InP crystal growth furnace based on VGF (Vertical Gradient Freeze) method

A crystal growth furnace and furnace wall technology, applied in crystal growth, single crystal growth, single crystal growth, etc., can solve problems such as the influence of temperature distribution stability, and achieve the effect of maintaining stable heating temperature and avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

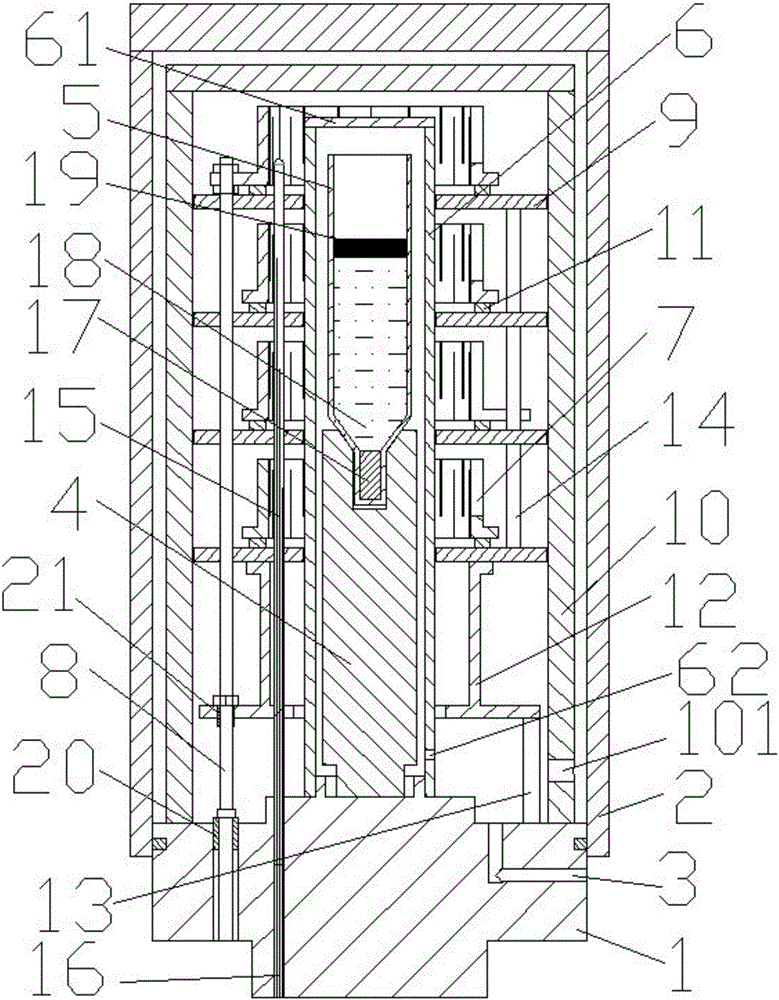

[0024] The present invention will now be further described in conjunction with the accompanying drawings and specific embodiments, so as to make the present invention clearer and easier to understand.

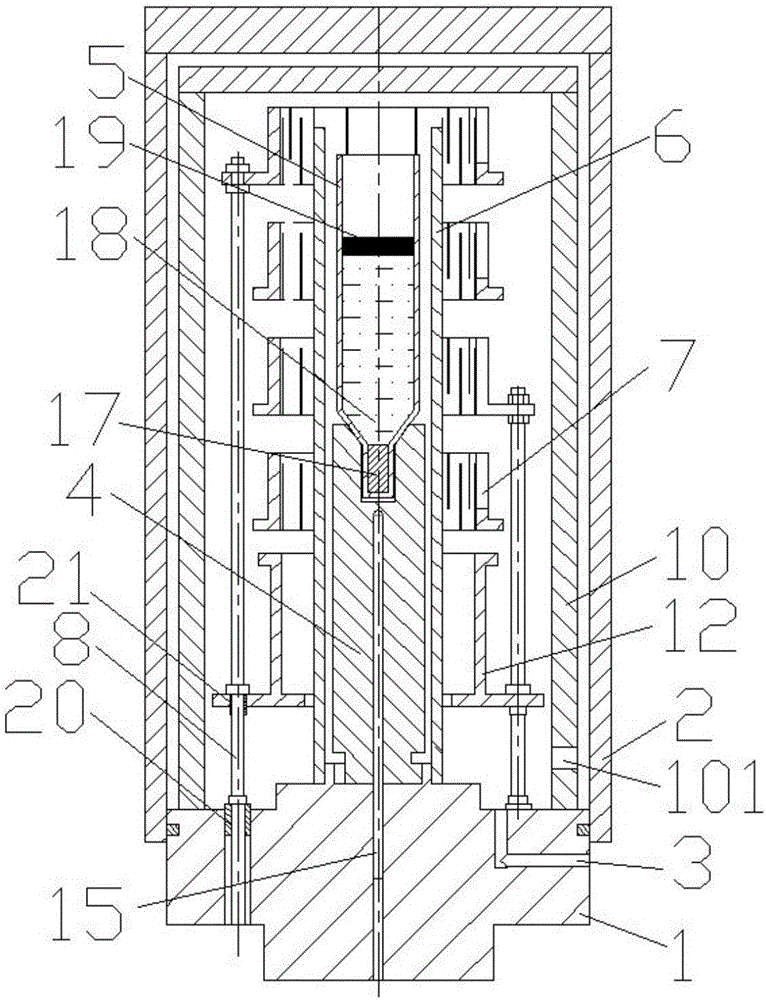

[0025] image 3 It is a schematic cross-sectional view of a preferred embodiment of the InP crystal growth furnace based on the VGF method of the present invention, as image 3 As shown, the InP crystal growth furnace based on the VGF method of the present invention includes: a furnace base 1, a furnace wall 2, and the furnace base 1 is fixedly connected to the furnace wall 2, and the sealing ring installed at the axial groove of the furnace base 1 form a confined space. A vent 3 is provided on the furnace base 1, and an inert gas is introduced into the furnace through the vent 3 or the cavity is vacuumed to realize the necessary InP crystal growth process conditions. A crucible holder 4 is fixedly connected to the center of the upper surface of the furnace base 1, a crucible...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com