Patents

Literature

73 results about "Indentation testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

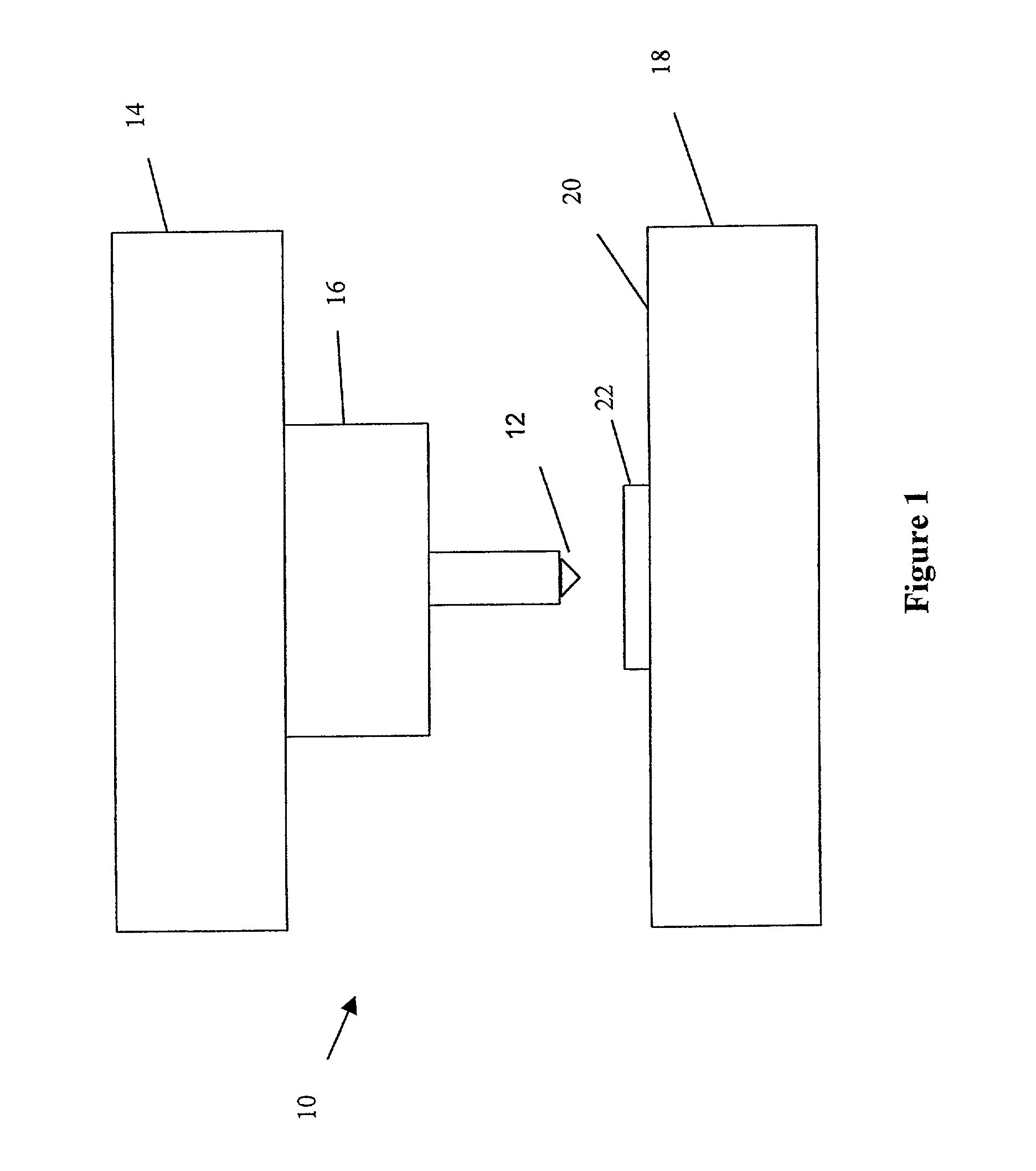

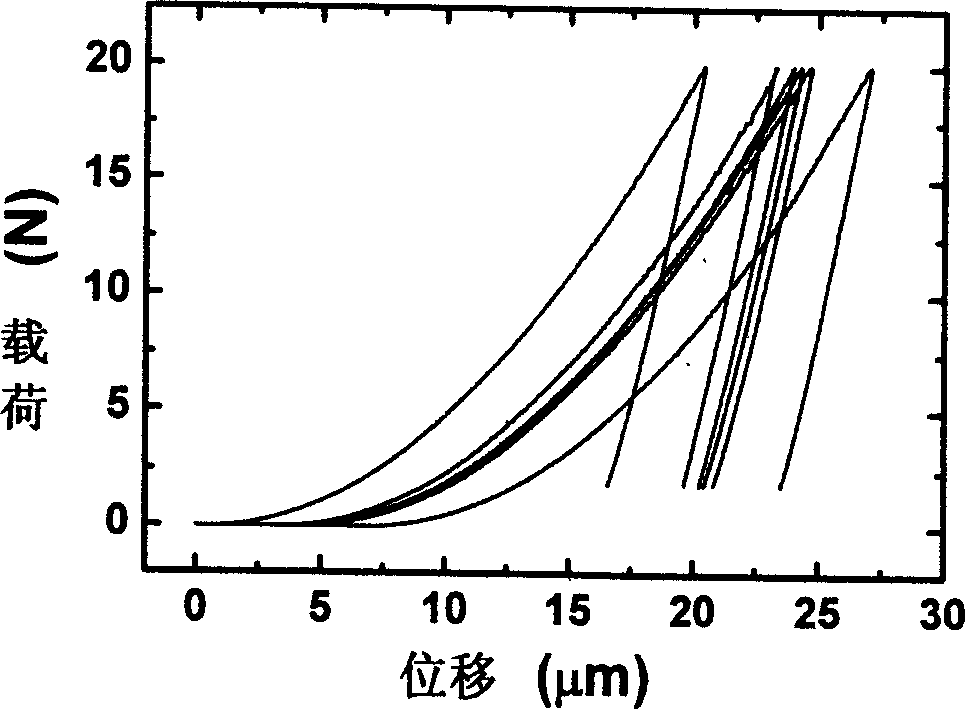

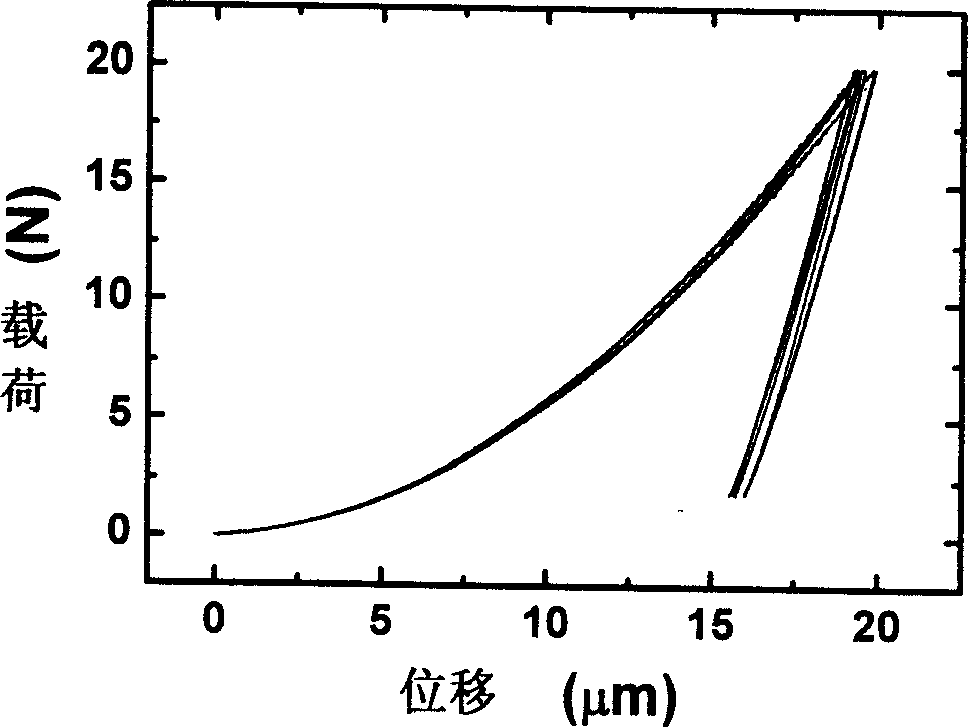

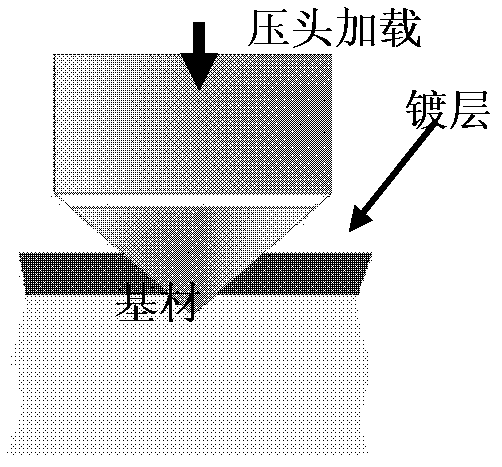

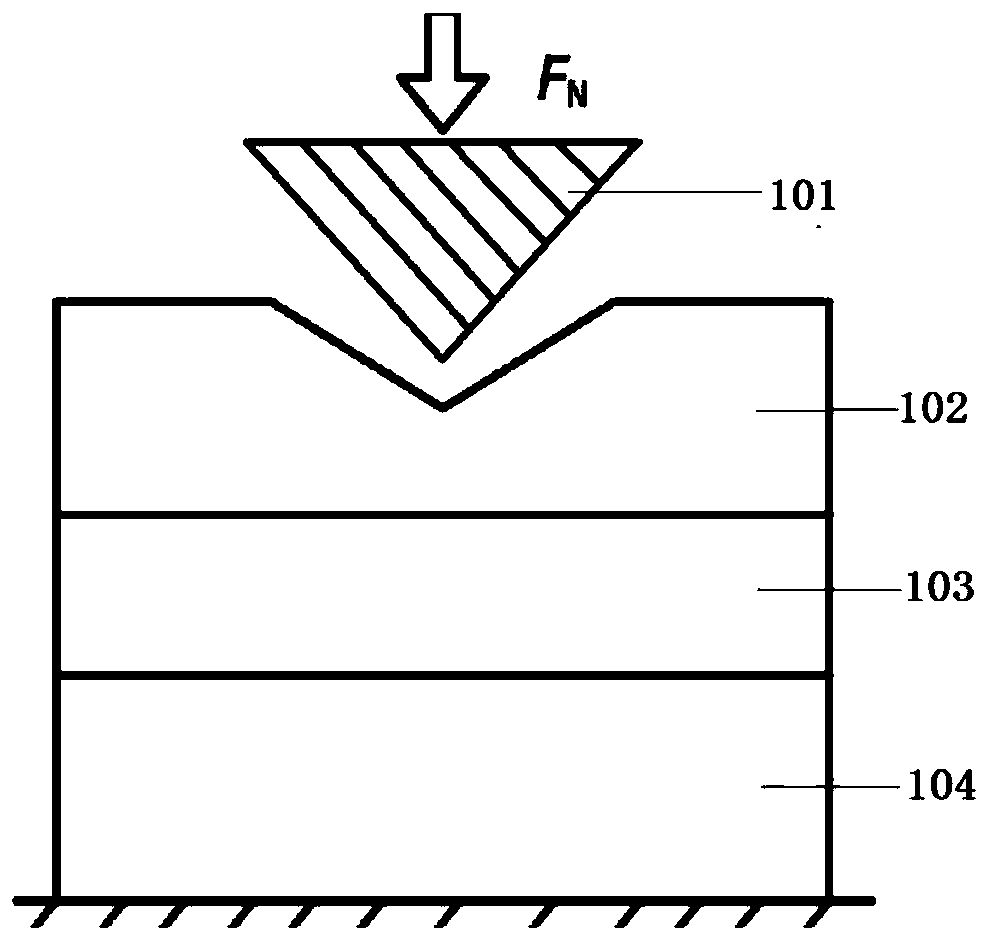

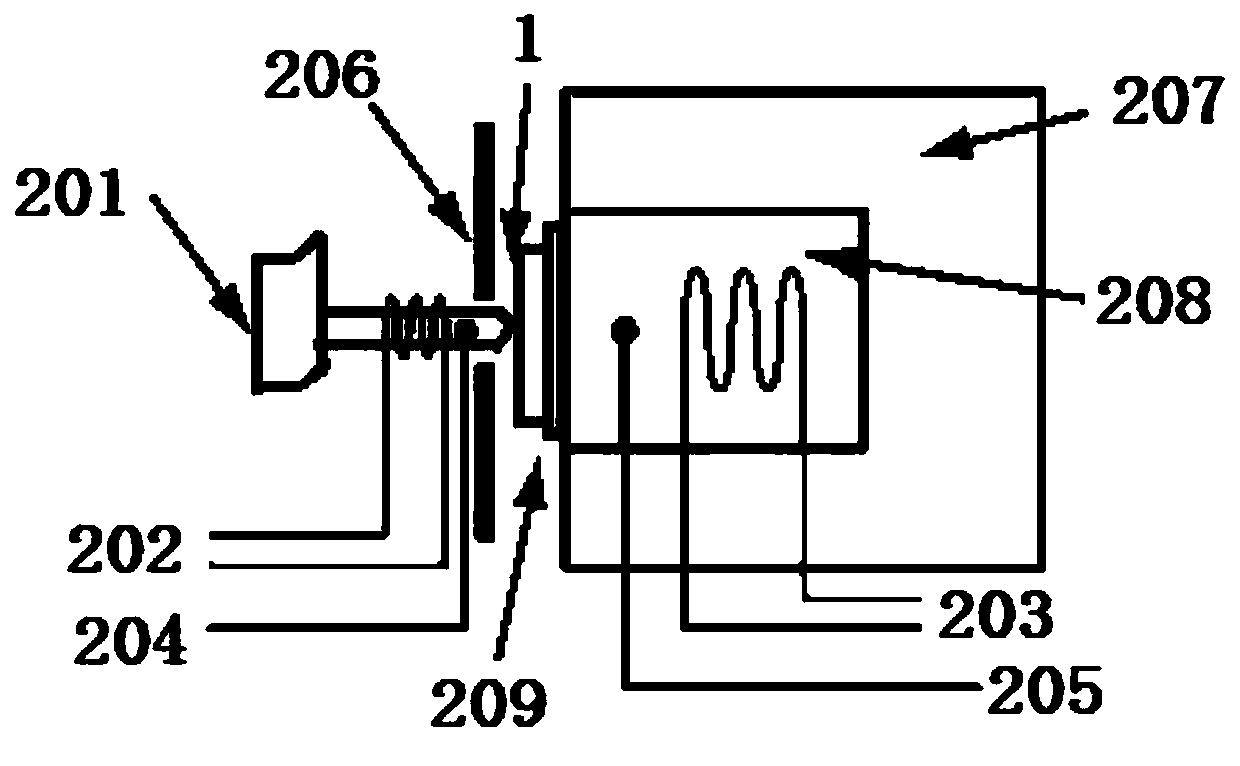

