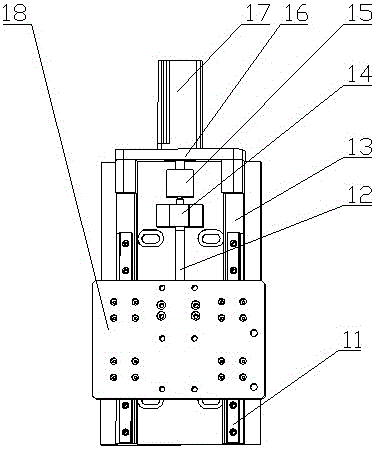

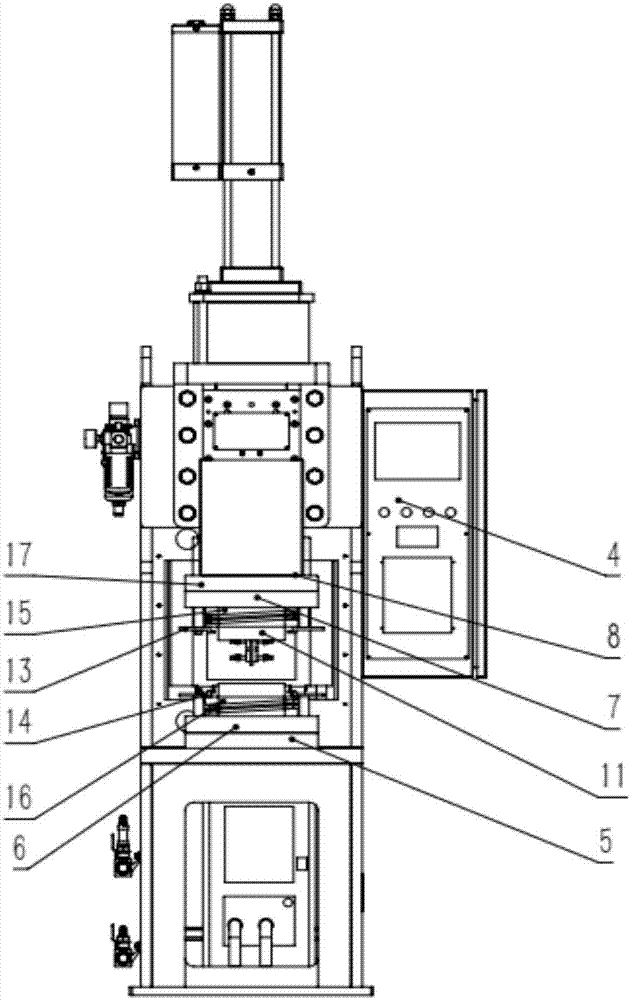

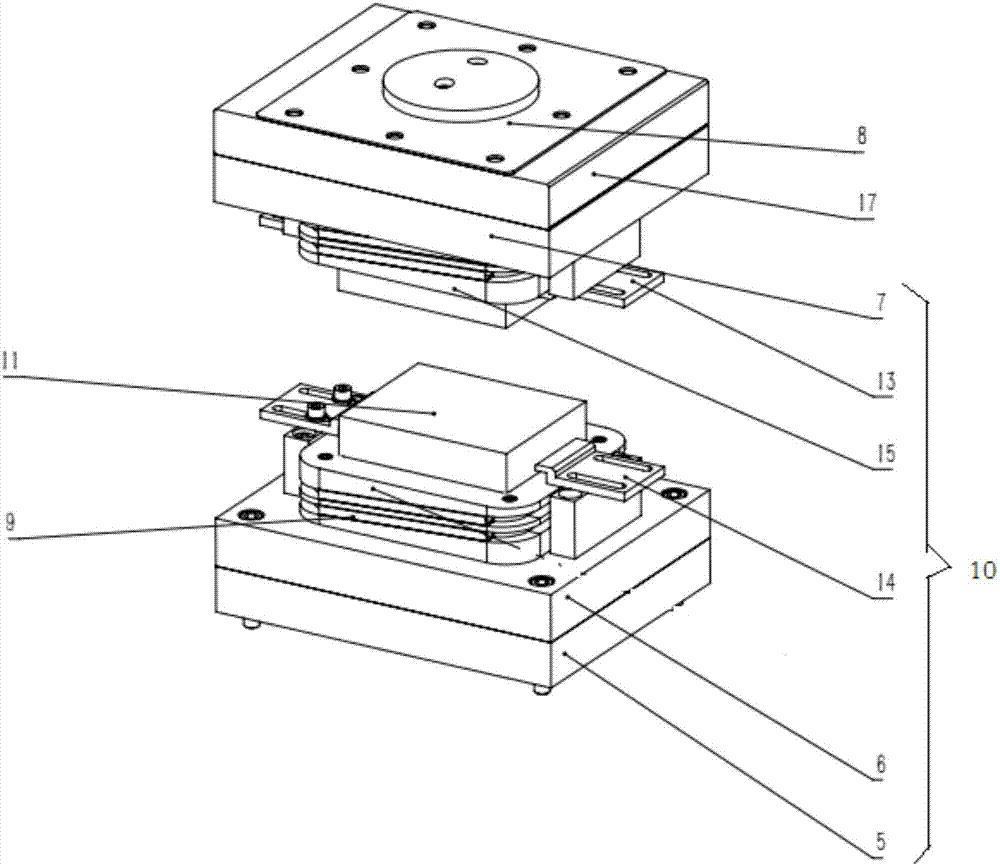

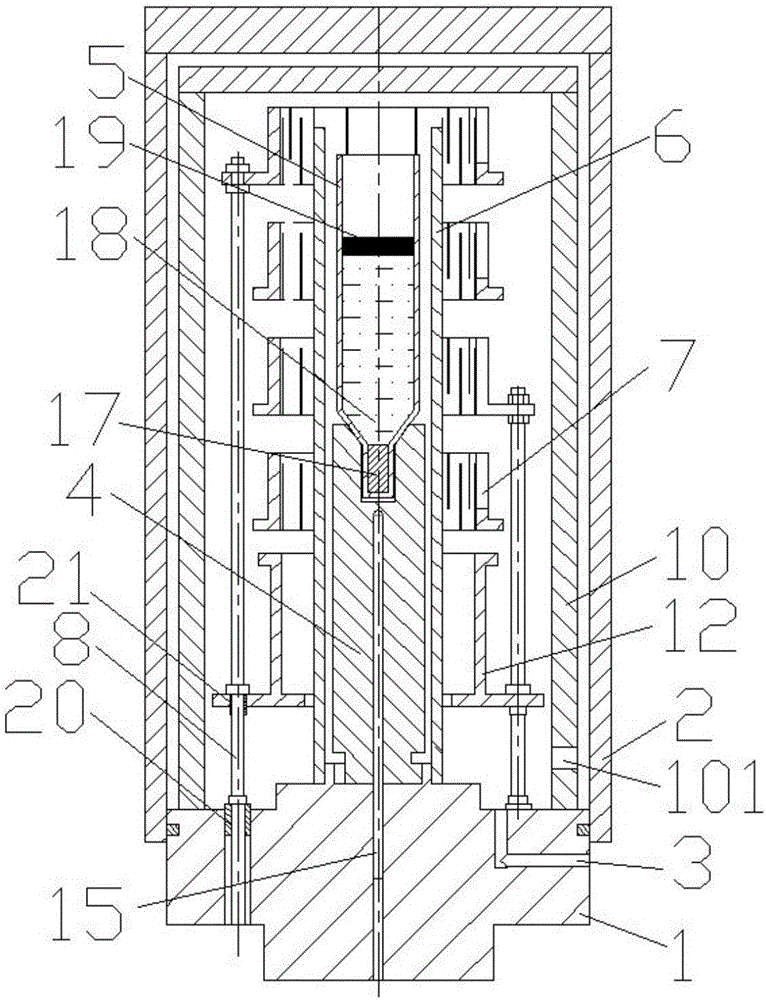

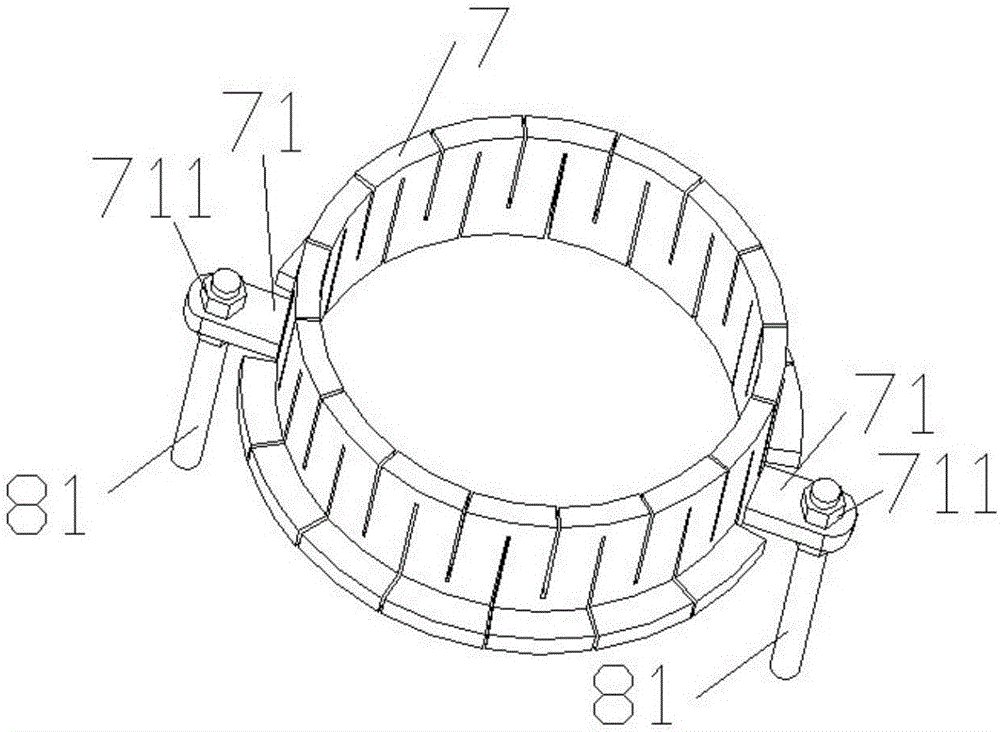

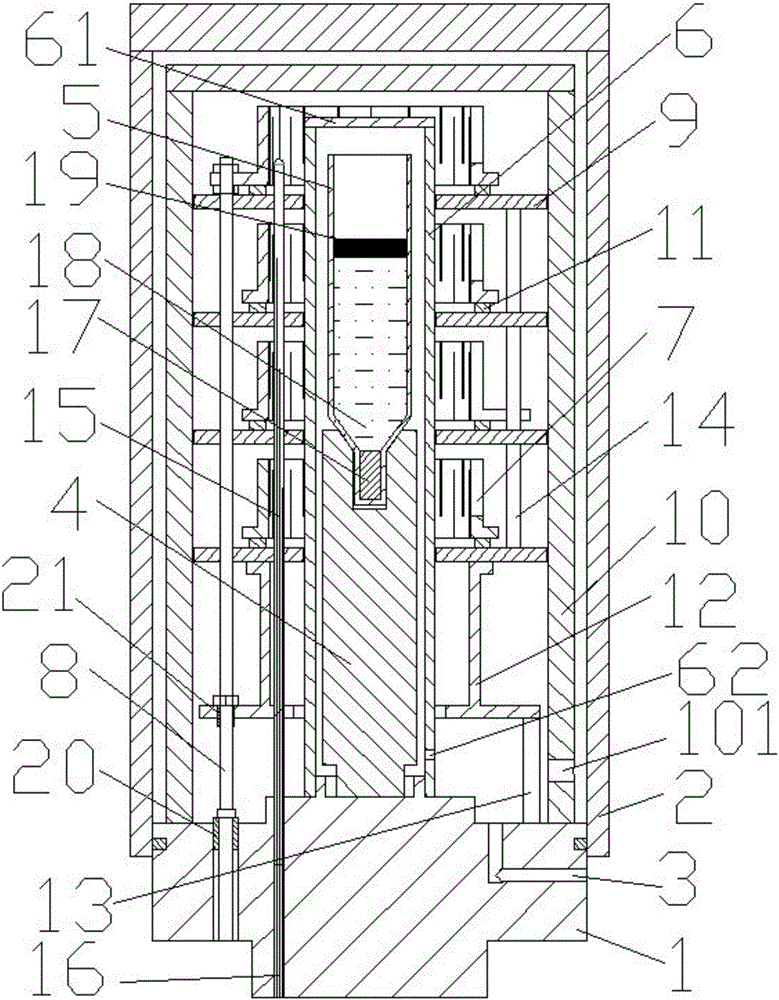

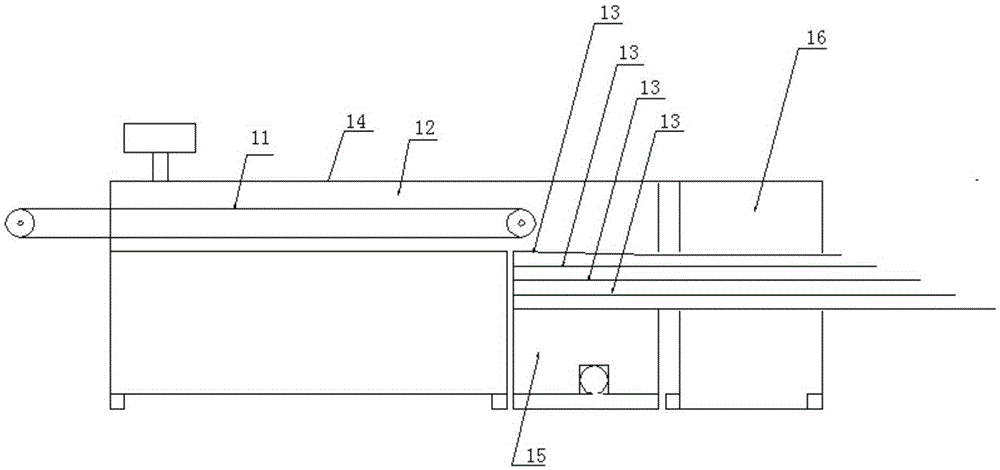

High-temperature micro-nano press mark test device and method in vacuum environment

PendingCN106404574AReduce the impact of collectionAvoid entanglementInvestigating material hardnessTest theoryMaterial hardness

The invention relates to a high-temperature micro-nano press mark test device and method in vacuum environment, and belongs to the field of mechanical and electronic integration precise instrument. The device can be used in vacuum environment; the oxidization caused by high-temperature environment on a press head and a test specimen can be prevented; the influence of air flowing on the test specimen heating is weakened; the stable heating temperature of the test specimen is ensured; further, the test analysis on the test specimen micro mechanical properties can be started; the characteristics parameters and the like of material hardness, elasticity modulus, creep properties and thermo-mechanical coupling effects are obtained so as to study the influence rule of variable-temperature and high-temperature environment on the material micro mechanical behaviors, deformation damage mechanisms and micro tissue structure evolution; the material and product design manufacturing, service prediction and reliability evaluation are guided. The structure of the device is compact; the measurement precision is high; the application range is wide; the wide application prospects are realized in the fields of material science, equipment manufacturing, ferrous metallurgy, national defense and military, aerospace and the like. According to the test method provided by the invention, the rich material micro mechanical property test theories and technical systems are combined.

