Etching device for high precision silicon senser chip

A sensor chip and corrosion device technology, applied in microstructure devices, manufacturing microstructure devices, decorative arts, etc., can solve problems such as easy undercutting, high requirements on process operations, and long processing time, and achieve a high degree of centralized control. , Improve the quality of the reaction, speed up the effect of the reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

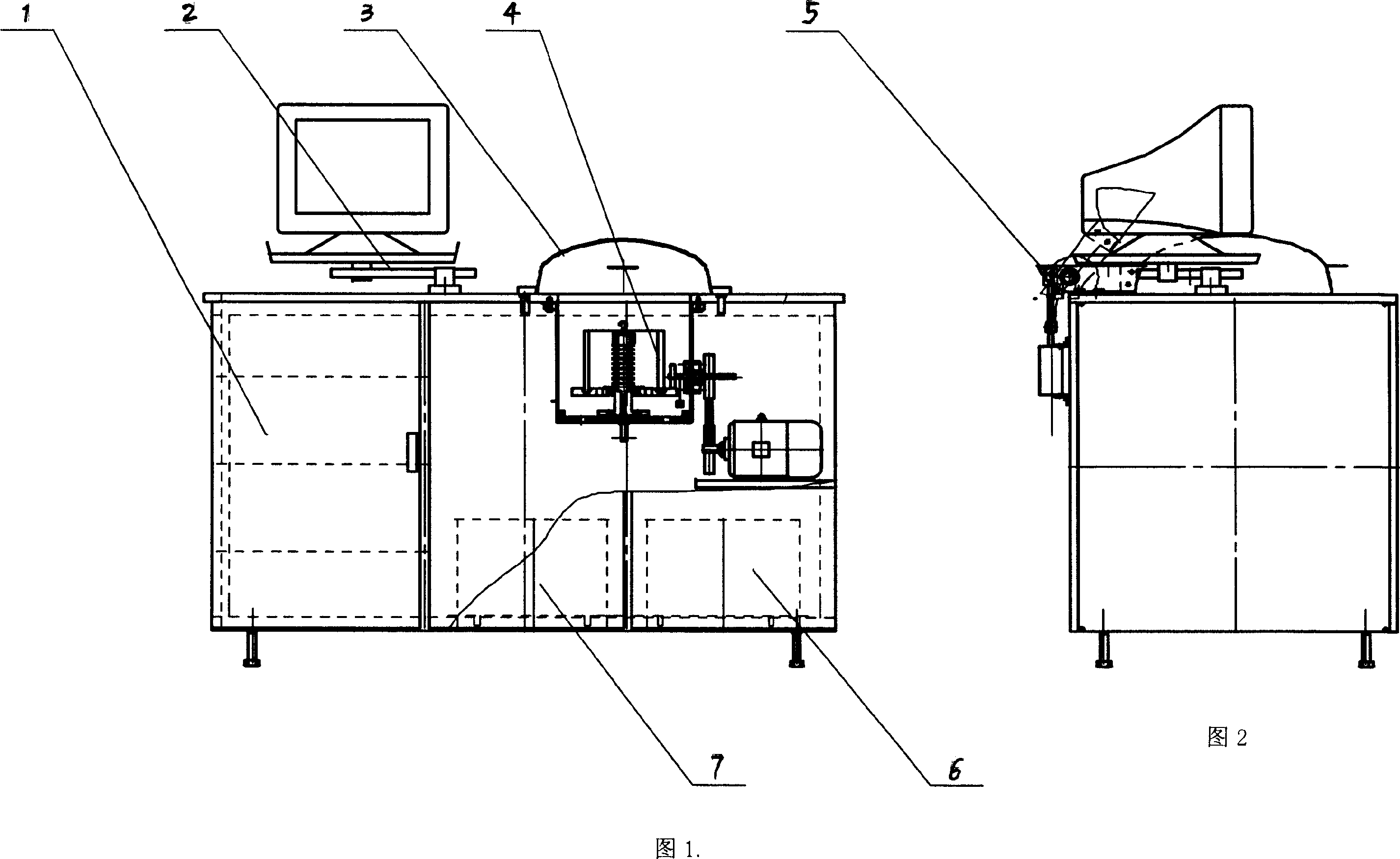

[0020] The composition of each component part of device of the present invention is illustrated in conjunction with accompanying drawing:

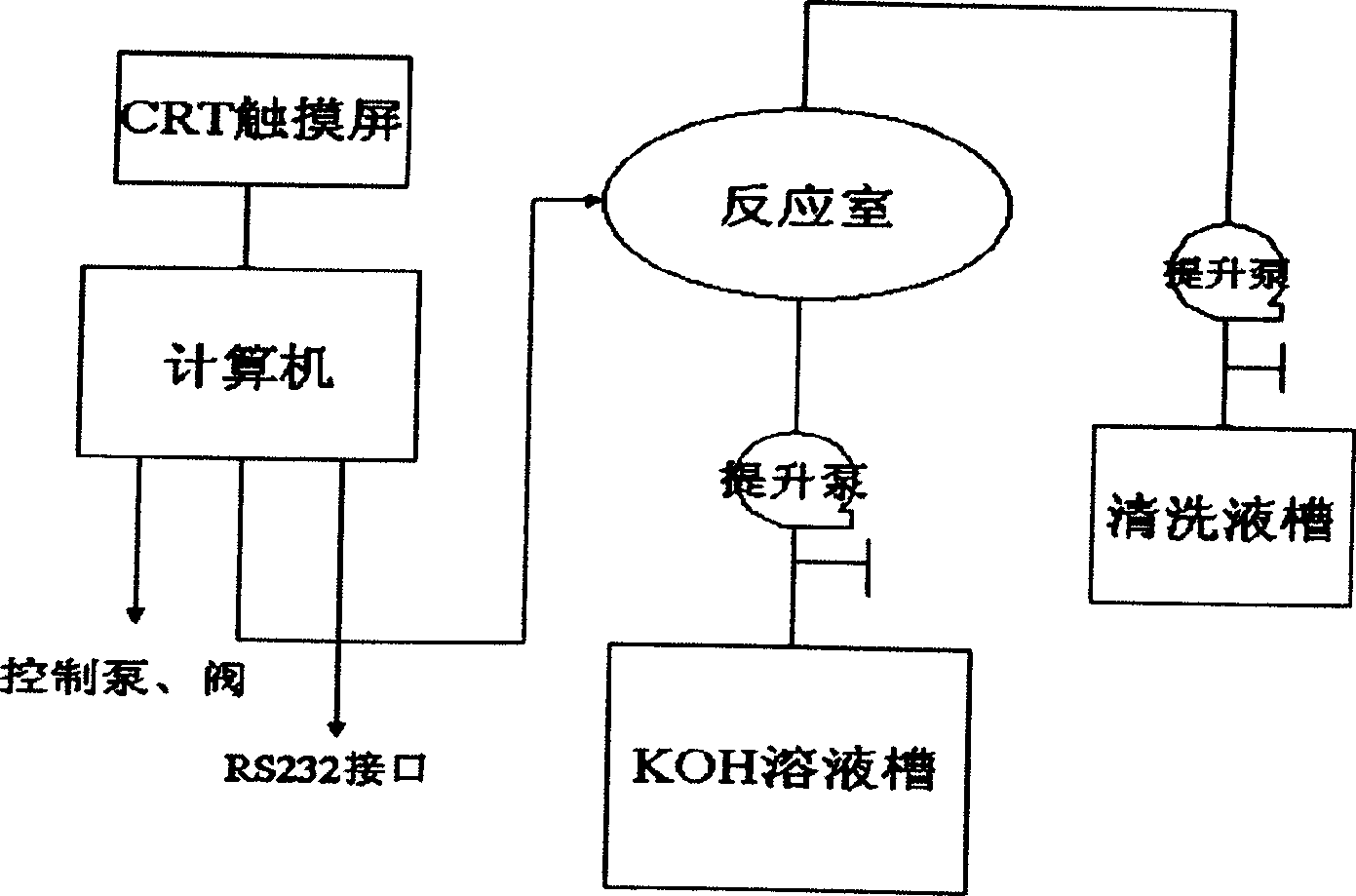

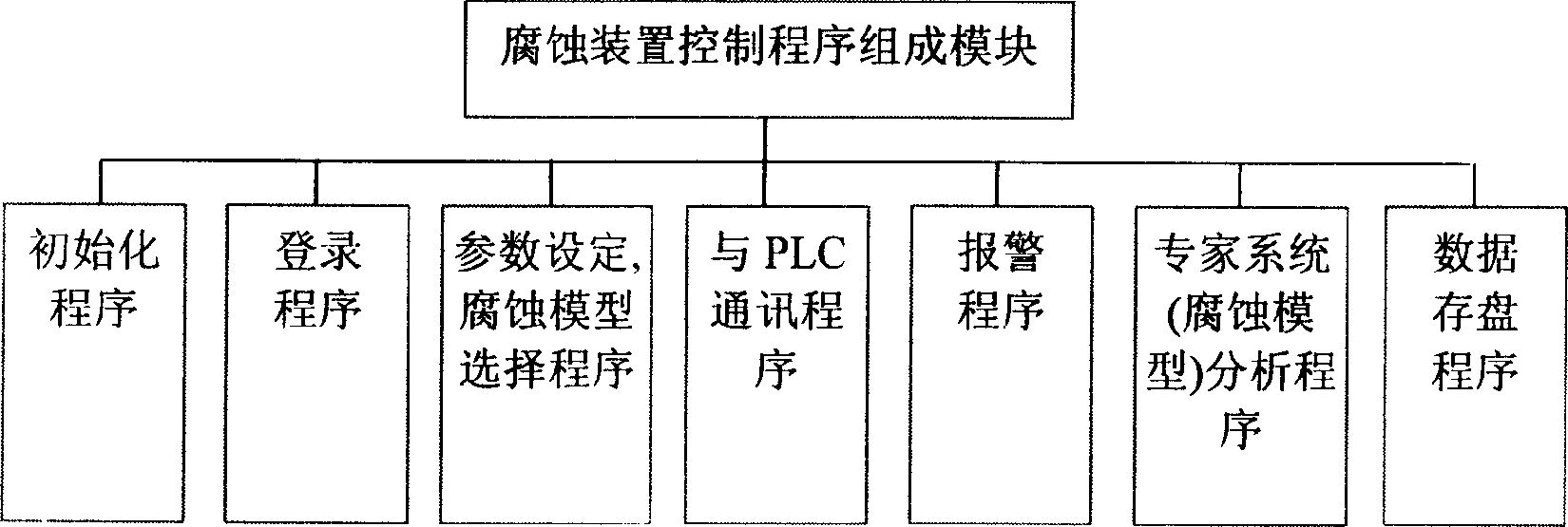

[0021] High-precision silicon sensor chip etching device, see image 3: It includes an industrial computer, a reaction chamber, a KOH liquid storage tank, and a cleaning liquid storage tank. It is characterized in that the computer 2 of the device 1 has a CRT touch screen and an operation control program, and communicates with the control circuit of the electric control cabinet, the reaction chamber 4 and the tube through the communication interface. The valves and pumps on the road are connected; the reaction chamber has a built-in transmission spray mechanism, and its spray pipe is connected to the submerged pump of the KOH liquid storage tank 7 and the cleaning liquid storage tank 6 through the liquid pipeline; the probes for temperature measurement and concentration measurement are respectively Set in the reaction chamber 4.

[0022] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com