Heat treatment method after silicon carbide monocrystal growth

A heat treatment method, silicon carbide single crystal technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of limited reduction effect, high requirements for crystal post-processing, high cost, etc., and achieve the reduction of the number of defects and easy Realize and improve the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

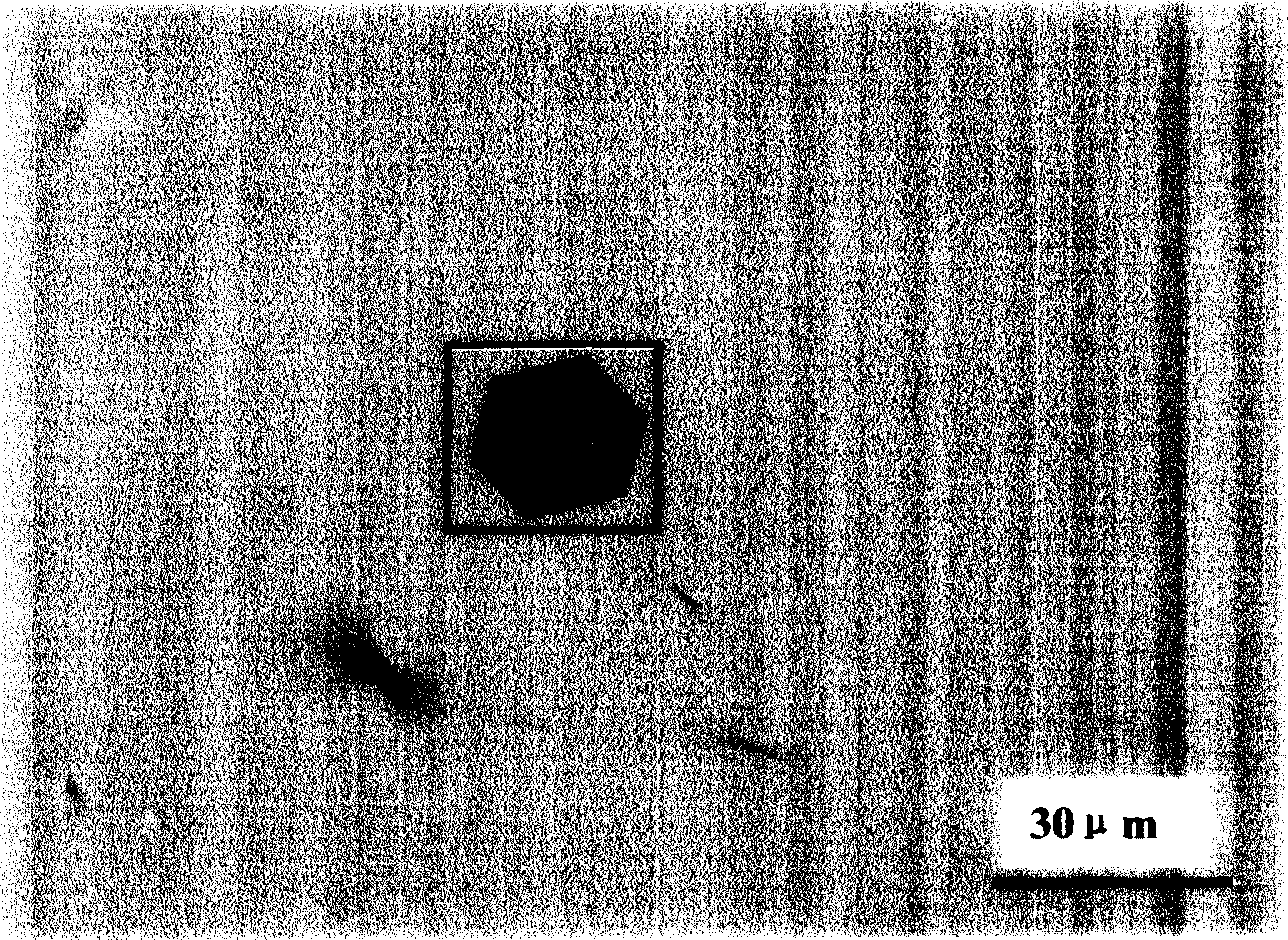

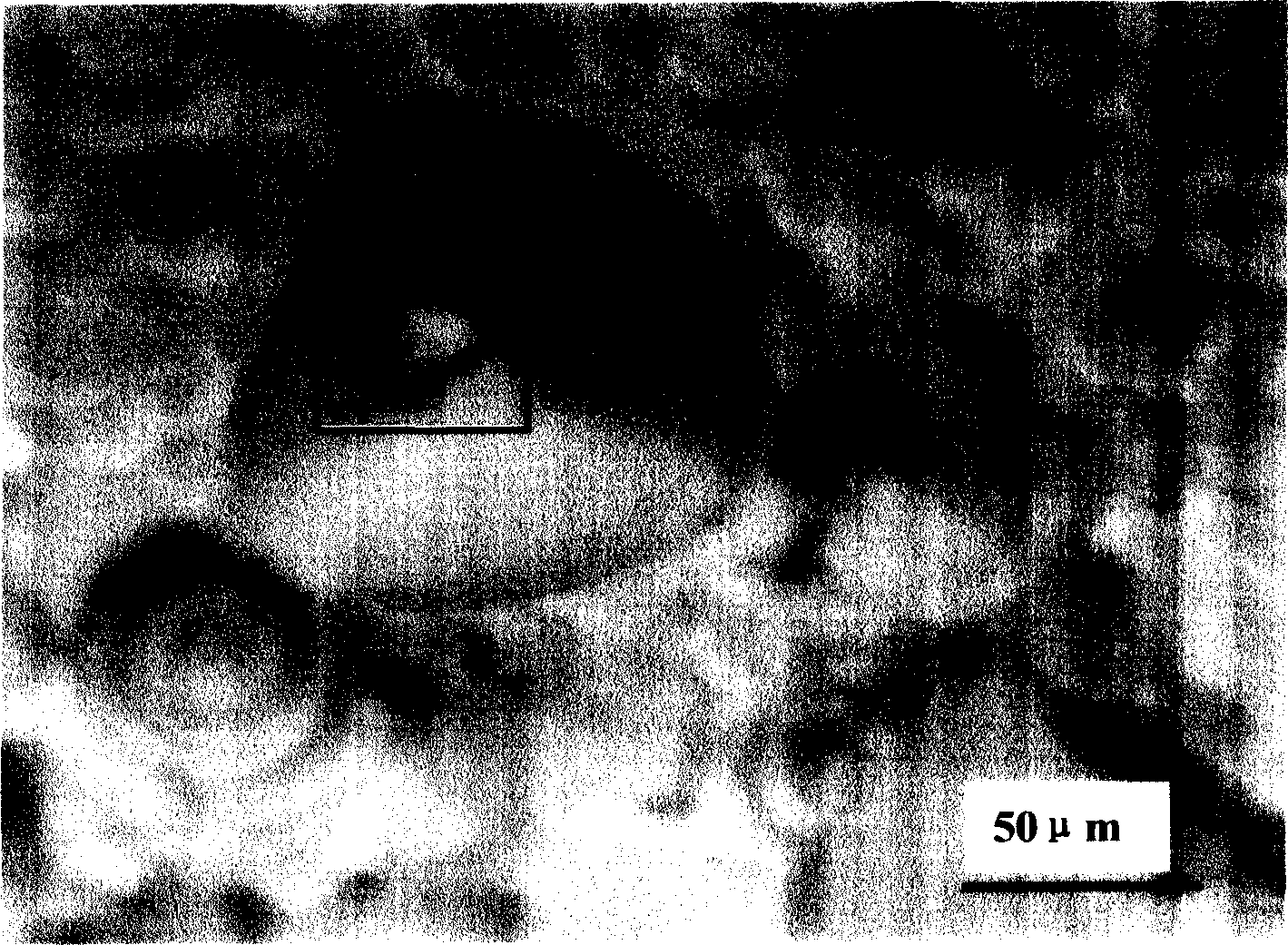

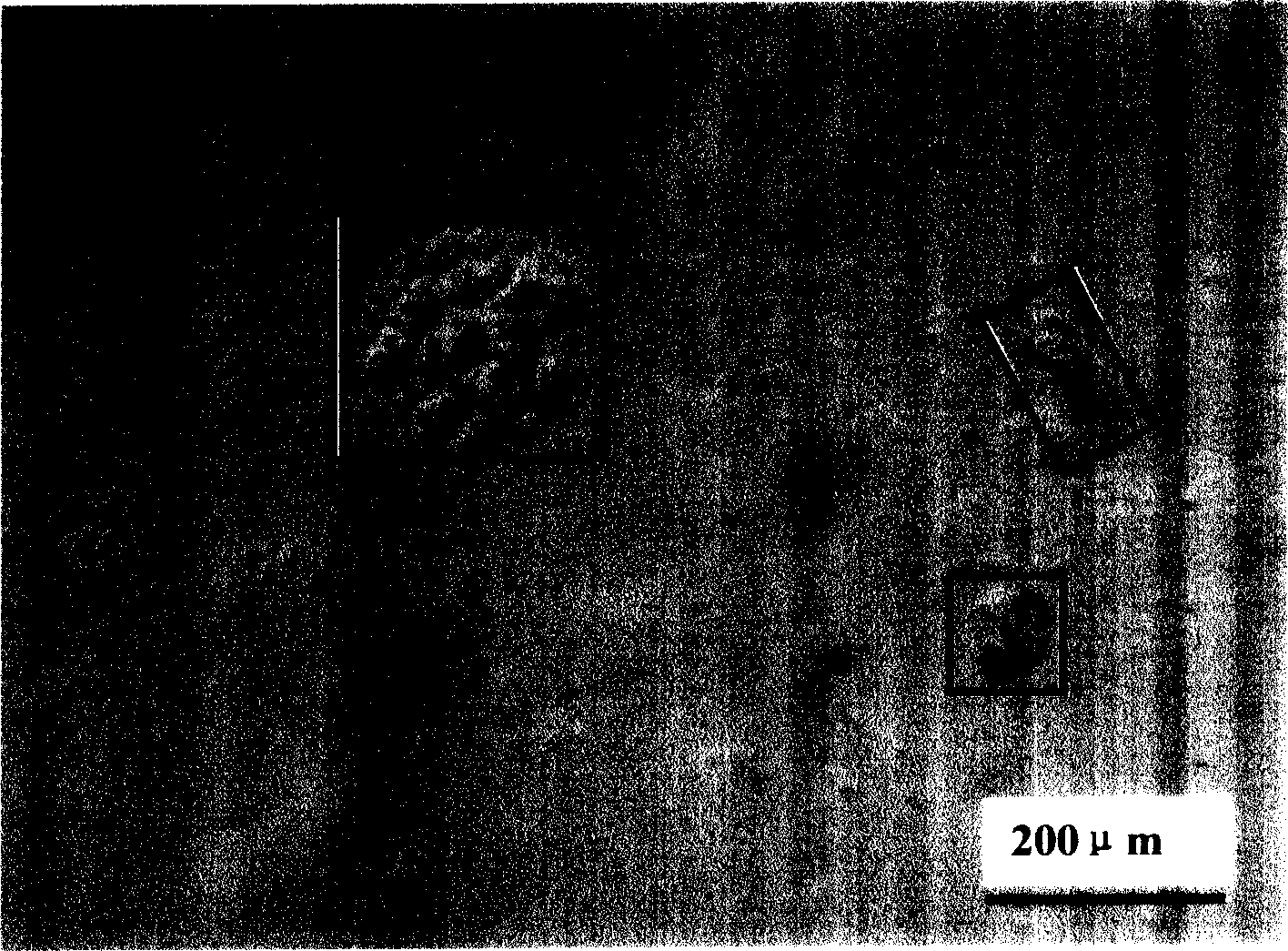

[0030] Cover a SiC single crystal with a diameter of 2 inches and a thickness of 1mm with a carbon film of 0.1mm thickness, and put it into a graphite crucible with an outer diameter of 80mm, a height of 80mm, an inner diameter of 70mm, and a depth of 75mm. The crucible contains 0.01mm particles with a height of 35mm A mixture of SiC powder and Si powder, the weight ratio of SiC powder and Si powder in the crucible is 10:1, and the SiC wafer coated with carbon film is placed in the powder at a height of 20 mm from the inner wall of the bottom of the crucible. Put the graphite crucible into the heating furnace, and after evacuating the heating furnace, pass Ar gas to make the pressure in the furnace reach 0.5 atm. Raise the temperature so that the temperature of the powder in the crucible reaches 2000°C, keep it warm for 0.5 hours and then cool it with the furnace to obtain a SiC single crystal that eliminates part of the microtubes and inclusions.

[0031] In this example, bef...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com