Owner:JILIN UNIV

Self-heating heating bag and preparation method thereof

InactiveCN101513373AEasy to useEasy to carryHeat-exchange elementsTherapeutic coolingActivated carbonHeating time

The invention provides a self-heating heating bag and a preparation method thereof. The self-heating heating bag consists of content and a bag body, wherein the content is sealed inside the bag body; and the content contains iron powder, deionized water, activated carbon, vermiculite, sodium chloride, and a water-absorbing resin. The self-heating heating bag can quickly increase the temperature after the unsealing, and has steady heating temperature and permanent heating time; and the self-heating heating bag adopts environment-friendly and safe raw materials, has no toxicity, and can be safely used for human bodies.

Owner:北京绿伞科技股份有限公司

Active carbon activation furnace and active carbon production method

The invention discloses an active carbon activation furnace and an active carbon production method and relates to the field of active carbon production equipment and active carbon production technologies. The safety of an active carbon production process can be improved to a certain extent; the activation furnace works stably for a long term; and the quality and the productive capacity of produced active carbon are greatly improved. The active carbon activation furnace comprises a furnace body, a material entry device and a discharge mechanism, wherein the furnace body is internally provided with a burning passage communicated with the interior of the furnace body; air is admitted to the burning passage; the interior of the furnace body is in a negative pressure state; and air pressure in the burning passage is lower than that in the furnace body. The active carbon production method comprises the following steps: A: arranging the burning passage and material passages, B: admitting steam into the material passages, C: leading liberated gas in the material passages into the burning passage, D: heating materials in the material passages, and E: admitting flue gas generated by burning into a steam generator for heat exchange. The active carbon activation furnace and the active carbon production method are mainly used for active carbon production.

Owner:张西进

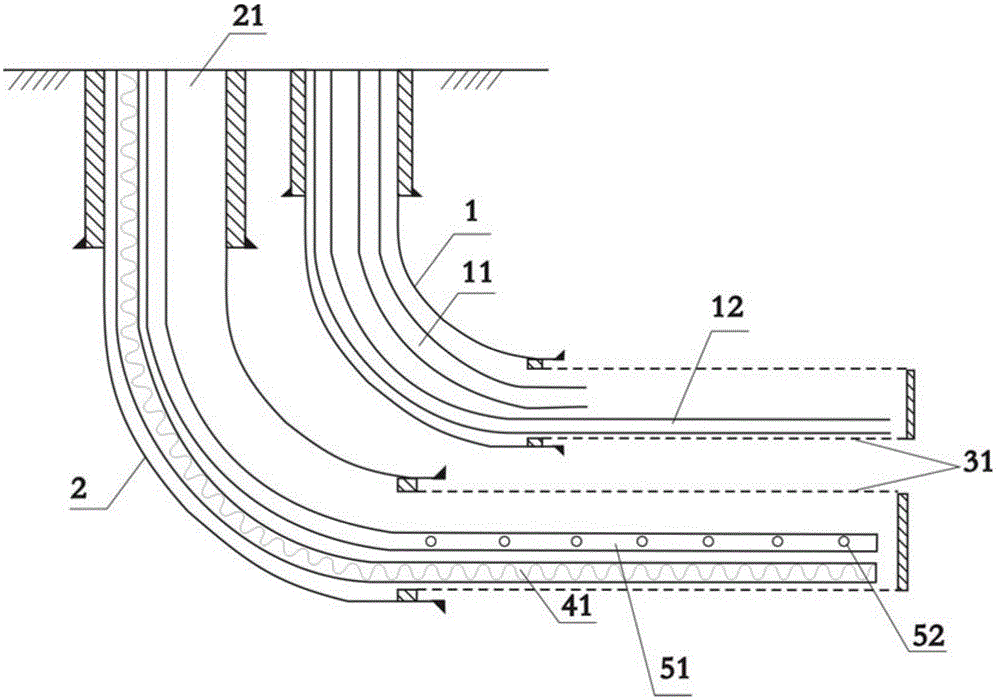

Well structure and method for underground modified mining of heavy oil and super heavy oil reservoir

ActiveCN104563981AFully exposed to the effect of modificationAchieve high temperature in-situ modificationFluid removalDrilling compositionElectrical resistance and conductanceMicrowave

The invention provides a well structure and a method for underground modified mining of a heavy oil and super heavy oil reservoir. The well structure comprises oil tubes, a catalyst injection tube and a heating device; injection holes unevenly distributed are formed in the horizontal section of the catalyst injection tube; the heating device comprises a high-energy fused salt heating tube, an electric heating tube, an electric resistance wire heating device, an electromagnetic heating device, a radio-frequency heating device or a microwave heating device; the oil tubes comprise parallel dual oil tubes, concentric dual oil tubes or single continuous punched oil tubes; the invention also provides the method for performing the modified mining on the heavy oil reservoir by utilizing the well structure. According to the well structure and the method for the underground modified mining of the heavy oil and super heavy oil reservoir, provided by the invention, oil can be rapidly dissolved and the viscosity of crude oil is greatly reduced, so the fluidity of mined fluid is further increased, and long-time continuous modification of the oil reservoir can be realized.

Owner:PETROCHINA CO LTD

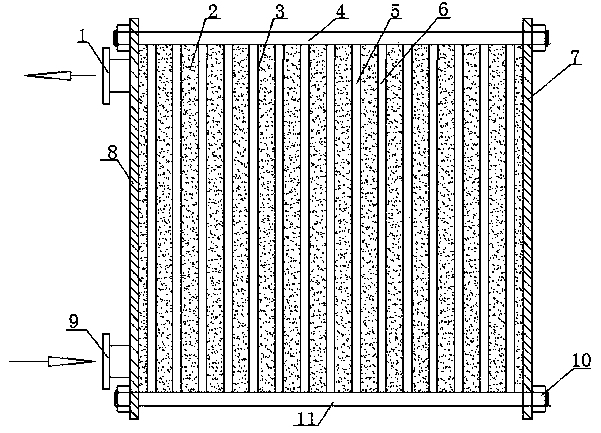

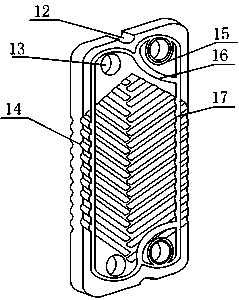

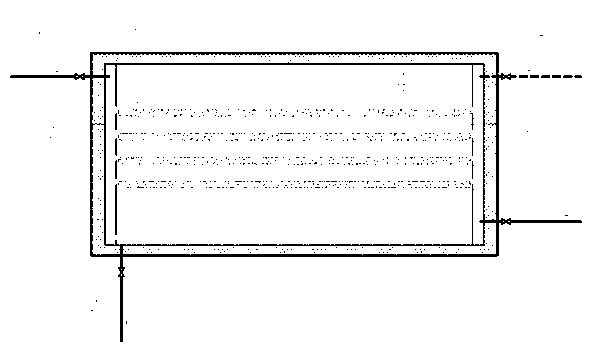

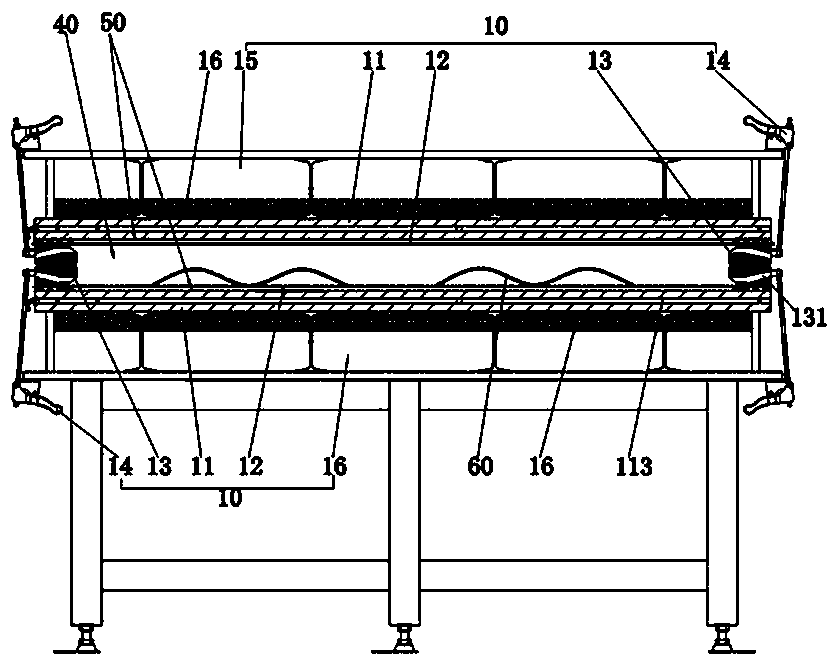

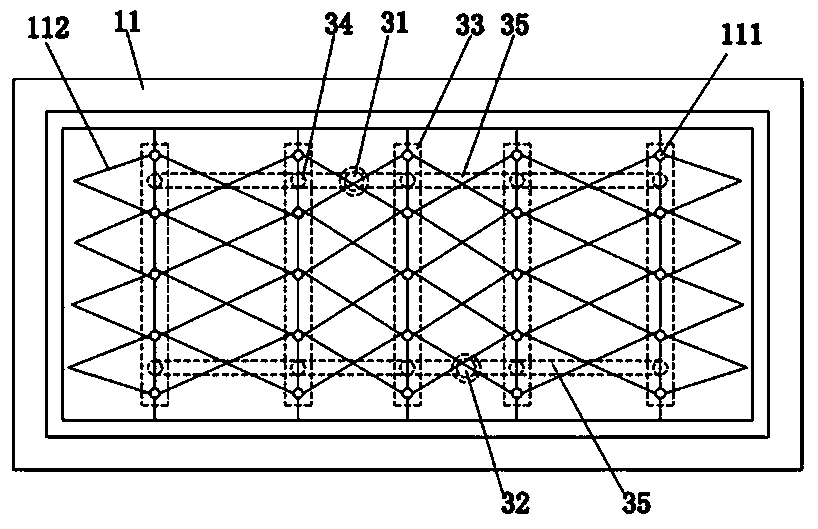

Plate type phase-change thermal storage heat exchanger capable of supplying heat stably

InactiveCN103900404AImprove sealingReduce volumeHeat storage plantsStationary plate conduit assembliesHot workingMechanical engineering

The invention discloses a plate type phase-change thermal storage heat exchanger capable of supplying heat stably. The plate type phase-change thermal storage heat exchanger comprises a plurality of seal boxes arranged in parallel. A phase-change thermal storage body is arranged in each seal box. Corner holes are formed in the four corners of each seal box respectively. A sealing part is arranged between any two adjacent seal boxes, and the two corner holes in the same side end of each seal box are separated through the sealing part. Any two adjacent sealing parts are arranged in parallel at the 180-degree included angle. Hot working medium flowing cavities and cold working medium flowing cavities are defined by the seal boxes through the sealing parts, wherein the hot working medium flowing cavities and the cold working medium flowing cavities are distributed alternately. The plate type phase-change thermal storage heat exchanger further comprises an outer frame. The seal boxes are pressed tightly and sealed by the outer frame. A cold working medium inlet and outlet and a hot working medium inlet and outlet are further formed in the outer frame and are communicated with the corner holes. The plate type phase-change thermal storage heat exchanger is small in size and convenient to assemble, disassemble and maintain; phase-change thermal storage materials are adopted for thermal storage, so the defect that heat supply is not stable is effectively overcome, the heat supply time is prolonged, the stable heat supply temperature can be maintained, the stability is good, and the working media do not influence each other.

