Patents

Literature

126 results about "Micropipe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A micropipe, also called a micropore, microtube, capillary defect or pinhole defect, is a crystallographic defect in a single crystal substrate. Today this is of great interest to makers of silicon carbide (SiC) substrates which are used in a variety of industries such as power semiconductor devices for vehicles and high frequency communication devices.

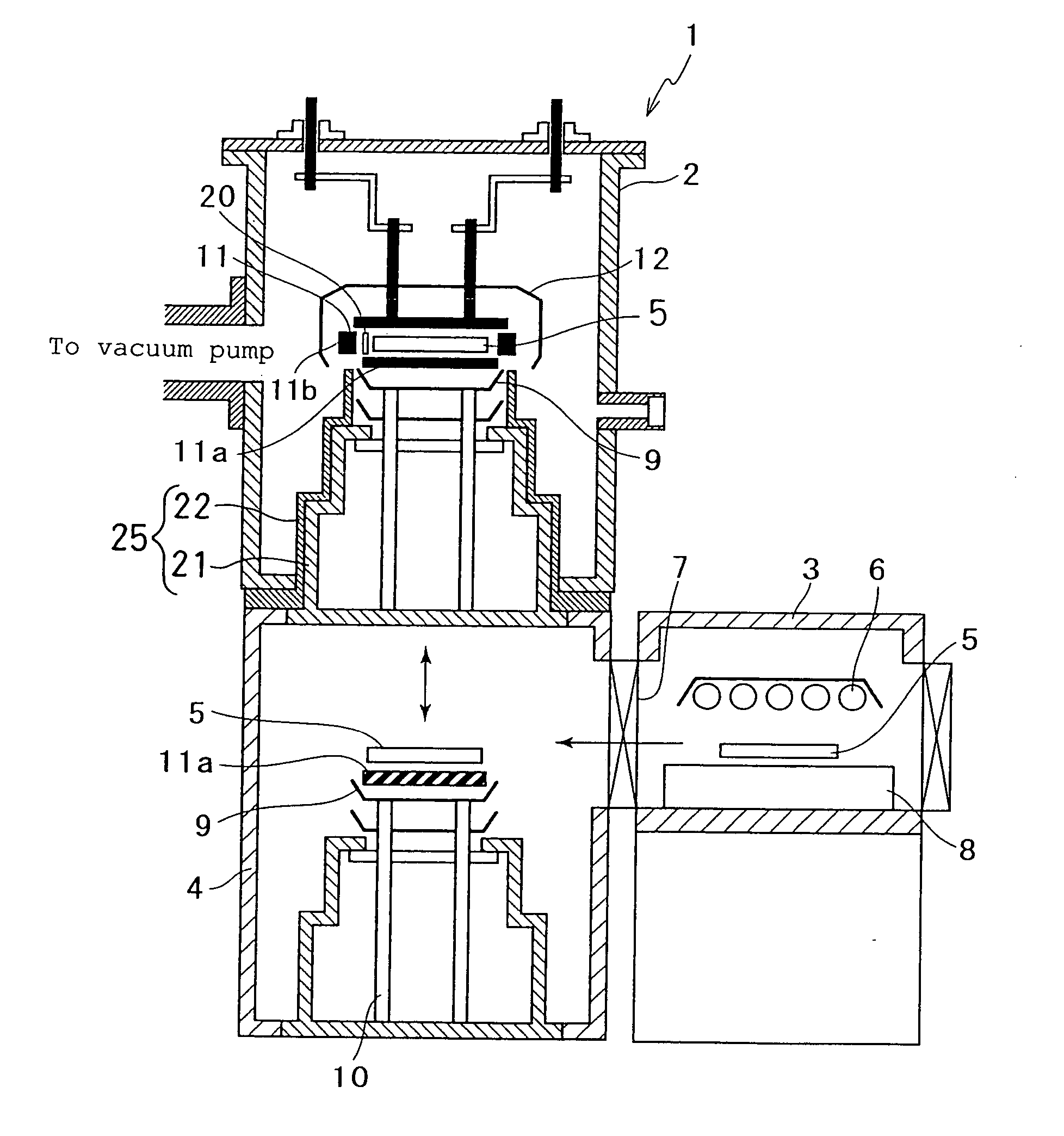

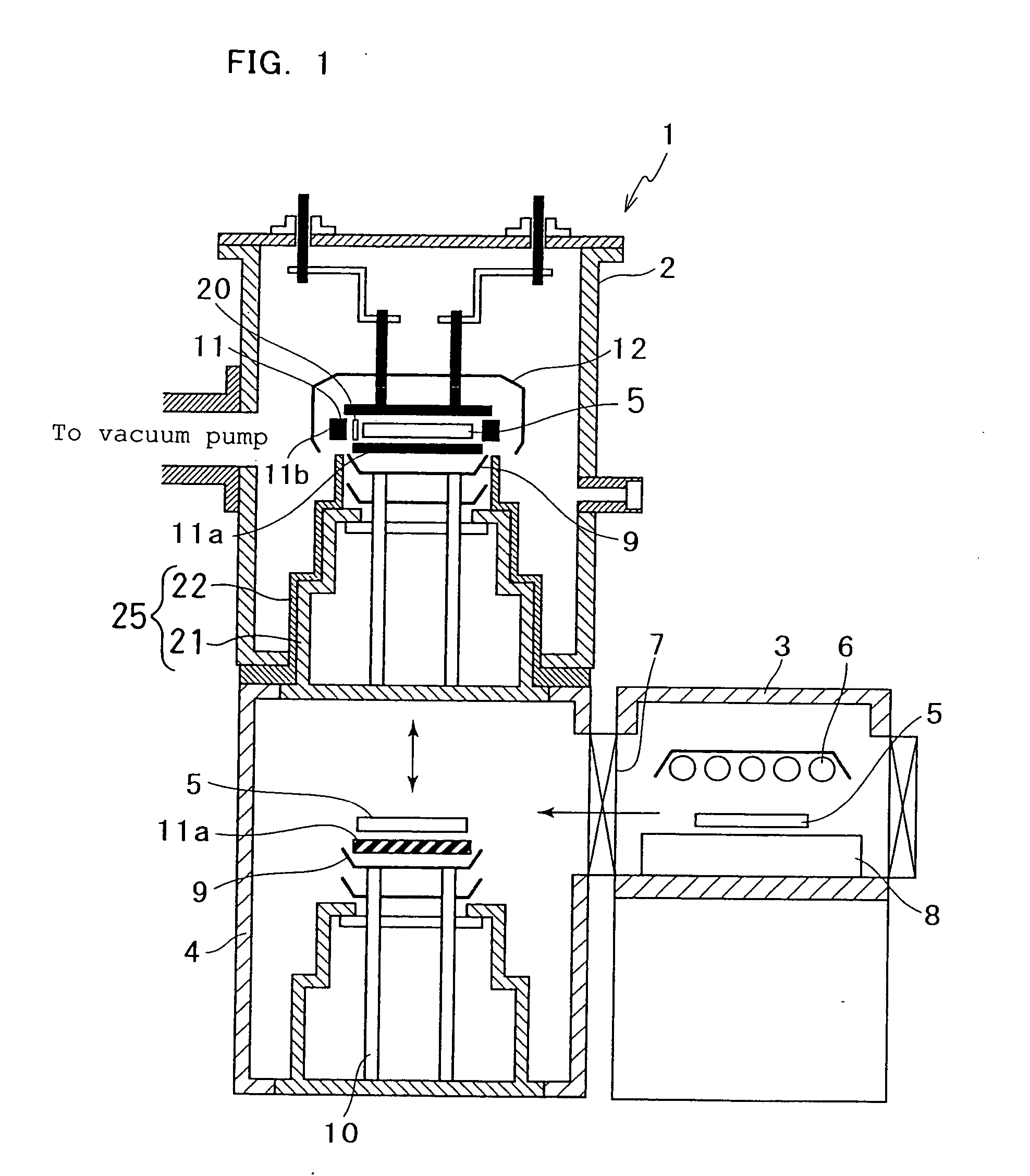

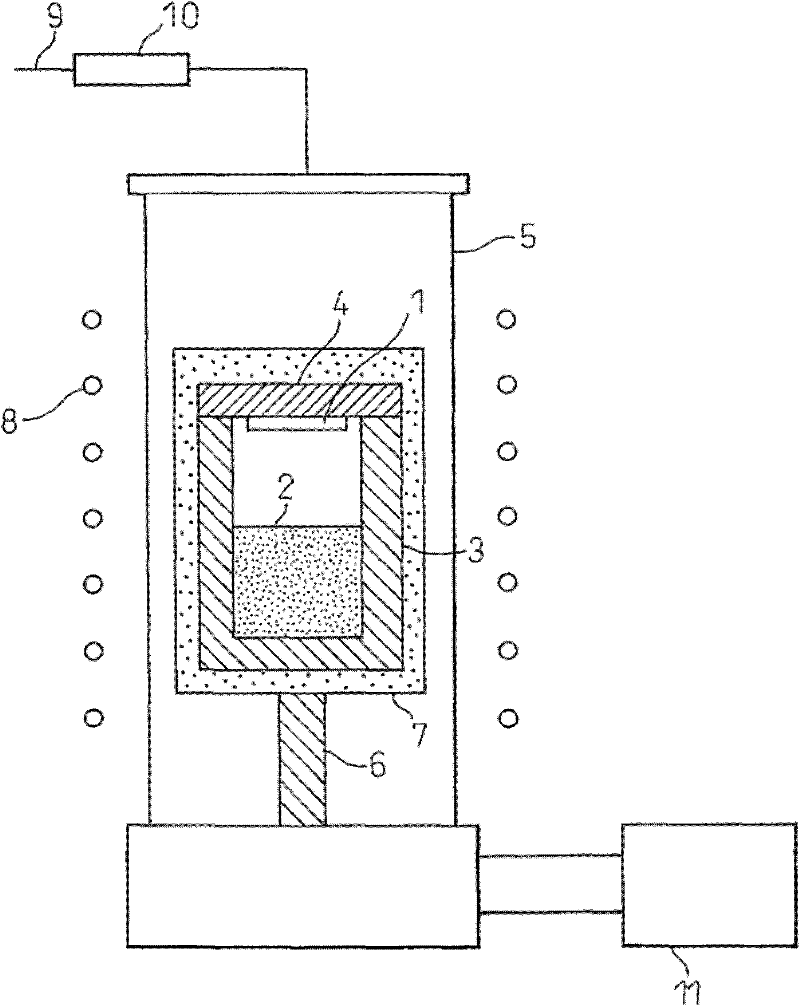

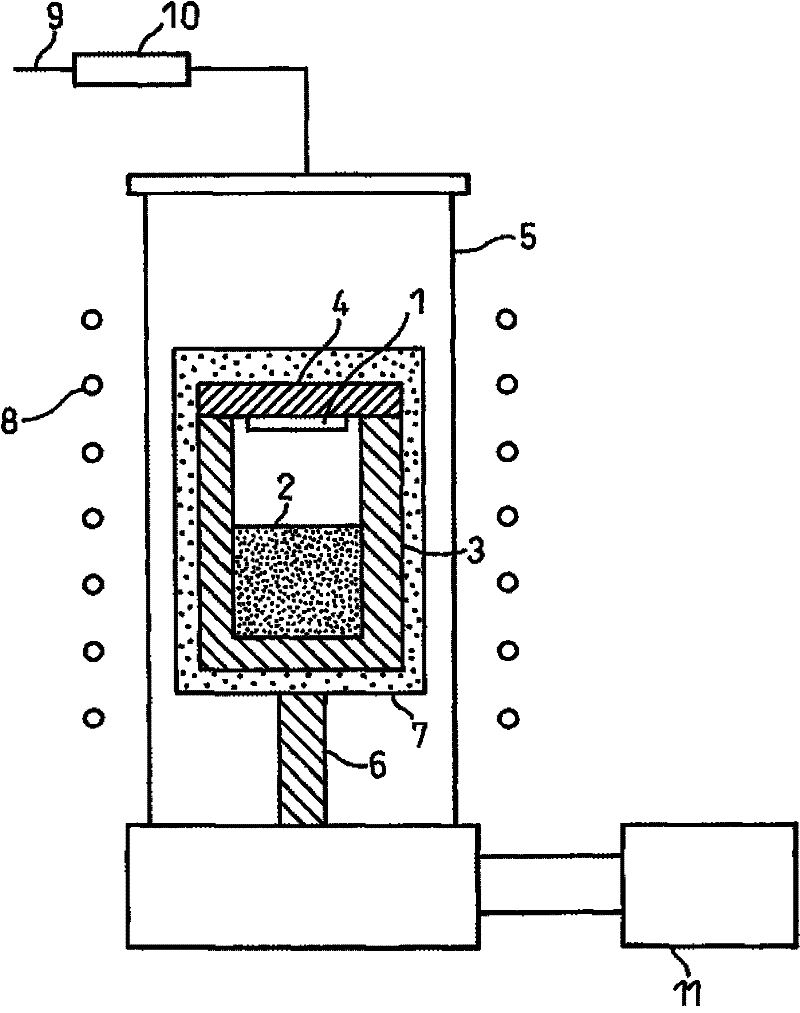

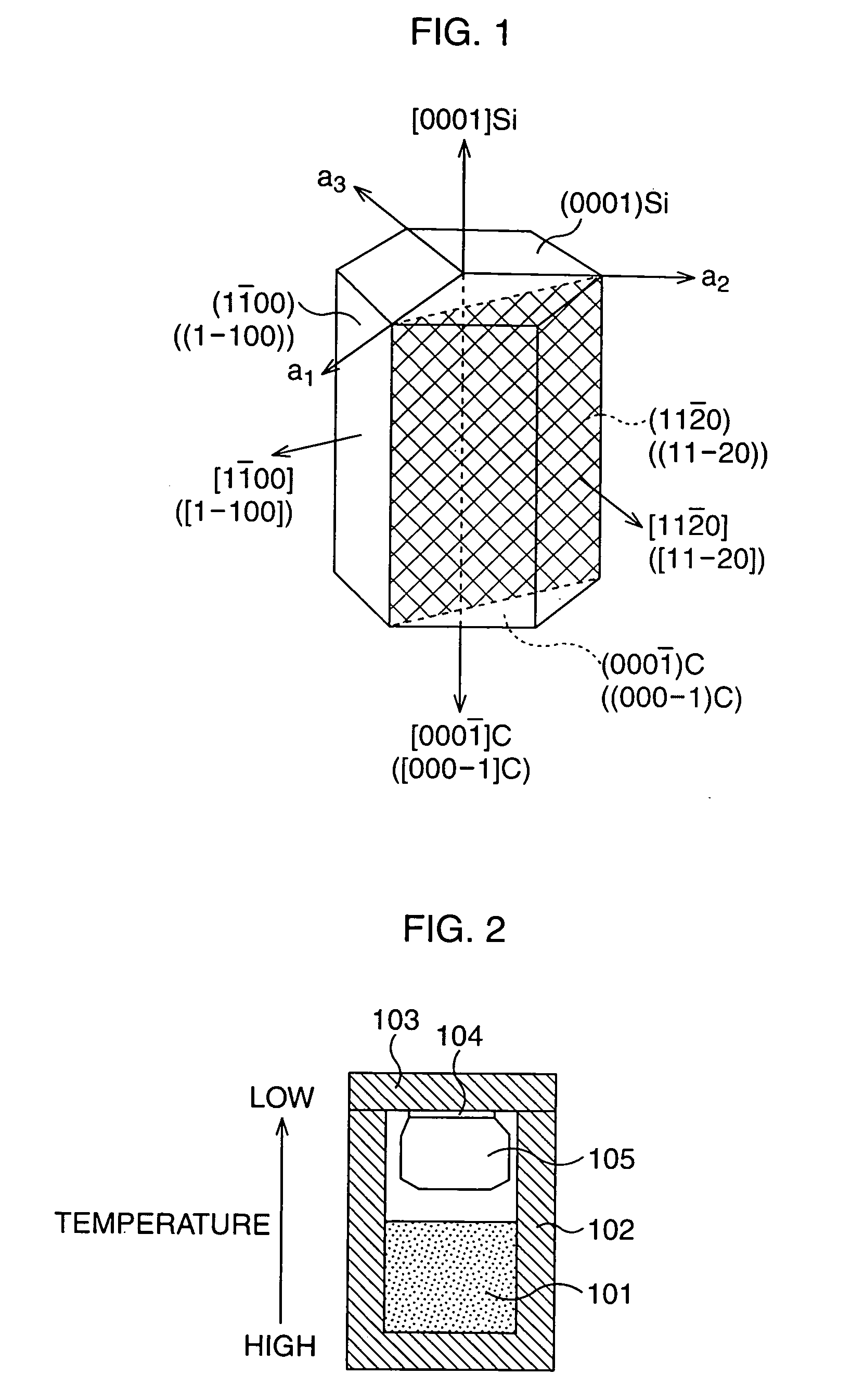

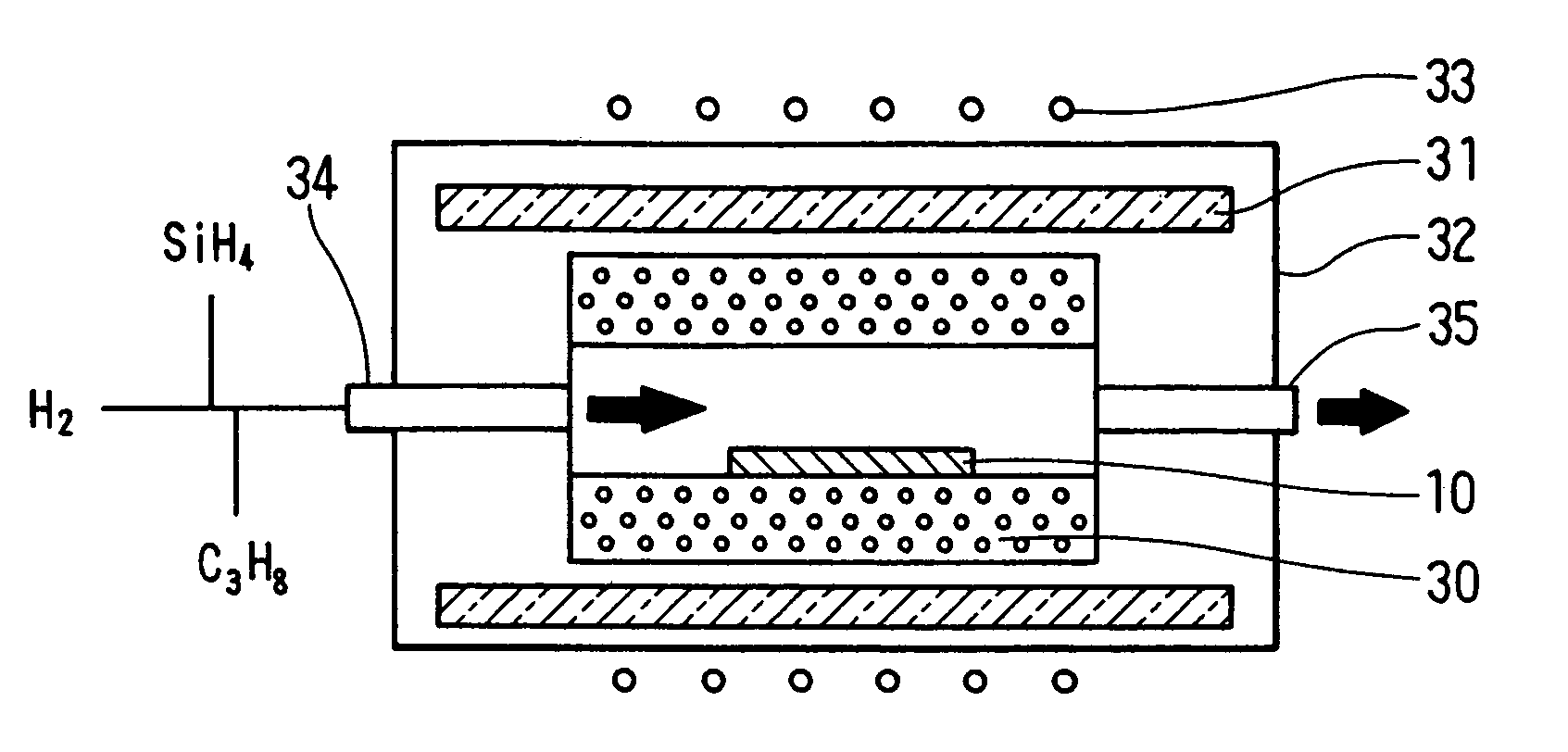

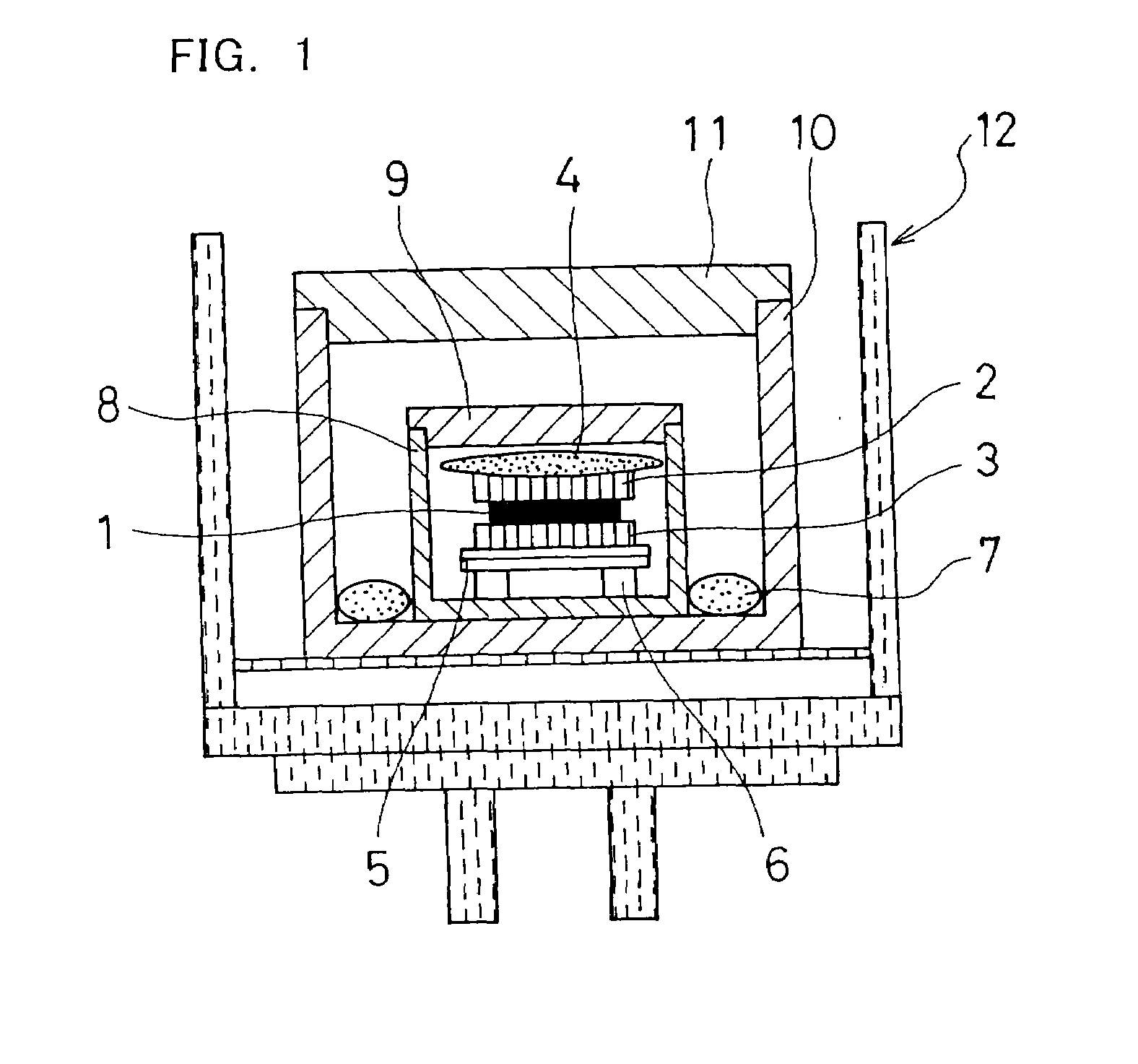

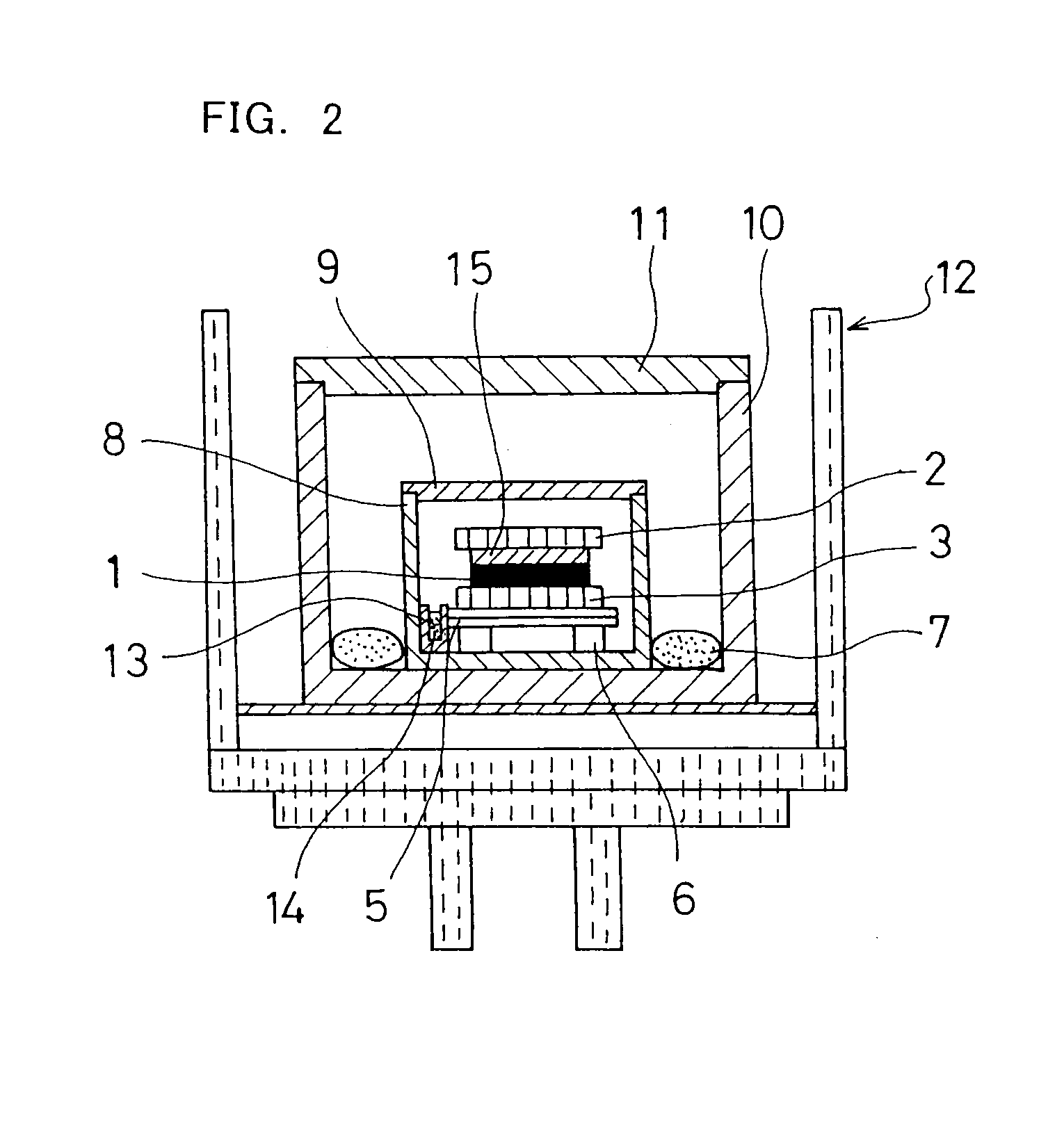

Method of heat treatment and heat treatment apparatus

InactiveUS20060249073A1No longer performedEfficient productionPolycrystalline material growthAfter-treatment detailsSeed crystalEquipment use

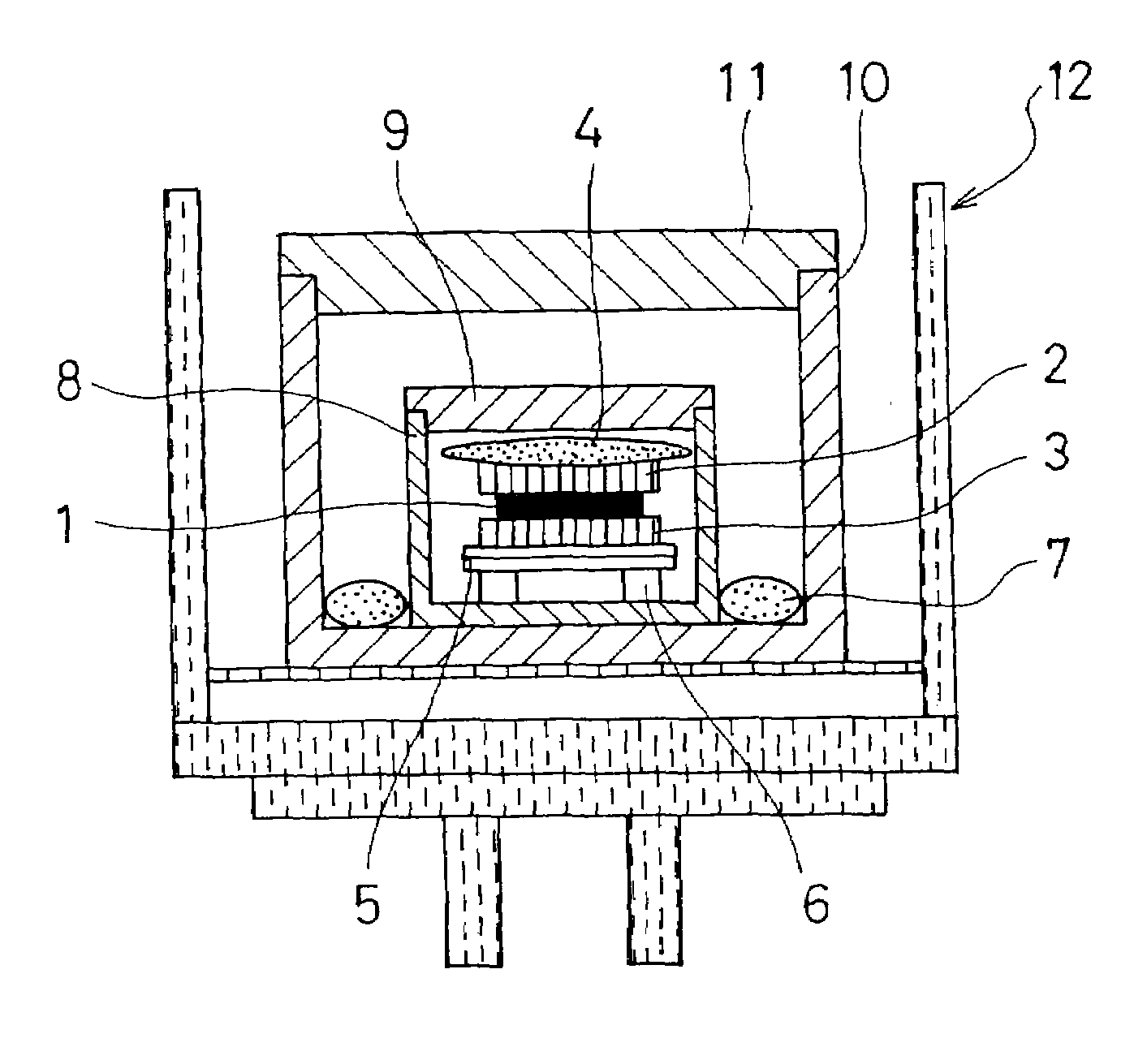

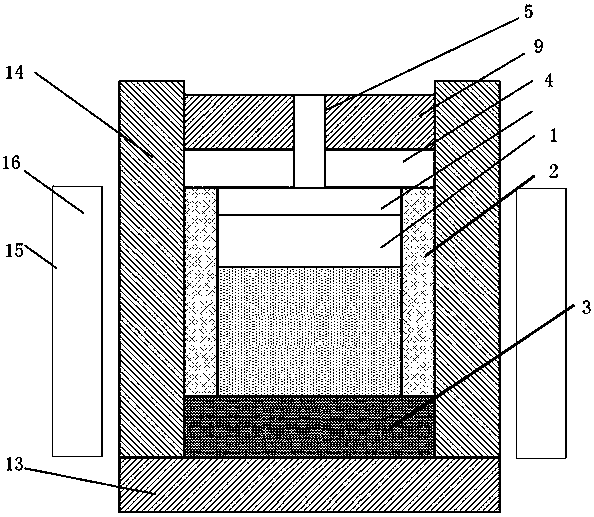

The present invention is a method suitable for heat treatment, or a heat treatment method for growing single crystal silicon carbide by a liquid phase epitaxial method, wherein a monocrystal silicon carbide substrate as a seed crystal and a polycrystal silicon carbide substrate are piled up, placed inside a closed container, and subjected to high-temperature heat treatment, by which very thin metallic silicon melt layer is interposed between the monocrystal silicon carbide substrate and the polycrystal silicon carbide substrate during heat treatment, and single crystal silicon carbide is liquid-phase epitaxially grown on the monocrystal silicon carbide substrate. The closed container is in advance heated to a temperature exceeding approximately 800° C. in an preheating chamber kept at a pressure of approximately 10−5 Pa or lower, the closed container is reduced in pressure to approximately 10−5 Pa or lower, and the container is transported and placed in the heat chamber, which is in advance heated to a prescribed temperature in a range from approximately 1400° C. to 2300° C., in a vacuum at a pressure of approximately 10−2 Pa or lower or in an inert gas atmosphere at a prescribed reduced pressure, by which the monocrystal silicon carbide substrate and the polycrystal silicon carbide substrate are heated in a short time to a prescribed temperature in a range from approximately 1400° C. to 2300° C. to produce single crystal silicon carbide which is free of fine grain boundaries and approximately 1 / cm2 or lower in density of micropipe defects on the surface. Further, the present invention is heat treatment equipment used in carrying out the heat treatment method.

