Patents

Literature

207results about How to "Improve response quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

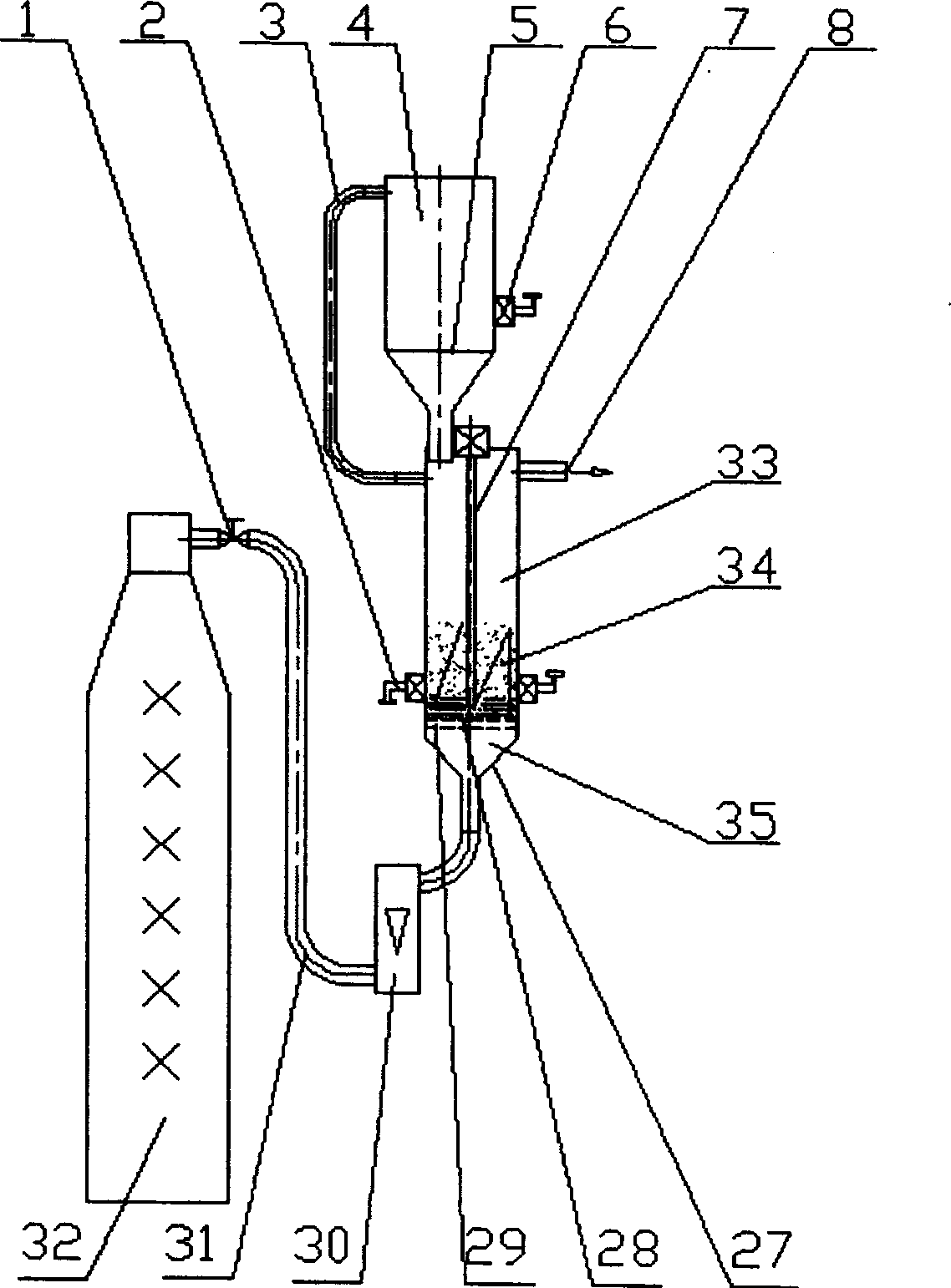

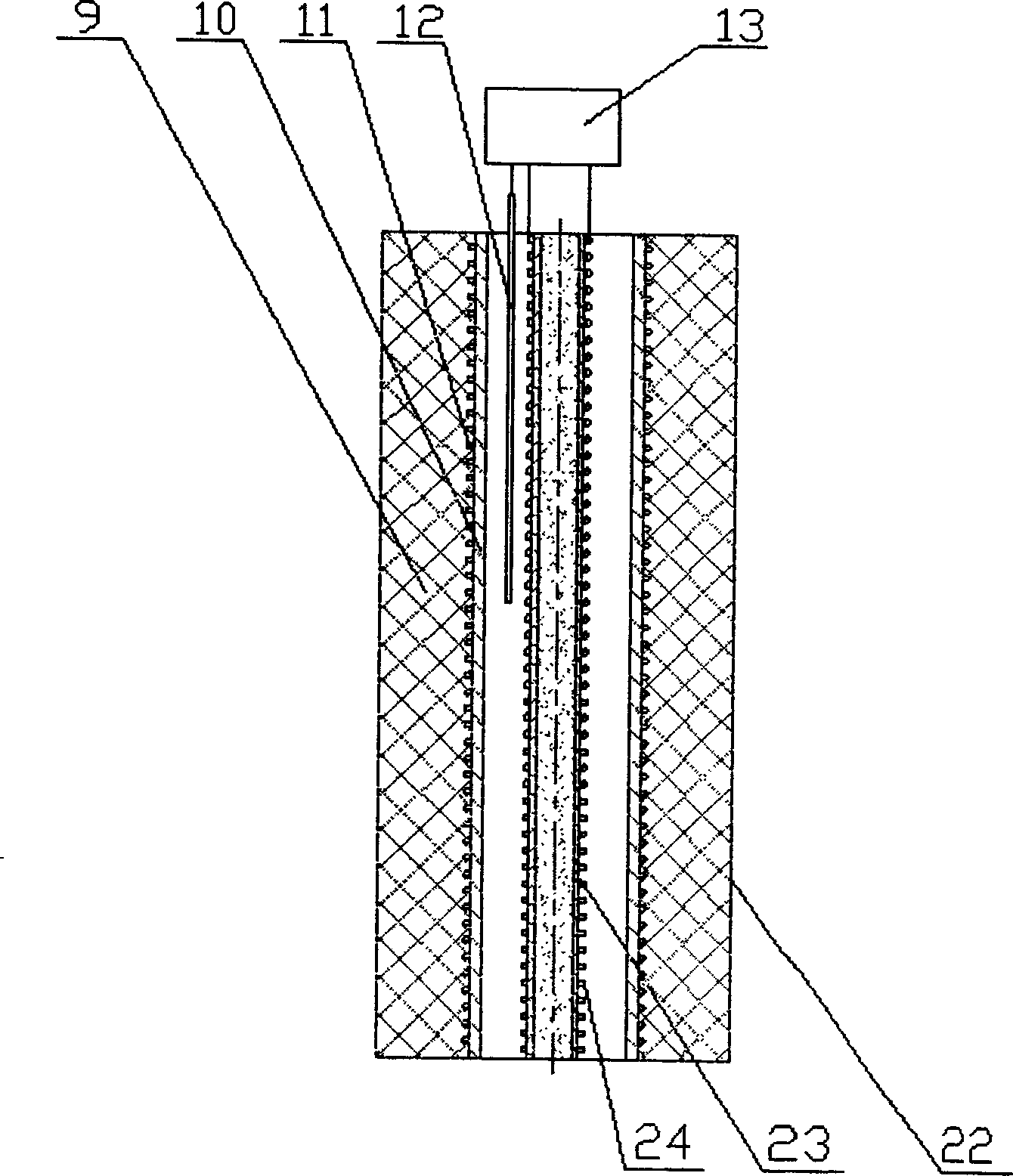

Process for ordinary pressure continuous synthesizing silicon nitride powder by fluidized bed tech.

ActiveCN1792774ALarge specific surface areaAvoid dependencyNitrogen compoundsCombustionFluidized bed

A process for continuously synthesizing silicon nitride powder under ordinary pressure by fluidized bed includes such steps as using N2 to carry the Si powder or the mixture of Si powder and silicon nitride in high-speed fluidized bed, fluidizing, fast leaving from the high-speed fluidized bed, coming in high-temp nitrifying furnace, combustion for synthetic reaction, cooling by heat exchanger, and collecting the product by bag capture.

Owner:UNIV OF SCI & TECH BEIJING

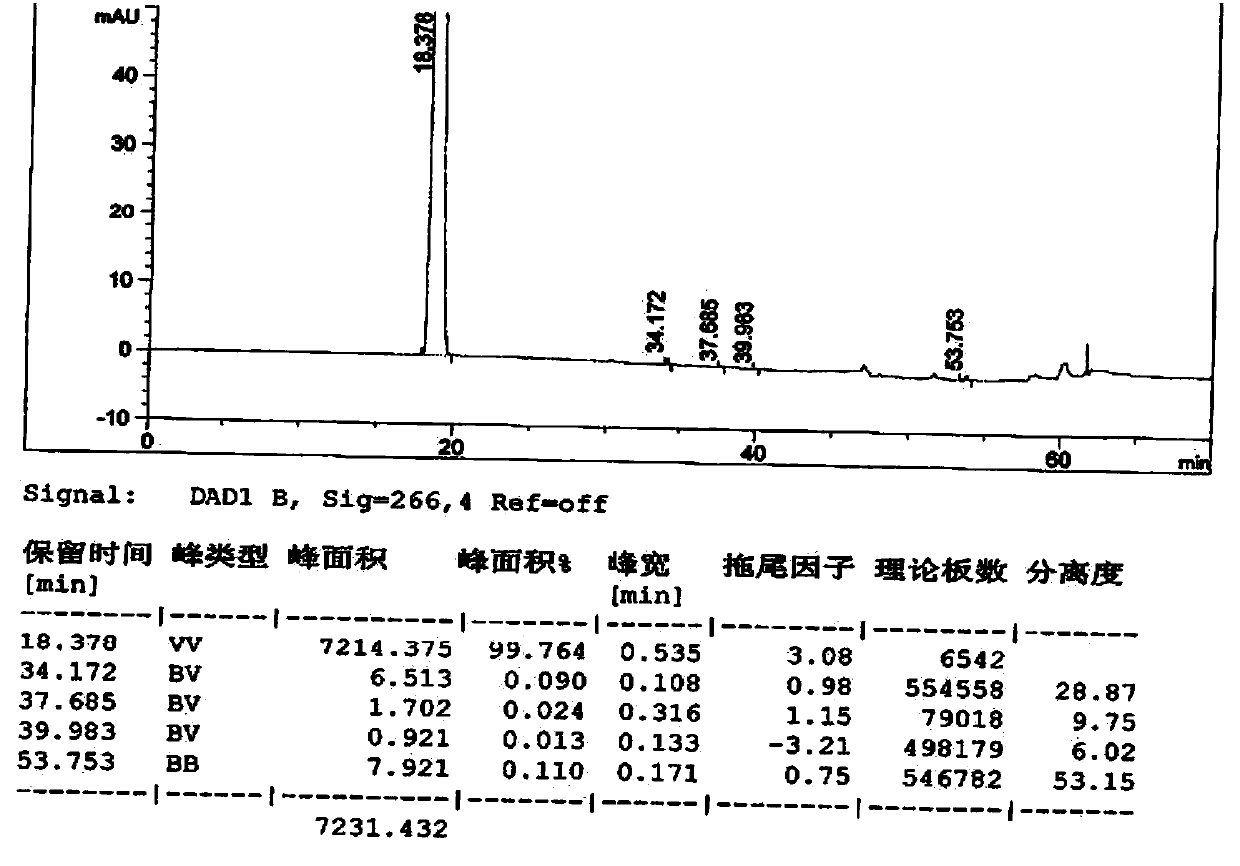

Preparation method of bromfenac sodium

ActiveCN104177272AFast responseReduce generationOrganic compound preparationAmino-carboxyl compound preparationDimethyl formamideDichloromethane

The invention relates to a preparation method of bromfenac sodium. The preparation method comprises the following steps of (a) reacting a compound represented by a formula (V) with an electrophilic substitutional reagent in the presence of N,N-dimethylformamide or dimethyl sulfoxide to obtain a compound represented by a formula (IV), (b) adding the compound represented by the formula (IV) into 2-methoxyethanol, adding phosphoric acid and carrying out acid hydrolysis to obtain a compound represented by a formula (III), (c) hydrolyzing the compound represented by the formula (III) with sodium hydroxide, extracting with dichloromethane and adding acetic acid to neutralize to obtain a compound represented by a formula (II) and (d) in the presence of an organic alcohol solvent, adding a sodium hydroxide solution, hydrolyzing the compound represented by the formula (II) to form a salt, adding the organic alcohol solvent, cooling and crystallizing to obtain bromfenac sodium. According to the preparation method disclosed by the invention, the reaction yield of the intermediate (IV) and the quality of the product are improved, high-purity bromfenac sodium can be obtained just by virtue of crystallizing with the organic alcohol solvent, the good environmental benefit is achieved and the generation of bromfenac sodium polymer impurity is reduced.

Owner:GUANGDONG XIANQIANG PHARMA +1

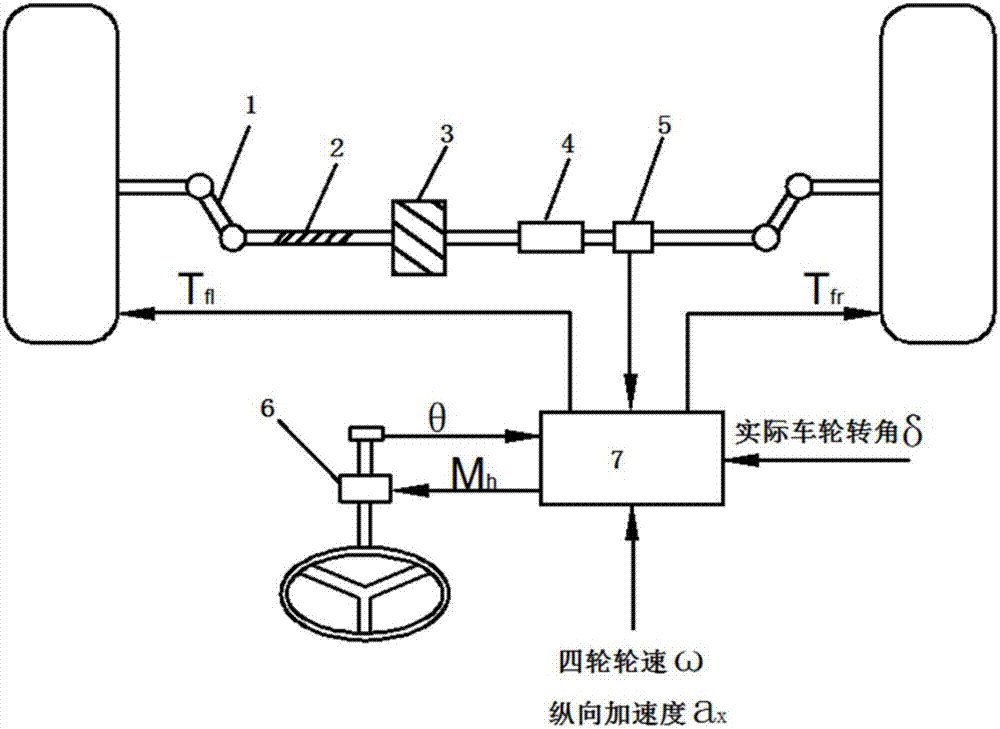

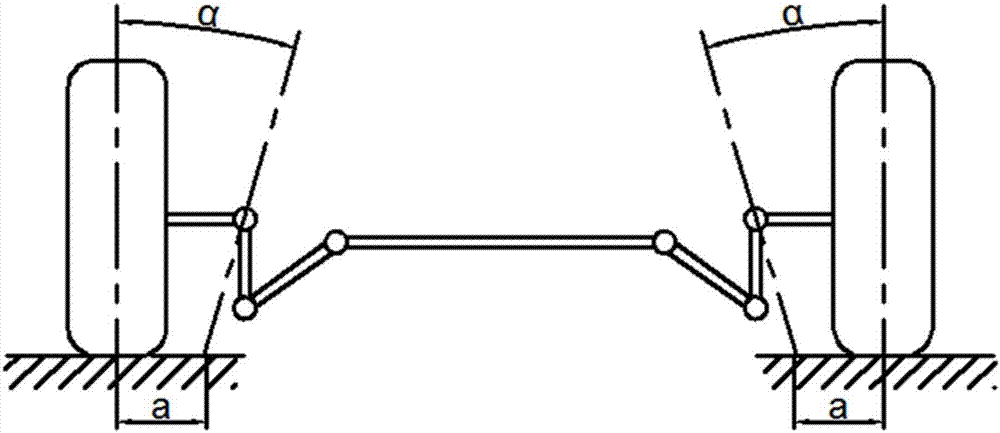

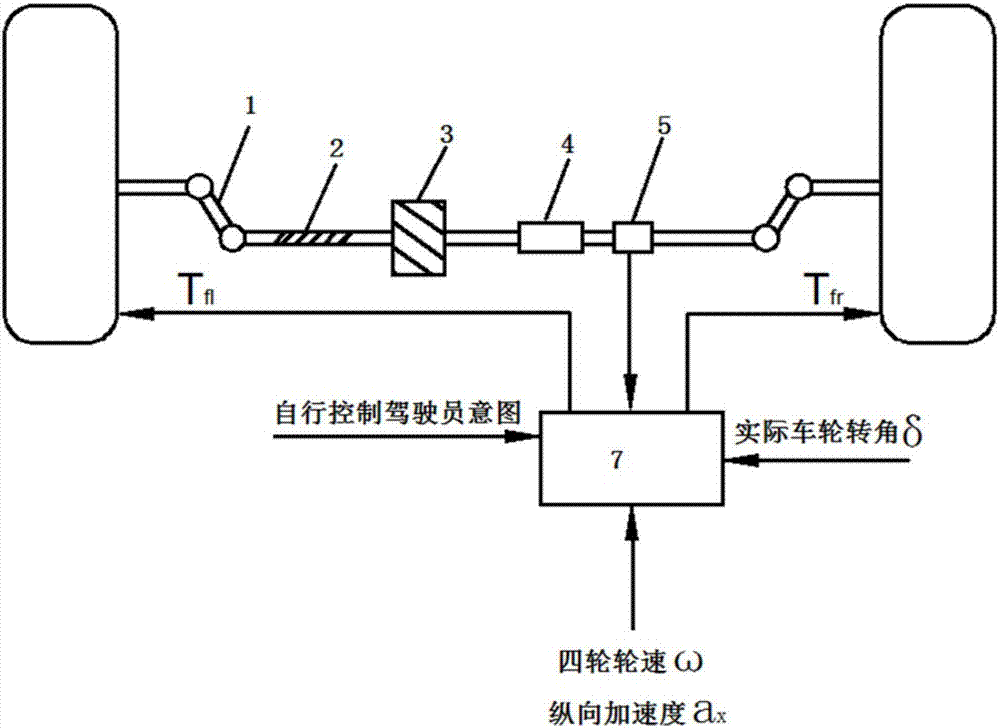

Drive-by-wire differential steering system and method for distributed driving electric vehicle

InactiveCN106915385ABig spaceImprove comfortSteering linkagesAutomatic steering controlSteering angleSteering wheel

The invention relates to a drive-by-wire differential steering system and method for a distributed driving electric vehicle. The drive-by-wire differential steering system for the distributed driving electric vehicle comprises a detection module, a drive-by-wire differential steering control module and a steering executing module, wherein the detection module is used for detecting running parameters; the drive-by-wire differential steering control module is used for obtaining target output torques of a front axle driving motor and a front axle right driving motor and transmitting a motor control signal; and the steering executing module is used for realizing differential steering of the electric vehicle. The drive-by-wire differential steering method for the distributed driving electric vehicle comprises the steps that a vehicle controller obtains the running speed of the electric vehicle; the drive-by-wire differential steering controller calculates according to a steering angle of a steering wheel and the running speed to obtain a front axle differential torque of the electric vehicle; the vehicle controller calculates to obtain a front wheel driving motor target torque; the drive-by-wire differential steering controller respectively obtains target output torques of a left front wheel and a right front wheel through calculation; and a motor controller controls a driving motor and a steering executing component to move and also controls a steering wheel aligning moment motor to output moment. Compared with the prior art, the drive-by-wire differential steering system for the distributed driving electric vehicle has the advantages of simple structure, accurate steering and so on.