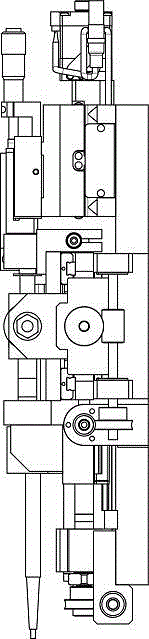

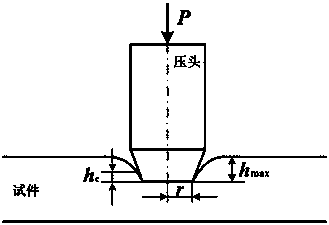

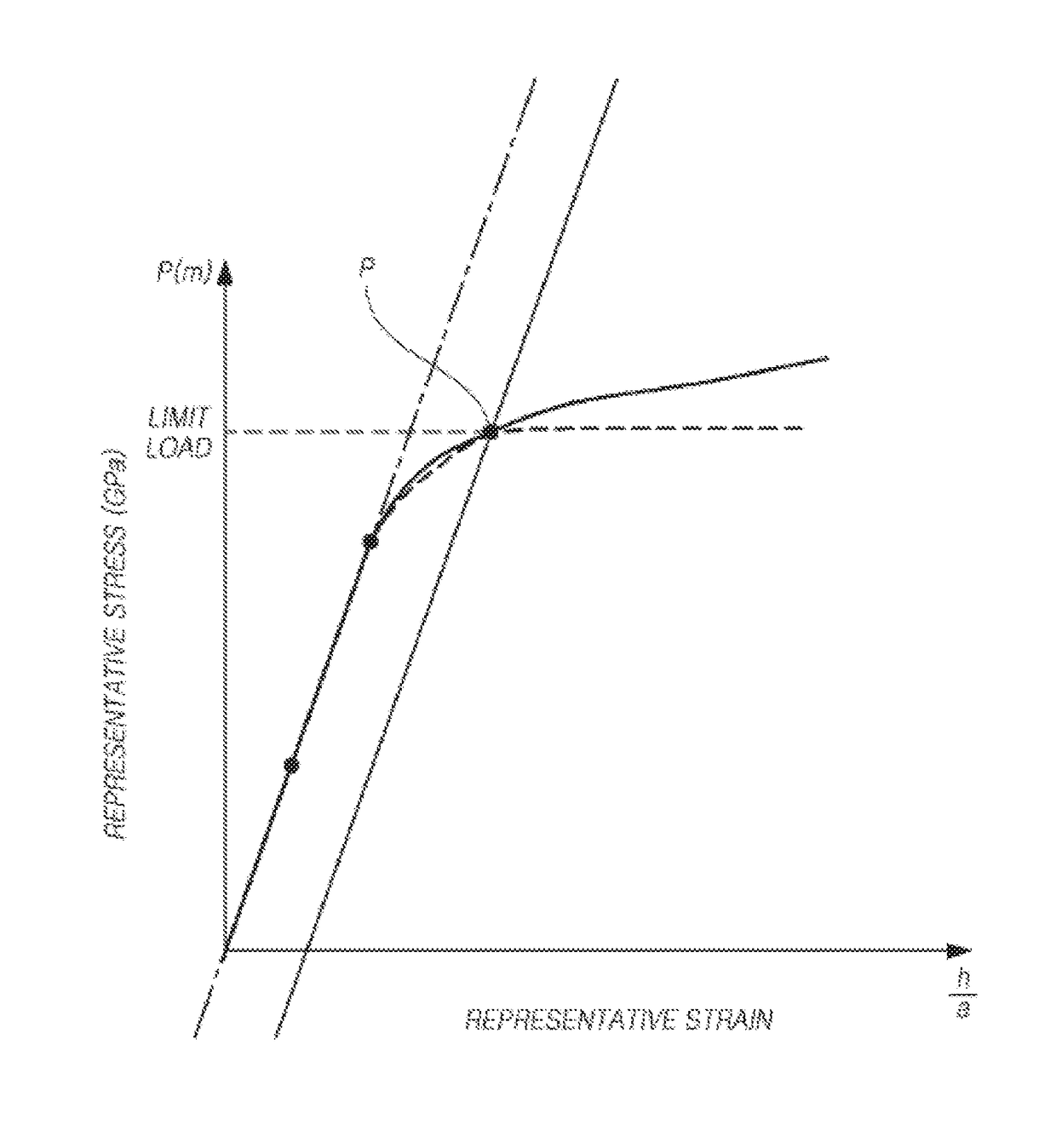

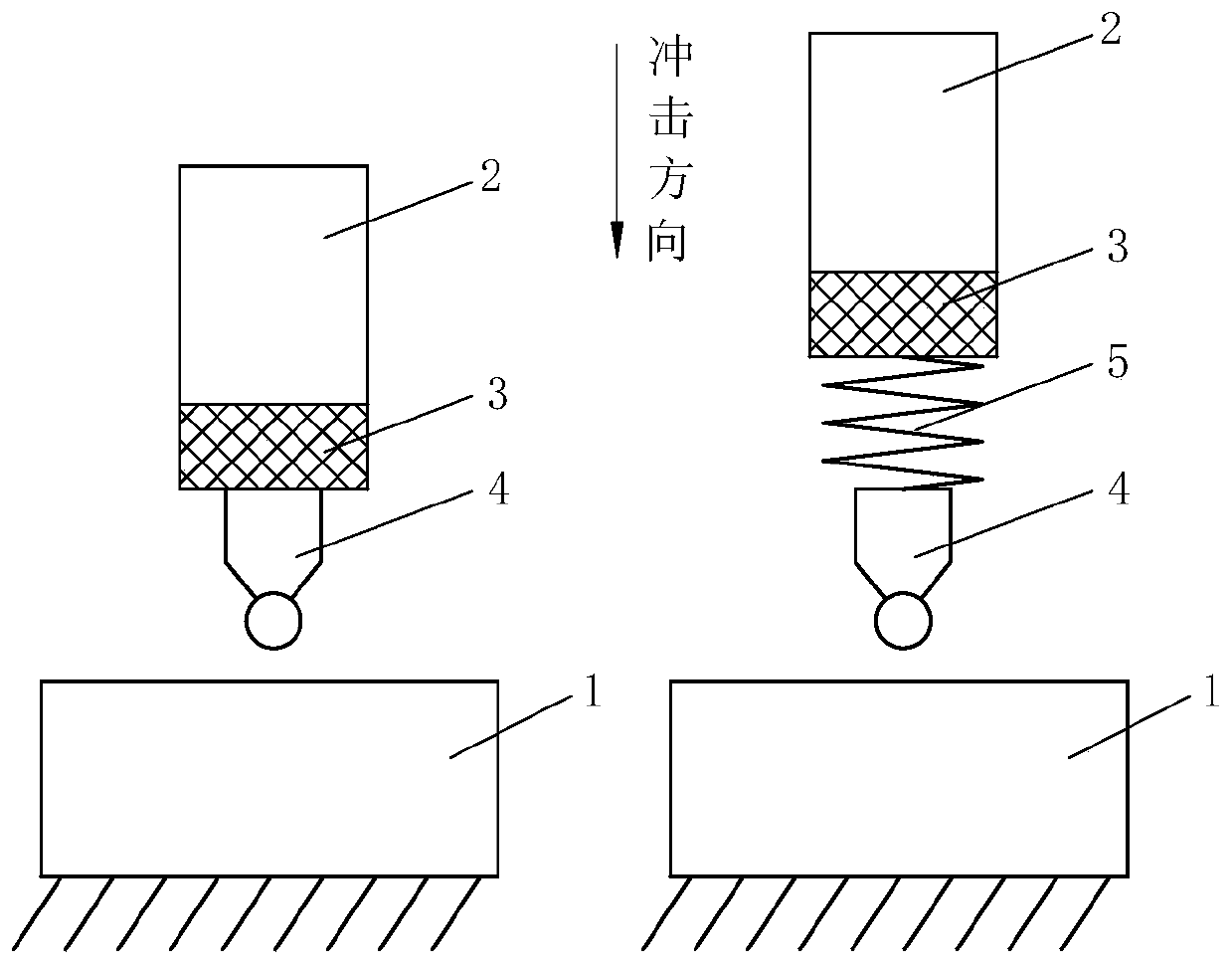

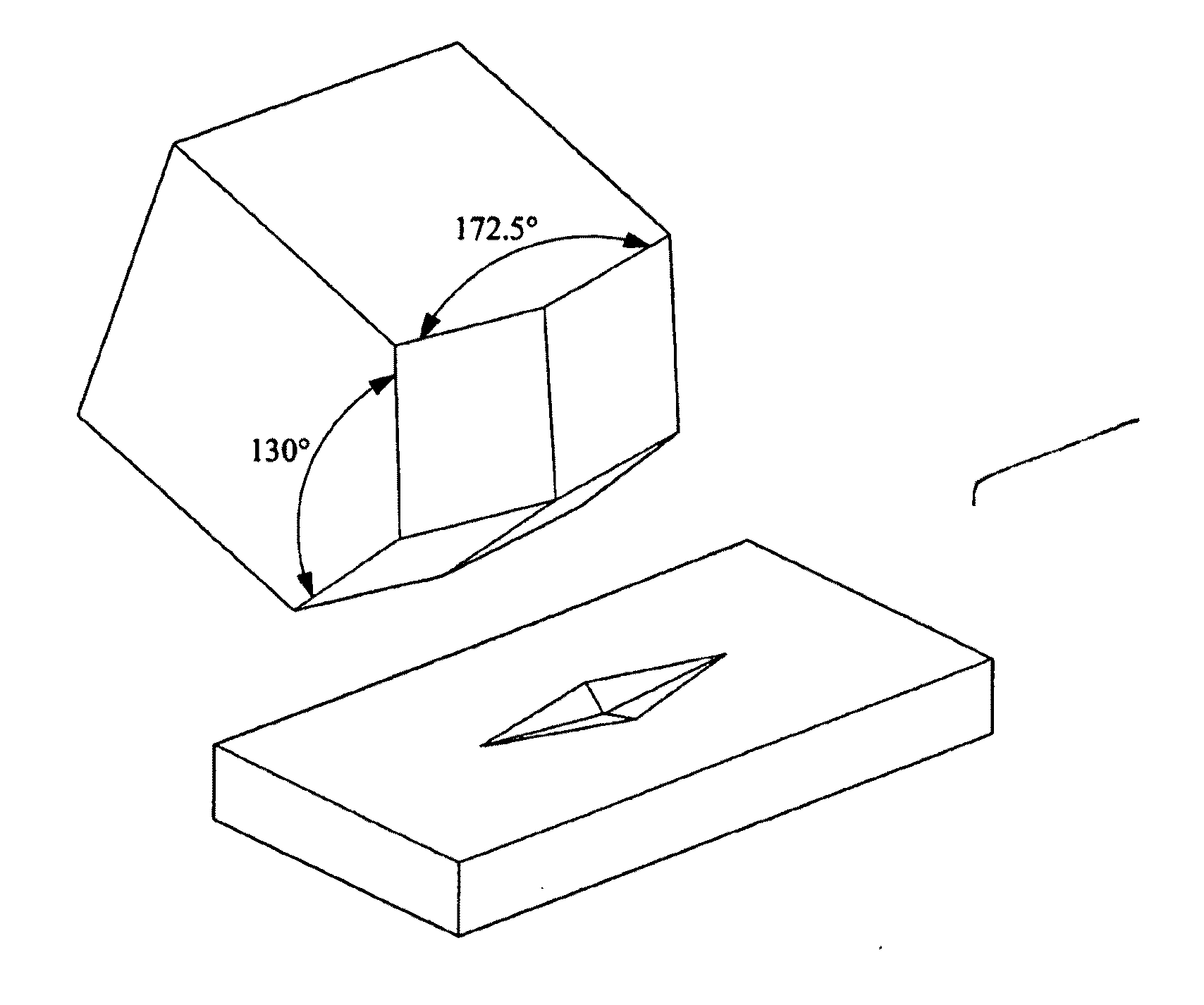

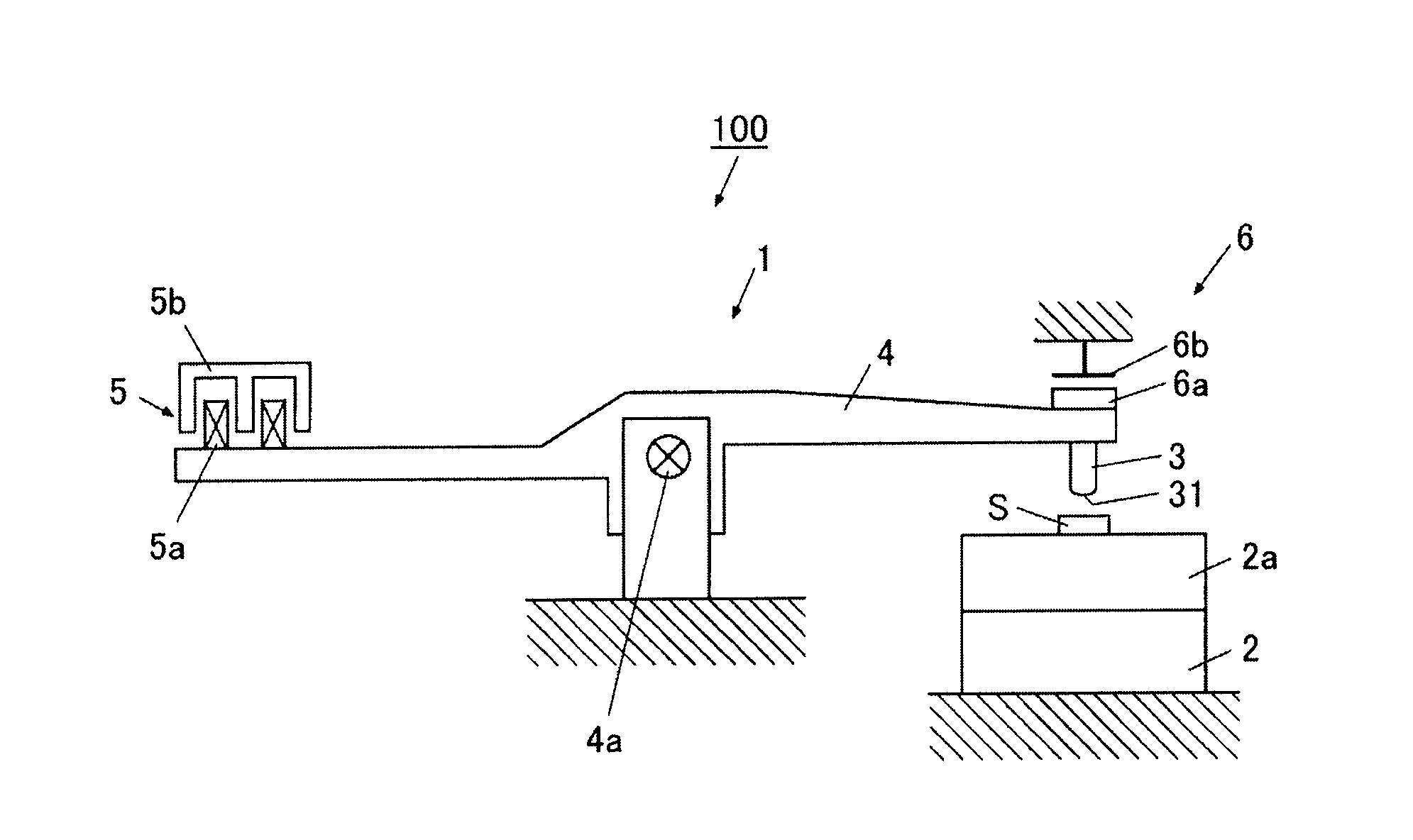

Indentation testing is one such test, as it produces a complex state of stress in the specimen. The indentation test, shown in the image below, is designed to characterize a material’s behavior under complex loading. The test is performed by pressing a stiff steel sphere into a softer test specimen.

Systems and methods for estimation and analysis of mechanical property data associated with indentation testing

