Coal quantity optimization prediction control method based on AGC optimization of thermal power plant

A predictive control and thermal power plant technology, applied in the control of combustion, combustion method, adaptive control, etc., can solve problems such as incompleteness, and achieve the effect of reducing workload, improving safety, and fast and stable main steam pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

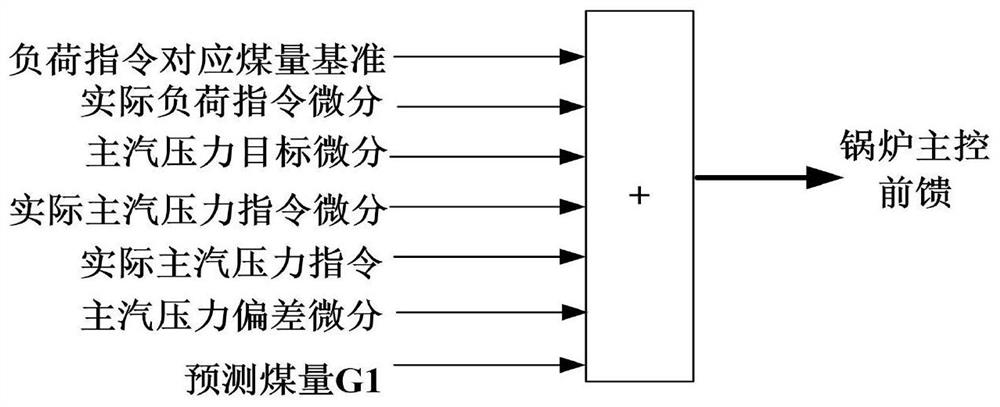

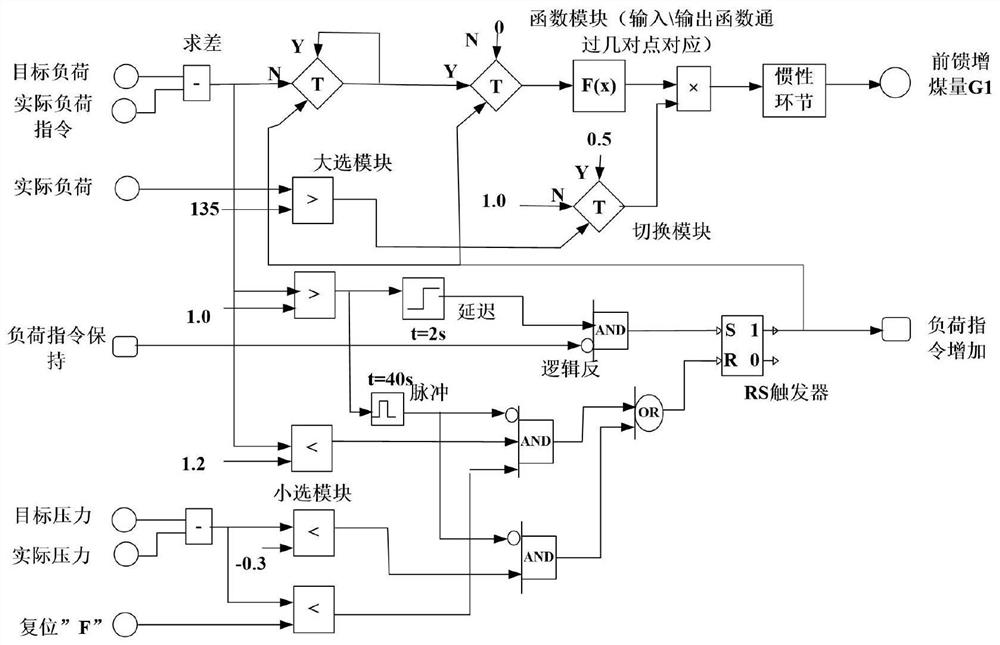

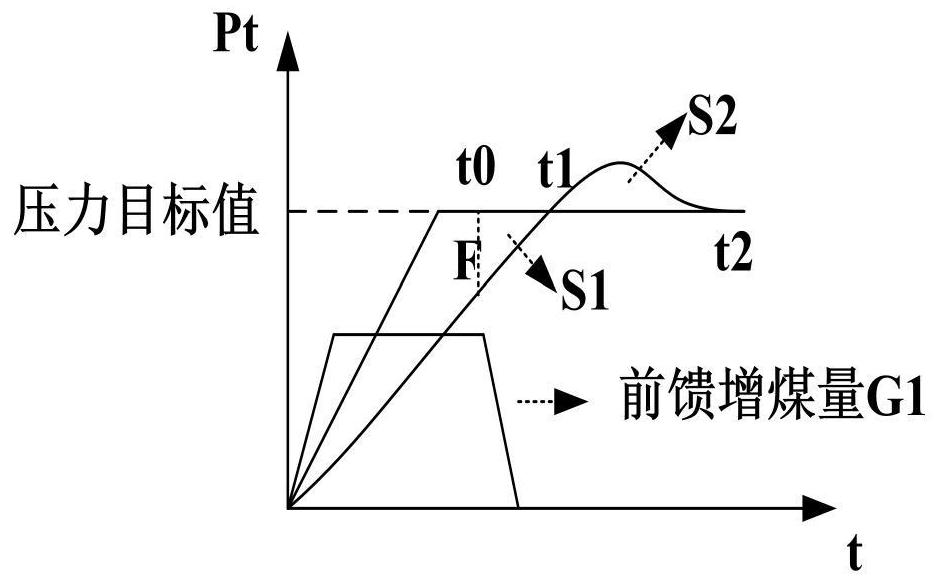

[0056] A coal quantity optimization predictive control method based on AGC optimization in a thermal power plant, including a feed-forward plus PID control strategy for the boiler master control in the AGC and CCS control systems, and, in order to improve the response speed and control accuracy of the boiler, also An intelligent feed-forward is added to design the coal quantity prediction link and plan the objective function. Through the DCS configuration programming of the power plant, the parameters can be automatically optimized, so that the feed-forward self-adaptation can be realized, the manual adjustment work can be reduced, and the main steam can be improved. The adjustment quality of pressure, and then improve the adjustment quality of CCS and AGC, such as figure 1 As shown, the intelligent feedforward of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com