Owner:TONGJI UNIV

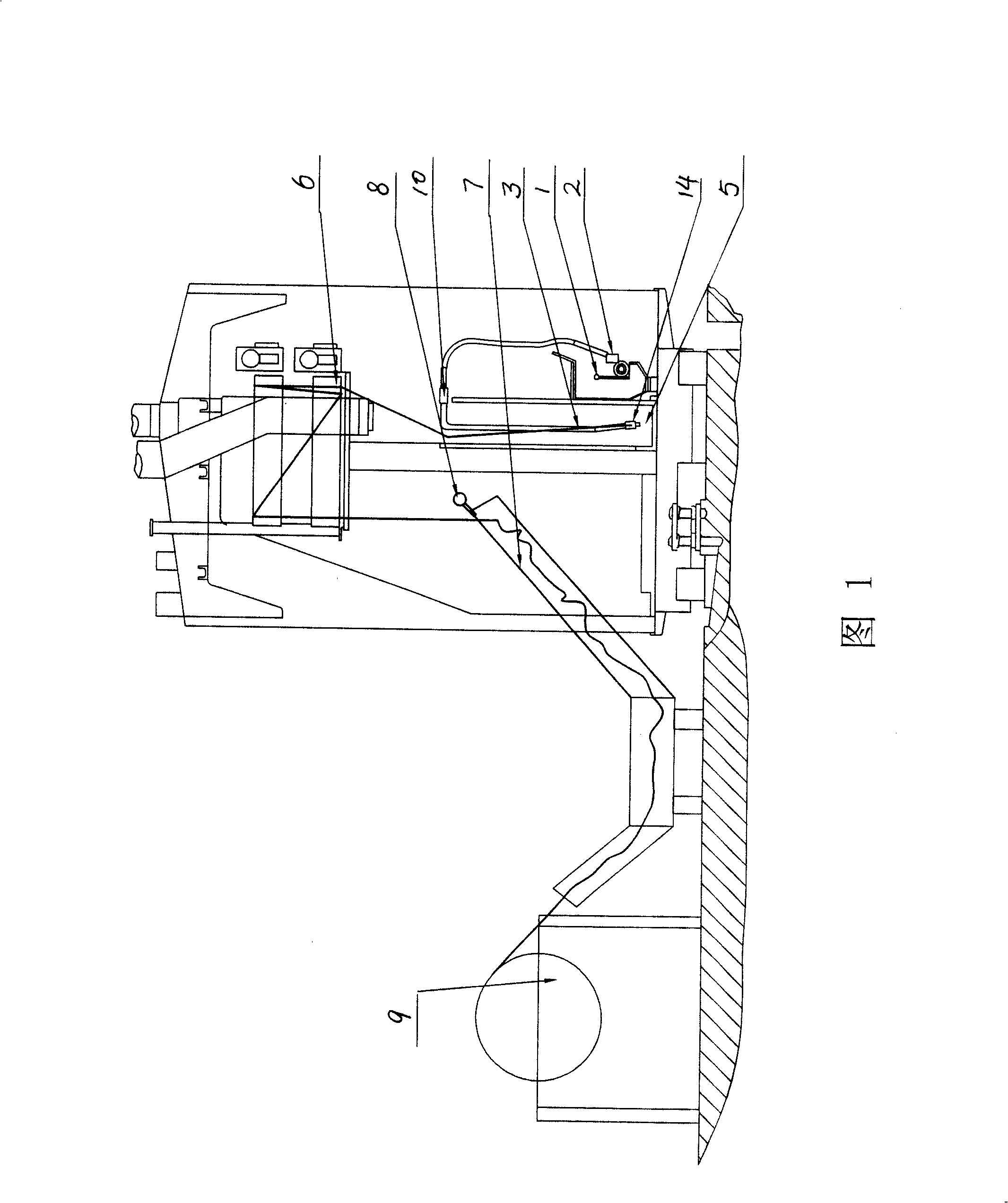

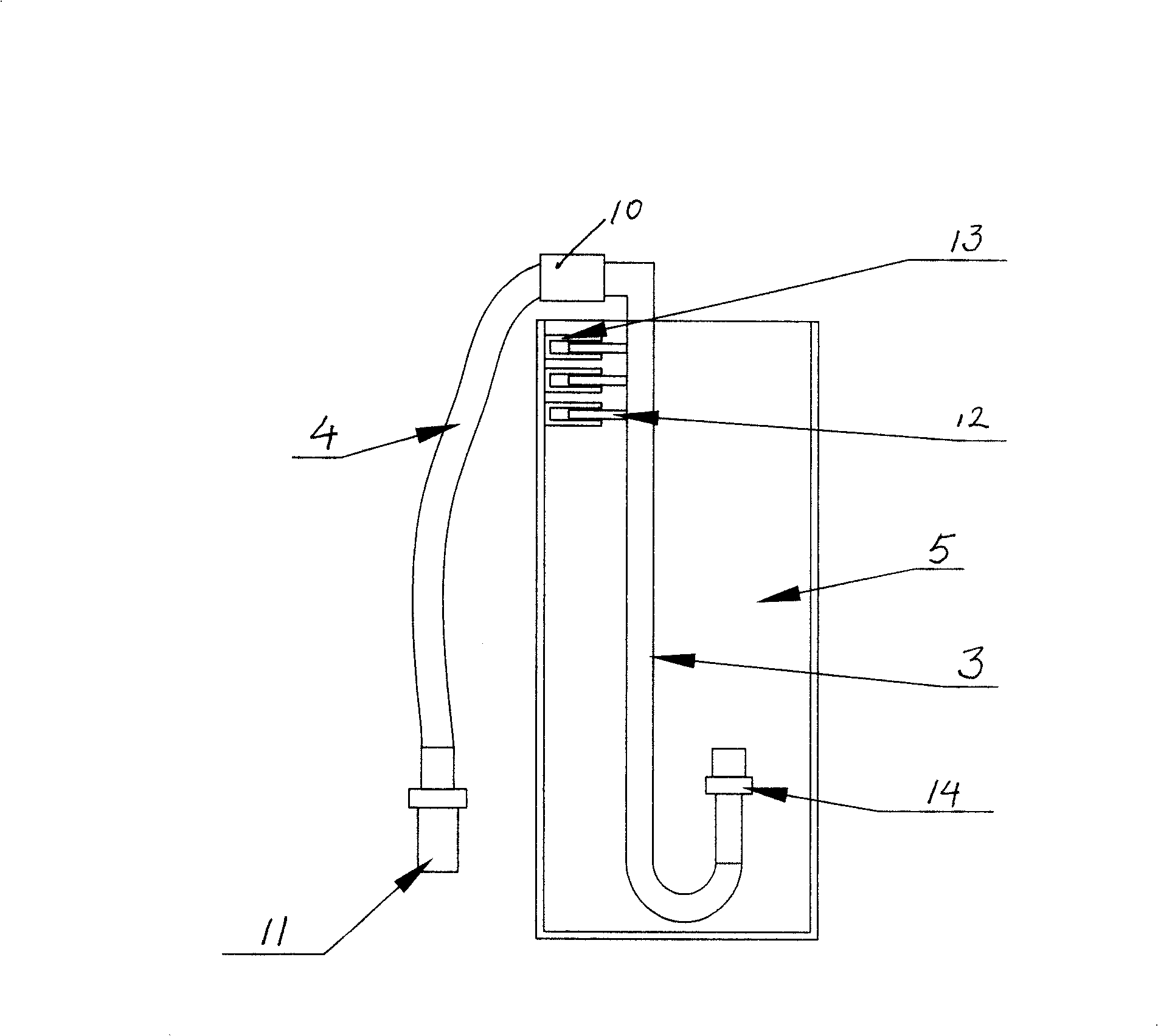

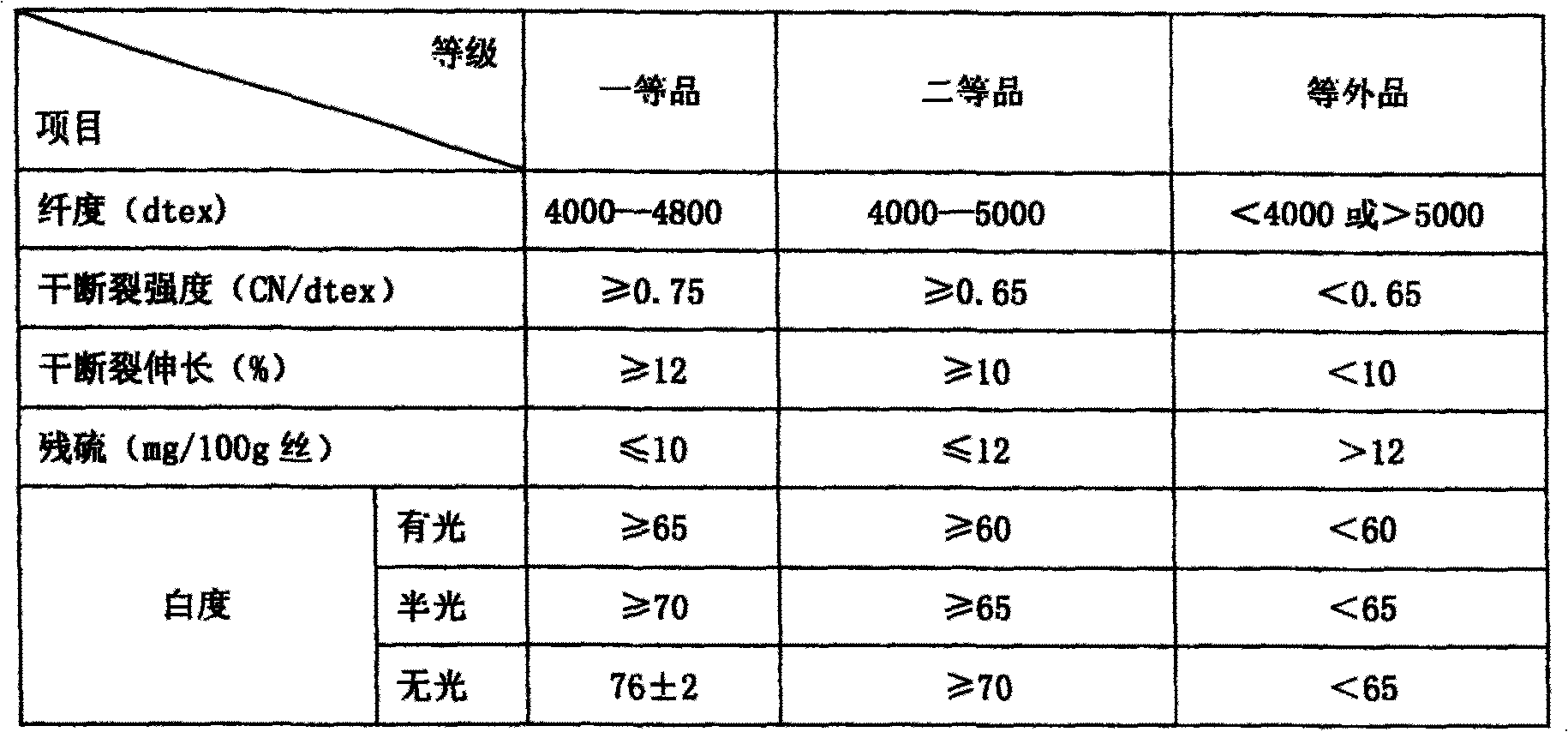

Special-shaped flattened rayon spinning technique

InactiveCN101245495AQuality assuranceGuaranteed performanceFilament/thread formingEngineeringNatural degradation

The invention discloses a spinning technique used for producing viscose artificial fiber of deformed and flat monofilament in the spinning field. The procedures of spinning technique comprises the processes of gel-supplying, metering, filtrating, spinning, solidification bath, drafting, deacidification, strand silk forming; in the process of drafting, strand silk is directly drafted from a nozzle to a drafting roll assembly which comprises at least two couples of drafting rolls with different diameters; linear speed difference of the drafting rolls generates drafting force for drafting the strand silk; in the process of deacidification, the strand silk falls into a deacidification trough from the drafting rolls for deacidification by a mode of soaking and washing; in the process of forming strand silk, a wring-loading style winding mechanism is adopted for winding the strand silk. The technique is applicable to the production of deformed and flat monofilament which substitutes the synthesized fiber material that is hard for natural degradation, and meets requirements of using green, environment friendly material in domestic and foreign package material, artware and clothing decoration fields, etc. The technique is also applicable to the production of other deformed monofilament, conventional monofilament and multifilament products.

Owner:YIBIN HIEST FIBER

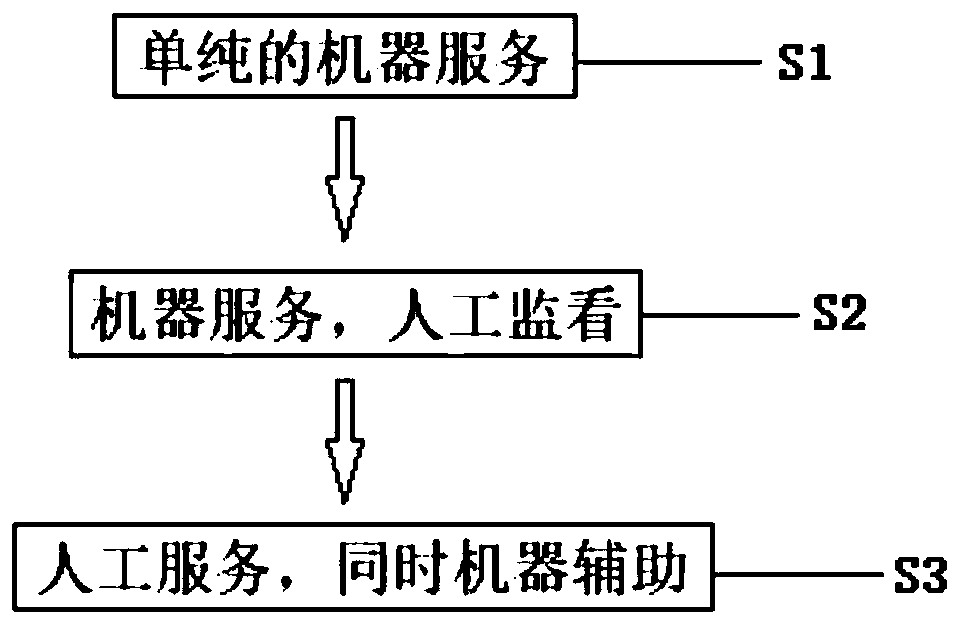

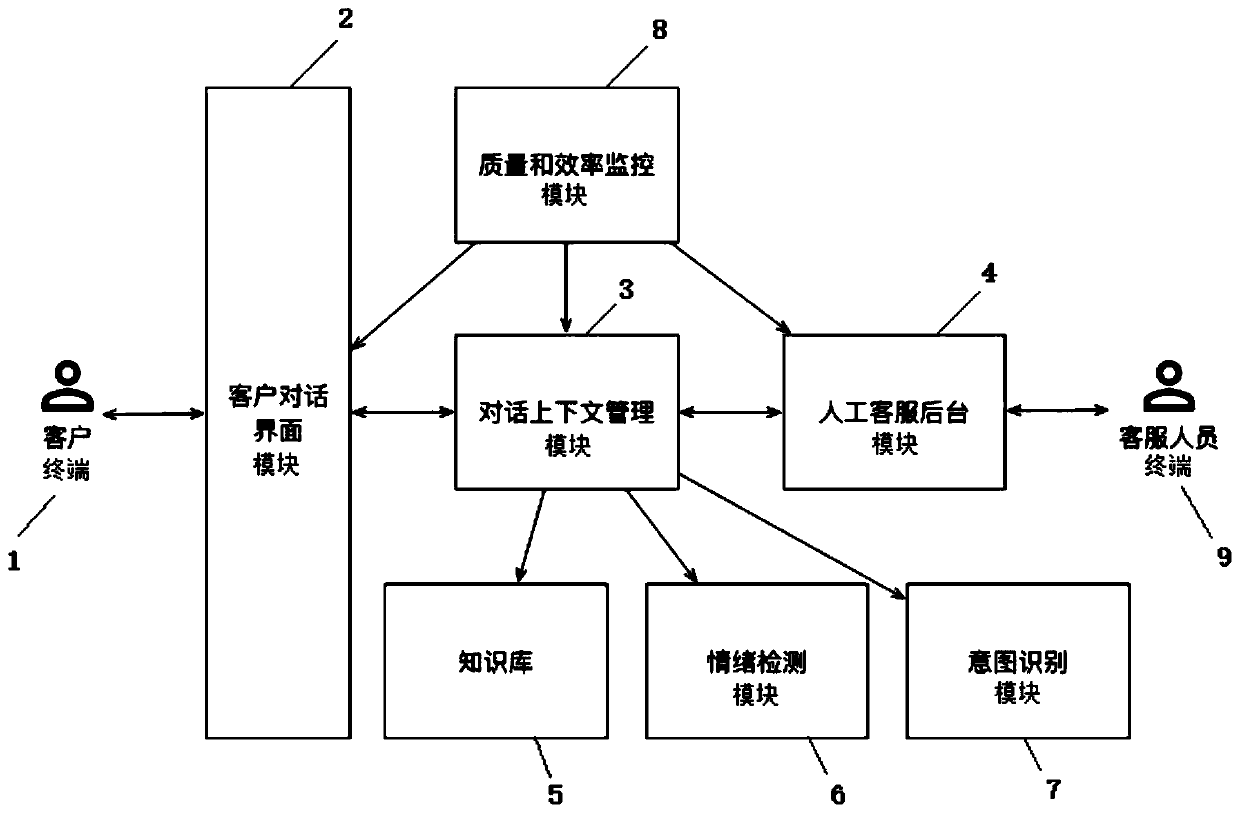

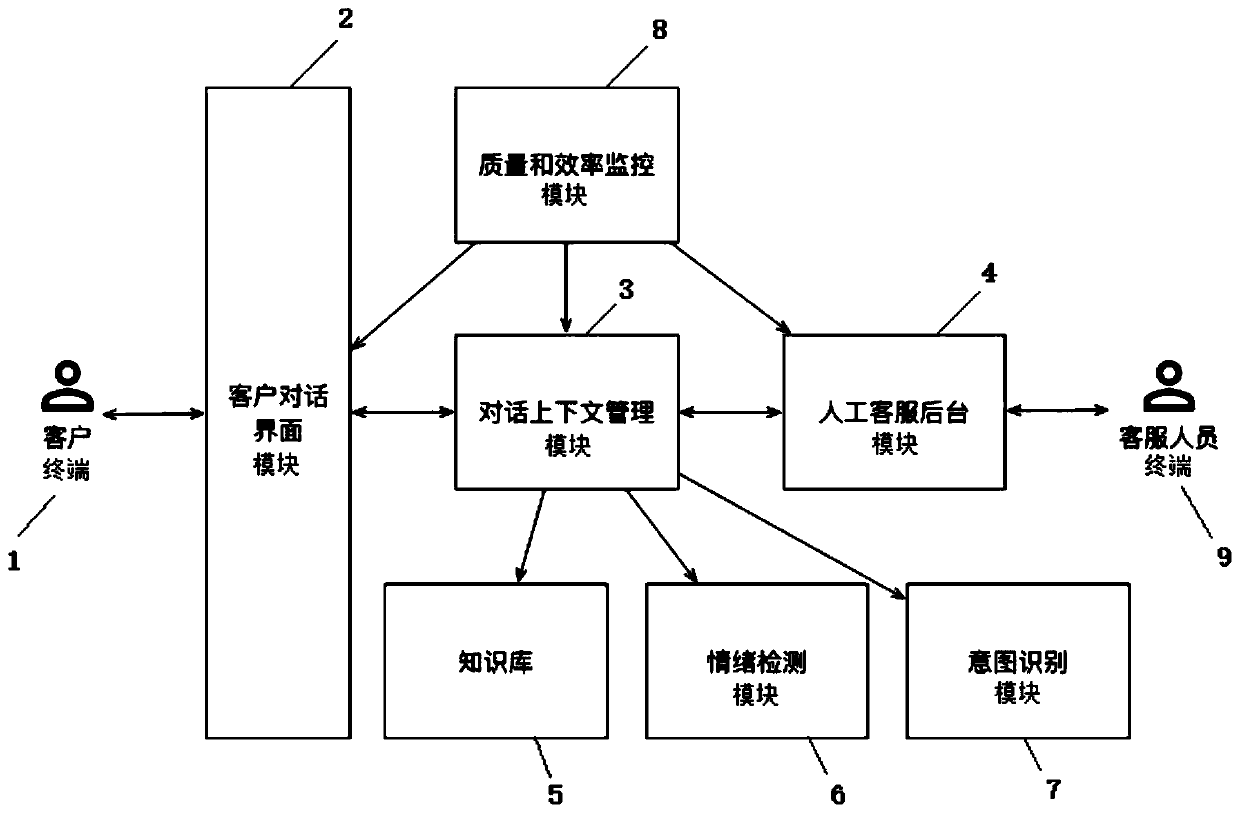

An efficient intelligent customer service method and system oriented to customer guidance in the field of electronic commerce

PendingCN109919671ASolve efficiency problemsSolve quality problemsMarketingSpecial data processing applicationsService experienceMan machine

The invention relates to an efficient intelligent customer service method and system oriented to customer guidance in the field of electronic commerce. According to the invention, the efficiency and quality problems of an intelligent customer service system in an e-commerce scene are solved; Index of service quality and service efficiency of consultation and response is reformulated, an integratedservice quality and service efficiency assessment standard taking a client as the center is defined, and a new mode and a new process of robot service and man-machine cooperation are provided. The first stage is pure machine service; In the second stage, machine service and manual monitoring are carried out; And the third stage is manual service, and meanwhile machine assistance is achieved. According to the invention, better consultation and response service experience is provided for a client, and man-machine switching is seamless and smooth; Emotion of the client is paid attention to and protected, manual service can be switched into in time, and more intimate and comprehensive service is obtained. And the service level, including the service quality and efficiency, can be quantified in real time, and can be fed back to the machine and the manual customer service in time to make corresponding adjustments.