Owner:SICHUAN PROVINCIAL ARCHITECTURAL DESIGN & RES INST

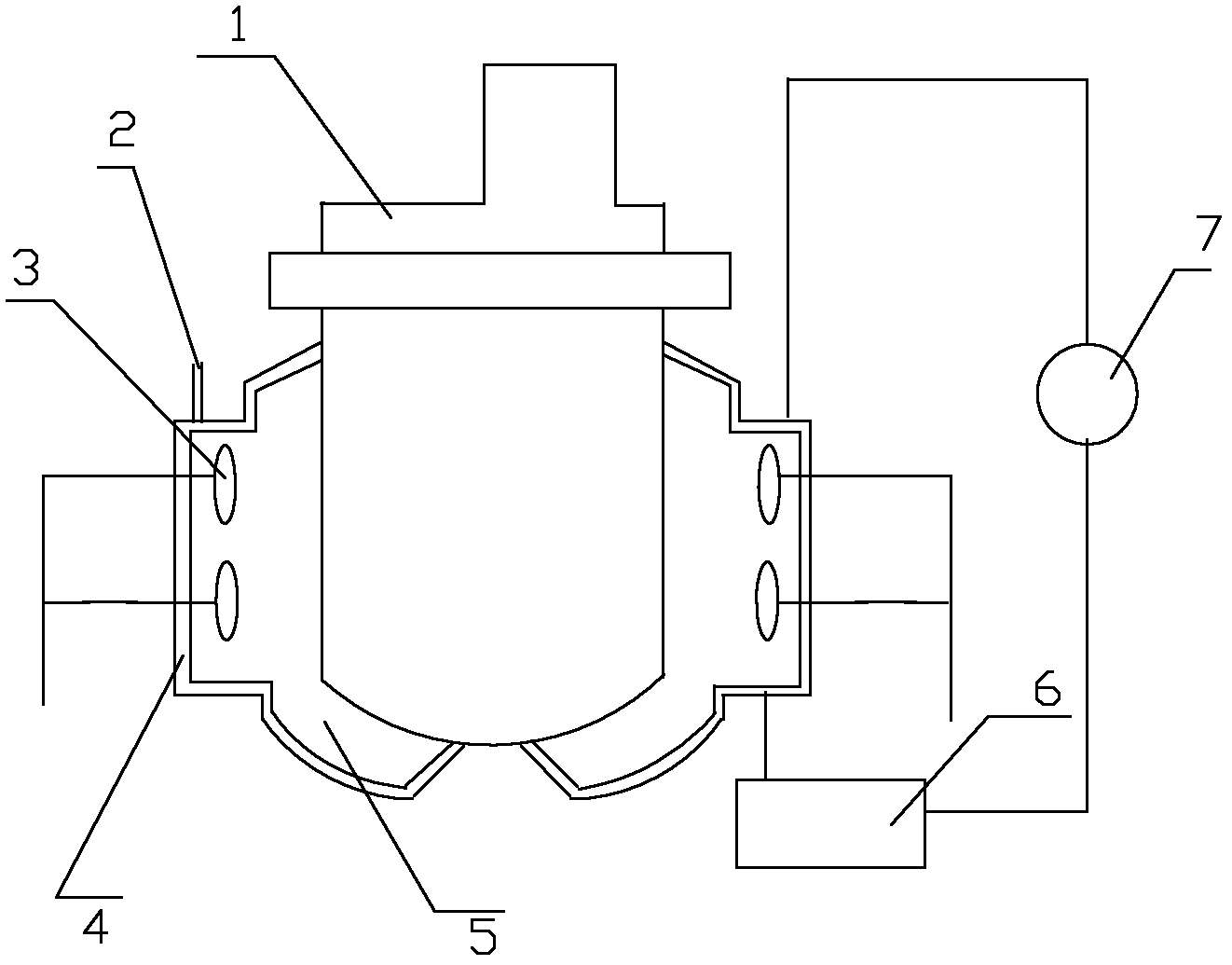

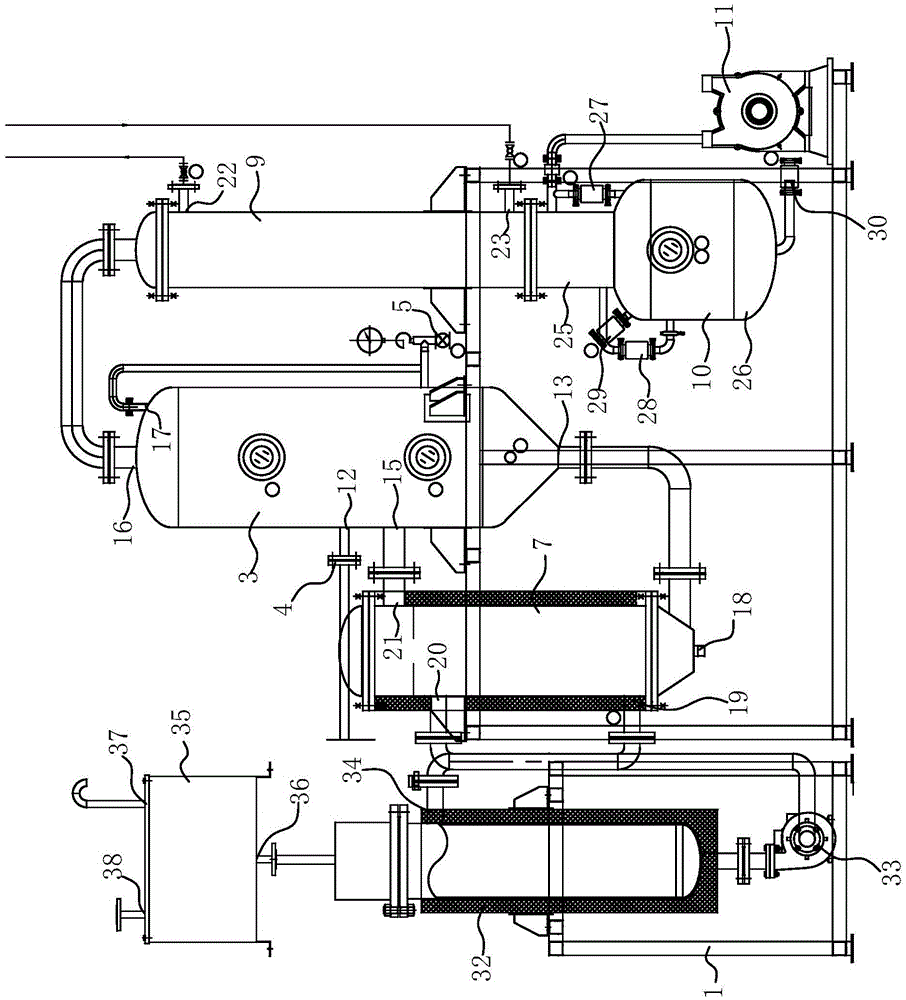

Conduction oil heating reaction kettle system

InactiveCN103100361AStable heating temperatureImprove response qualityChemical/physical/physico-chemical processesThermal fluidsOil pump

The invention discloses a conduction oil heating reaction kettle system. The system comprises a reaction kettle, a heat-conducting jacket arranged outside the reaction kettle and filled with conduction oil, and a plurality of parallel electric heating devices in the heat-conducting jacket, and further comprises an oil tank and a circulating oil pump for circulating the oil in the heat-conducting jacket and the oil in the oil tank. The heat-conducting jacket is connected with the oil tank through the circulating oil pump which is used for circuiting the oil in the heat-conducting jacket and the oil in the oil tank; and therefore, the conduction oil in the heat-conducting jacket is always at a constant temperature to heat the reaction kettle, the stabilization of the heating temperature is guaranteed, and the reaction quality is greatly improved.

Owner:天津市天诚化工有限公司

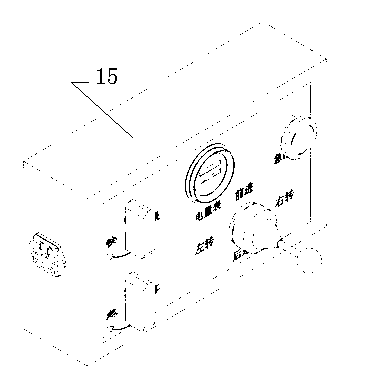

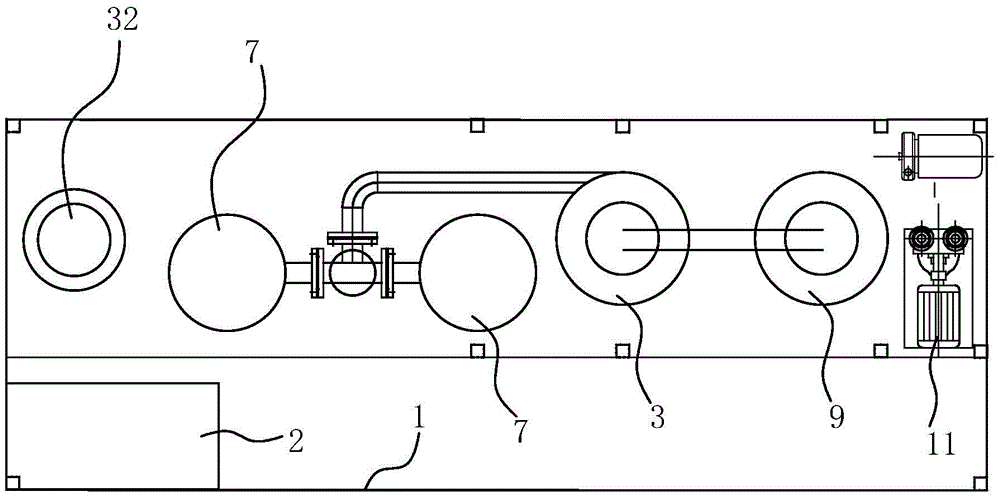

Multifunctional SF6 inflating trolley

InactiveCN103129591AAvoid rubbingExtended service lifeHand carts with multiple axesHand cart accessoriesFree rotationElectric machinery

The invention discloses a multifunctional SF6 inflating trolley. The multifunctional SF6 inflating trolley comprises a power transfer system for bearing and carrying air bottles and is characterized in that the power transfer system is a double-motor driven caterpillar band system for achieving 360-degree free rotation of a machine. The multifunctional SF6 inflating trolley further comprises a front flat ground walking wheel and a back flat ground walking wheel which are used for walking on the flat ground and are provided with a front flat ground walking wheel rising and falling mechanism and a back flat ground walking wheel rising and falling mechanism for controlling the walking wheels to perform rising and falling driving. The multifunctional SF6 inflating trolley is simple in structure, safe, reliable and labor-saving and improves carrying efficiency.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO LTD MAINTENANCE BRANCH +2

Closed type plane phase change hot accumulating tank heating system

InactiveCN103062828AMeet different heat transfer needsLarge heat storageLighting and heating apparatusCentral heating systemInsulation layerEngineering

The invention discloses a closed type plane phase change hot accumulating tank heating system. The system comprises a hot accumulating water tank (1), a clamping plate (2), a flow-guide slot (3), a phase change hot accumulating plate (4), an insulating layer (5), a water tank heat exchanging tube (6), a water injecting tube (7), a hot water supplying tube (8), a heating supplying source (10), a drain tube (11) and a hot water heat exchanger (12), wherein valves are installed on tubes and are used for adjusting the flow, and the hot water supplying tube is connected to the hot accumulating tank in a closing or opening mode. When the heating supplying source heats the hot accumulating water tank through the water tank heat exchanging tube, the surplus heat can be stored in a phase change hot accumulating material. When the heating supplying source stops running or the water of the hot accumulating water tank fails to reach the heating temperature through the heating, the phase change hot accumulating plate can release the heat, and the heating hot water maintains at the heating temperature. The phase change hot accumulating material has large hot accumulating amount and stable temperature, the defect of unstable hearting of the heating supplying source is solved, and the system can reduce the volume of the hot accumulating water tank greatly.

Owner:CHONGQING UNIV

Open planar phase change heat storage tank

InactiveCN102997733AMeet different heat transfer needsLarge heat storageHeat storage plantsInsulation layerThermal insulation

The invention discloses an open planar phase change heat storage tank. The heat storage tank mainly comprises a heat storage water tank (1), a clamping groove plate (2), a guide groove (3), a phase change heat storage plate (4), a thermal insulation layer (5), a high-temperature hot water injection pipe (6), a hot water supply pipe (7) and a water return pipe (8). Valves are installed on the pipes to regulate flow, a phase change heat storage material is installed in the phase change heat storage plate, a phase change material with the phase change temperature to be equal to hot water temperature is adopted according to requirements, and a phase change temperature range is 0-100 DEC G. When high-temperature hot water is supplied, the hot water is injected in the heat storage water tank, and heat of the hot water is stored in the phase change heat storage material. When supply of the high-temperature hot water is stopped, the phase change heat storage plate releases heat to enable water in the water tank to maintain the phase change temperature and supplies heat. The open planar phase change heat storage tank utilizes the advantages of large heat storage and stable temperature of the phase change material, overcomes the defect of unstable heat supply of a heat supply source, prolongs heat supply time, maintains stable heat supply temperature, and can greatly reduces volume of the heat storage water tank.

Owner:CHONGQING UNIV

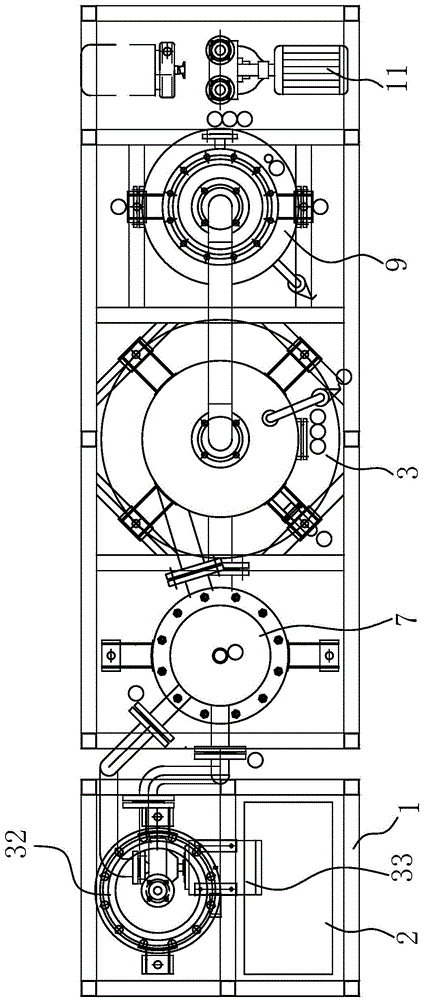

Chemical nickel waste liquid integrated processing system

ActiveCN105601016ARealize resource reuseSolve resource reuseWaste water treatment from metallurgical processMultistage water/sewage treatmentLiquid wasteCooling tower

Disclosed is a chemical nickel waste liquid integrated processing system. The chemical nickel waste liquid integrated processing system is characterized in that solid-liquid separation can be performed on chemical nickel waste liquid, and the system comprises an evaporation device, a cooling tower, a conduction oil circulating device, an electric control cabinet and an automatic control unit; the evaporation device comprises a steam-liquid separator, a feeding electric valve, an emptying valve, a heating chamber, a condenser, a water storage tank and a vacuum pump; the water storage tank is composed of a first tank body and a second tank body. The chemical nickel waste liquid integrated processing system is high in integration degree, small in occupied area and capable of safely, stably and effectively removing phosphorus, nickel and COD in chemical nickel waste liquid, no secondary pollution is generated, and the processed chemical nickel concentrated solution has the recycling value.

