Microchannel type photocatalytic microreactor based on nanorod array and preparation method thereof

A nano-rod array and micro-reactor technology, which is applied in the cross-field of nanotechnology, microfluidic technology and photocatalysis technology, can solve the problems of reducing the solid-liquid contact area of catalysts, the difficulty of agglomeration, separation and recovery of nano-catalysts, and large-scale application, achieving The effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

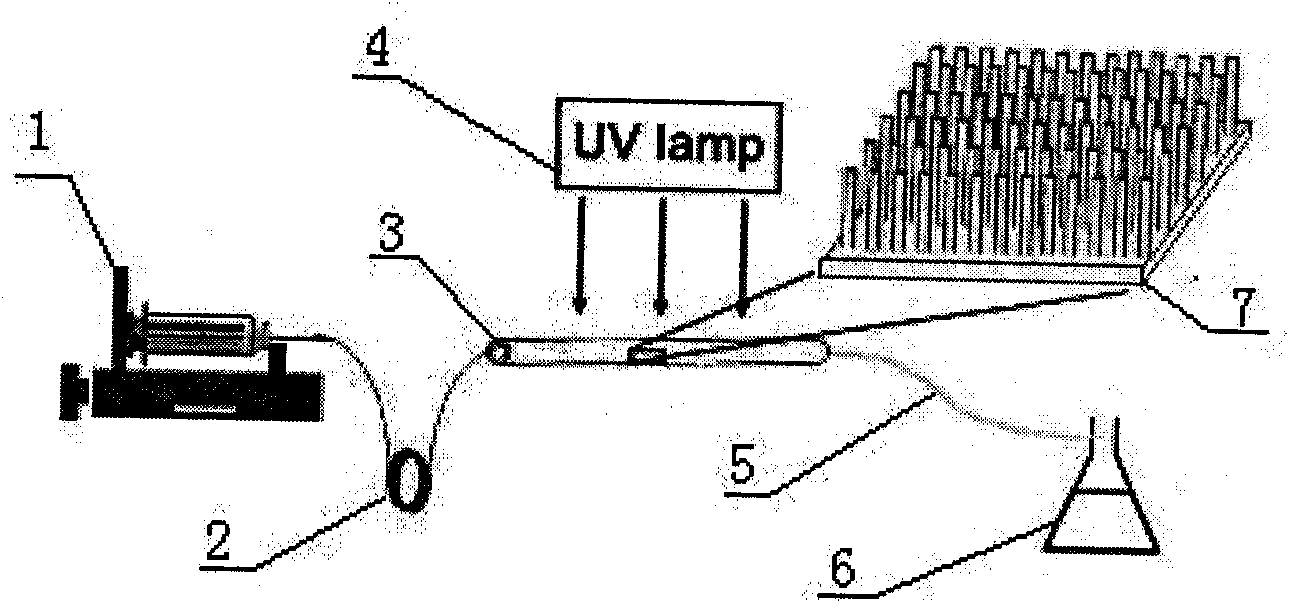

[0032] Embodiments of the present invention also relate to a preparation method of a microchannel photocatalytic microreactor based on a nanorod array, comprising the following steps: (1) selecting a quartz capillary as the microchannel in the photocatalytic zone; Prepare vertically grown semiconductor nanorod arrays on the surface as photocatalysts; (3) take two polytetrafluoroethylene microtubes as fluid delivery channels, and seal them to one end of the quartz capillary with epoxy resin, and then take a polytetrafluoroethylene The microtube is used as a fluid receiving channel, and is sealed to the other end of the quartz capillary with epoxy resin; (4) Two polytetrafluoroethylene microtubes used as fluid delivery channels are respectively connected to two syringes placed on the microinjection pump , place the UV lamp directly above the horizontally placed quartz capillary, and place the fluid receiver at the polytetrafluoroethylene microtube as the fluid receiving channel. ...