Owner:THE NEW IND RES ORG

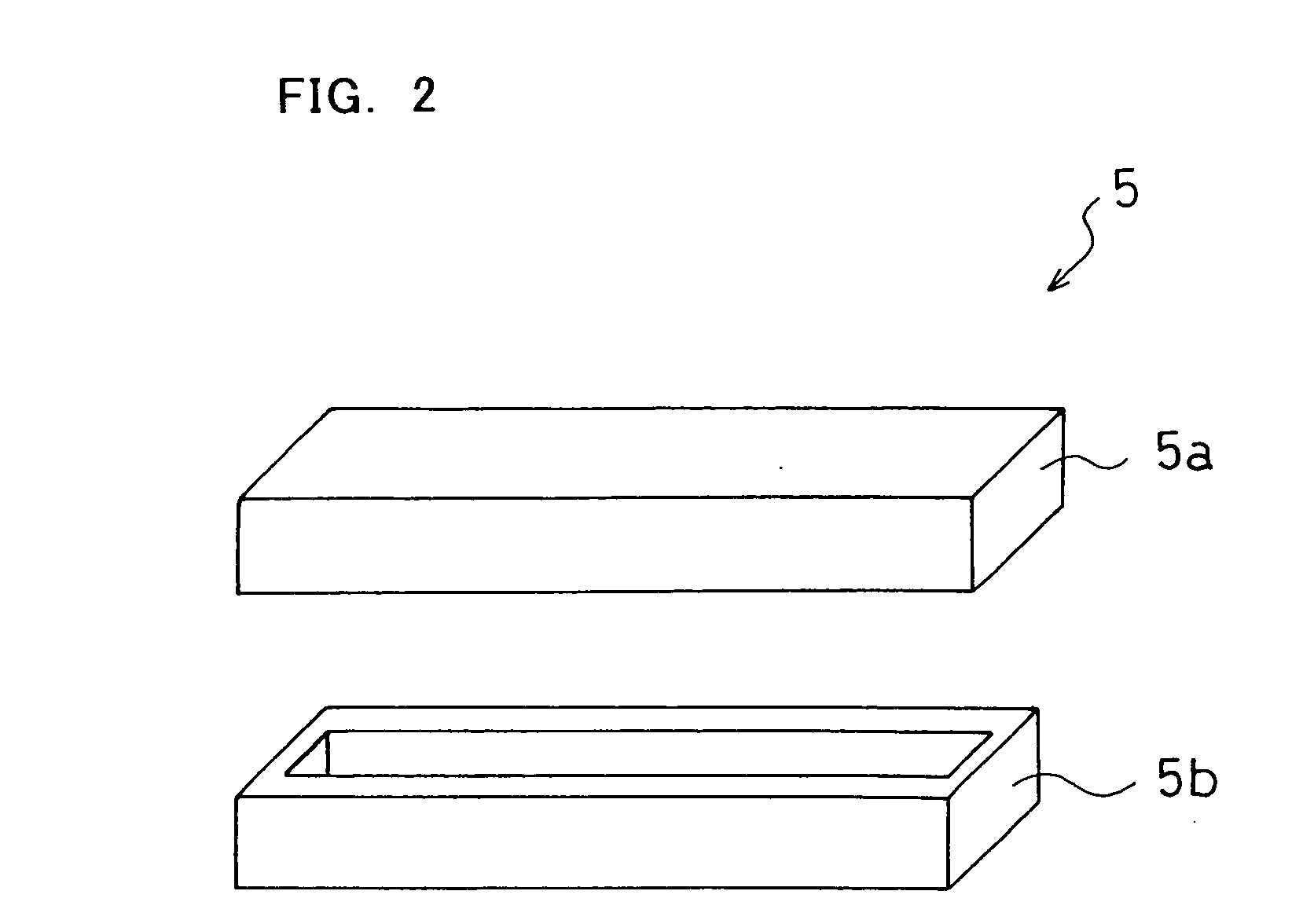

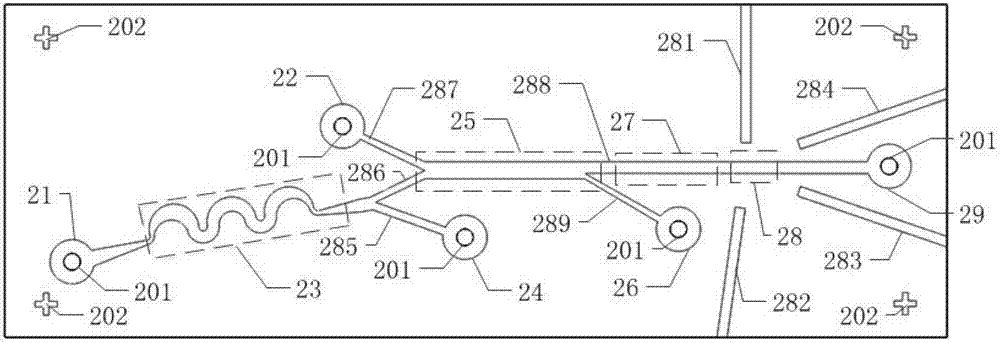

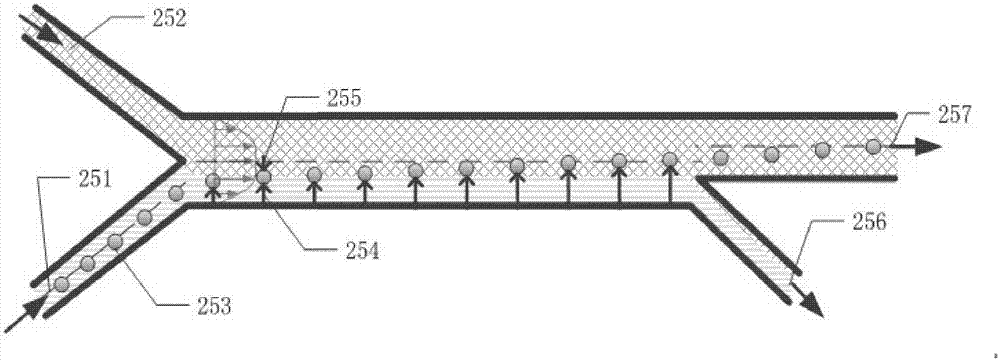

Integrated chip system for high-throughput sorting and counting detection of biological particles, and application

ActiveCN103191791AMeet the damageNo damageMaterial analysis by optical meansLaboratory glasswaresInertial effectLiquid Change

The invention discloses an integrated chip system for high-throughput sorting and counting detection of biological particles, and an application. The chip system comprises a main microfluidic chip, a micropipe, a sample liquid micropump, an exchange liquid micropump, a first waste liquid collecting device, a second waste liquid collecting device, a third waste liquid collecting device, laser emitters, photoelectric conversion devices, optical fibers and a computer, wherein the main microfluidic chip comprises an asymmetric curved flow path, a first branch channel, a second branch channel, a third branch channel, a main flow path, a branch flow path, aligning marks, etc. The system utilizes the asymmetric curved flow path to realize pre-focusing and sorting for the particles, utilizes a liquid changing flow channel to realize change of a carrier liquid of to-be-tested particles and particle cleaning, and utilizes a viscoelastic effect and an inertial effect of a viscoelastic fluid to realize focus of single equilibrium position of section centers of the particles. The system does not need a sheath liquid, complex pre-cleaning of the particles, and optical alignment, has advantages of high speed, high precision, integration, miniaturization, automation, low cost, simple production process, easy batch production, etc.

Owner:SOUTHEAST UNIV

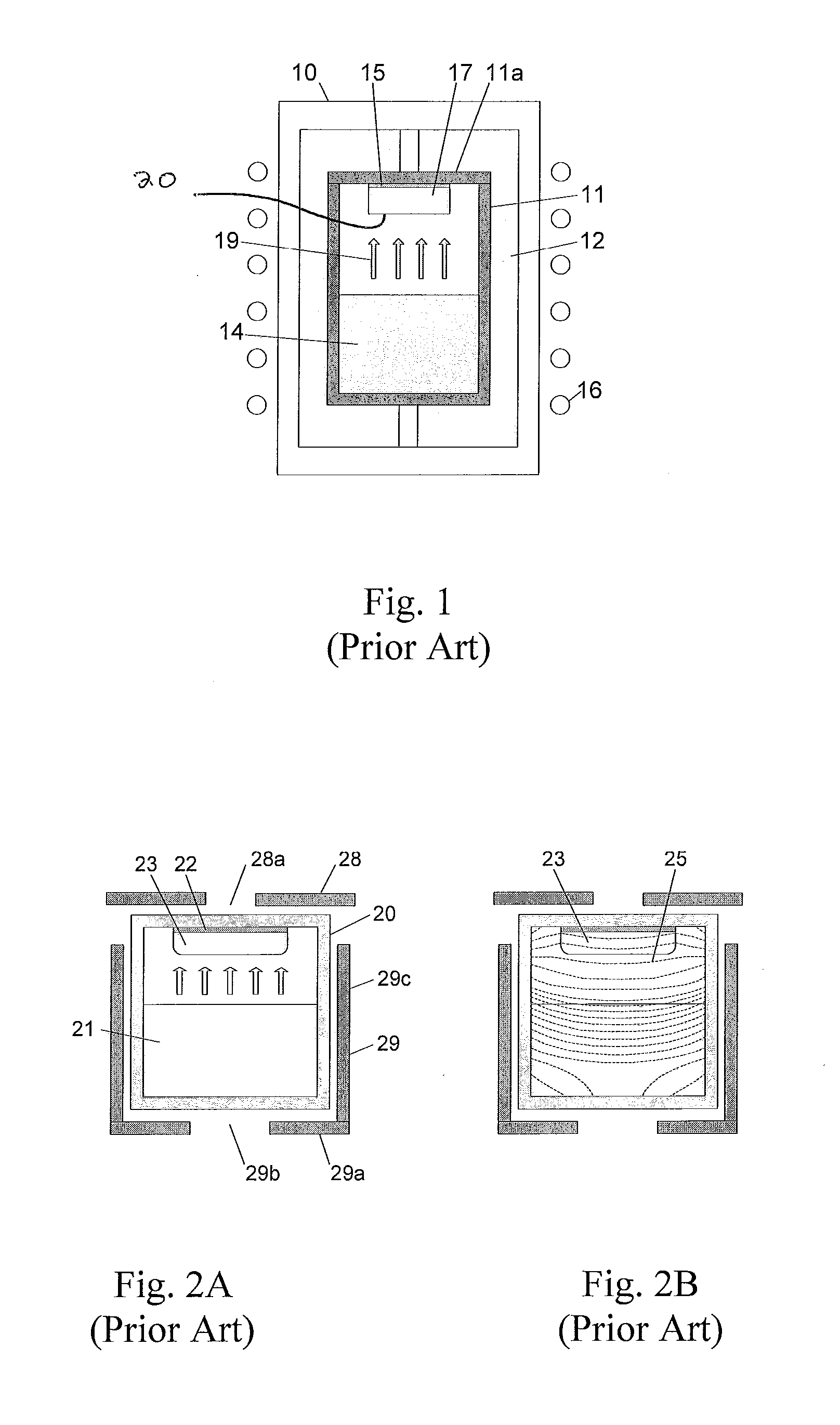

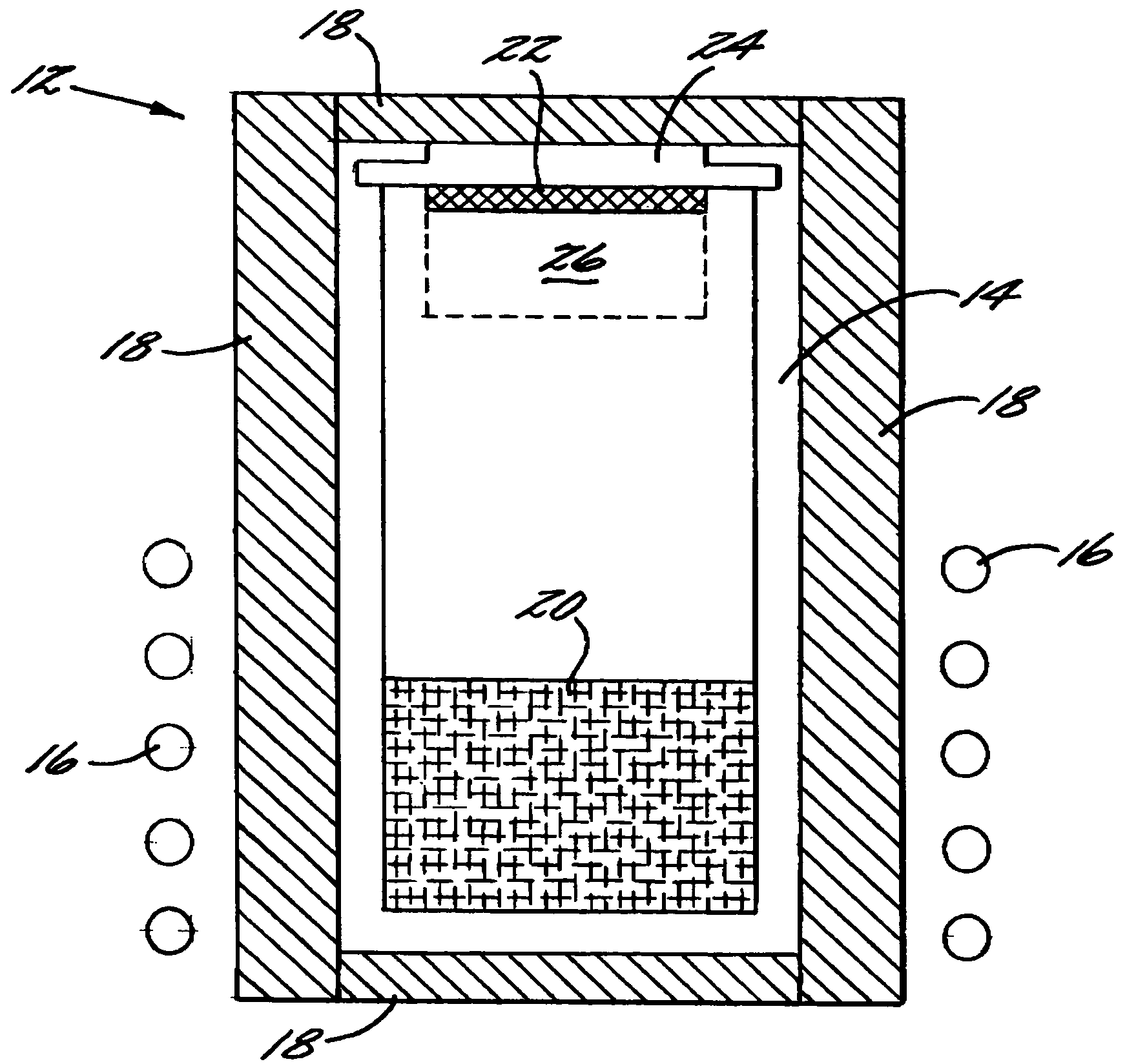

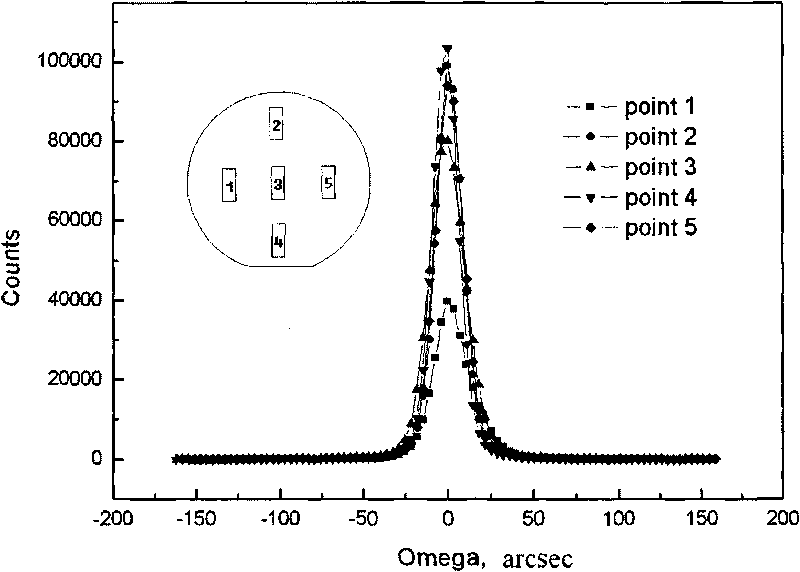

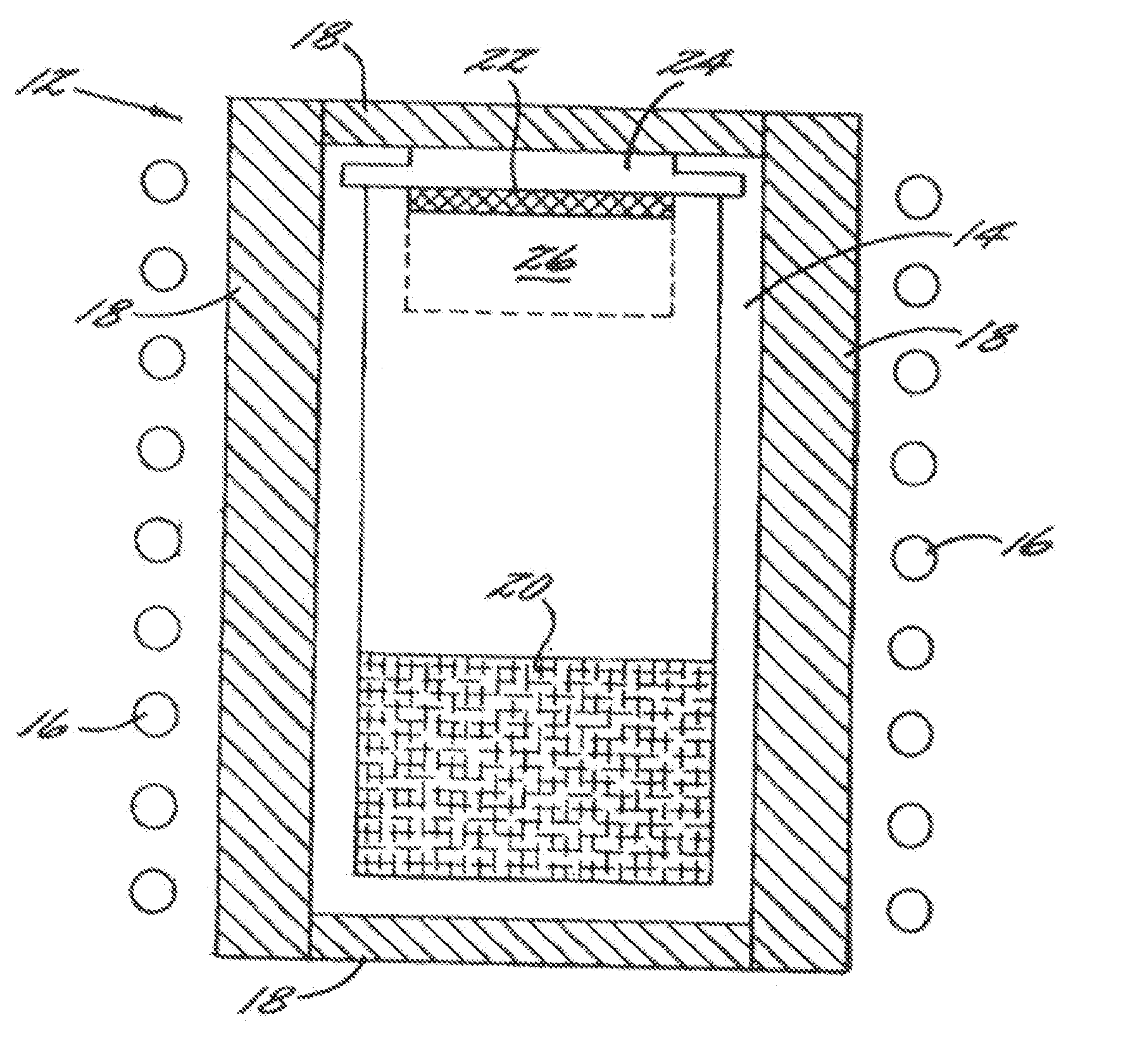

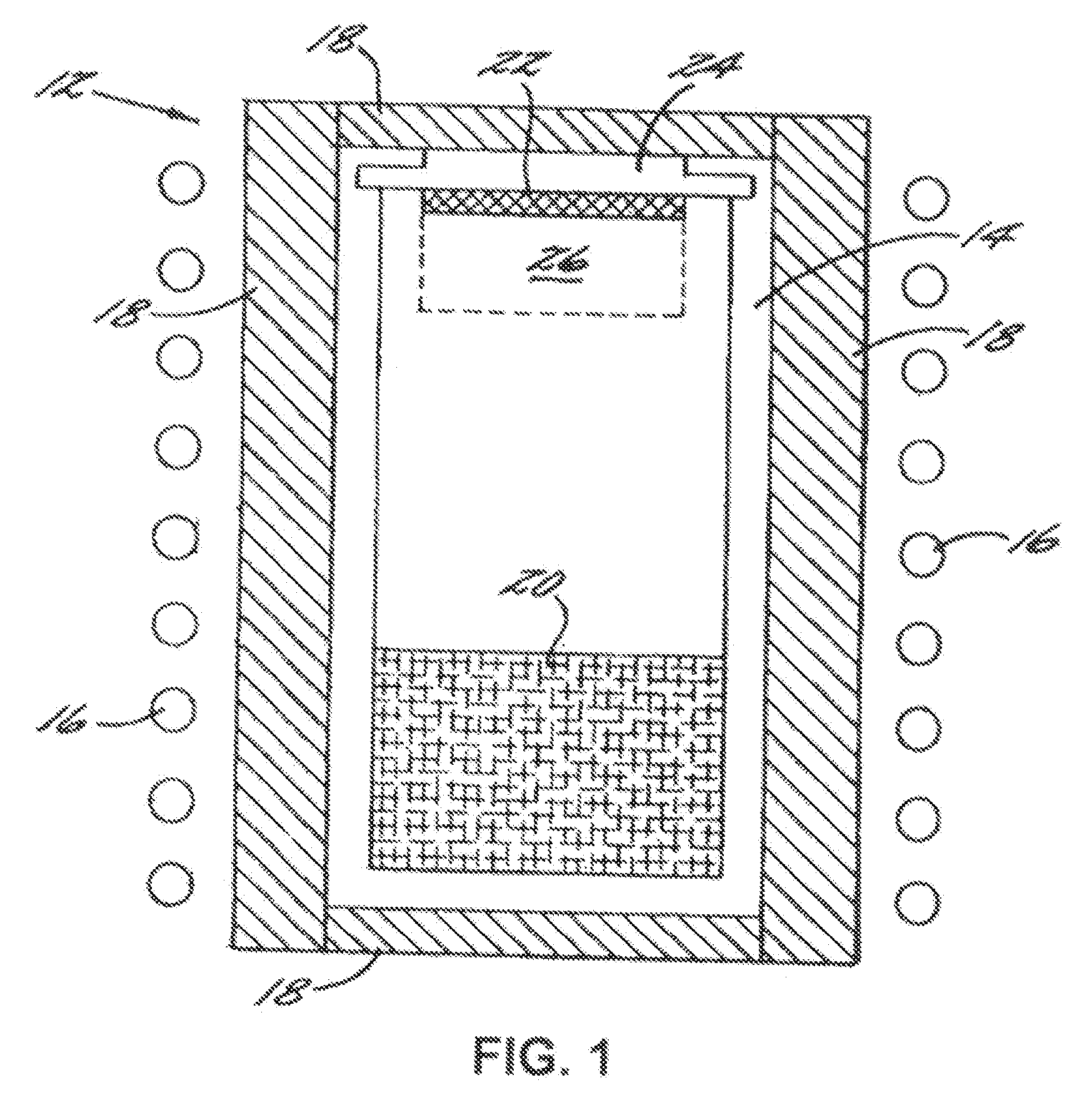

Large Diameter, High Quality SiC Single Crystals, Method and Apparatus

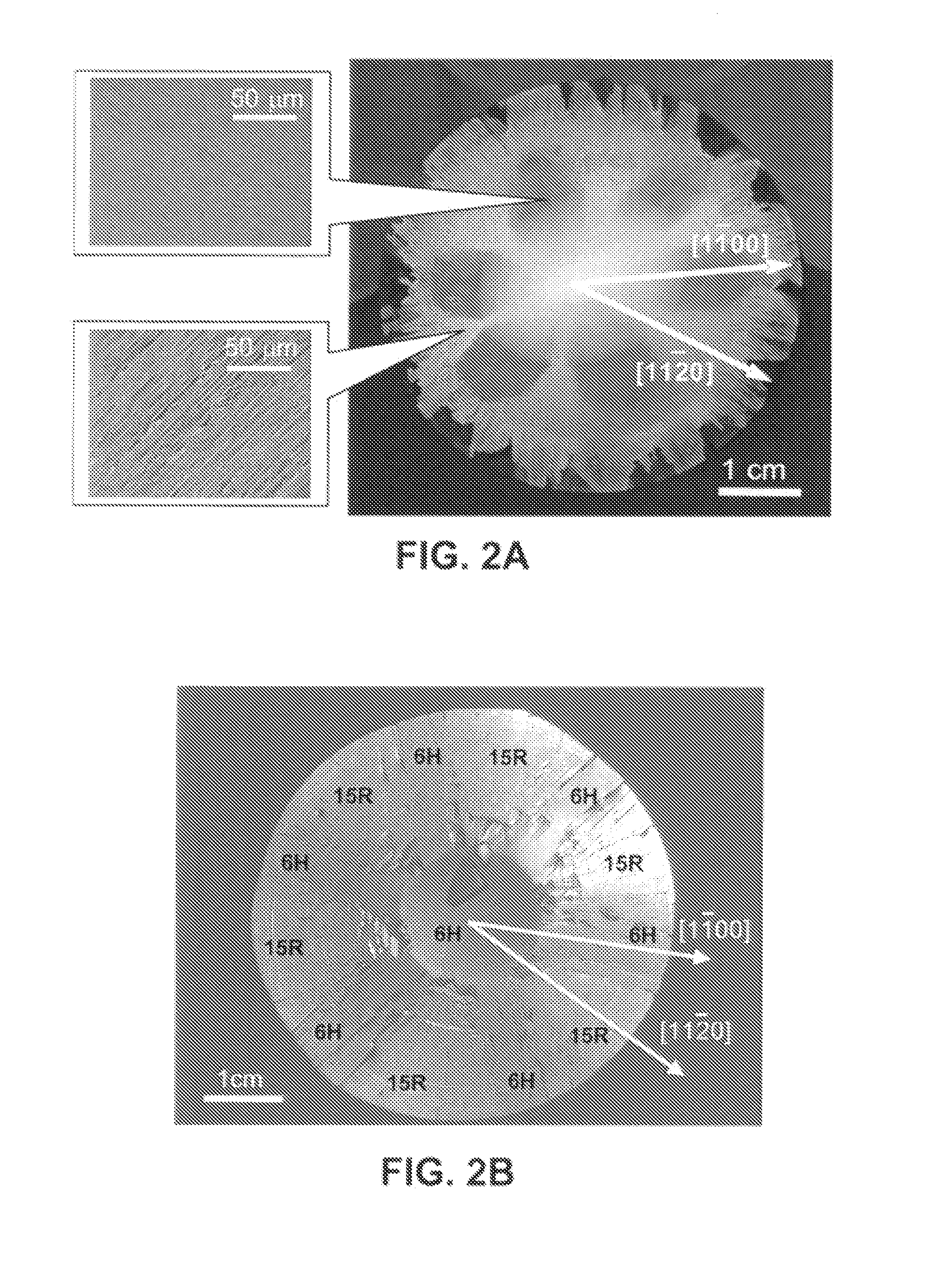

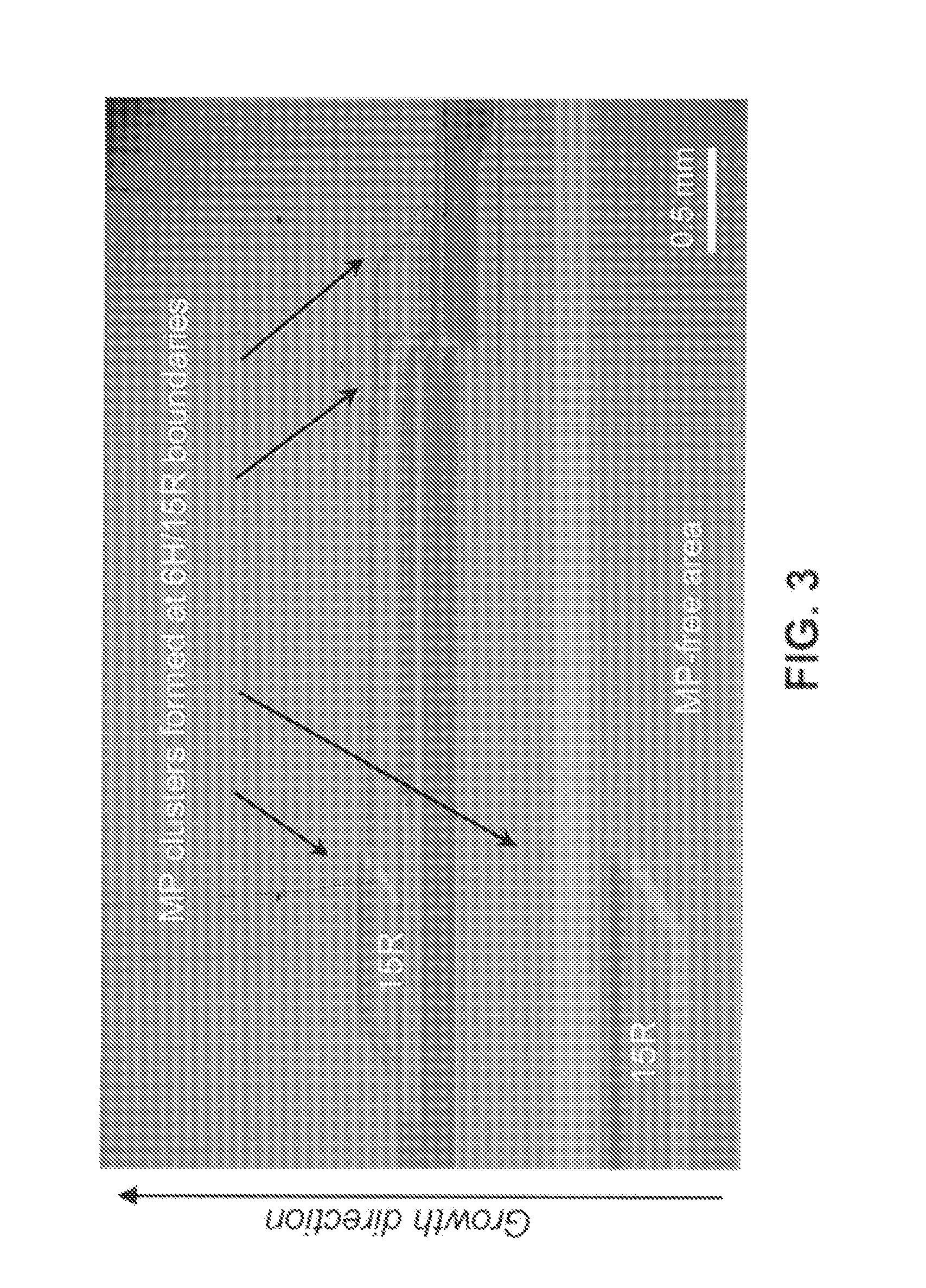

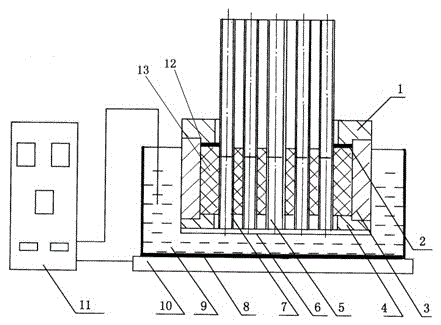

ActiveUS20130280466A1Increase temperaturePolycrystalline material growthLayered productsParticulatesStacking fault

A method and system of forming large-diameter SiC single crystals suitable for fabricating high crystal quality SiC substrates of 100, 125, 150 and 200 mm in diameter are described. The SiC single crystals are grown by a seeded sublimation technique in the presence of a shallow radial temperature gradient. During SiC sublimation growth, a flux of SiC bearing vapors filtered from carbon particulates is substantially restricted to a central area of the surface of the seed crystal by a separation plate disposed between the seed crystal and a source of the SiC bearing vapors. The separation plate includes a first, substantially vapor-permeable part surrounded by a second, substantially non vapor-permeable part. The grown crystals have a flat or slightly convex growth interface. Large-diameter SiC wafers fabricated from the grown crystals exhibit low lattice curvature and low densities of crystal defects, such as stacking faults, inclusions, micropipes and dislocations.

Owner:II VI DELAWARE INC

Single-crystal silicon carbide and single-crystal silicon carbide wafer

ActiveUS20110206929A1Reduce defectsQuality improvementPolycrystalline material growthLayered productsCarbideOptoelectronics

The present invention provides single-crystal silicon carbide and a single-crystal silicon carbide wafer of good-quality that are low in dislocations, micropipes and other crystal defects and enable high yield and high performance when applied to a device, wherein the ratio of doping element concentrations on opposite sides in the direction of crystal growth of the interface between the seed crystal and the grown crystal is 5 or less and the doping element concentration of the grown crystal in the vicinity of the seed crystal is 2×1019 cm−3 to 6×1020 cm−3.

Owner:SHOWA DENKO KK

Low micropipe 100 mm silicon carbide wafer

ActiveUS7314521B2Polycrystalline material growthSemiconductor/solid-state device manufacturingSingle crystalMicropipe

Owner:CREE INC

Silicon carbide substrate and method of manufacturing the same

ActiveUS20130071643A1Improve performanceImprove device performanceAfter-treatment apparatusPolycrystalline material growthStacking faultSingle crystal

A silicon carbide substrate capable of stably forming a device of excellent performance, and a method of manufacturing the same are provided. A silicon carbide substrate is made of a single crystal of silicon carbide, and has a width of not less than 100 mm, a micropipe density of not more than 7 cm−2, a threading screw dislocation density of not more than 1×104 cm−2, a threading edge dislocation density of not more than 1×104 cm−2, a basal plane dislocation density of not more than 1×104 cm−2, a stacking fault density of not more than 0.1 cm−1, a conductive impurity concentration of not less than 1×1018 cm−2, a residual impurity concentration of not more than 1×1016 cm−2, and a secondary phase inclusion density of not more than 1 cm−3.

Owner:SUMITOMO ELECTRIC IND LTD

Low micropipe 100 mm silicon carbide wafer

ActiveUS20070209577A1Polycrystalline material growthFrom chemically reactive gasesSingle crystalMicropipe

A high quality single crystal wafer of SiC is disclosed having a diameter of at least about 100 mm and a micropipe density of less than about 25 cm−2.

Owner:CREE INC

Silicon carbide single crystal and silicon carbide single crystal wafer

InactiveCN102187019AReduce defectsImprove qualityPolycrystalline material growthSemiconductor/solid-state device manufacturingLow densityCrystallographic defect

Owner:NIPPON STEEL CORP

Method for preparing high-purity semi-insulating silicon carbide crystalloid

ActiveCN101724893AIncreased concentration of point defectsHigh resistivityPolycrystalline material growthFrom condensed vaporsShallow donorElectrical performance

The invention discloses a method for preparing a high-purity semi-insulating silicon carbide crystalloid under the circumstance of compensating elements without deep energy level. The electrical resistivity of the crystalloid is larger than 106 ohm / cm and can reach more than 109 ohm / cm under a proper condition. The electrical resistivity of the crystalloid is controlled by the fast growth speed of the crystalloid, wherein the speed is fast enough to lead the electrical performance of the crystalloid. The requirement of the special growth of the crystalloid is larger than 0.6mm / h, preferably, is more than 2mm / h, and the crystalloid is crystallized and grown under the extreme nonequilibrium state of thermodynamics to increase the concentration of primary point defects such as a hollow bit, a hollow bit group or an inverse bit, and the like, in the crystalloid; the completely grown silicon carbide crystalloid is fast cooled to be 1000-1500 DEG C with faster temperature-reducing speed to ensure the concentration of the point defects of the crystalloid to be thick enough to compensate the different concentration between the shallow donor and the shallow acceptor which are undesignedly doped to achieve the semi-insulating electric performance. The method improves the electrical resistivity of the crystalloid and reduces the quantity of crystalloid microtubules.

