Feeding tank temperature control method and system

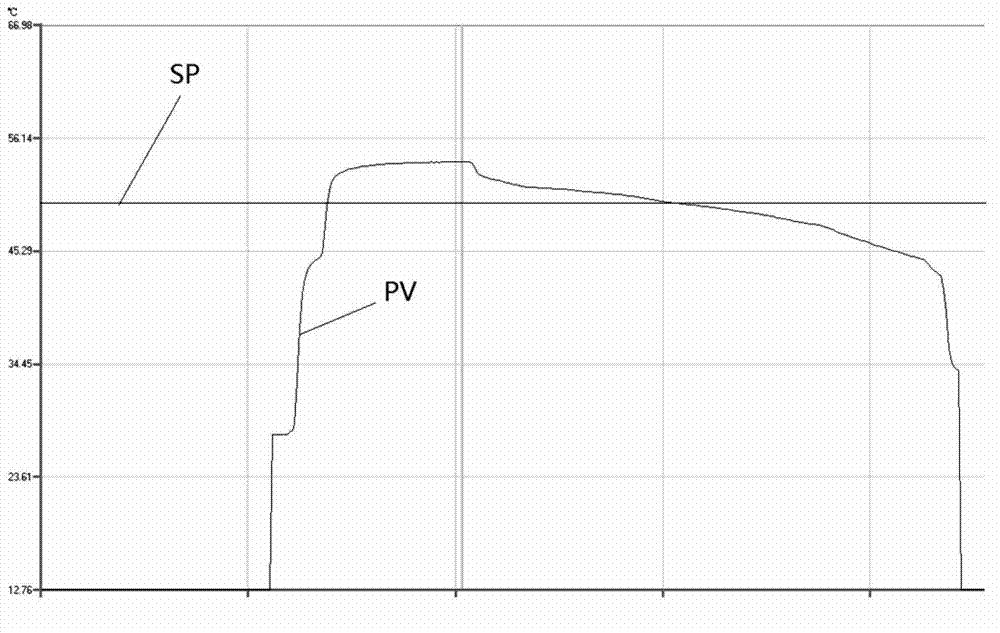

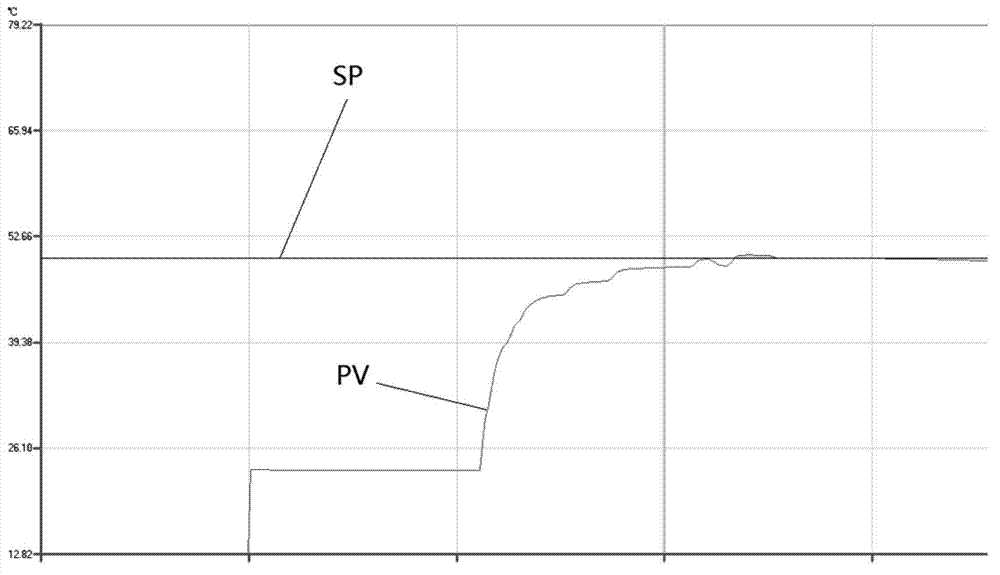

A temperature control method and heating temperature technology, which are applied in the direction of temperature control using electric methods, auxiliary controllers with auxiliary heating devices, etc., can solve problems such as uneven stirring of material liquid, over-temperature, unstable temperature control, etc. , to increase the heating speed, reduce the heating speed and improve the heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

