Large-scale and rapid digital decomposition chip for liquid phase samples, and use method thereof

A large-scale, sample technology, applied in chemical instruments and methods, biochemical equipment and methods, analytical materials, etc., can solve the problems of large influence, large flow resistance of micro-channels, and time-consuming decomposition process, so as to increase the layout Density, reduced time, effect of increasing the number of digital decompositions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

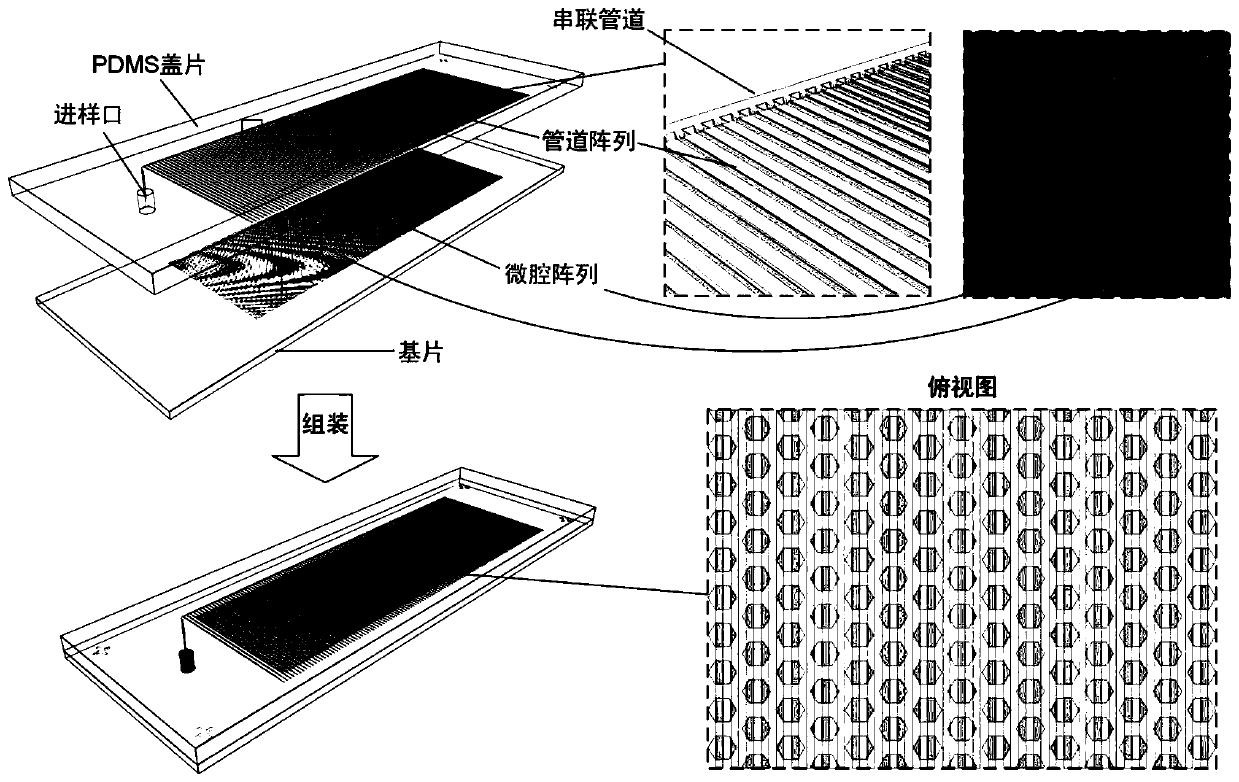

[0035] In the present invention, the large-scale and rapid digital decomposition chip of the liquid phase sample is applied in the digital PCR analysis

[0036] (1) Chip preparation: use soft lithography to fabricate an integrated micropipe array PDMS cover sheet and an integrated microcavity array PDMS substrate containing about 20,000 microcavities, wherein each microcavity is cylindrical in shape, The diameter is 100 microns, and the depth is 100 microns; the non-structural surface of the integrated microcavity array PDMS substrate is bonded to the glass plate to form a composite substrate, and then the side integrated with the microchannel array on the PDMS cover is integrated with the composite substrate. One side of the microcavity array is aligned and bonded, so that the micropipe array area covers the microcavity array area, and a large-scale and fast digital decomposition chip for liquid phase samples is obtained;