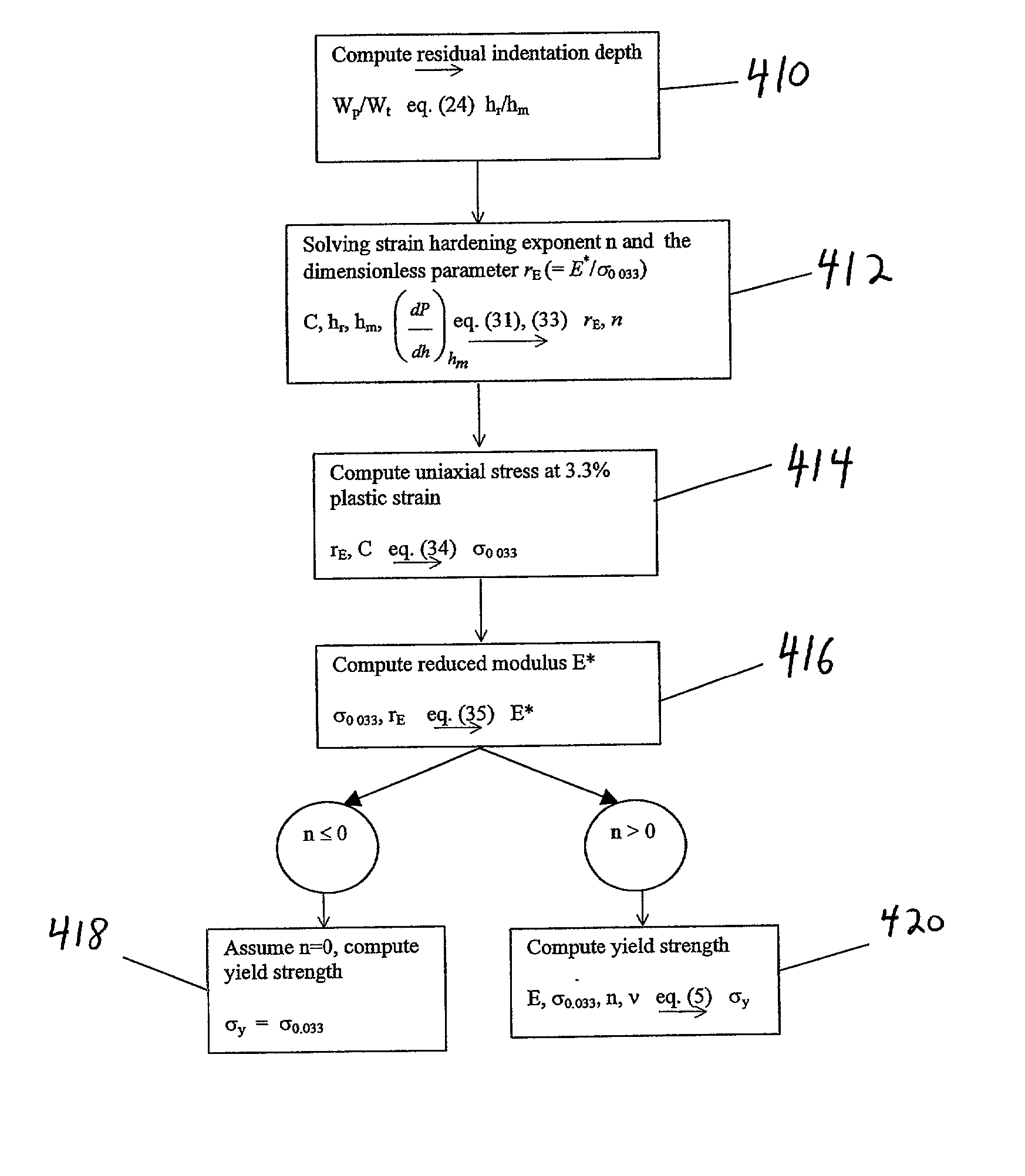

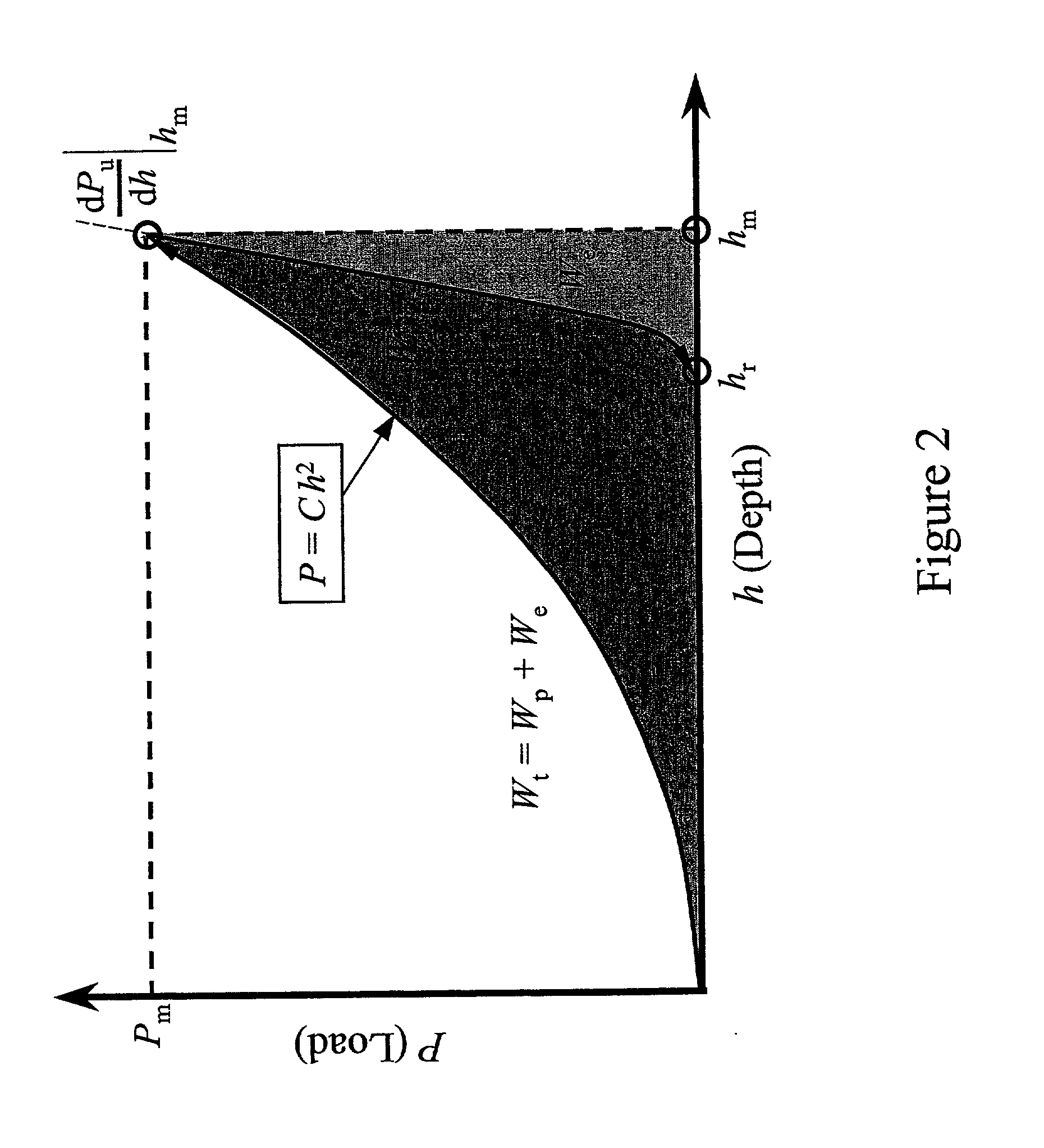

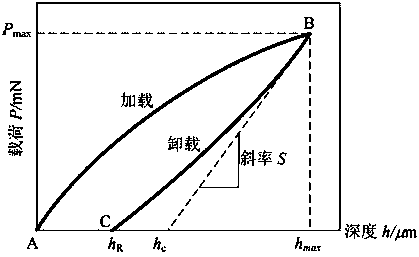

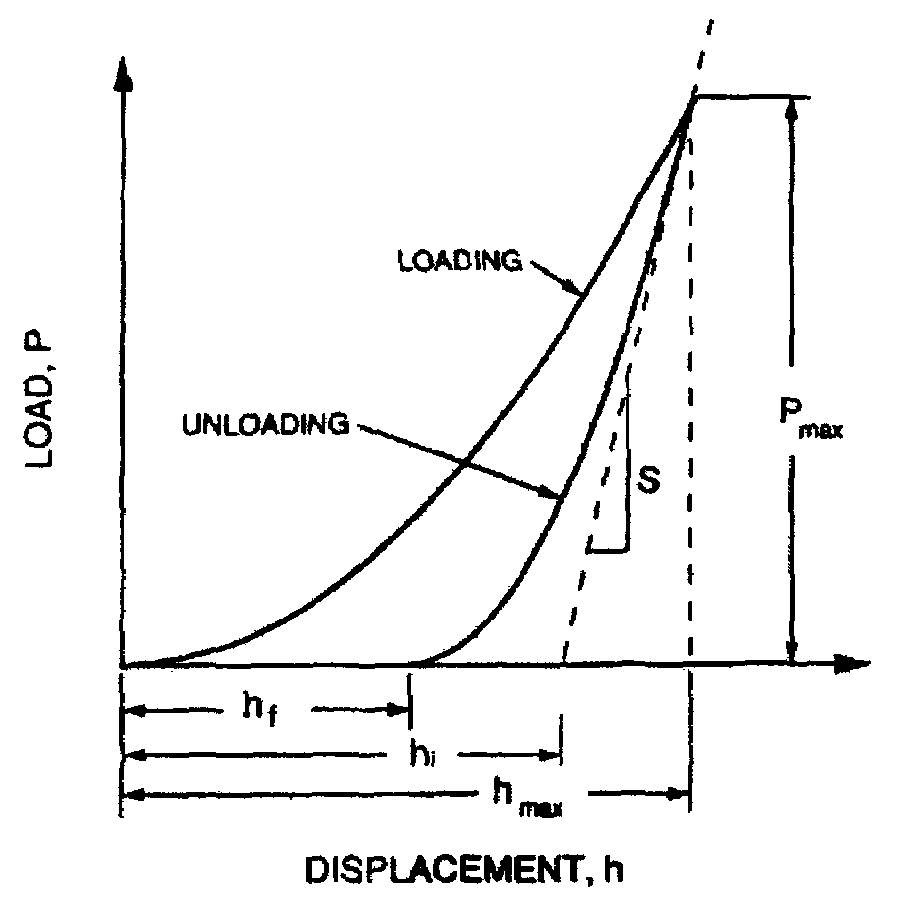

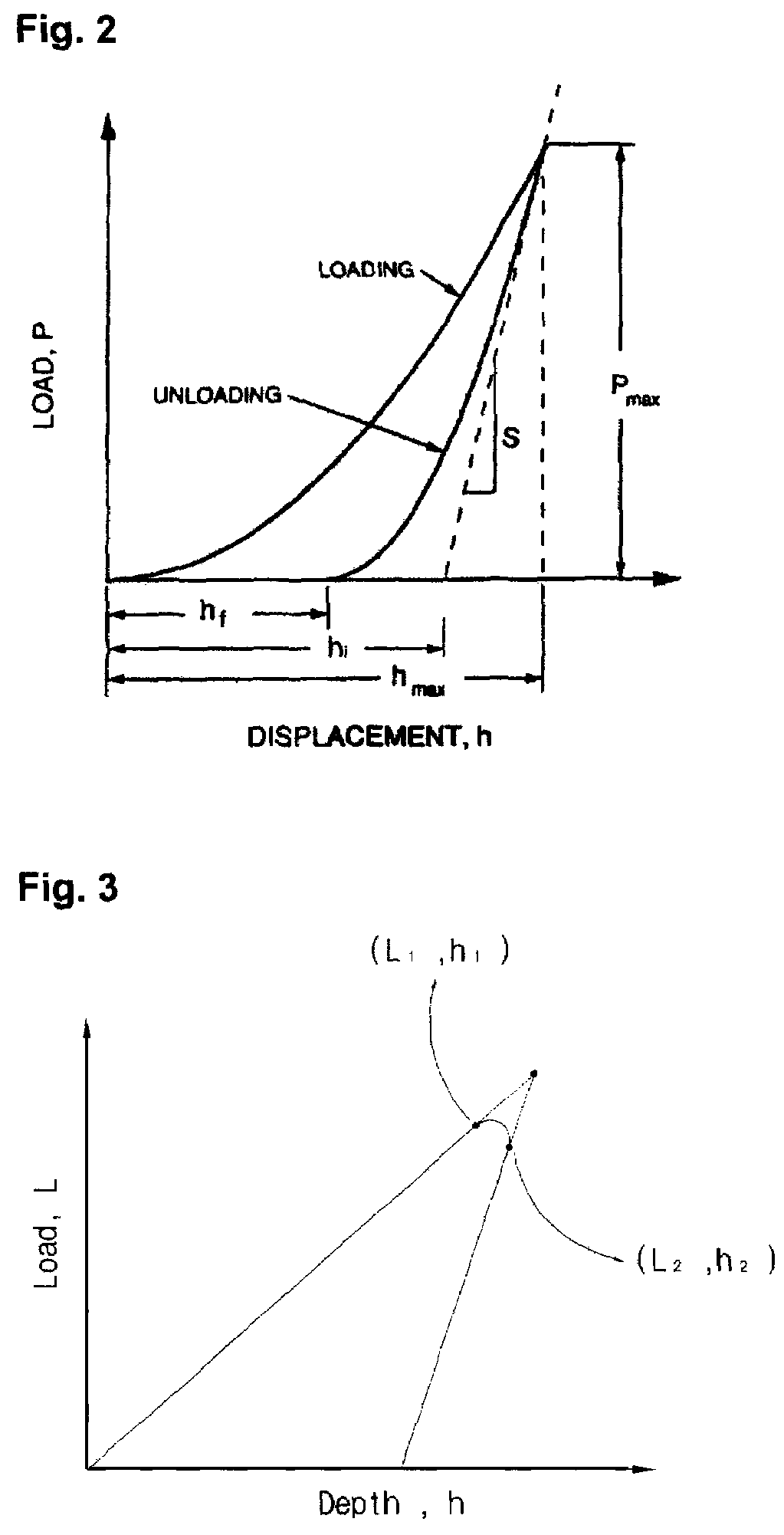

Systems and methods are disclosed that can provide estimates of elasto-plastic properties of material samples using data from instrumented indentation tests. Alternatively, or in addition, estimated load-depth curves can be constructed by certain methods and systems provided based on known mechanical properties. Some disclosed systems and methods use large deformation theory for at least part of the analysis and / or determinations and / or may account for strains of at least 5% in the area of contact between the indenter and the material sample, which can result in more accurate estimates of mechanical properties and / or deformation behavior.

