Method for continuous preparation of C.I. acid orange 10 in micro-channel

An acid orange, micro-channel technology, applied in chemical instruments and methods, azo dyes, organic dyes, etc., to achieve the effects of strong corrosiveness, simple production process and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

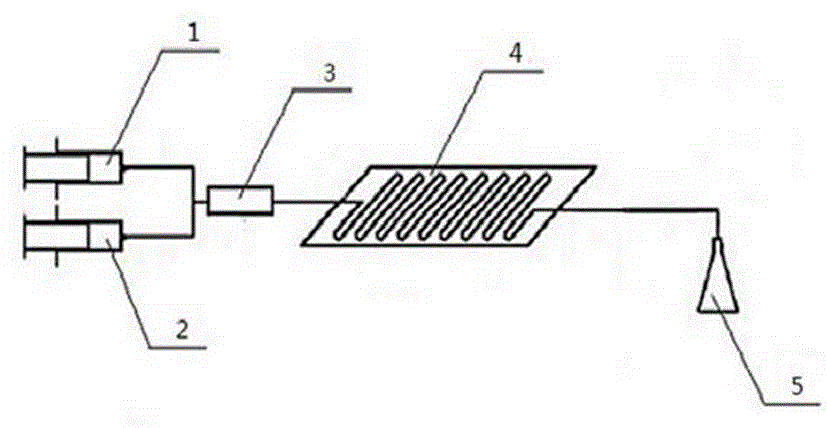

Method used

Image

Examples

Embodiment 1

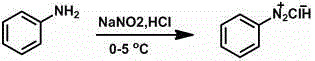

[0030] Dissolve 0.005 mol of aniline and 0.29 mol of 37.5% hydrochloric acid in water to prepare 10 mL of a mixed solution with a final aniline concentration of 0.5 mol / L, as feed solution A; dissolve 0.005 mol of sodium nitrite in water to form a final concentration of 0.5 mol of sodium nitrite / L mixed solution 10 mL, as the feed liquid B; slowly add the feed liquid B to the feed liquid A, and control the temperature of the reaction liquid at 0-5°C during the feeding process to prevent the temperature from rising suddenly. Stir and react in a conventional reactor for 30 minutes under normal conditions to obtain 20 mL of aniline diazonium salt feed solution C; take 1.75 g (0.005 mol) of G salt and dissolve it in baking soda solution to prepare a 20 mL feed solution with a final concentration of 0.25 mol / L D; Feed liquid C and feed liquid D are sent to the microchannel reactor 4 by the calibrated syringe pump (model LSP01-1A, manufacturer: Baoding Lange Constant Flow Pump Co., ...

Embodiment 2

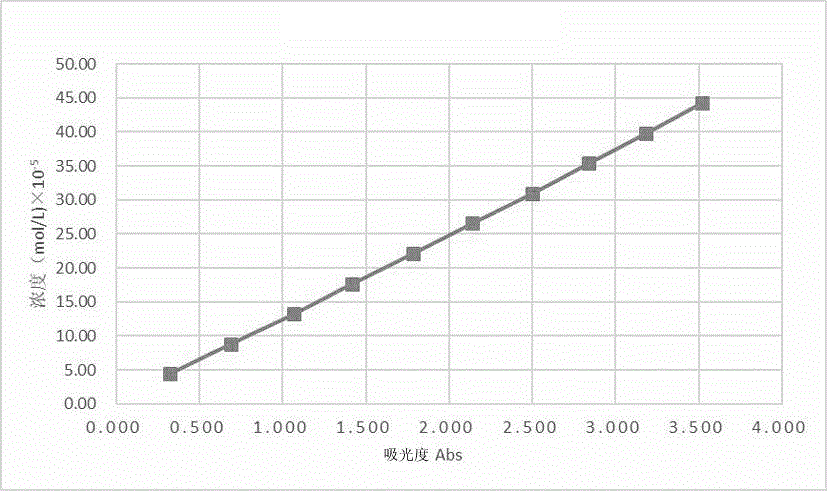

[0032] Feed liquid A, feed liquid B are the same as embodiment 1; Feed liquid C and feed liquid D are injected into the microchannel reactor by a certain flow rate and reacted respectively, and process parameters such as flow rate, reaction temperature, residence time, internal diameter are shown in Table 2, Collect the effluent liquid E to obtain C.I. Acid Orange 10. Use a UV ultraviolet detector to detect the absorbance Abs value at the position of the maximum absorption peak wavelength 475nm, and compare it with the standard working curve of C.I. Acid Orange 10 c=(12.42*Abs+0.158)*10 -5 The one-way yield measured by mol / L was 87.5-94.0%, as shown in Table 2 for details.

[0033] The impact of each process condition of table 2 on reaction

[0034]

[0035] It can be concluded from the data in Table 2 that the process conditions set in Example 1 are optimal process conditions.

[0036] Comparative example 1 (preparation of C.I. acid orange 10 by conventional batch reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com