Owner:上海宝尊电子商务有限公司

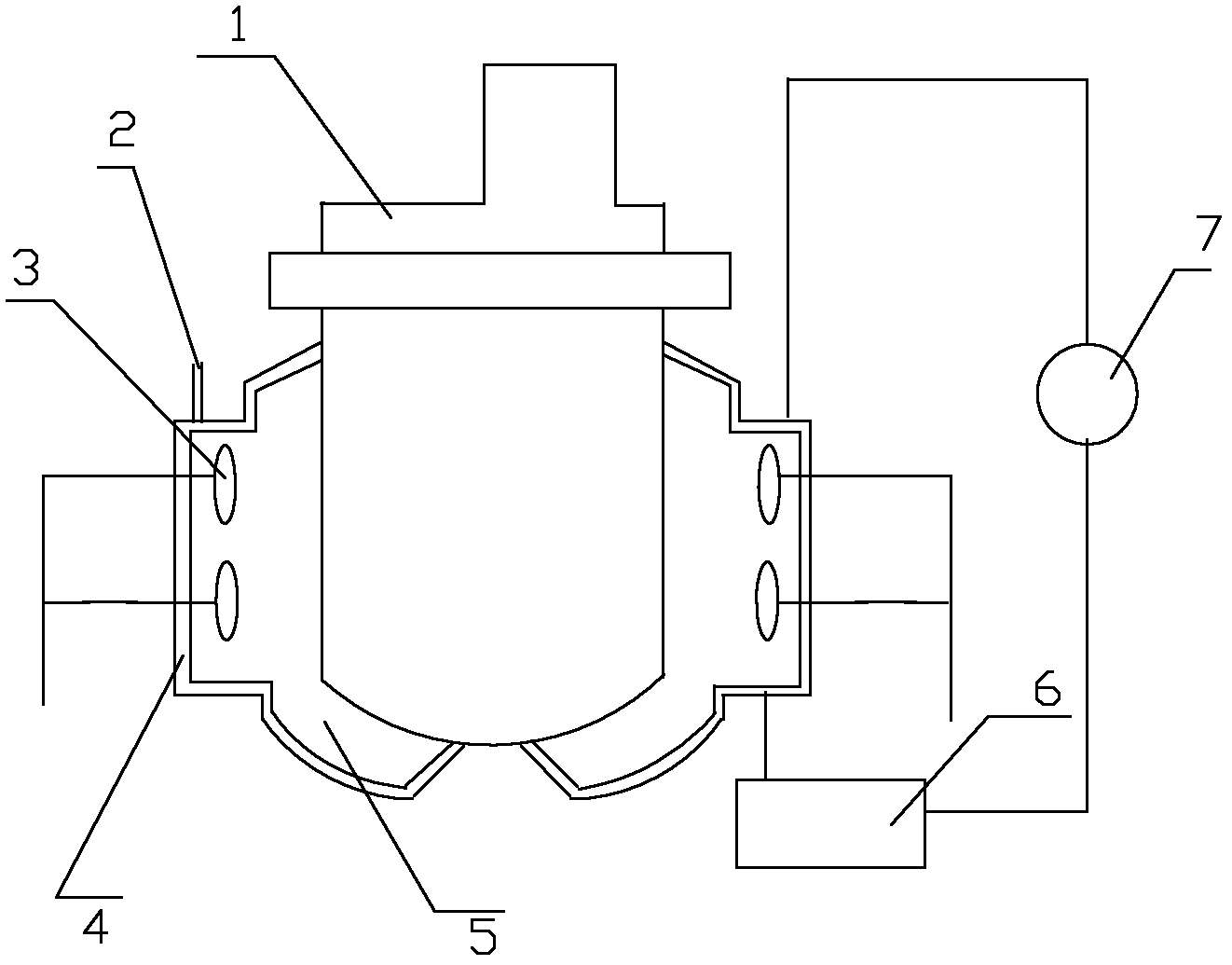

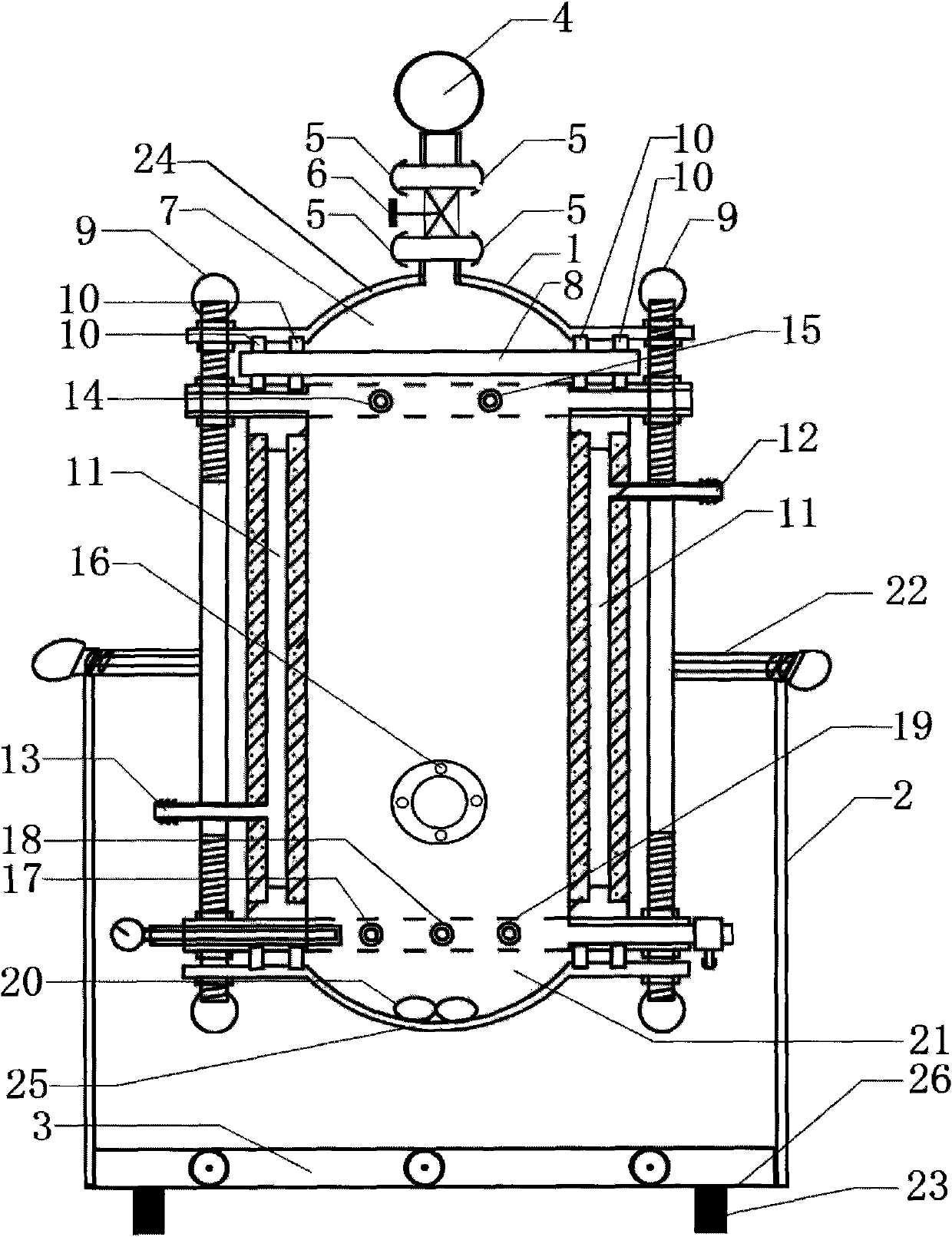

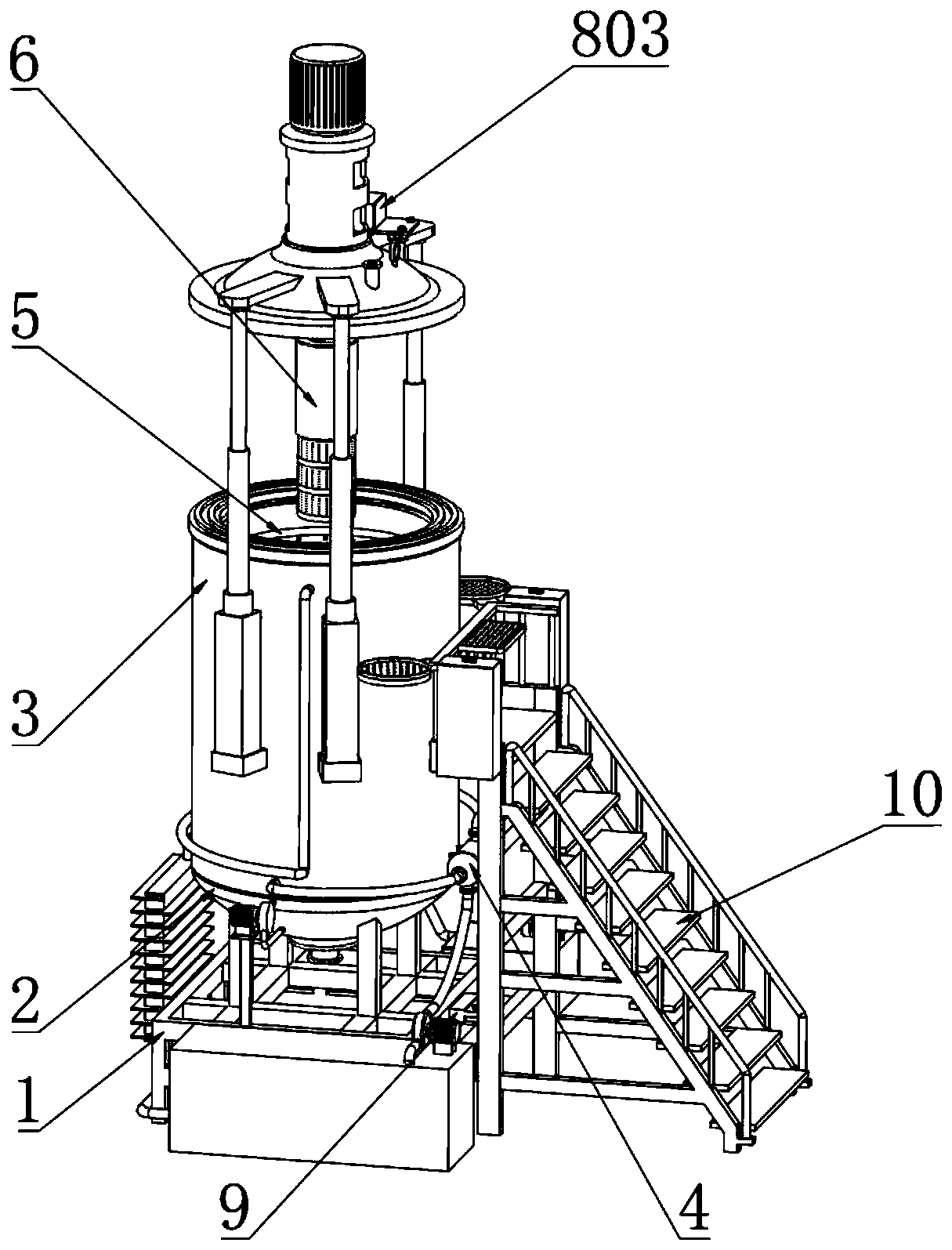

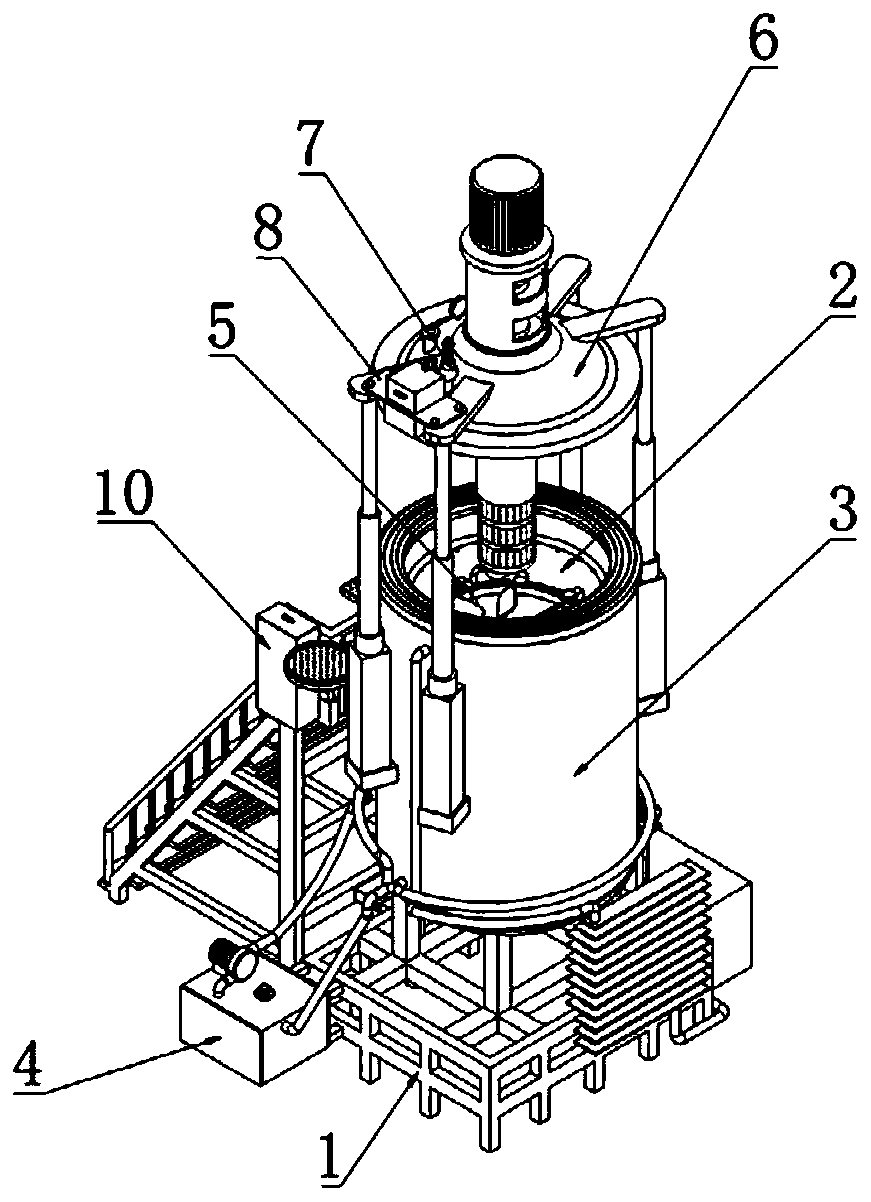

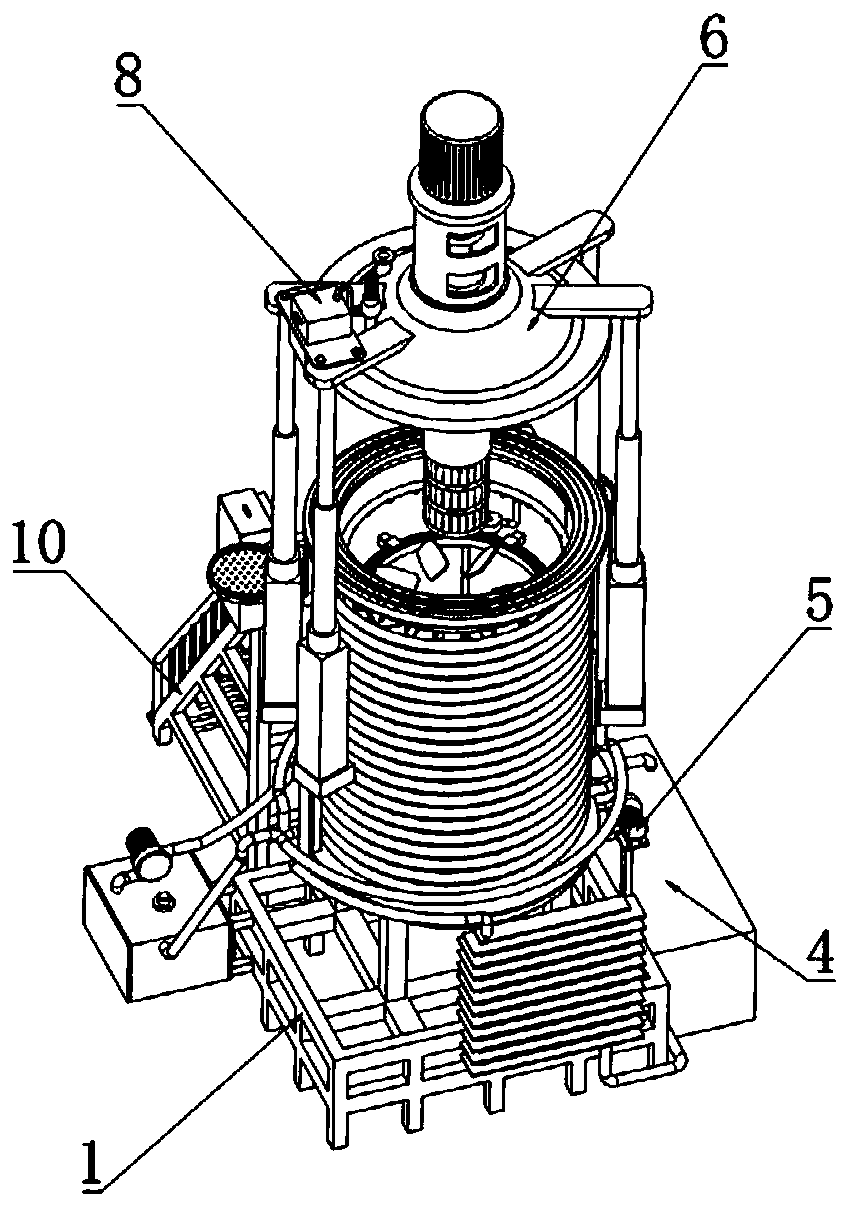

Conduction oil heating reaction kettle system

InactiveCN103100361AStable heating temperatureImprove response qualityChemical/physical/physico-chemical processesThermal fluidsOil pump

The invention discloses a conduction oil heating reaction kettle system. The system comprises a reaction kettle, a heat-conducting jacket arranged outside the reaction kettle and filled with conduction oil, and a plurality of parallel electric heating devices in the heat-conducting jacket, and further comprises an oil tank and a circulating oil pump for circulating the oil in the heat-conducting jacket and the oil in the oil tank. The heat-conducting jacket is connected with the oil tank through the circulating oil pump which is used for circuiting the oil in the heat-conducting jacket and the oil in the oil tank; and therefore, the conduction oil in the heat-conducting jacket is always at a constant temperature to heat the reaction kettle, the stabilization of the heating temperature is guaranteed, and the reaction quality is greatly improved.

Owner:天津市天诚化工有限公司

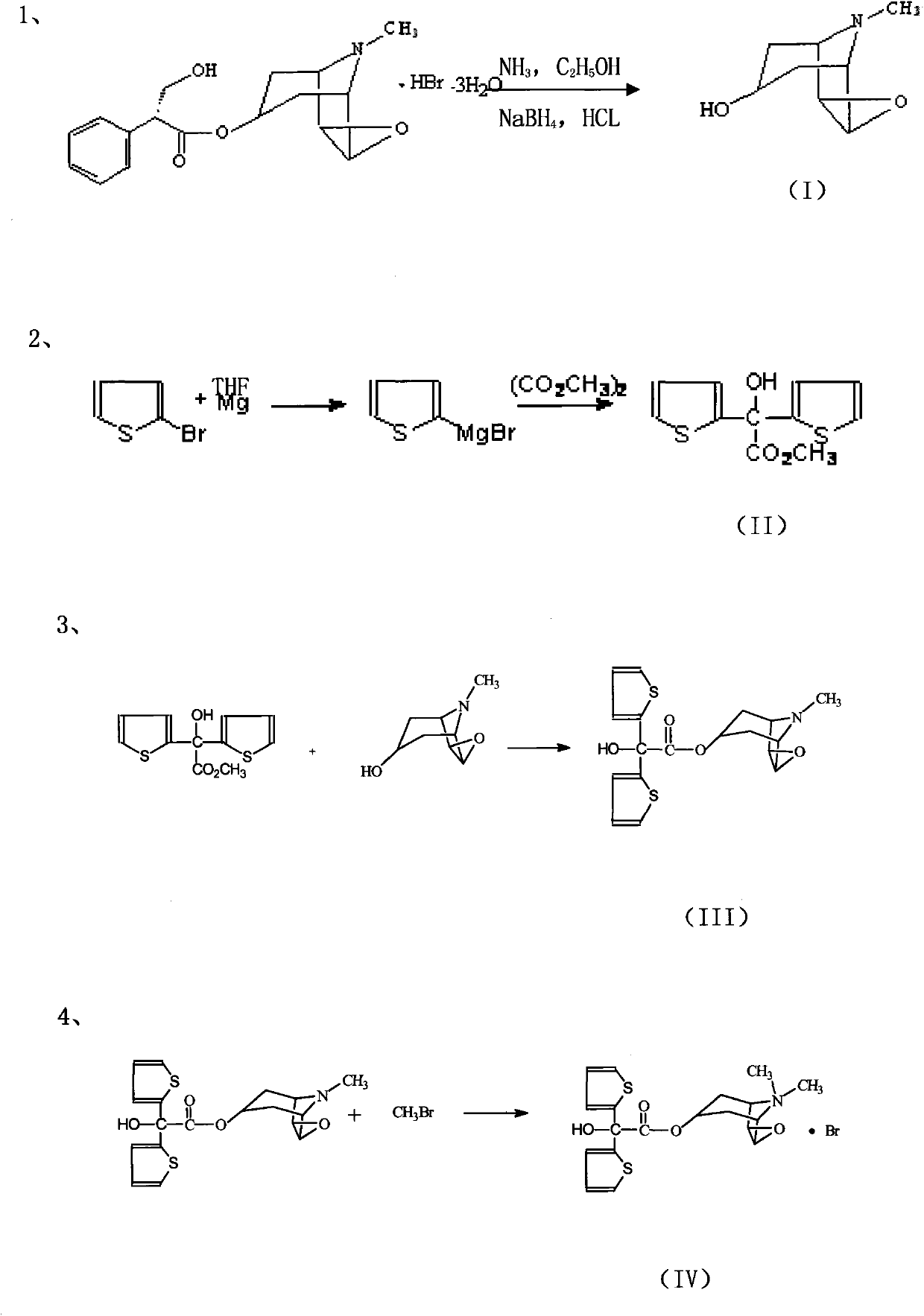

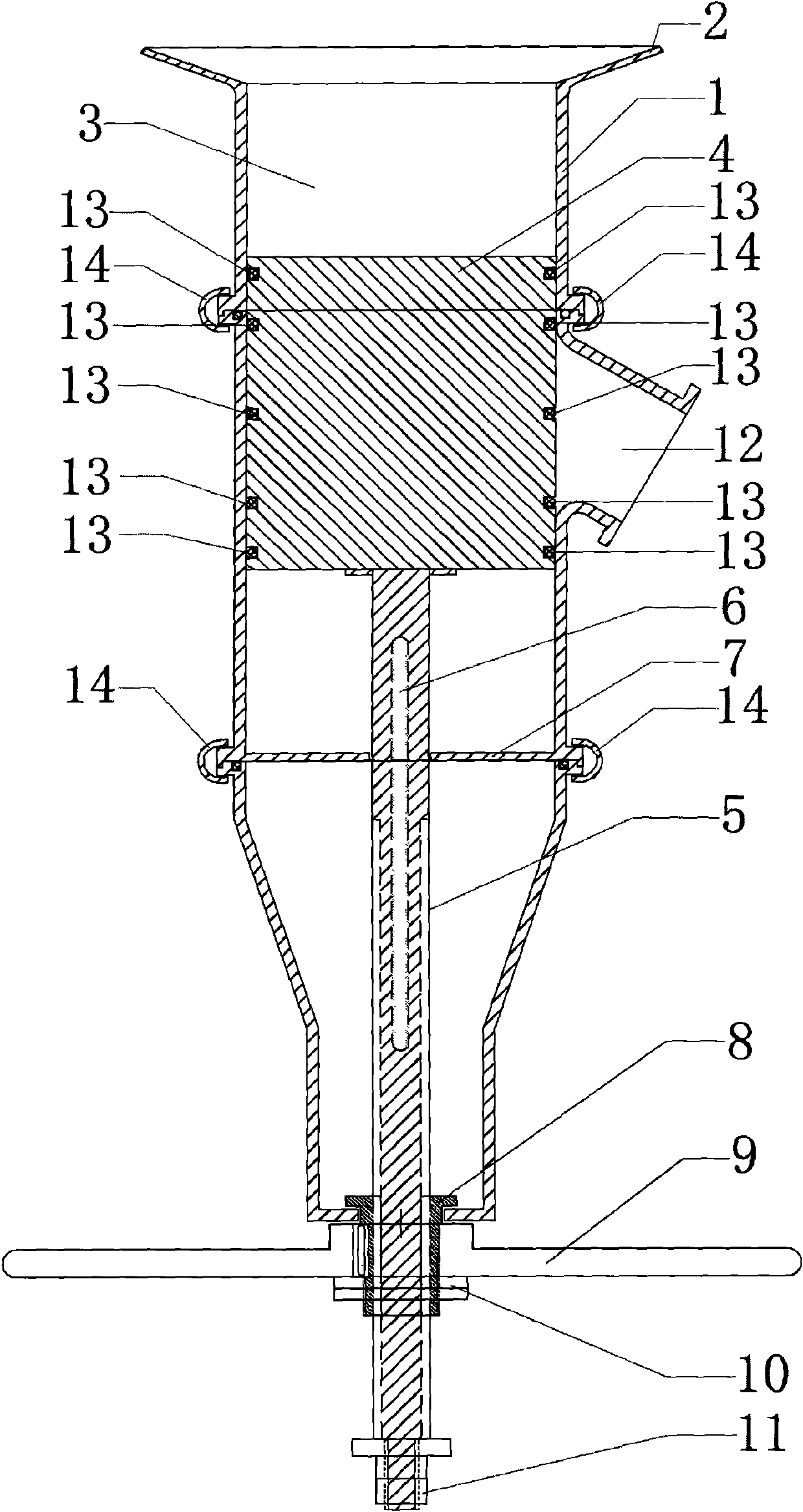

Tiotropium bromide anhydride and preparation method thereof

ActiveCN101768158AQuality improvementHigh yieldOrganic chemistryFiltration separationGrignard reagentDimethyl oxalate

The invention discloses a method for preparing tiotropium bromide anhydride, which comprises the steps of: under the anhydrous and anaerobic condition, preparing an intermediate I by taking a special kettle bottom valve and a multi-functional reaction kettle as a reactor, taking a special filter as refining equipment and taking hydrobromic scopolamine as an initial raw material through reduction hydrogenation reaction; preparing an intermediate II by performing addition reaction of Grignard reagent and dimethyl oxalate in tetrahydrofuran, wherein the Grignard reagent is prepared from bromothiophene by taking tetrahydrofuran as a medium through iodine catalysis; preparing an intermediate III by performing ester exchange condensation reaction of the intermediate I and the intermediate II under the action of sodium; preparing an intermediate IV from the intermediate III through methylation bromination reaction; and preparing the tiotropium bromide anhydride by performing the activated carbon decoloration and recrystallization on the intermediate IV by using aqueous solution and acetonitrile methanol isopropyl ether solution. Compared with those in the prior art, reaction products of the method have the advantages of good quality, high yield, controlled reaction process, safe production and good environmental protection effect.

Owner:HONGYI SCI & TECH CO LTD NANCHANG

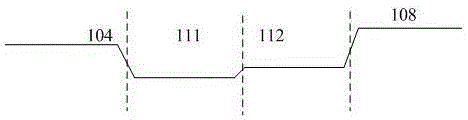

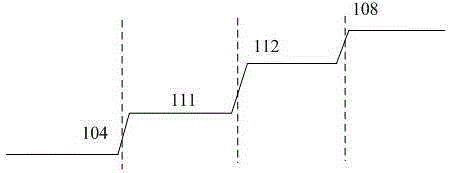

Method for improving carrier transmission efficiency of backside illumination image sensor

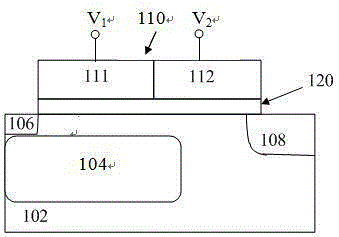

InactiveCN105161462AFlexible potential adjustmentImprove reaction speedSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringFloating diffusion

The invention provides a method for improving the carrier transmission efficiency of a backside illumination image sensor. The method comprises the following steps of: forming a photodiode and a floating diffusion region; forming a transfer transistor, wherein the source electrode of the transfer transistor is a carrier collecting region of the photodiode, the drain electrode of the transfer transistor is the floating diffusion region, the polycrystalline silicon gate electrode of the transfer transistor successively comprises, along the direction from the source electrode to the drain electrode of the transfer transistor, a P-type doped gate region and an N-type doped gate region, the P-type doped gate region at least partially covers the carrier collecting region of the photodiode, and the N-type doped gate region at least partially covers the channel region of the transfer transistor; applying a first voltage signal to the P-type doped gate region and applying a second voltage signal to the N-type doped gate region in order that the potential in the channel region is distributed in a stepped manner so as to improve the transmission efficiency of the carriers from the photodiode to the floating diffusion region, wherein the first voltage signal is not higher than the second voltage signal.

Owner:GALAXYCORE SHANGHAI

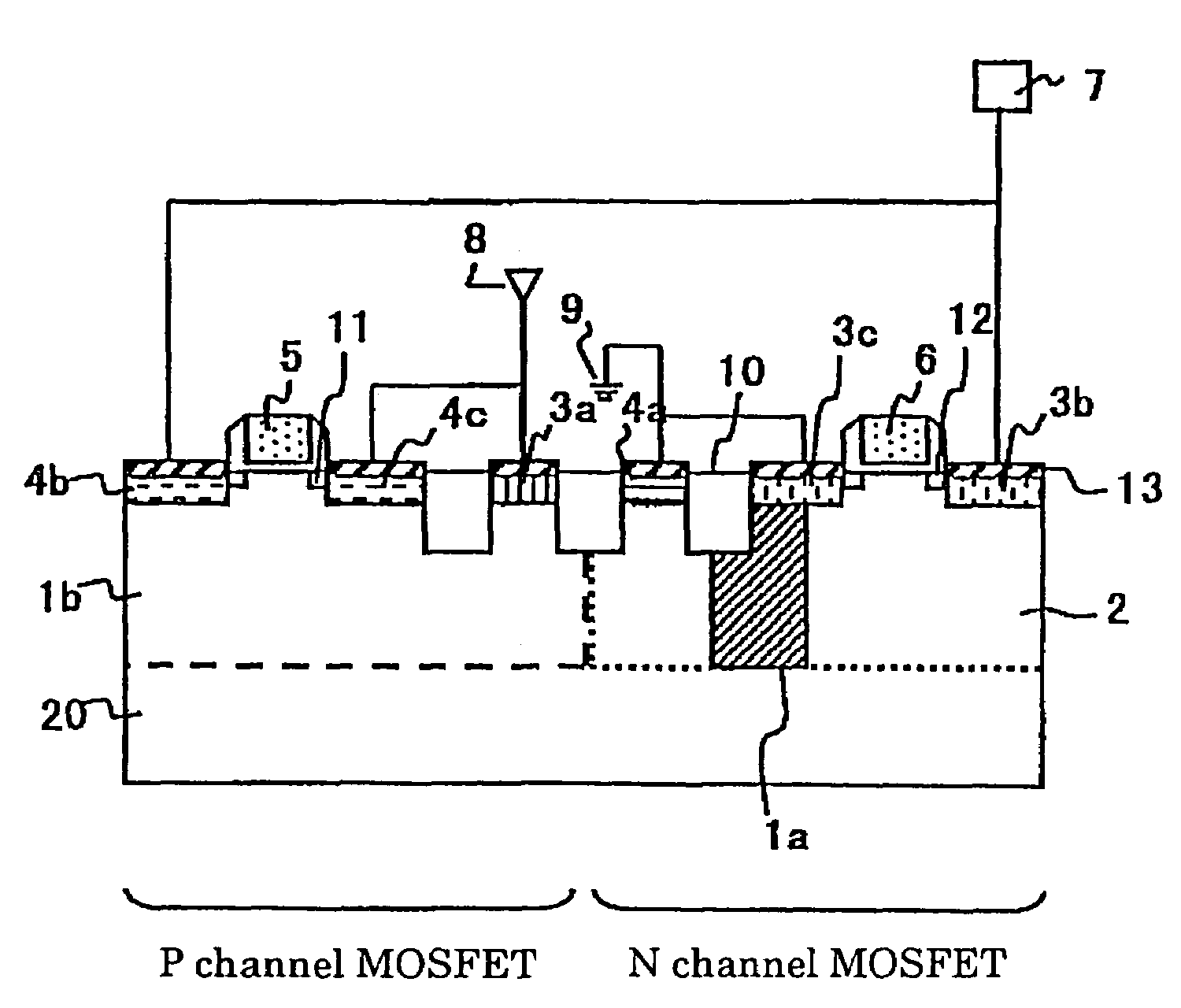

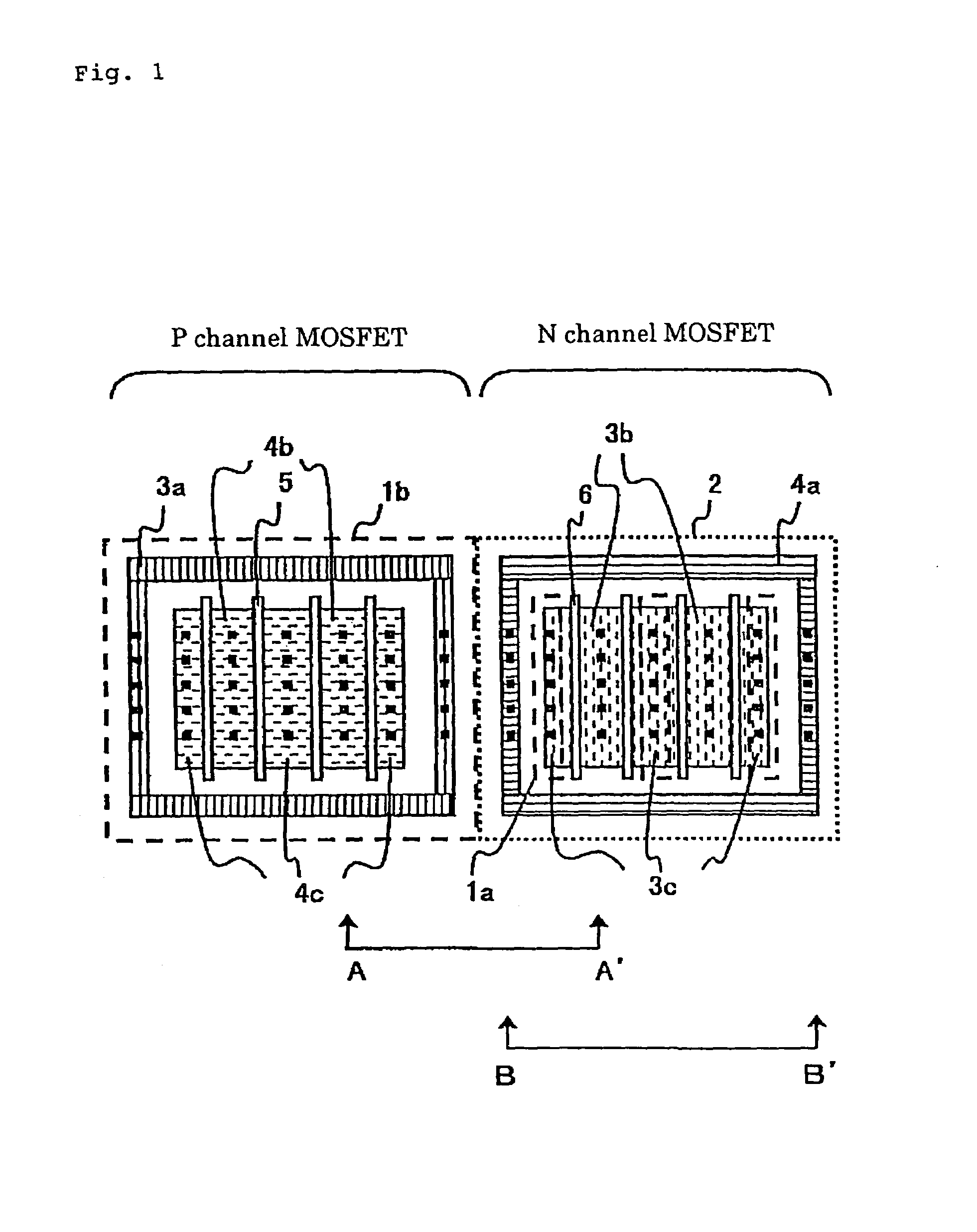

Semiconductor device

InactiveUS7064392B1Improve drivabilityQuality improvementTransistorSemiconductor/solid-state device detailsDopantField-effect transistor

In an N-channel type field effect transistor constituting an input / output protection circuit, an N-type well 1a with a lower dopant concentration than the source region 3c is formed under the source region 3c.

