Evaluation method for bulk silicon carbide single crystals and reference silicon carbide single crystal used in said method

一种碳化硅单晶、评价方法的技术,应用在通过测量材料受应力时其光学性质的变化力的计量、材料激发分析、力/扭矩/功测量仪等方向,能够解决再现性不充分、晶格常数差、晶格常数不同等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

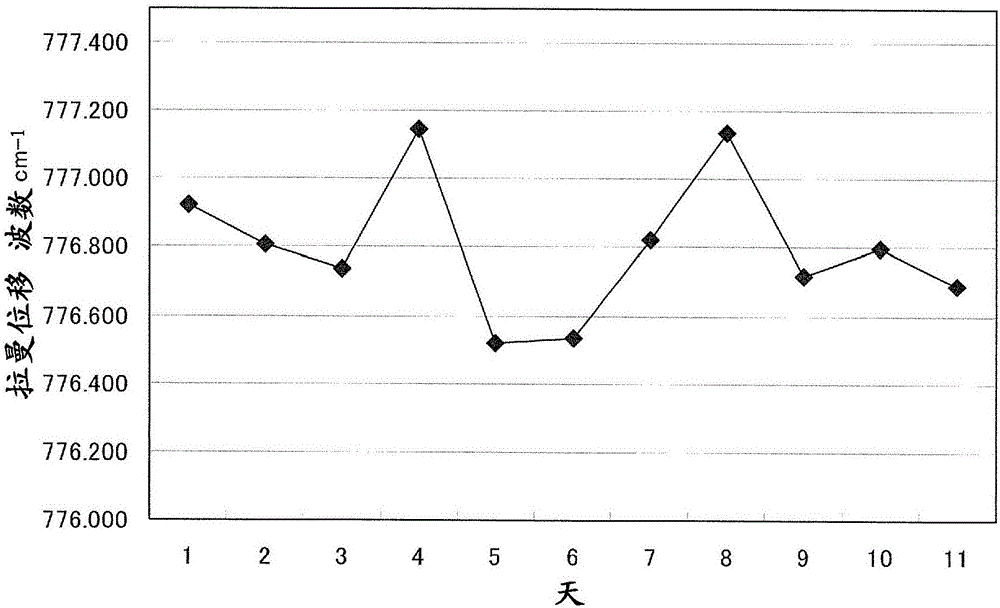

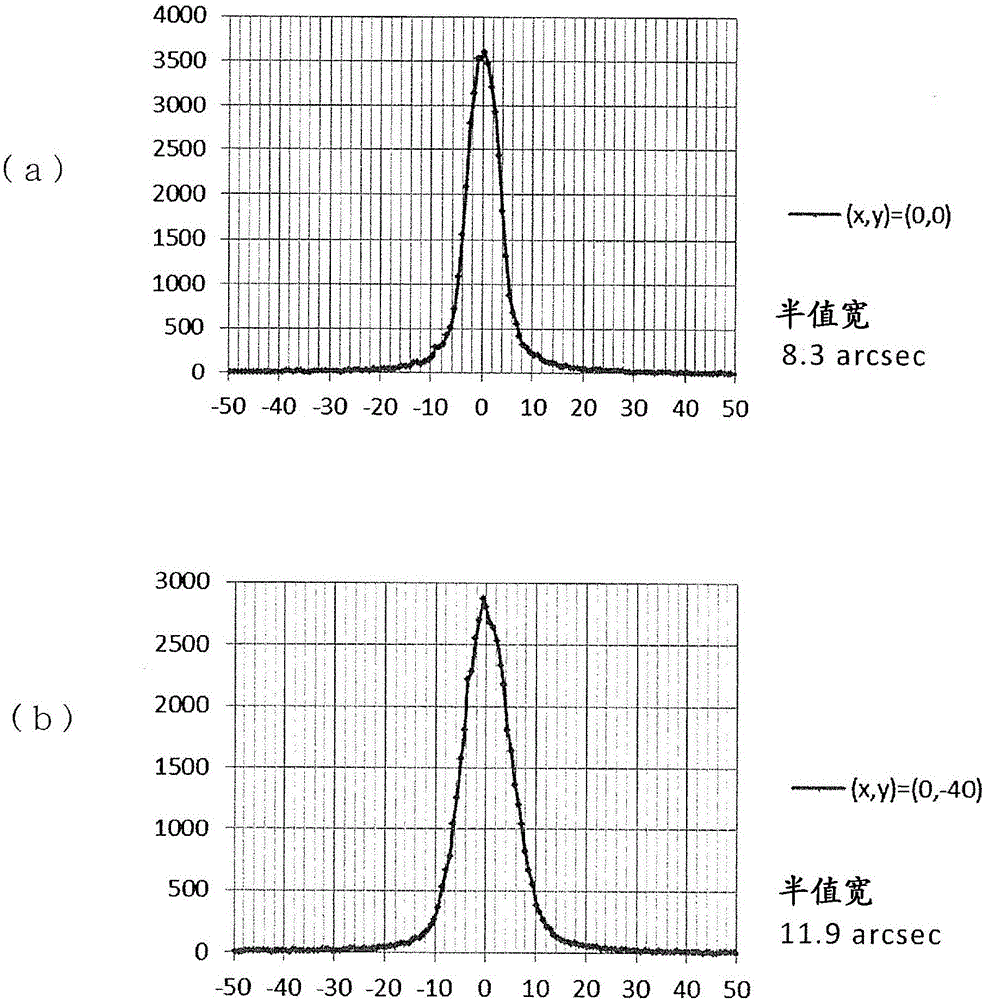

[0052] First, a 2-inch (diameter 55 mm) 4H-type SiC single crystal ingot manufactured by the sublimation recrystallization method was ground, cut into a thickness of 0.5 mm using a multi-wire saw, polished to a thickness of 0.36 mm by diamond polishing, and finally Chemical mechanical polishing (CMP) thereby processes the substrate. The surface roughness Ra was set at 0.1 nm. Then, a 10 mm square piece was cut out from the center of the substrate to obtain a SiC single crystal for reference with a thickness of 0.35 mm and a size of 10 mm×10 mm. Furthermore, a SiC single crystal ingot of the reference SiC single crystal was obtained, and the nitrogen concentration was 6×10 18 ~9×10 18 atom / cm 3 , In addition, observation of etch pits was carried out by molten alkali etching near the obtained reference SiC single crystal, and the result was that the dislocation density was 4.8×10 3 / cm 2 , 0.6 microtubules / cm 2 . Furthermore, an X-ray rocking curve was measured for a wafe...