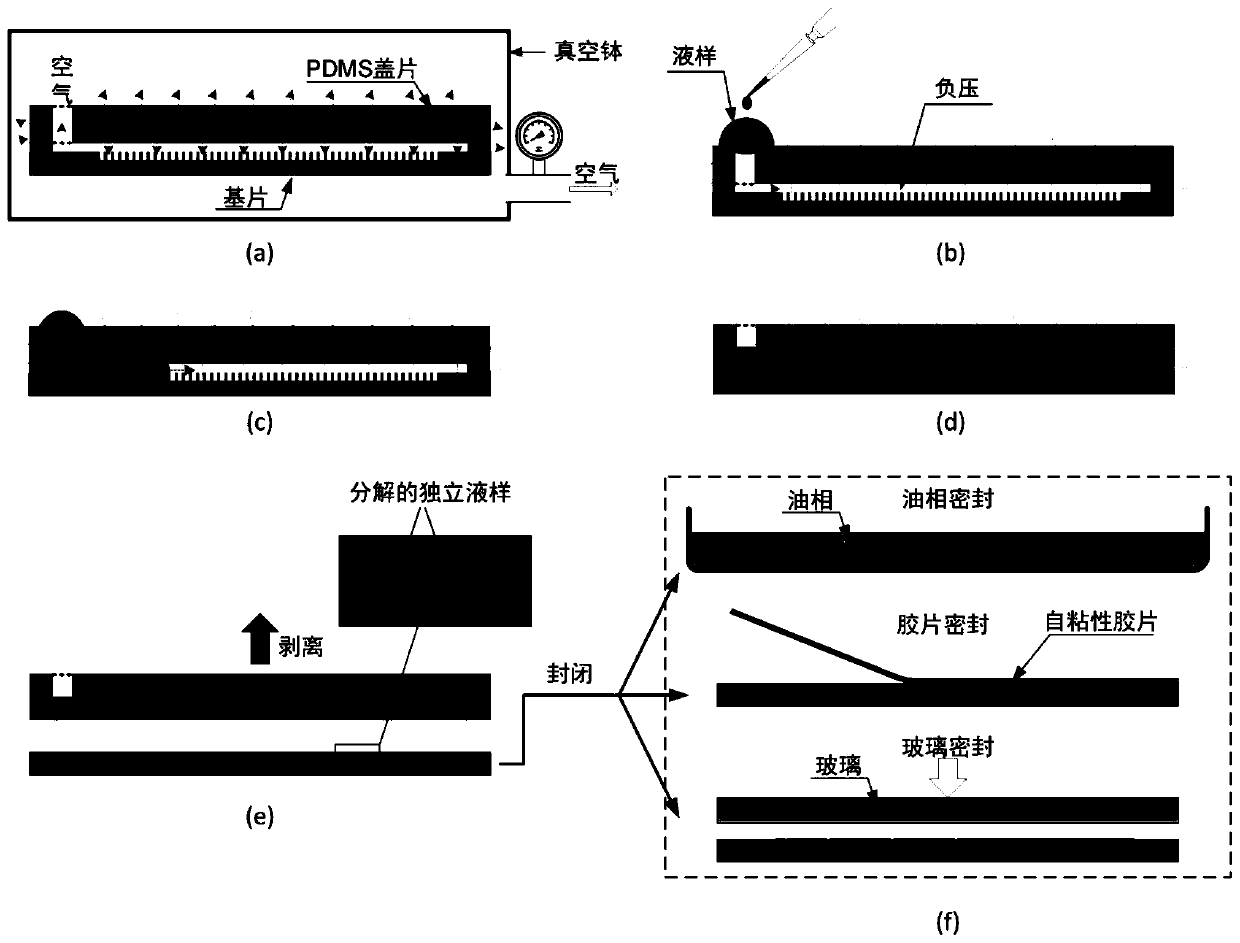

[0037] (2) Chip degassing: the chip obtained in step...