Owner:NEC ELECTRONICS CORP

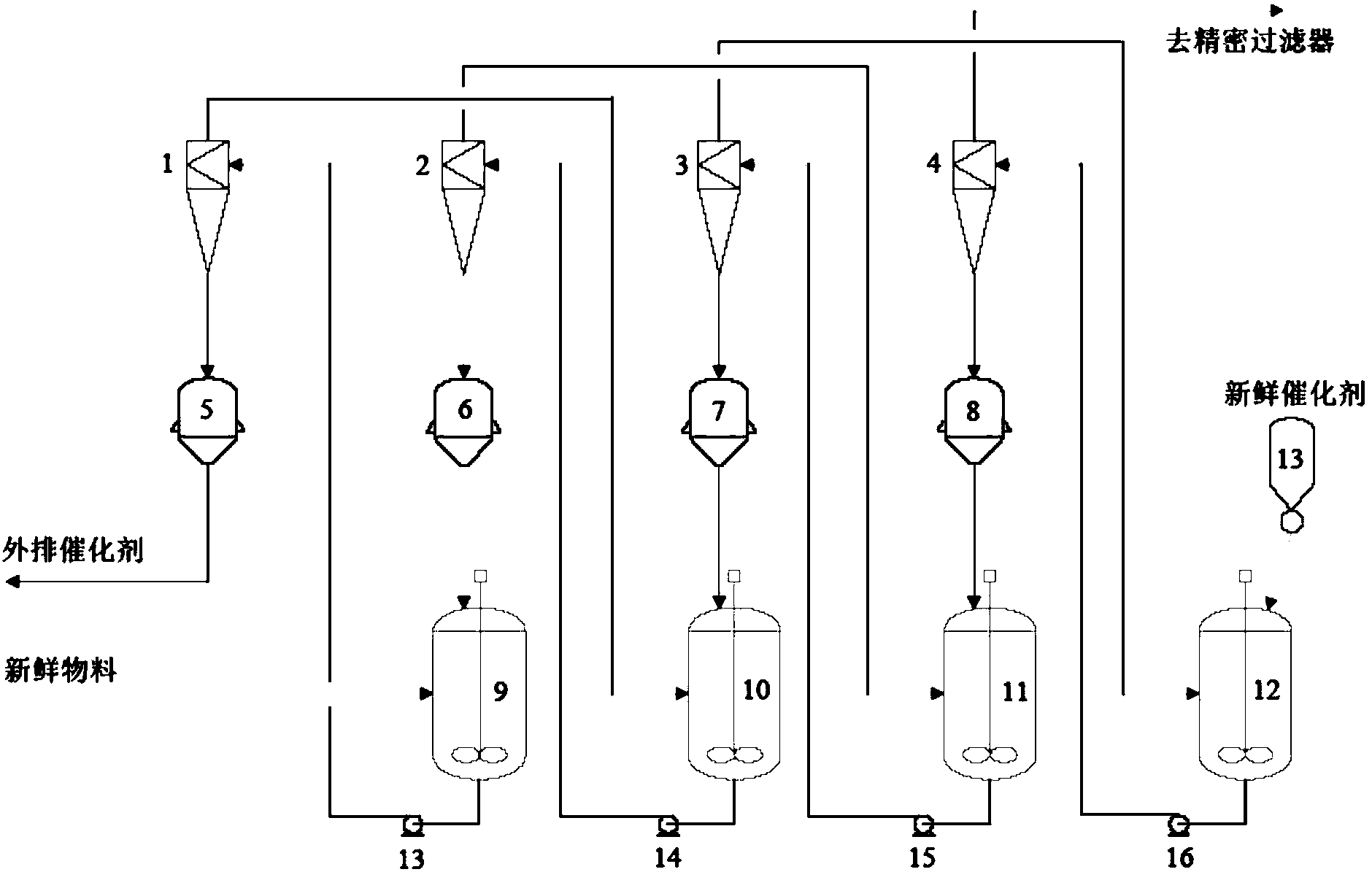

Method and device for utilizing catalyst in ethylidene norbornene isosynthesis technology

ActiveCN104058912AWater inactivationImprove efficiencyHydrocarbon by isomerisationNorborneneReaction system

The invention relates to a method and device for utilizing catalyst in the ethylidene norbornene isosynthesis technology, and provides the method for utilizing the catalyst in the ethylidene norbornene isosynthesis technology. The method comprises the steps that a multi-level stirring reaction kettle set is composed of two or more stirring reaction kettles connected in series; fresh vinyl norbornene raw materials continuously enter a reaction system to be reacted through the first-level stirring reaction kettle in the multi-level stirring reaction kettle set, the obtained ethylidene norbornene passes through grading whirlcones arranged among the multiple levels of stirring reaction kettles in the multi-level stirring reaction kettle set, liquid and solid separation is carried out on the obtained ethylidene norbornene , and then continuous discharging is carried out through the last-level stirring reaction kettle in the multi-level stirring reaction kettle set; the fresh catalyst continuously enters the reaction system through the last-level stirring reaction kettle to be involved in the reaction and enters the grading whirlcones arranged among the multiple levels of stirring reaction kettles in the multi-level stirring reaction kettle set, liquid and solid separation is carried out on the fresh catalyst, and then the fresh catalyst is discharged out of the first-level stirring reaction kettle.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION

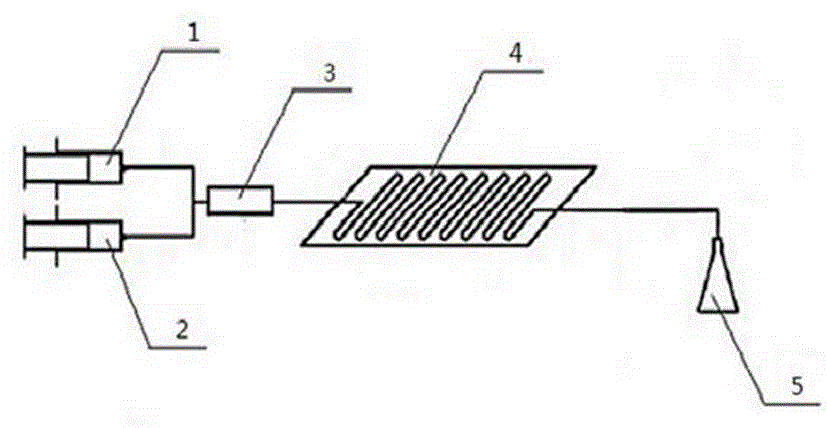

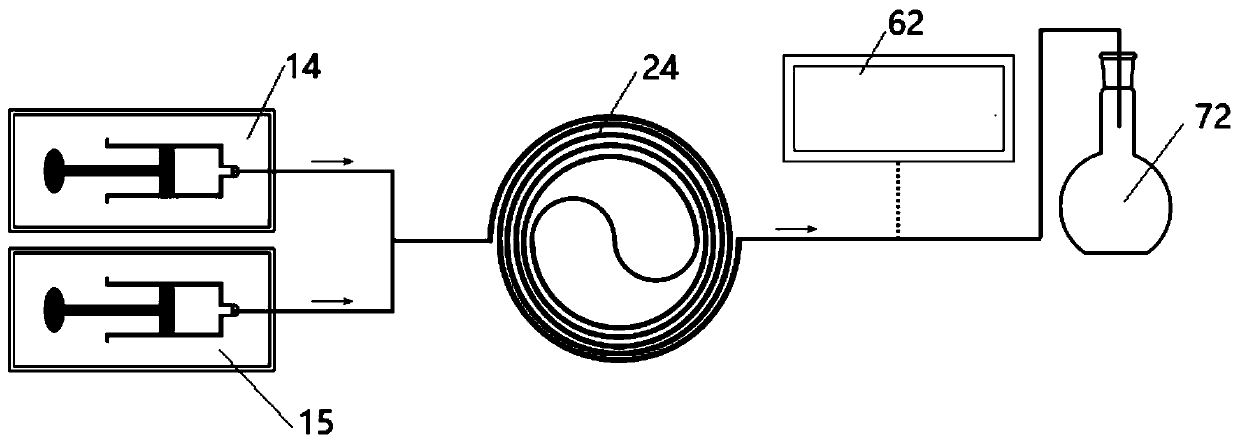

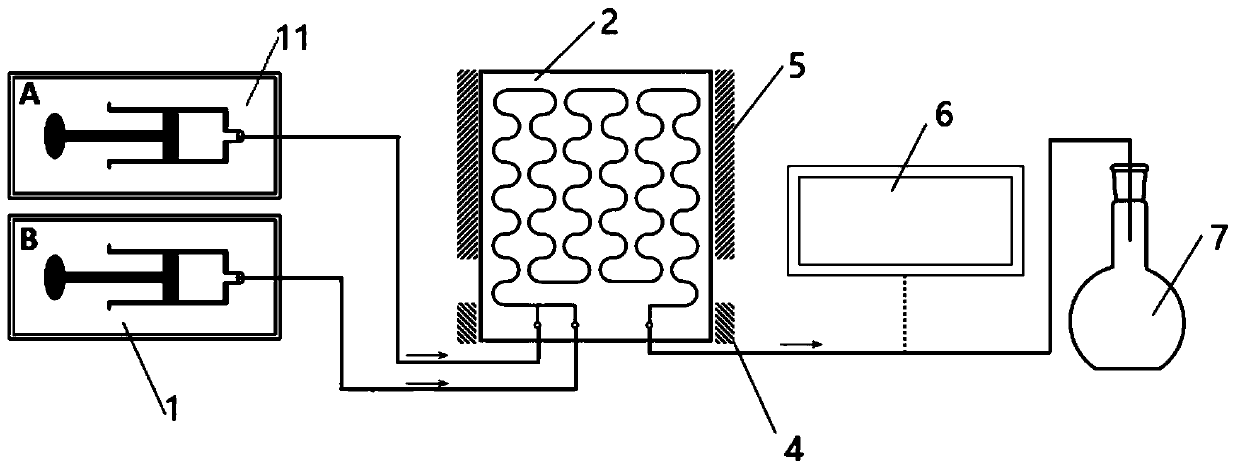

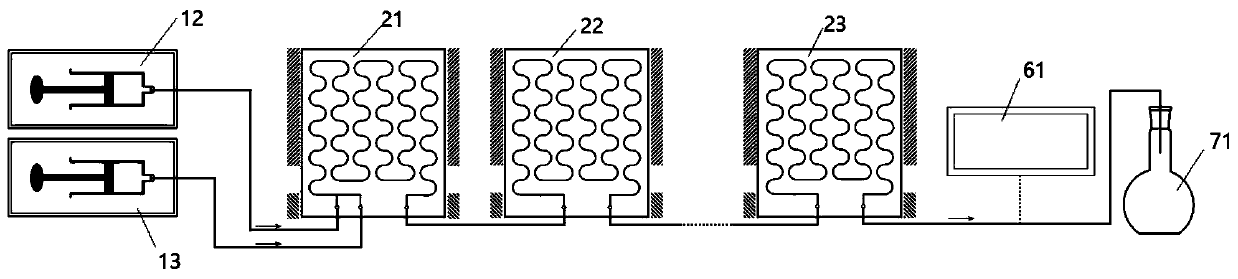

Flow chemical reaction device

InactiveCN110201614AAvoid leakage of toxic and harmful substancesAvoid operator hazardsChemical/physical/physico-chemical microreactorsMicrofluidic chipMicro fluidic

The invention belongs to the technical field of organic synthesis and discloses a flow chemical reaction device. The device comprises one or more reactors, and each reactor is provided with a discharging port and two or more feeding ports; a sealed micro pipe is arranged in each reactor, and two or more feeding ports are communicated with the corresponding discharging port through the corresponding micro pipe; each feeding port is communicated with a liquid injection device through a pipe, the liquid injection devices are used for injecting samples into the reactors, the device further comprises a process reinforcement device matched with the reactors, and the process reinforcement device provides required external reaction conditions for the reactors. According to the device, the whole reaction and detection process is conducted in a sealed environment, leakage of poisonous and harmful substances is avoided, the danger of experiments with explosion risks to operators is avoided, and the safety of the chemical synthesis process is improved. In addition, a micro-fluidic chip is used as the continuous flow chemical reaction device of the reactors, continuous synthesis is achieved, manual participation is reduced, the reaction time is shortened, and the production efficiency is improved.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

Method for increasing output of white carbon black in vanadium extraction through stone coal roasting and alkali leaching

InactiveCN101962190AImprove reaction efficiency and qualityImprove reaction efficiencySilicaCarbon blackCoal

The invention discloses a method for increasing the output of white carbon black in vanadium extraction through stone coal roasting and alkali leaching. In order to overcome the defects of low extraction amount of the white carbon black in the vanadium extraction through stone coal blank roasting and alkali leaching and the like, the method comprises the following steps of: adding sodium hydroxide into roasting stone coal powder in the mass ratio of 10-15%, and stirring for 24 h under the pressure of 0.2-1 MPa at the temperature of 120-200 DEG C to obtain water glass; and preparing white carbon black from the obtained water glass by using a conventional method, and extracting vanadium from the filtrate subjected to white carbon black extraction. When used for extracting the white carbon black in the vanadium extraction through stone coal roasting and alkali leaching, the method greatly improves reaction efficiency and quality, and the extraction rate of carbon dioxide in the stone coal reaches 35-40% and is increased by more than 7 times as compared with the prior art.

Owner:台泥(怀化)水泥有限公司

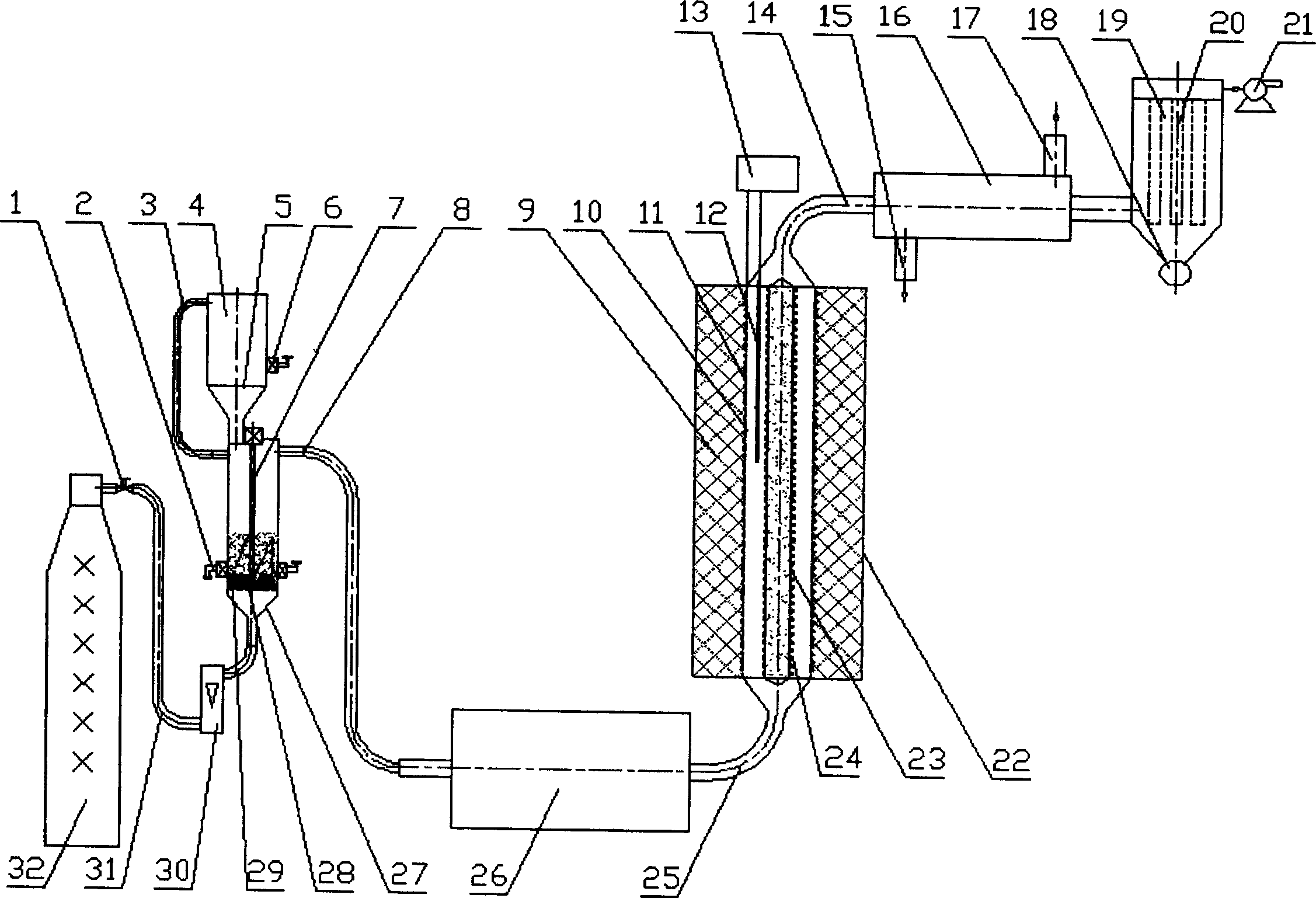

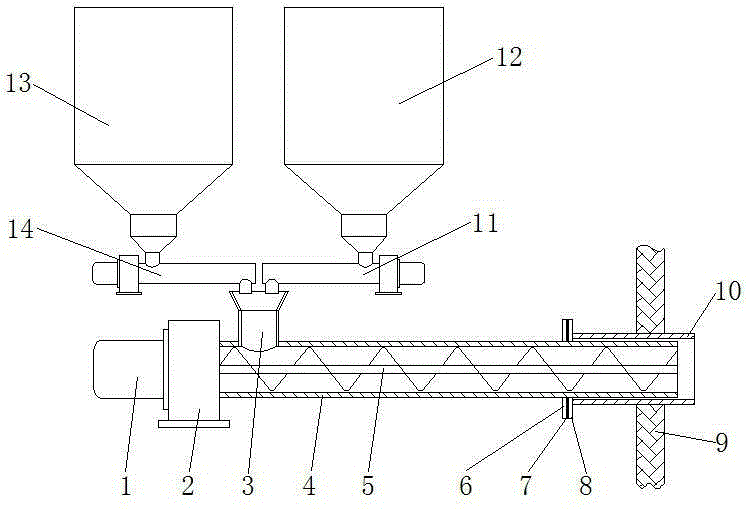

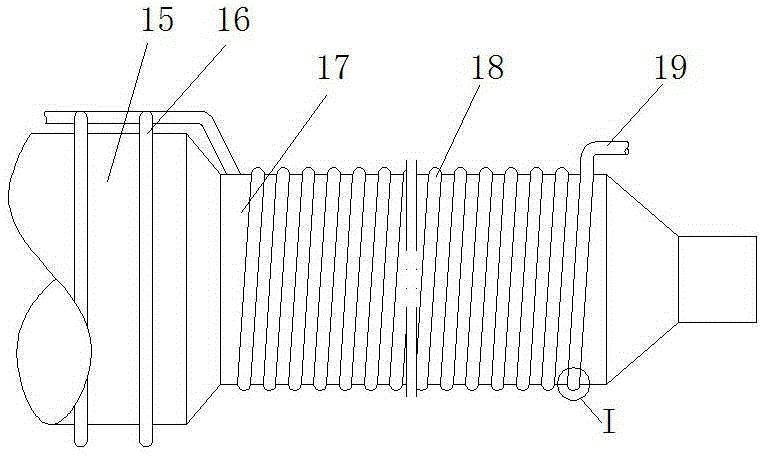

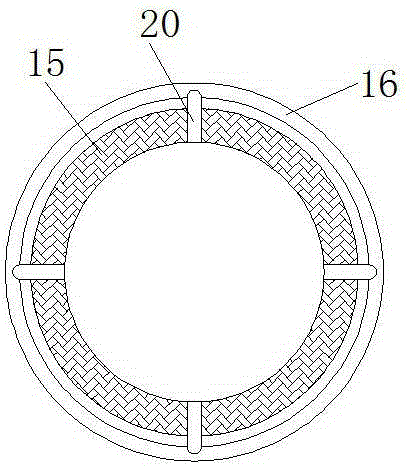

Production method and device of calcium cyanamide

InactiveCN105217655ASmall fluctuationSmall temperature fluctuationsCyanamideGranularityCalcium cyanamide

The invention relates to a production method and device of calcium cyanamide. The method comprises the steps that smashed calcium carbide, catalysts and melted calcium cyanamide are added into corresponding feed bins; the smashed calcium carbide and catalysts are ball-milled to be with required granularity according to the weight proportion and sent into the calcium carbide bin; after the melted calcium cyanamide is ball-milled to be with the granularity ranging from 0.01 mm to 30 mm, the calcium cyanamide is sent to the melted calcium cyanamide bin; the materials in the calcium carbide bin and melted calcium cyanamide bin are sent to a rotary nitriding furnace according to proportions. The device comprises the rotary nitriding furnace, a feeding device installed on the furnace end, a nitrogen input device of a furnace body reaction zone and a cooling device of a furnace body cooling zone, a feed screw conveyor is installed on the furnace end, a heating device is installed on the nitrogen input device of the furnace body reaction zone, and a cooling device is arranged on the furnace body cooling zone. The production method and device of the calcium cyanamide have the advantages that the reaction temperature in the furnace can be adjusted in time, the temperature in the furnace is small in fluctuation, and the discharging and cooling effects are good.

