Process for ordinary pressure continuous synthesizing silicon nitride powder by fluidized bed tech.

A technology of silicon nitride powder and silicon nitride, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of high equipment cost and poor safety, reduce production cost, improve production efficiency, and improve production safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

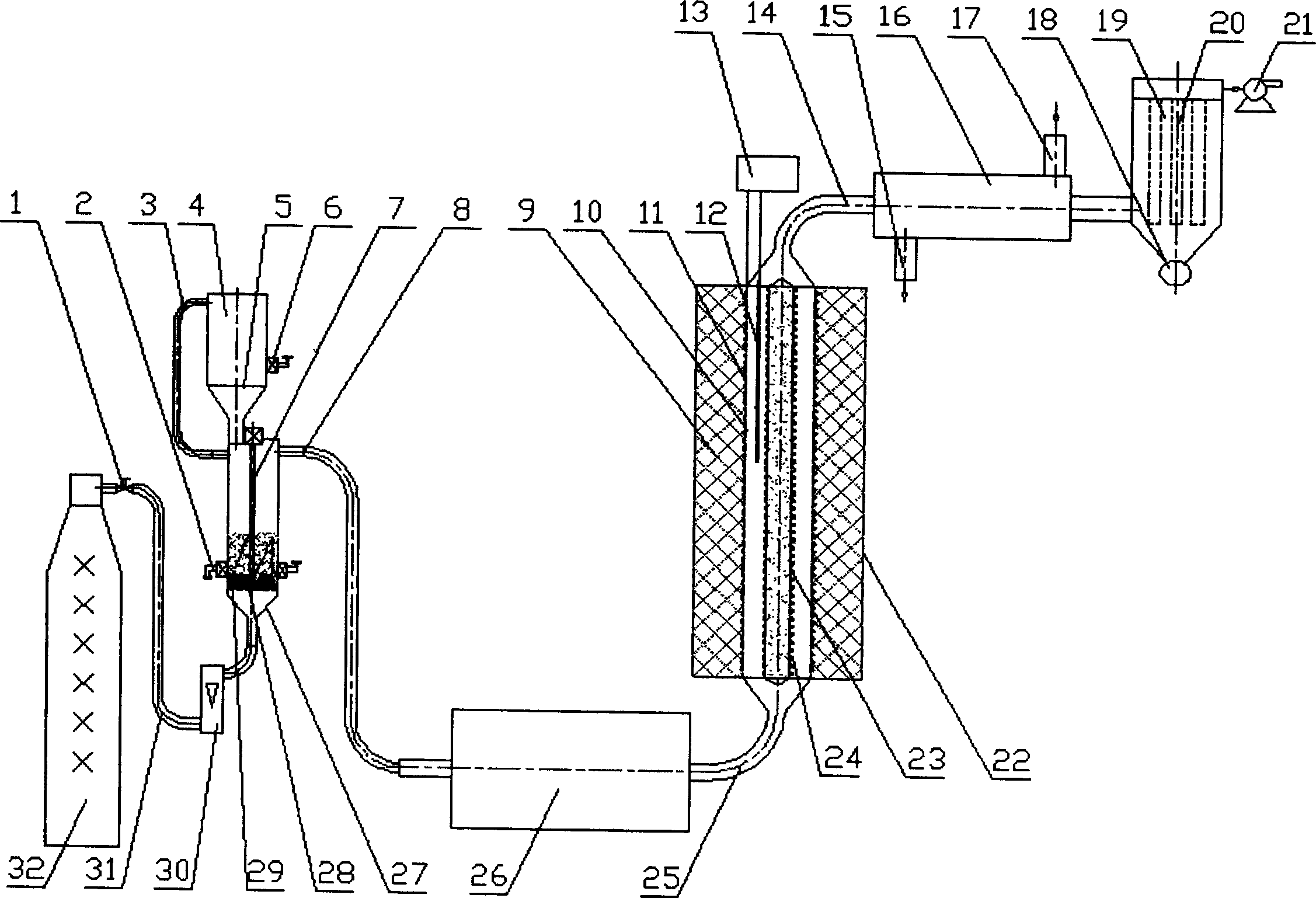

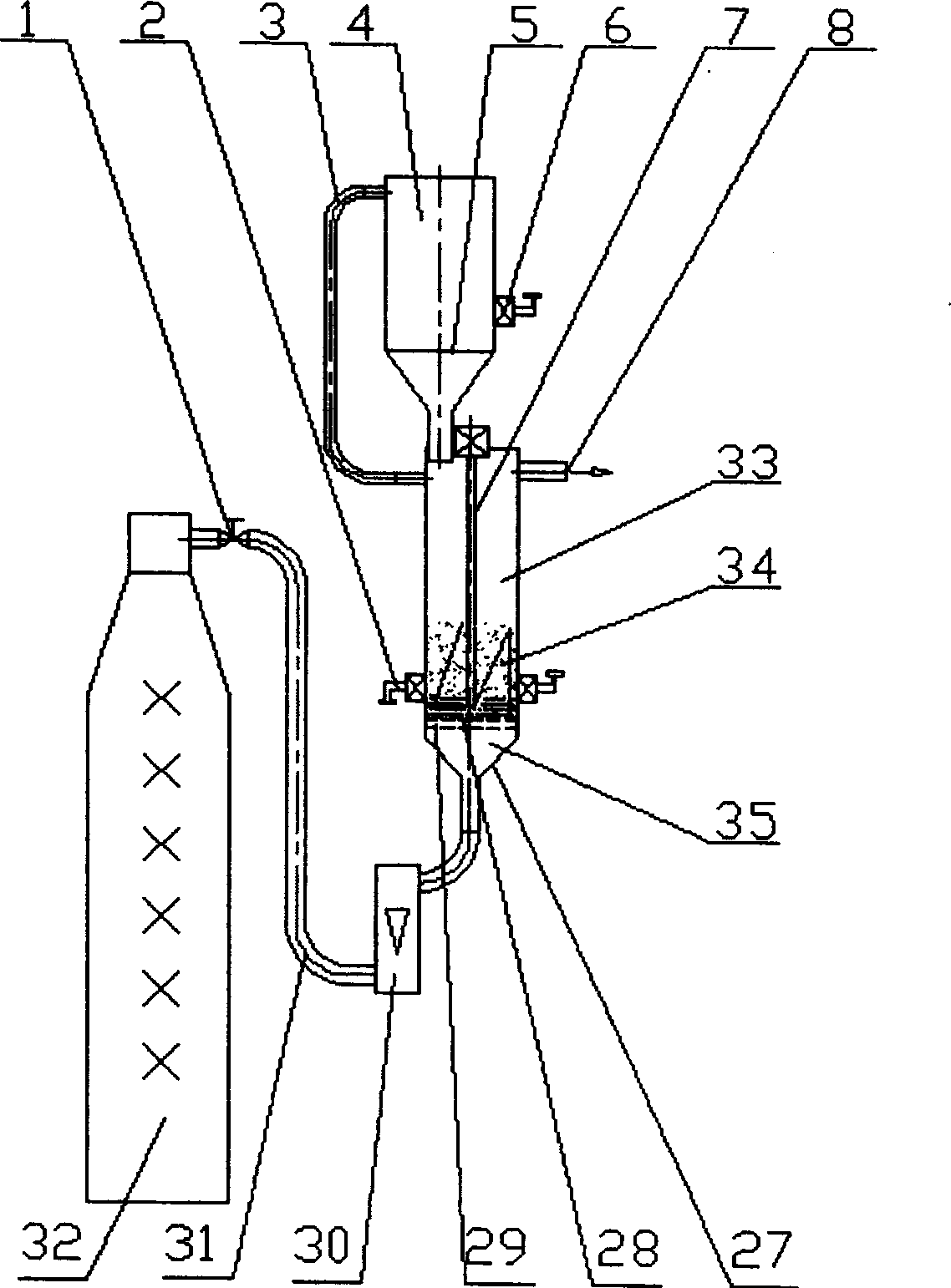

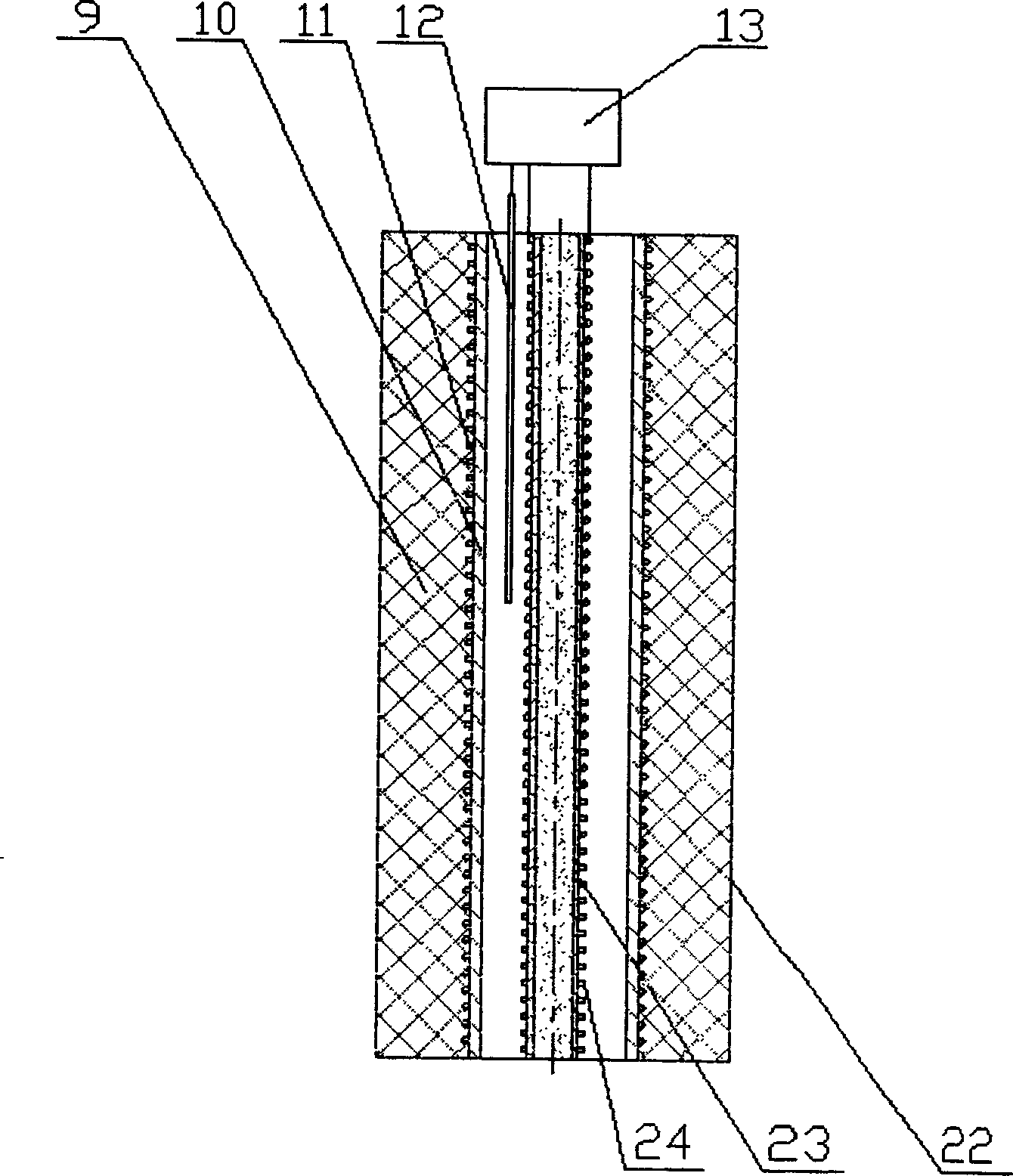

Method used

Image

Examples

Embodiment 1

[0031]Example 1: Put 60g of Si powder with an average particle size of 10 μm in an oven, dry at 90°C for 8 hours under the protection of nitrogen, and stir once every 1 hour to speed up the drying speed, and then put the dried silicon powder in Sieve in a 400-mesh sieve, collect the sifted silicon powder and put