Flow chemical reaction device

A chemical reaction and strengthening device technology, applied in chemical/physical/physical chemical reactors, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as high labor costs, low efficiency, and low safety, and achieve improved Productivity, shortened response time, and improved safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

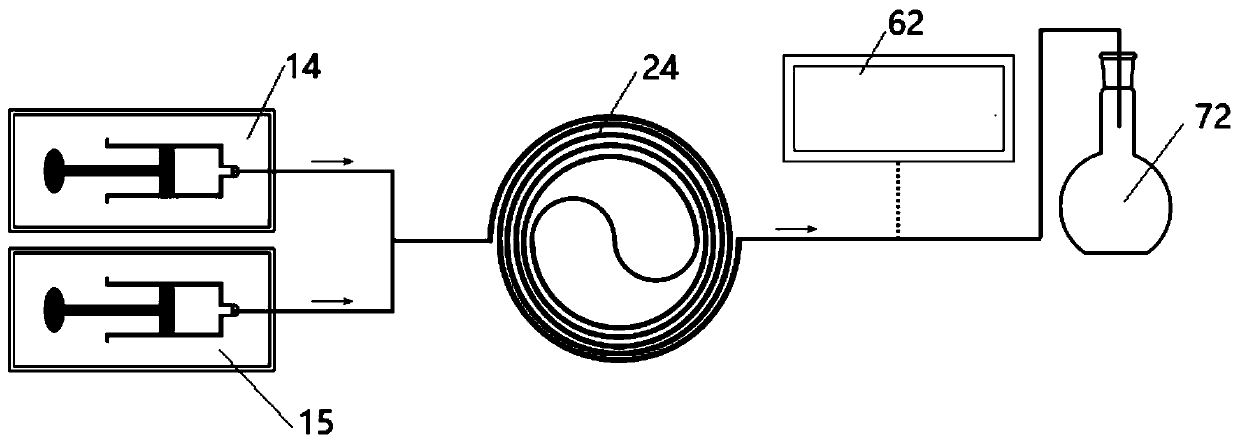

[0035] This embodiment provides a flow chemical reaction device, such as figure 1 , comprising a reactor 24, two liquid injection devices 14,15, a detection device 62 and a collection container 72, wherein the liquid injection devices 14,15 communicate with two sample inlets of the reactor 24 through pipelines, and the liquid injection devices 14,15 The output reagent solutions are mixed in the reactor 24 and sent to the chemical reaction. The sample outlet of the reactor 24 communicates with the detection device 62 and the collection container 72 through pipelines.

[0036] In this embodiment, the reactor 24 adopts a section of micropipeline coil, and the pipeline coil is made of chemically resistant polymer material, silicon dioxide or stainless steel. In this embodiment, the micropipeline coil adopts tetrafluoroethylene-perfluoroalkoxyethylene The base ether copolymer (PFA) material has good corrosion resistance. The diameter of the micropipe is 100-1000um, and the length ...