Owner:BEILITE CHEM CO LTD

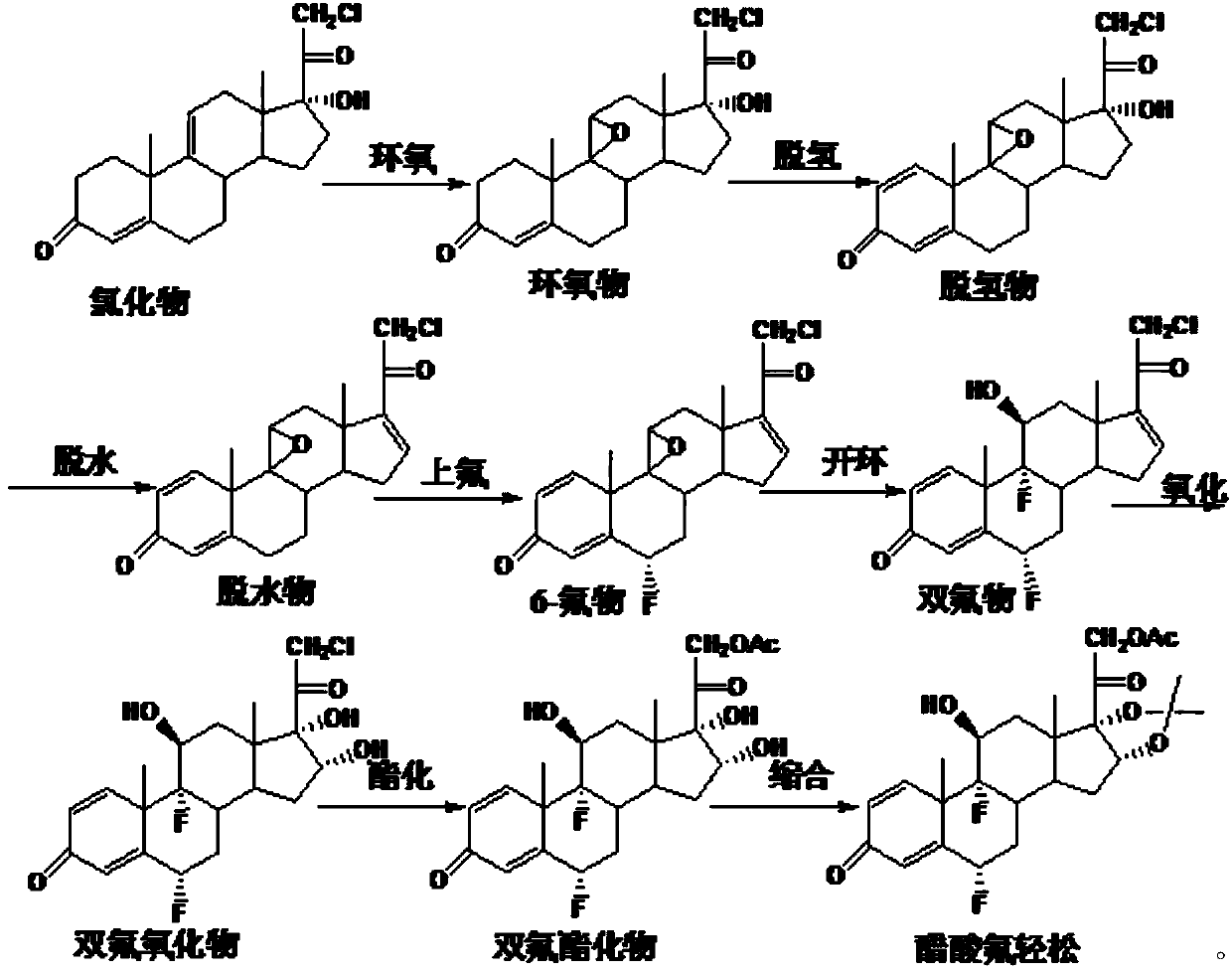

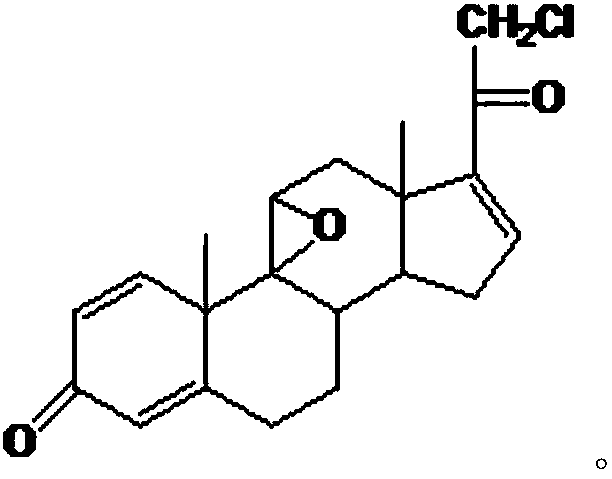

Preparation method of fluocinonide

InactiveCN107619426AEffectively control side effectsHigh reaction yieldSteroidsFermentationEpoxySide effect

The invention relates to a preparation method of fluocinonide, in particular to preparation of fluocinonide. The preparation method of the fluocinonide comprises the following steps: taking chloride as an initiator; and successively carrying out 9,11-epoxy, 1,2-dehydrogenation, 17-dehydration, 6-fluorination, 9,11-ring-opening, 16,17-position double-bond dihydroxy oxidation, 21-position esterification and 16,17-position condensation to obtain the fluocinonide. The novel process has high industrial value, side effects can be controlled effectively, and reaction yield and quality are improved; high-risk reaction is not involved in technological design, and industrialization is easy to implement; and high-pollution reaction does not exist, and environmental protection treatment pressure is relieved.

Owner:TIANJIN JINYAO GRP

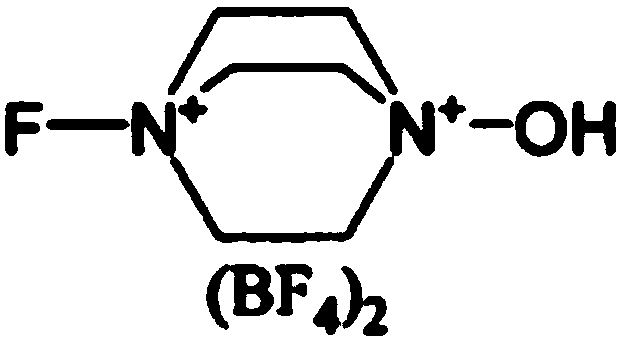

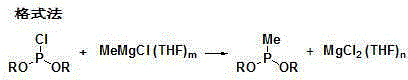

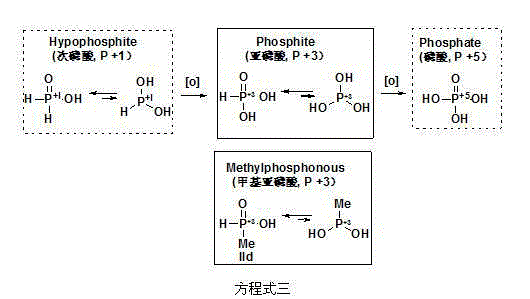

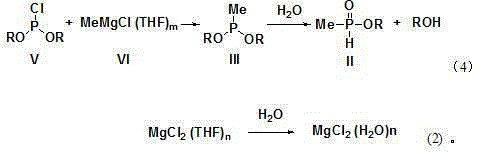

Synthesis and purification method of methyl phosphinate compounds

ActiveCN105131034AAvoid difficultyReduce production processGroup 5/15 element organic compoundsGrignard reagentCombinatorial chemistry

The invention relates to a synthesis and purification method of methyl phosphinate compounds. The method concretely comprises the following steps: adding brine to a solution containing a methyldialkyl phosphinate and magnesium chloride mixture in an inert solvent at a low temperature, and separating to obtain methylalkyl phosphinate or methyldialkyl phosphinate. The method solves the post-treatment and purification difficulties of a Grignard reagent method, and has the advantages of industrial production, effective reduction of the generation of methyl phosphonous acid, mild process conditions, and excellent reaction yield and product quality.

Owner:HEBEI VEYONG BIO CHEM

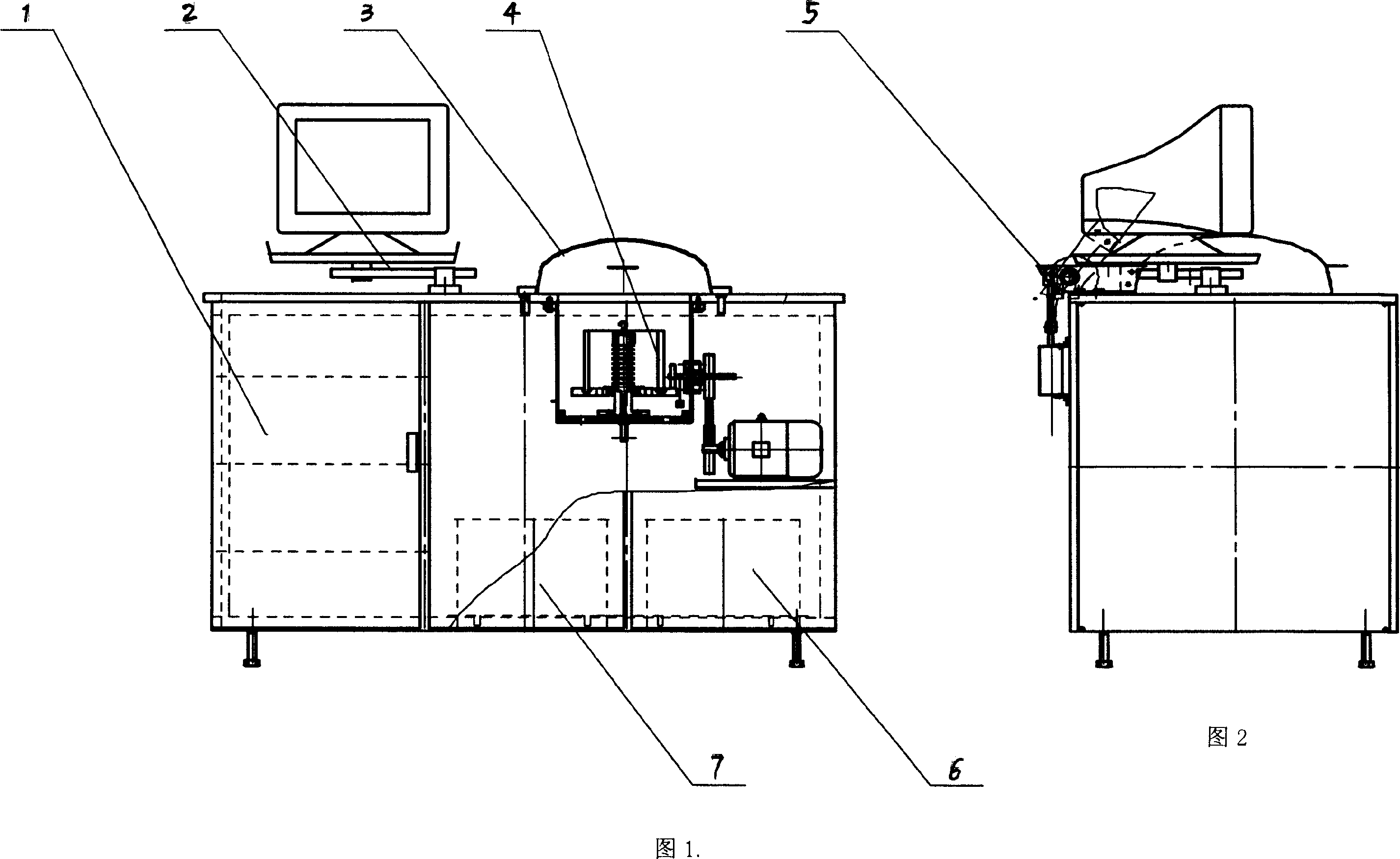

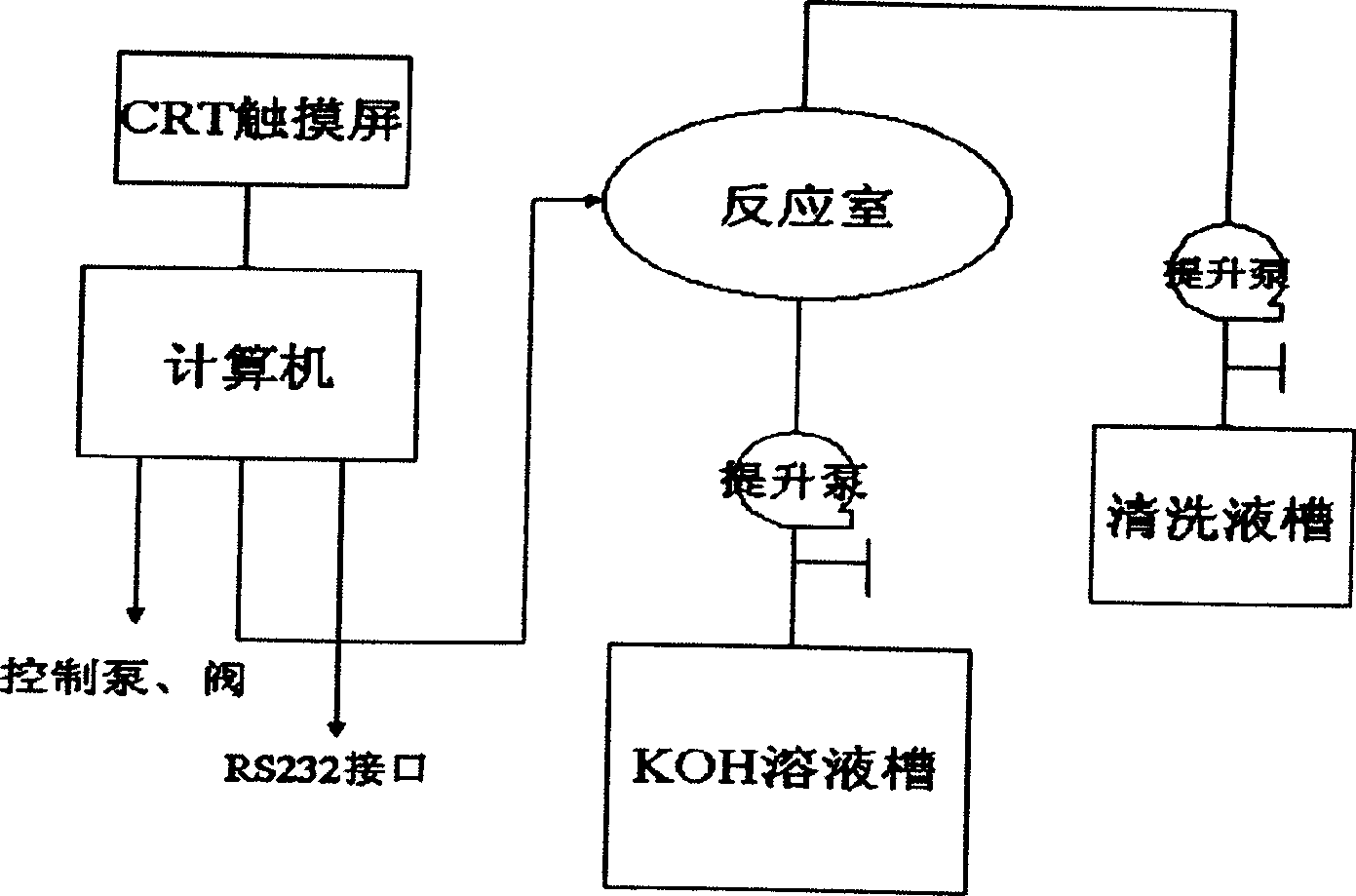

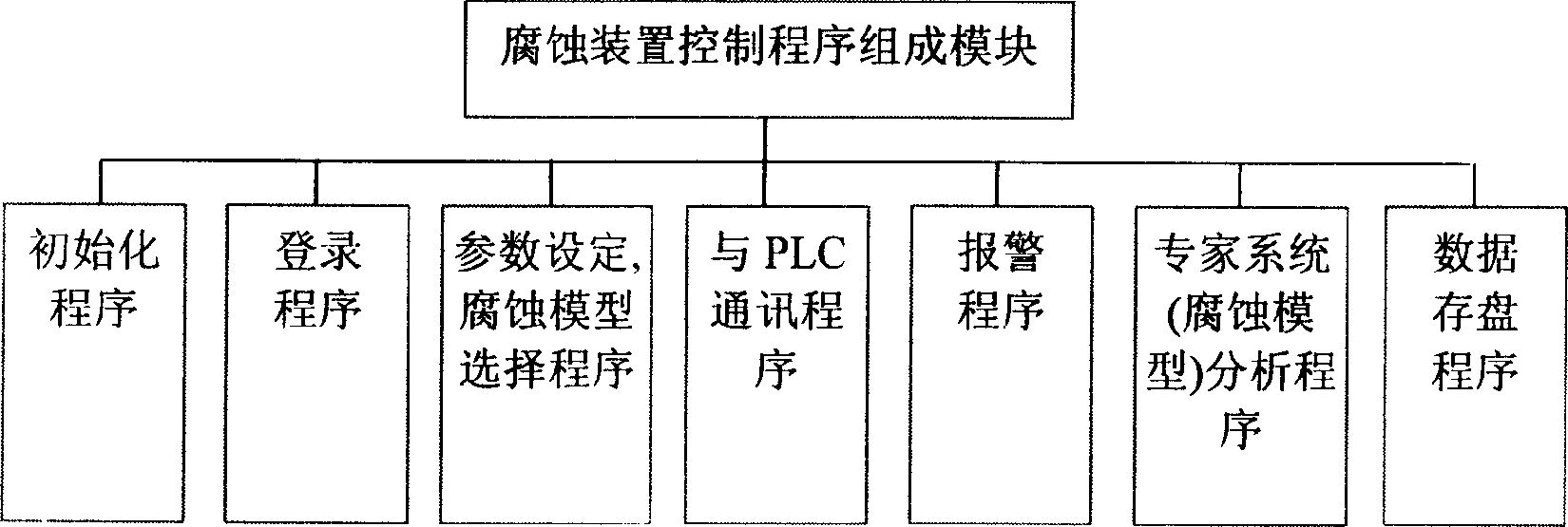

Etching device for high precision silicon senser chip

InactiveCN1601708AReduce defects such as poor exhaustTimely exclusionDecorative surface effectsSemiconductor/solid-state device manufacturingCommunication interfaceLiquid storage tank

The equipment includes industrial control computer, electric appliance control cabinet, reaction chamber, KOH stock solution pot and cleaning liquid stock solution pot. The computer including CRT touch screen and job control program through communication interface is connected to control circuit of electric control cabinet, reaction chamber as well as valves and pumps on pipe. Transmission sprinkle mechanism is built in reaction chamber, and sprinkle tube through liquid pipe is connected to immersible pumps in KOH stock solution pot and cleaning liquid stock solution pot. Probes for detecting temp and density of KOH are setup in the reaction chamber. Computer control is adopted in the equipment. Thus simple operation and production in scale (six wafers in four inches in one time) are realized. Sprinkle technique makes etching process in better environment of washing out and reacting. The suitable wafer to be etched includes all wafers with diameters smaller than 110mm.

Owner:SHENYANG ACAD OF INSTR SCI

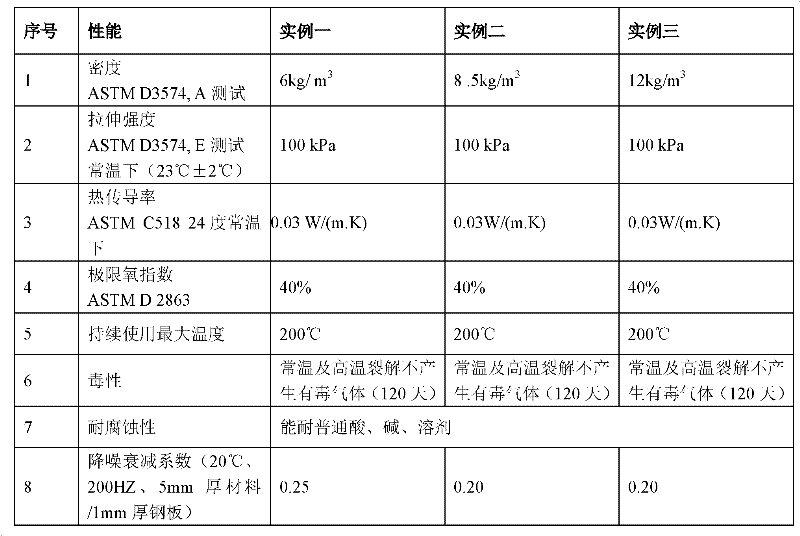

Preparation method of low-density polyimide soft foam

The invention provides a preparation method of low-density polyimide soft foam, comprising the following steps of: (A) preparing A powder: mixing binary anhydride D1, de-ionized water and C1-C2 alkyl monohydric alcohol to react to be transparent at a temperature of 60-90 DEG C; reducing the temperature to 25-55 DEG C and adding diamine or diisocyanate DA1 which has the equal mol amount of the binary anhydride; reacting at the state that the temperature is less than or equal to 40 DEG C for 30-120 min and cooling to a room temperature; continually agitating for 120 min to obtain a liquid resinprecursor polyamide-ester with the solid content of 55-65% and viscosity of less than 10000 cp; drying in vacuum and crushing to obtain the A powder; (2) preparing B powder: mixing binary anhydride D2 with diamine DA2 to synthesize polyamic acid resin with the viscosity of 800-1500 p and the solid content of 15-40%; drying, carrying out ring closing, and ageing to obtain the B powder with Tg morethan 300 DEG C; (3) foaming, fully mixing the A powder and the B powder, foaming, carrying out ring closing and aging to obtain the multipurpose polyimide soft foam, wherein the mass percentage of the B powder in the A powder and the B powder is x and x is more than 0 and less than or equal to 40%.

