Homogeneity blast heating vacuum drying box

A technology of vacuum drying oven and blast heating, applied in the direction of drying solid materials without heating, heating device, drying solid materials, etc., can solve the problem of unreasonable design of heating device and blast device, uniform heating and blasting uniformity different, affecting the performance of the items to be dried, etc., to achieve the effect of simple structure, improved drying uniformity, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

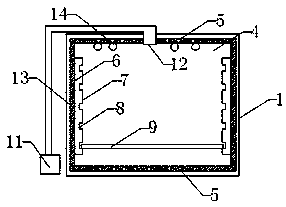

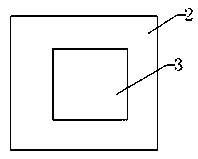

[0020] The invention discloses a uniform blast heating vacuum drying oven, which comprises a heating box body 1 and a box door 2, the box door 2 is located at the front port of the heating box body 1, one side of which is connected to the The heating box casing 1 is hingedly connected, and when the box door 2 is closed, the front port of the heating box casing 1 can be sealed. There is an observation window 3 on the said box door 2 .

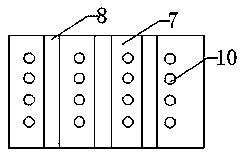

[0021] Only one side of the heating box body 1 facing the box door 2 is an open structure, that is, the above-mentioned front port, and the heating box body 1 is closed with the box door 2 to form a heating cavity 4 . A set of heating pipes 5 are respectively embedded in the top and bottom of the heating box body 1 facing the heating cavity 4, and the left and right side walls of the heating box body 1 are facing the heating cavity 4. A group of blast panels 6 are respectively installed in some parts, and the blast panels 6 of the two groups ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com