Multi-component gas simulation mixing system

A technology for simulating mixing and multi-components, which can be used in the analysis of gas mixtures, the control of various fluid ratios, and the analysis of materials, etc. Instability and other problems, to avoid concentration distribution deviation, improve mixing uniformity, and avoid water vapor condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with accompanying drawing, and its content is explanation of the present invention rather than limitation:

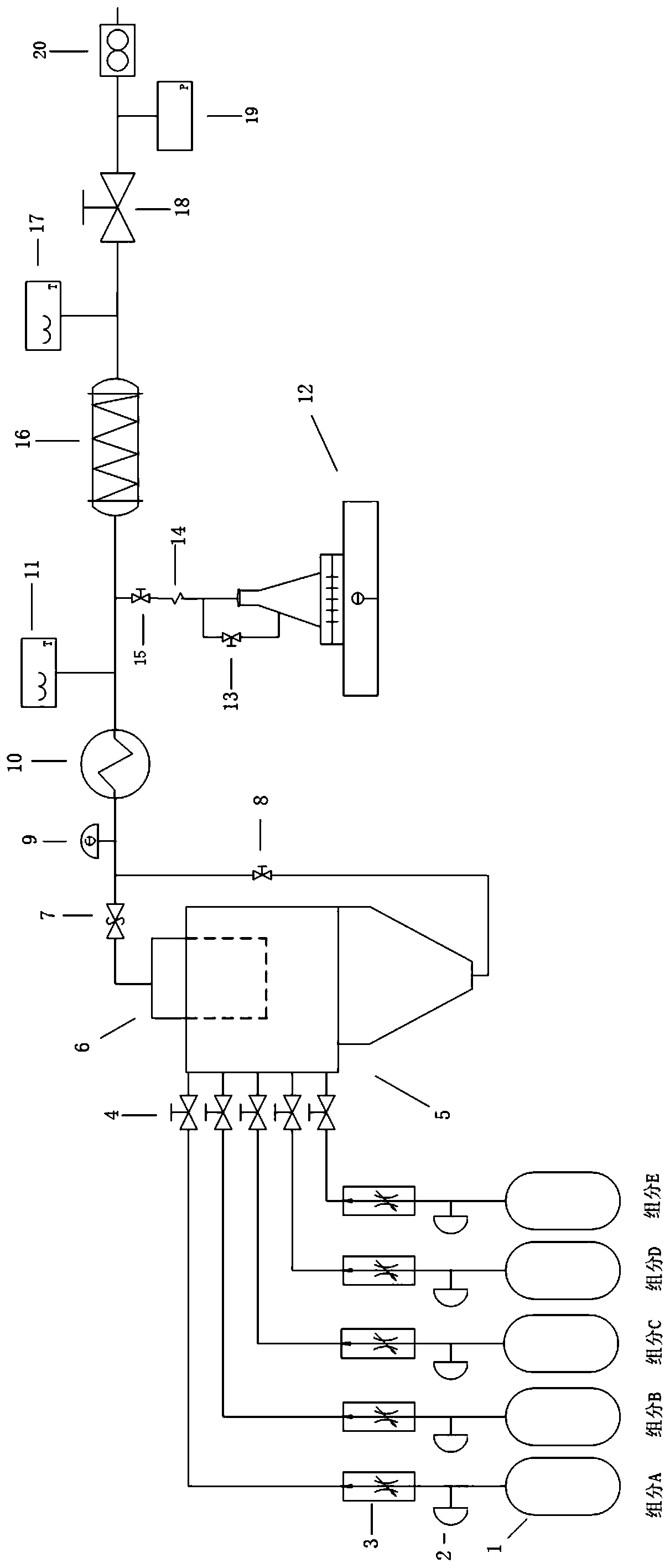

[0034] Such as figure 1 , is the multi-component gas simulation mixing system of the present invention, including a gas mixing unit, a water vapor generating unit and a monitoring unit connected in sequence through the main pipeline of the system, and an air intake unit connected to the gas mixing unit;

[0035] The air intake unit includes a number of gas storage devices 1, which are respectively connected to the cylinder through the air intake pipeline, and the air intake pipeline is provided with a switch 2, a flow rate setting device 3 and an air intake regulating valve 4 in sequence.

[0036] The mixing unit includes a rotary mixer 5 and a central tube 6; the upper part of the rotary mixer 5 is a cylindrical tube, and the lower part is a conical tube; the inlet end of the central ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com