High-temperature micro-nano press mark test device and method in vacuum environment

A vacuum environment and testing device technology, applied in measuring devices, testing material hardness, instruments, etc., can solve problems such as inability to provide test pieces and indenters, measurement signal drift, and inability to guarantee the temperature difference between indenters and test pieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

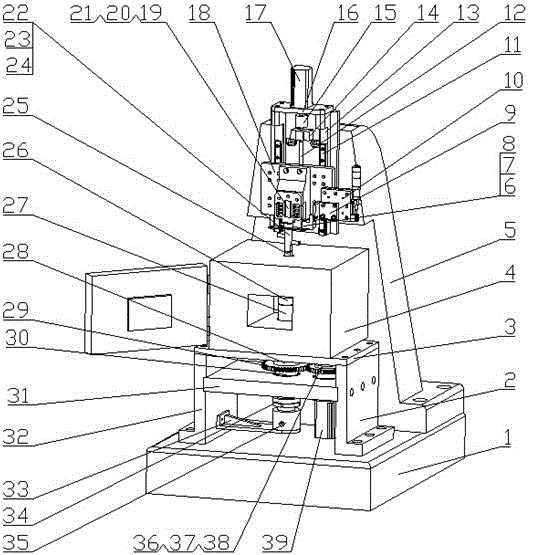

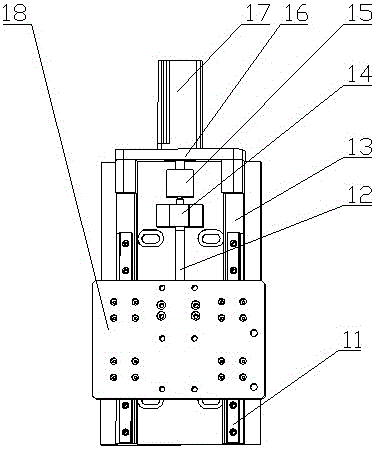

[0085] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

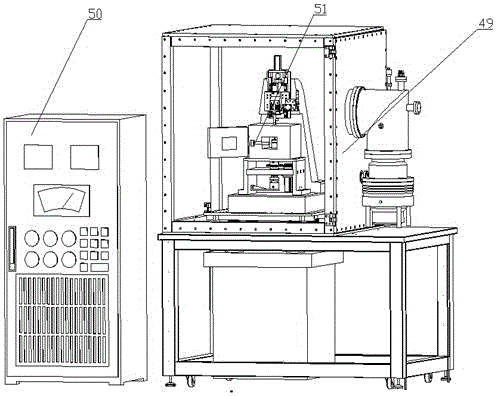

[0086] see figure 1 and figure 2 As shown, the high-temperature micro-nano indentation test device in a vacuum environment of the present invention is mainly composed of six parts: a frame, a Z-direction macro adjustment module, an indentation precision loading module, an indentation test module, a heating module and an eccentric point change mechanism. . The device is small in size and easy to integrate in the vacuum chamber system to prevent the oxidation of the indenter and the test piece, thereby increasing the test temperature. The main body of the device is fixed in the vacuum chamber system 49 through the marble base 1 . The Z-direction macro adjustment module is assembled on the marble substrate 5 . The indentation precision loading module is installed on the Z-direction macro adjustment module throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com