Embodiment 2

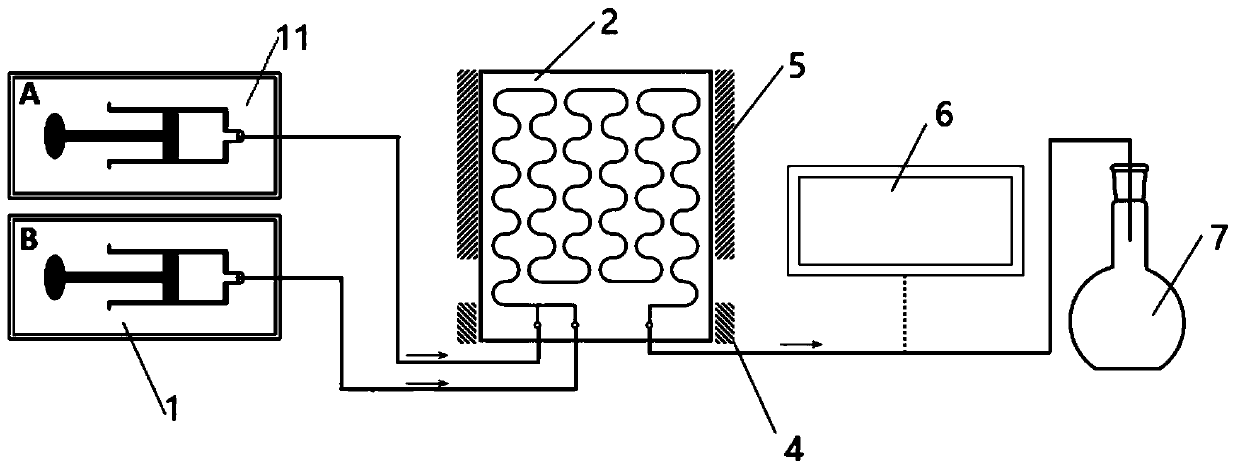

[0043] This embodiment provides a flow chemical reaction device, such as figure 2, including two syringe pumps 1, 11, a reactor, a detection device 6 and a collection container 7, the reactor in this embodiment is a microfluidic chip 2, the micropipe in the microfluidic chip 2 in this embodiment It is an S-shaped pipe, and the microfluidic chip is made of high-temperature-resistant and chemical-resistant borosilicate glass, and a continuous S-shaped pipe or a circular pipe with a scale of 100-1000um is etched in the glass chip. In this embodiment, the diameter of the S-shaped pipeline is about 200um, and the total volume of the pipeline is about 70ul. One end of the S-shaped pipeline is provided with two sample inlets, and the other end is provided with a sample outlet. The injection ports of the two syringe pumps 1 and 11 pass through the The tubing communicates with the two injection ports.

[0044] The detection device 6 is a Waters high electrospray mass spectrometer, an...

Embodiment 3

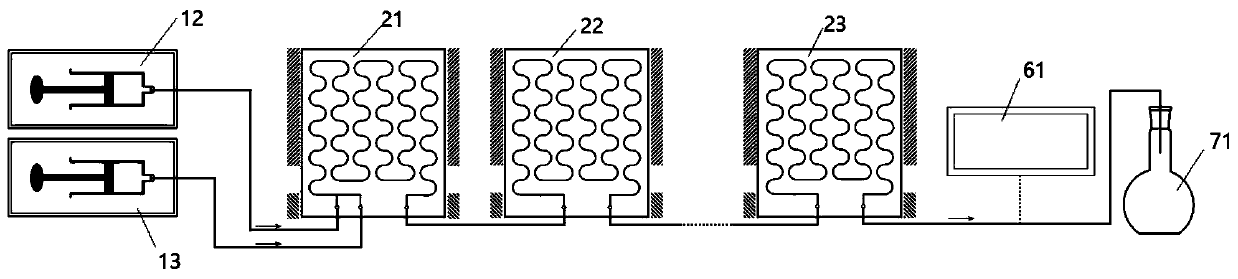

[0053] In order to increase the time for the reaction solution to be extracted and retained in the microfluidic chip, the number of microfluidic chips can be increased as required, such as image 3 , the flow chemical reaction device provided in this embodiment includes three microfluidic chips 21, 22, 23, two liquid injection pumps 12, 13, a detection device 61, and a collection container 71, wherein two liquid injection devices 12 , the liquid injection port of 13 communicates with the two sample inlets on the microfluidic chip 21 through pipelines, and the remaining two microfluidic chips 22, 23 are connected in sequence, and the detection device 61 is arranged on the downstream of the microfluidic chip 23 for The attribute of the reaction product is detected, and the collection container 71 is used to collect the detected reaction product. In this embodiment, the exterior of each microfluidic chip 21, 22, 23 is also equipped with a corresponding process intensification dev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com