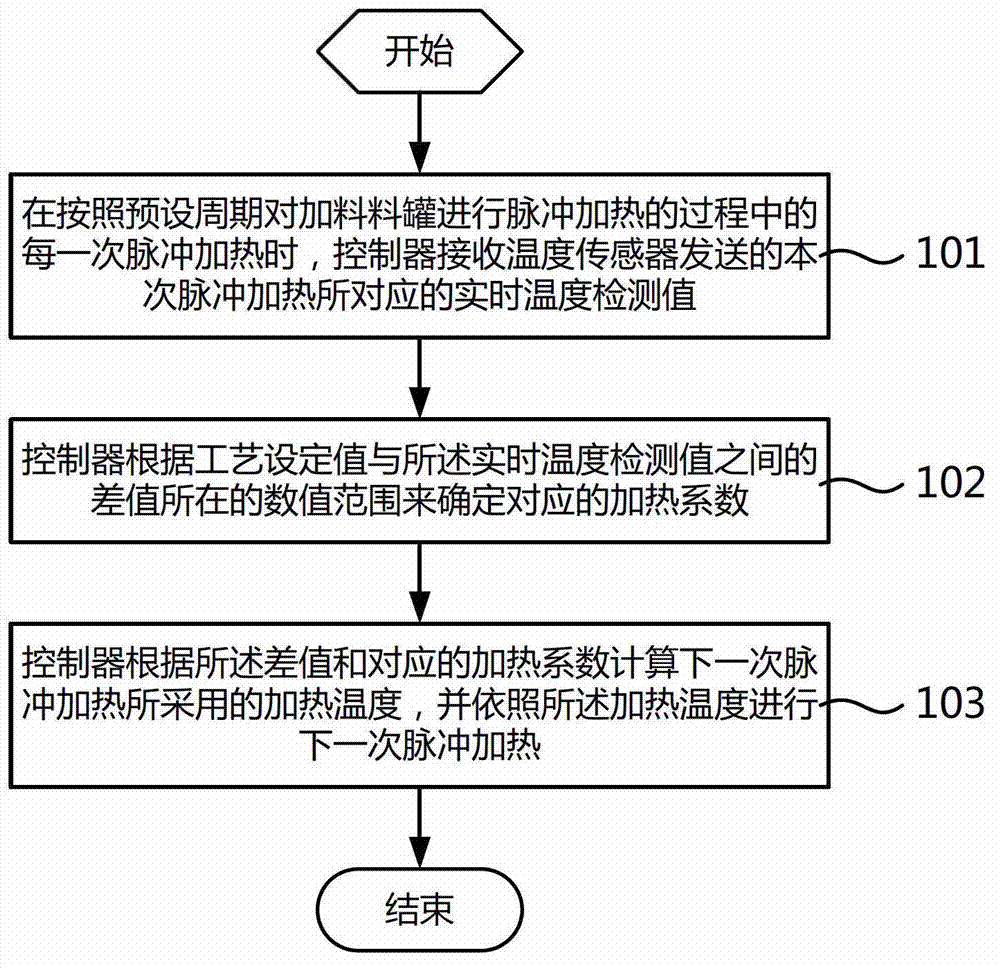

[0038] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0039] In the present invention, the existing pulsed stepping heating method can be changed into a segmented pulsed stepping heating method, and different heating coefficients are used in different time periods.

[0040] Such as figure 2 Shown is a schematic flow chart of an embodiment of the method for controlling the temperature of the feeding tank of the present invention. In this embodiment, the temperature control process of the feed tank includes:

[0041] Step 101. During each pulse heating in the process of pulse heating the feeding tank according to the preset cycle, the controller receives the real-time temperature detection value corresponding to this pulse heating sent by the temperature sensor;

[0042] Step 102, the controller determines the corresponding heating coefficient according to the numerical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com