Owner:BEIJING TIANKE HEDA SEMICON CO LTD

Micropipe-free silicon carbide and related method of manufacture

ActiveUS20080067524A1Reduce instabilityPolycrystalline material growthSemiconductor/solid-state device manufacturingSource materialCrucible

Micropipe-free, single crystal, silicon carbide (SiC) and related methods of manufacture are disclosed. The SiC is grown by placing a source material and seed material on a seed holder in a reaction crucible of the sublimation system, wherein constituent components of the sublimation system including the source material, reaction crucible, and seed holder are substantially free from unintentional impurities. By controlling growth temperature, growth pressure, SiC sublimation flux and composition, and a temperature gradient between the source material and the seed material or the SiC crystal growing on the seed material during the PVT process, micropipe-inducing process instabilities are eliminated and micropipe-free SiC crystal is grown on the seed material.

Owner:CREE INC

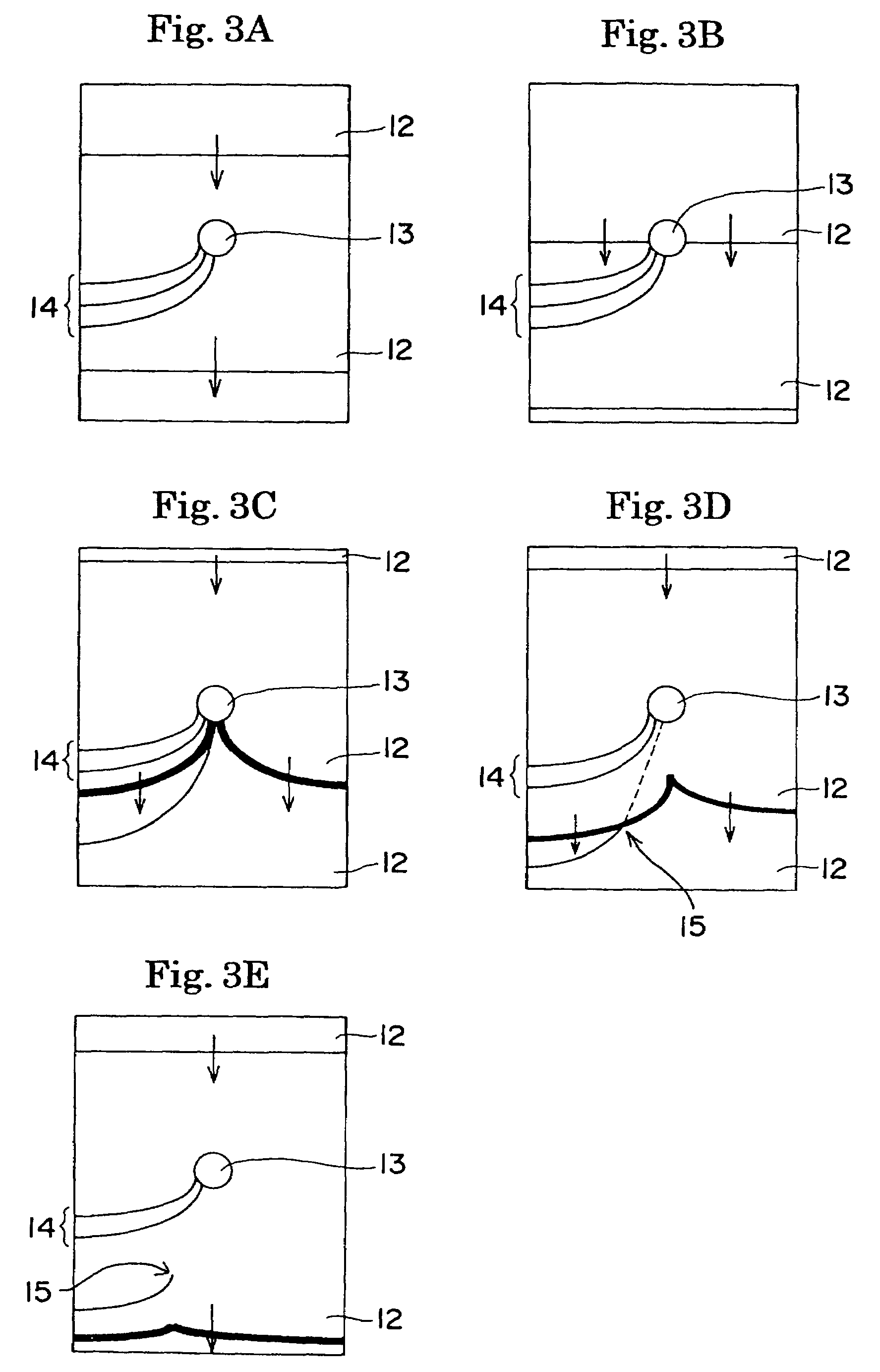

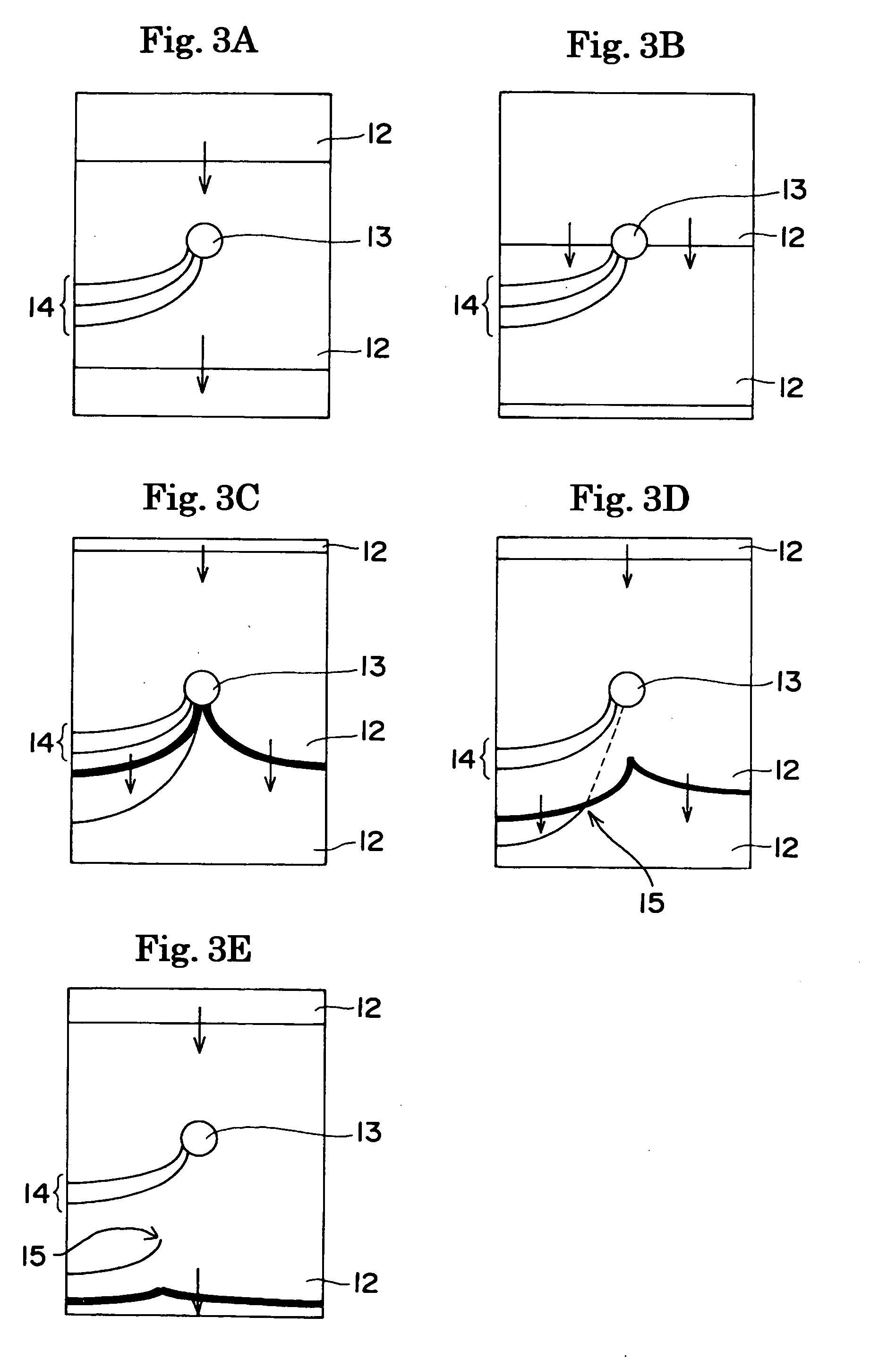

Method for preparing SiC crystal and SiC crystal

InactiveUS7081420B2Reduce in quantityPolycrystalline material growthSemiconductor/solid-state device manufacturingSingle crystal substrateSingle crystal

A process for closing hollow-core defects, called micropipes, during growth by CVD of a SiC crystal on a SiC single crystal substrate having hollow-core defects, and a crystal obtained according to the process, by contacting the SiC crystal with a source gas adjusted to a C / Si atom ratio range in which the crystal growth rate is determined by the carbon atom supply limitation, then epitaxially growing and laminating a plurality of SiC crystal layers, wherein hollow-core defects in the SiC single crystal substrate dissociate into a plurality of dislocations given by small Burghers vector in order not to propagate to the crystal surface. In addition, the present invention provides a fabrication process of a SiC crystal, wherein a first SiC crystal is made as a buffer layer, and a further SiC crystal is layered thereon using a source gas adjusted to be higher than that of the C / Si ratio when forming the buffer layer, whereby a desired film property is conferred.

Owner:SHOWA DENKO KK

Method for preparing sic crystal and sic crystal

InactiveUS20050181627A1Number of defectReduce in quantityPolycrystalline material growthSemiconductor/solid-state device manufacturingSingle crystal substrateSingle crystal

A process for closing hollow-core defects, called micropipes, during growth by CVD of a SiC crystal on a SiC single crystal substrate having hollow-core defects, and a crystal obtained according to the process, by contacting the SiC crystal with a source gas adjusted to a C / Si atom ratio range in which the crystal growth rate is determined by the carbon atom supply limitation, then epitaxially growing and laminating a plurality of SiC crystal layers, wherein hollow-core defects in the SiC single crystal substrate dissociate into a plurality of dislocations given by small Burgers vector in order not to propagate to the crystal surface. In addition, the present invention provides a fabrication process of a SiC crystal, wherein a first SiC crystal is made as a buffer layer, and a further SiC crystal is layered thereon using a source gas adjusted to be higher than that of the C / Si ratio when forming the buffer layer, whereby a desired film property is conferred.

Owner:SHOWA DENKO KK

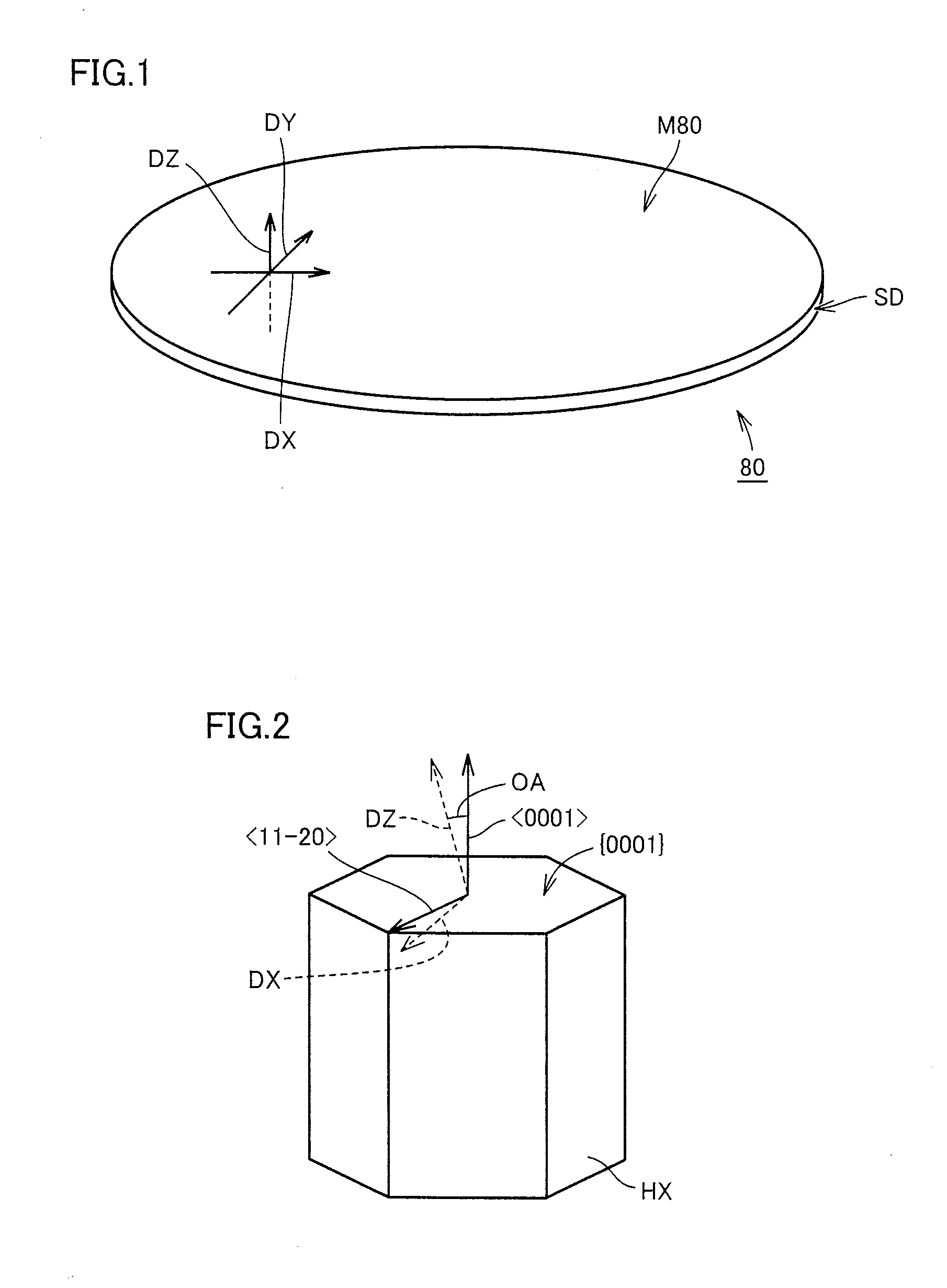

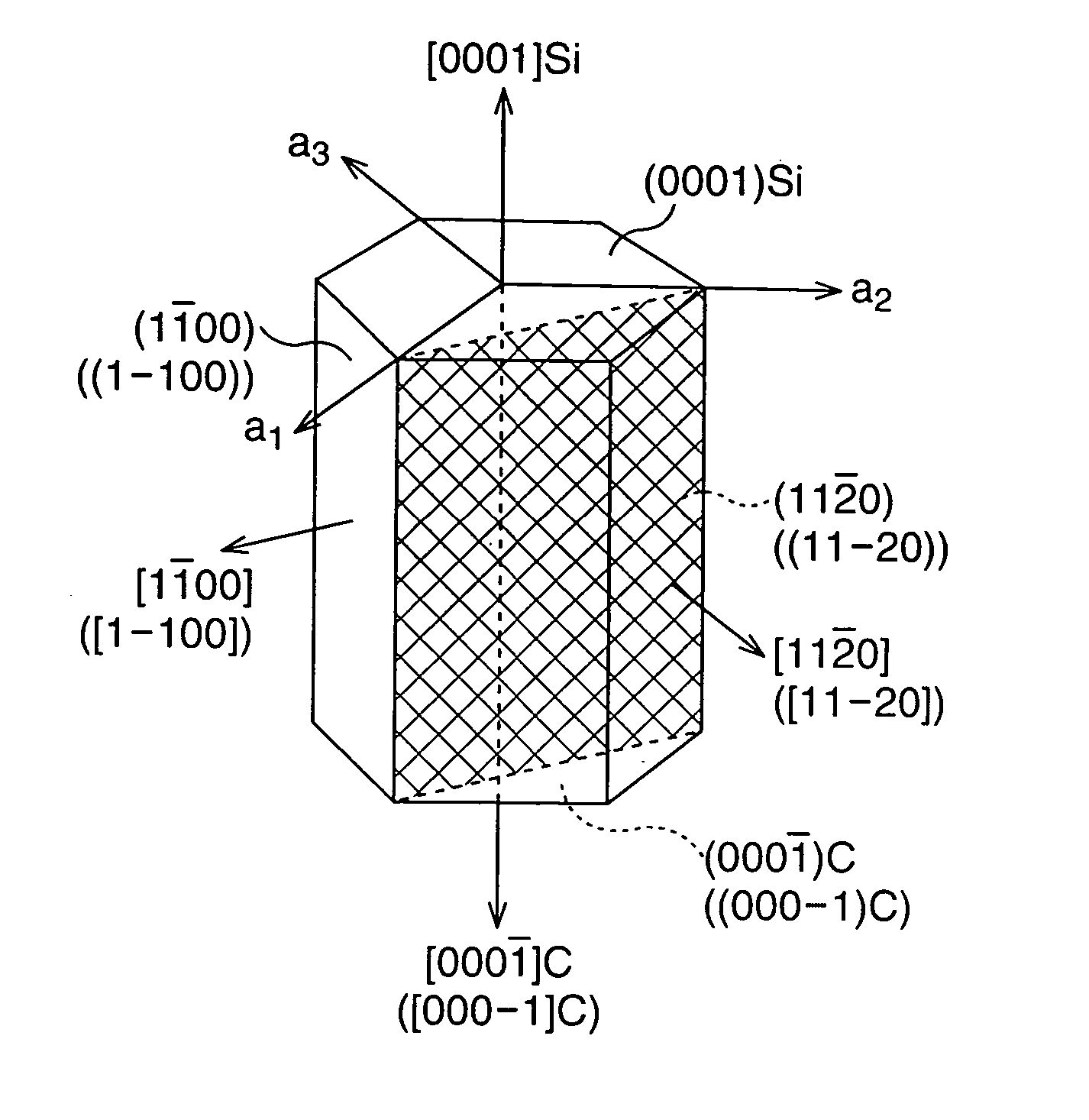

Seed crystal of silicon carbide single crystal and method for producing ingot using same

InactiveUS20050160965A1Few defectSuitable for practicalPolycrystalline material growthFrom solid stateWaferingStacking fault

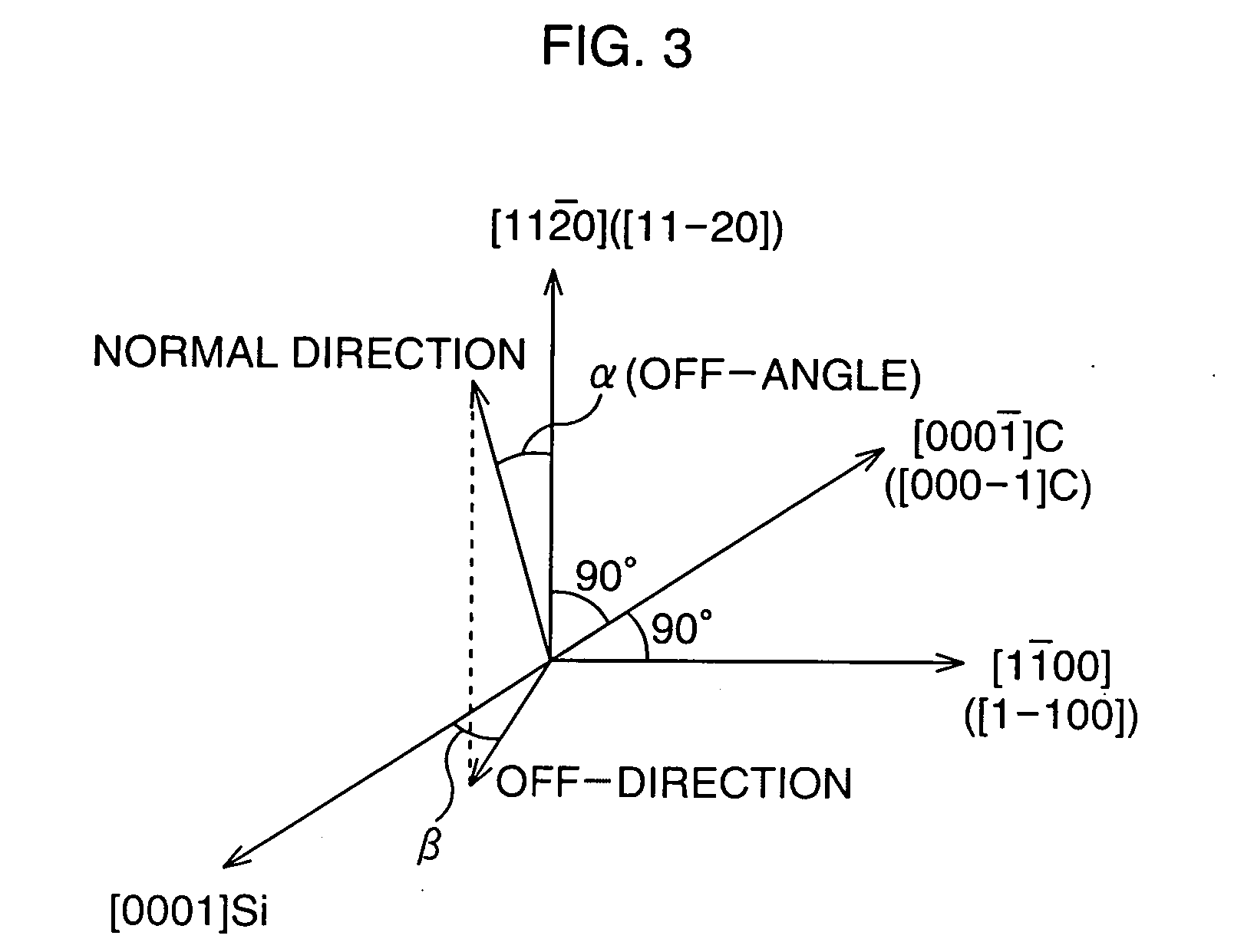

The present invention relates to a seed crystal consisting of a silicon carbide single crystal suitable for producing a substrate (wafer) for an electric power device, a high-frequency device or the like, and a method for producing an ingot using the same. A single crystal growing face of a seed crystal consisting of a silicon carbide single crystal is inclined at an angle ranging from 3 degrees or more to 60 degrees or less with respect to the (11-20) face to a direction inclined at an angle ranging from −45 degrees or more to 45 degrees or less from a <0001> direction to the [1-100] direction. By performing crystal growth using such a seed crystal, a high quality silicon carbide single crystal ingot can be obtained. According to the present invention, it is possible to obtain material consisting of a silicon carbide single crystal of favorable quality, which has few crystal defects such as micropipe defects and stacking faults, and the diameter is suitable for practical application.

Owner:NIPPON STEEL CORP

Microchannel type photocatalytic microreactor based on nanorod array and preparation method thereof

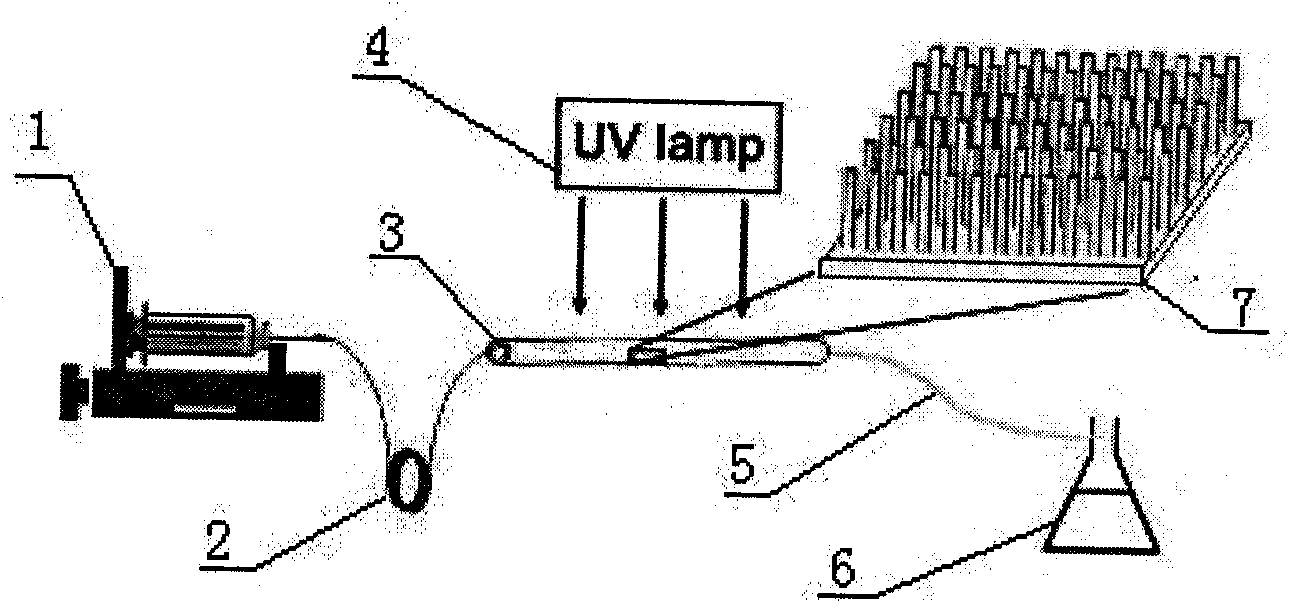

InactiveCN101670260AIncrease contact areaSolve the problem of time-consuming and laborious separationPhysical/chemical process catalystsEnergy based chemical/physical/physico-chemical processesMicroreactorEngineering

The invention relates to a microchannel type photocatalytic microreactor based on a nanorod array and a preparation method thereof. The photocatalytic microreactor uses a quartz capillary as a photocatalytic region microchannel, uses a semiconductor nanorod array which vertically grows on the inner surface of the microchannel as a photocatalyst, uses a polytetrafluoroethylene micropipe as a fluidconveying and receiving channel, uses an ultraviolet lamp as a light source, and uses a micro-injection pump to convey organic substances into the microchannel, thereby achieving the purpose of continuous, quick and efficient photocatalytic degradation of the organic substances. By adjusting the pushing speed of the micro-injection pump, the complete degradation of the organic substances is realized; and moreover, the microchannel type photocatalytic microreactor still has high photocatalytic activity after being continuously used for 100 hours, and the degradation rate for the organic substances is still more than 80%.

