SERS (Surface Enhanced Raman Scattering) probe molecule self-collecting micropipe as well as preparation method and application thereof

A probe molecule and microtubule technology, applied in the field of SERS probe molecule self-collecting microtubule and its preparation, can solve the problems of limiting SERS application and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

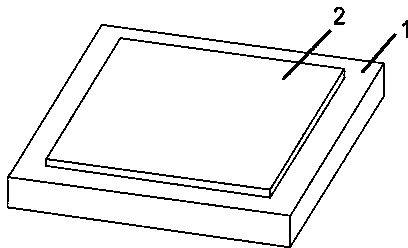

[0033] Si is selected as the substrate; a patterned photoresist layer is set on the Si substrate as a sacrificial layer, and the photoresist layer is covered on the surface of the Si substrate by spin coating, and the spin coating rate is 3000 rpm. The time is 35s.

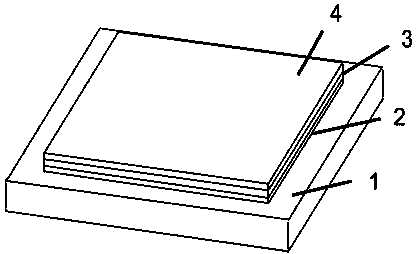

[0034] Using the physical vapor deposition method of electron beam evaporation, a microtube outer wall film with a thickness of 8 nm and made of Au was deposited on the sacrificial layer at a deposition rate of 3 ? / s; The film on the inner wall of the tube, the deposition rate is 0.3 ? / s;

[0035] Among them, during the deposition process, by changing the deposition parameters, such as deposition rate, substrate temperature and deposition pressure, etc., a thin film with required parameters can be prepared.

[0036] Make an angle of 60 degrees between the normal direction of the substrate and the incident direction of the evaporation source (7), such as Figure 7 As shown, there is a shadow effect in the deposit...

Embodiment 2

[0040] Similar to the previous embodiment, electron beam evaporation is used to deposit a thin film on the above-mentioned Si substrate covered with a sacrificial layer, and the material used is Au / TiO 2 / Pt, the deposition thickness is 8 nm / 8 nm / 6 nm, and the deposition rate is 3 ? / s, 0.5 ? / s, and 0.3 ? / s, respectively.

[0041]The crimping process is done by a supercritical dryer. The sample is immersed in acetone, and the sacrificial layer is removed with acetone to release the stress, so that the film above the sacrificial layer is curled up to form microtubes.

[0042] Put the obtained microtubules into a solution of ethanol with a lipoic acid content of 2.5mmol / L, soak for 14 hours to form a self-assembled monolayer on the outer surface, then rinse with deionized water, and finally obtain a self-assembled monolayer on the outer surface The membrane, ie the SERS probe molecules self-collecting microtubules.

[0043] Put the above sample into the triphenylmethane content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com