Owner:苏州市东方环境工程有限公司

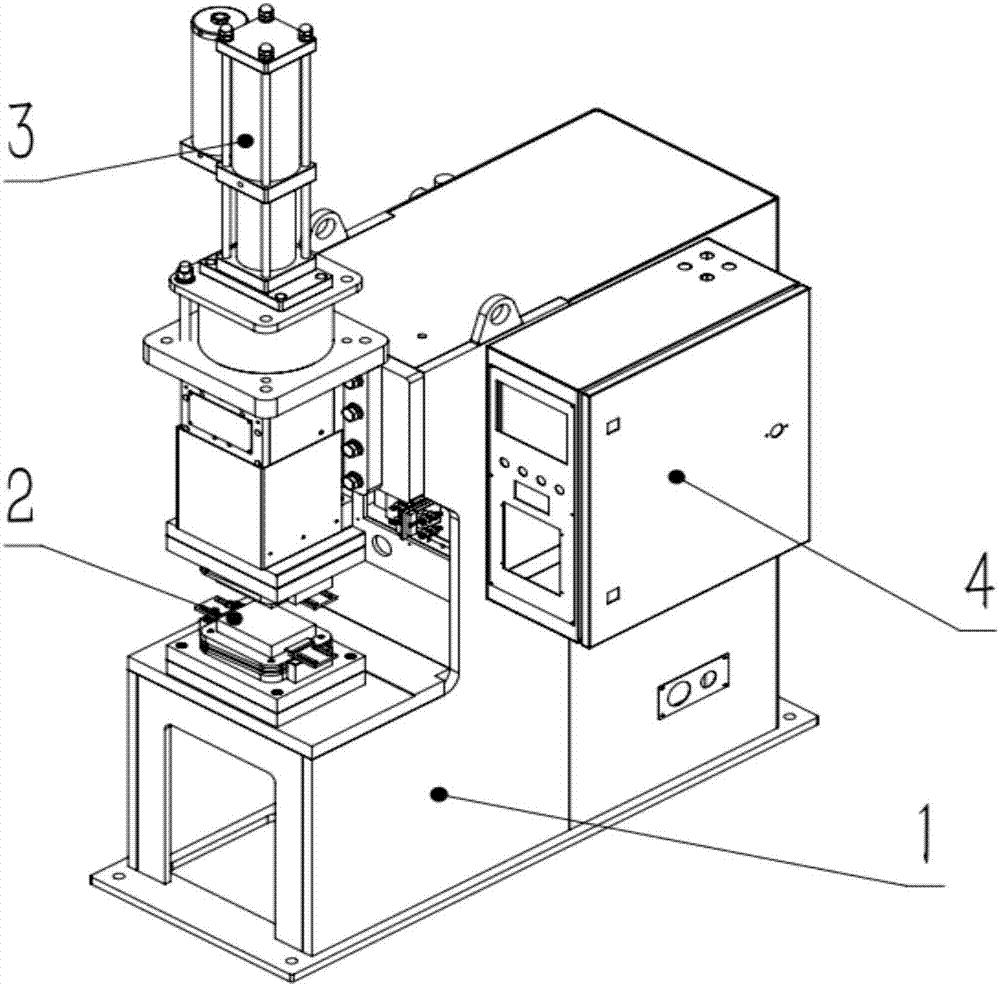

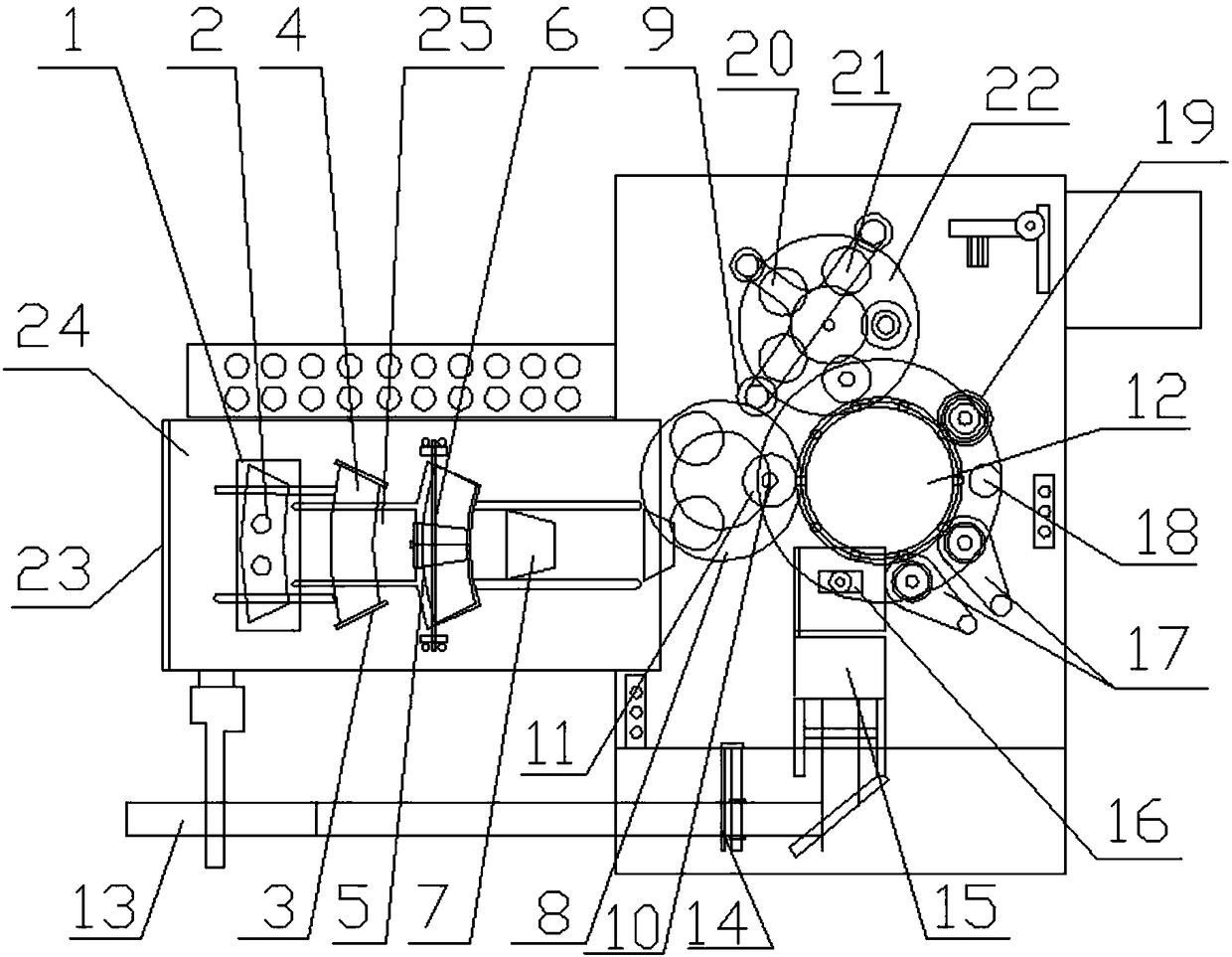

Aluminum soft connection welder and welding process

InactiveCN107378224AStable heating temperatureHeating evenlyWelding/soldering/cutting articlesNon-electric welding apparatusTemperature controlAgricultural engineering

The invention discloses an aluminum soft connection welder which comprises a rack, a welding mechanism, pressurizing equipment and a control cabinet. The welding mechanism is mounted on the rack, the pressurizing equipment is arranged above the welding mechanism, the control cabinet is arranged on one side of the rack, the welding mechanism comprises a lower seat, a lower supporting platform and an upper supporting platform, the lower supporting platform is arranged on the lower seat, the upper supporting platform and the lower supporting platform are in up-down arrangement, the upper supporting platform is connected with the pressurizing equipment through an insulating plate, the lower supporting platform is a cell body, a disc-type induction coil is arranged in the lower supporting platform, the lower end of the upper supporting platform is connected with an upper graphite platform while the upper end of the same is connected with a lower graphite platform, two graphite electric agglomerates are arranged between the upper graphite platform and the lower graphite platform, and a connecting member is put between the graphite electric agglomerates. The aluminum soft connection welder can realize uniform heating and is more accurate in temperature control.

Owner:无锡海菲焊接设备有限公司

Novel surface photovoltaic module laminating machine and machining method thereof

PendingCN109461792AExtended service lifeGuaranteed contact areaFinal product manufacturePhotovoltaic energy generationState of artEngineering

The invention aims at the problem that in the prior art, the heating efficiency of a laminating machine in the laminating process is low, and provides a surface photovoltaic module laminating machine.The surface photovoltaic module laminating machine comprises an upper heating box and a lower heating box which are arranged face to face, a gas supplying, heating and pressurizing device and a vacuumizing device; each heating box comprises a cavity top plate, an elastic cavity partition plate and pressing strips which arrange the edges of the cavity partition plate on the cavity top plate in a sealing mode, wherein a heating cavity is formed between the cavity partition plate and the cavity top plate; the pressing strips of the two heating boxes face each other, the two cavity partition plates which are arranged face to face and the pressing strips form a sealed laminating cavity when the upper heating box and the lower heating box are closed, and the vacuumizing device is communicated with the two heating cavities and the laminating cavity; the gas supplying, heating and pressurizing device is communicated with the heating cavities and can fill heated and pressurized gas into the heating cavities; and the cavity partition plates are directly heated while pressure is generated by means of the heated gas, and therefore the heating efficiency in the laminating process is greatly improved.

Owner:HEBEI NORMAL UNIVERSITY OF SCIENCE AND TECHNOLOGY

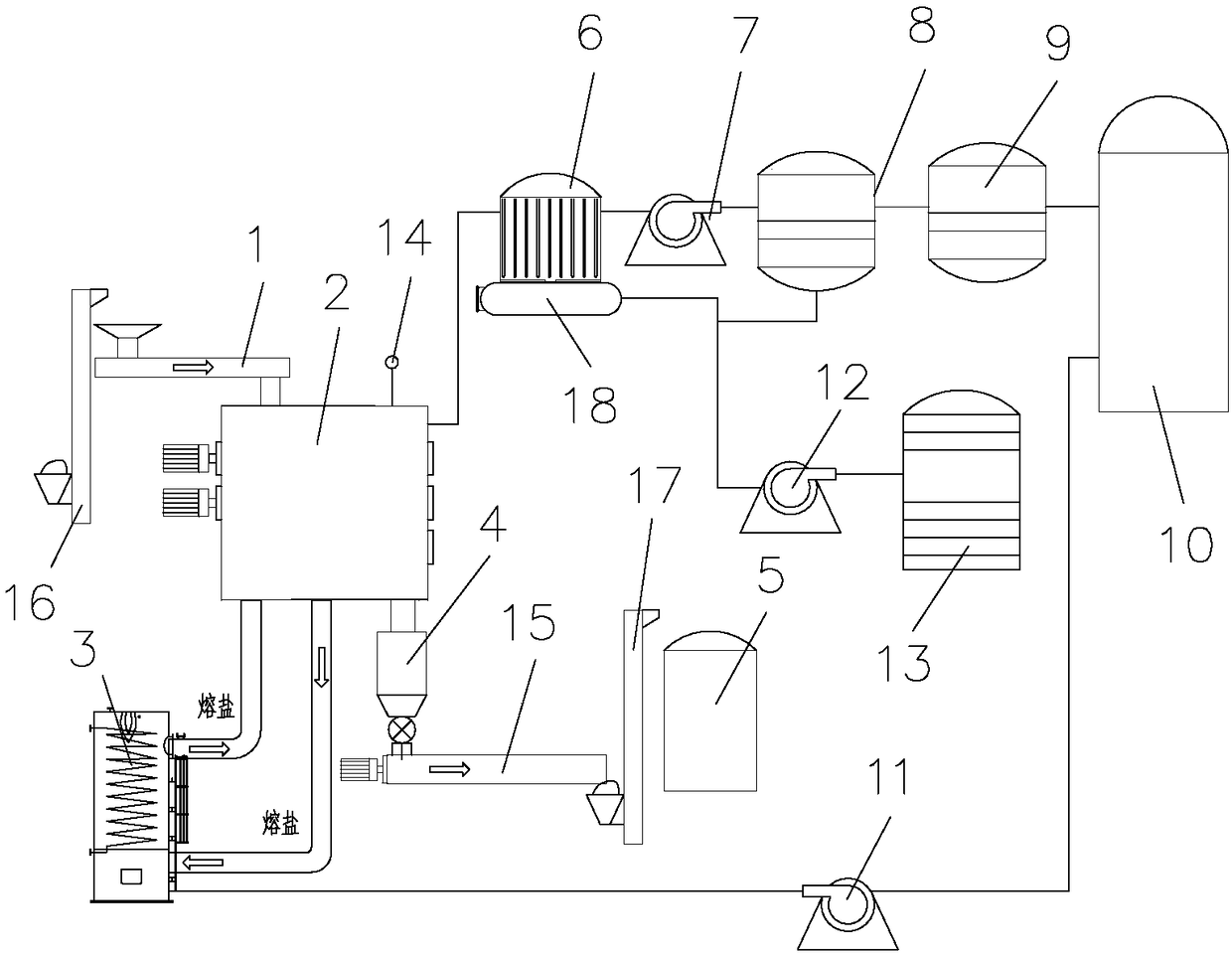

Carbonization cracking system for waste plastics

PendingCN108285800AStable heating temperatureReduce energy consumptionProductsReagentsEnergy consumptionSpecific heat

The invention discloses a carbonization cracking system for waste plastics. The system utilizes a molten salt furnace to provide heating heat for a cracking furnace, so that a material in the crackingfurnace is continuously cracked, and a combustible gas generated by cracking of the material is used as a fuel of the molten salt furnace to maintain continuous heating of the molten salt by the molten salt furnace; the molten salt circularly flows in the cracking furnace and the molten salt furnace, so that a cracking chamber is heated continuously; and because a specific heat capacity of the molten salt is larger, the molten salt has a temperature of about 500 DEG C when flowing out from the molten salt furnace, and the molten salt has a temperature of about 480 DEG C when flowing back to the molten salt furnace, a cracking temperature difference is only about 20 DEG C, so that the entire carbonization cracking process is performed in a very stable temperature range. According to the system provided by the invention, in the above way, firstly, the material can be fully cracked; and secondly, the combustible gas generated by cracking is directly utilized, so that the molten salt furnace does not need to consume an external combustible gas, energy consumption of the carbonization cracking system is reduced, and a utilization rate of the material is improved.

Owner:光大绿色环保技术服务江苏有限公司

Full-automatic medium-speed paper container molding machine

InactiveCN108162481AReasonable structural designHigh degree of intelligencePaper-makingBox making operationsMolding machinePulp and paper industry

The invention discloses a full-automatic medium-speed paper container molding machine. The machine comprises a paper rack; the paper rack is provided with a paper sucking mechanism and a paper conveying mechanism; the end part of the paper conveying mechanism is connected with a cup cylinder molding mechanism; a ultrasonic sealing mechanism is arranged above the cup cylinder molding mechanism; a cup cylinder demolding and feeding mechanism is arranged at the downstream of the ultrasonic sealing mechanism; an outlet end of the cup cylinder demolding and feeding mechanism is aligned to a manipulator turntable; an oil coater is arranged on one side of the manipulator turntable; a cup cylinder top feeding connecting rod is arranged on the manipulator turntable, and is connected with a moldingstation mold; a main rotating station disc is arranged at the front part of the molding station mold; a cup bottom raw paper rack is mounted on one side of a panel, and is connected with a paper pulling mechanism; the paper pulling mechanism is connected to a cup bottom blanking molding mechanism by a paper feeding mechanism; the cup bottom blanking molding mechanism is positioned at the lower part of the main rotating station disc; a bottom heating mechanism, a folding molding mechanism and a knurling mechanism are arranged on the main rotating station disc; and a winding port molding bottomsupport station disc is mounted on one side of the main rotating station disc.

Owner:ANHUI YIBAILI ENVIRONMENTAL TECH CO LTD

Production technology of Rosa roxburghii tea

InactiveCN102366013AEvenly heatedRapid sterilizationTea substituesNutritive valuesProcess engineering

The invention discloses a production technology of a Rosa roxburghii tea. The production technology comprises the following steps: 1, selecting wild Rosa roxburghii in a strong wind rolling net mode, and selecting wild Rosa roxburghii in size by screening; drying by a ventilated constant temperature dryer, carrying out microwave sterilization, crushing into particles with the size of 40 meshes, and carrying out vacuum packaging on the particles. The ecological, natural, green and healthy Rosa roxburghii tea provided in the invention allows an original flavor and nutrition values of Rosa roxburghii to be well preserved.

Owner:兴义市东泰天然果蔬开发有限公司

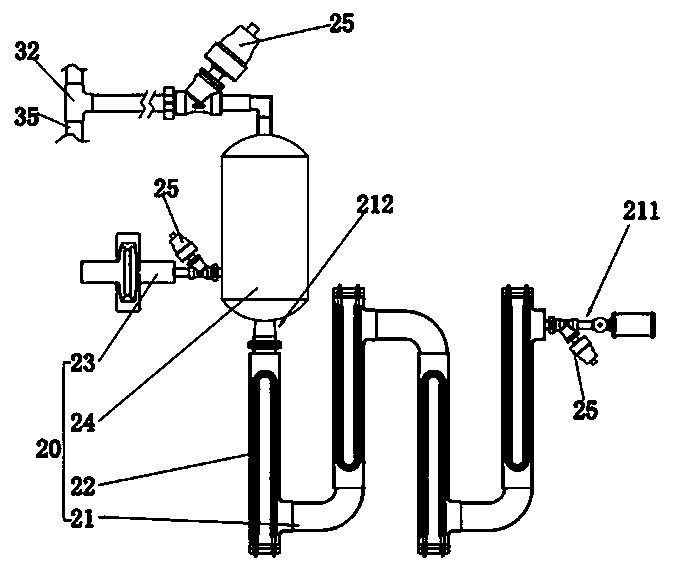

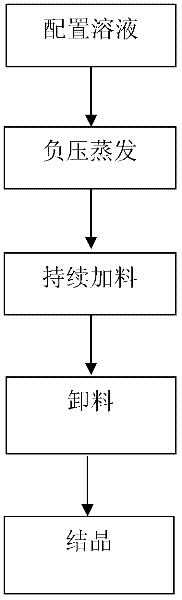

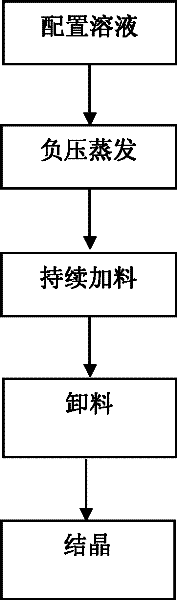

Negative pressure evaporation and step-by-step feeding method of nickel sulfate solution

The invention discloses a negative pressure evaporation and step-by-step feeding method of a nickel sulfate solution. The method comprises the following steps: preparing the nickel sulfate solution to be produced; performing vacuum pumping on a negative pressure evaporator; performing continuous heating on the solution in the negative pressure evaporator; performing cooling and crystallization on the concentrated solution; and further performing step-by-step feeding. The method is characterized in that the step-by-step feeding and the vacuum pumping operation are simultaneously performed. Therefore, the volume of the evaporation device can be fully utilized, the number of times of operation can be reduced, and the purpose of improving working efficiency can be further achieved. The method disclosed by the invention has the characteristics of fast evaporation speed, high production efficiency and simple operation, the number of equipment used by the method is small, and the equipment occupies small area, and is environment-friendly and pollution-free.