Owner:LIYANG HUAJING ELECTRONICS MATERIAL +1

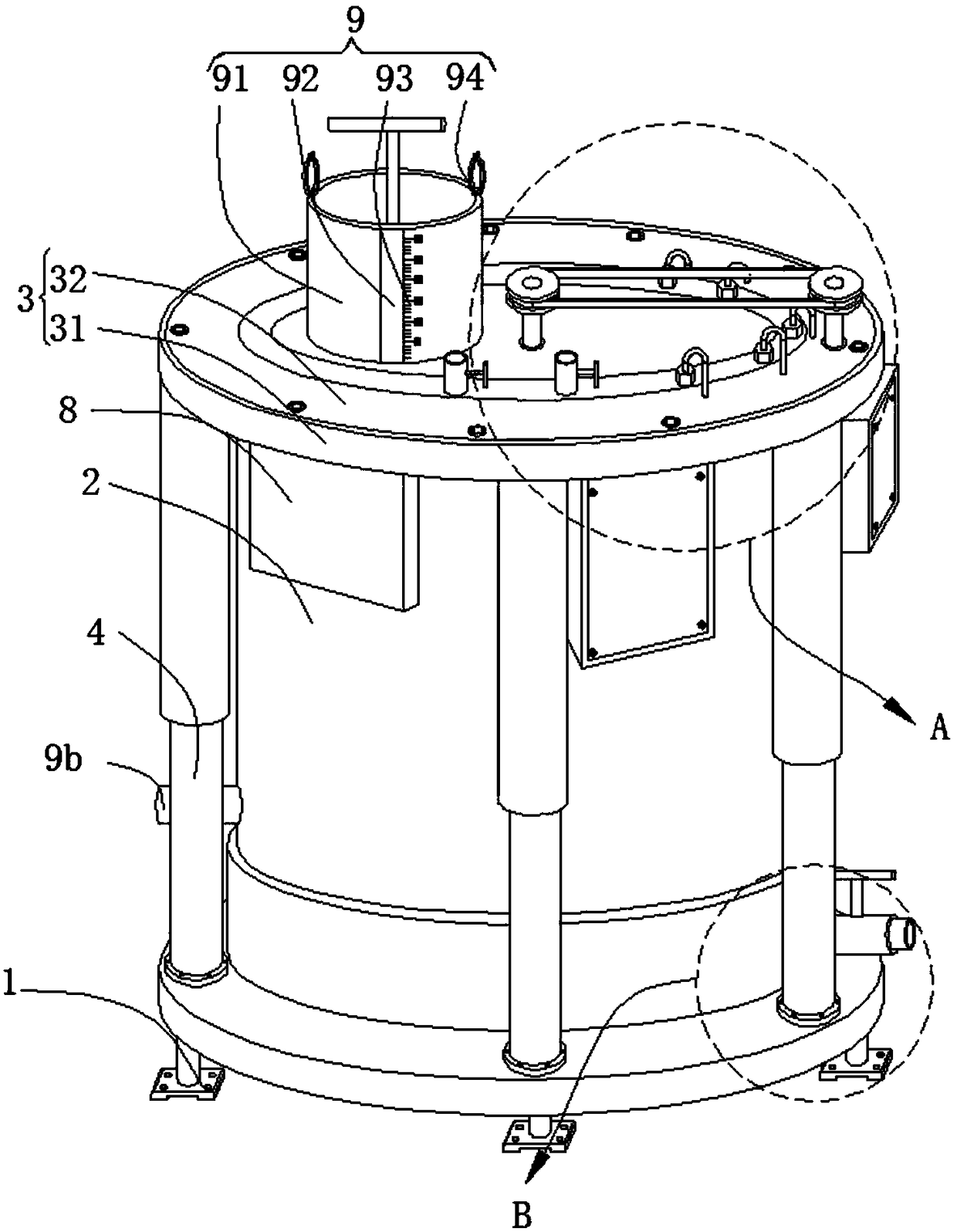

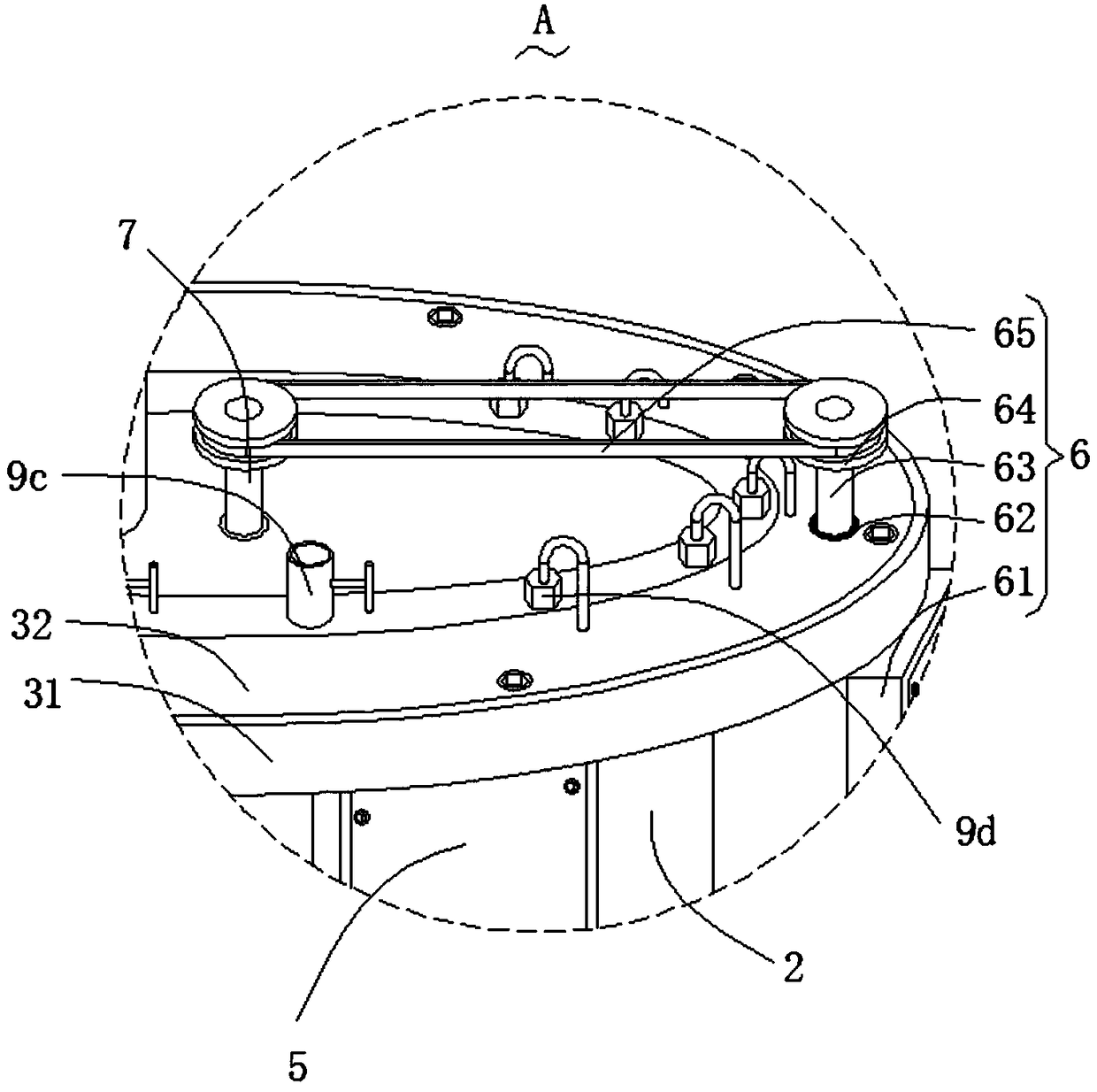

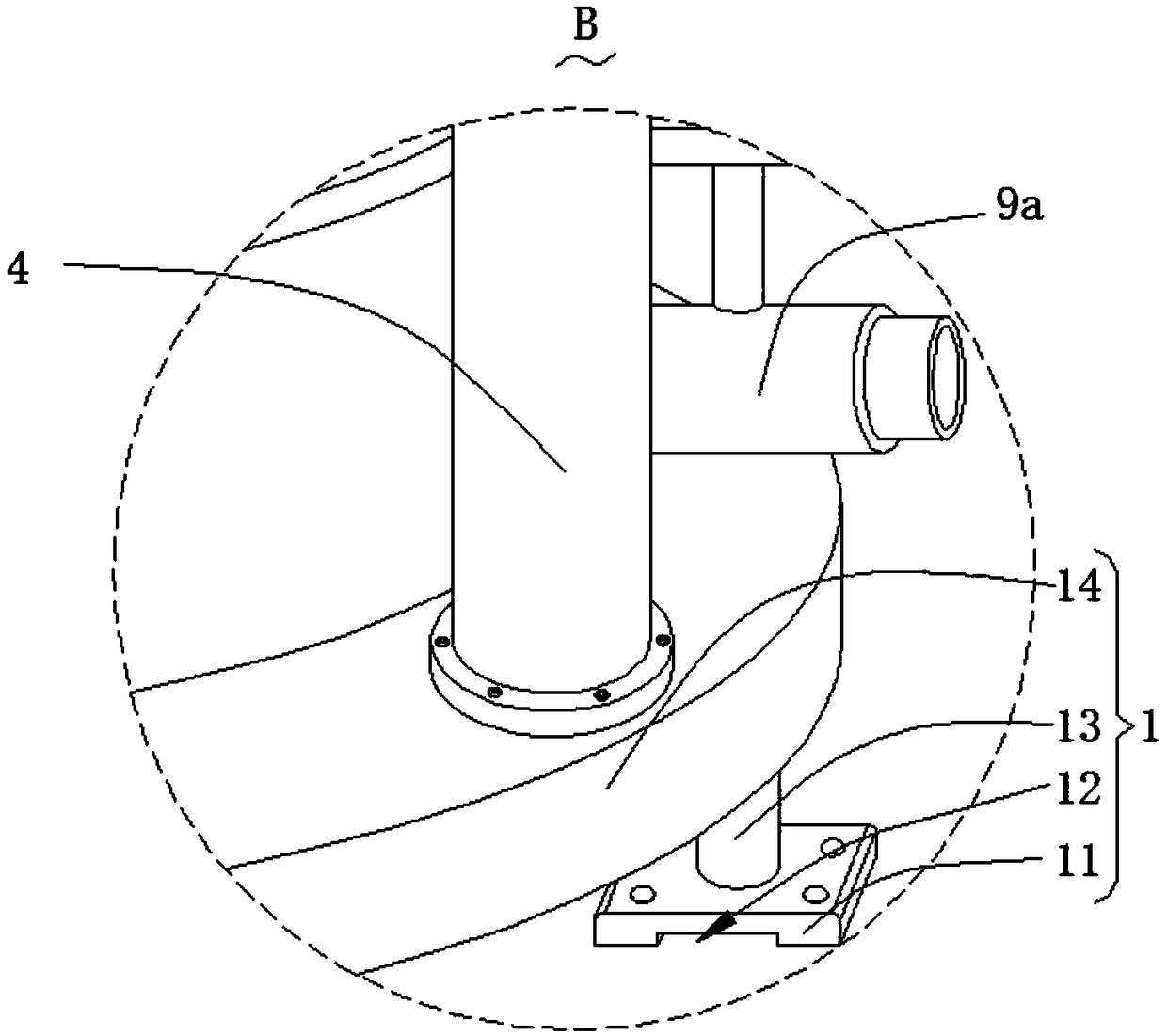

Petrochemical engineering reaction kettle

ActiveCN108261999AImprove stabilityEasy to cleanChemical/physical/physico-chemical stationary reactorsFeed devicesWater dischargeInlet valve

The invention relates to the field of petrochemical engineering equipment, in particular to a petrochemical engineering reaction kettle. The petrochemical engineering reaction kettle comprises a support structure, a storage structure, a fixing structure, an overhaul structure, a first driving structure, a second driving structure, a stirring structure, a wiring box, a blanking structure, a blanking water valve, a water discharge valve and an electric heating block, wherein the fixing structure is used for fixing the storage structure; the blanking structure is used for controlling the reactionmixture ratio of petrochemical engineering; the blanking water valve is used for discharging finished product petroleum; the stirring structure is used for realizing stirring in inside; the wiring box is connected with a power supply; the electric heating block, the water inlet valve and the water discharge valve are used for controlling the reaction temperature. The first driving structure drives the overhaul structure, so that the storage structure is in abut contact with the support structure; the inside of the storage structure can be conveniently cleaned during the reaction kettle cleaning and maintaining; the reaction speed is high; the temperature of the storage structure during the stirring can be conveniently controlled.

Owner:源通重工集团有限公司

Method for preparing amide using nonhomogeneous phase oximation rearrangement

ActiveCN100386307CLow costGood economic valueOrganic compound preparationCarboxylic acid amides preparationBeckmann rearrangementReaction temperature

The present invention discloses oximation and rearrangement process of preparing amide with aliphatic and / or cyclic aliphatic ketone as material. The preparation process includes catalytic reaction of ketone, hydrogen peroxide solution and ammonia inside inert solvent to produce ketoxime solution, Beckmann rearrangement of the oil phase product under the action of fuming sulfuric acid, and hydrolysis to neutralize and produce amide. The present invention has shortened technological process, lowered cyclohexyl ketoxime rearranging reaction temperature, lowered sulfuric acid consumption and reduced side product.

Owner:HUBEI JINXIANGNING CHEM ENG TECHENOLOGY CO LTD

Method for preparing biodiesel from oil with high acid value

ActiveCN102533455AIncrease contact areaExtension of timeFatty acid esterificationBiofuelsBiodieselReaction rate

The invention discloses a method for preparing biodiesel from oil with a high acid value. The method comprises the steps as follows: mixing oil with a high acid value with methanol, adding compound acid catalyst, carrying out esterification reaction, removing crude methanol through flash vaporization, adding potassium hydroxide methanol solution, performing transesterification reaction, removing crude methanol through flash vaporization again, standing liquid from which crude methanol is removed and settling for 4 to 5 hours, and removing glycerol through separation to obtain crude biodiesel.The method has the characteristics of low device investment, simple process, low manufacturing cost, high reaction rate and high conversion rate of products.

Owner:山东锦江生物能源科技有限公司

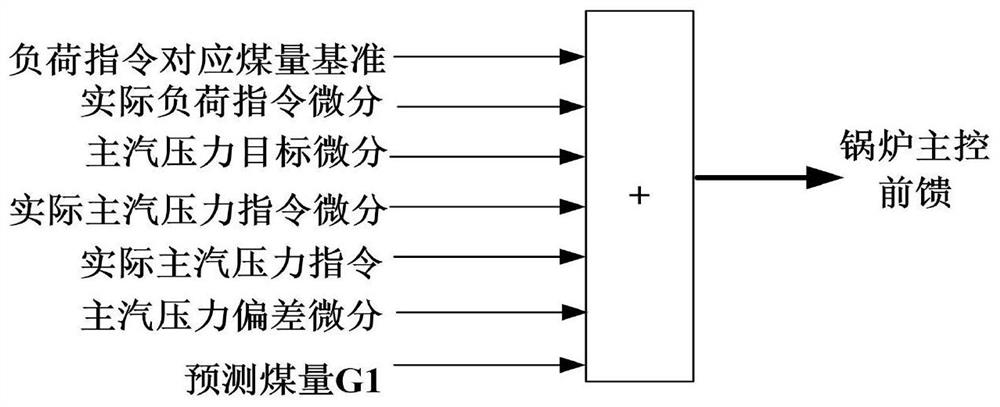

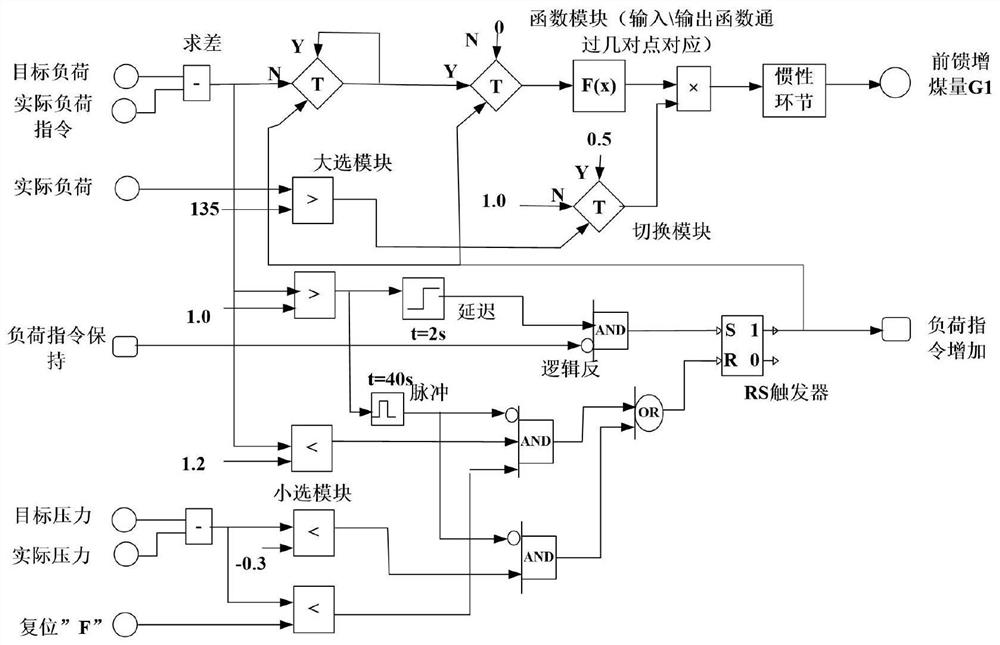

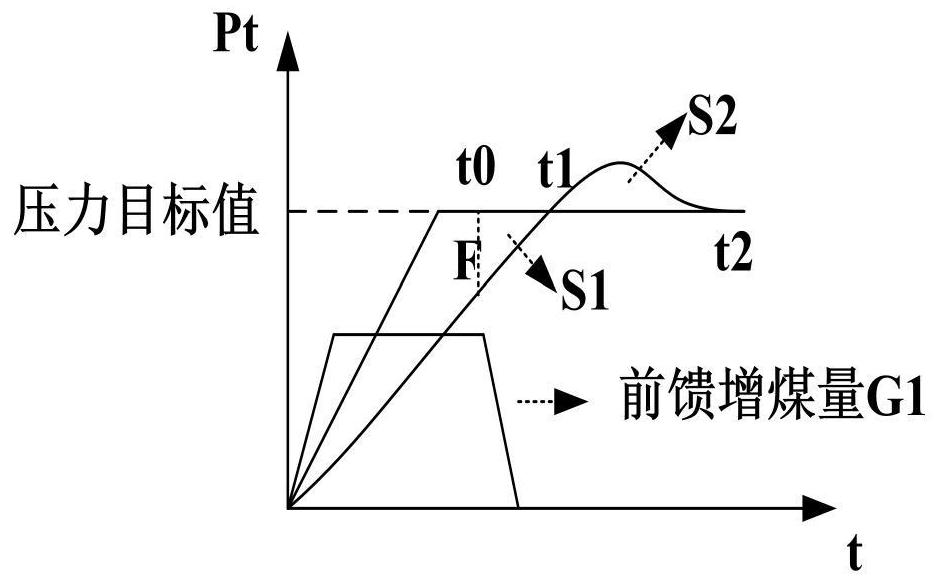

Coal quantity optimization prediction control method based on AGC optimization of thermal power plant

InactiveCN112286057AImprove response qualityReduce workloadFuel supply regulationTotal factory controlSteam pressureProcess engineering

The invention discloses a coal quantity optimization prediction control method based on AGC optimization of a thermal power plant, wherein the method comprises the steps that: a control strategy of feedforward and PID for boiler main control in AGC and CCS control systems is employed, an intelligent feedforward is added, a coal quantity prediction link is designed and an objective function is planned for improving the response speed and control precision of a boiler, and through the DCS configuration programming of the power plant, automatic parameter optimization is realized; when a load instruction changes and a load changes from a current instruction to a target instruction, a large amount of fuel is immediately fed into the boiler under the feedforward action, and the fed fuel amount and the feeding time are related to the deviation between the target load and an actual load instruction, the deviation between a main steam pressure target value and main steam pressure and reset F trigger; therefore, the main control of the unit boiler is realized. Feedforward self-adaption can be achieved, manual adjustment work is reduced, the adjustment quality of main steam pressure can be improved, and then the adjustment quality of CCS and AGC is improved.

Owner:INNER MONGOLIA POWER GRP

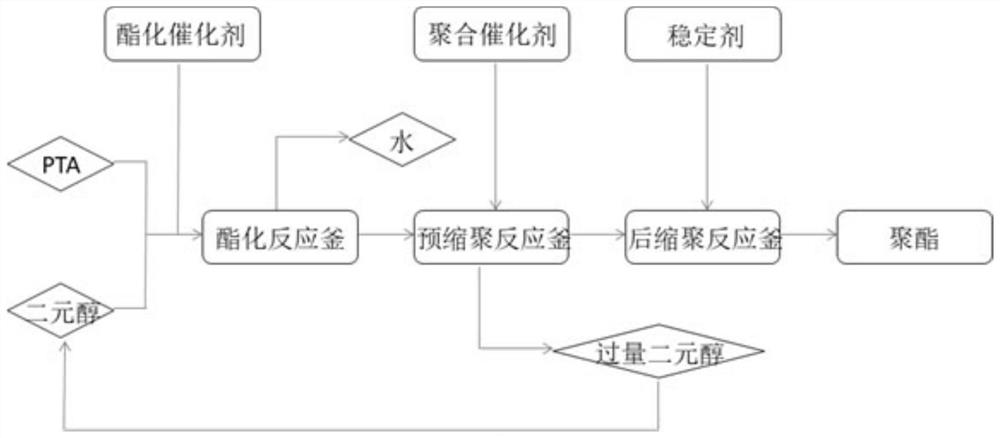

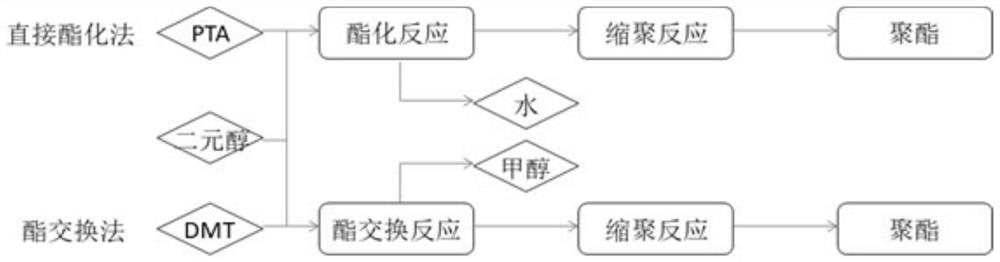

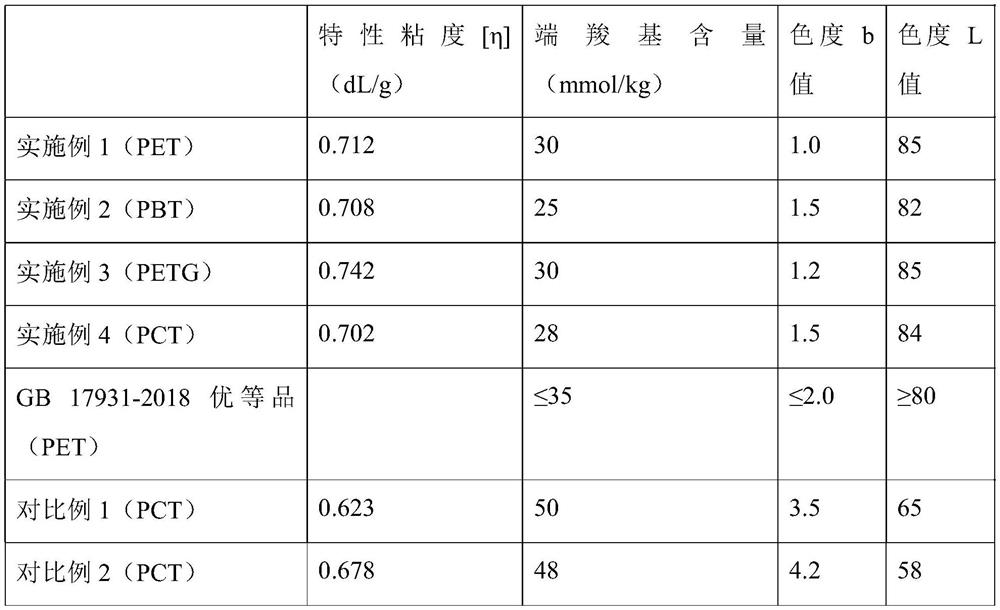

Efficient synthetic method of terephthalic polyester

The invention provides an efficient synthetic method of terephthalic polyester, the method comprises the following steps: taking terephthalic acid and various dihydric alcohols as raw materials, sequentially carrying out esterification, pre-polycondensation and post-polycondensation to obtain high-quality polyester, wherein the catalyst is a composite catalyst consisting of an esterification catalyst, a polymerization catalyst and a stabilizer, and is added in sections; and post-polycondensation adopts a continuous production process, so that material back-mixing is avoided, side reactions are effectively reduced, the reaction efficiency and the reaction stability are improved, and indexes such as viscosity, terminal carboxyl group content and chromaticity of the product are also obviously improved.

Owner:CHINA TIANCHEN ENG

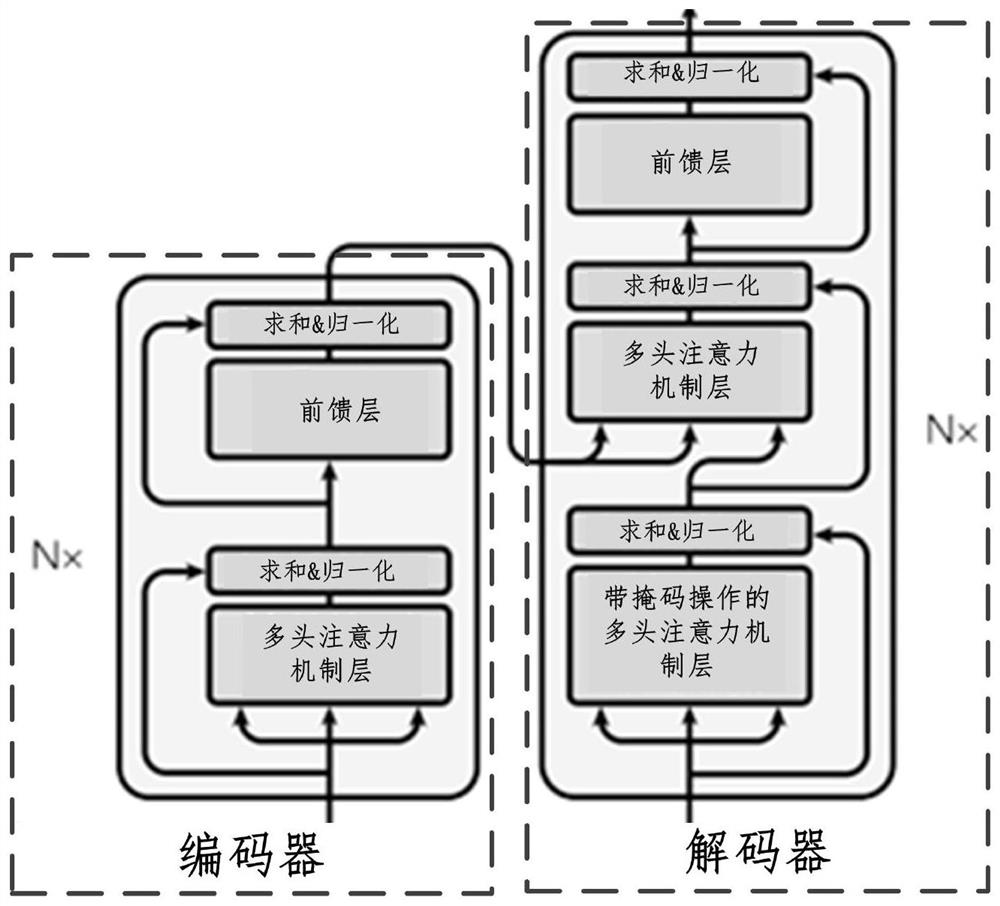

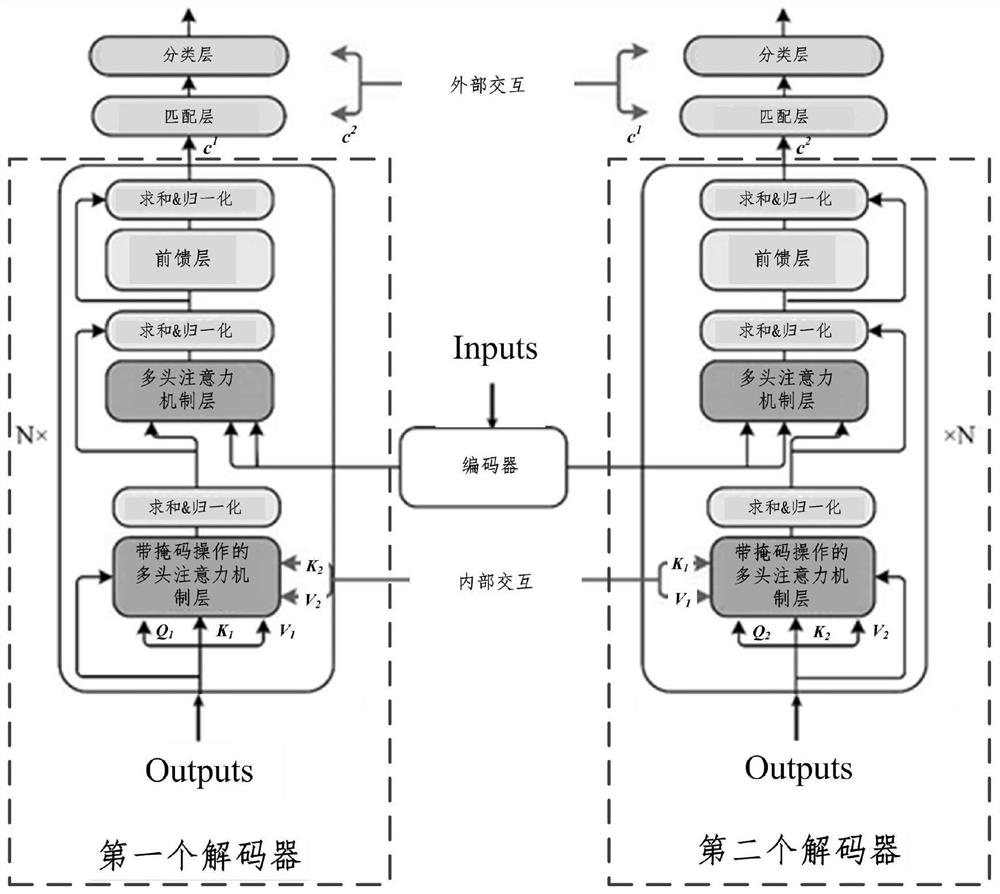

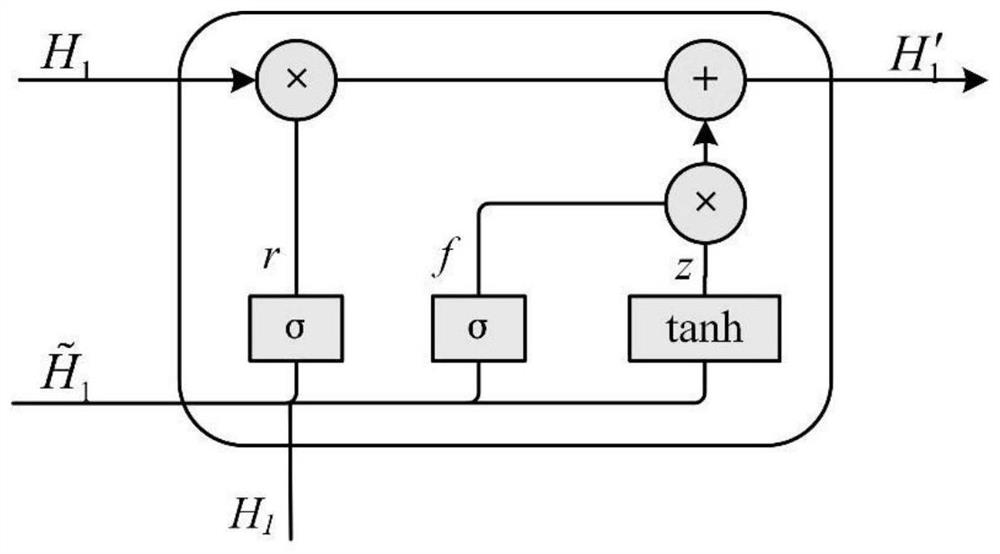

Bilingual emotional dialogue generation system based on interactive decoding

ActiveCN111986687AQuality improvementImprove response qualitySpeech analysisCharacter and pattern recognitionNatural language processingConfusion

The invention relates to a bilingual emotional dialogue generation system based on interactive decoding. Multi-language information complementation is adopted, and high-quality emotion replies can begenerated. The traditional emotional dialogue generation model is trained and tested by using a single corpus, a bilingual material (Chinese and English) is used for training and testing the model, and in the process of generating emotion replies, a Chinese decoder and an English decoder carry out information complementation through an internal and external interaction mechanism. Wherein the internal interaction is used for mining dynamic context information between answers in different languages by virtue of an auxiliary effect of redundant information between languages, and generating replies by utilizing more sufficient information, so that the confusion degree is reduced, the quality of answer contents is improved, and high-quality emotion replies are generated; after the context information of the other decoder is fully considered in external interaction, emotion words or common words are selected and generated through the type selector, and grammatical rationality and emotion naturalness of reply are balanced.