it into a vibrating fluidized feeder. The inner diameter of the vibrating feeder is 40mm, and the height is 200mm. The particles are hollow alumina balls with a diameter of 100 μm, and high-purity nitrogen gas is introduced from the bottom, and the nitrogen flow rate is 0.3m 3 / h. After the silicon powder is rapidly fluidized by nitrogen, under the vibration force of the vibration motor, the stirring of the stirring motor and the impact of the fluidized particles, the agglomerated ultrafine powder is broken and entrained to form a gas-solid two-phase flow. It is preheated to 900°C by an electric heating tube preheater. The inner diameter of the inner tube of the prehe...

Embodiment 2

[0032] Example 2: Mix Si powder with an average particle size of 20 μm and silicon nitride powder as a nucleating agent at a mass ratio of 1:1, take 120 g of the powder, put it in an oven, and store it at 90 ° C under nitrogen protection. Dry for 8 hours, and stir once every 1 hour to speed up the drying speed. Then put the dried material into a 400-mesh screen and sieve it. Collect the sieved material and put it into the storage bin. The inner diameter of the storage bin is 80mm , with a height of 100mm. Turn on the vibrating screening motor, and some materials will fall into the vibrating fluidized feeder. When the height of the material reaches 60mm, turn off the vibrating screening motor. The inner diameter of the vibrating feeding device is 40mm, the height is 200mm, 2 vibration motors, 1 stirring motor, the fluidized particles are hollow alumina balls with a diameter of 100μm, and high-purity nitrogen gas is introduced from the bottom, and the flow rate of nitrogen gas i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com