Owner:DONGHUA UNIV

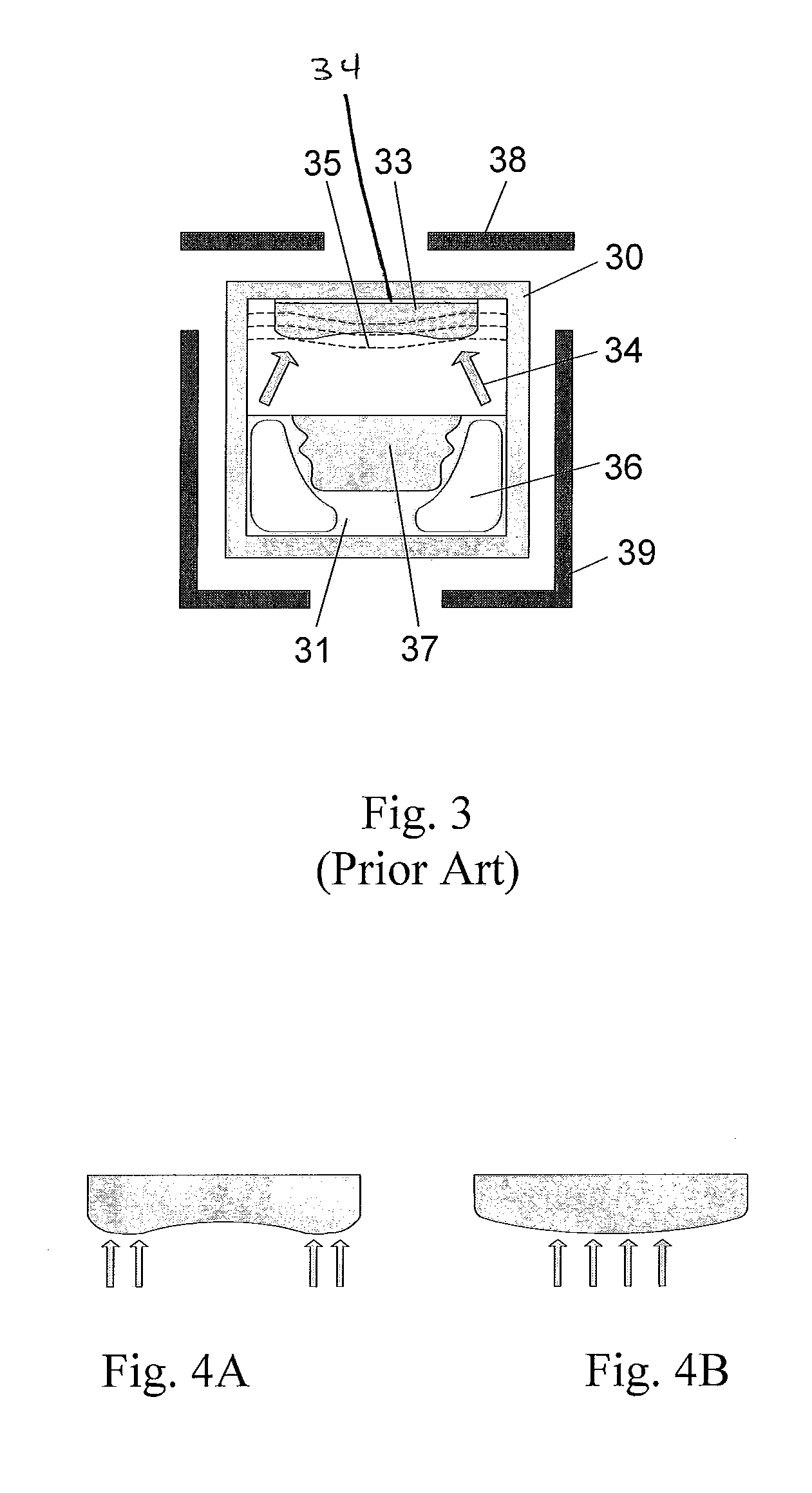

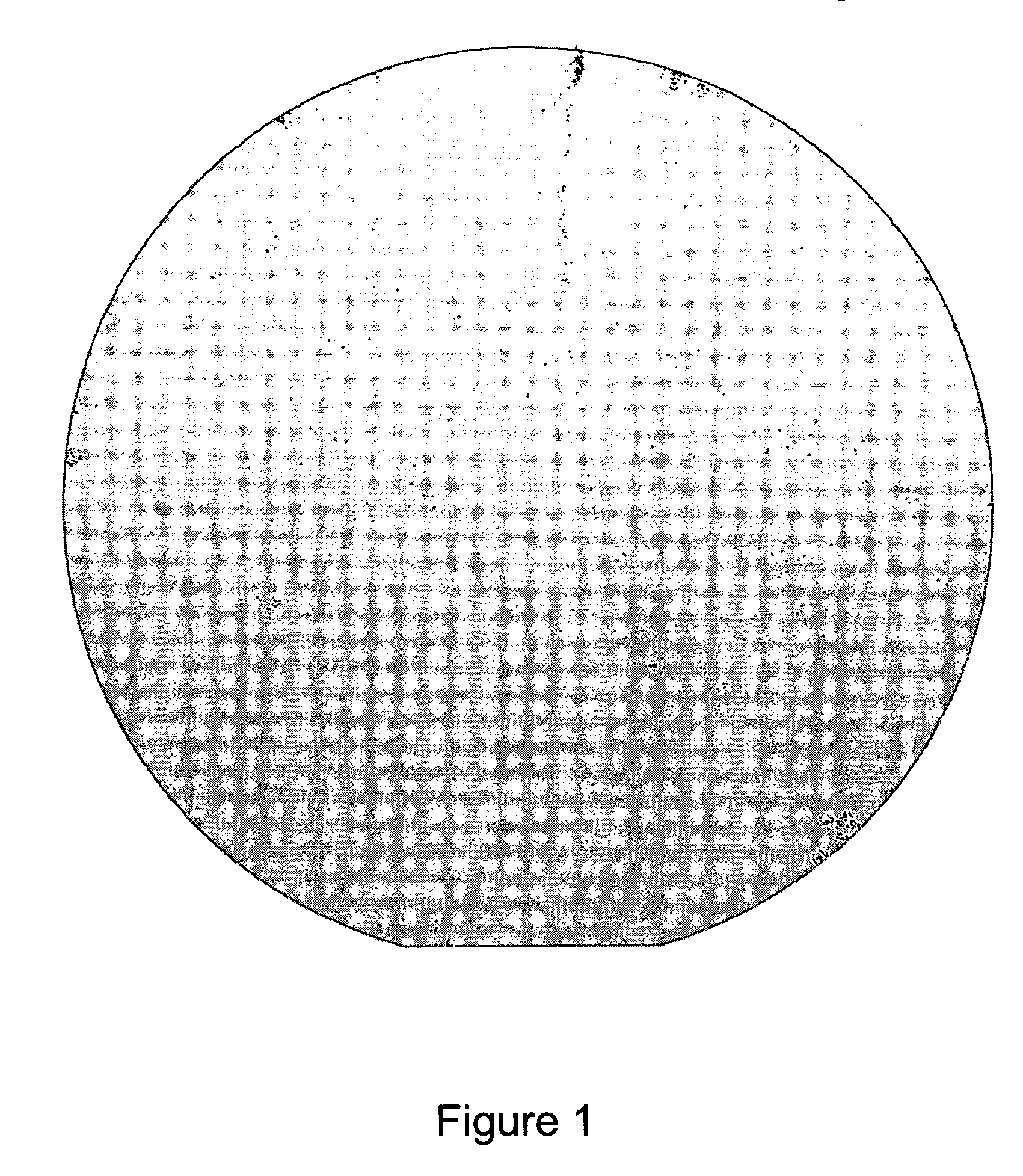

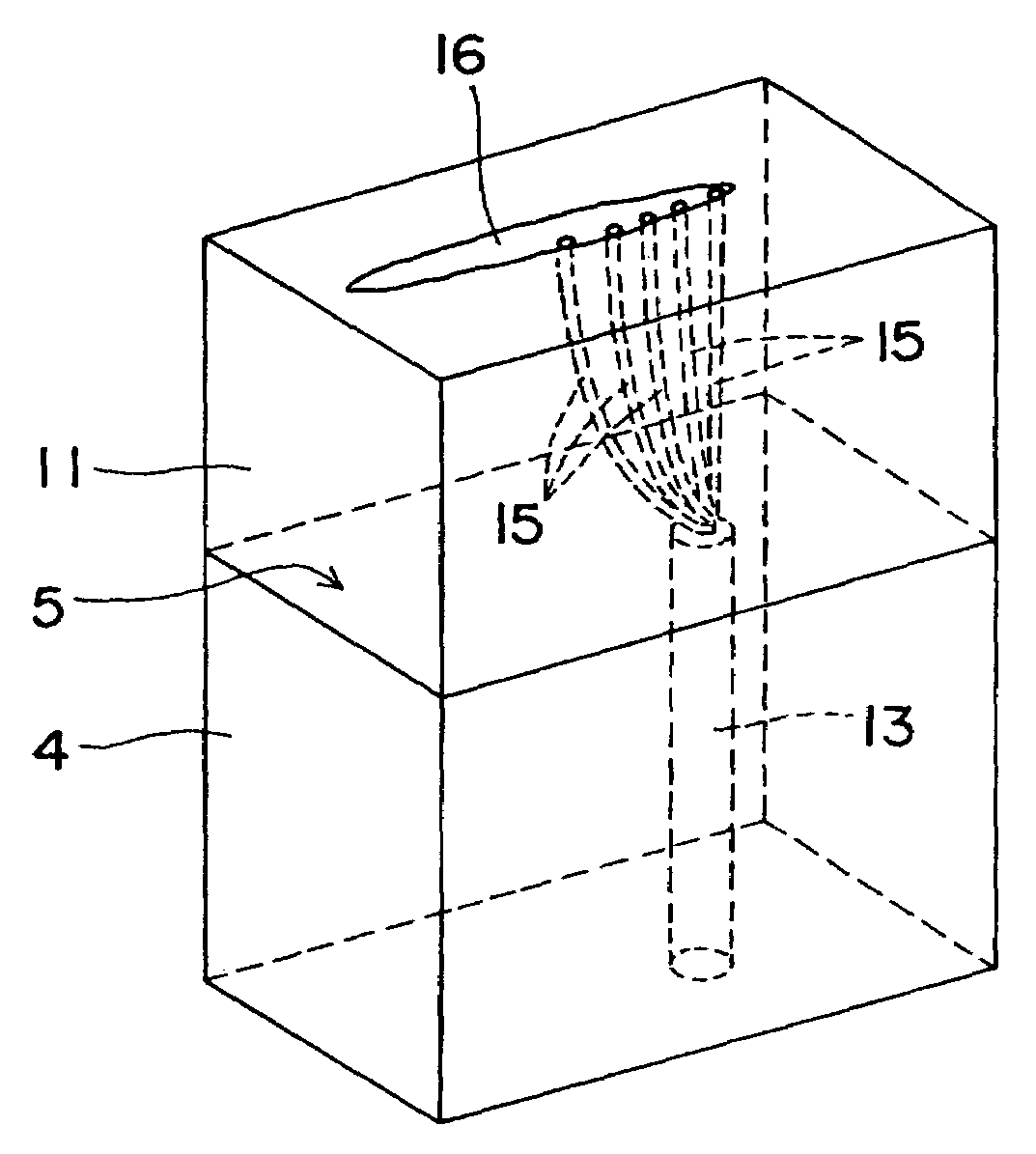

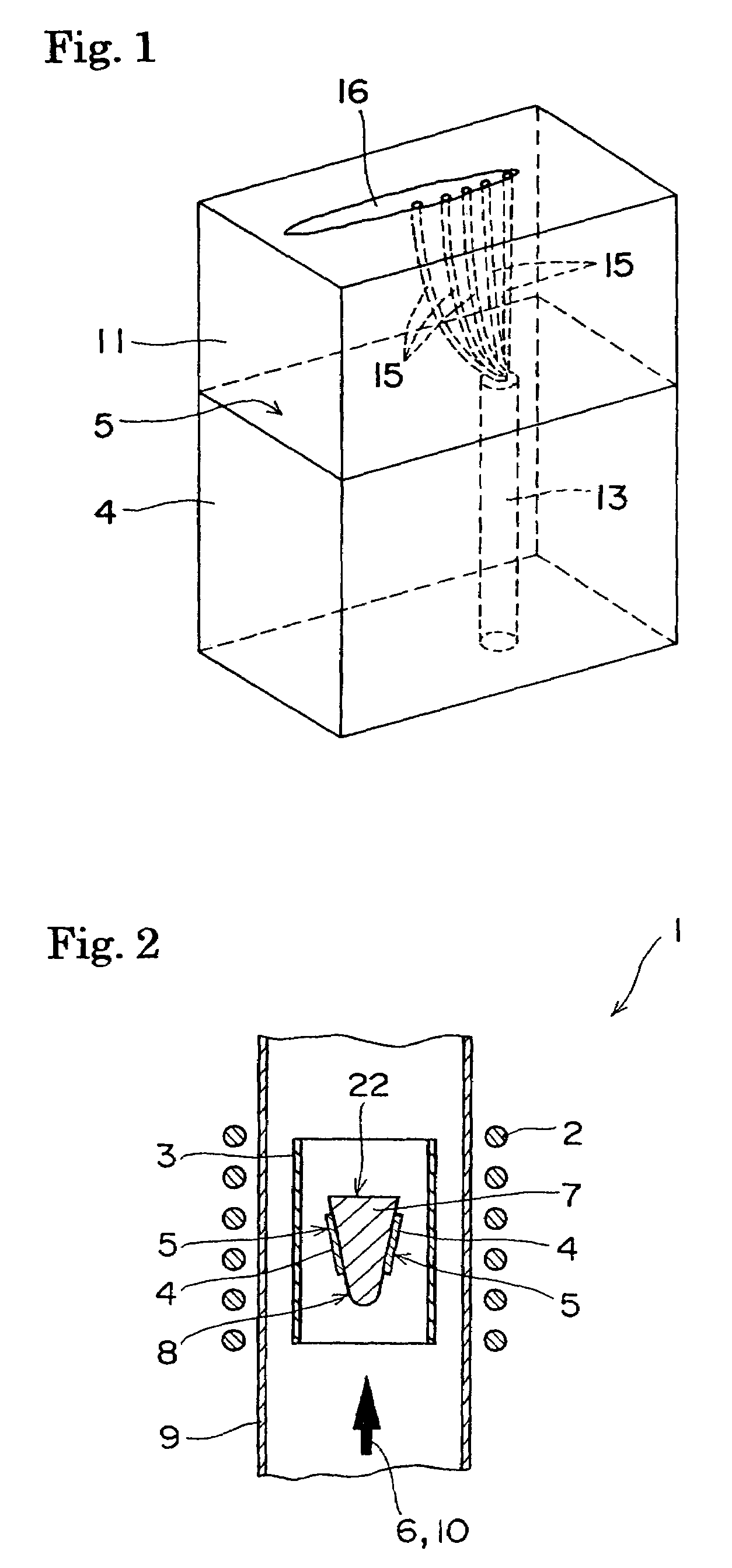

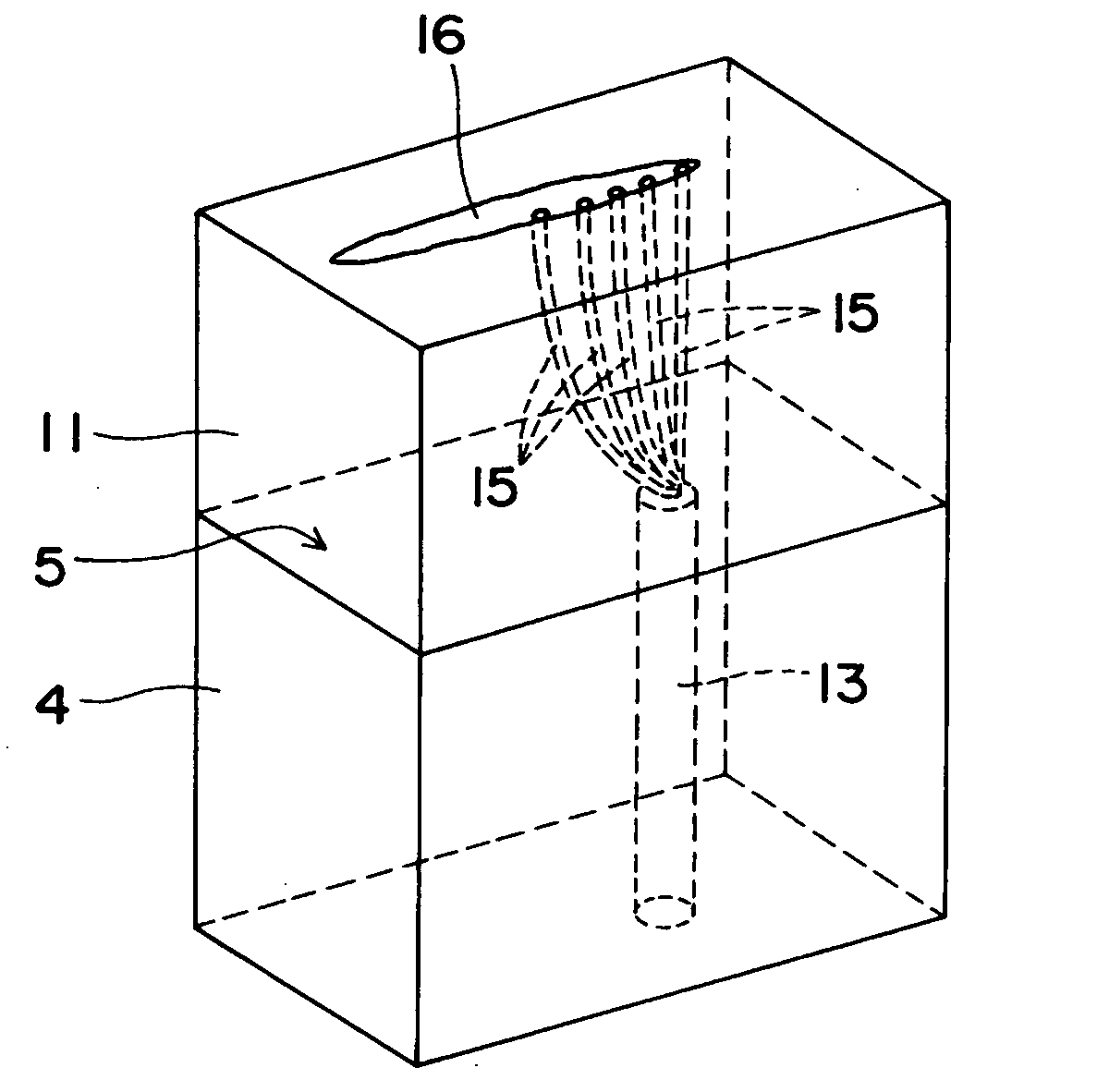

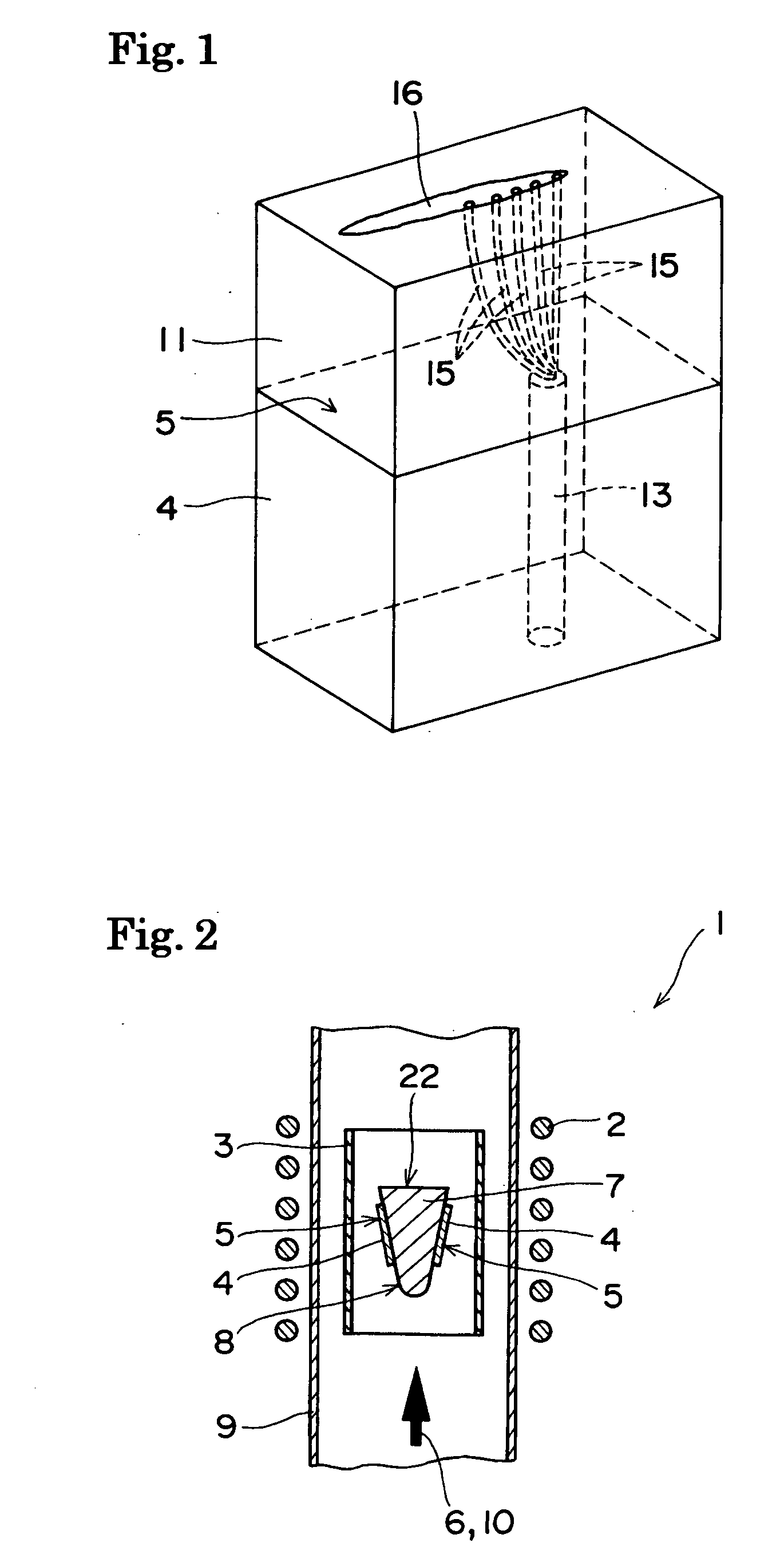

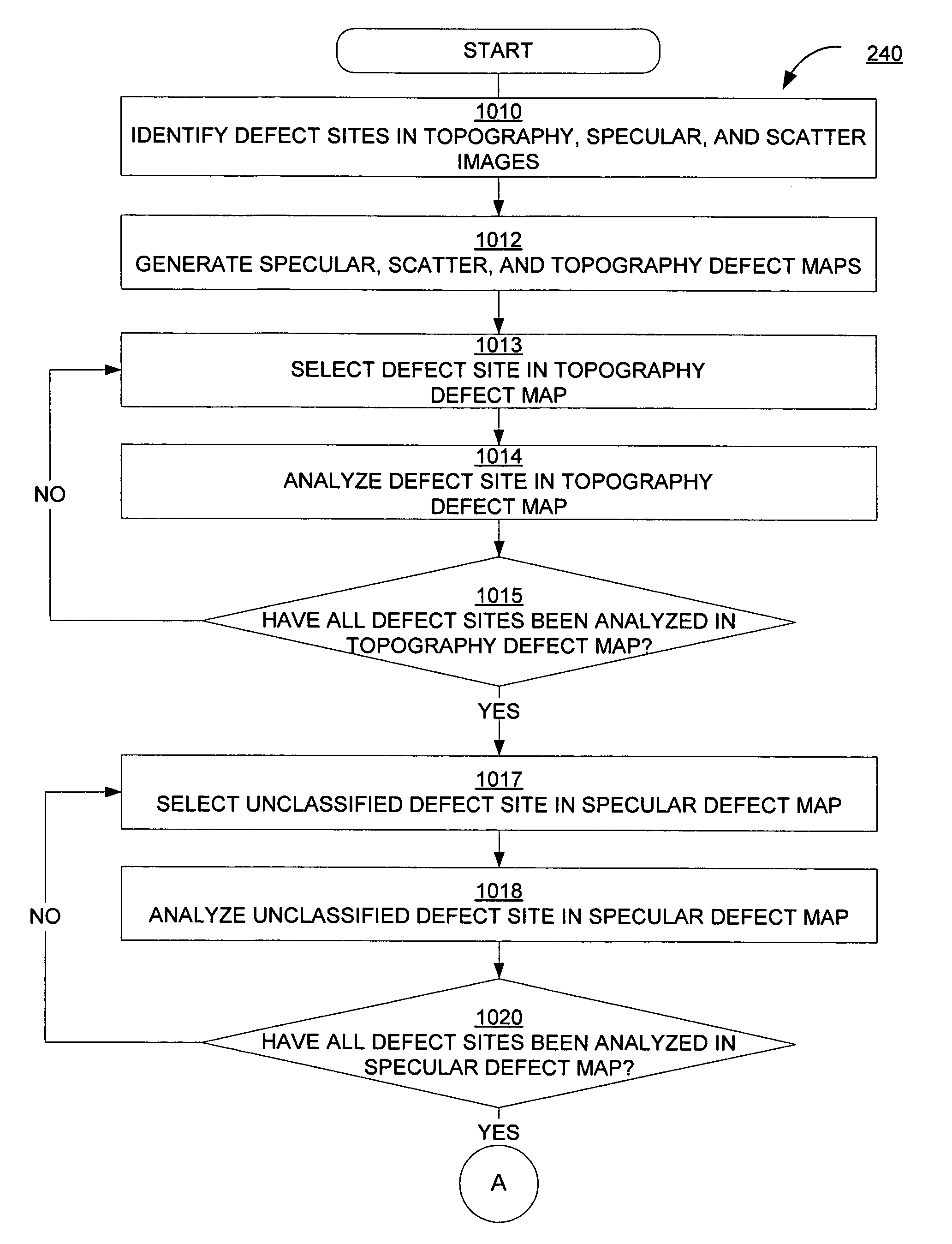

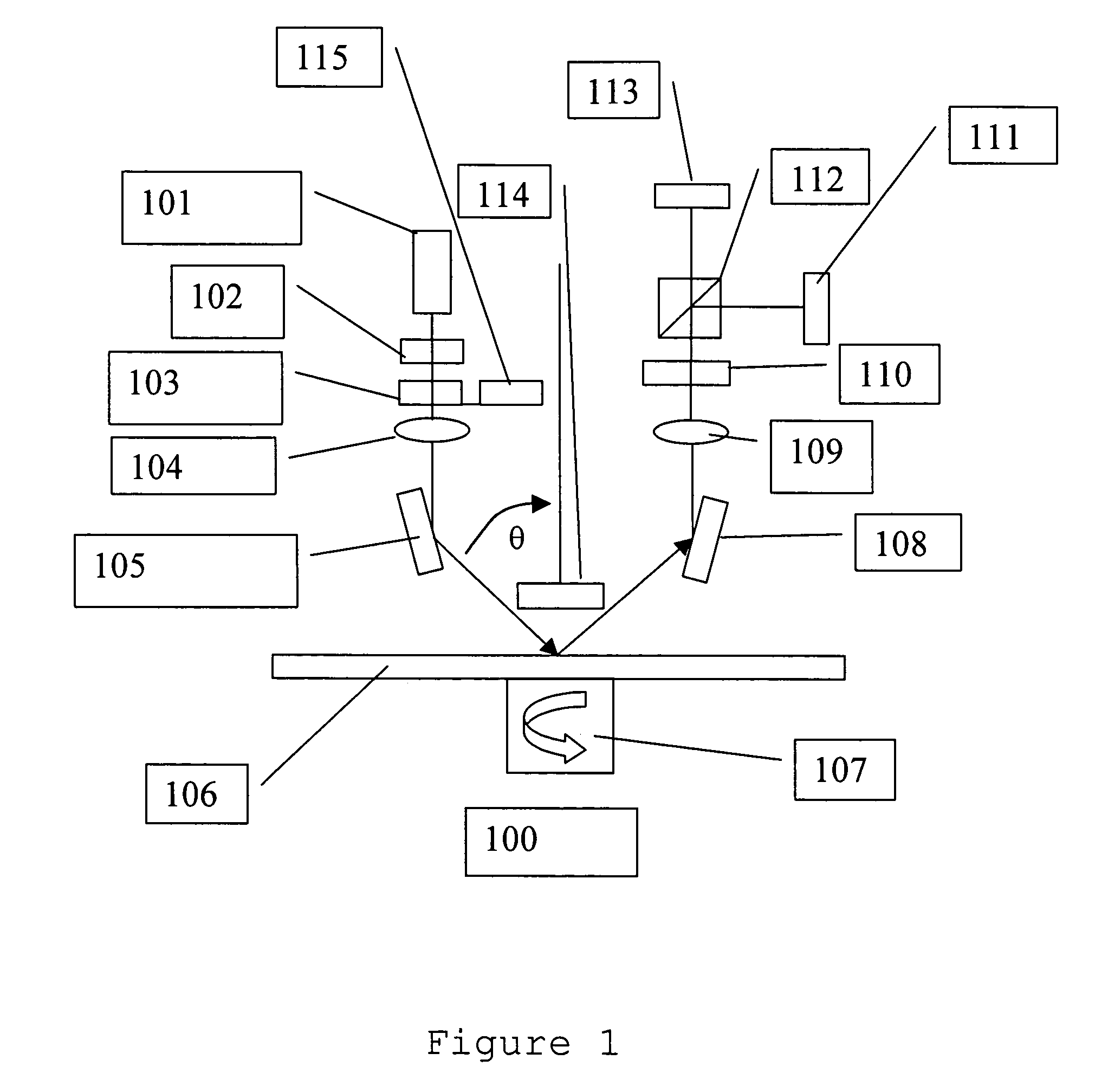

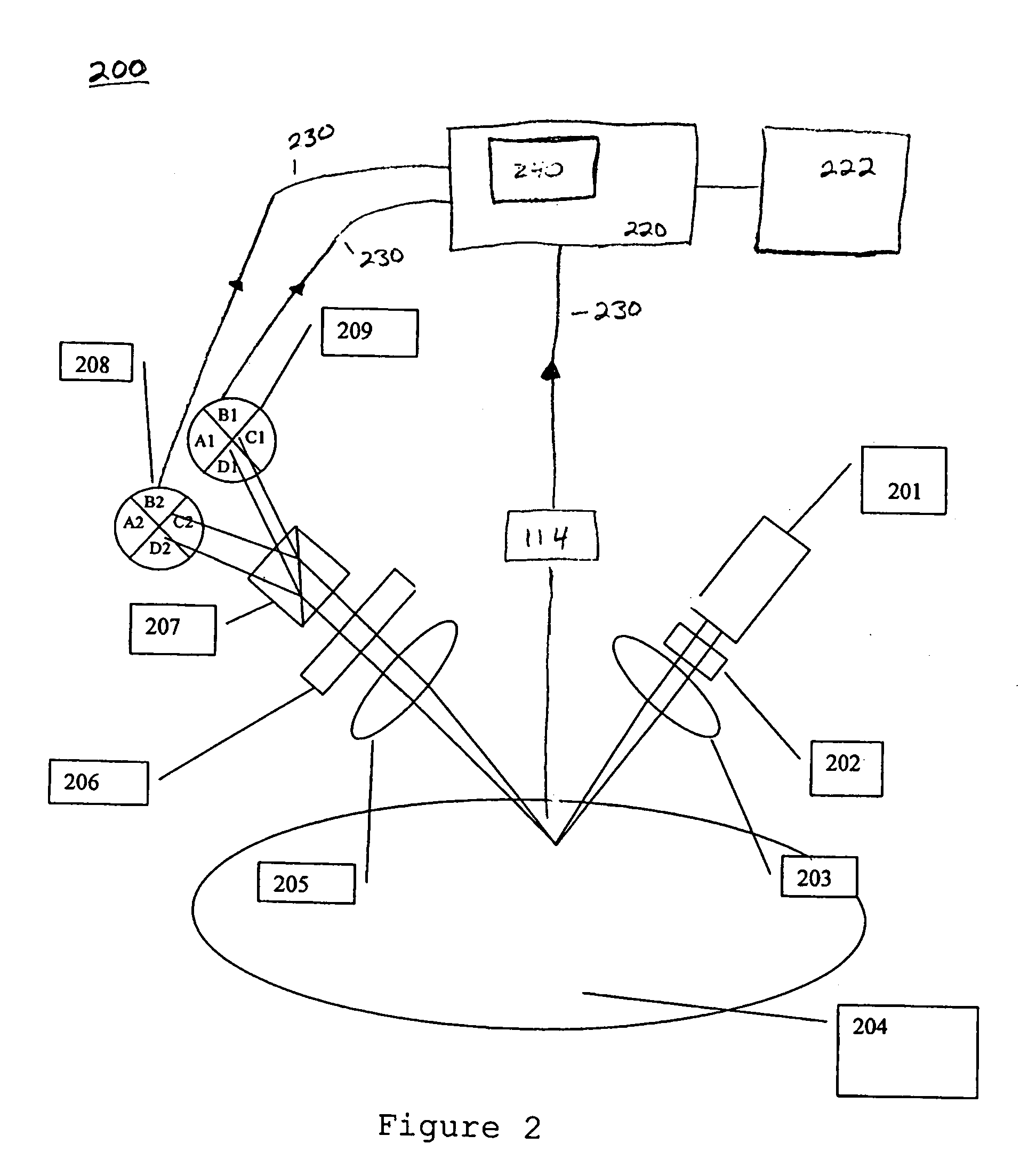

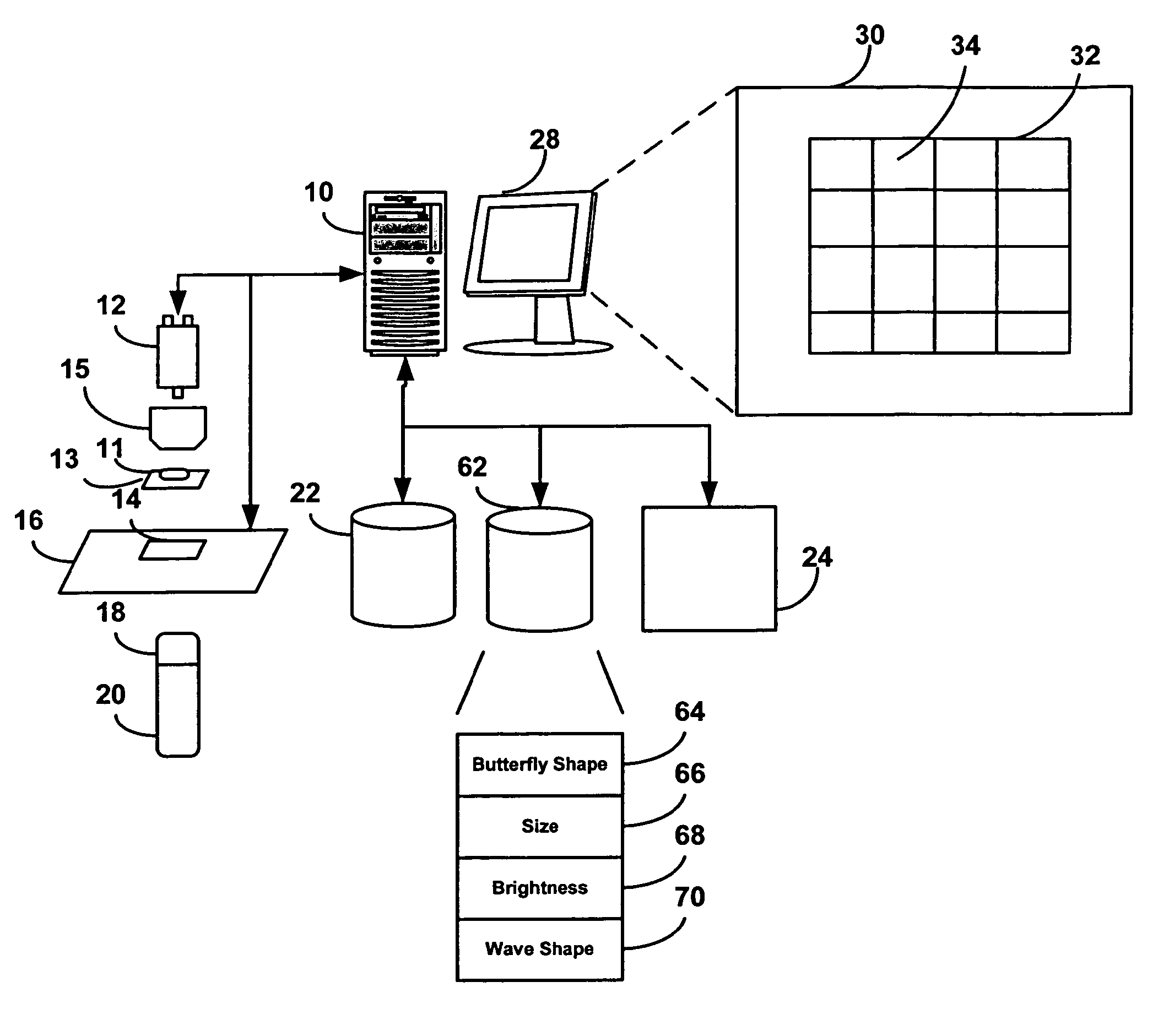

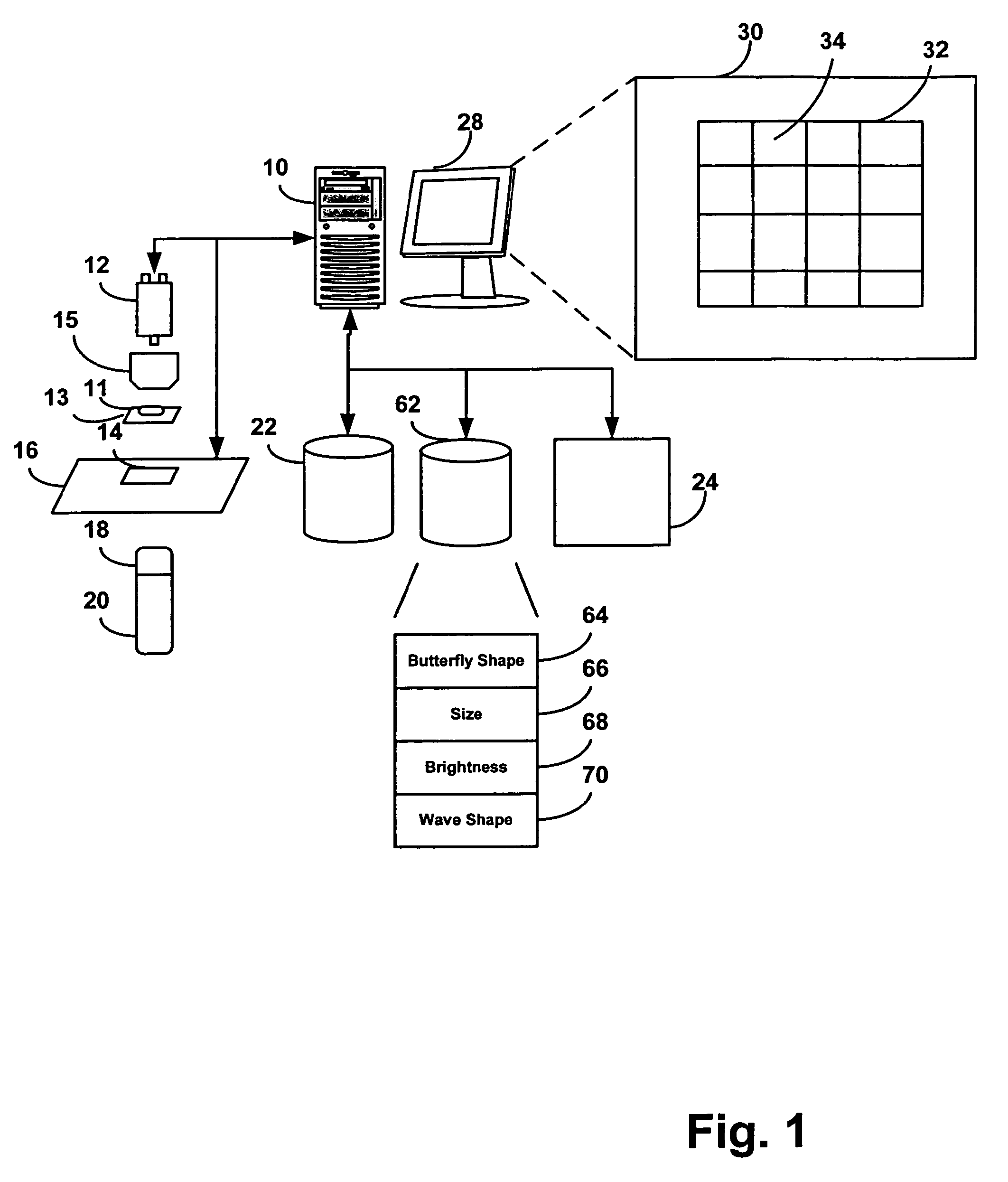

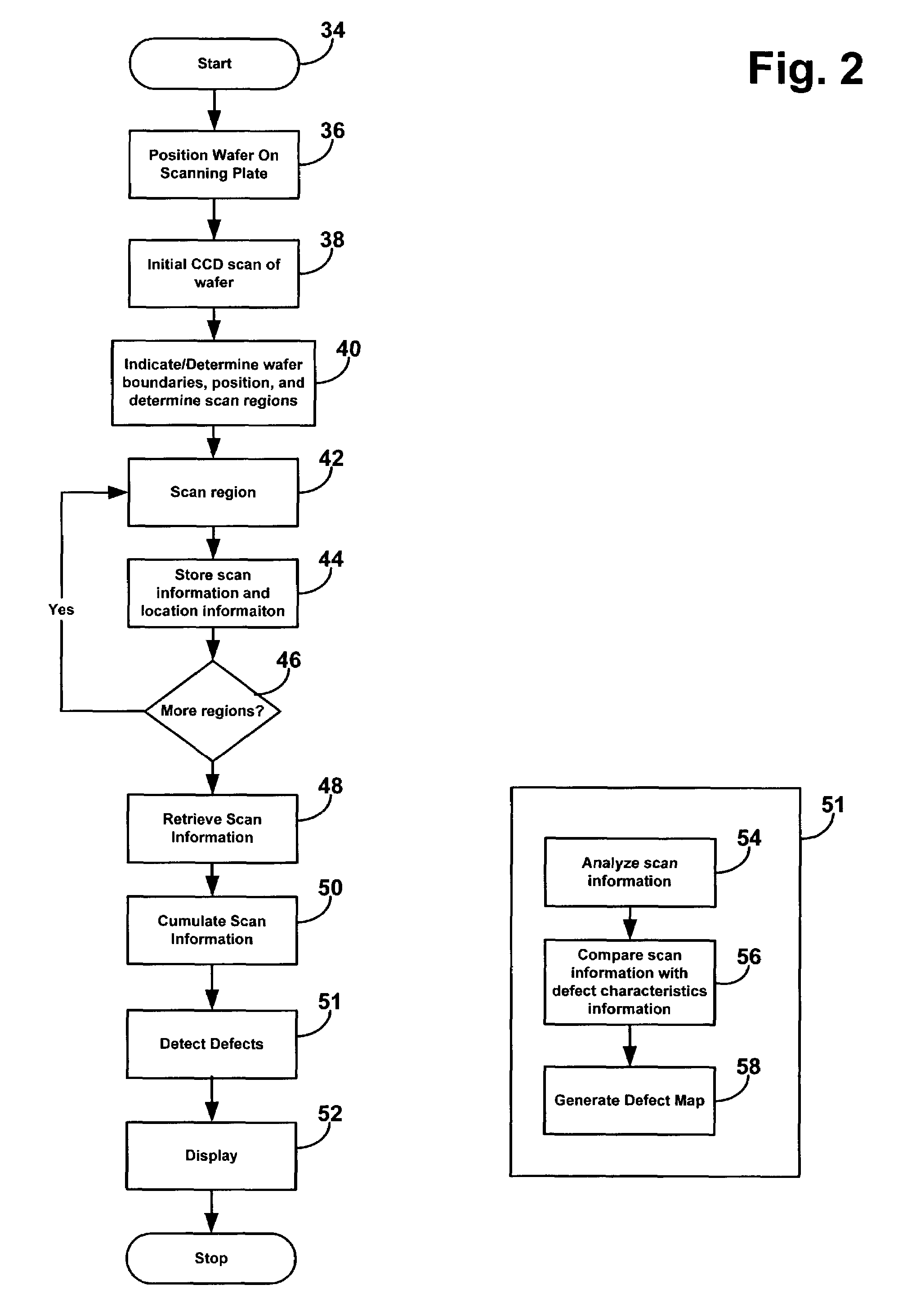

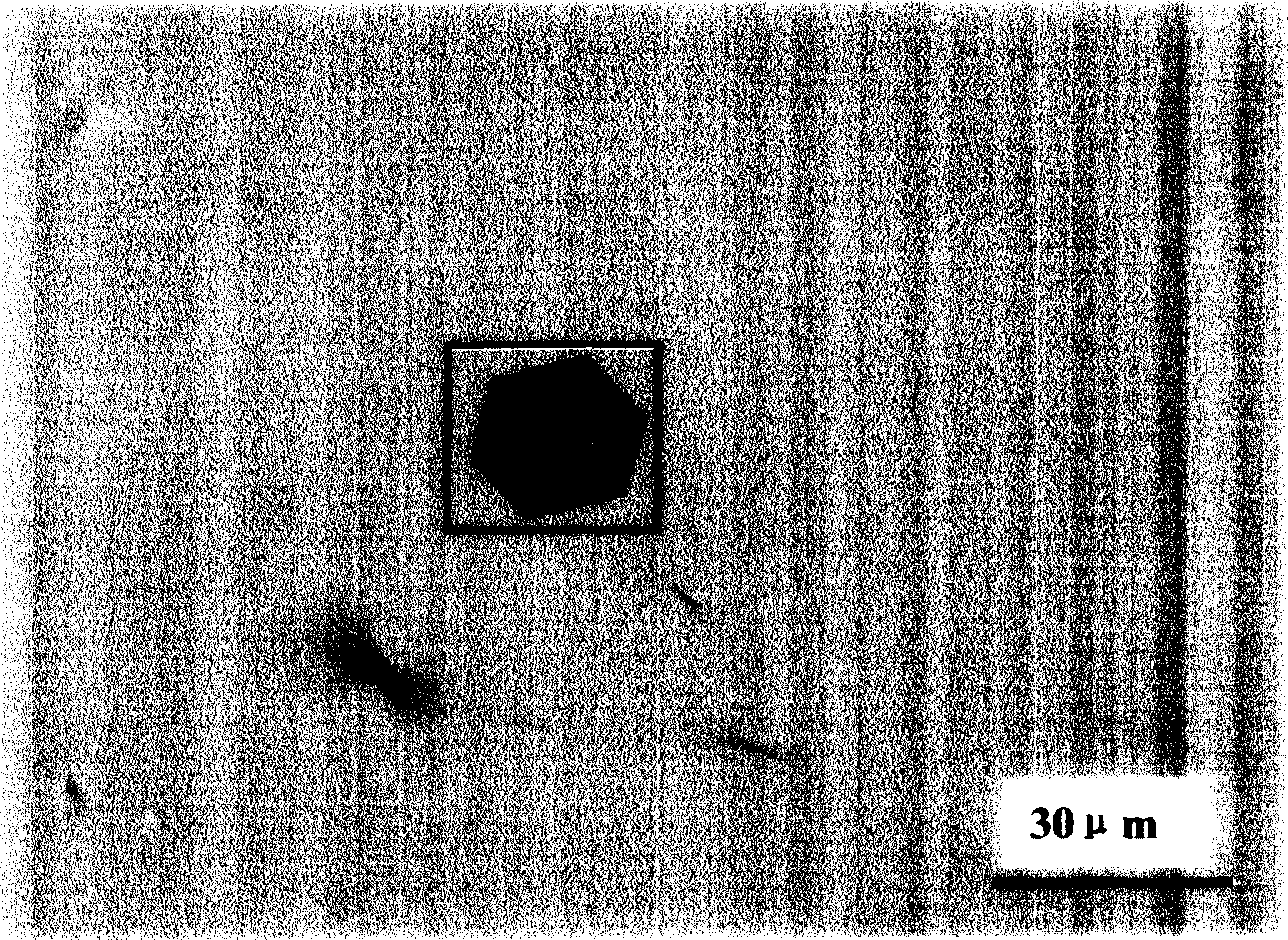

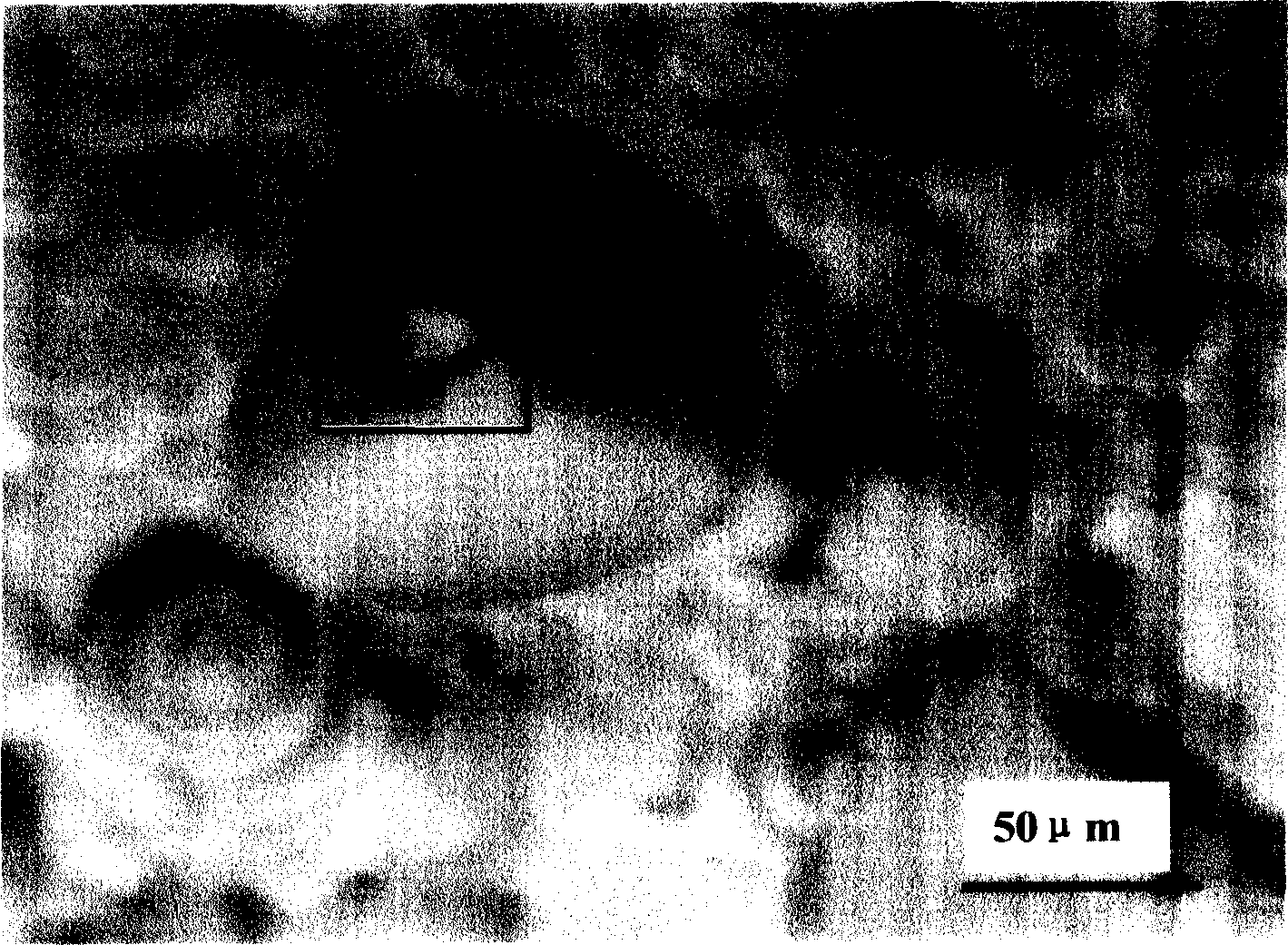

System and method for classifying, detecting, and counting micropipes

ActiveUS7201799B1Accurate measurementOvercome limitationsPolycrystalline material growthAfter-treatment detailsDefect sizeNon invasive

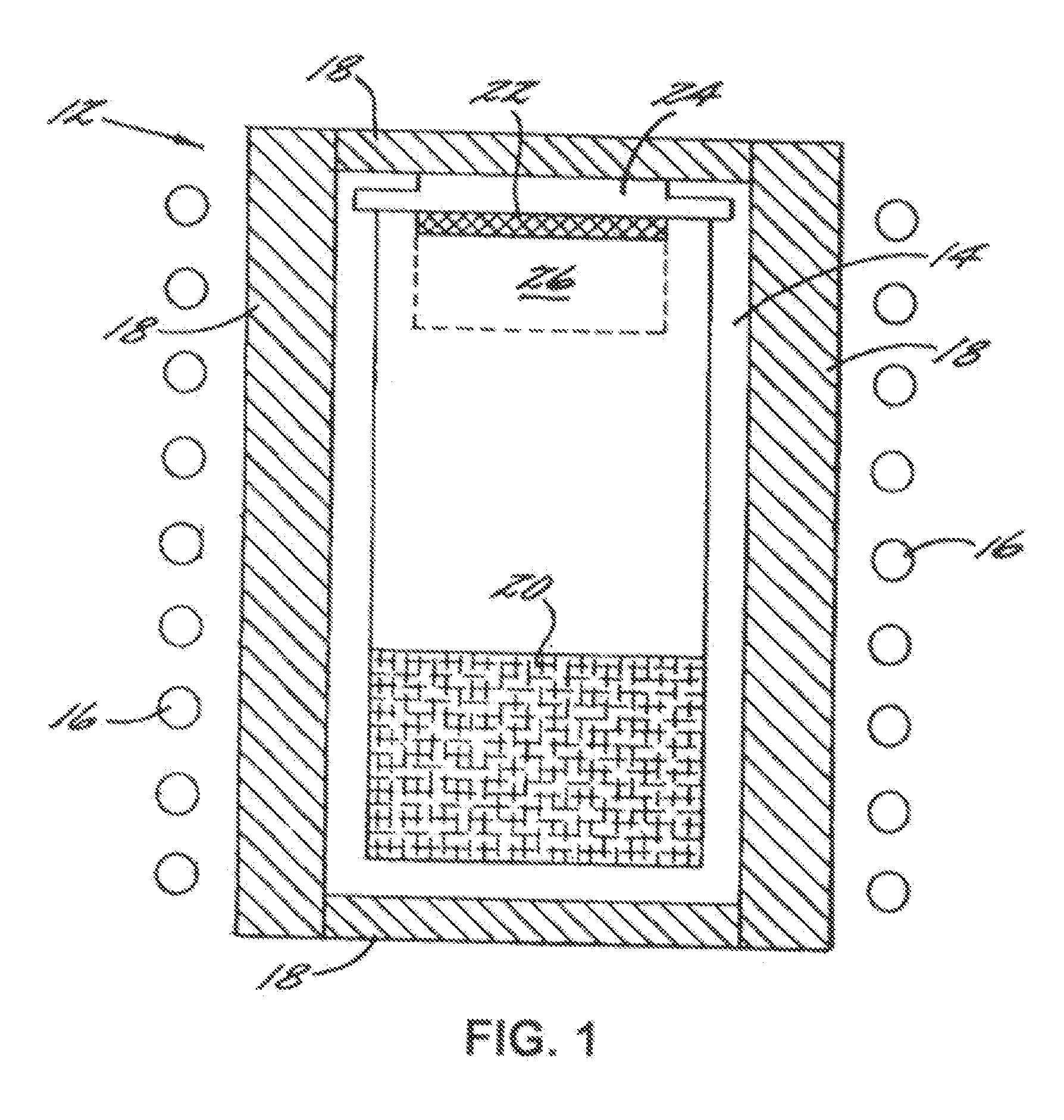

An automated, non-invasive method for classifying, detecting, and counting micropipes contained within silicon wafers, and generally any assortment of transparent wafers. Classifying, detecting, and counting micropipes takes place through the use of a data processing algorithm that incorporates information regarding: defect size; pit signature; area of pit signature when comparing a topography, specular, or scatter images; and detecting a tail within the standard pit signature. The method of the present invention teaches the development of a topography defect map, specular defect map, and scatter defect map for a complete analysis of the surface of a particular transparent wafer. Conventional detection, classification, and counting of micropipes involve characterization of micropipes in a manual fashion and rely upon an extremely invasive form of sample preparation. The method disclosed in the present invention is completely automated and non-invasive with regards to the treatment of the transparent wafer to be analyzed.

Owner:KLA TENCOR TECH CORP

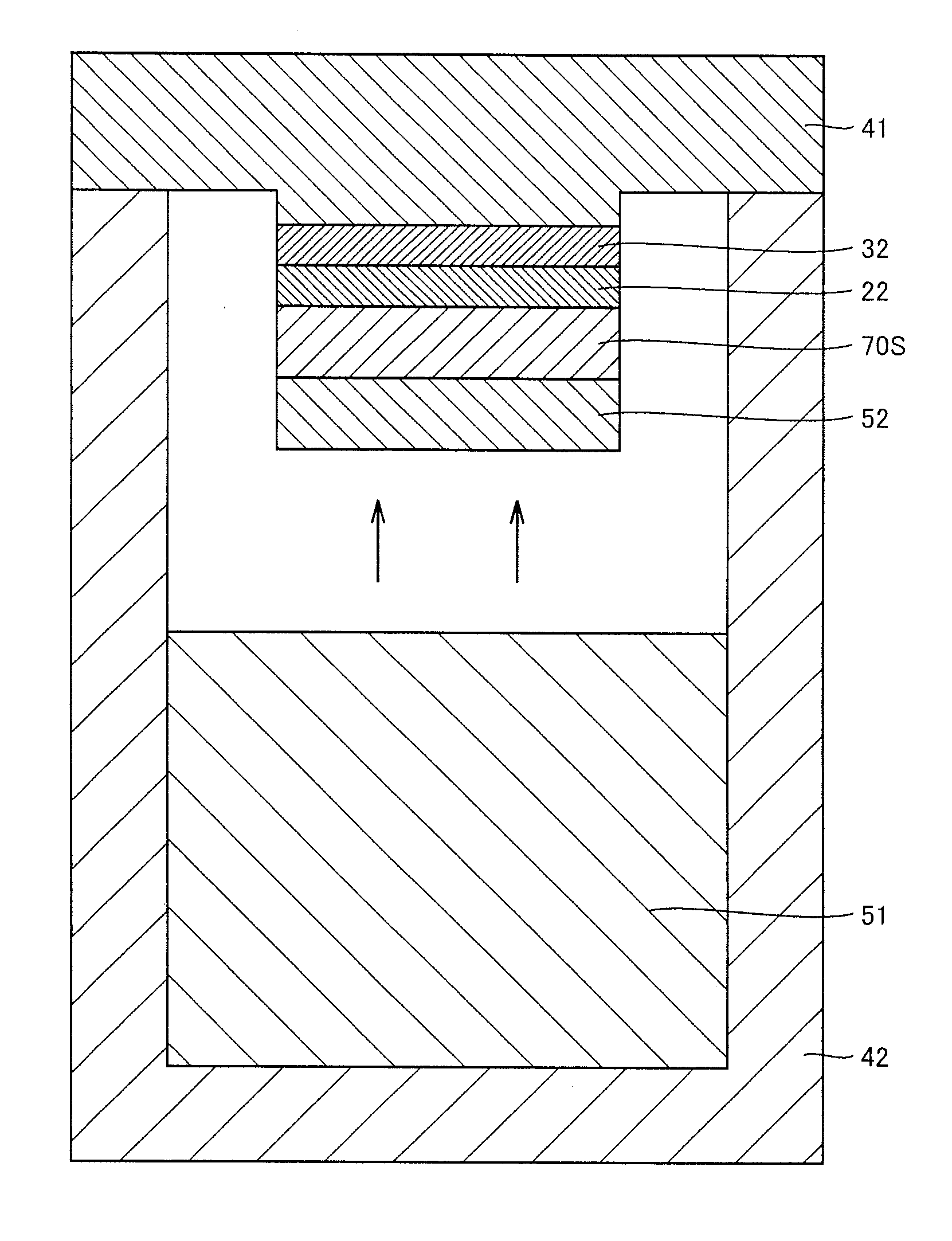

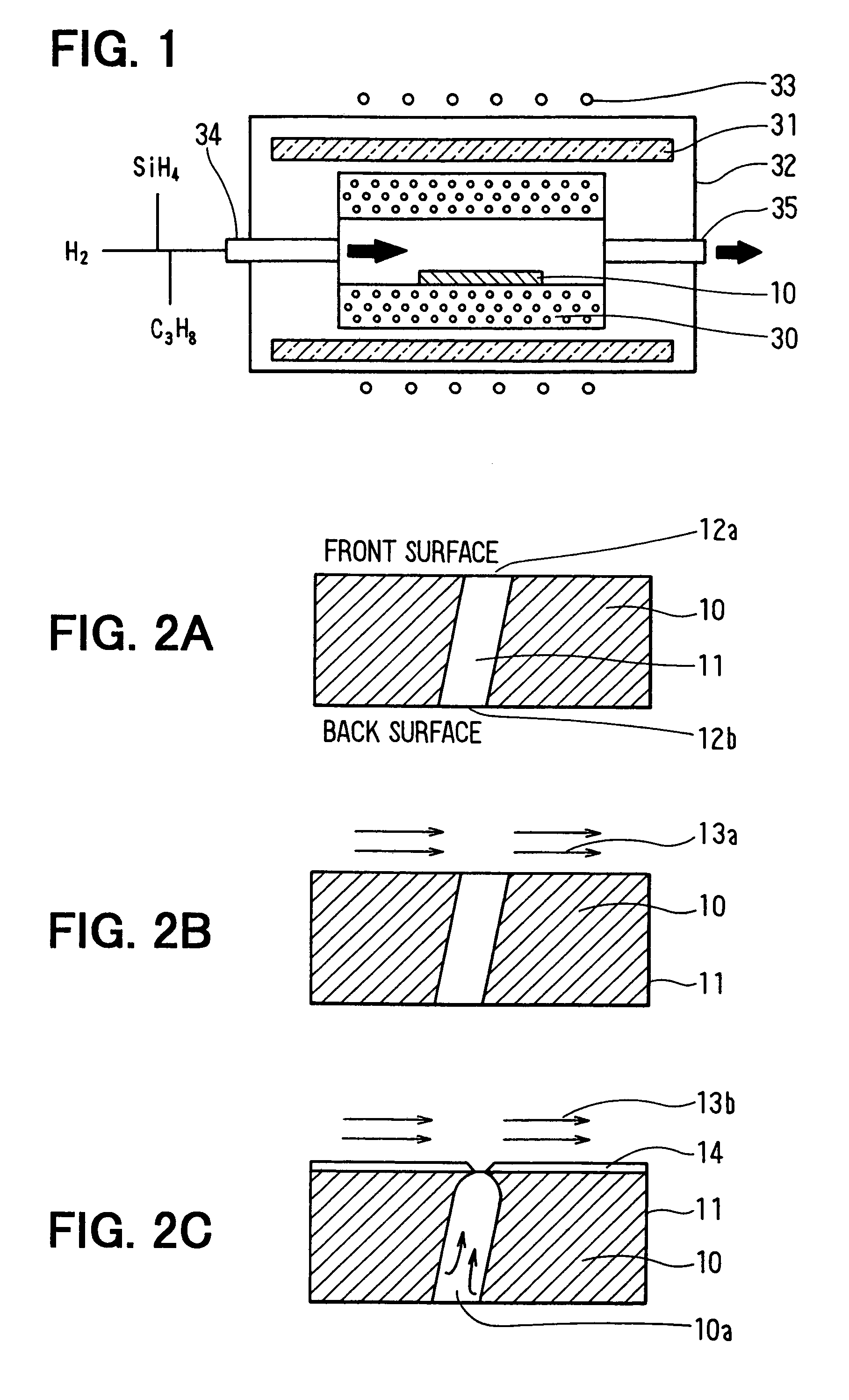