Embodiment 2

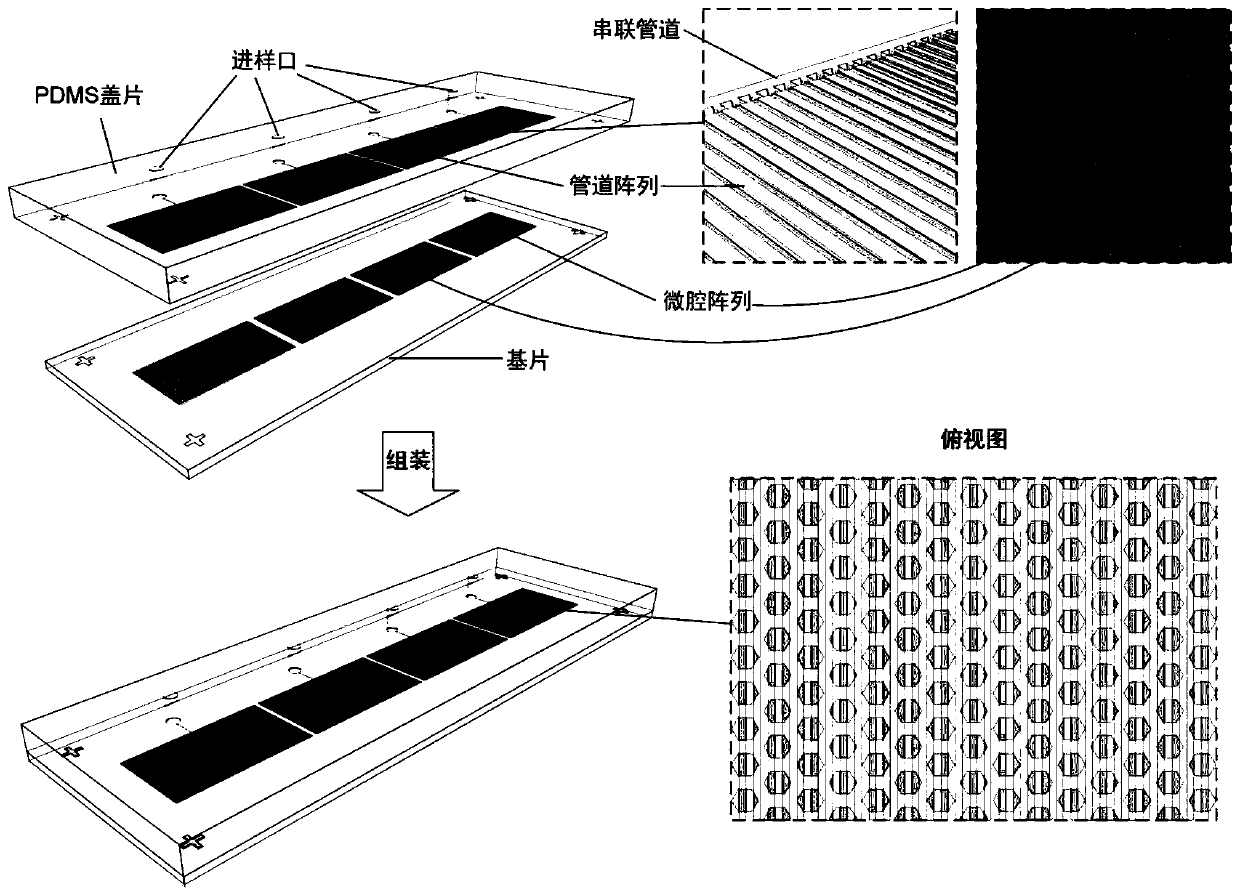

[0044] In the present invention, the large-scale and rapid digital decomposition chip of the liquid phase sample is applied in the digital ELISA analysis

[0045] The large-scale and fast digital decomposition chip of the liquid phase sample in the present invention is applied to the digital ELISA analysis, and the flow chart of the method for using the chip is as follows: Figure 5 shown.

[0046] (1) Chip preparation: using soft lithography technology to fabricate an integrated micropipe array PDMS cover sheet and an integrated microcavity array PDMS substrate containing about 100,000 microcavities, wherein each microcavity is cylindrical in shape, The diameter is 6 microns, and the depth is 5 microns; the side of the PDMS cover slip integrated with the micro-channel array is aligned with the side of the substrate with the micro-cavity array, so that the area of the micro-channel array covers the area of the micro-cavity array, and the liquid Large-scale and rapid digit...

Embodiment 3

[0054] In the present invention, the large-scale and rapid digital decomposition chip of liquid phase samples is applied in single-cell analysis

[0055] The large-scale and rapid digital decomposition chip of the liquid phase sample in the present invention is applied to single-cell analysis, and the flow chart of the method for using the chip is as follows: Image 6 shown.

[0056] (1) Chip preparation: using soft lithography technology to fabricate an integrated micropipe array PDMS cover sheet and an integrated microcavity array PDMS substrate containing about 100,000 microcavities, wherein each microcavity is cylindrical in shape, The diameter is 60 microns, and the depth is 50 microns; the side of the PDMS cover slip integrated with the micro-cavity array is aligned with the side of the substrate with the micro-cavity array, so that the area of the micro-pipe array covers the area of the micro-cavity array, and the liquid Large-scale and rapid digital decomposition ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com