Novel surface photovoltaic module laminating machine and machining method thereof

A photovoltaic module and laminator technology, applied in photovoltaic power generation, sustainable manufacturing/processing, electrical components, etc., can solve problems such as low heating efficiency, achieve the effects of improving efficiency, increasing service life, and ensuring temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following is attached Figure 1-5 Shown, the present invention is described in further detail. Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "bottom" and "top "Face", "inner" and "outer" refer to directions toward or away from, respectively, the geometric center of a particular component.

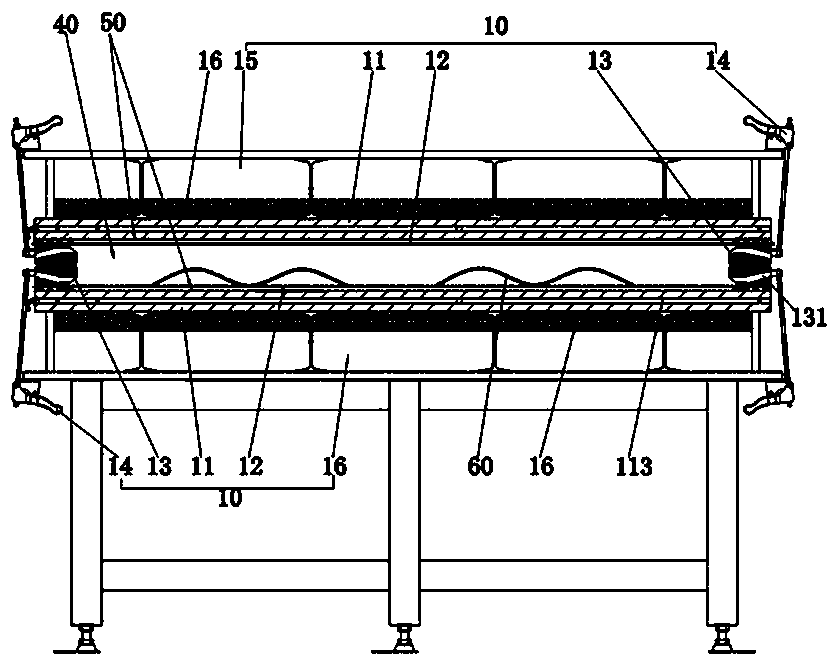

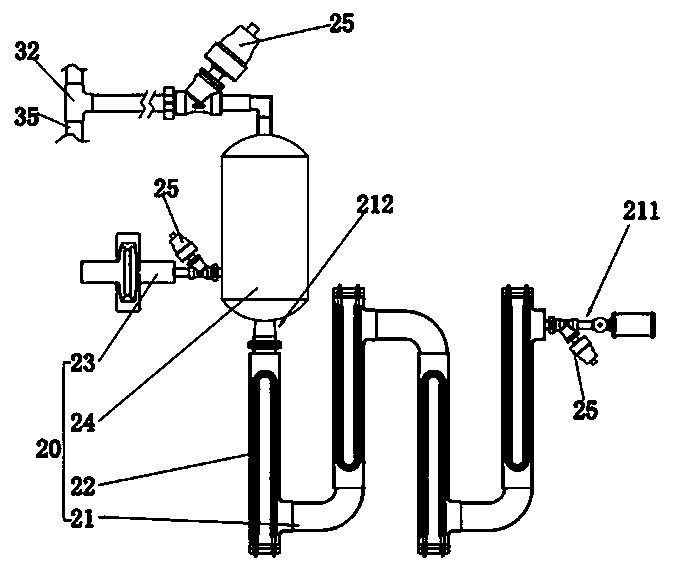

[0028] Such as figure 1 and figure 2 As shown, a new type of curved surface photovoltaic module laminator with the structure of the embodiment of the present invention includes two upper and lower heating boxes 10 oppositely arranged, an air supply heating and pressing device 20 and a vacuuming device.

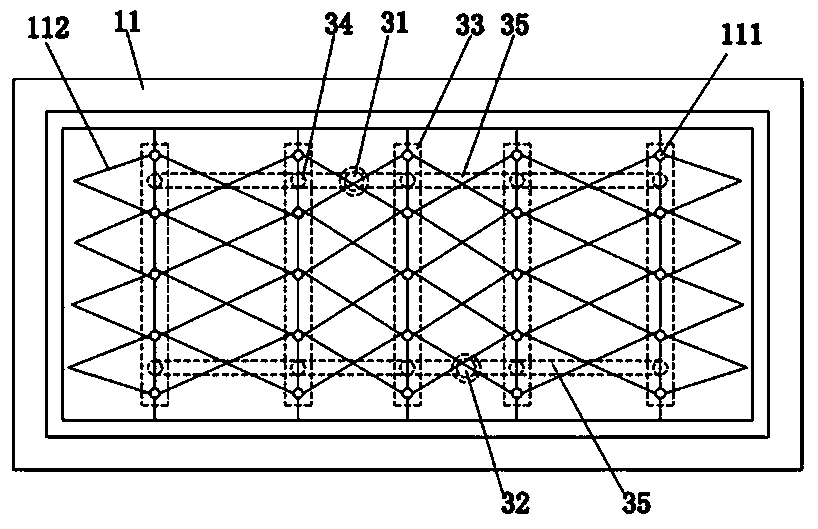

[0029] Each heating box 10 includes a chamber ceiling 11 , an elastic chamber partition 12 , a bead 13 and a connecting piece 14 . The chamber partition plate 12 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com