Owner:广东芳源新材料集团股份有限公司

Processing line of bast fiber

ActiveUS8650717B2Easy to collectEasy to processContinuous processingFibre cleaning/openingCardingEngineering

A processing line of bast fiber is provided. The processing line is comprised of various devices for carding, cutting, degumming, high temperature washing, separating and water washing, softening, drying, batching and applying oil, permeating and reconditioning, stretching-breaking carding, and combing and sorting. The processing line of bast fiber can improve production efficiency, and improve the yield of long hemp fibers. Moreover, the produced fiber has stable quality and is convenient for post-processing.

Owner:WUHAN HEMP BIOLOGICAL TECH CO LTD +2

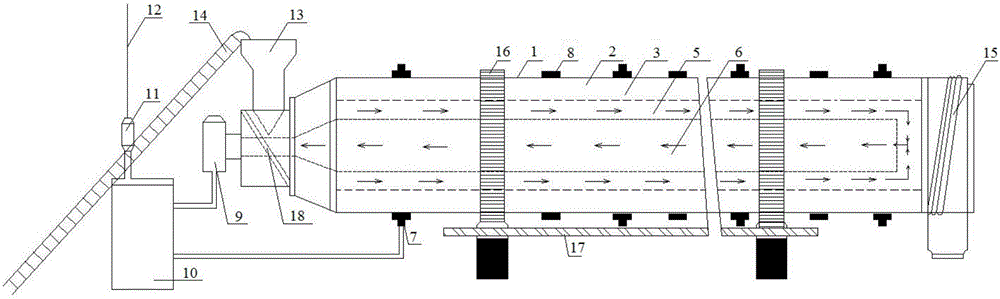

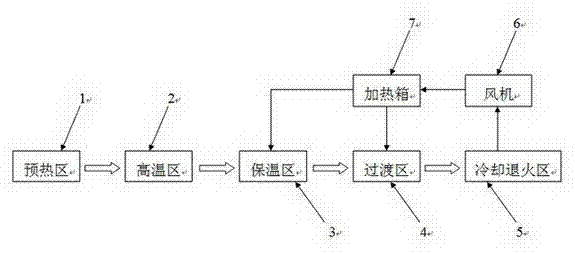

Roller kiln for producing microcrystalline foam ceramic

ActiveCN103175395AStable heating temperatureSmall temperature differenceFurnace typesCeramic materials productionHeat conservationAir blower

The invention relates to the field of sintering kilns, in particular to a roller kiln for producing microcrystalline foam ceramic. The roller kiln for producing the microcrystalline foam ceramic comprises a preheating zone, a high temperature zone, a heat preservation zone and a cooling annealing zone. A burner of the preheating zone is arranged below a product. A burner of the high temperature zone is arranged above the product, the spraying direction of the burners is perpendicular to the moving direction of the product, and the caustic surface of the burner is arranged like a Chinese character 'pin'. An impulse burner is adopted as a burner of the heat preservation zone, a transition zone is arranged between the heat preservation zone and the cooling annealing zone, and the transition zone is an air brattice formed by a hot air burner. The hot air burner is connected with an air pipe, and the air pipe is further connected with the cooling annealing zone and the heat preservation zone. An air blower and a heating box are also arranged inside the air pipe, an air inlet of the air blower is connected with the cooling annealing zone, and an air outlet of the air blower is connected with the transition zone and the heat preservation zone through the heating box. According to the roller kiln for producing the microcrystalline foam ceramic, heated temperature of the microcrystalline foam ceramic is stable, temperature difference is small, product quality is improved, and production efficiency is greatly improved. Due to the fact that a hot air circulating system is adopted, energy consumption is reduced, and the roller kiln for producing the microcrystalline foam ceramic is environmentally friendly and saves energy.

Owner:刘德文

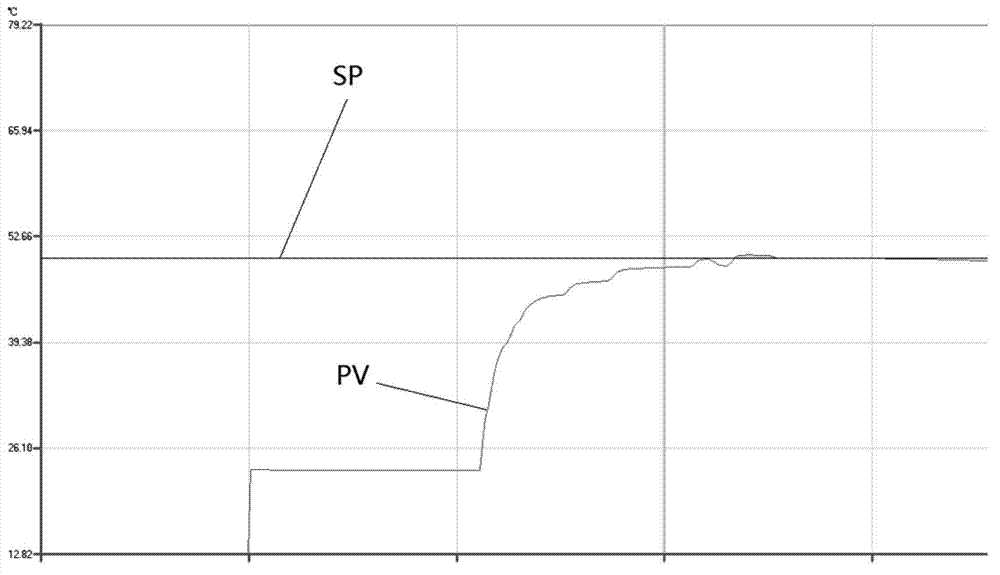

Dynamic control method for heating heat pump water system

ActiveCN105042671ASolve the defect that the indoor temperature rises slowlyRaise the room temperatureLighting and heating apparatusEnergy efficient heating/coolingThermodynamicsWater circulation

The invention relates to a dynamic control method for a heating heat pump water system. The method comprises the following specific steps that a heating water circulating system is prepared; the temperature to be reached is set and recorded as T<0>; indoor temperature is measured, and recorded as T<S>; the difference value of the indoor temperature T<S> and the temperature T<0> to be reached is obtained through comparison, and when |T<0>-T<S>|>=5, a high heating mode is started; when |T<0>-T<S>|<5, an energy saving mode is started; and when the energy saving mode is started, the water temperature of an intermediate-temperature container and the temperature of an outlet C of a three-way thermostatic valve need to be dynamically adjusted according to the difference value of the indoor temperature T<S> and the temperature T<0> to be reached to dynamically adjust heating temperature to ensure that the indoor temperature is proper. The dynamic control method has the beneficial effects that according to the control method, the single heating form of a heat pump water heater is changed to heating with the high heating mode and the energy saving mode. Under the high heating mode, the indoor temperature can be improved fast; and when the indoor temperature is close to the set temperature, the high heating mode is automatically converted to the energy saving mode, it can be guaranteed that the indoor temperature is constant, and the indoor temperature is prevented from exceeding comfortable temperature.

Owner:JIANGSU TENESUN ELECTRICAL APPLIANCE

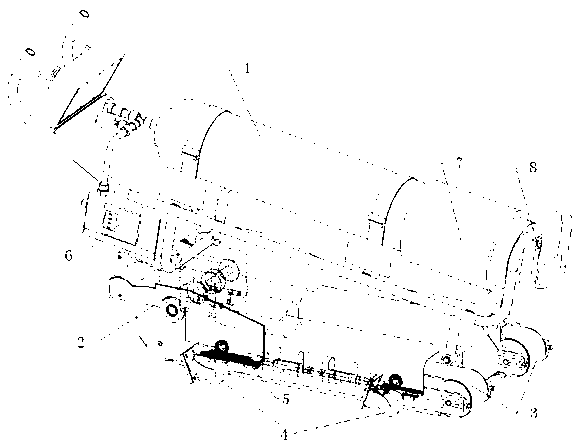

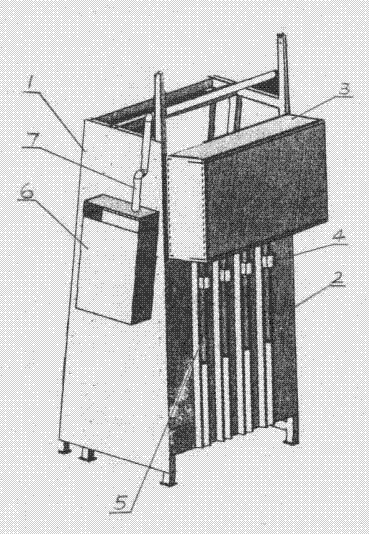

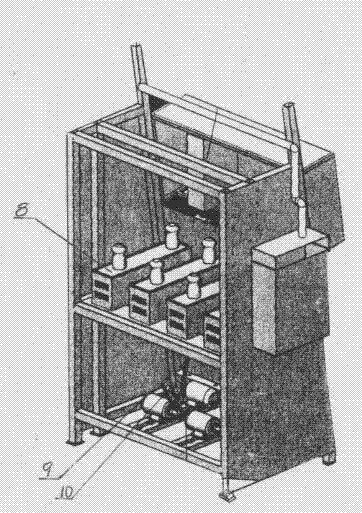

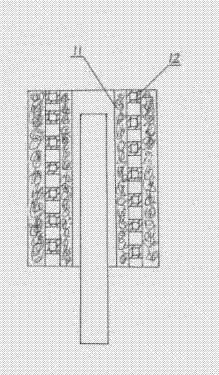

Automatic feeding medium-frequency diathermic furnace for forging automobile half axle

InactiveCN102554106AReduce labor intensityRealize half shaft automatic feedingHandling devicesForge furnacesHeating timeAutomatic control

The invention discloses an automatic feeding medium-frequency diathermic furnace for forging an automobile half axle, which comprises a vertical frame (1). A group of medium-frequency power supplies (8) are arranged in the frame, a group of medium-frequency induction furnaces connected with the medium-frequency power supplies are arranged outside the frame, central lines of hearths of the group of medium-frequency induction furnaces are arranged approximately vertically, a feeding mechanism feeds bars to be heated into the hearths along the central lines of the hearths from the bottoms of the hearths, and an electric control device is used for automatically controlling heating temperature and heating time. The bars are vertically fed into the hearths to be heated, the diathermic furnace is controlled to stop heating after needed temperature is reached, and the bars are automatically discharged, so that the drawbacks of short circuit and the like caused by slag falling in the prior art are avoided, quality is ensured, and the labor intensity of workers is reduced.

Owner:SICHUAN CHANGFENG AXLE

Heating cable

InactiveCN103260275ASmall footprintNot easy to burn outHeating element shapesCable/conductor manufactureEnvironmental resistanceHazardous substance

Provided is a heating cable. The manufacture method of the heating cable includes the steps: (1) heating, (2) pre-heating environment-friendly low-smoke-zero-halogen plastics, (3) paying off, (4) extruding and wrapping the environment-friendly low-smoke-zero-halogen plastics and nylon; (5) lettering and cooling, and (6) drying and winding. According to the heating cable, no black smoke is exhausted when the cable is in an open fire, produced harmful substances and poisonous gases are little, the density of smoke under a non-flame state is not higher than 250, and the density of the smoke under a flame state is not higher than 100, the oxygen index is not lower than 30%, hydracid gas release content is not higher than 5mg / g, and the PH vale is not lower than 4.3. The heating cable is suitable for being used in a road of a cold area, a pipeline, a tank body temperature rising ice melting and planting greenhouse, an automobile engine, a house and cables needing to keep warm.

Owner:JIANGSU QIDI ALLOY

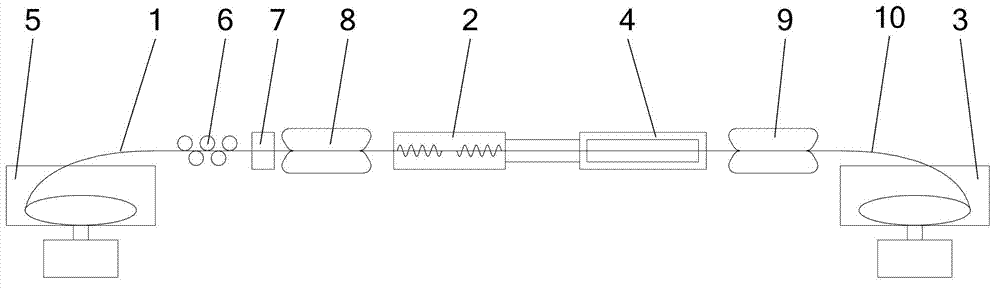

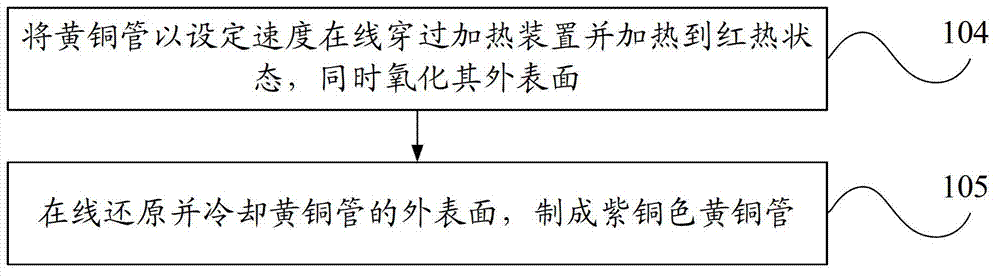

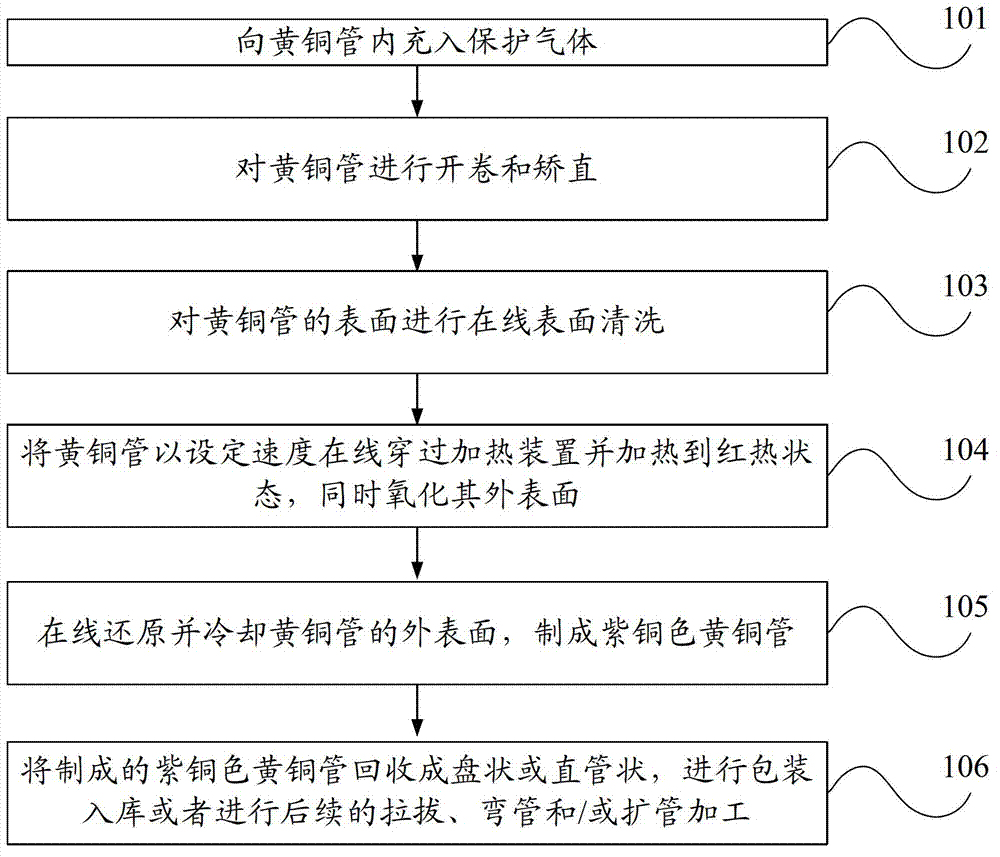

Purple bronze brass tube and manufacturing method and production line thereof

InactiveCN103243291ADense outer surfaceUniform outer surfaceSolid state diffusion coatingProduction lineShielding gas

The invention provides a purple bronze brass tube and a manufacturing method and production line of the purple bronze brass tube. The manufacturing method of the purple bronze brass tube comprises the following steps: allowing the brass tube to penetrate through the heating device on line at a set speed and heating to a red hot state, and oxidizing the outer surface; and reducing and cooling the outer surface of the brass tube on line, and manufacturing the purple bronze brass tube. The purple bronze brass tube production line comprises a heating device and a reduction tank, wherein reducing and cooling liquid is filled in the reduction tank. Compared with the prior art, the manufacturing method of the purple bronze brass tube has the advantages that process steps are less, yield is high, production efficiency of the purple bronze brass tube is high, lots of brass tube pickling process are eliminated in the related technology, the outer protective gas of the brass tube is canceled, the manufacturing cost is obviously reduced, the brass tube is energy-saving and environment-friendly, the manufactured purple bronze brass tube is dense and uniform in outer surface and can serve as a finished tube, drawing, bending, tube expanding and other subsequent treatment can be performed, and the color layer does not drop.