Owner:MASSACHUSETTS INST OF TECH

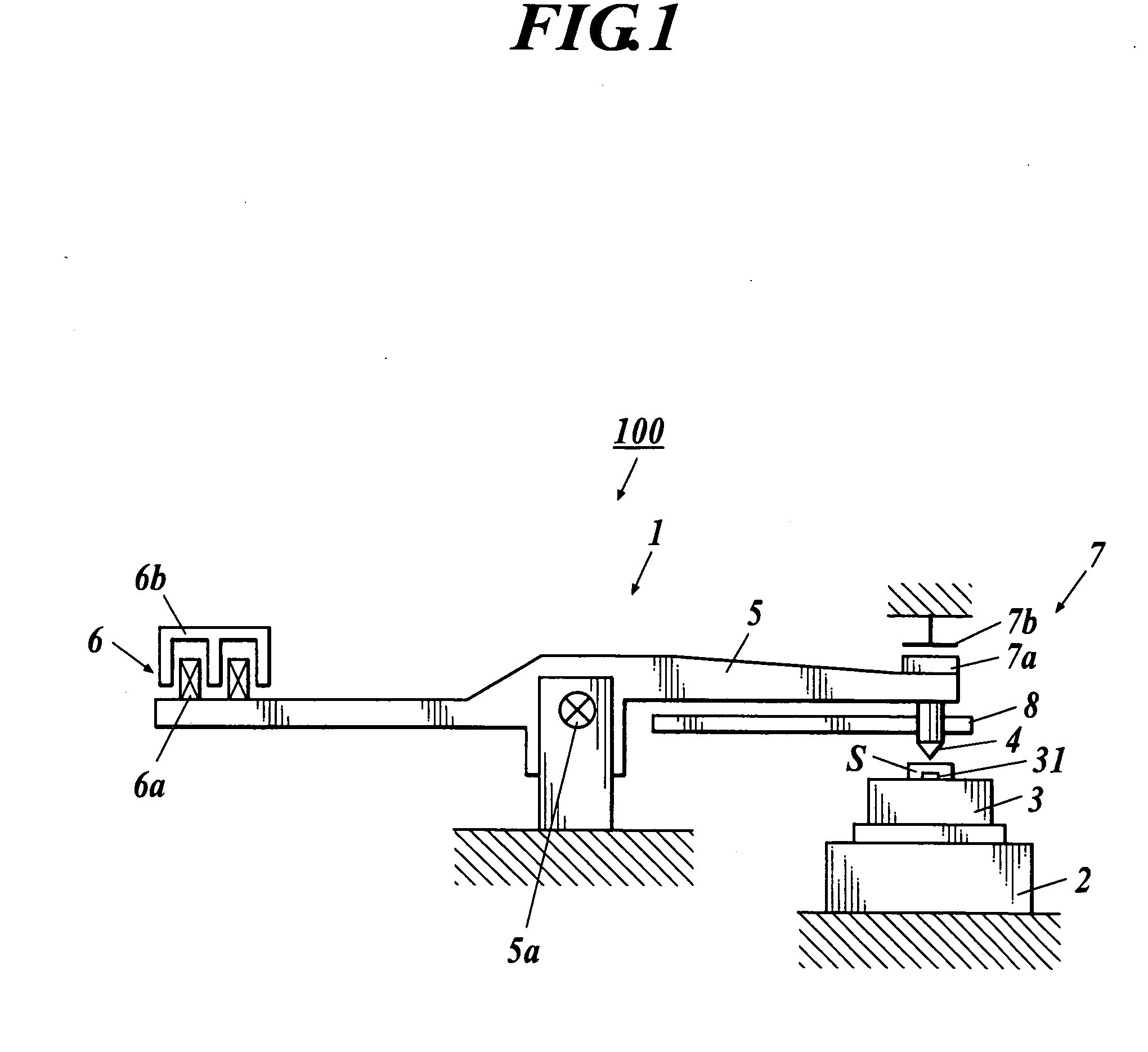

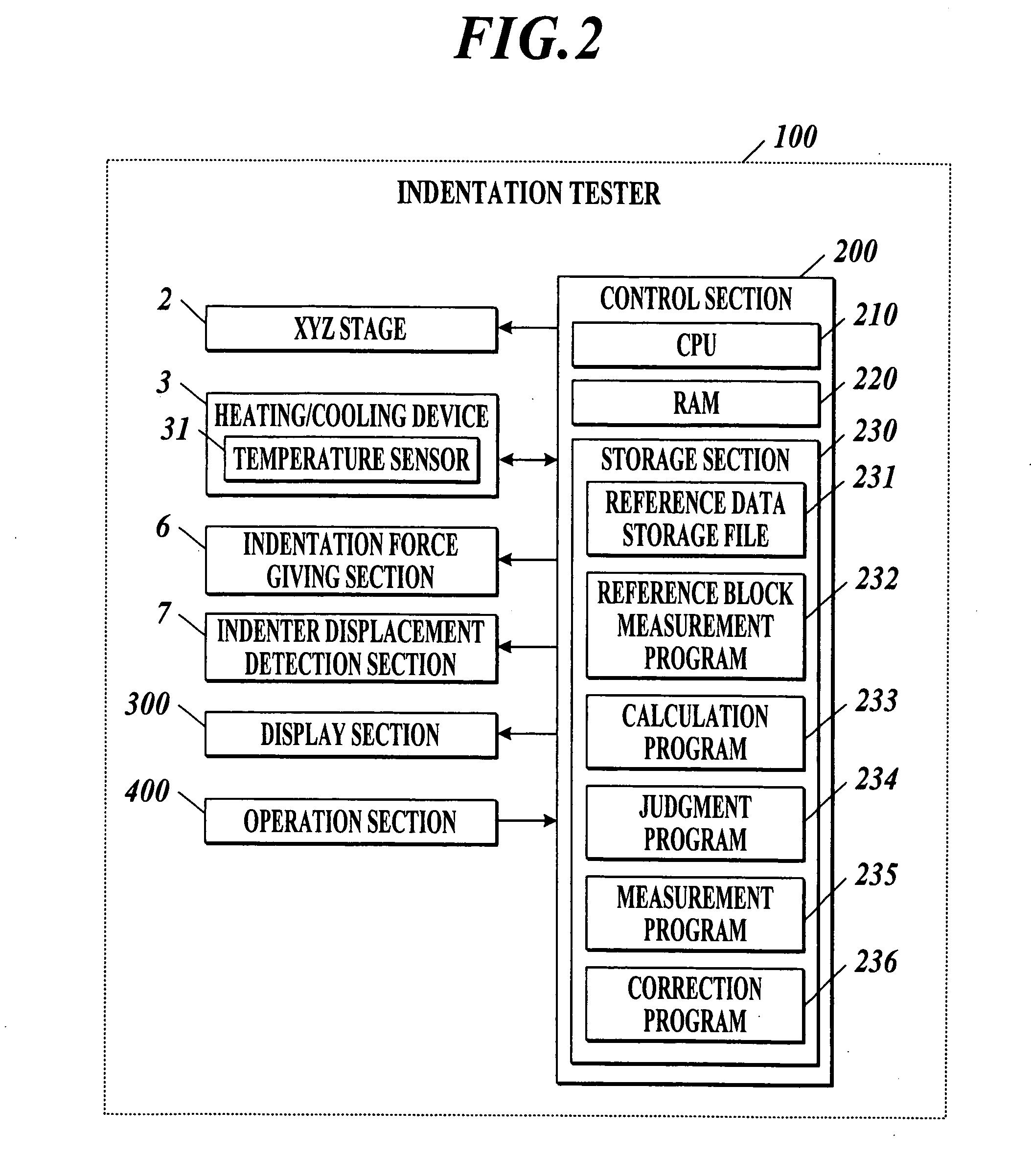

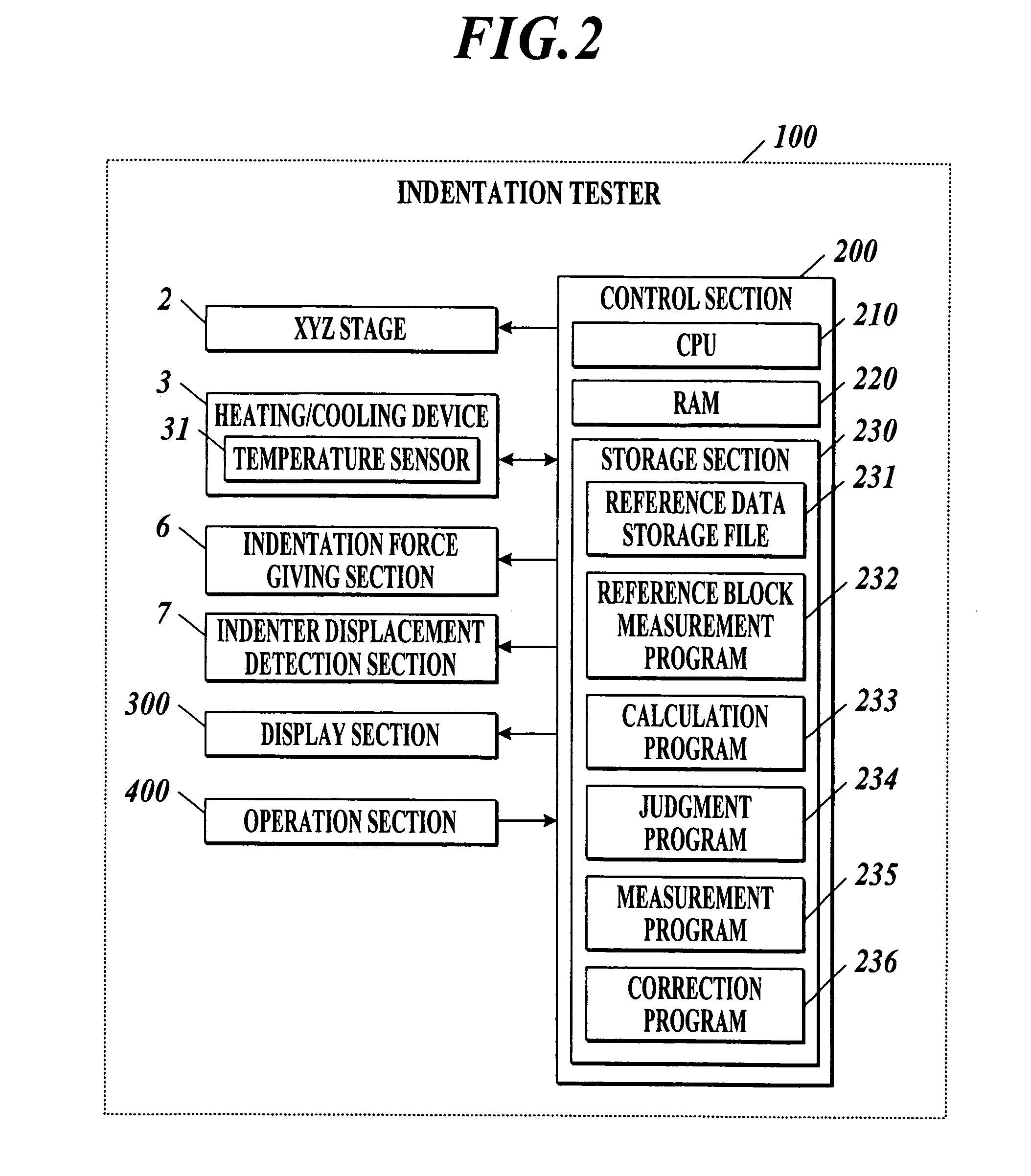

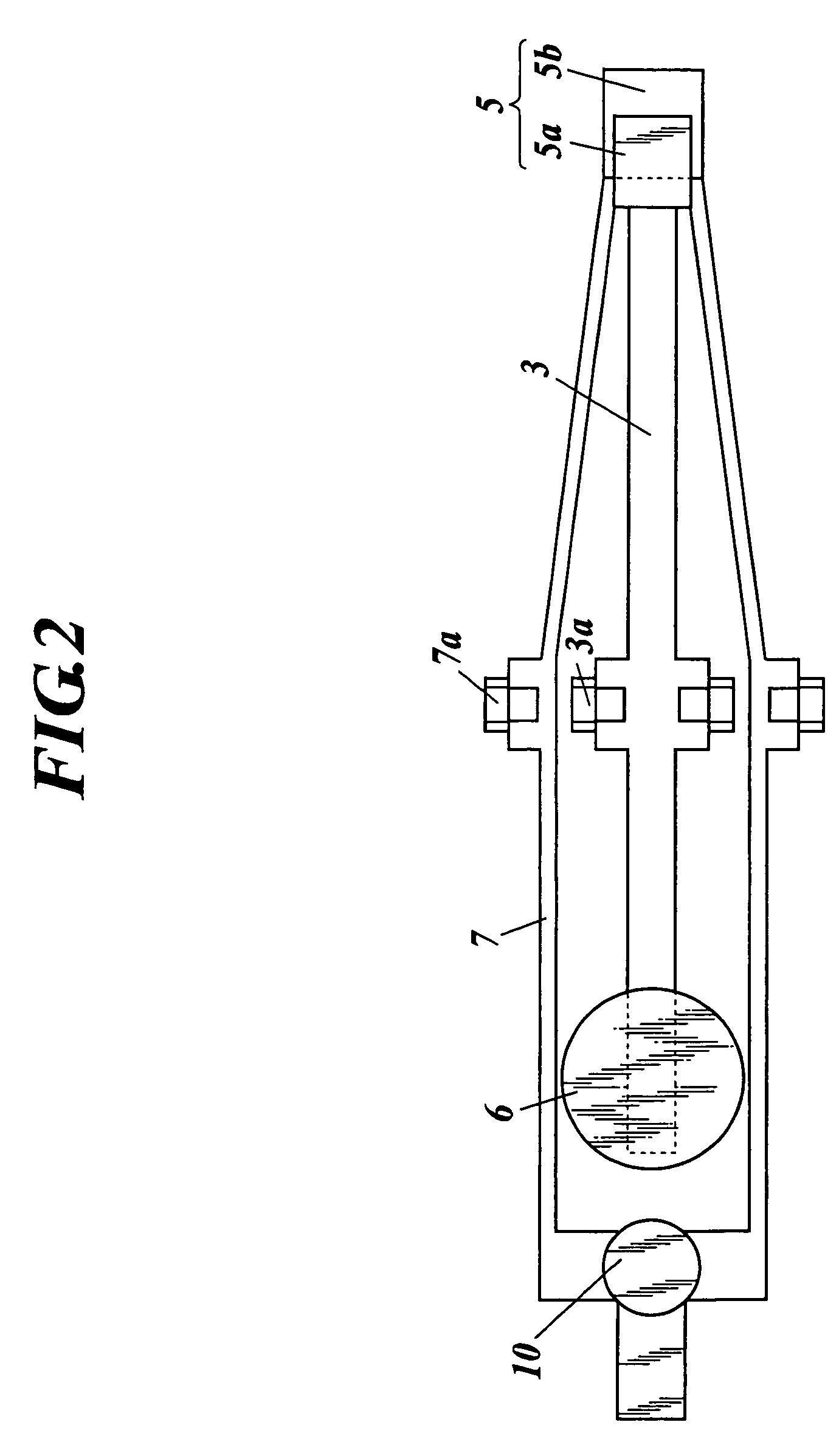

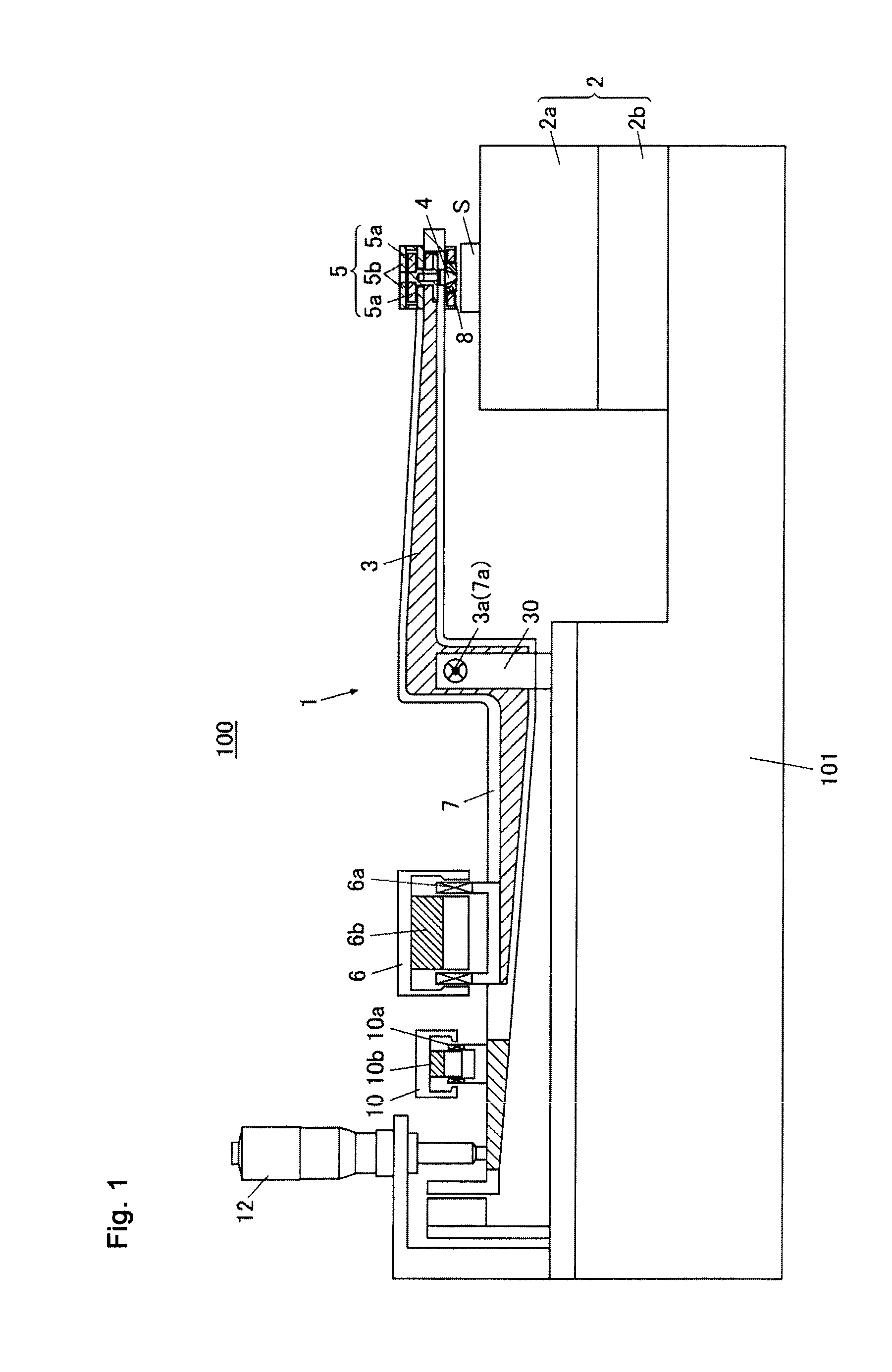

Test management method for indentation tester and indentation tester

Disclosed a test management method for an indentation tester which includes a control section and forms an indentation on a surface of a heated or cooled sample by pressing an indenter to which a load is applied onto the surface of the sample, the test management method including the steps of: measuring a predetermined reference block as the sample under a plurality of temperature environments to obtain a test result; calculating a test error caused by temperature environment based on the test result by the control section; and judging whether or not the test error is within a predetermined range by the control section.

