Drying device used for textile printing and dyeing

A drying equipment and textile technology, applied in the field of printing and dyeing processing, can solve the problems that fabrics are easy to overlap each other, affect the drying effect, and appear wrinkles, and achieve the effects of increasing drying uniformity, simple structure, and reducing wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

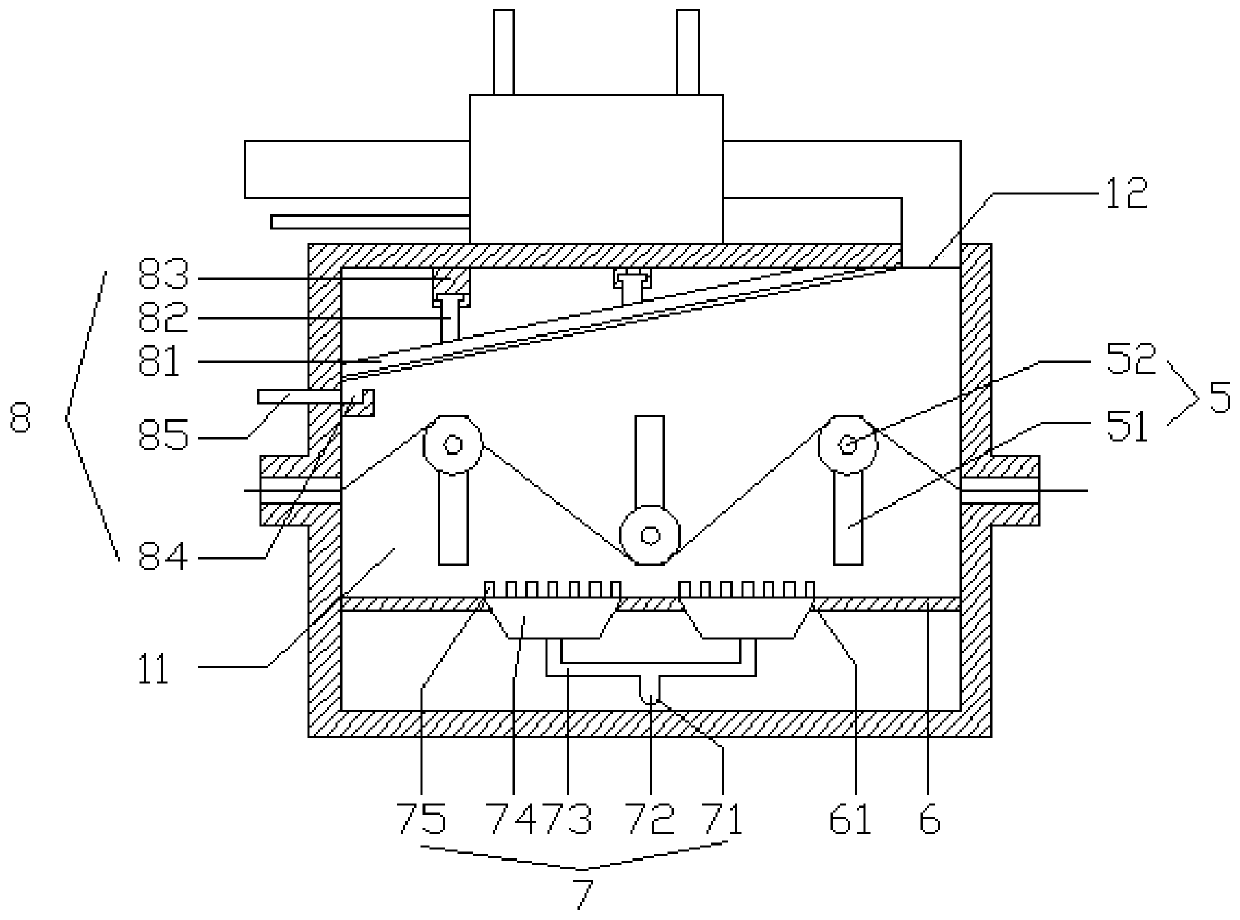

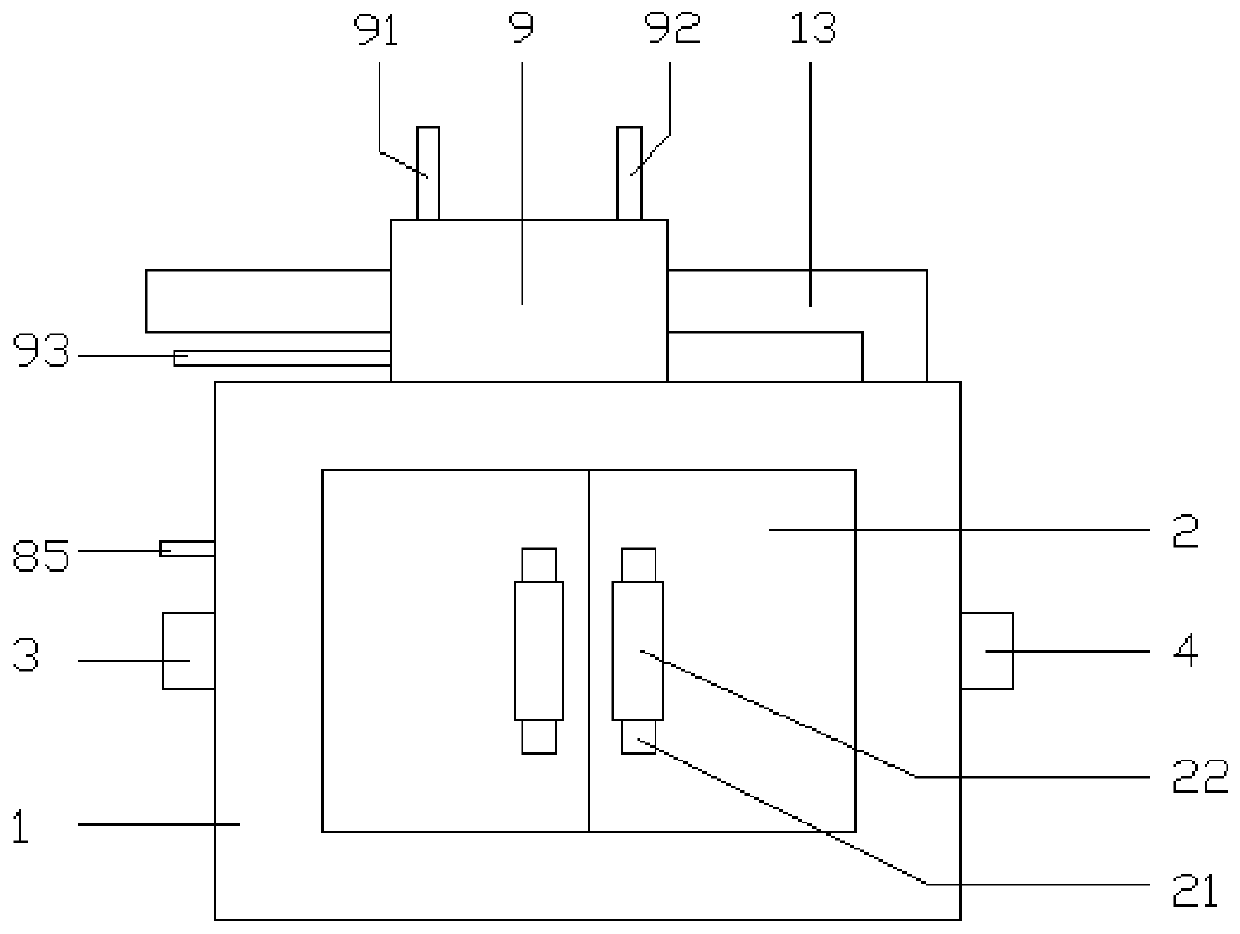

[0018] Referring to the accompanying drawings, a drying device for textile printing and dyeing according to the present invention includes a device main body 1, a movable warehouse door 2, a material inlet 3, a material outlet 4, a material guide mechanism 5, a partition 6, a drying mechanism 7, a guide A flow mechanism 8 and a waste heat collection device 9, a group of movable doors 2 are arranged on the front side of the main body 1 of the equipment, and the movable doors 2 are left and right symmetrical, and a material inlet 3 is arranged on the left side of the main body 1 of the equipment. The right side of the equipment main body 1 is provided with a material outlet 4 corresponding to the material inlet 3, and the inside of the equipment main body 1 is provided with a drying cavity 11, and the inside of the drying cavity 11 is provided with a material guide mechanism 5, a partition plate 6, drying mechanism 7 and diversion mechanism 8, a partition 6 is provided below the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com