Owner:JIANGSU XINGRONG HI TECH

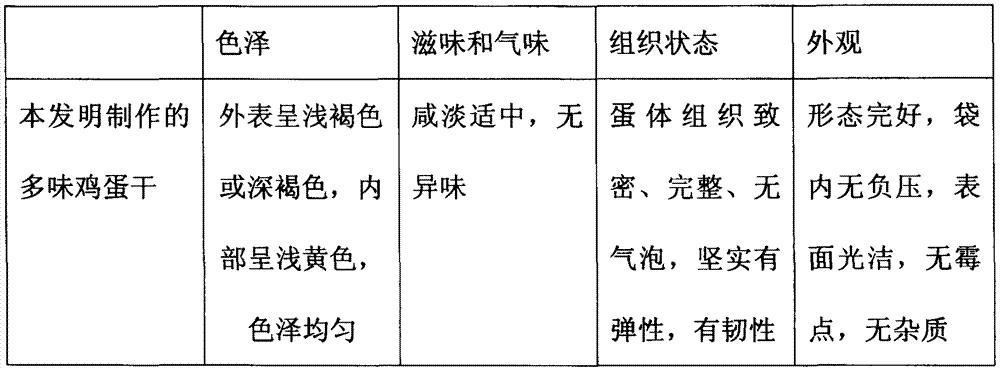

Preparing process of dried multi-flavor eggs

The invention discloses a preparing process of dried multi-flavor eggs. The preparing process comprises the following steps: (1) cleaning, disinfecting and shelling fresh and raw farm eggs by virtue of a cleaning, disinfecting, detecting and crashing integrated device, reserving egg white and yolk, and uniformly stirring so as to obtain a farm egg liquid; (2) adding sugar, salt, sodium glutamate and soy sauce to the farm egg liquid, uniformly stirring, pouring into a mold, boiling at high temperature of 120-130 DEG C under 2.0-3.0Mpa for 10-20min, demolding, and marinating in brine; and (3) drying by virtue of a multi-layer drying device, then packaging, sterilizing, cooling, inspecting and packing so as to obtain a finished product. The preparing process of the dried multi-flavor eggs disclosed by the invention adopts the fresh and raw farm eggs as a main raw material and improves a conventional processing technology, so that the prepared dried eggs are rich in nutrition, multi-flavored, capable of satisfying hobbies of different consumers on flavor and good in taste, and have functions of invigorating brain and improving intelligence, protecting liver, preventing arteriosclerosis, preventing cancers, delaying aging and the like; and the dried eggs are delicate in mouth feel, and have the advantages of being ready to enjoy when opened, convenient to eat, long in storage time and the like.

Owner:ANHUI GUANGLIN EGG PROD

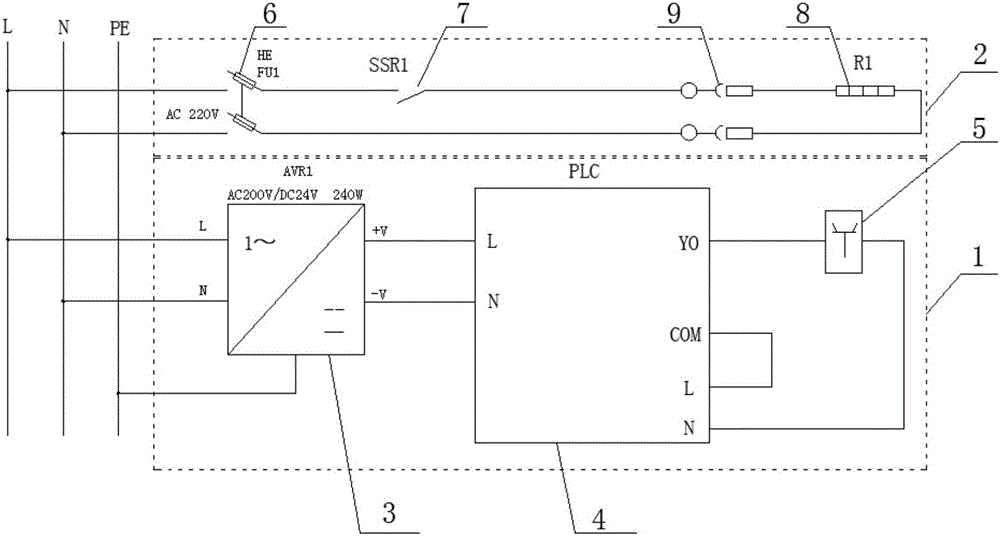

Temperature controller

ActiveCN105974961AReduce lossPrecise heatingTemperature control using digital meansTemperature controlControl signal

The invention relates to a temperature controller comprising a first temperature control module and a second temperature control module. The first temperature control module and the second temperature control module are respectively connected with an external AC power supply. The first temperature control module is used for heating to set temperature and then automatically disconnects. The second temperature control module is used for heating to set temperature and then periodically acquiring heating control signals outputted by the second temperature control module and regulating and controlling heating temperature of the next period according to the heating control signals acquired in the current period until heating temperature is stable. Compared with controllers in the prior art, heating temperature can increase to target temperature through heating and remain stable so that the loss can be effectively reduced, the processing precision can be enhanced and the yield rate can be enhanced.

Owner:QUANZHOU HANWEI MACHINERY MFG

Multi-component gas simulation mixing system

PendingCN110865662AAvoid Concentration Distribution DeviationsAvoid condensationControlling ratio of multiple fluid flowsAnalysing gaseous mixturesThermodynamicsSystems design

The invention discloses a multi-component gas simulation mixing system, which belongs to the technical field of gas simulation mixing. After each component gas independently enters a rotary mixer, thecomponent gases are fully and uniformly mixed in an annular gas mixing chamber. Water vapor is added by a water vapor generation unit. After relevant parameters of multiple component gases and the water vapor are adjusted through data fed back by a monitoring unit, a simulated mixed gas is obtained and connected into a required system. The system is reasonable in design, wide in application range, easy and convenient to operate and high in efficiency. The concentration and flow velocity distribution uniformity of multiple component gases is improved, and accurate adjustment and control of moisture can be achieved.

Owner:HUANENG CLEAN ENERGY RES INST

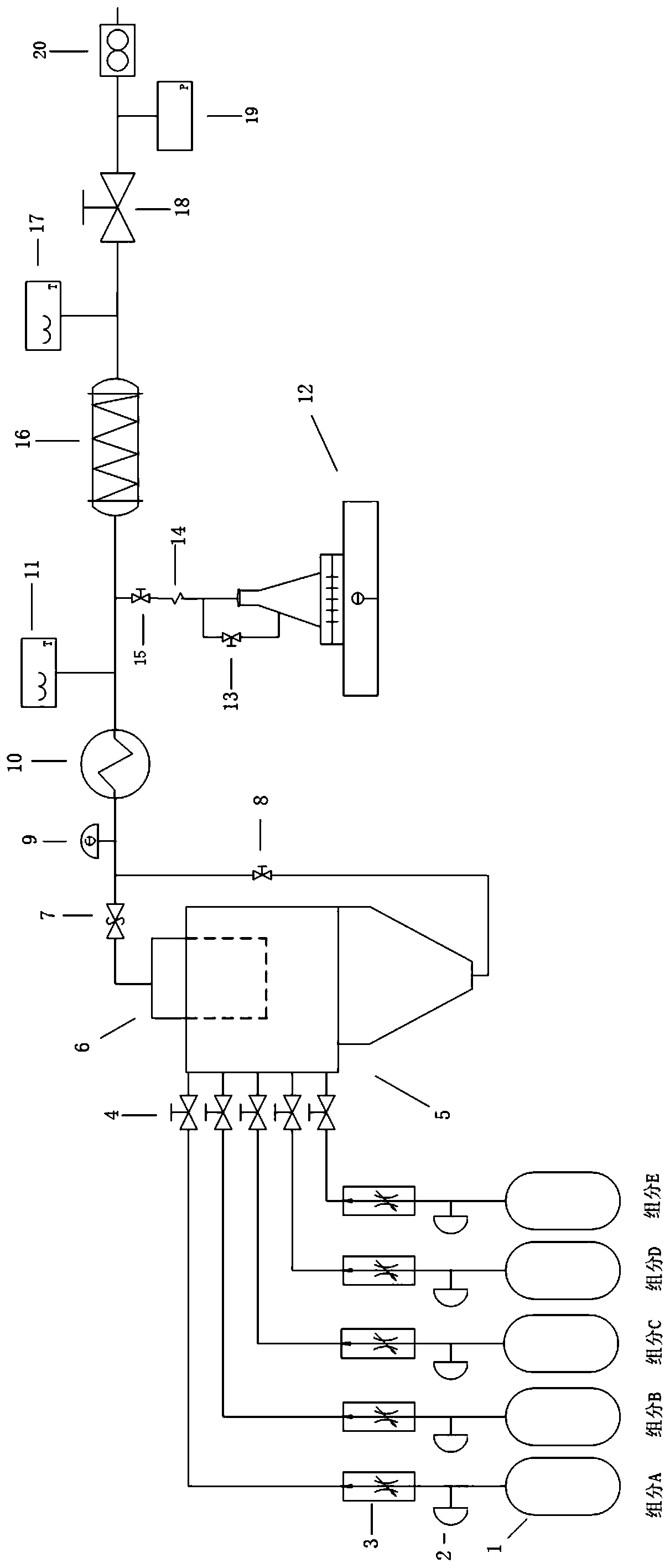

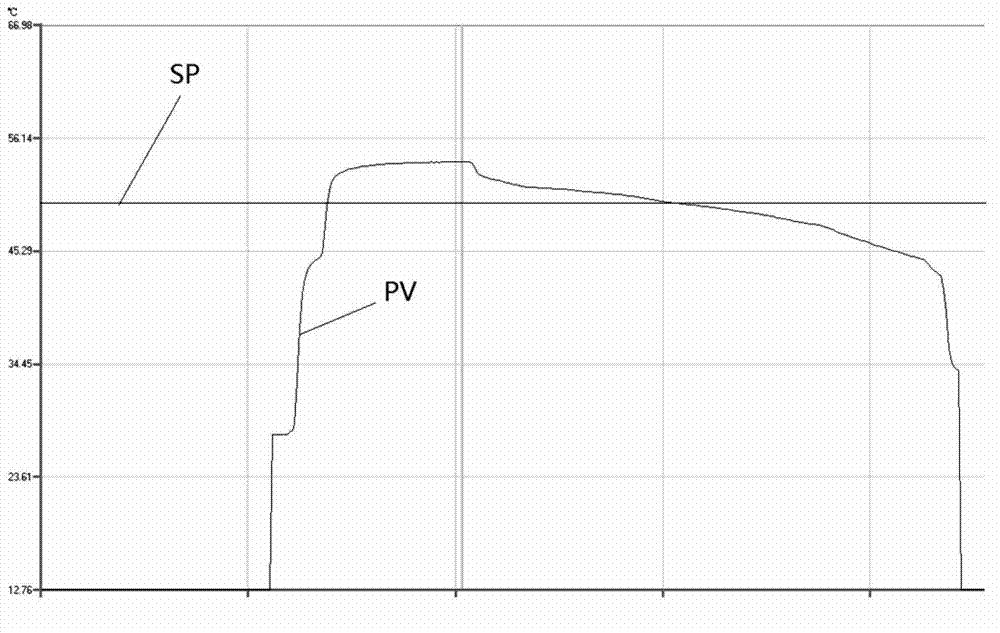

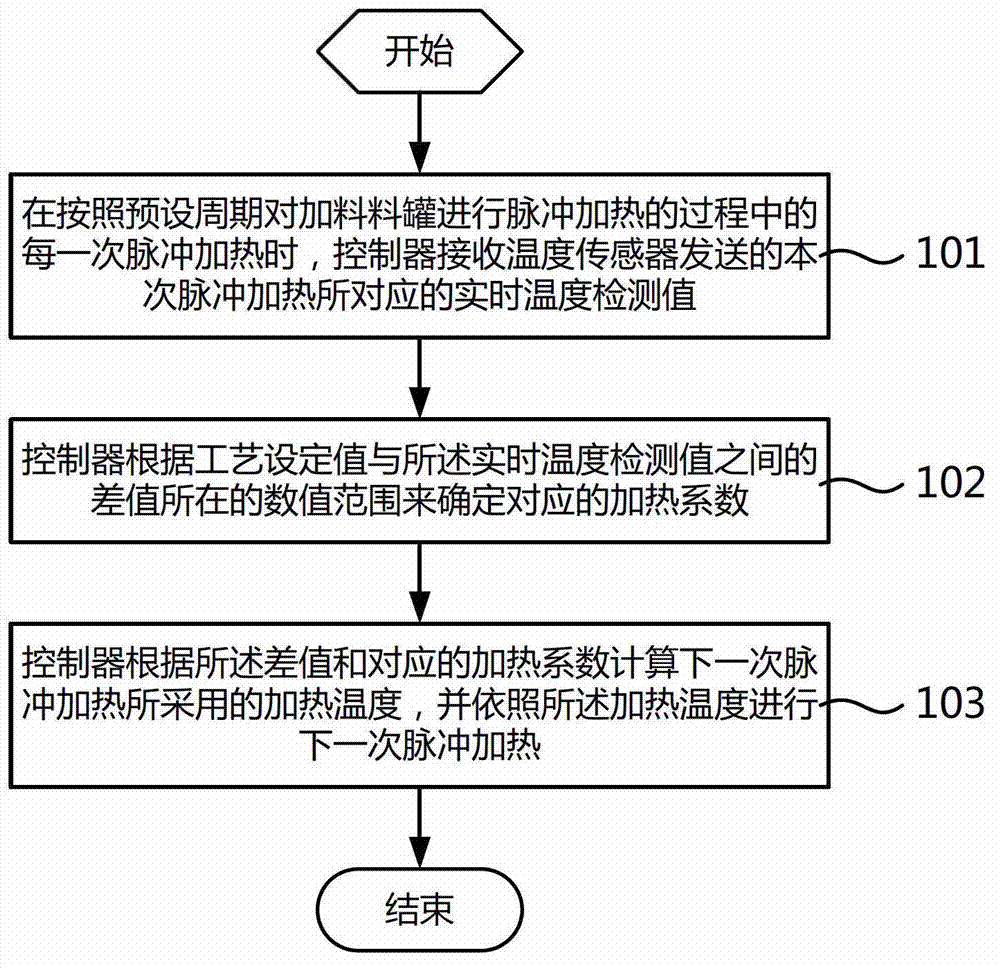

Feeding tank temperature control method and system

ActiveCN103257658BAvoid overheatingImprove heating efficiencyAuxillary controllers with auxillary heating devicesTemperature controlNumerical range

The invention relates to a feeding tank temperature control method and system. The method includes the steps that in each time of pulse heating in the process of pulse heating on a feeding tank according to a preset period, a controller receives a real-time temperature detection value sent by a temperature sensor and corresponding to the time of pulse heating; the controller determines corresponding heating coefficients according to numerical ranges where difference values between a process set value and the real-time temperature detection values are in, wherein the numerical range where a smaller difference value is in corresponds to a smaller heating coefficient, and the numerical range where a larger difference value is in corresponds to a larger heating coefficient; the controller calculates the heating temperature adopted in a next time of pulse heating according to the difference values and the corresponding heating coefficients, and the next time of pulse heating is carried out according to the heating temperature. The feeding tank temperature control method and system can overcome shortcomings existing in impulse type step-by-step heating in the prior art, improve feed liquid heating efficiency and enhance heating effects.