Owner:MITUTOYO CORP

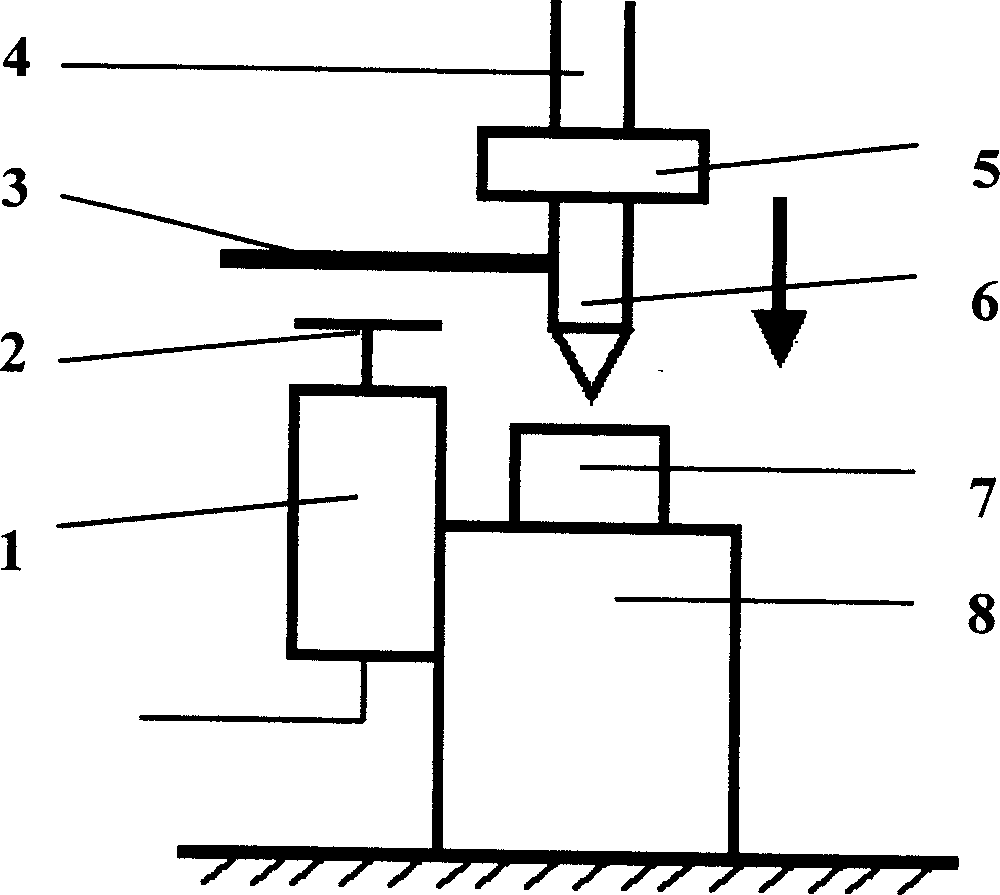

Improved method of impression testing function for material tester and improving device thereof

InactiveCN1752736AGreat advantageAvoid Displacement Measurement ErrorsInvestigating material hardnessMaterials testingContact type

The invented improved method includes the following steps: firstly, measuring loaded / unloaded displacement-loaded curve, then utilizing pressed depth measurement method to making data process so as to obtain hardness and modulus of the tested material. The improved equipment of the material testing machine also includes a sample table directly mounted on the base of material testing machine and a non-contact type displacement sensor mounted on the sample table of material testing machine.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