Owner:HEFEI UNIV OF TECH

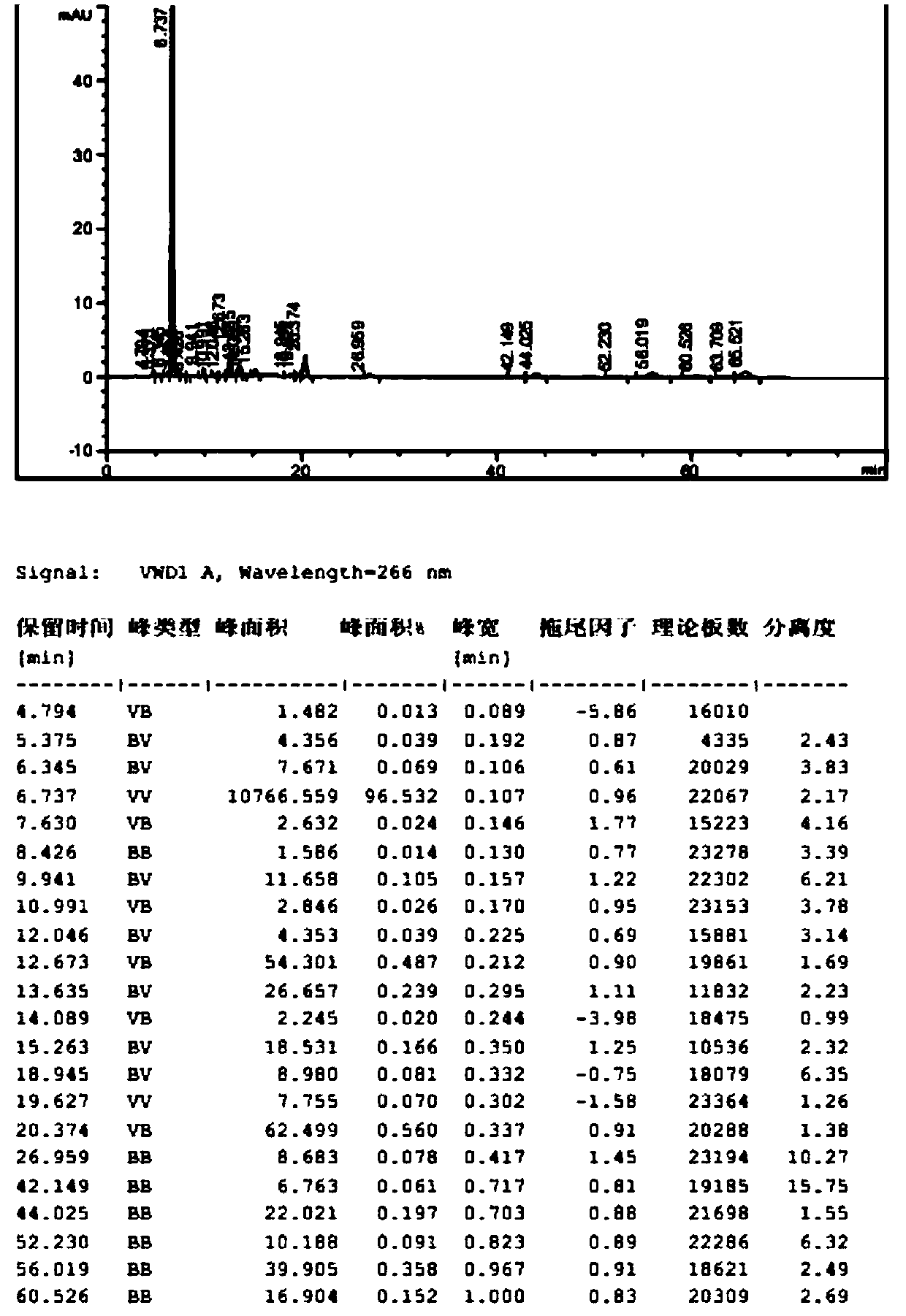

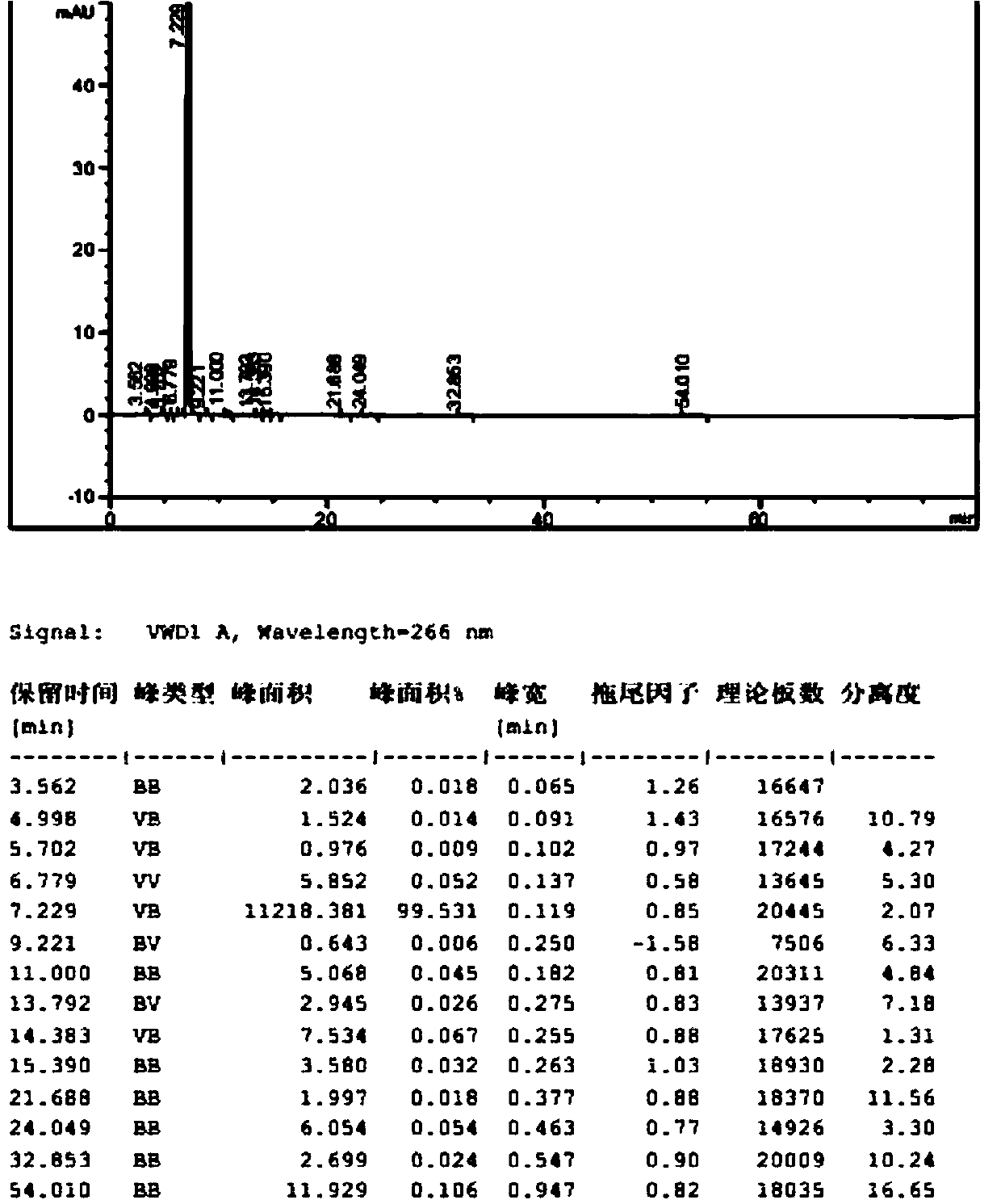

Preparation method for cefuroxime sodium and preparation thereof

ActiveCN106565748AImprove stabilityGood colorAntibacterial agentsOrganic active ingredientsCefuroxime SodiumImpurity

The invention discloses a preparation method for cefuroxime sodium and a preparation thereof, belonging to the technical field of medicine preparation. The preparation method comprises the following three steps: preparation of 3-deacetyl-7-aminocephalosporanic acid; preparation of cefuroxime acid; and preparation of cefuroxime sodium. According to the invention, charging and reaction manners are changed to improve reaction quality, and a crystallization system and a crystallization manner are changed at the same time; so prepared cefuroxime sodium and the preparation thereof have good colors, good stability, low impurity content and a purity increased by 0.2 to 0.3% compared with products produced by conventional processes, which is beneficial for improving the health level of people in China.

Owner:NORTH CHINA PHARMA HEBEI HUAMIN PHARMA

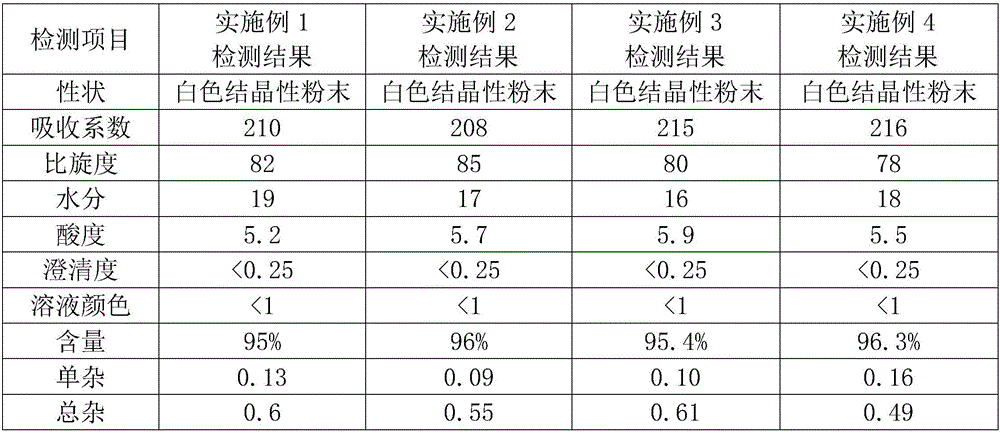

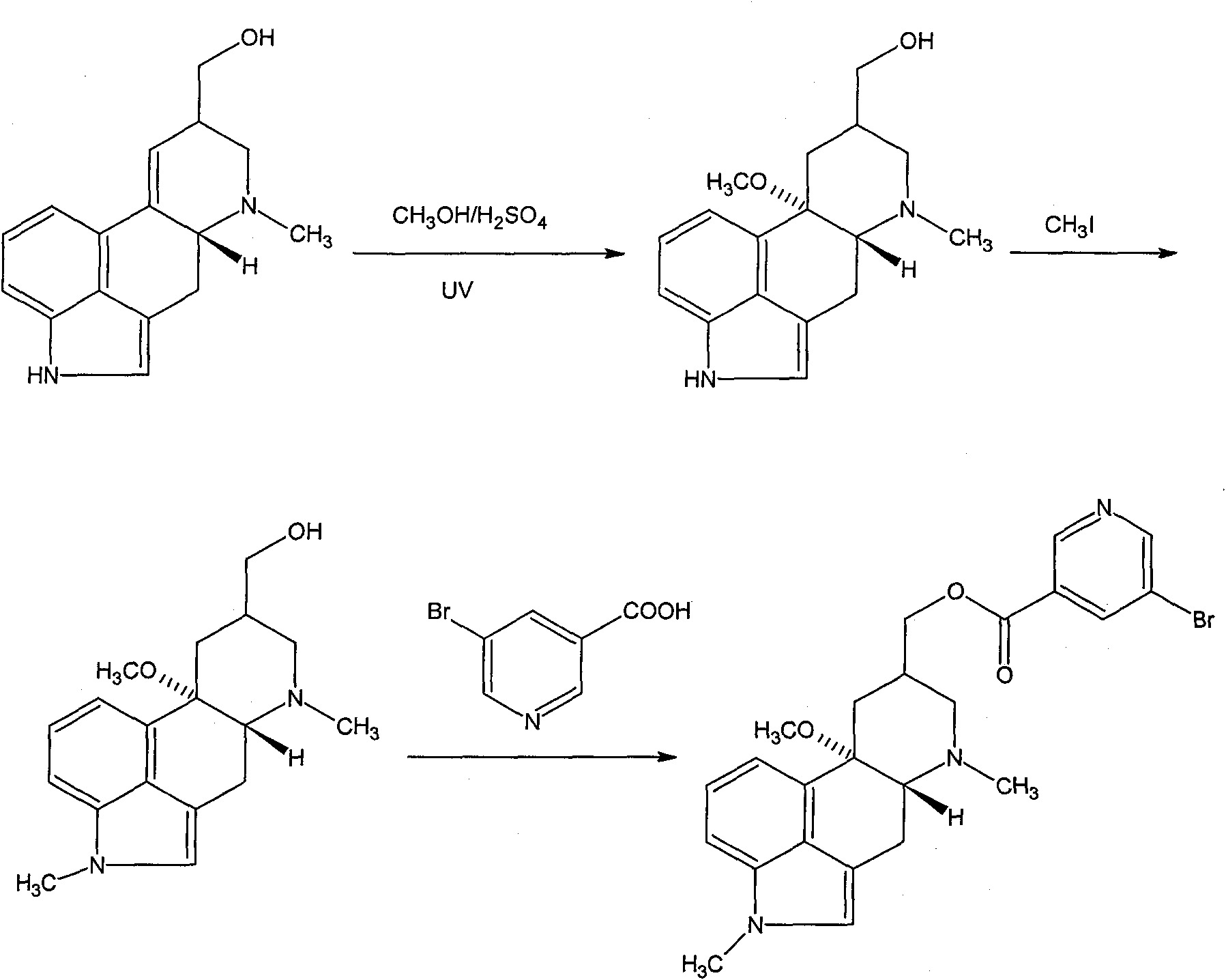

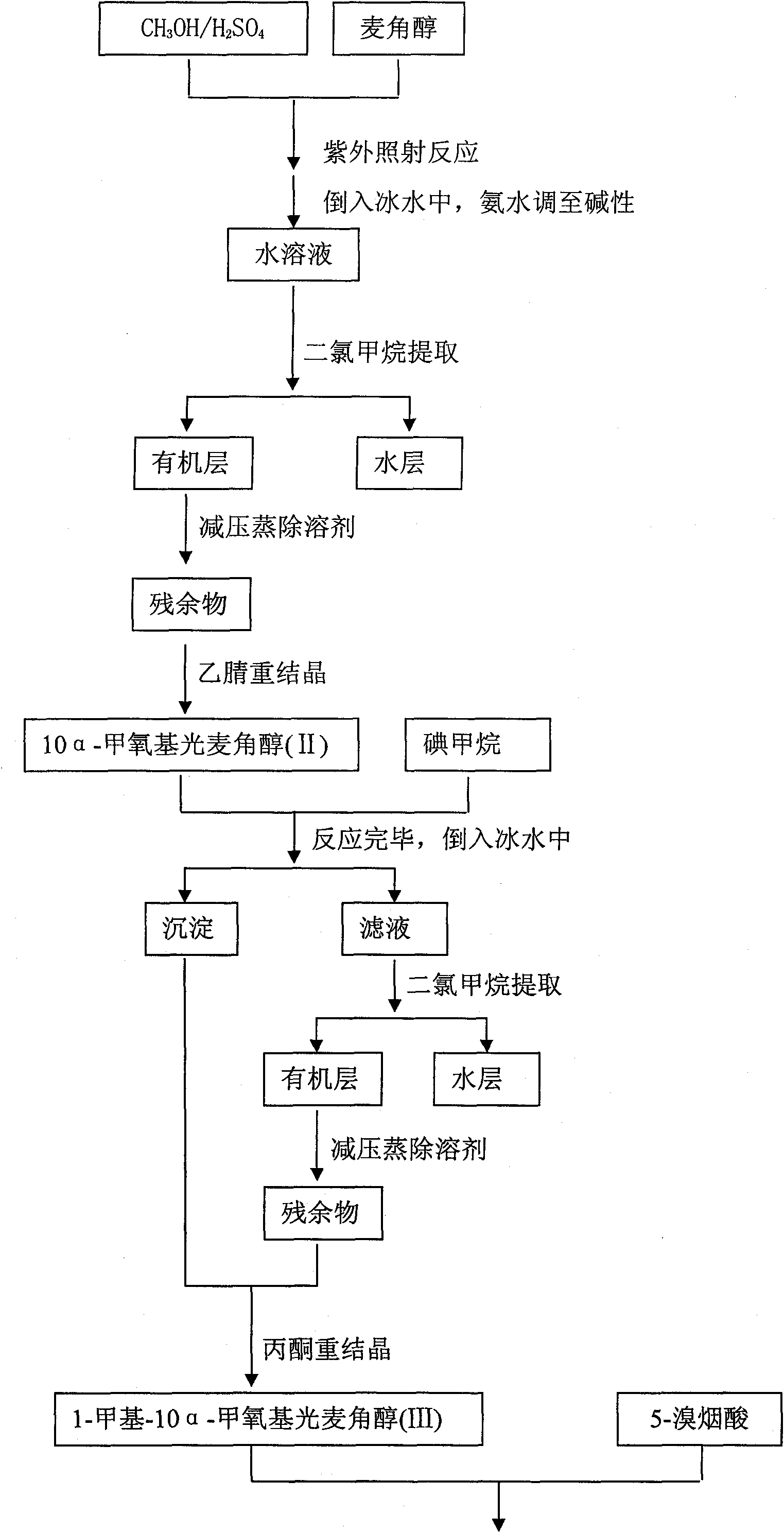

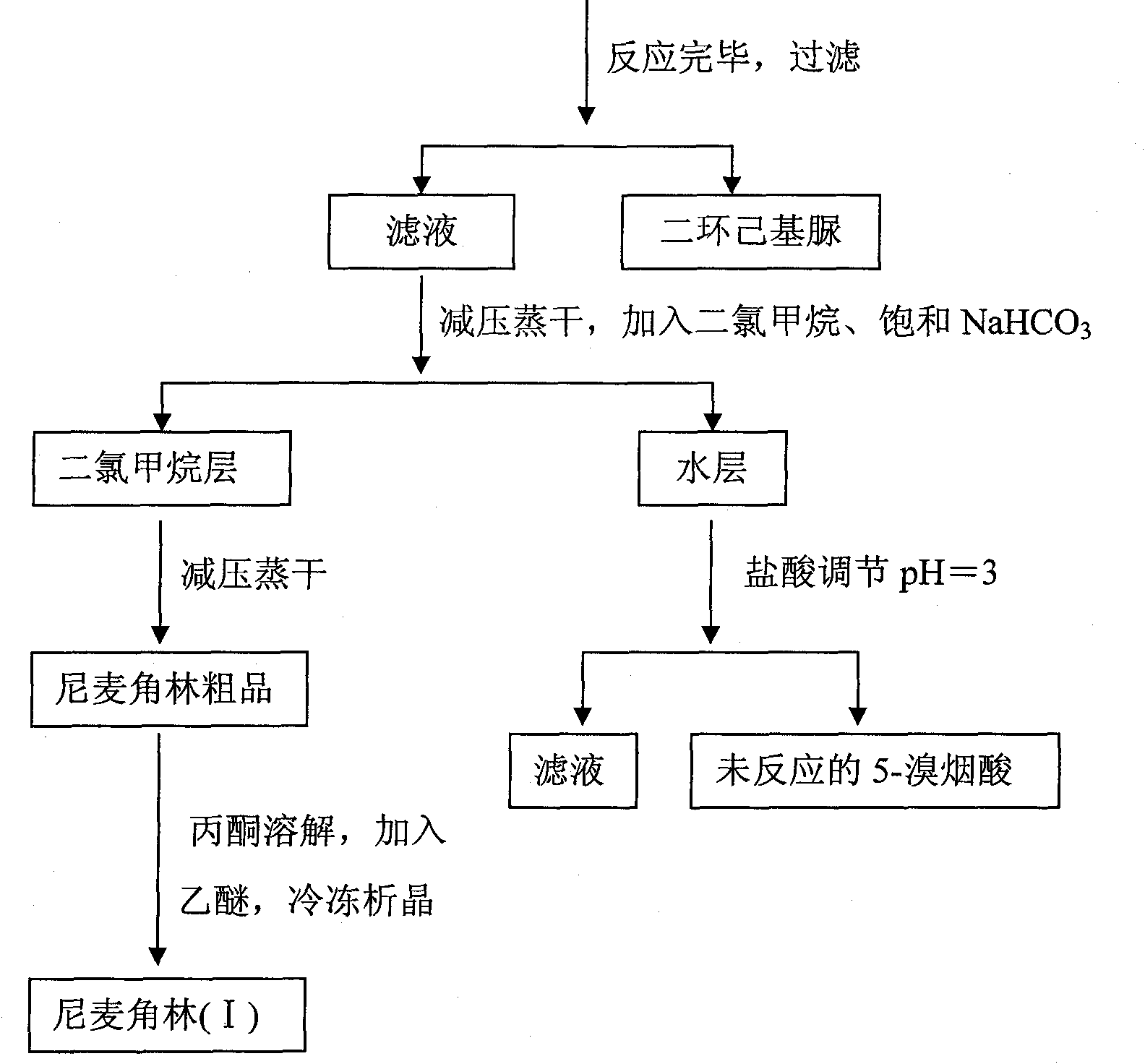

Method for producing nicergoline

InactiveCN101781296AFewer synthetic stepsMild reaction conditionsProductsOrganic chemistryLysergolNiacin

The invention discloses a method for producing nicergoline, which takes a multifunctional reaction kettle with a special kettle bottom valve as a reactor, a special filter as refining equipment and lysergol as an original raw material and comprises the following steps: directly carrying out photoreaction at room temperature in sulfuric acid-methanol to obtain 10alpha-methoxy optical lysergol; reacting the 10alpha-methoxy optical lysergol with methyl iodide under an alkaline condition to obtain 1-methyl-10alpha-methoxy optical lysergol; and directly forming ester with 5-bromine niacin to produce the nicergoline. Compared with the method for producing the nicergoline through current synthesis equipment, the disclosed production process of the nicergoline has the advantages of few reaction steps, mild reaction conditions, convenient refinement, simple operation, good effects of heat preservation, oxidation resistance, sealing property and environmental protection of the used special equipment, complete reaction, simple structure of reaction equipment, convenient operation, easy disassembling, assembling and cleaning, high filtering efficiency, high reaction quality and yield, and stable product quality.

