Preparation method of low-density polyimide soft foam

A polyimide and low-density technology, applied in the field of preparation of low-density polyimide soft foam, can solve the problems of low compression and tensile strength of polyimide foam, achieve no degradation in performance, and speed up reaction quality , the effect of speeding up the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

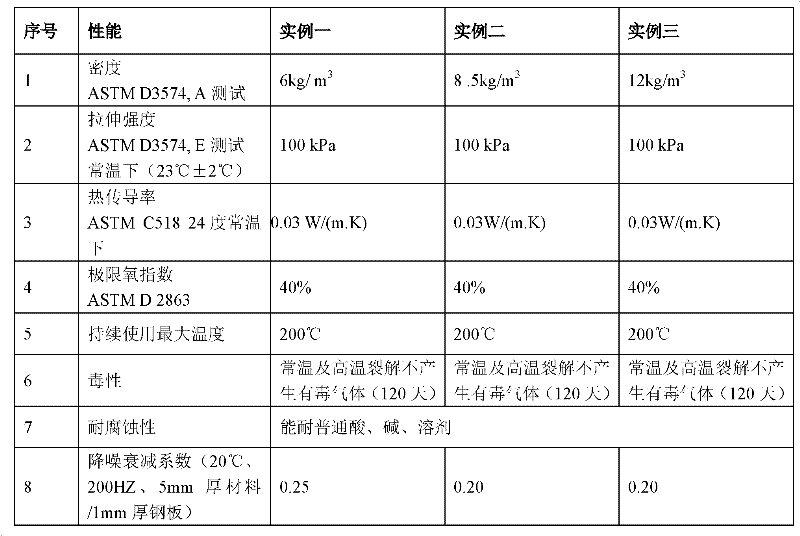

Examples

example 1

[0037] low density foaming powder

[0038] Spread 150g of A powder on a 30×30×12cm tray, put it into a microwave oven, 600W power, 180°C foaming, the foaming ratio is about 35 times within 20 minutes, and the density is controlled at 6.5KG / M 3 , increase the power to 2000W, turn on the dual-bond polymerization aging after 15 minutes, and age in an oven at 320°C for 5 hours to obtain a low-density product foam.

example 2

[0040] Foaming with higher density foaming powder

[0041] Add 30 grams of powder B and 120 grams of powder A to obtain 150 g of mixed powder, spread them all on a tray of 30×30×12 cm, put them in a microwave oven, 600W power, foam at about 180°C, and foam after 20 minutes The magnification is about 28 times, the power is increased to 2000W, the preliminary polymerization aging is carried out for 20 minutes, and the aging is carried out in an oven at 320°C for 5 hours to obtain a foam with a higher foaming density.

example 3

[0043] Foaming with higher density foaming powder

[0044] The amount of powder B added is 60 grams, and the amount of powder A added is 90 grams to obtain 150 g of mixed powder. Spread them on a tray of 30×30×12 cm, put them in a microwave oven, 600W power, foam at about 180°C, and the foaming ratio after 20 minutes About 18 times, increase the power to 2000W, conduct preliminary polymerization aging for 20 minutes, and age in an oven at 320°C for 5 hours to obtain foam with higher foaming density.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com