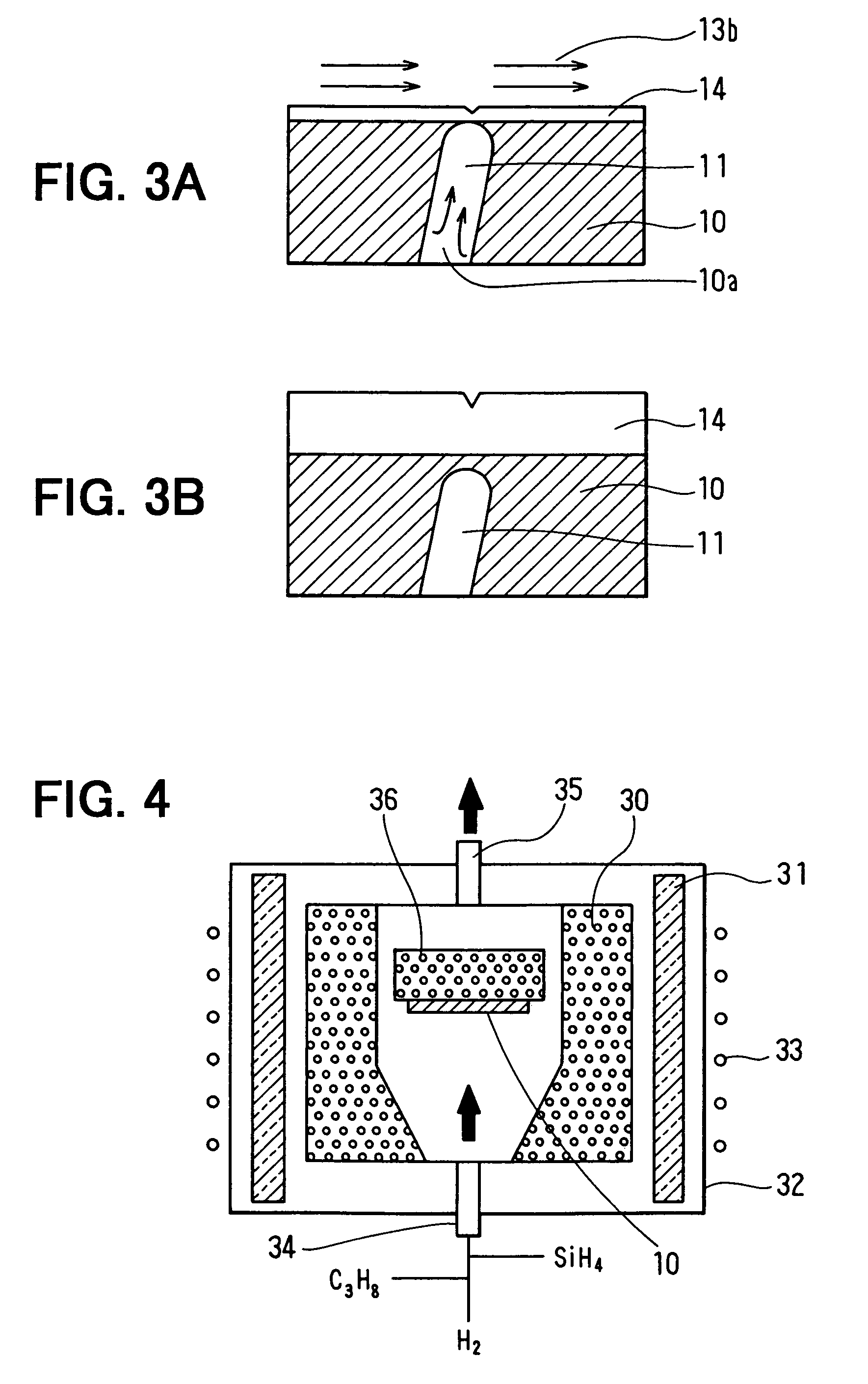

Manufacturing method of silicon carbide single crystals

InactiveUS7147714B2Easy to openEasily occludedPolycrystalline material growthFrom chemically reactive gasesOptoelectronicsSingle crystal

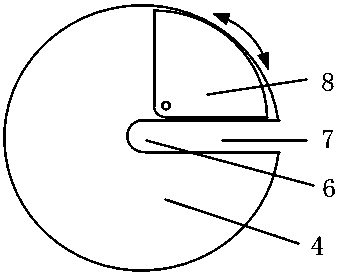

When a SiC substrate is heated up to around 1800°C., sublimation of SiC occurs from the SiC substrate. Moreover, temperature of the front surface of the SiC substrate is lower than that of the back surface of the SiC substrate. Therefore, sublimation gas sublimed from a back-surface vicinity of the substrate, where temperature is high, moves to a front-surface vicinity of the substrate, where temperature is low, through the hollow micro-pipe defect. Epitaxial growth proceeds on the front surface of the substrate while the sublimation gas is recrystallized at the front-surface vicinity of the substrate, so that the micro-pipe defect is occluded.

Owner:DENSO CORP

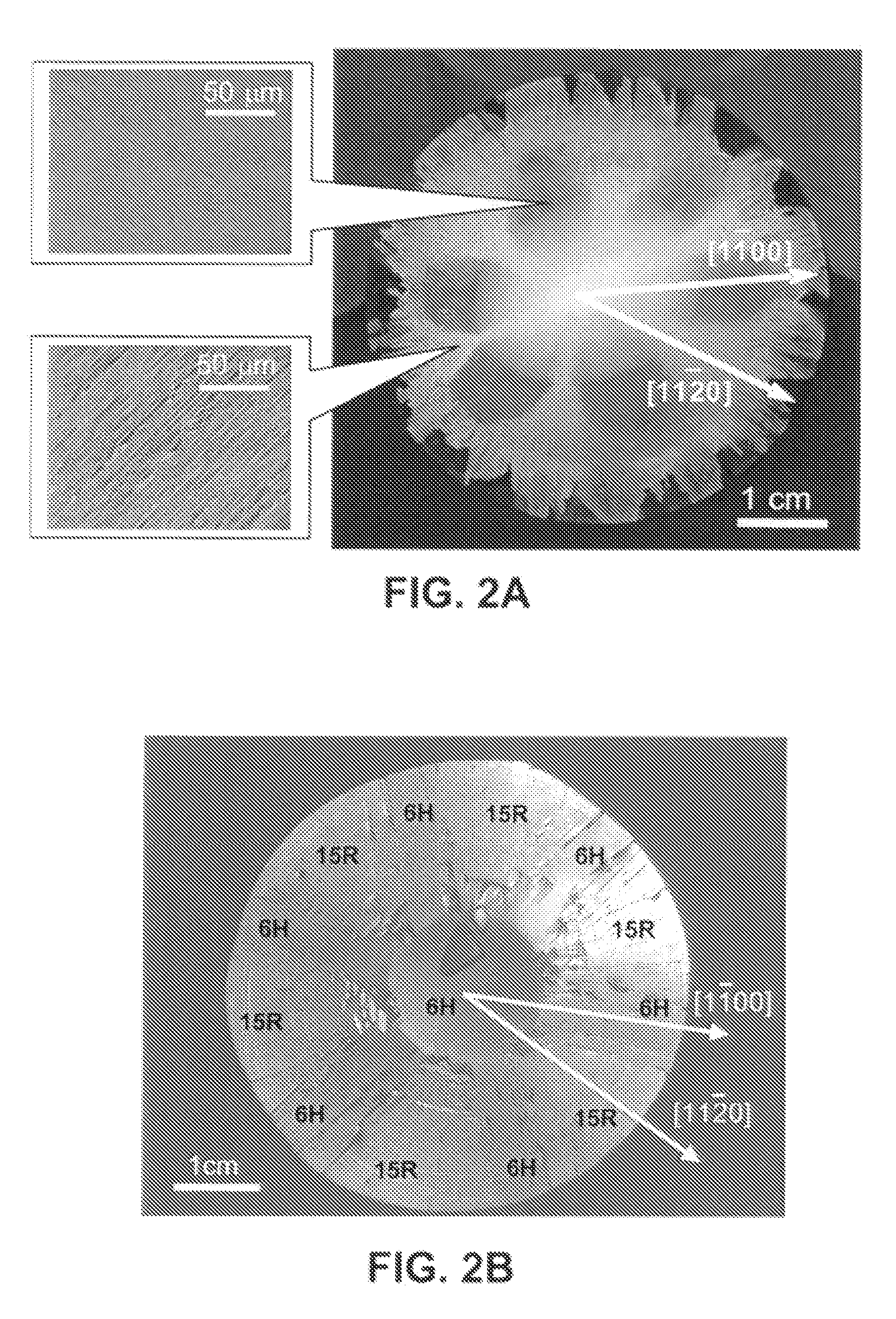

System and method for detecting defects in semiconductor wafers

ActiveUS7220978B2Rapid and inexpensiveDelineation defectPolarisation-affecting propertiesInvestigating moving sheetsNon destructivePolarizer

A system and method for detecting defects in semiconductor wafers in a rapid non-destructive manner. Defects in semiconductor wafers can include micropipes and screw dislocations, stress striations, planer defects, polytype inclusions, and others. When a wafer is illuminated by polarized light, the defects induce birefringence of the polarized light that can be visualized by a polariscope to detect defects in wafers. Defects can cause linearly inputted polarized light to emerge as elliptically polarized light after transmission through a wafer having defects. Placing the wafer between a set of polarizers under the cross poles condition allows for a rapid non-destructive system and method for delineating and locating defects within a semiconductor wafer.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

