Production method and device of calcium cyanamide

A technology of calcium cyanamide and a production method, applied in the direction of cyanamide and the like, can solve the problems affecting the safety and efficient production of the rotary nitriding furnace, the deformation service life of the furnace body in the cooling section, and the uneven temperature of the furnace body in the cooling section. Improve reaction efficiency and product quality, reduce investment and maintenance costs, and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

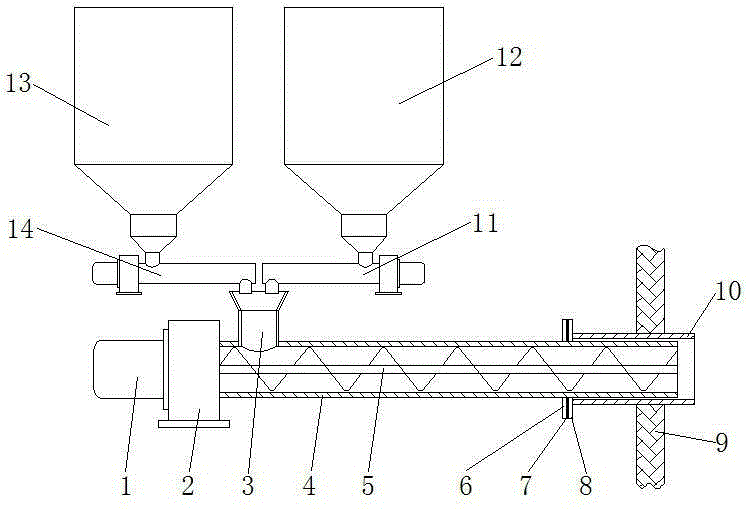

[0035] A kind of production method of calcium cyanamide, its processing step is:

[0036] 1) According to the existing process, add the crushed calcium carbide, fluorite or calcium chloride as a catalyst, sodium chloride and calcium cyanamide to the respective silos;

[0037] 2) Send the crushed calcium carbide, fluorite or calcium chloride, sodium chloride as a catalyst into the ball mill according to the weight ratio of the existing process, and after ball milling to the required particle size, send the calcium carbide material to the powder by the hoist. warehouse;

[0038] 3) Send the above-mentioned crushed returned calcium cyanamide into a ball mill for ball milling to a particle size of 0.01 mm, and then send it to the returned calcium cyanamide silo with a hoist;

[0039] 4) Through the feeding device installed under the discharge port of the calcium carbide silo and the returned calcium cyanamide silo, the materials in the calcium carbide silo and the returned calciu...

Embodiment 2—5

[0049] Example The ball mill particle size of returned calcium cyanamide 2 0.5mm 3 3mm 4 10mm 5 30mm

[0050] On the basis of Example 1, the ball mill particle size of the returned furnace calcium cyanamide is changed as shown in the table above, and all the other conditions are constant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com