Owner:LONGYAN CIGARETTE FACTORY

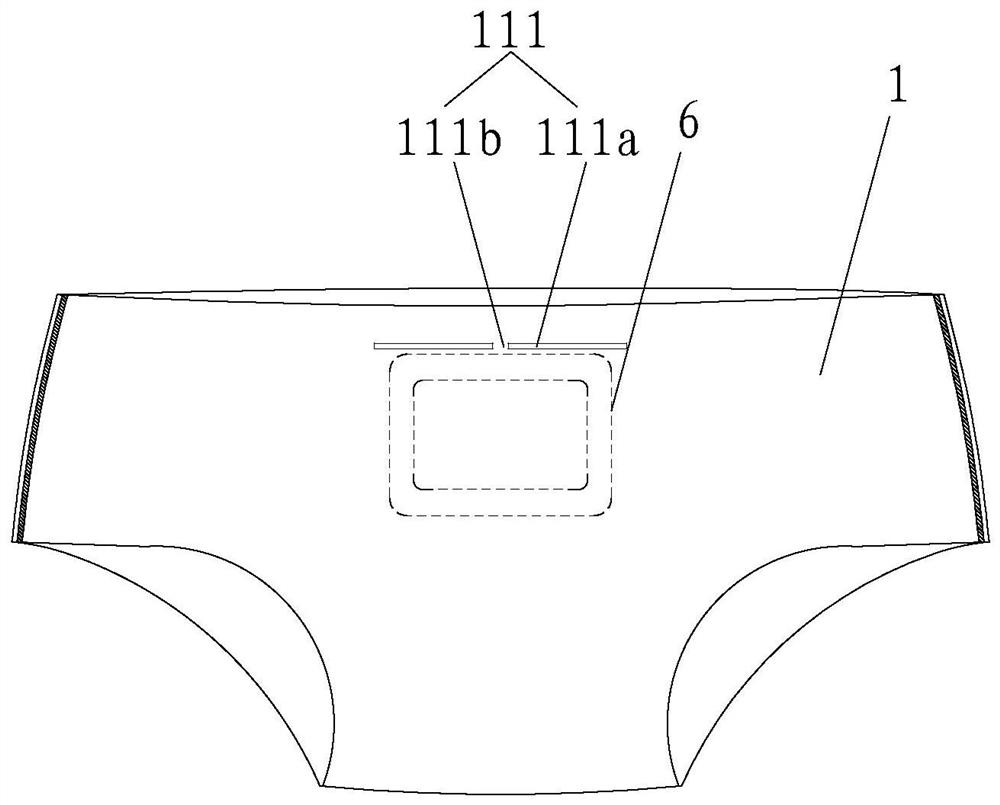

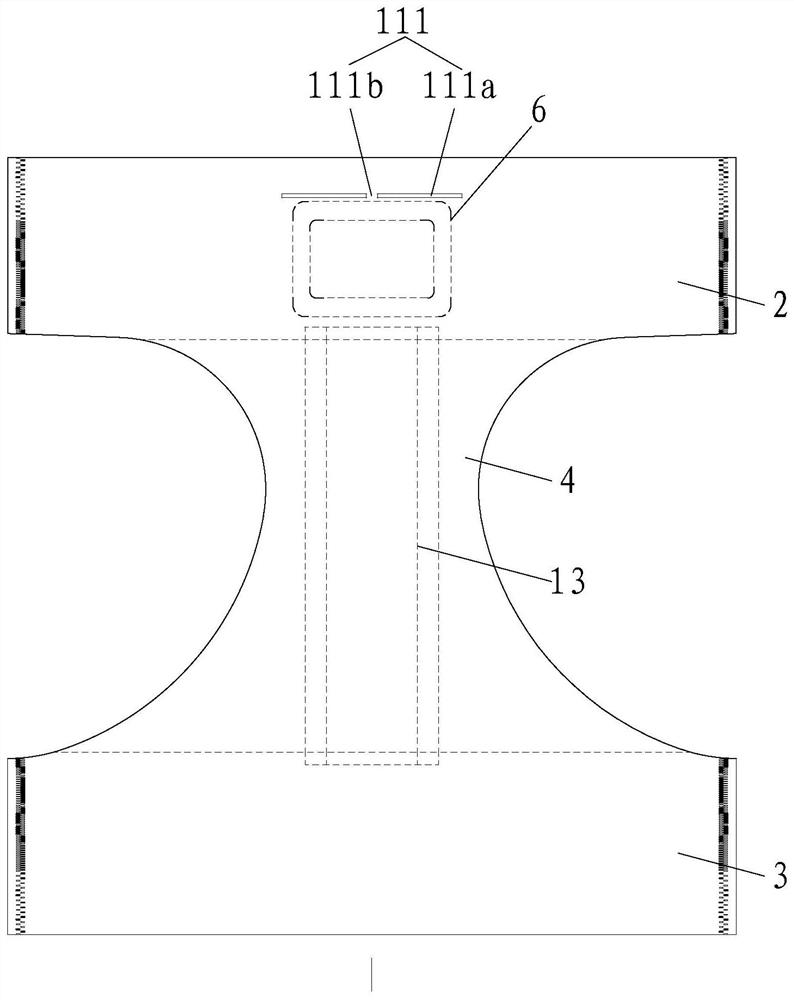

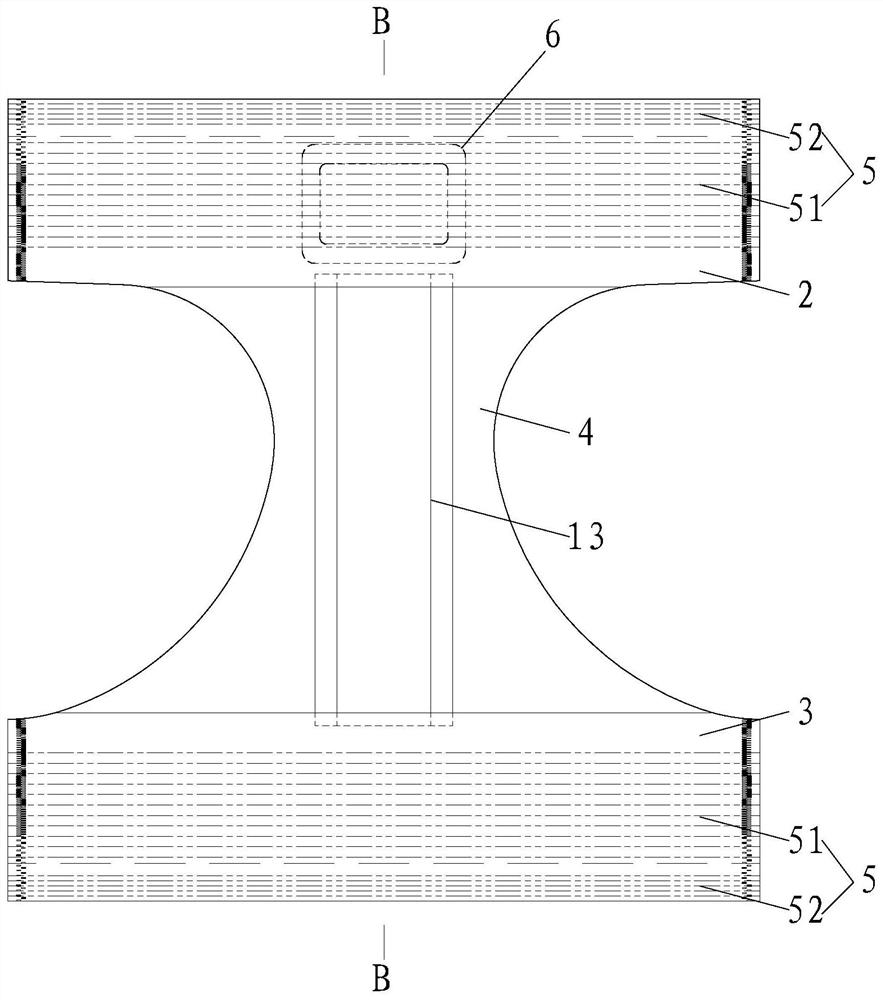

Production process of uterus warming sanitary pants

ActiveCN112603655ARealize the operationFever does not reachAntipyreticAnalgesicsWoven fabricManufacturing engineering

The invention relates to disposable hygienic products, in particular to a production process of uterus-warming hygienic pants. The production process comprises the following steps of: 1, inputting outer-layer non-woven fabric, arranging waist-surrounding waistline rubber bands and abdomen waistline rubber bands at the front waist and the rear waist of the outer-layer non-woven fabric, and forming dummy cutting holes in the outer-layer non-woven fabric; 2, compounding a uterus warming patch at the front waist part of the outer-layer non-woven fabric; 3, compounding an inner-layer non-woven fabric on the outer-layer non-woven fabric; 4, compounding absorption core bodies on the inner-layer non-woven fabric; 5, folding the outer-layer non-woven fabric to enable the outer-layer non-woven fabric to cover the two ends, in the length direction, of each absorption core body; 6, cutting out a leg circumference area between every two adjacent absorption core bodies; 7, folding the middle of the outer-layer non-woven fabric, and then performing thermal compression on the front waist part and the rear waist part; and 8, cutting off the middle part of a thermal compressed part. With the sanitary pants adopted, the technical problems that existing sanitary pants are not reasonable enough in structure, low in production efficiency and high in cost can be solved.