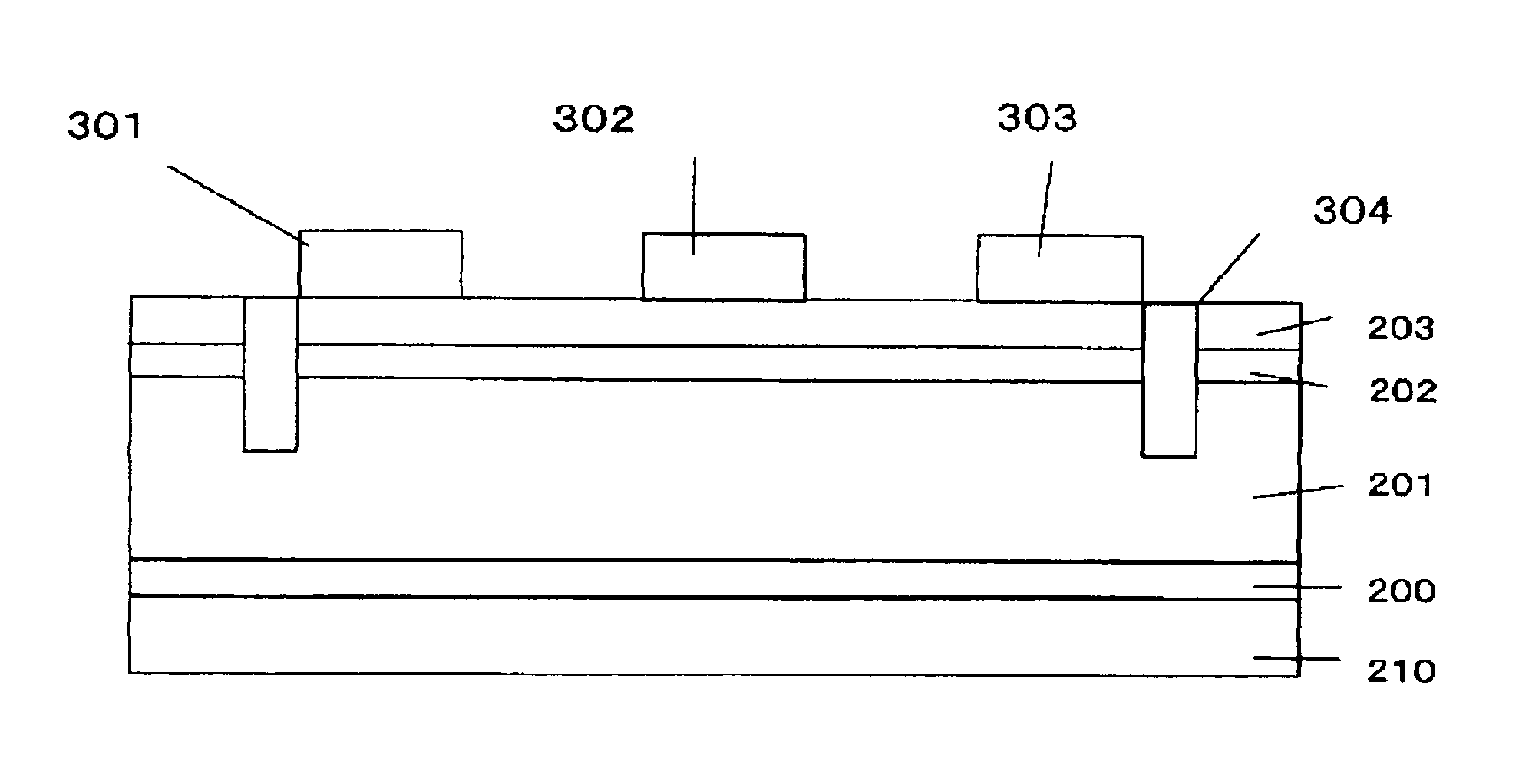

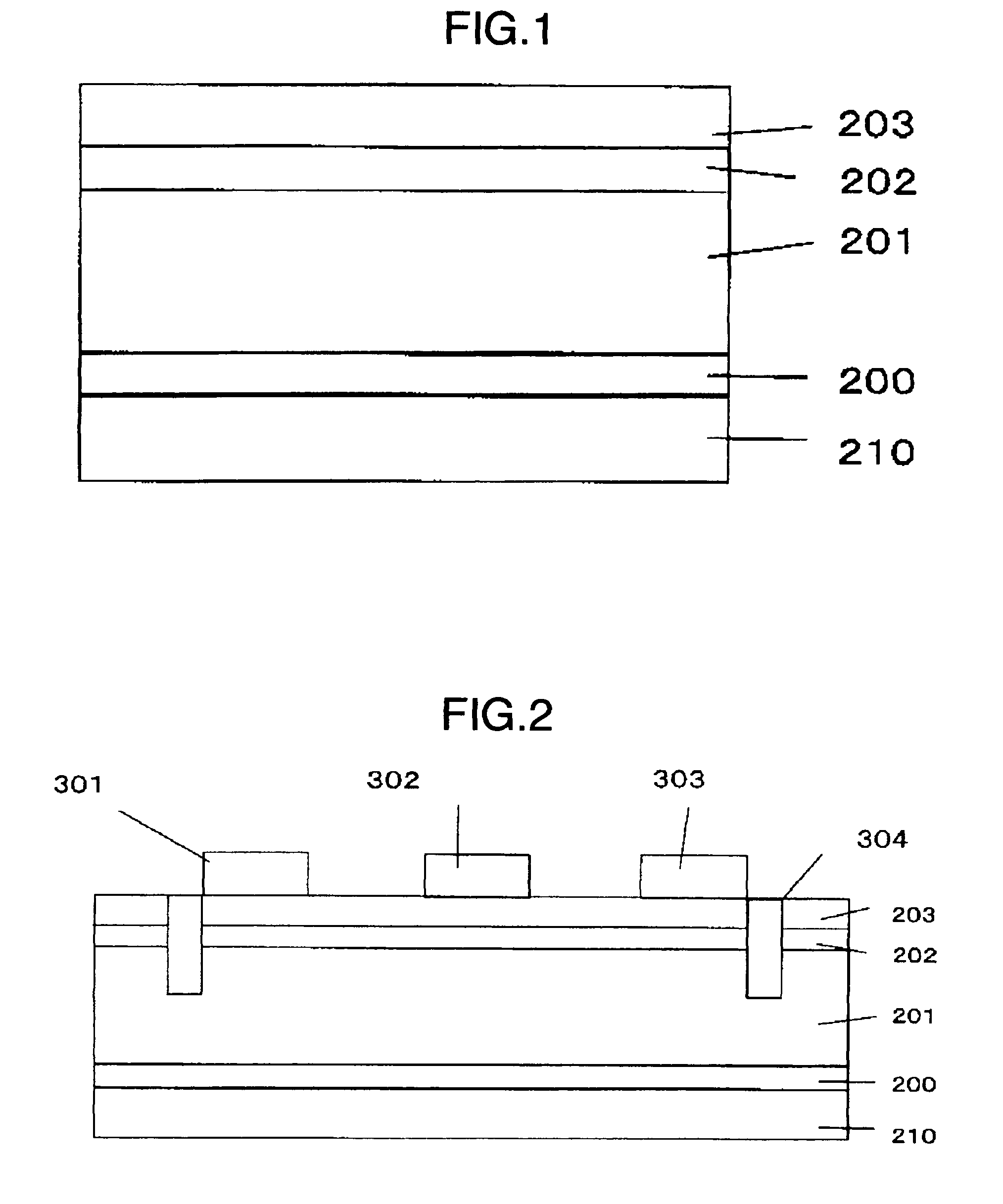

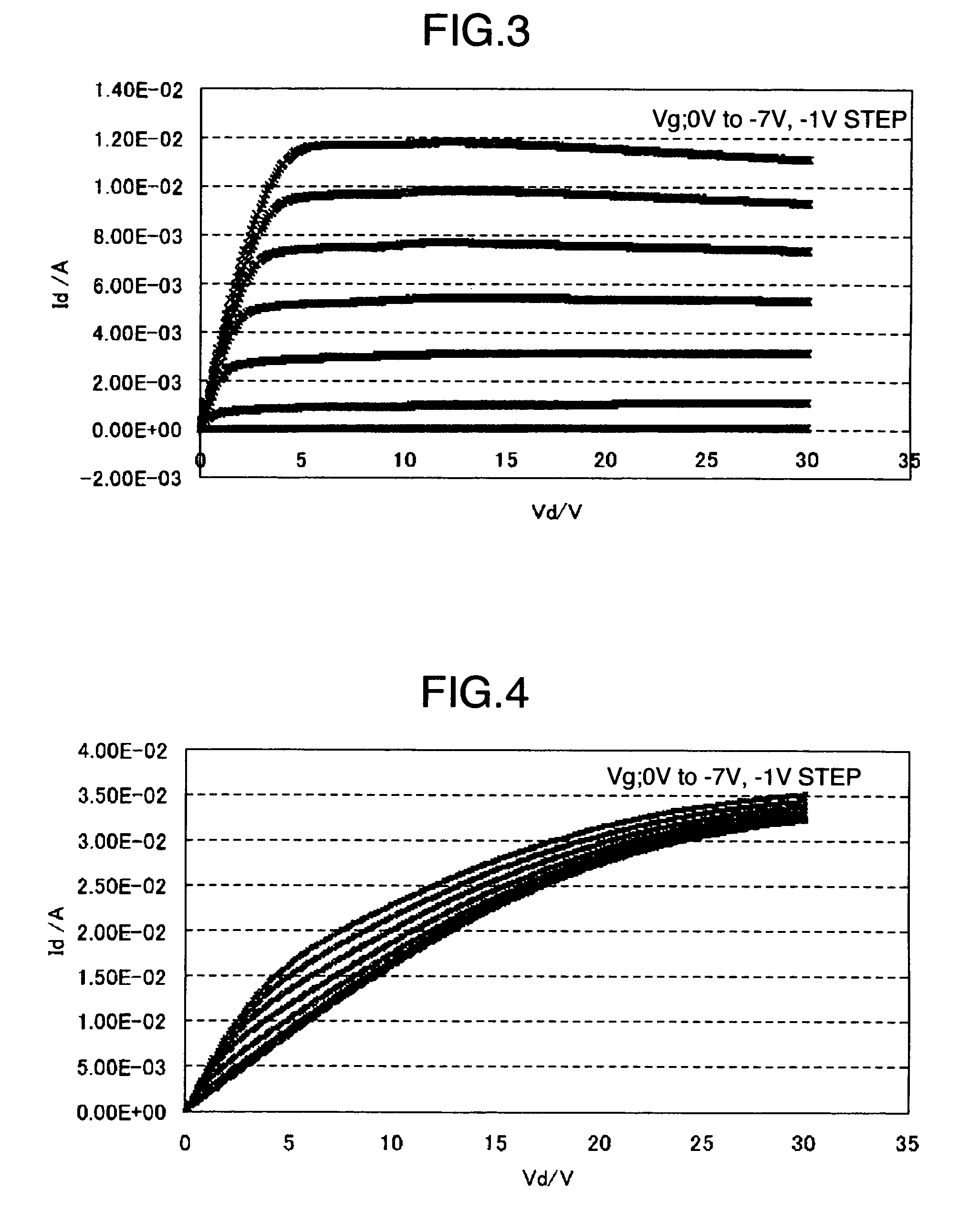

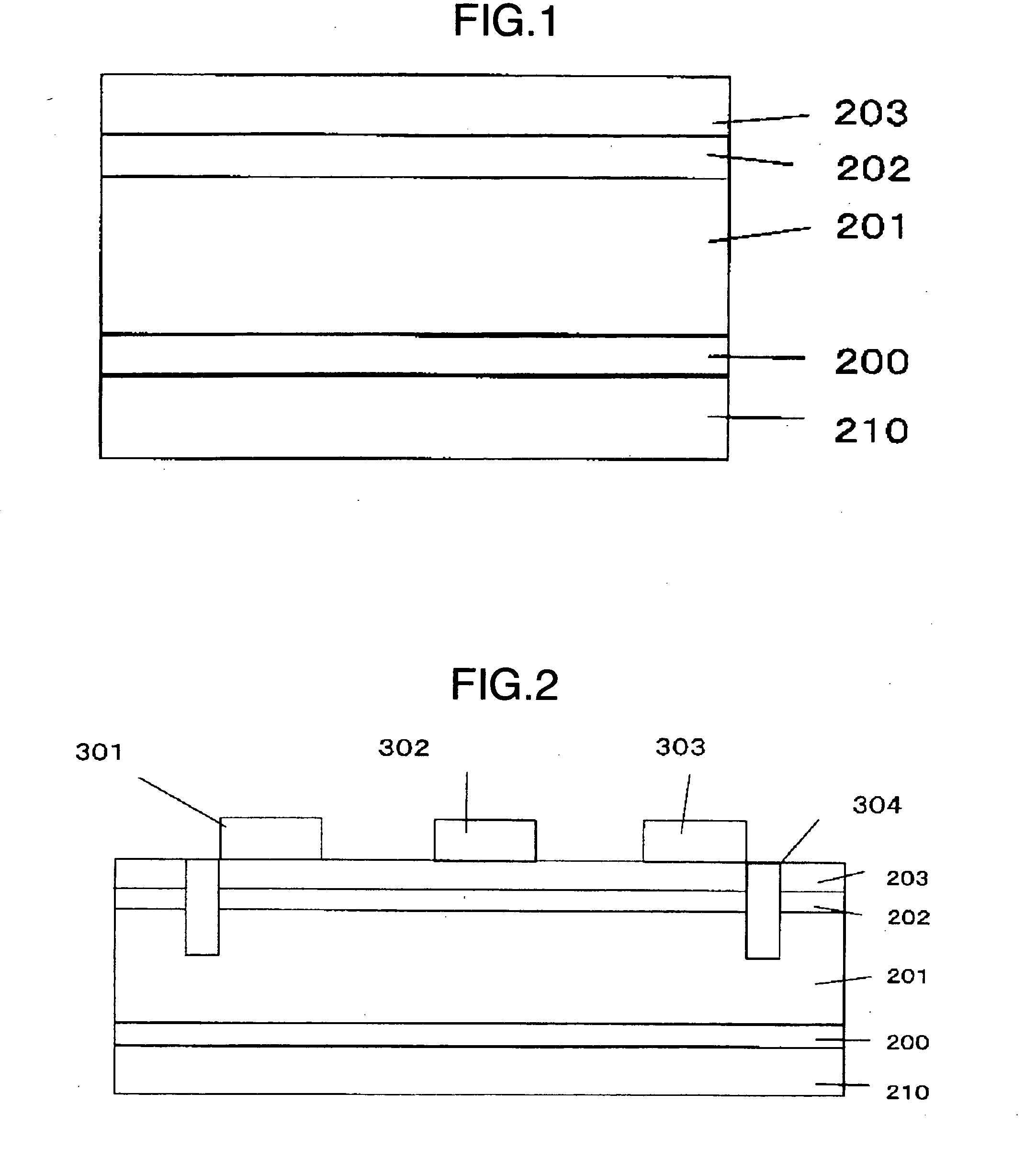

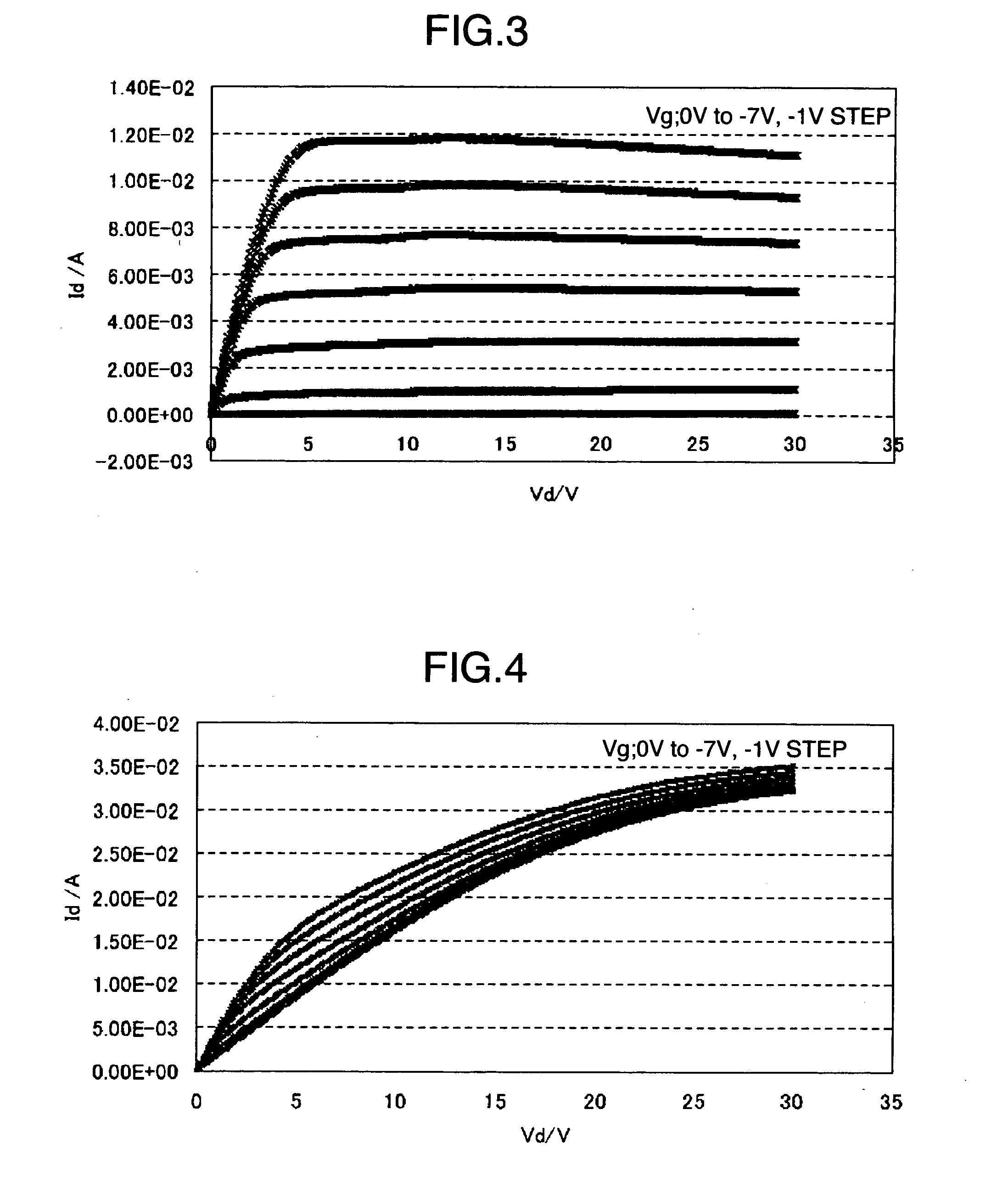

Epitaxial substrate for field effect transistor

ActiveUS7750351B2Improve featuresExtreme significance in industrial useSemiconductor/solid-state device detailsSolid-state devicesSingle crystalField-effect transistor

Owner:SUMITOMO CHEM CO LTD +1

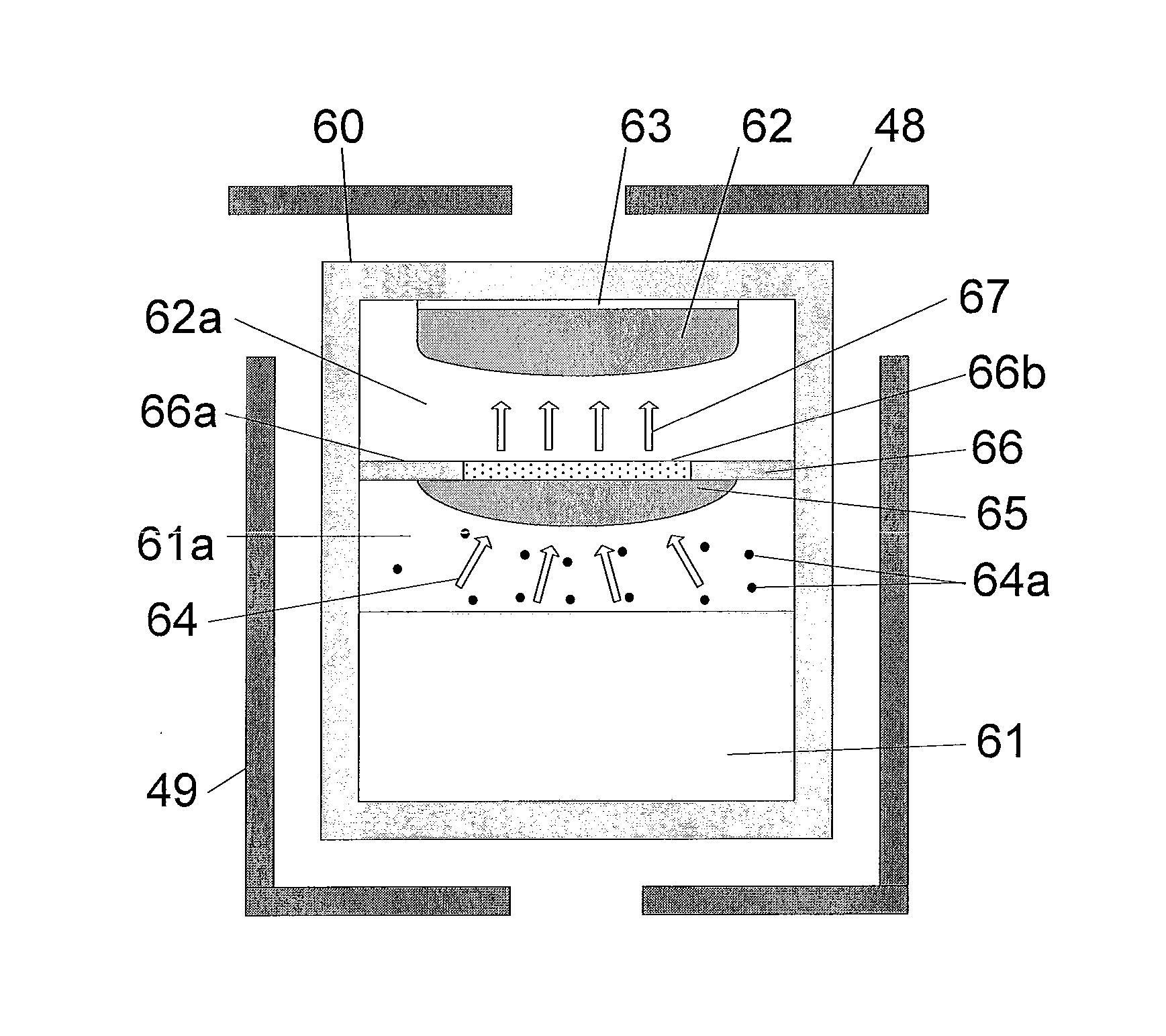

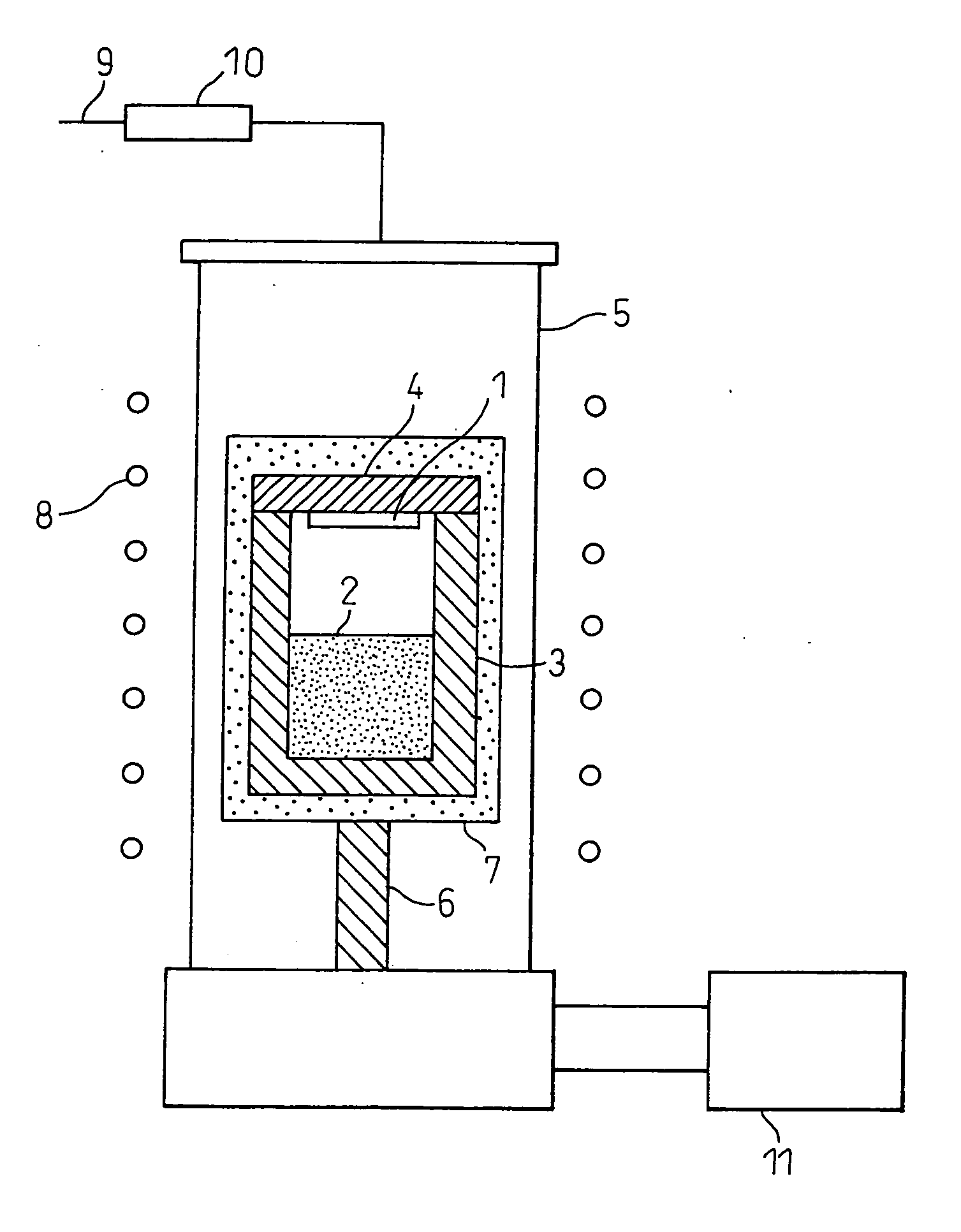

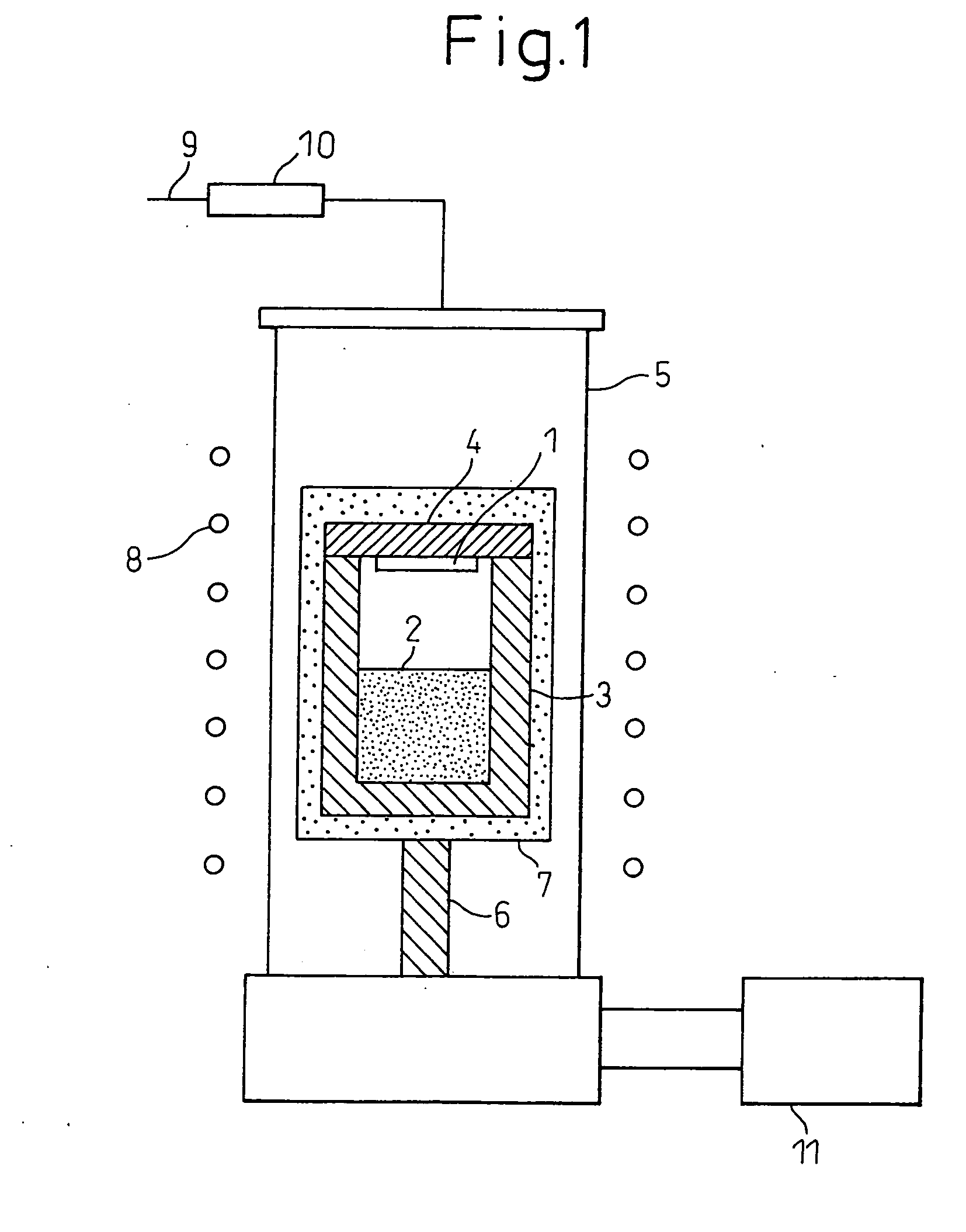

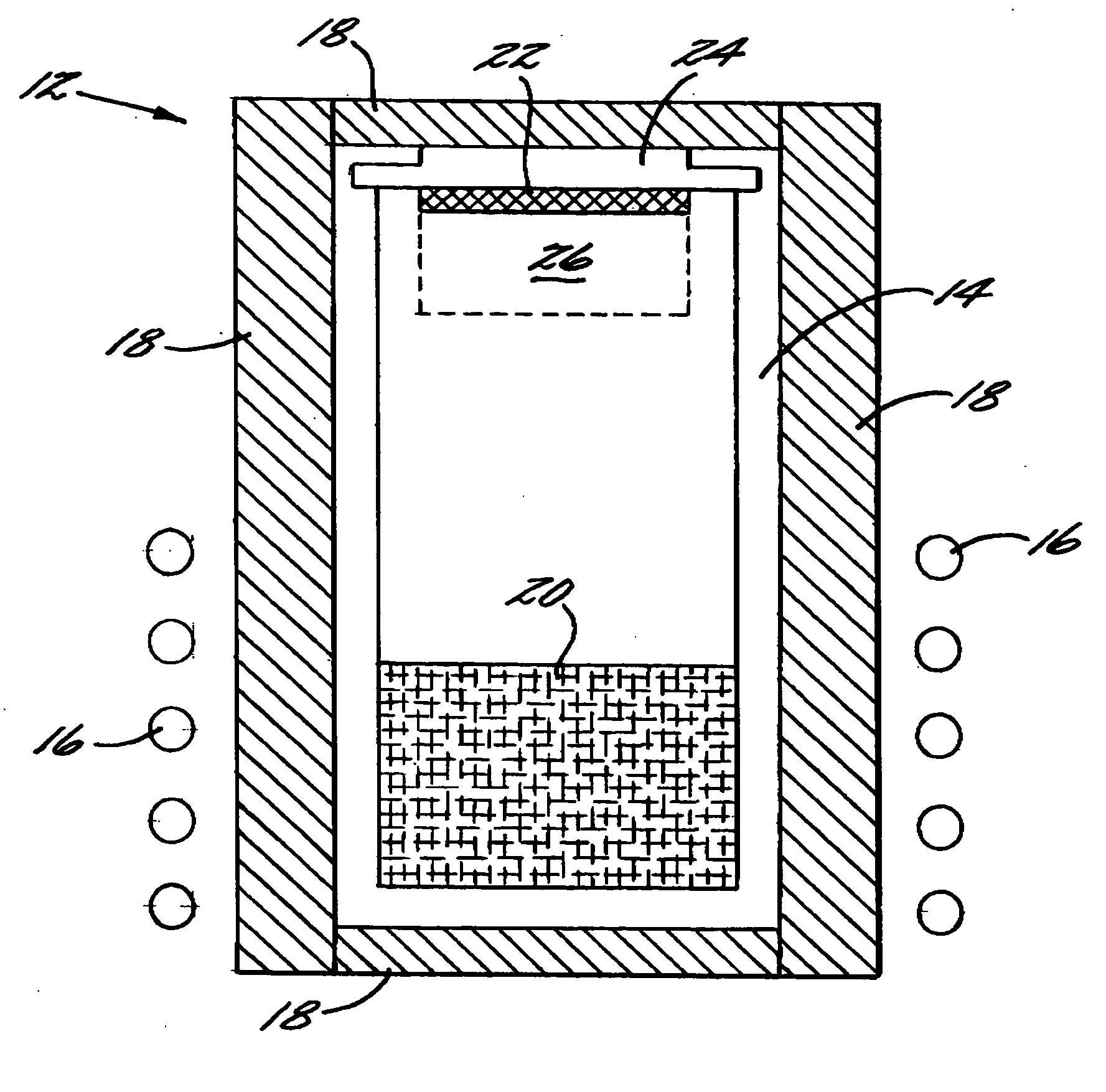

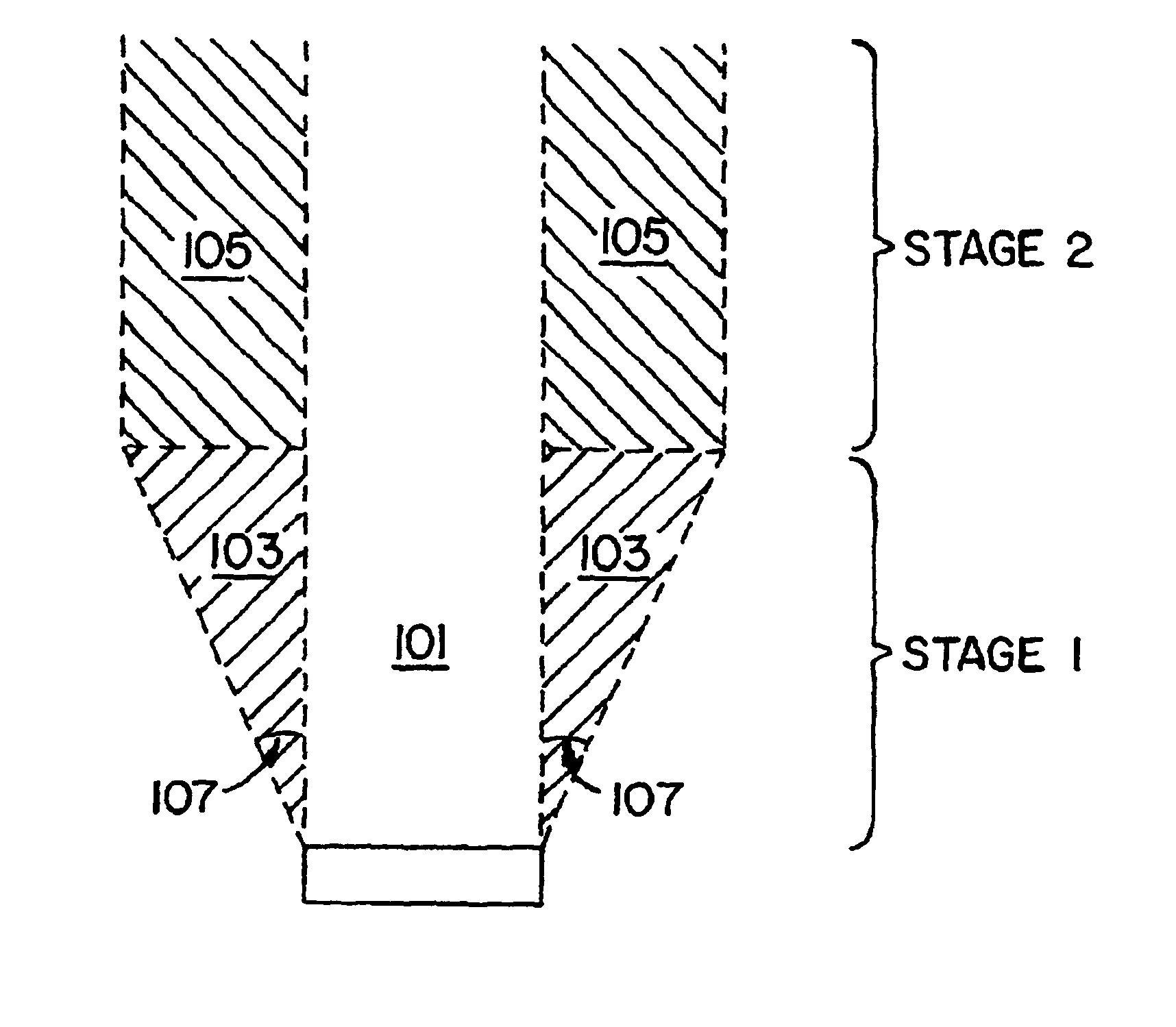

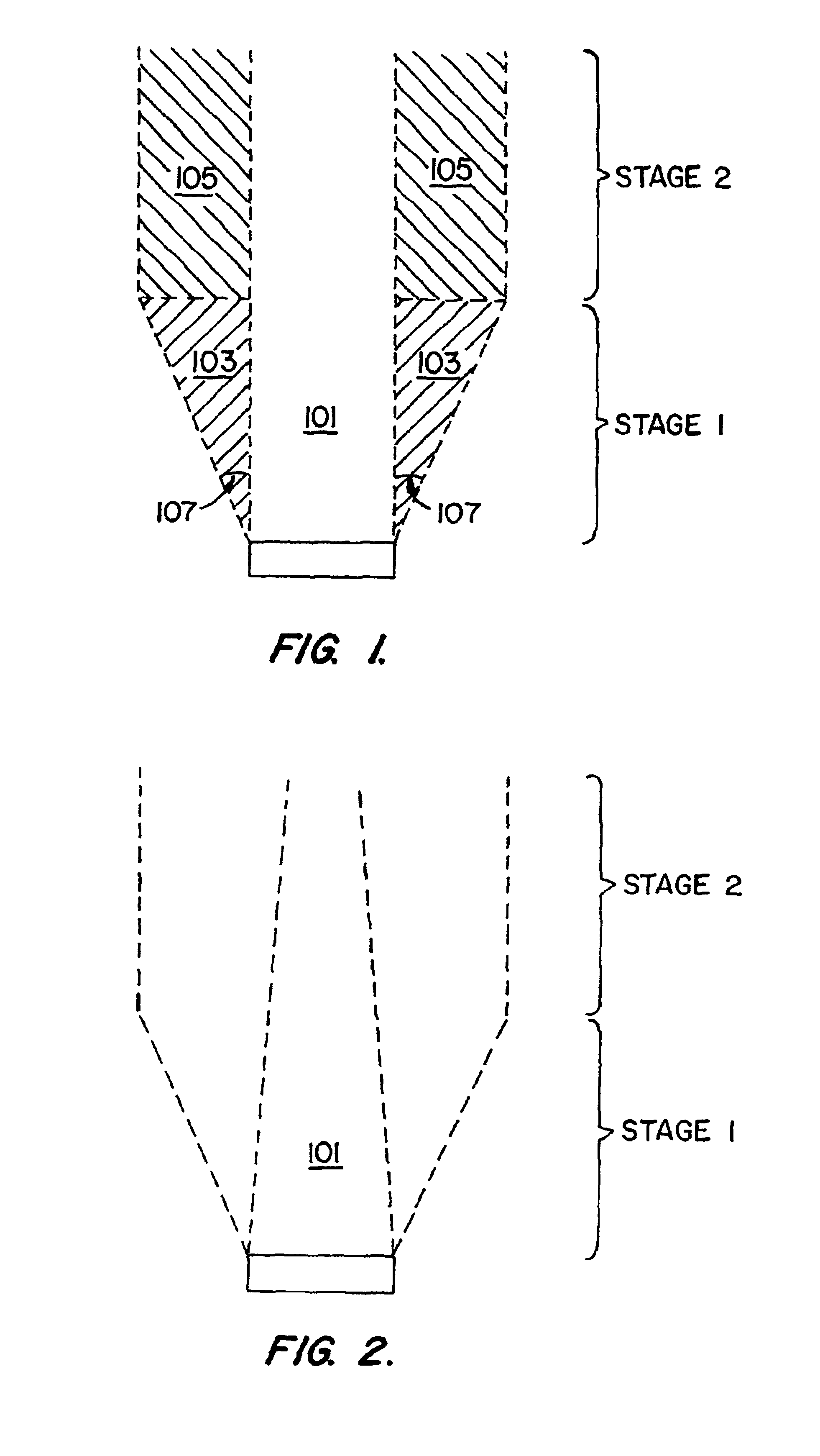

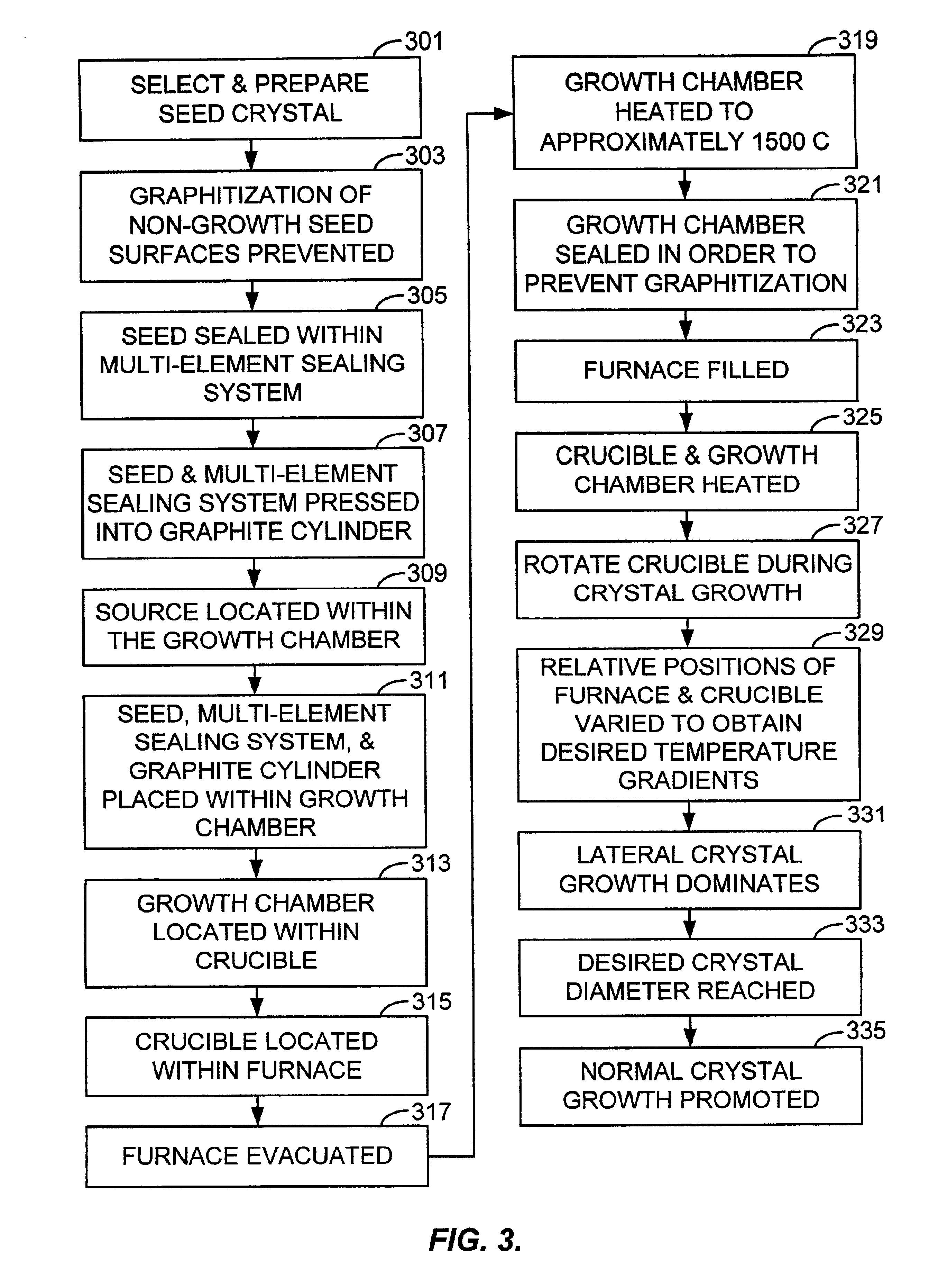

Apparatus for growing low defect density silicon carbide

InactiveUS6863728B2Reduce defect densityReduce generationAfter-treatment apparatusPolycrystalline material growthCarbide siliconMaterial defect

A low defect (e.g., dislocation and micropipe) density silicon carbide (SiC) is provided as well as an apparatus and method for growing the same. The SiC crystal, grown using sublimation techniques, is preferably divided into two stages of growth. During the first stage of growth, the crystal grows in a normal direction while simultaneously expanding laterally. Although dislocations and other material defects may propagate within the axially grown material, defect propagation and generation in the laterally grown material are substantially reduced, if not altogether eliminated. After the crystal has expanded to the desired diameter, the second stage of growth begins in which lateral growth is suppressed and normal growth is enhanced. A substantially reduced defect density is maintained within the axially grown material that is based on the laterally grown first stage material.

