Waste circuit board element removing system and process

A technology for waste circuit boards and components, which is applied to the removal of solid waste, printed circuits, manufacturing tools, etc. It can solve the problems of unstable temperature in the heating chamber, mixed capacitance and resistance, and fluctuations, so as to simplify the later sorting work, Prevent PCB board from scorching and avoid environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

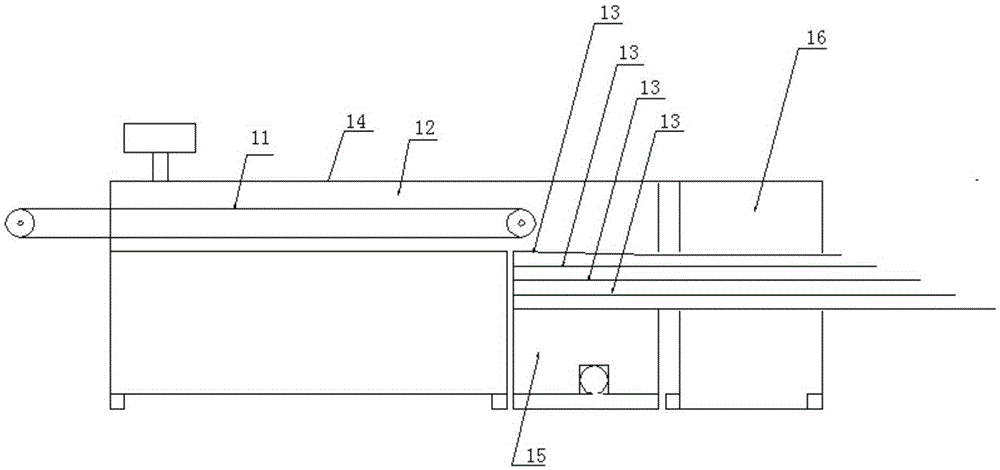

[0035] This specific embodiment provides a system for removing waste circuit board components, which can avoid the problems of unstable heating temperature and heavy sorting workload in the later stage on the basis of avoiding air pollution and preventing damage to components. This specific embodiment also provides a process for removing waste circuit board components based on the above-mentioned waste circuit board component removal system.

[0036] Hereinafter, an embodiment will be described with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solutions of the invention described in the claims.

[0037] see figure 1 , The waste circuit board component removal system provided in this specific embodiment includes a material conveying device 11, a reflow sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com