Embodiment 1

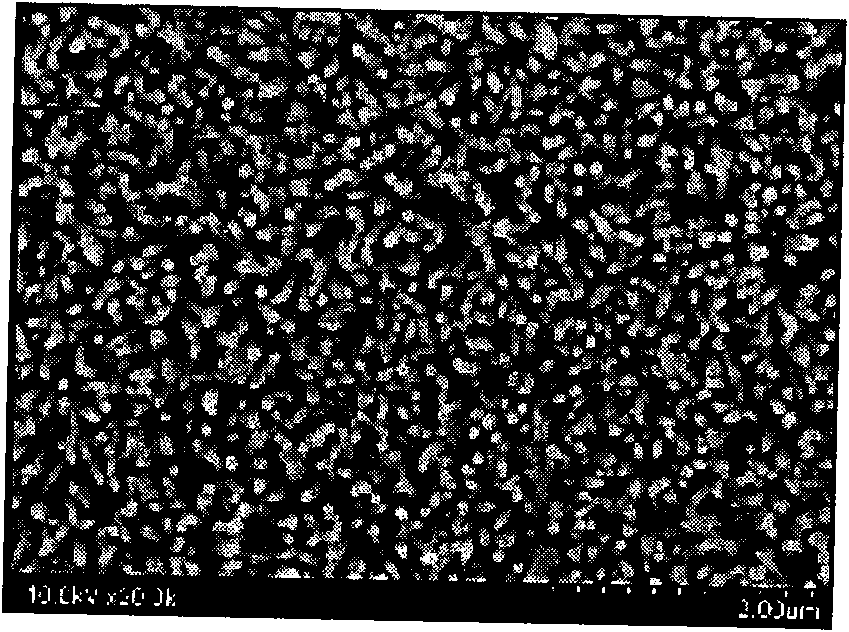

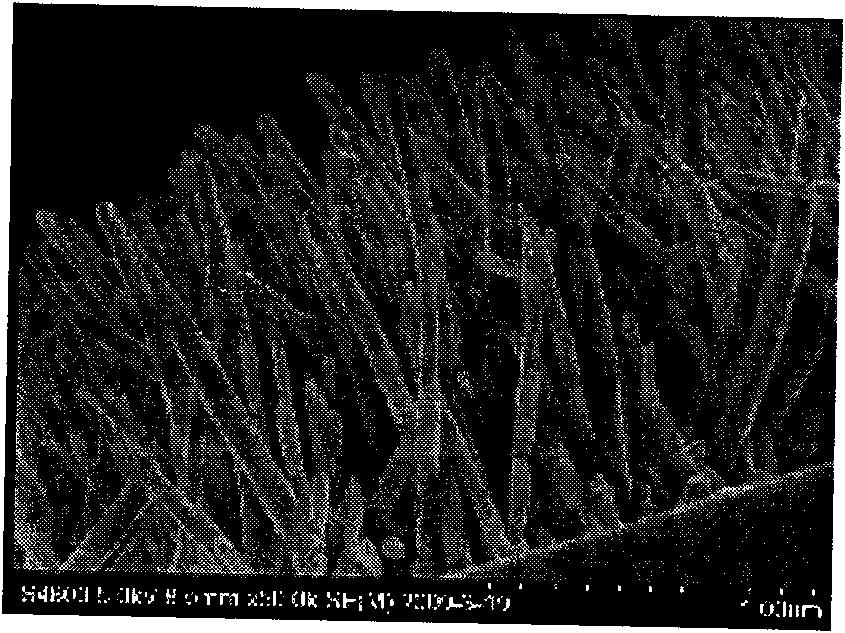

[0036] Example 1: Measure a quartz capillary with a length of 20 cm, an inner diameter of 530 μm, and an outer diameter of 660 μm with a ruler. ZnO nano-seeds were prefabricated on the inner surface of the quartz capillary microchannel by traditional liquid-phase chemical method, and then vertically grown ZnO nanorod arrays were prepared on the inner surface. figure 2 and image 3 For the field emission scanning electron microscope photo of the ZnO nanorod array on the microchannel inner surface that the present embodiment obtains, it can be seen that: the ZnO nanorod array vertically grows on the microchannel inner surface ( image 3 ), and evenly distributed ( figure 2 ). Then take two polytetrafluoroethylene microtubes with an inner diameter of 300 μm and a length of 80 cm as fluid delivery channels, and seal them to one end of the quartz capillary with epoxy resin, and then take another polytetrafluoroethylene microtube with an inner diameter of 800 μm and a length of ...

Embodiment 2

[0037] Example 2: Measure a quartz capillary with a length of 10 cm, an inner diameter of 550 μm, and an outer diameter of 700 μm with a ruler. ZnO nano-seeds were prefabricated on the inner surface of the quartz capillary microchannel by traditional liquid-phase chemical method, and then a vertically grown ZnO nanorod array was prepared on the inner surface, and TiO was introduced into the microchannel with the ZnO nanorod array. 2 nanosol and dried to obtain TiO 2 ZnO coated with nanoparticles, namely ZnO / TiO 2 nanorod arrays. Figure 5 The coupled semiconductor ZnO / TiO on the inner surface of the microchannel obtained in this embodiment 2 Field emission scanning electron microscope photograph of the nanorod array, it can be seen that compared with pure ZnO nanorods, TiO 2 The surface of the coated nanorods becomes slightly rougher and the diameter becomes slightly larger. Then take two polytetrafluoroethylene microtubes with an inner diameter of 400 μm and a length of 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com