Owner:HONGYI SCI & TECH CO LTD NANCHANG

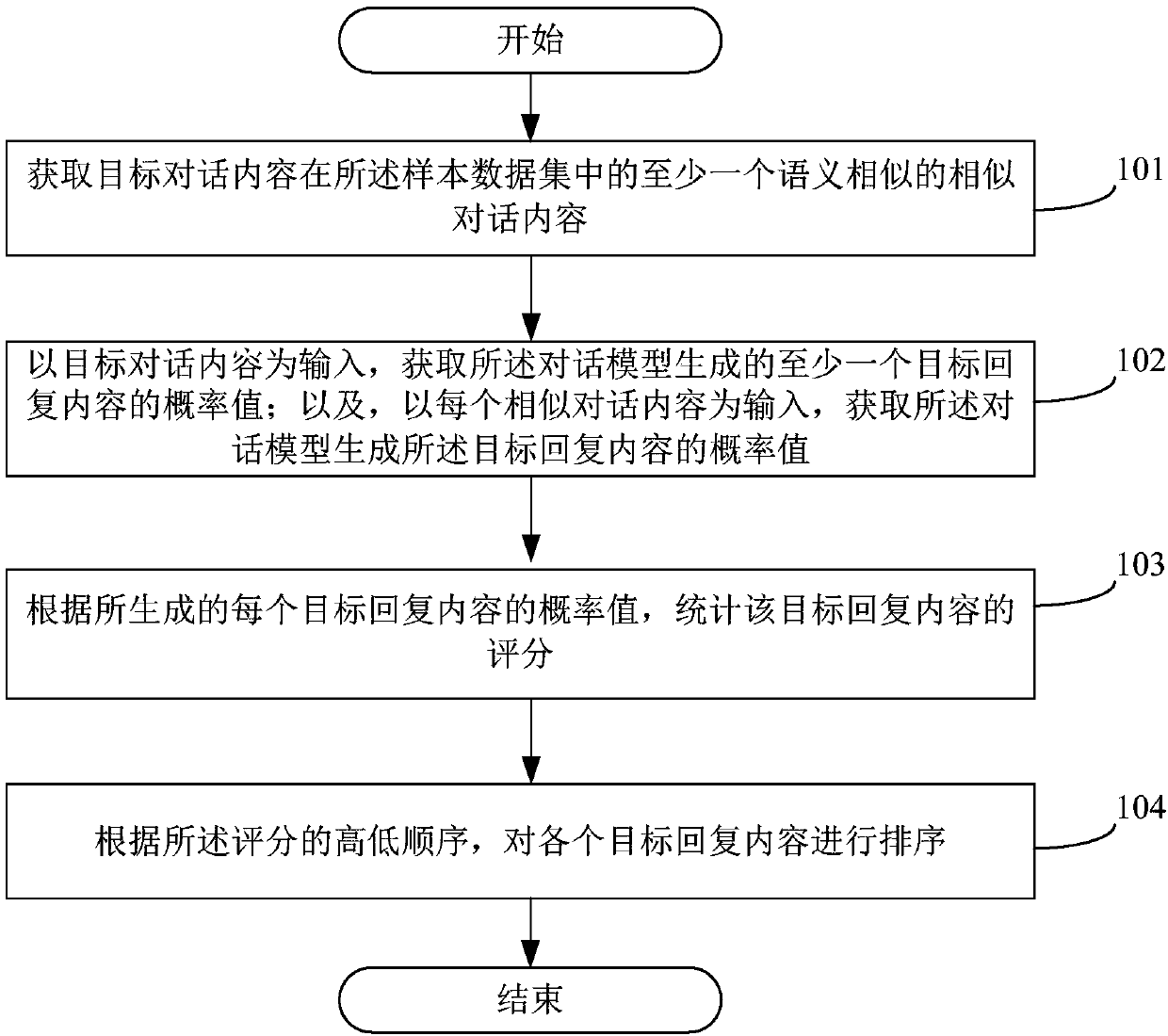

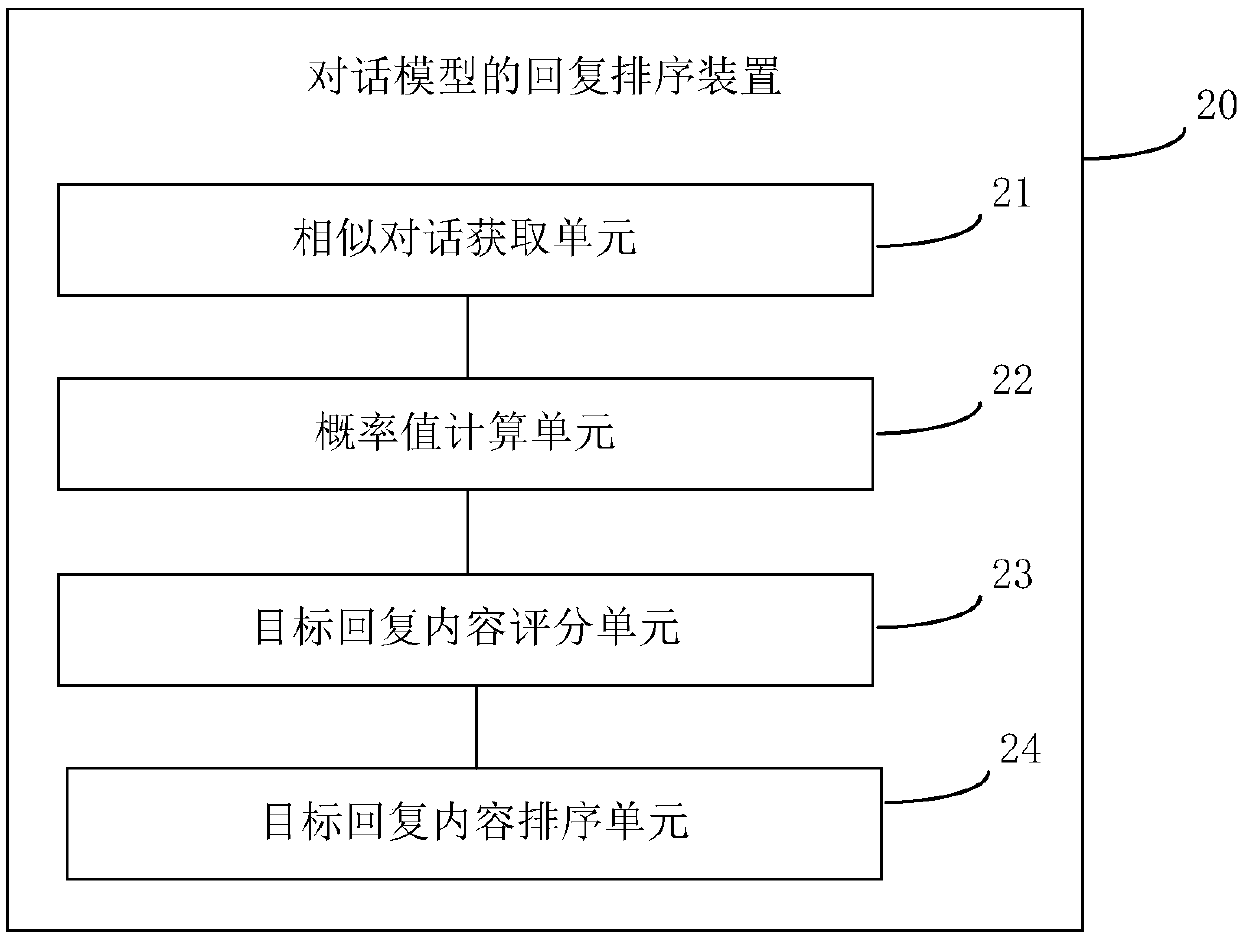

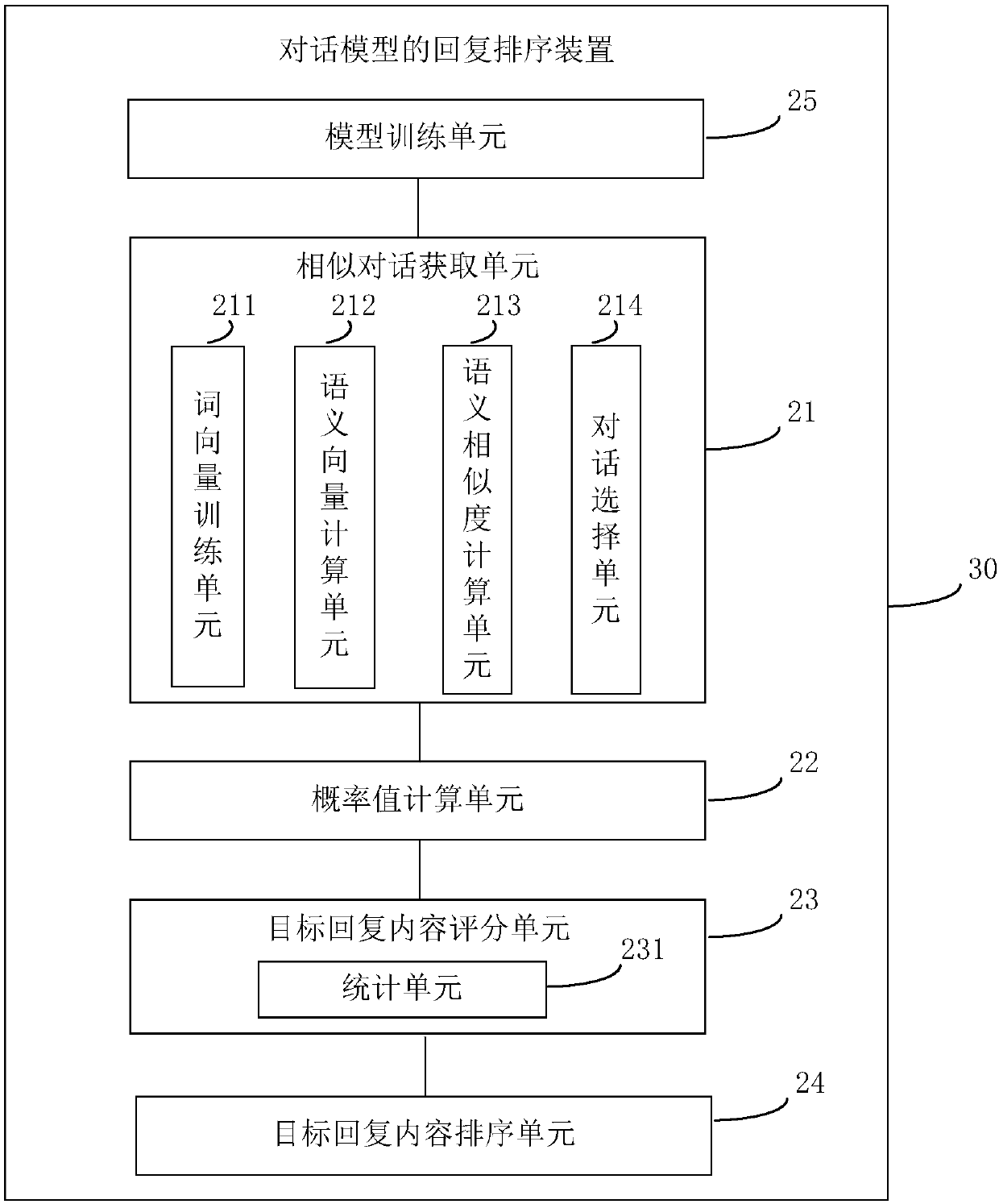

Reply sorting method and device of dialogue model and computer readable storage medium

ActiveCN110019722AImprove response qualityImprove rankingNatural language translationSemantic analysisRankingHuman–computer interaction

The embodiment of the invention provides a reply sorting method and device of a dialogue model and a computer readable storage medium. The reply sorting method of the dialogue model is characterized in that the generation probability of the same target reply content under the target dialogue content and the similar dialogue content is counted to serve as the score of the sorting of the target reply content, the ranking of sentences suitable for the target dialogue content P in the target reply content can be effectively improved, and therefore the reply quality of the dialogue model is improved.

Owner:RICOH KK

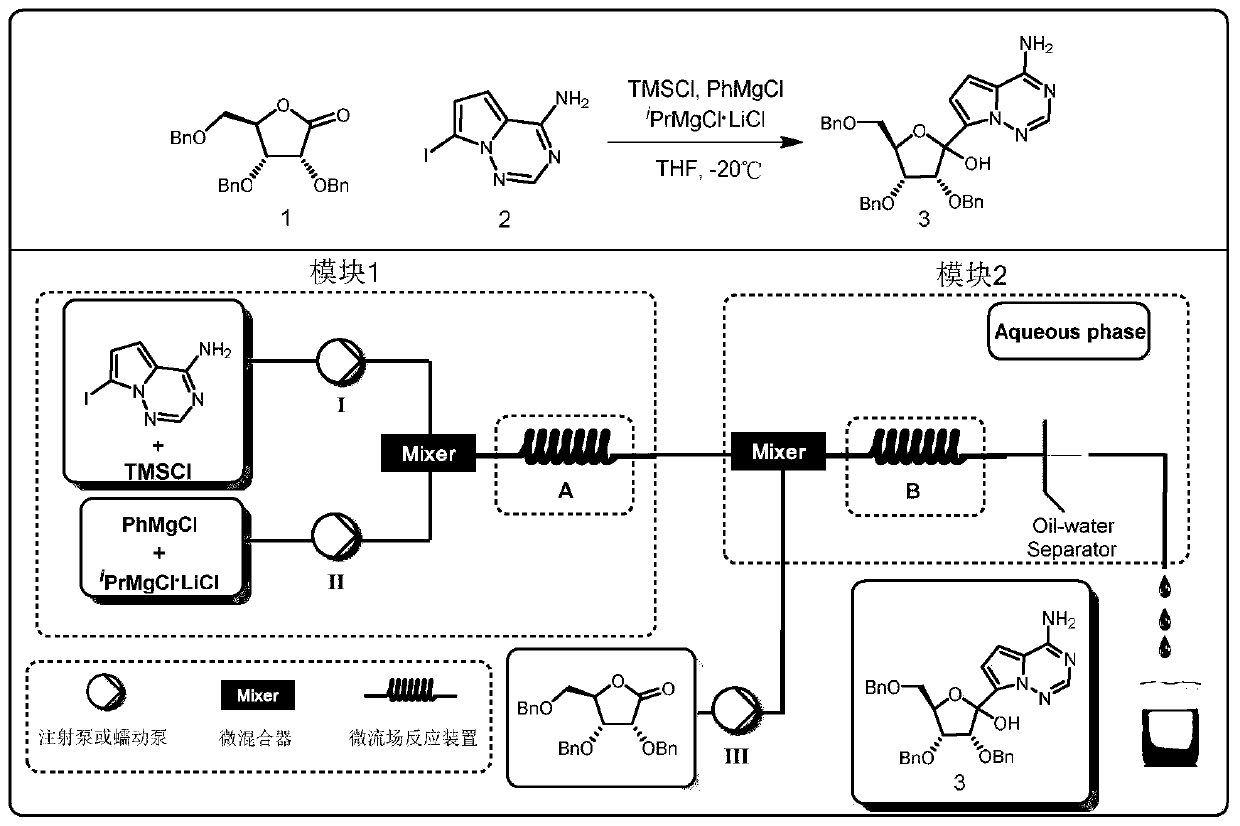

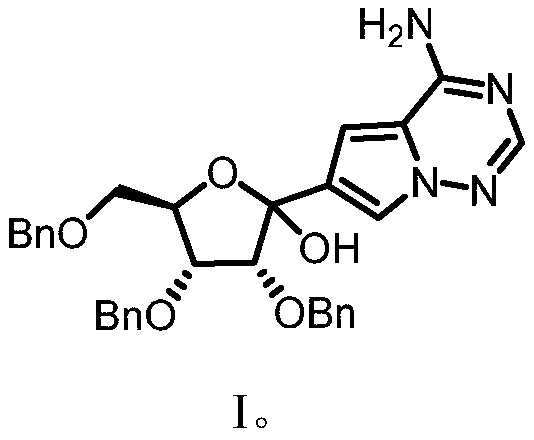

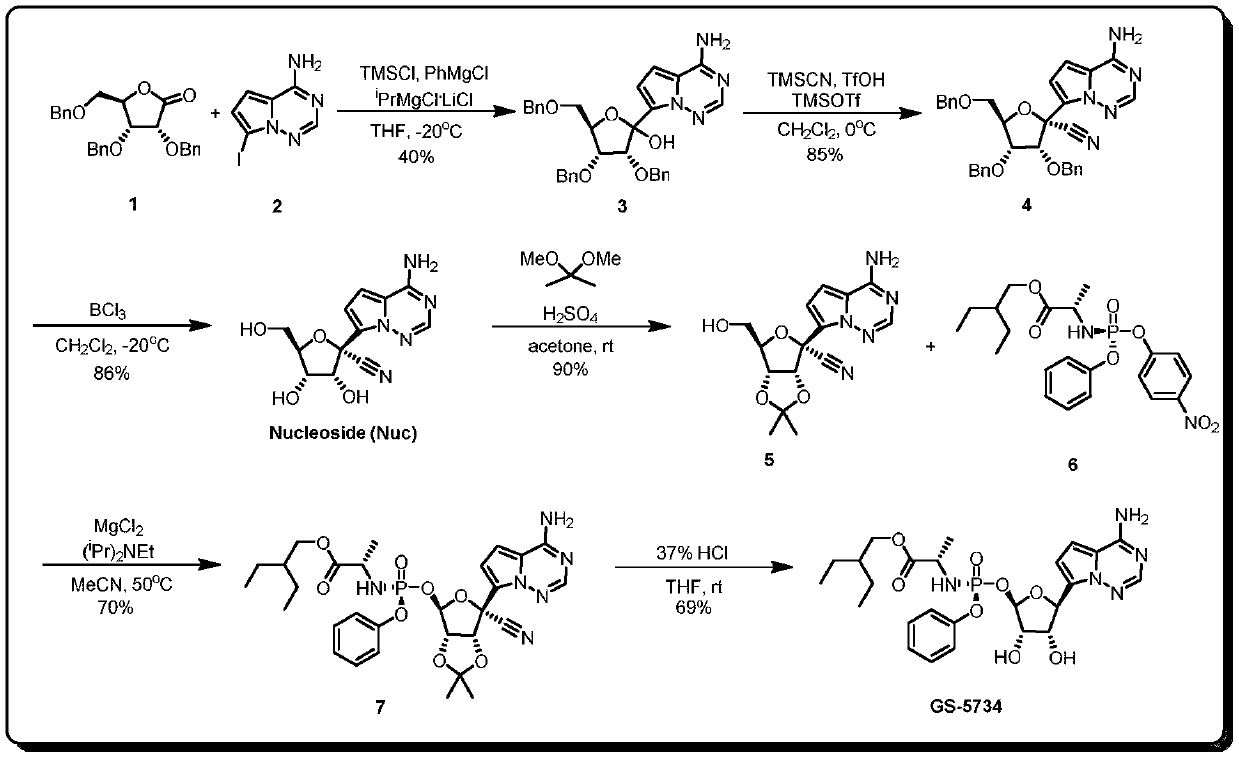

Method for preparing key intermediate of Remdesivir by using micro-channel reaction device

ActiveCN111484537AAvoid Yield DropsLarge specific surface areaSugar derivativesChemical/physical/physico-chemical microreactorsOrganosolvPhenyl group

The invention discloses a method for preparing a Remdesivir key intermediate by using a micro-channel reaction device, comprising the following steps of: (1) adding 7-iodopyrrolo [2, 1-f] [1, 2, 4] triazine-4-amine into an organic solvent, and adding trimethylchlorosilane to obtain a mixed solution as a first material; taking an organic mixed solution of phenyl magnesium chloride and isopropyl magnesium chloride. magnesium chloride as a second material; adding 2, 3, 5-tri-O-benzyl-D-ribose-1, 4-lactone into an organic solvent to be used as a third material; (2) respectively pumping the first material and the second material into a first micro-mixer of a micro-channel reaction device at the same time, mixing, and introducing into the first micro-reactor for reaction; and (3) pumping an effluent of the first micro-reactor and the third material into a second micro-mixer of the micro-channel reaction device at the same time, mixing, introducing into the second micro-reactor for reaction,and collecting an effluent, thereby obtaining the product.

Owner:NANJING UNIV OF TECH

Environment-friendly cooling reaction kettle for chemical production

ActiveCN111530400AScientific and reasonable structureEasy to useChemical/physical/physico-chemical stationary reactorsFeed devicesProcess engineeringChemical agent

The invention discloses an environment-friendly cooling reaction kettle for chemical production. The environment-friendly cooling reaction kettle includes a supporting underframe, a reaction kettle main body is fixedly connected to the middle of the top end of the supporting underframe; a protective shell is fixedly connected to the middle of the outer side of the reaction kettle main body; one side of the supporting underframe is fixedly connected with a cooling oil tank. The top of the cooling oil tank is fixedly connected with a cold oil pump through an oil pipe; the input end of the cold oil pump is electrically connected with the output end of mains supply; one end of the cold oil pump is fixedly connected with a lower cooling oil pipe; a heat exchanger is fixedly connected to the bottom of one side, corresponding to the protective shell, of the top of the lower cooling oil pipe; according to the reaction kettle, the temperature of the reaction kettle can be slowly and quickly reduced through a temperature conversion mechanism, damage to the reaction kettle due to sudden temperature drop is prevented, the production safety of the reaction kettle is improved, the phenomenon ofenvironmental pollution caused by chemical agent leakage due to explosion of the reaction kettle is prevented, and the environmental protection performance of the reaction kettle is improved.

Owner:宁夏宏民生物科技有限公司

Synthesis method of 9, 9-di [4-(2-hydroxyethoxy) phenyl] fluorene

ActiveCN112142574AAvoid side effectsHigh reaction yieldEther separation/purificationOrganic compound preparationChemical synthesisAlkane

Owner:ZHEJIANG ZHONGXIN FLUORIDE MATERIALS CO LTD

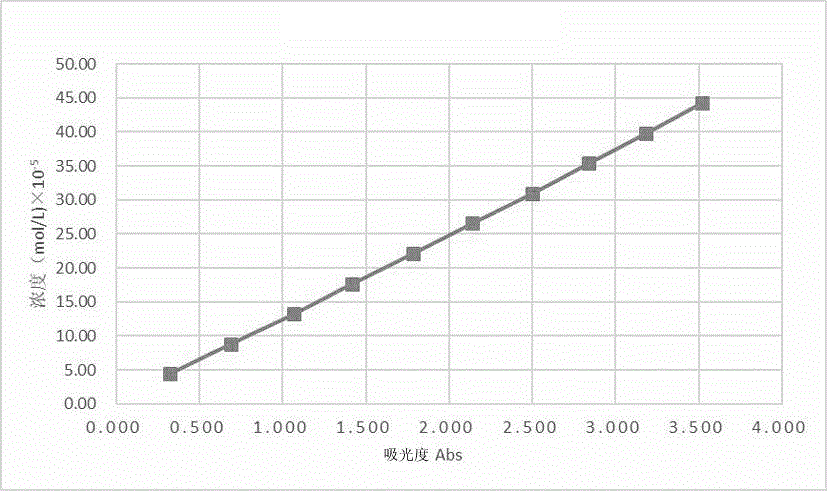

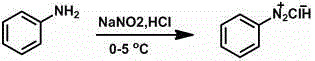

Method for continuous preparation of C.I. acid orange 10 in micro-channel

The invention relates to a method for continuous preparation of C.I. acid orange 10 in a micro-channel. The method comprises the steps: a material liquid A prepared by dissolving phenylamine and concentrated hydrochloric acid in water is subjected to a diazotization reaction with a sodium nitrite aqueous solution, and a material liquid C containing phenylamine diazonium salt is obtained; the material liquid C and a sodium bicarbonate aqueous solution of G salt are sent into a micro-channel reactor by an injection pump and are subjected to a coupling reaction, and after posttreatment, the C.I. acid orange 10 is obtained. With adopting of the micro-channel reactor, the reaction time is shortened, the reaction efficiency and the product quality are improved, and the product selectivity is greatly improved; the reaction system has no amplifying effect, and can be amplified by multiple times through parallel connection; moreover, the method has the advantages of stability of the continuous reaction, simple and convenient operation, short production cycle, cheap and easily obtained raw materials, simple production process and the like, and is suitable for industrialized production; and the micro-channel reactor is made of a polytetrafluoroethylene material, thereby having the advantages of simple preparation, good solvent resistance, strong corrosion resistance and the like, and being conducive to industrial application.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Synthesis method of 9, 9-di [4-(2-hydroxyethoxy) phenyl] fluorene Synthesis method of 9, 9-di [4-(2-hydroxyethoxy) phenyl] fluorene](https://images-eureka.patsnap.com/patent_img/0d815d88-7982-4bb9-9267-b2f8049dca79/BDA0002714875040000011.png)

![Synthesis method of 9, 9-di [4-(2-hydroxyethoxy) phenyl] fluorene Synthesis method of 9, 9-di [4-(2-hydroxyethoxy) phenyl] fluorene](https://images-eureka.patsnap.com/patent_img/0d815d88-7982-4bb9-9267-b2f8049dca79/BDA0002714875040000012.png)

![Synthesis method of 9, 9-di [4-(2-hydroxyethoxy) phenyl] fluorene Synthesis method of 9, 9-di [4-(2-hydroxyethoxy) phenyl] fluorene](https://images-eureka.patsnap.com/patent_img/0d815d88-7982-4bb9-9267-b2f8049dca79/BDA0002714875040000021.png)