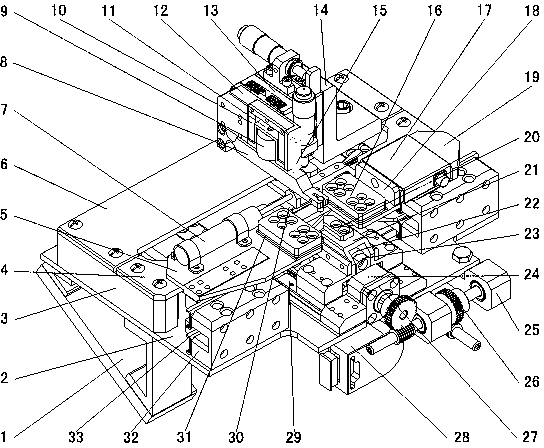

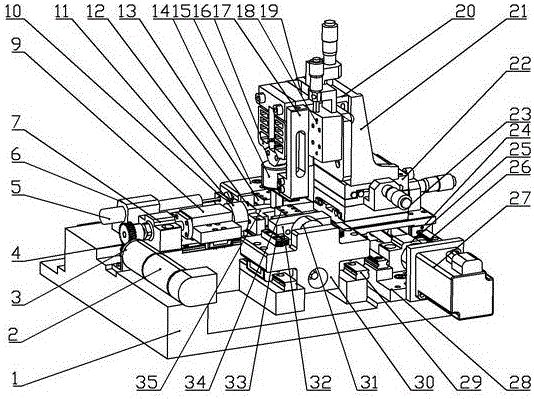

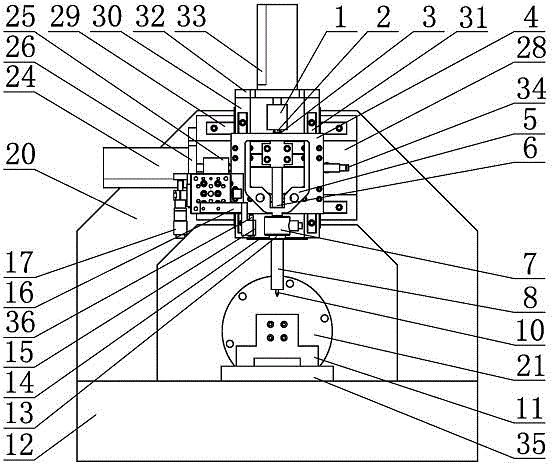

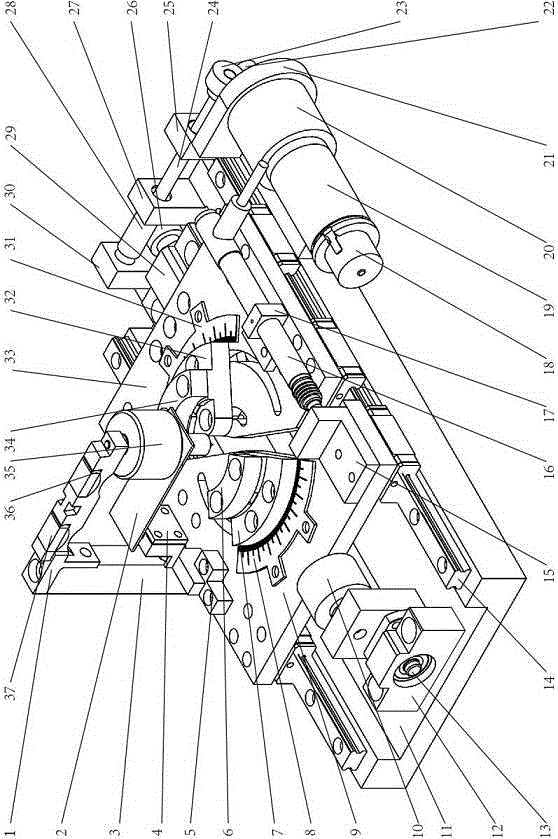

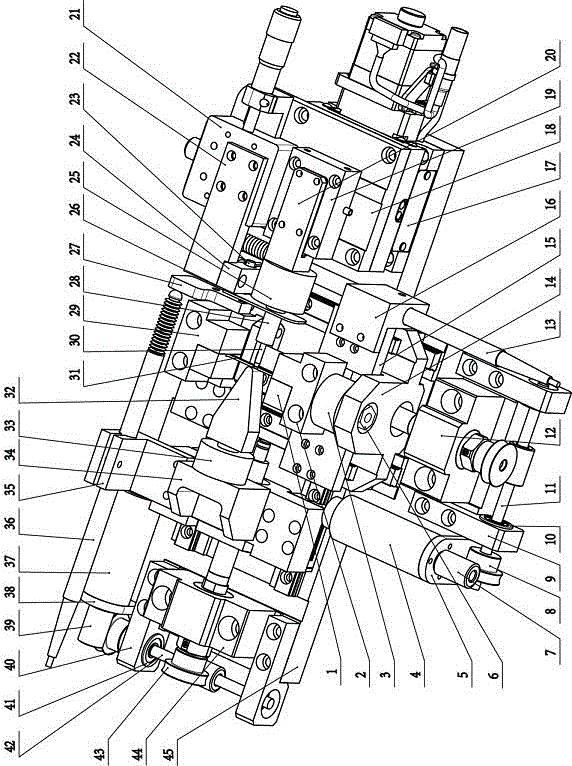

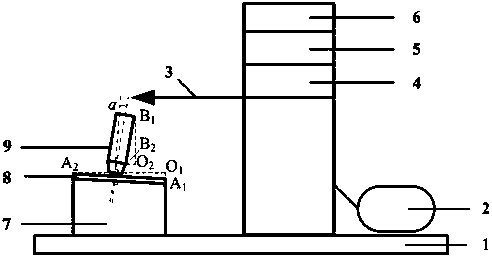

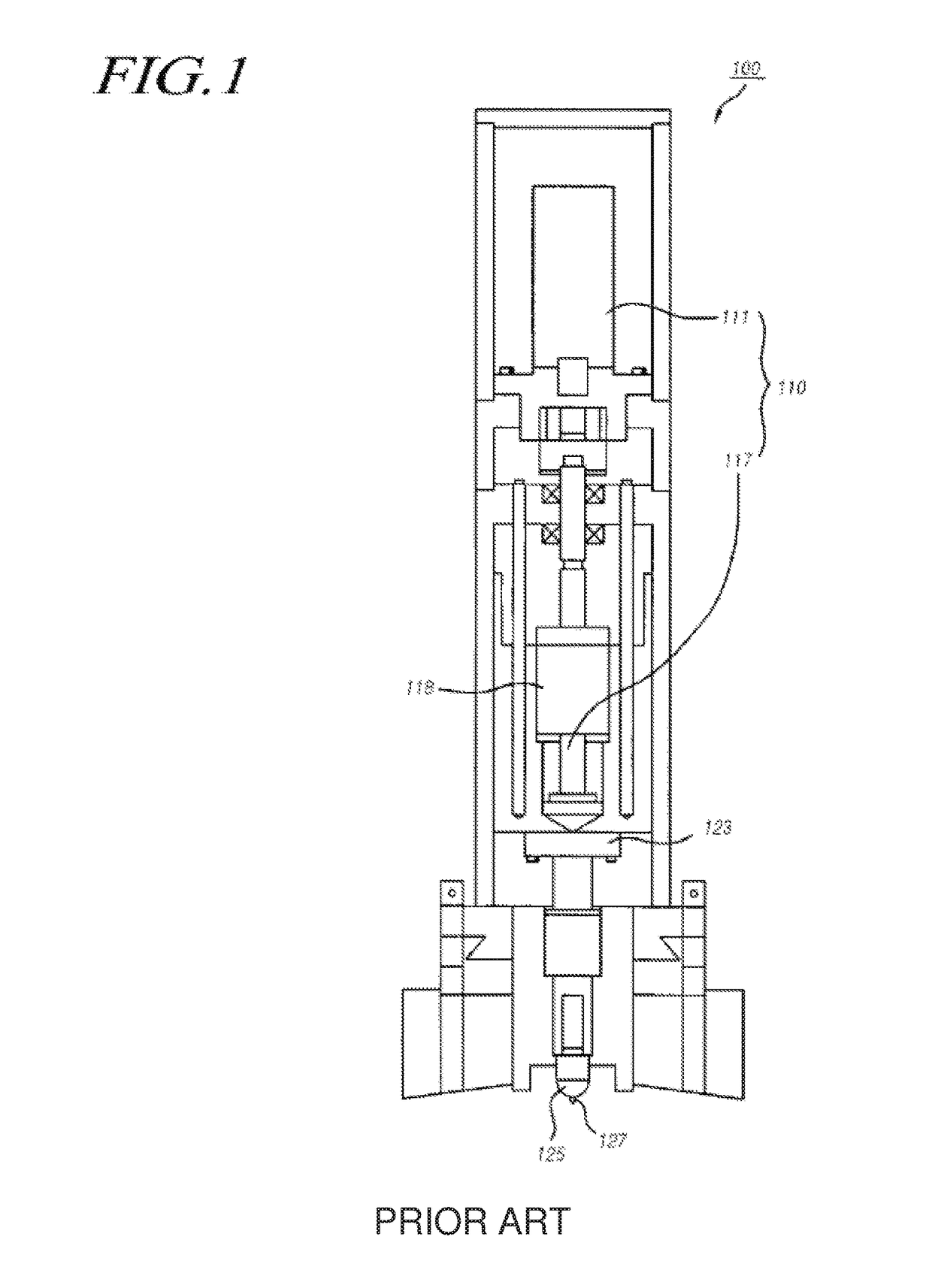

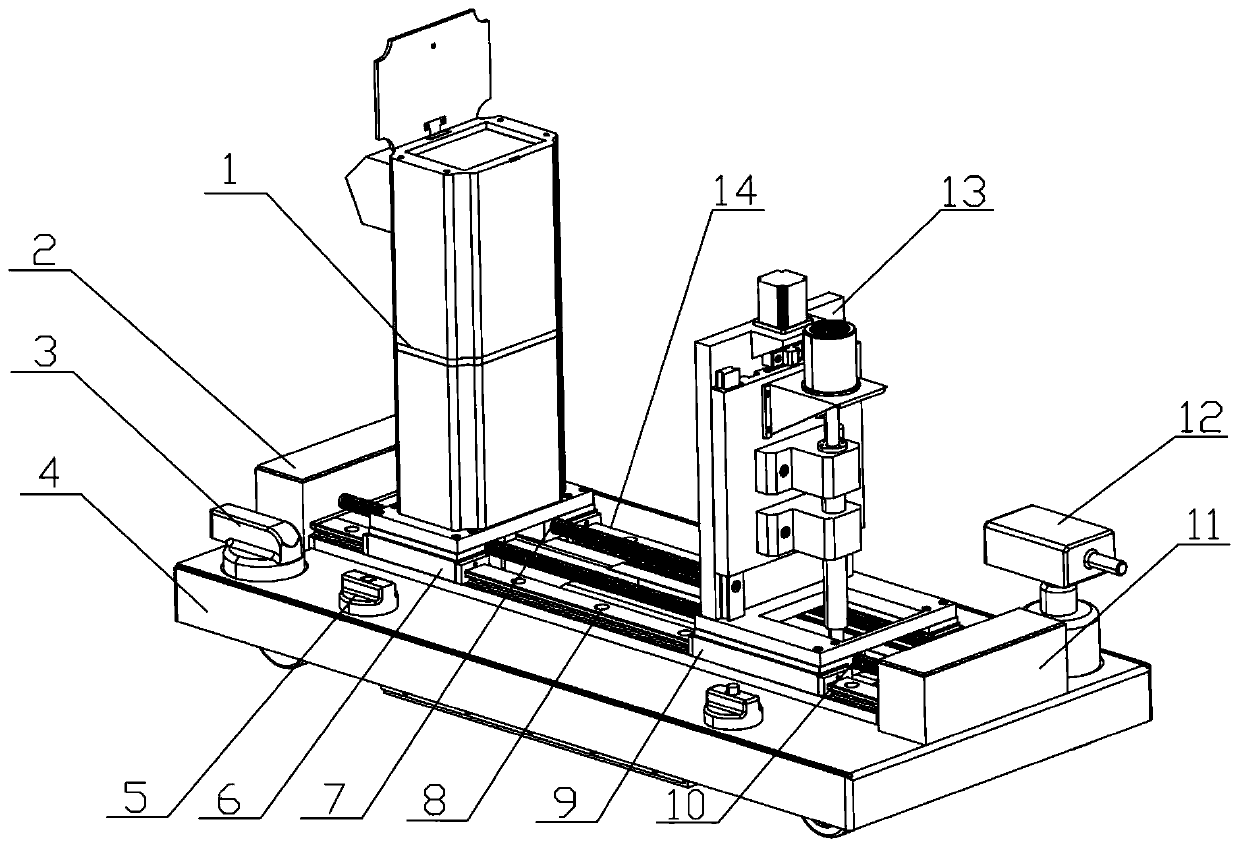

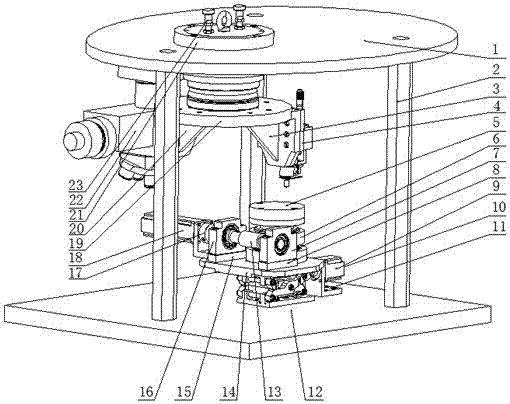

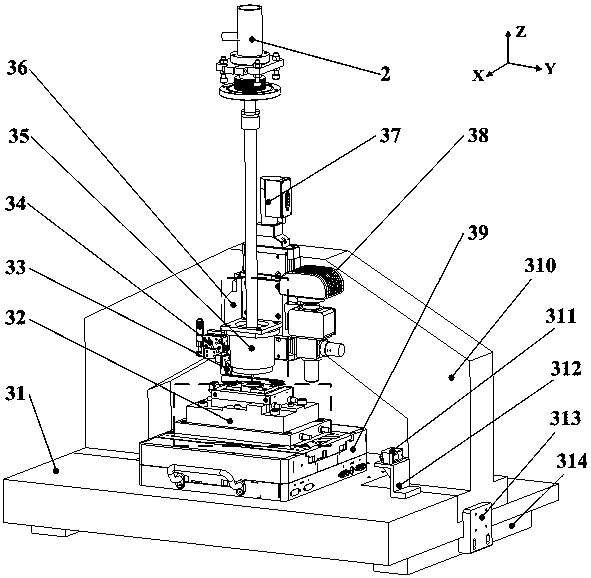