Embodiment 2

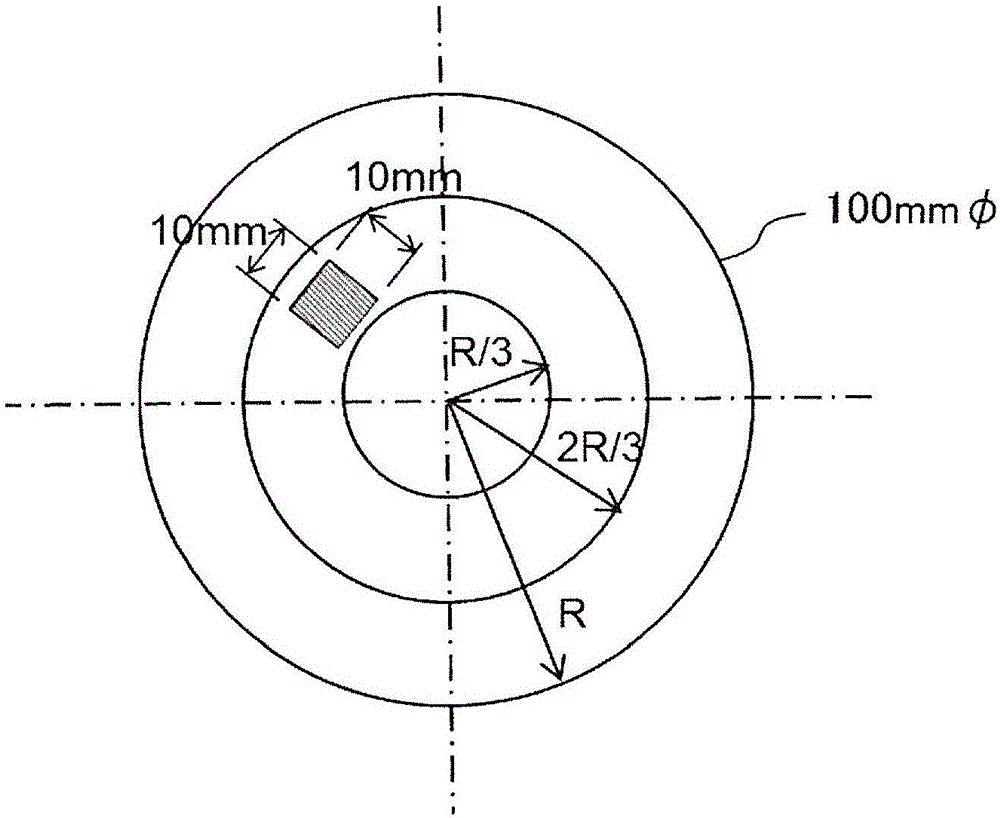

[0062] A 4-inch (diameter 105 mm) 4H-type SiC single crystal ingot manufactured by the sublimation recrystallization method is ground and cut into a thin plate with a thickness of 2 mm using a multi-wire saw, and the center part of the radius connecting the center and the circumference is cut. A 15mm square piece was cut out. In this Example 2, a slightly thick sheet was made in consideration of handleability. Next, the Si surface and the C surface were polished together by diamond polishing to obtain a reference SiC single crystal having a surface roughness Ra of 0.3 nm, a thickness of 1.9 mm, and a size of 15 mm×15 mm. Furthermore, a SiC single crystal ingot of the reference SiC single crystal was obtained, and the nitrogen concentration was 4.0×10 19 atom / cm 3 , In addition, the observation of corrosion pits was carried out by molten alkali etching near the obtained reference SiC single crystal, and the dislocation density was 3.7×10 3 / cm 2 , 0.3 microtubules / cm 2 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com