Owner:THE FOX GROUP

Method for producing single crystal silicon carbide

InactiveUS20090038538A1Easy to useReduce conductivityPolycrystalline material growthLiquid-phase epitaxial-layer growthMicrometerCarbide

Single crystal SiC, having no fine grain boundaries, a micropipe defect density of 1 / cm2 or less and a crystal terrace of 10 micrometer or more is obtained by a high-temperature liquid phase growth method using a very thin Si melt layer. The method does not require temperature difference control between the growing crystal surface and a raw material supply polycrystal and preparation of a doped single crystal SiC is possible.

Owner:KWANSEI GAKUIN EDUCATIONAL FOUND

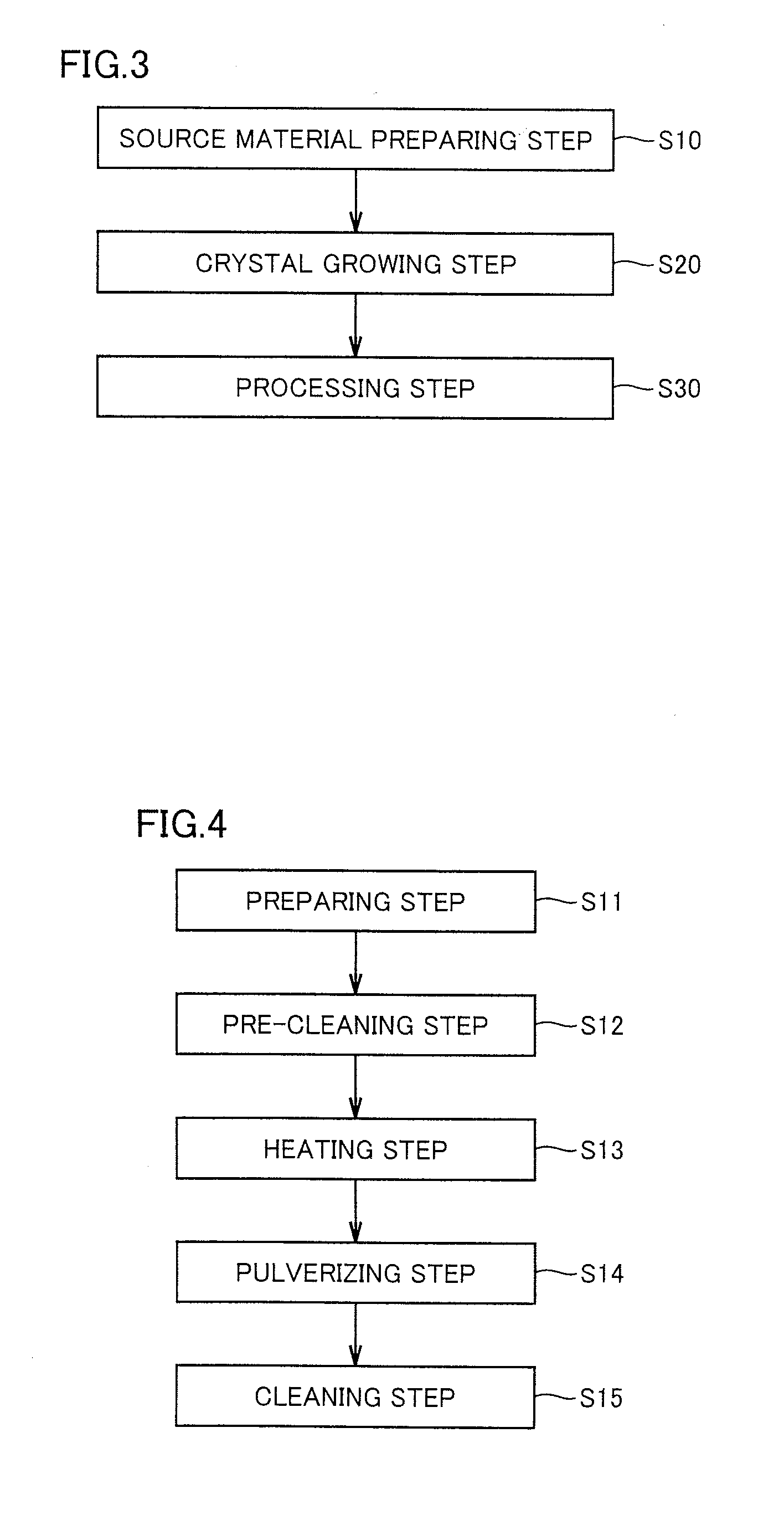

Heat treatment method after silicon carbide monocrystal growth

ActiveCN1884639AQuality improvementReduce in quantityPolycrystalline material growthAfter-treatment detailsCarbon filmCrucible

The invention discloses a heat disposing method of carborundum monocrystalline, which comprises the following steps: placing SiC monocrystalline with carbon film and powder material in the copple; heating argon to preset temperature; keeping temperature for certain time; cooling argon along with furnace; recrystallizing SiC crystal and solid diffusion to eliminate partial micro-pipe and pack defect. The invention reduces defect quantity of micro-pipe and package in the SiC monocrystalline, which improves SiC monocrystalline quality.

Owner:BEIJING TIANKE HEDA SEMICON CO LTD

Epitaxial substrate for field effect transistor

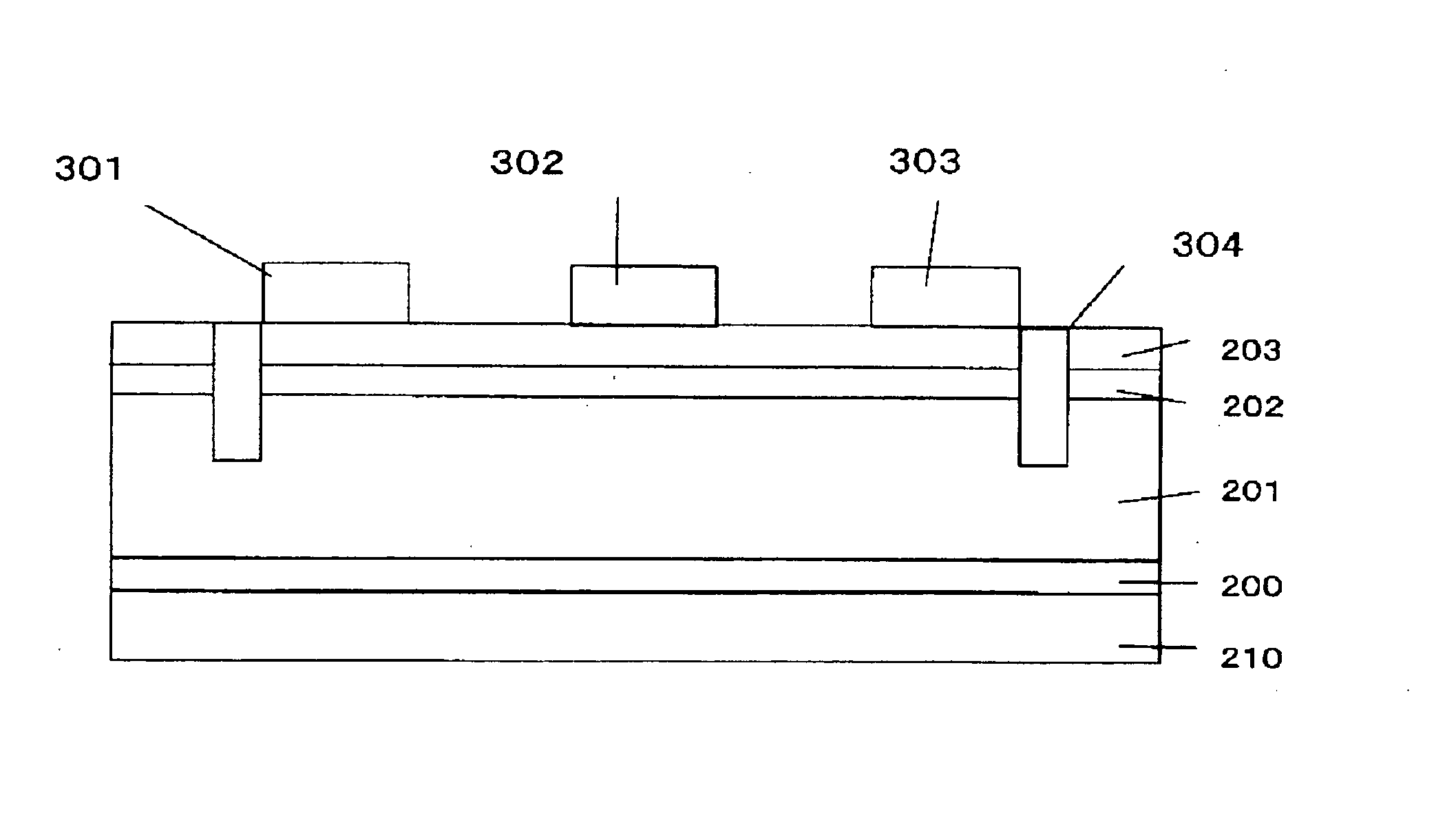

ActiveUS20070069253A1Improve featuresExtreme significance in industrial useTransistorBulk negative resistance effect devicesSingle crystalField-effect transistor

An epitaxial crystal for a field effect transistor which has a nitride-based III-V group semiconductor epitaxial crystal grown on a SiC single crystal base substrate having micropipes by use of an epitaxial growth method, wherein at least a part of the micropipes spreading from the SiC single crystal base substrate into the epitaxial crystal terminate between an active layer of the transistor and the SiC single crystal base substrate.

Owner:SUMITOMO CHEM CO LTD +1

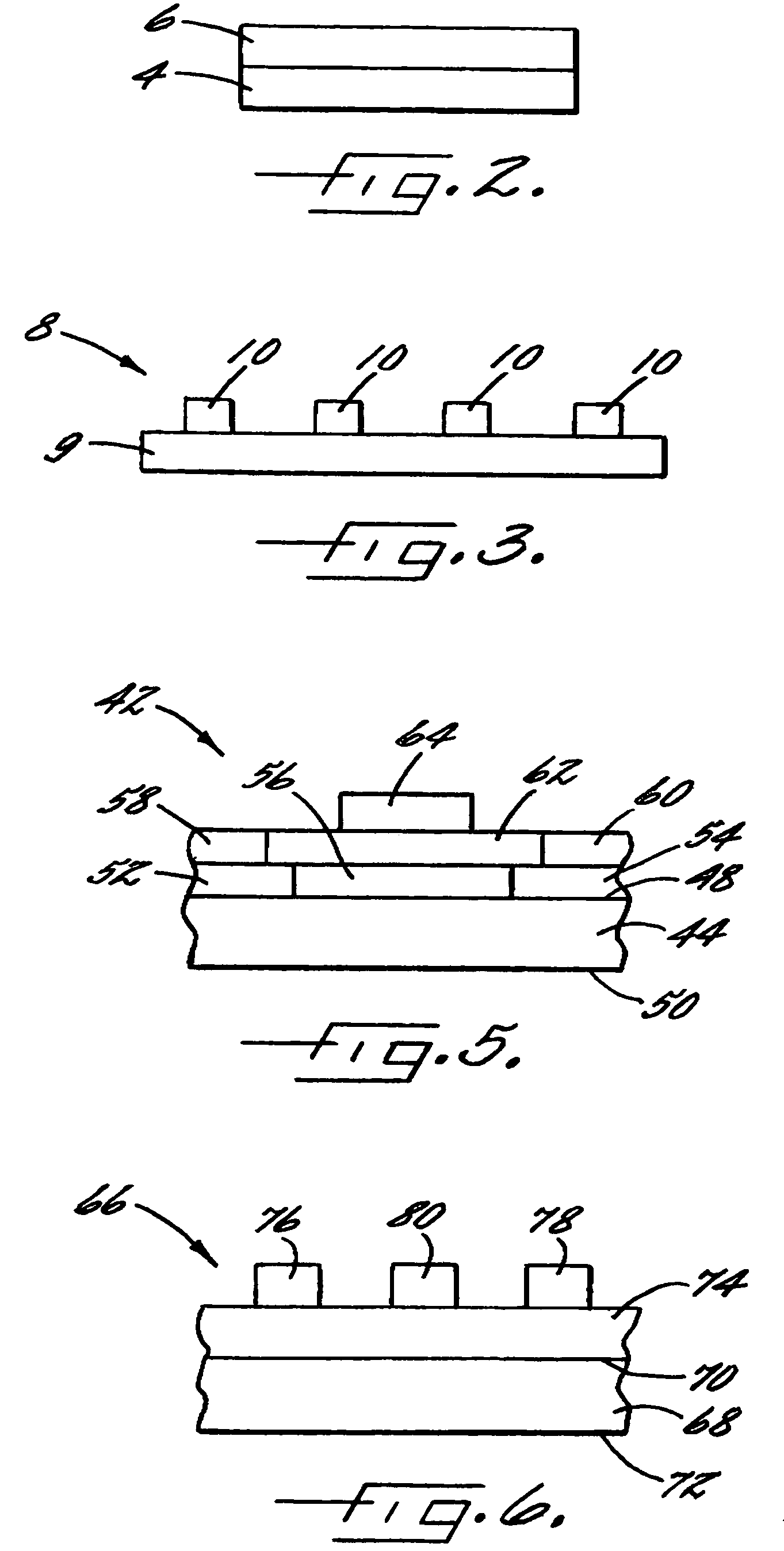

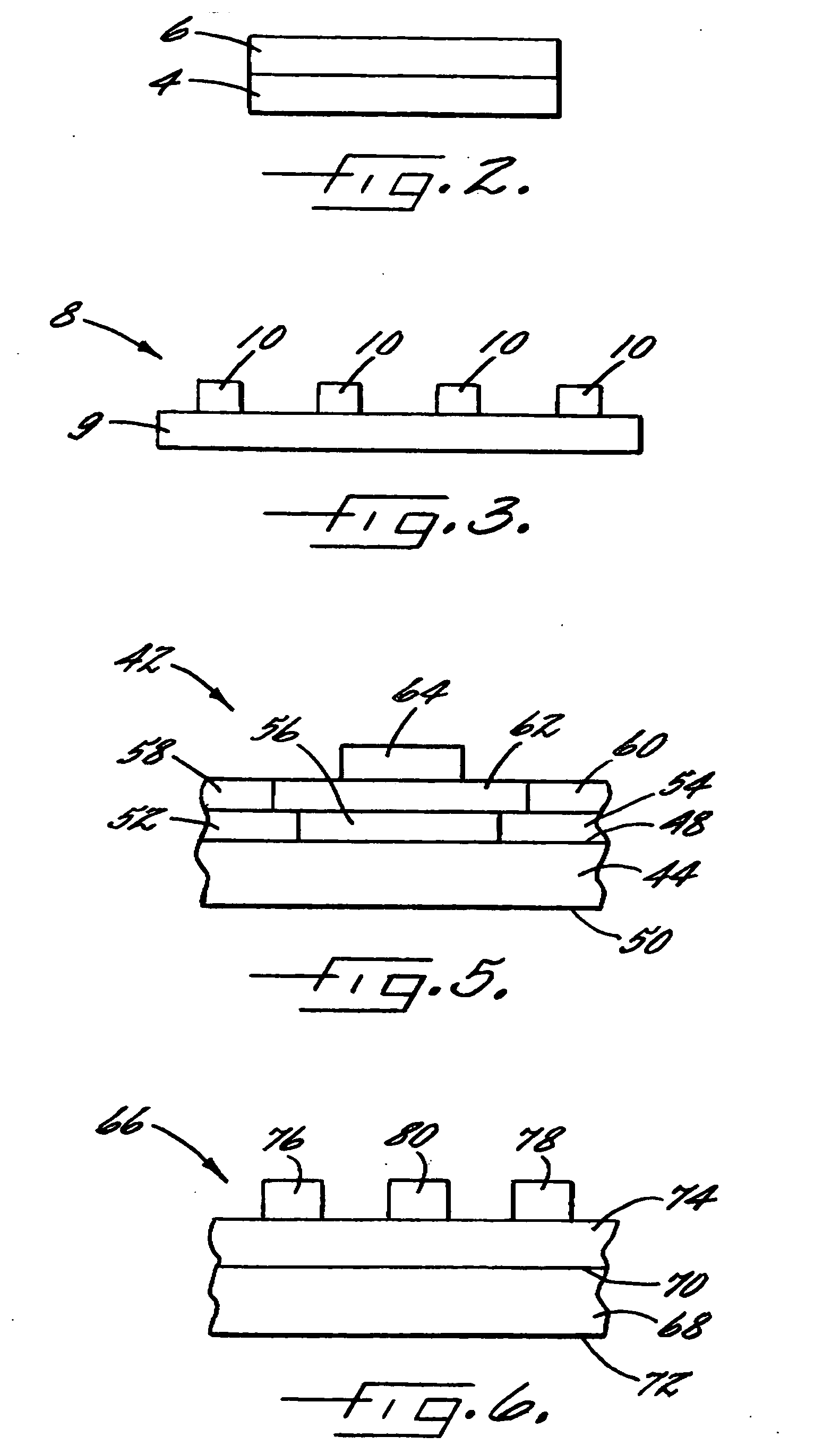

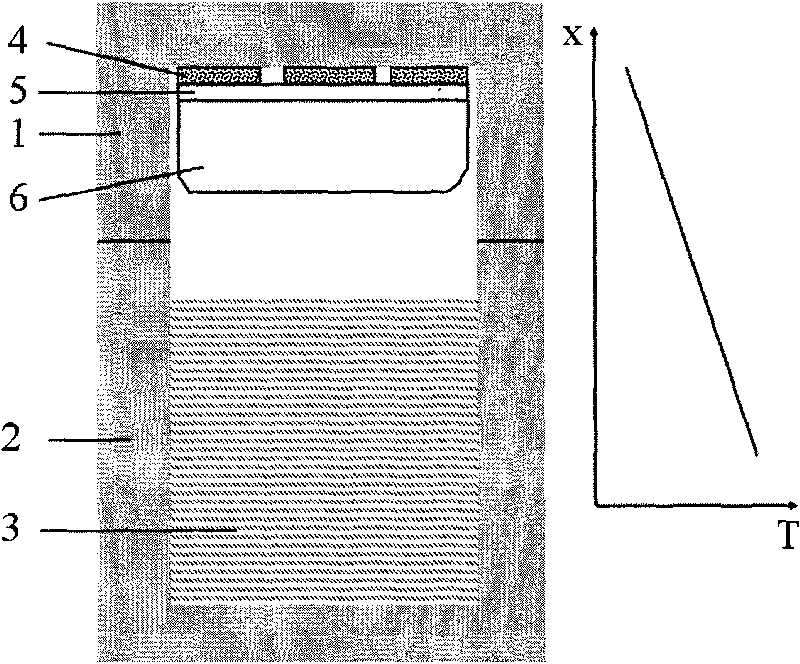

Single crystal SiC and a method of producing the same

InactiveUS6203772B1Quality improvementLarge capacityFrom gel statePolycrystalline material growthProduction rateSurface roughness

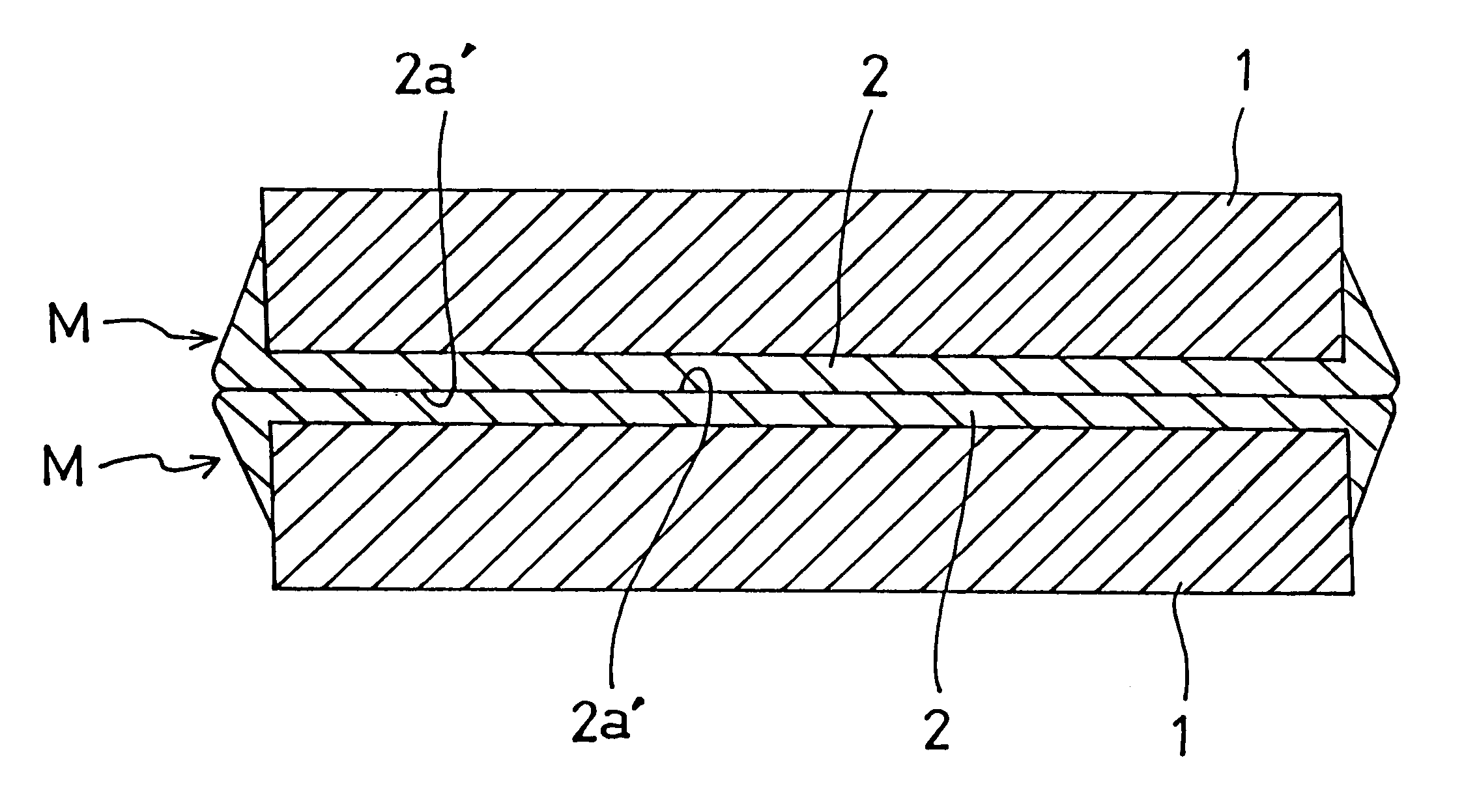

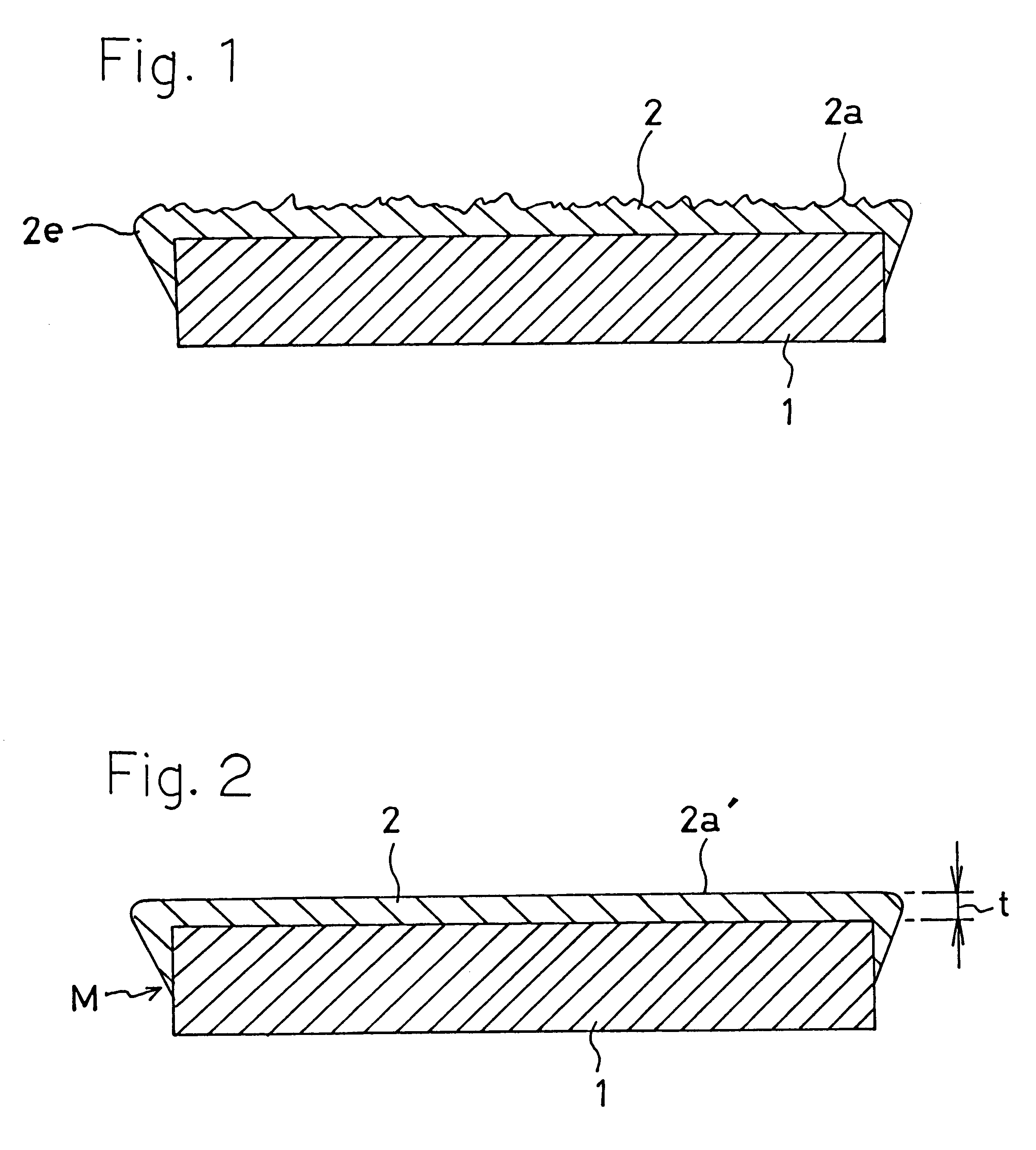

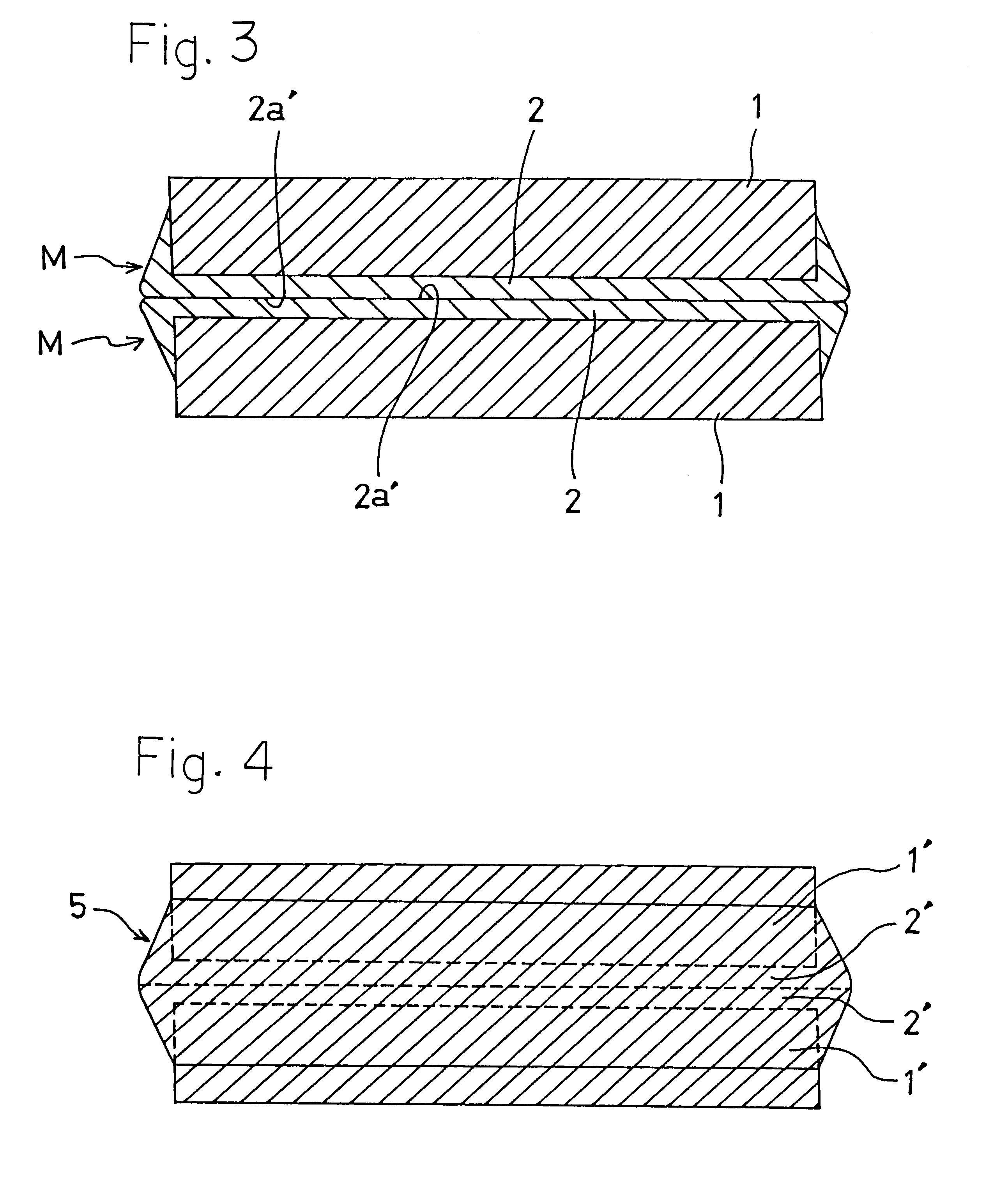

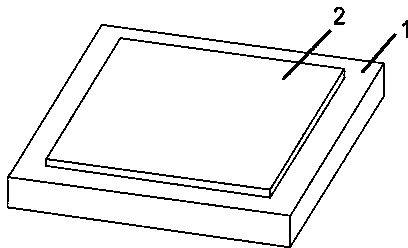

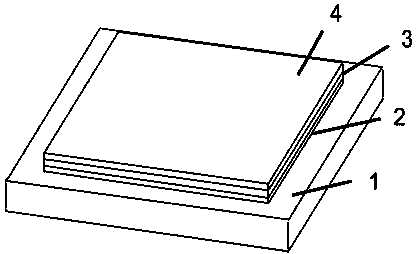

The single crystal SiC according to the present invention is produced in the following manner. Two complexes M in each of which a polycrystalline film 2 of beta-SiC (or alpha-SiC) is grown on the surface of a single crystal alpha-SiC substrate 1 by thermochemical deposition, and the surface 2a of the polycrystalline film 2 is ground so that the smoothness has a surface roughness of 200 angstroms RMS or smaller, preferably 100 to 50 angstroms RMS are subjected to a heat treatment under a state where the complexes are closely fixed to each other via their ground surfaces 2a', at a temperature of 2,000° C. or higher and in an atmosphere of a saturated SiC vapor pressure, whereby the polycrystalline films 2 of the complexes M are recrystallized to grow a single crystal which is integrated with the single crystal alpha-SiC substrates 1. Large-size single crystal SiC in which impurities, micropipe defects, and the like do not remain, and which has high quality can be produced with high productivity.