Owner:QUANZHOU HANWEI MACHINERY MFG

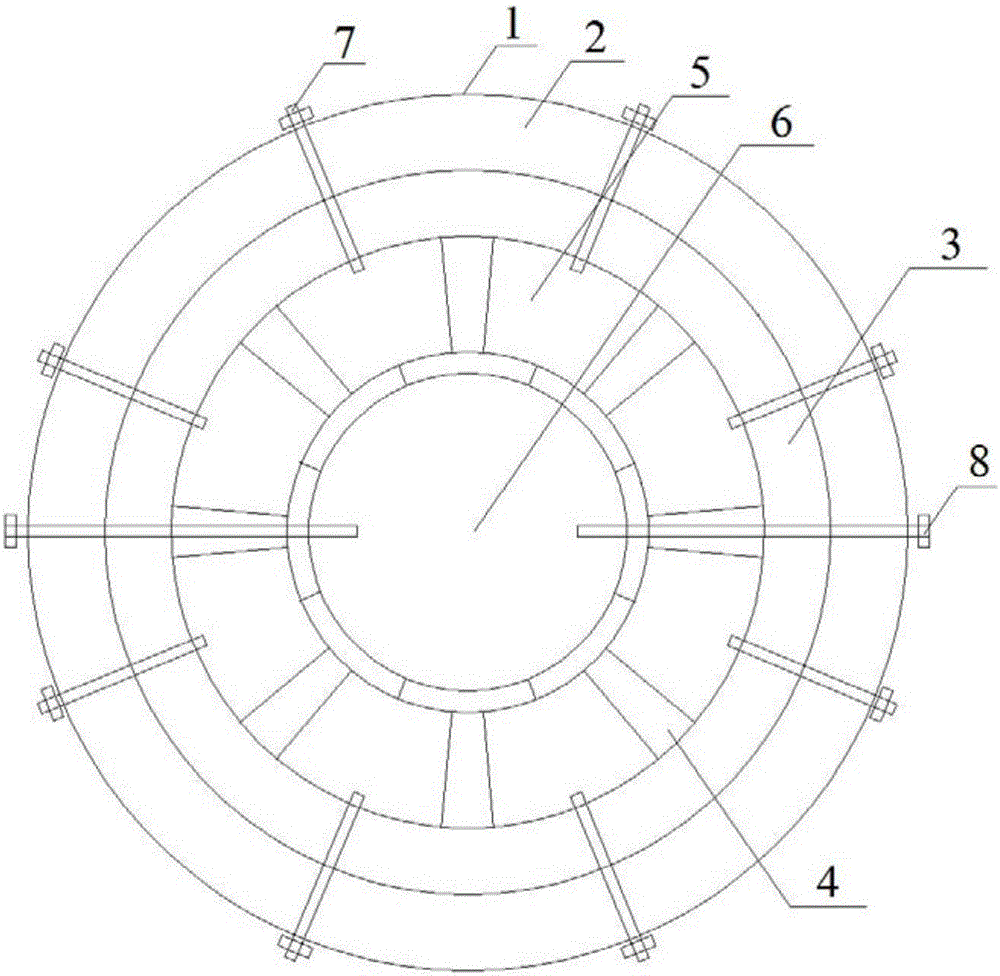

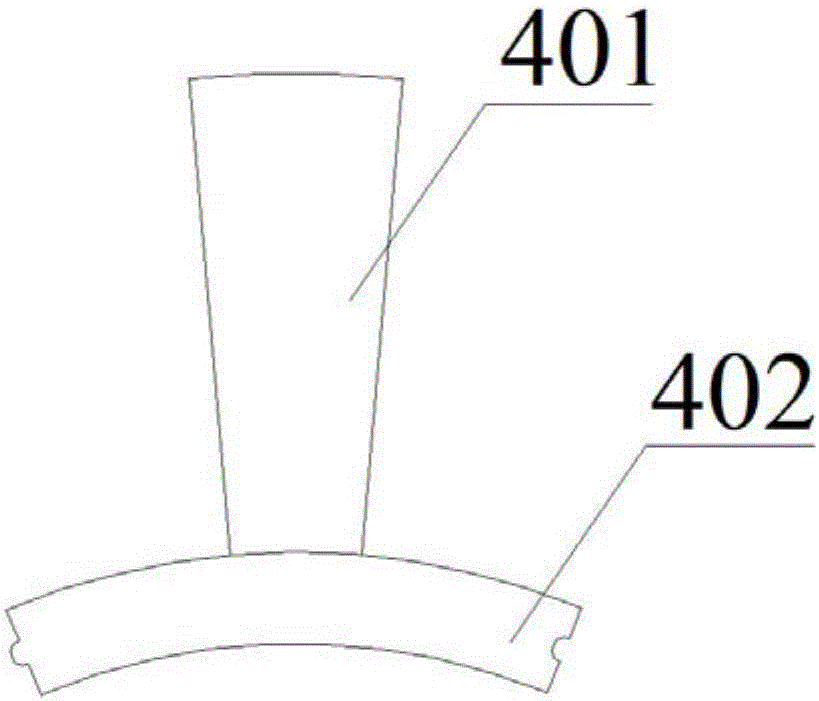

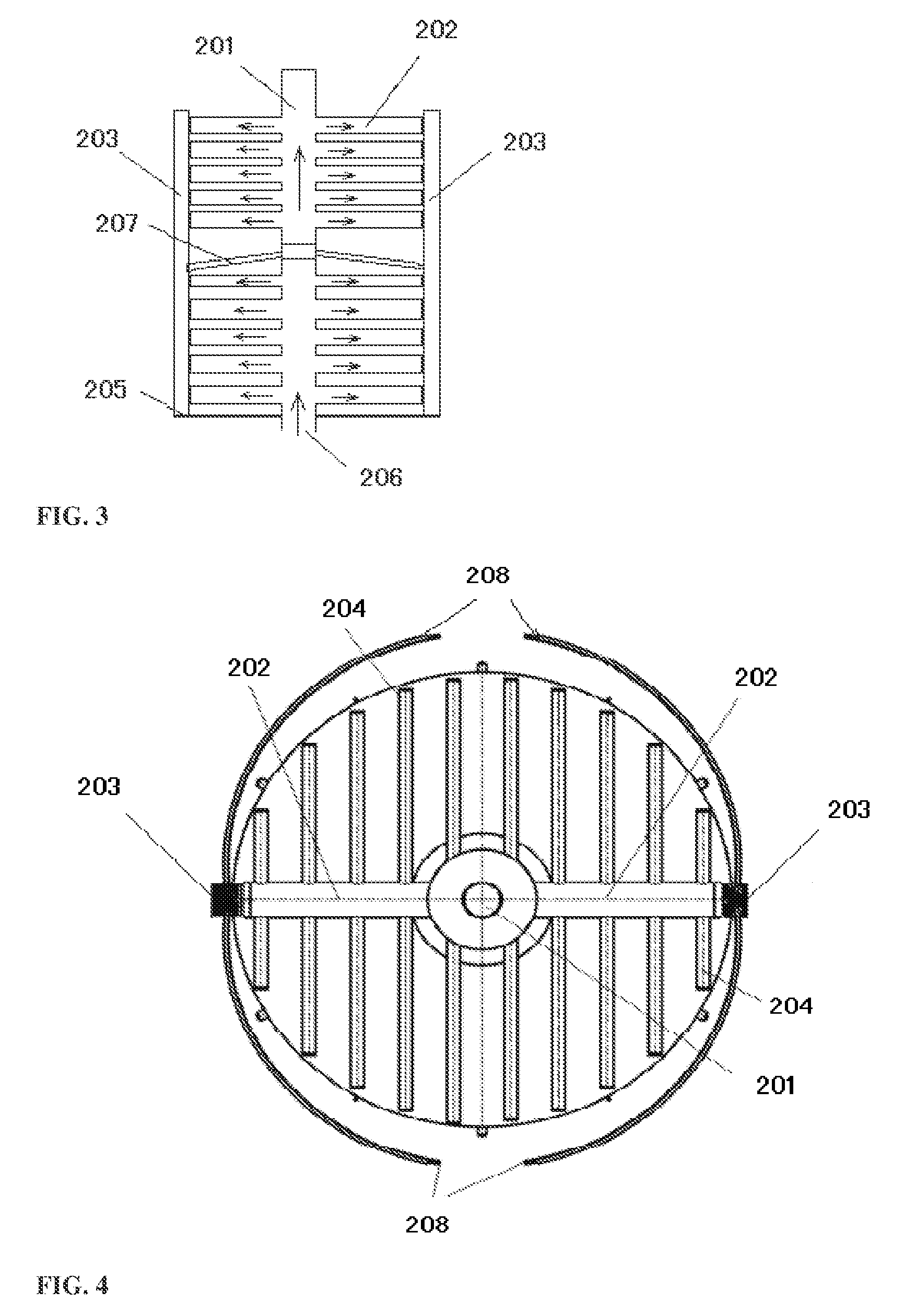

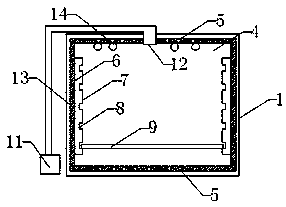

InP crystal growth furnace based on VGF (Vertical Gradient Freeze) method

ActiveCN106521615AStable heating temperatureAvoid interferencePolycrystalline material growthFrom frozen solutionsVertical gradientCrucible

The invention discloses an InP crystal growth furnace based on a VGF (Vertical Gradient Freeze) method and belongs to the technical field of semiconductor crystal growth equipment. The InP crystal growth furnace disclosed by the invention comprises a furnace base and a furnace wall, wherein a sealed space is formed between the furnace base and the furnace wall; a vent hole is formed in the furnace base; the upper surface of the furnace base is fixedly connected with a crucible support; a crucible is arranged above the crucible support; an isolation barrel without a bottom surface is coaxially arranged on outer sides of the crucible support and the crucible; a plurality of sections of heating elements are arranged at the periphery of the isolation barrel at intervals in the vertical direction; each section of the heating element is fixedly provided with an electrode mounting base; a heating electrode is connected with each heating element through the corresponding electrode mounting base and extends to the outer part of the furnace base; and the bottom of each section of the heating element is fixedly connected with a heater mounting plate. Heat convection and heat radiation between the adjacent heating elements are separated through the heater mounting plate to keep the heating temperature of the heating elements stable.

Owner:珠海鼎泰芯源晶体有限公司

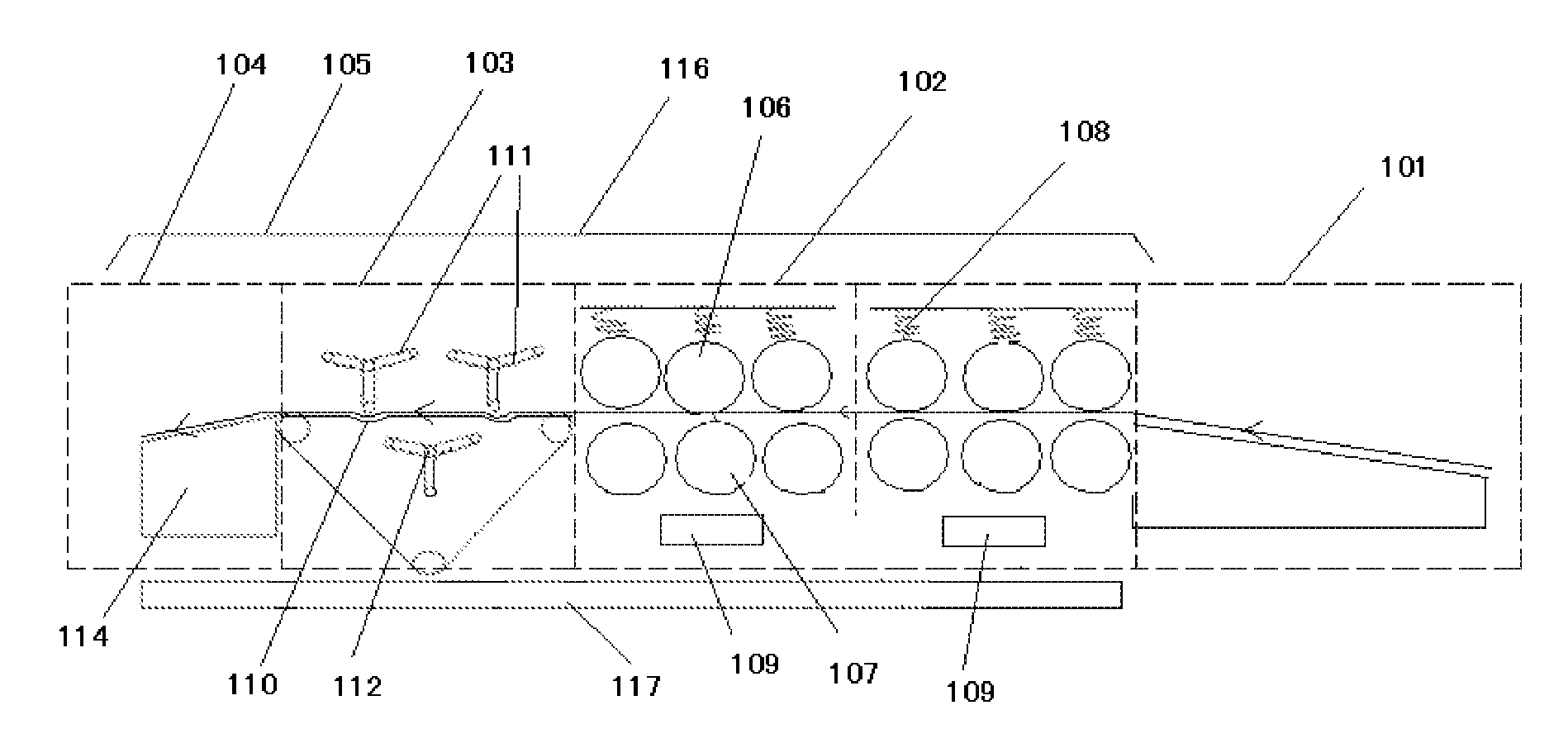

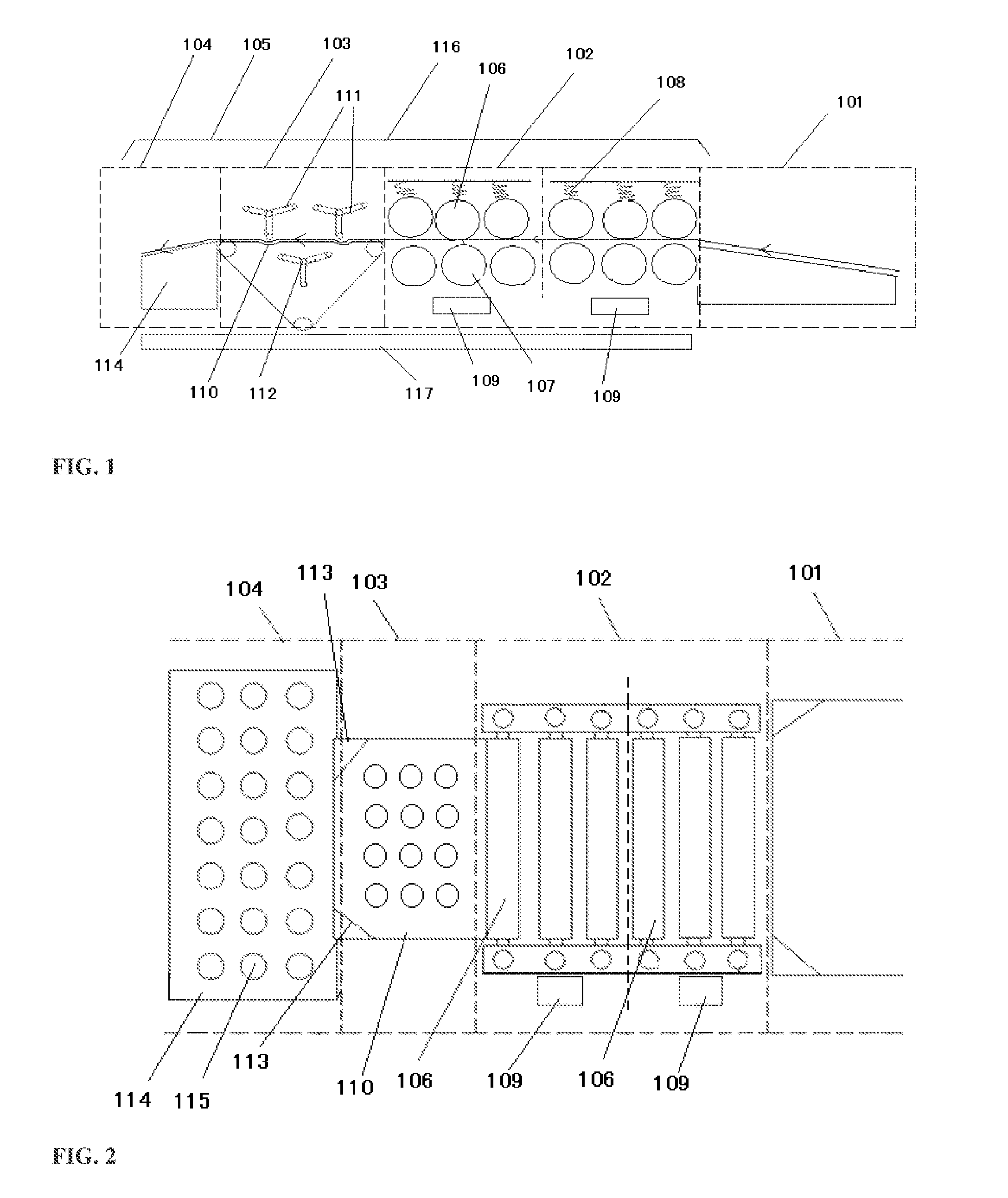

Waste circuit board element removing system and process

InactiveCN105327934AControl heating temperatureStable heating temperatureSievingScreeningAir pollutionHeating temperature

The embodiment of the invention discloses a waste circuit board element removing system. The waste circuit board element removing system comprises a material conveying device, a reflow soldering heating device, a vibration sieve and a waste gas collecting device. The material conveying device is used for conveying a waste circuit board and passes through the reflow soldering heating device. The vibration sieve comprises a vibration driving mechanism and a plurality of layers of sieve nets driven by the vibration driving machine. The waste gas collecting device comprises a housing covering the reflow soldering heating device and the vibration sieve inside and a waste gas processing device used for collecting and processing waste gas inside the housing. In this way, by means of the waste circuit board element removing system, the problems of unstable heating temperature and heavy workloads of separation in the later period can be avoided on the basis of avoiding air pollution and preventing damages to elements. The invention further provides a waste circuit board element removing process based on the waste circuit board element removing system.

Owner:GREE ELECTRIC APPLIANCES INC

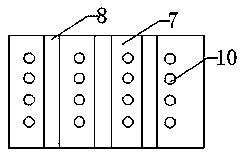

Homogeneity blast heating vacuum drying box

InactiveCN108917294AImprove drying uniformityUniform heating temperatureDrying solid materials without heatDrying gas arrangementsAir blowerUltimate tensile strength

The invention discloses a homogeneity blast heating vacuum drying box. The homogeneity blast heating vacuum drying box comprises a heating box body and a box door, the side, facing the box door, of the heating box body is of an open structure, and the heating box body and the box door are closed to form a heating cavity; one set of heating pipe is embedded in the parts, facing the heating cavity,of the top and bottom of the heating box body respectively, one set of blasting panel is mounted on the parts, facing the heating cavity, of the left side wall and the right side wall of the heating box body respectively, and the two sets of blasting panels are connected with a same air blower through air inlet pipelines; and the sides, facing the heating cavity, of the blasting panels are evenlyprovided with ventholes. On the one hand, the homogeneity blast heating vacuum drying box make the heating temperature at each position of the heating cavity from bottom to top be the same, on the other hand, the intensity of the drying air applied to to-be-dried objects on different grids in the heating cavity is the same; the internal heating temperature is homogenous and stable, the intensity of the drying air on the same grid is the same, the whole drying homogeneity of the drying box is effectively improved, and the drying quality is improved.

Owner:苏州布莱尔仪器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com