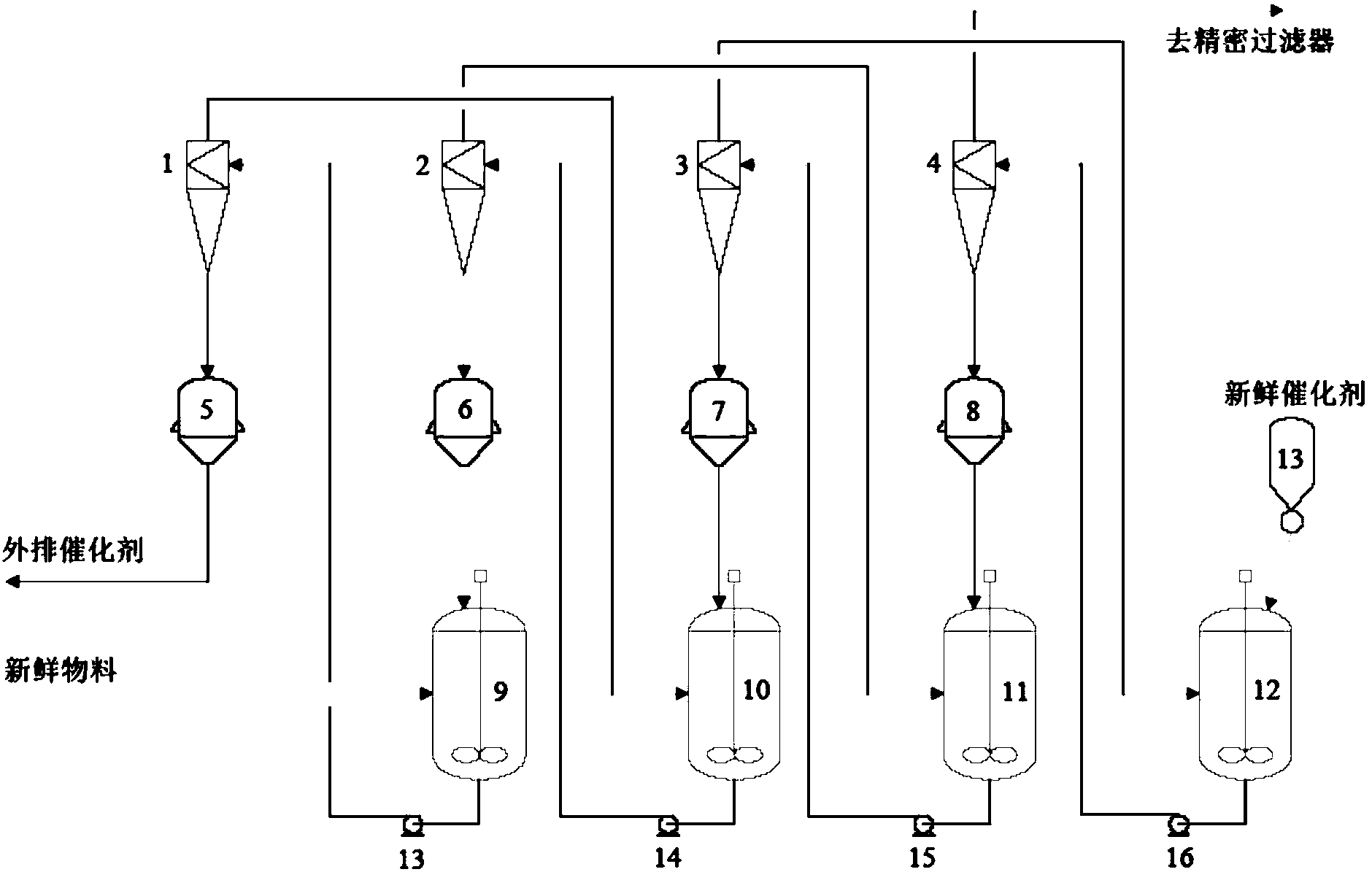

Method and device for utilizing catalyst in ethylidene norbornene isosynthesis technology

A technology for ethylidene norbornene and isomerization synthesis, which is applied in the chemical industry and can solve problems such as reducing work efficiency and removing deactivated catalysts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] In a 15,000-ton / year ENB isomerization synthesis device, according to the method and device of the present invention, it is used to maximize the high-efficiency utilization of the catalyst, and at the same time play a role in purifying the discharges of all levels and the final product, and continuously operate the device The spent catalyst is removed. Its specific operation process and effects are described as follows:

[0068] 1. Operating conditions

[0069] The device adopts 4-stage series stirred reactors, with a single full volume of 12.5m 3 , filling coefficient 0.6, material filling volume 7.5m 3 . The reactor is operated intermittently, the residence time of a single reactor is 8 hours, and the reaction unloading time is 1 hour. The feed to the first-stage reactor is 8063kg / time, the output to the last-stage reactor is 7200kg / time, and the catalyst feed is 237kg / time. The graded cyclone at all levels is composed of six DN50 cyclone tubes connected in paral...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com