Owner:NISSIN ELECTRIC CO LTD

Micropipe-free silicon carbide and related method of manufacture

ActiveUS20080083366A1Polycrystalline material growthSemiconductor/solid-state device manufacturingSource materialCrucible

Owner:CREE INC

Method and device for welding thin-wall micropipes of fluoroplastic heat exchanger

ActiveCN102744879AFast thermal conductionUniform and easy to control temperatureHeat exchange apparatusMolten stateHeat carrier

The invention discloses a method for welding thin-wall micropipes of a fluoroplastic heat exchanger, which is characterized in that the fluoroplastic thin-wall micropipes are heated by metal bath as a heat carrier; a welding mold is placed in the metal bath; row tubes are placed in the welding mold to enable thermal expansion of a fluoroplastic end plate in the welding mold to be hindered in order to generate radial pressure; and the radial pressure is superposed with the pressure from the thermal expansion of an expansion core that is inserted in the fluorplastic heat exchanger, so that under molten state, the fluoroplastic end plate and the row tubes composed of the fluoroplastic thin-wall micropipes are molten together, and the welding purpose is achieved.

Owner:ZHUZHOU HONGDA POLYMER MATERIALS

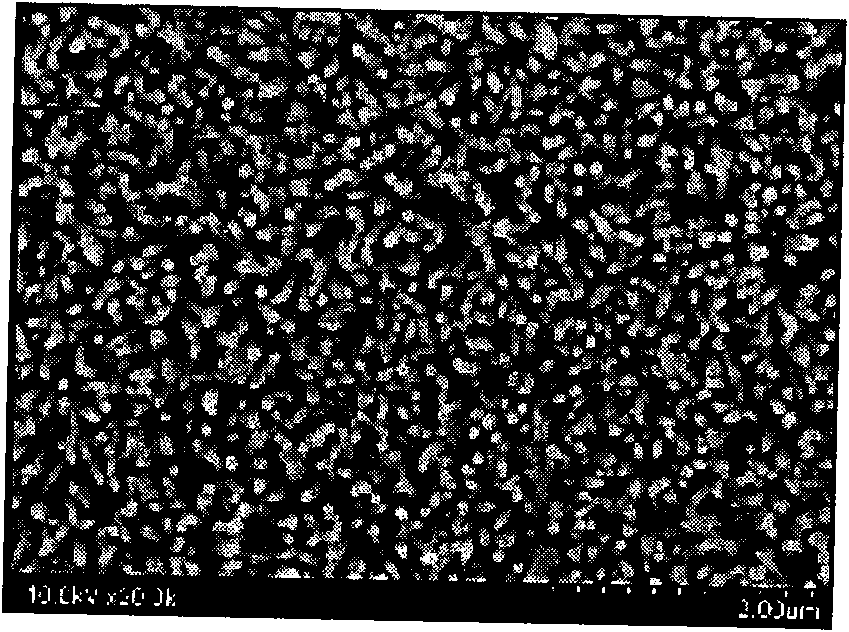

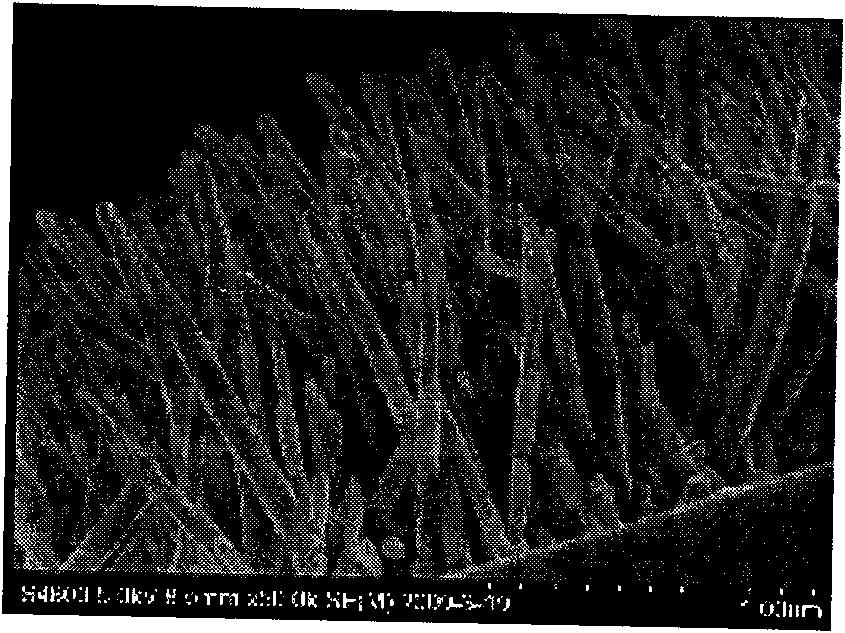

SERS (Surface Enhanced Raman Scattering) probe molecule self-collecting micropipe as well as preparation method and application thereof

InactiveCN103774088AEasy to collectEasy to detectMaterial nanotechnologyVacuum evaporation coatingOptical spectrometerThin membrane

The invention belongs to the technical field of micro-nano devices, and particularly relates to an SERS (Surface Enhanced Raman Scattering) probe molecule self-collecting micropipe as well as a preparation method and an application thereof. The preparation method comprises the steps: preparing a substrate, making a sacrificial layer on the substrate; depositing film layers of different materials with internal stress on the sacrificial layer, wherein the materials of the deposited film layers are capable of providing better SERS characteristics or capable of catalytically decomposing H2O2 to generate oxygen; selectively removing the sacrificial layer between the film layer and the substrate, releasing a film and coiling into a micropipe; and immersing the micropipe in a solution containing a defined amount of coupling agent for certain time, forming a self-assembled single-layer film on the outer surface of the micropipe, and finally obtaining the SERS probe molecule self-collecting micropipe. The device can be used for collecting and detecting a probe molecule in the solution. An SERS signal of the probe molecule is measured by a Raman spectrometer.

Owner:FUDAN UNIV

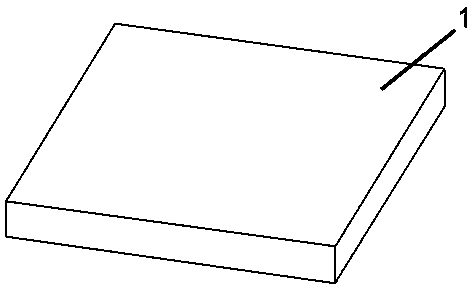

Thermal field structure for growing large-sized silicon carbide monocrystal

PendingCN107604439AIncreased Axial Growth MomentumIncrease axial dimensionAfter-treatment apparatusPolycrystalline material growthCrucibleGraphite

The invention provides a thermal field structure for growing large-sized silicon carbide monocrystal. The structure integrally comprises a crucible, a crucible cover, a seed crystal rod, an upper insulating layer structure, a lower insulating layer structure, a lateral insulating layer structure and an induction coil, wherein the crucible is divided into a cylindrical bottomless structure and a crucible support, the cylindrical bottomless structure is put on the crucible support and is made of a high-purity graphite material, and the crucible support is made of a high-temperature-resistance insulating material; the lower end of the seed crystal rod has a seed crystal tray structure, and is moved along with height reduction of a solid raw material in the sublimating process; the induction coil structure outside the lateral insulating layer structure can be moved downwards from top, so that a reasonable interval between a growing interface of crystal and a raw material can be ensured. The thermal field structure can be used for reducing the probability of crystal fracture and effectively reducing the defects of micropipe, stress and the like inside the crystal, and realizes the growth of large-sized half-insulating silicon carbide monocrystal.

Owner:HARBIN AURORA OPTOELECTRONICS TECH

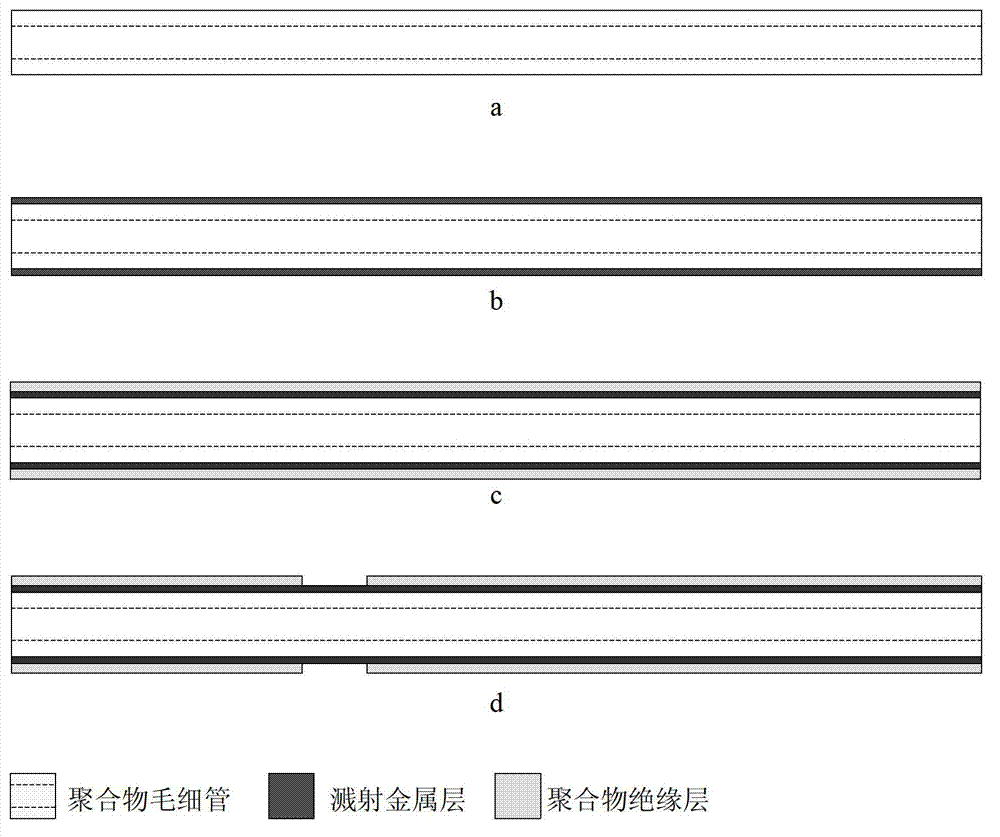

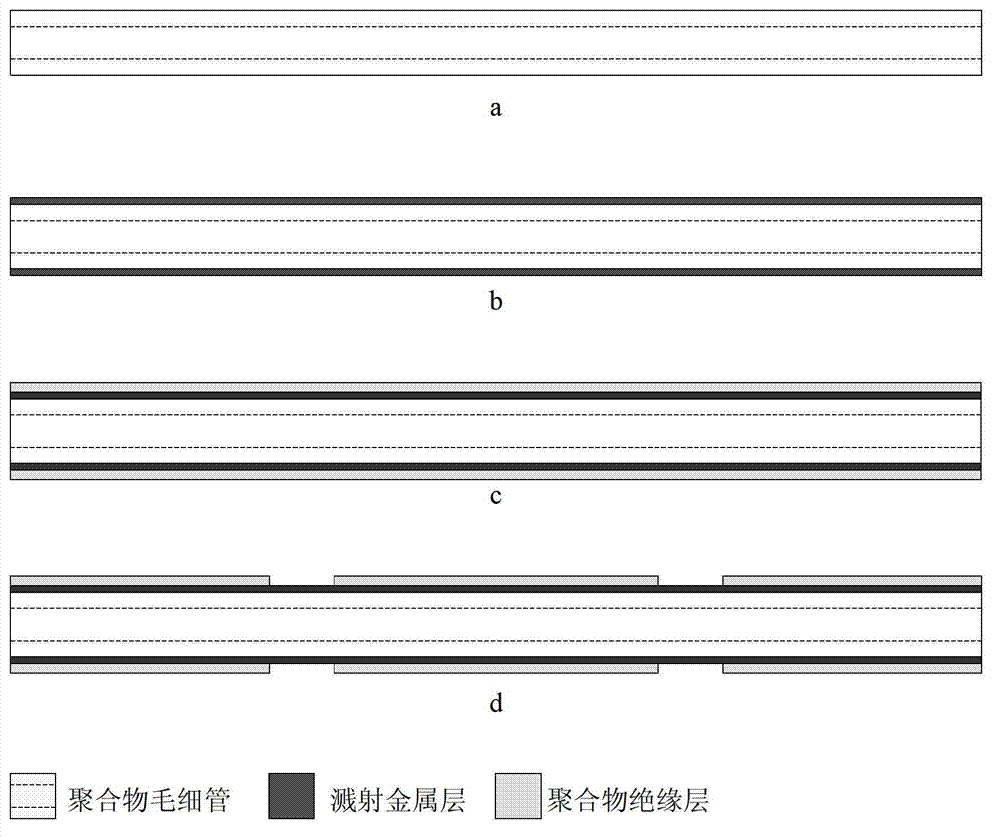

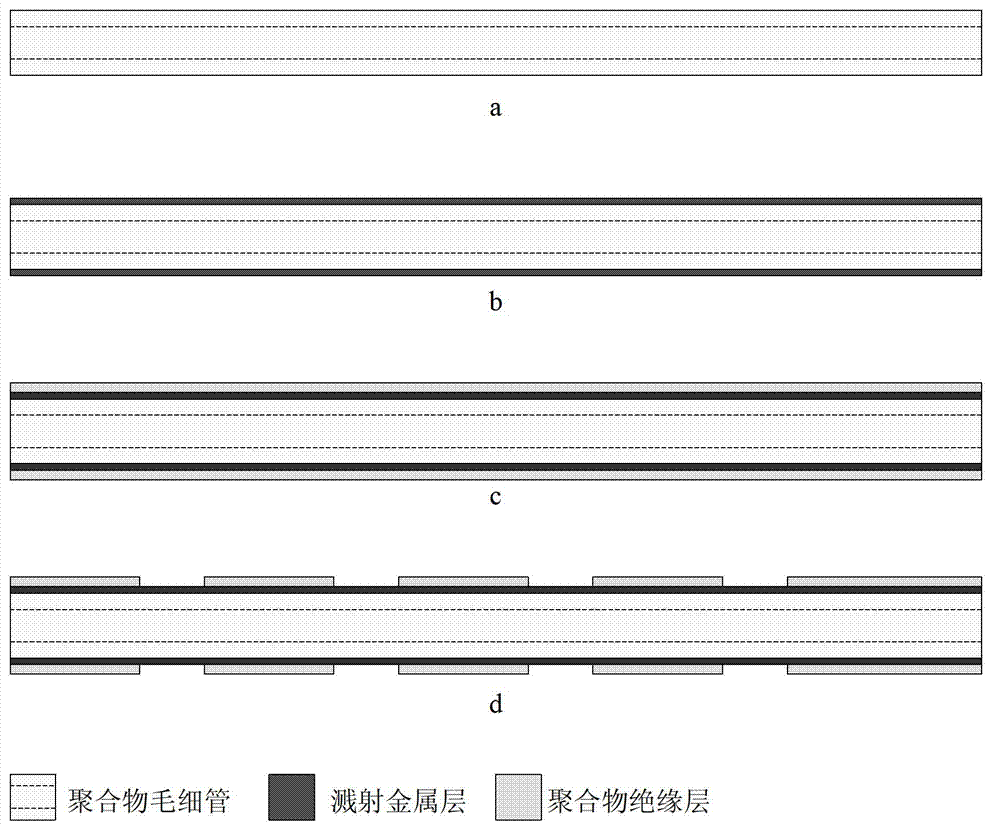

Flexible tubular microelectrode and preparation method thereof

InactiveCN102815664ASimple processLow costFixed microstructural devicesVolume/mass flow by thermal effectsInsulation layerPolymer insulation

The invention discloses a flexible tubular microelectrode and a preparation method thereof. The preparation method comprises the following steps of: firstly, cutting a section of a polymer capillary; secondly, sputtering a metal layer on the surface of the polymer capillary; thirdly, deposing a polymer on the surface of the capillary as an electrode insulation layer; and at last, etching the polymer insulation layer on the surface of the capillary by utilizing laser, and exposing a metal electrode point to obtain the tubular microelectrode. According to the flexible tubular microelectrode prepared by the invention, when electric simulation and electrographic recording are carried out on a physiological tissue by the electrode, a fluid medicine is transported to a tissue organ by a microtubule channel, and a flexible micro-size is beneficial for test or experiment operation and production of an embedded medical device.

Owner:SHANGHAI JIAO TONG UNIV

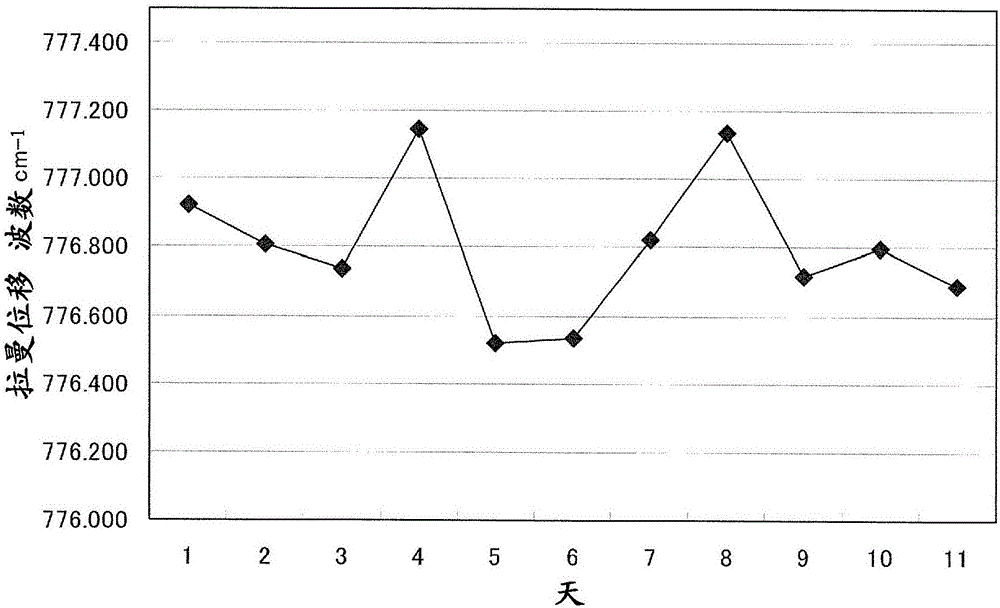

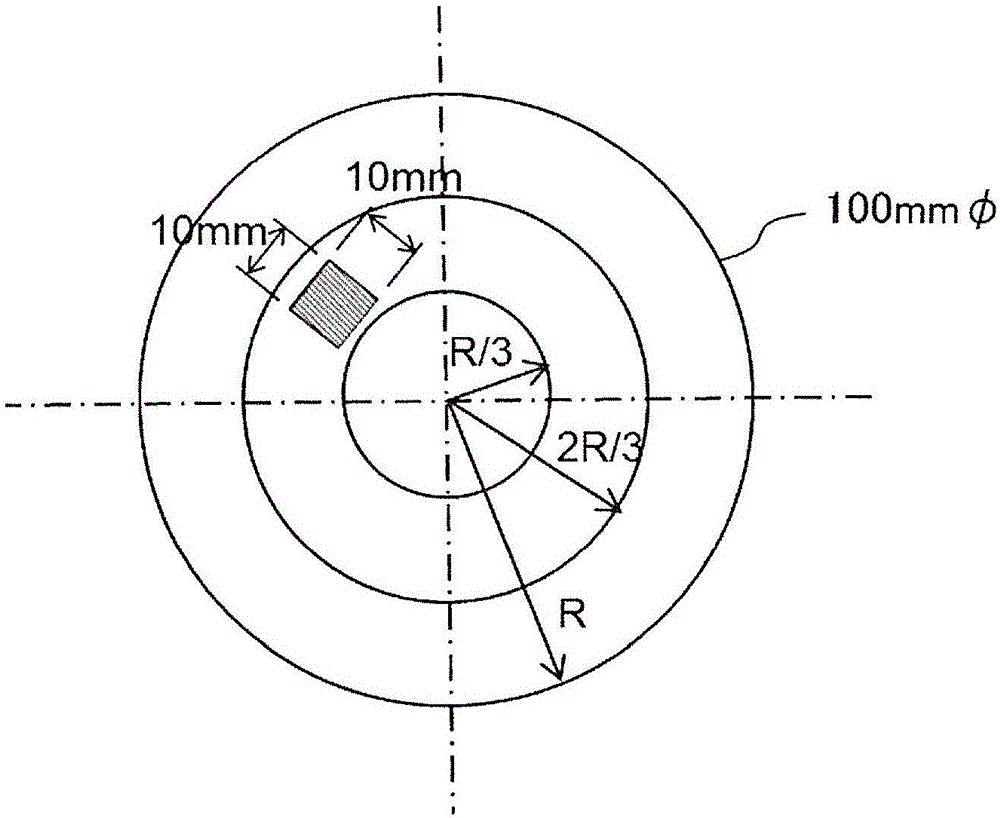

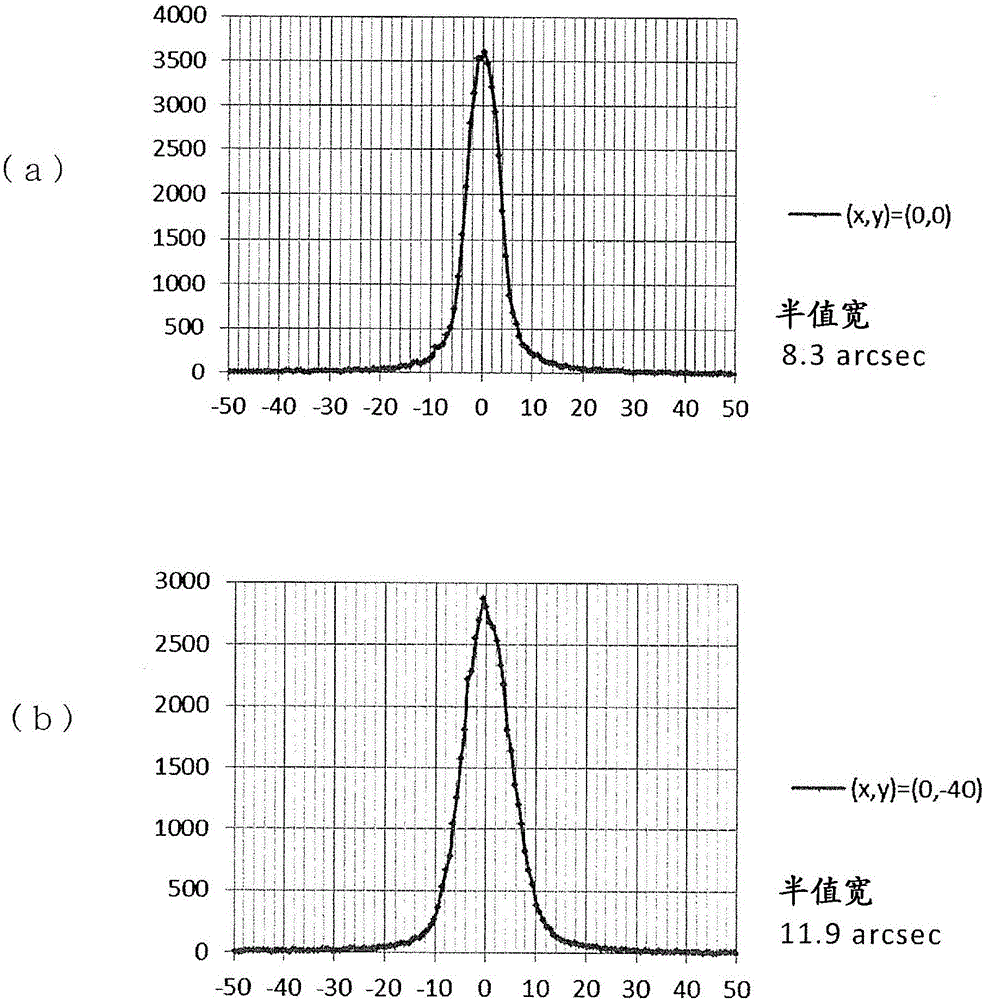

Evaluation method for bulk silicon carbide single crystals and reference silicon carbide single crystal used in said method

ActiveCN106415245AForce measurement by measuring optical property variationRaman scatteringSurface roughnessSingle crystal

Owner:RESONAC CORPORATION

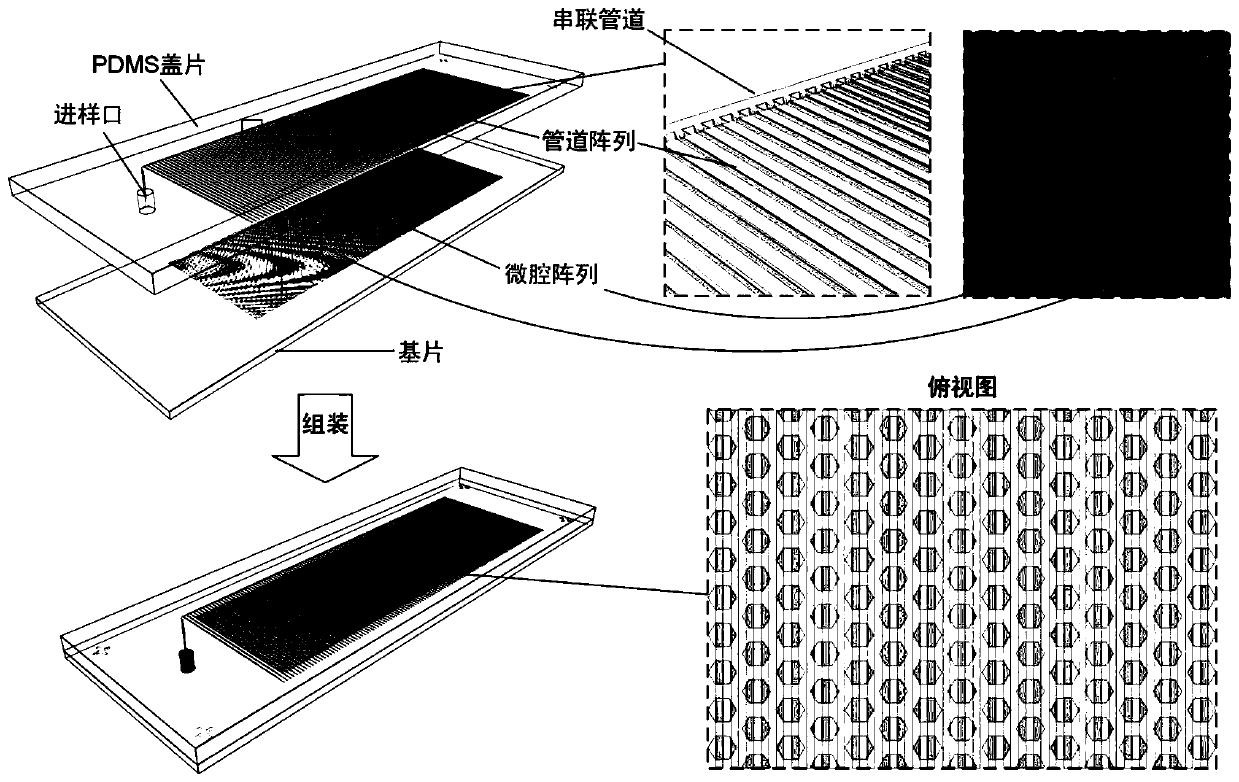

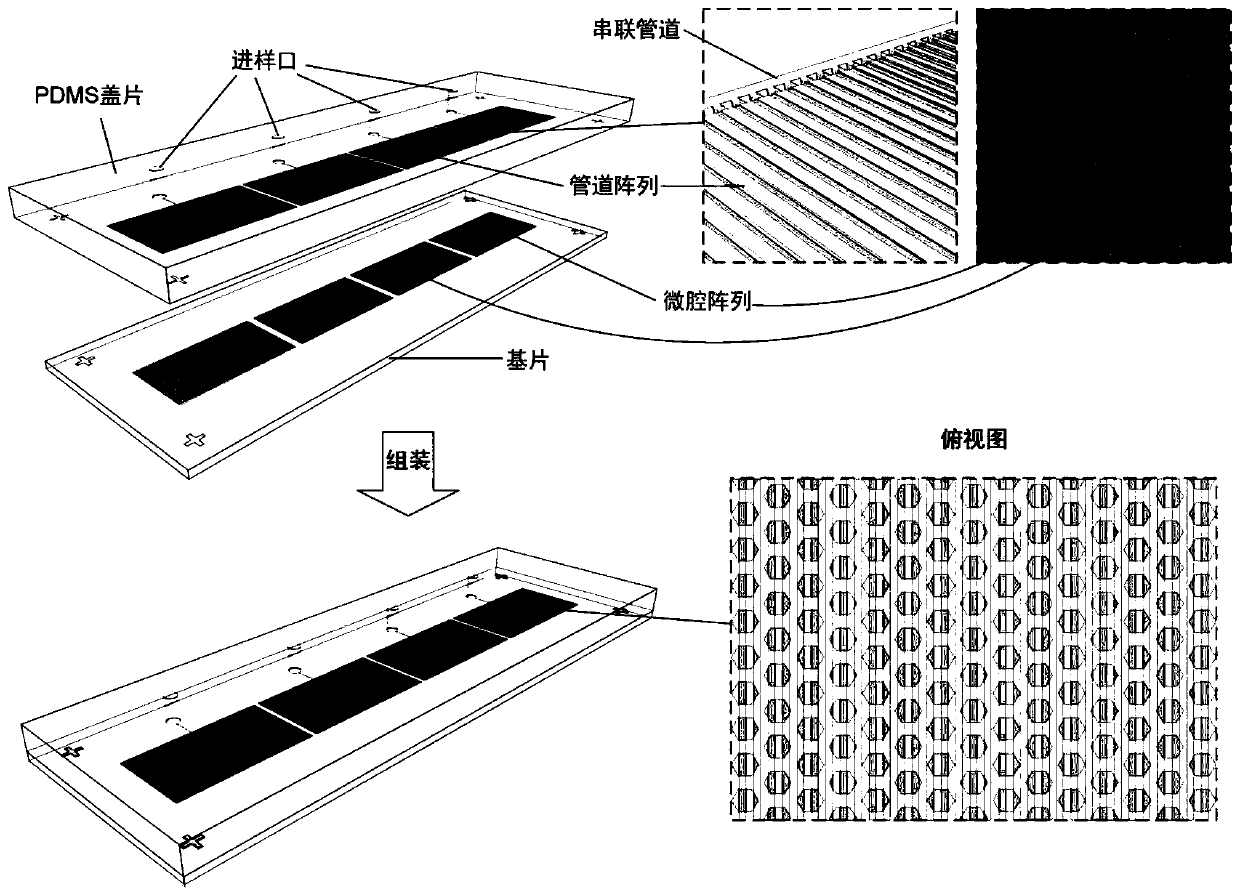

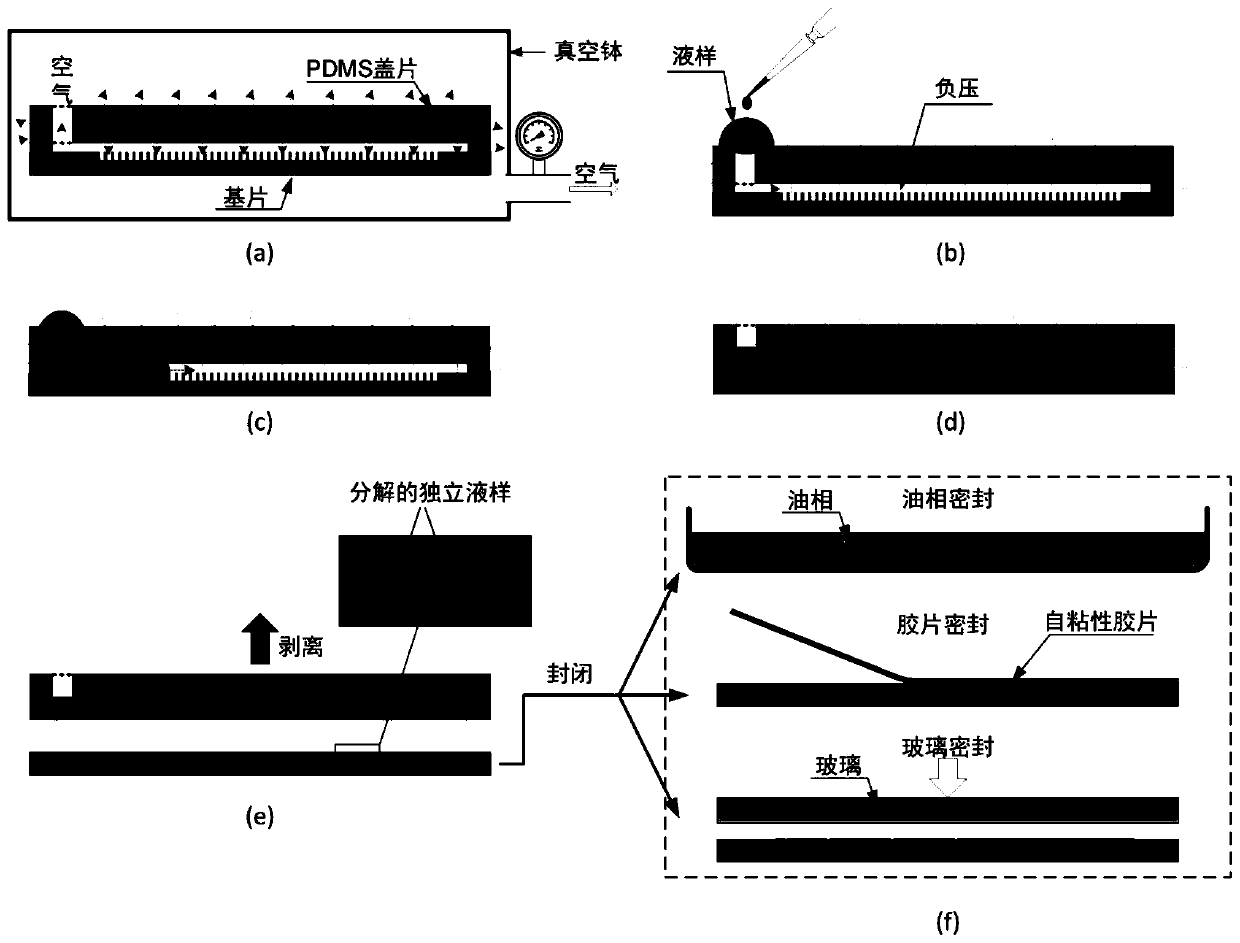

Large-scale and rapid digital decomposition chip for liquid phase samples, and use method thereof

ActiveCN110437992ARapid Digital DecompositionDigital Disaggregation RealizationBioreactor/fermenter combinationsBiological substance pretreatmentsDecompositionGas phase

The present invention relates to a large-scale and rapid digital decomposition chip for liquid phase samples and a use method thereof, and belongs to the technical field of microfluidic chip analysis.The chip is composed of a polydimethylsiloxane cover sheet integrated with micro-pipe arrays and a substrate sheet integrated with microcavity arrays in a reversible bonding manner. The chip realizesseparation of the micropipe arrays and the microcavity arrays, can increase arrangement density of microcavities per unit area of the chip, increases the digital decomposition number of the liquid samples, can also avoid lengthy digital decomposition operation steps based on removal of residual sample liquid in sample injection microchannels based on a gas phase or an oil phase, and greatly shortens time for large-scale and digital decomposition of the liquid phase samples. In addition, the use of the chip does not require precise micro-pump drive and complex micro-valve control, also does not require complicated macro-micro interfaces, can realize the large-scale automatic decomposition and uniform distribution of the liquid phase samples easily, quickly and at low cost, and is expectedto promote development and widespread application of a digital analysis technology.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com