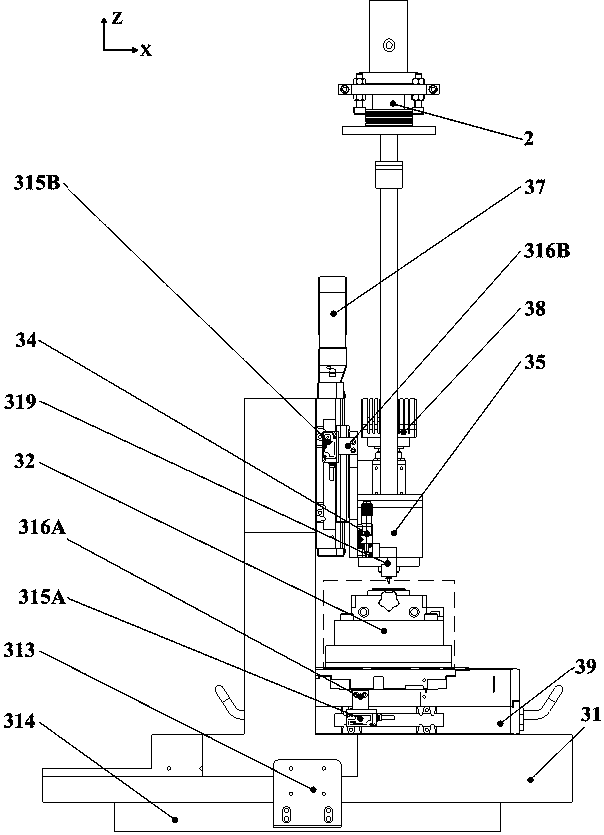

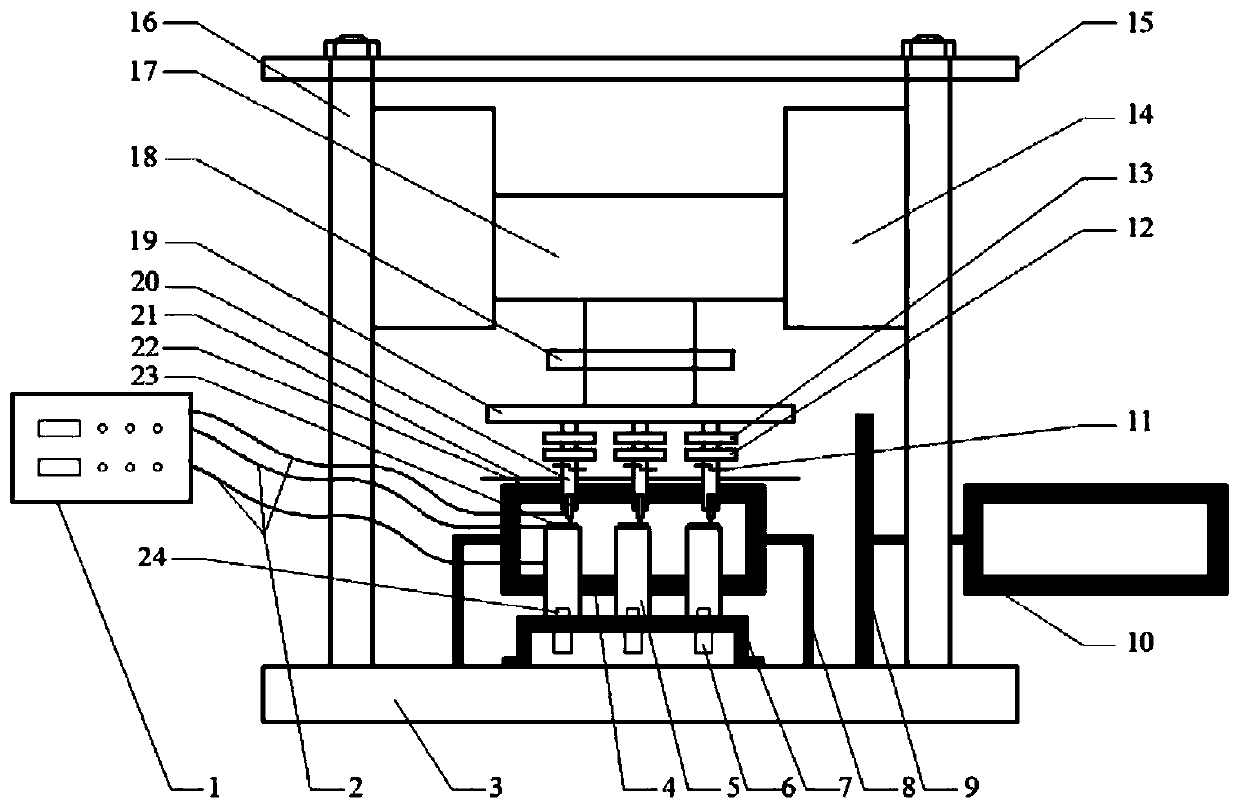

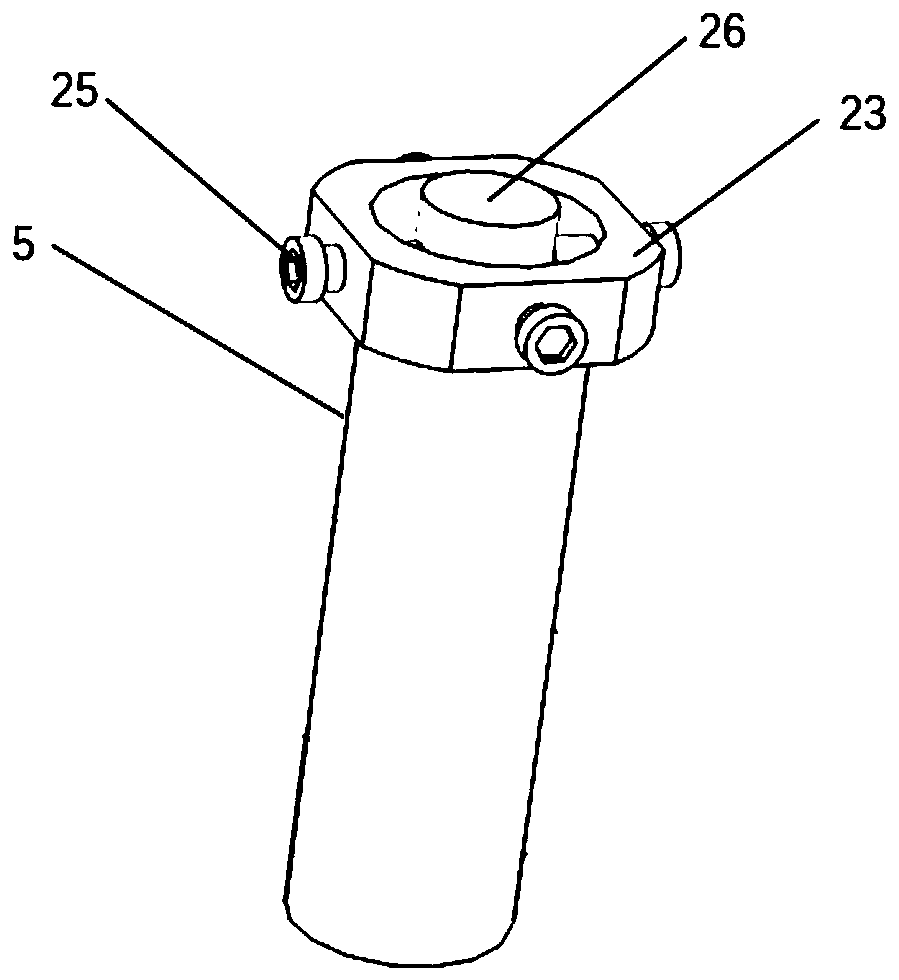

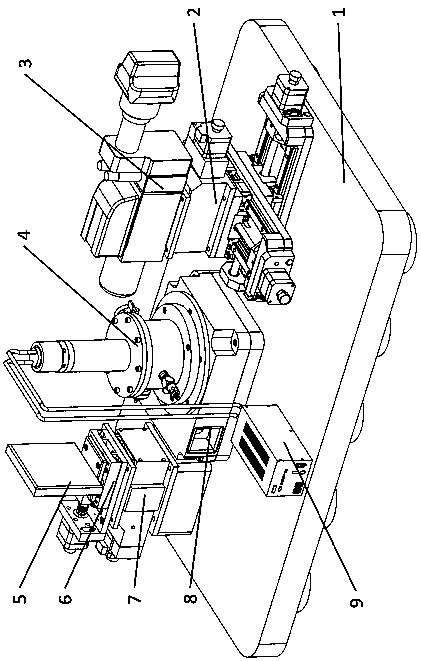

In-situ nano-indentation tester based on adjustable stretching-bending preload

ActiveCN103308404AAccurately record force in real timeAccurately record the amount of deformation in real timeMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesScientific instrumentIndentation testing

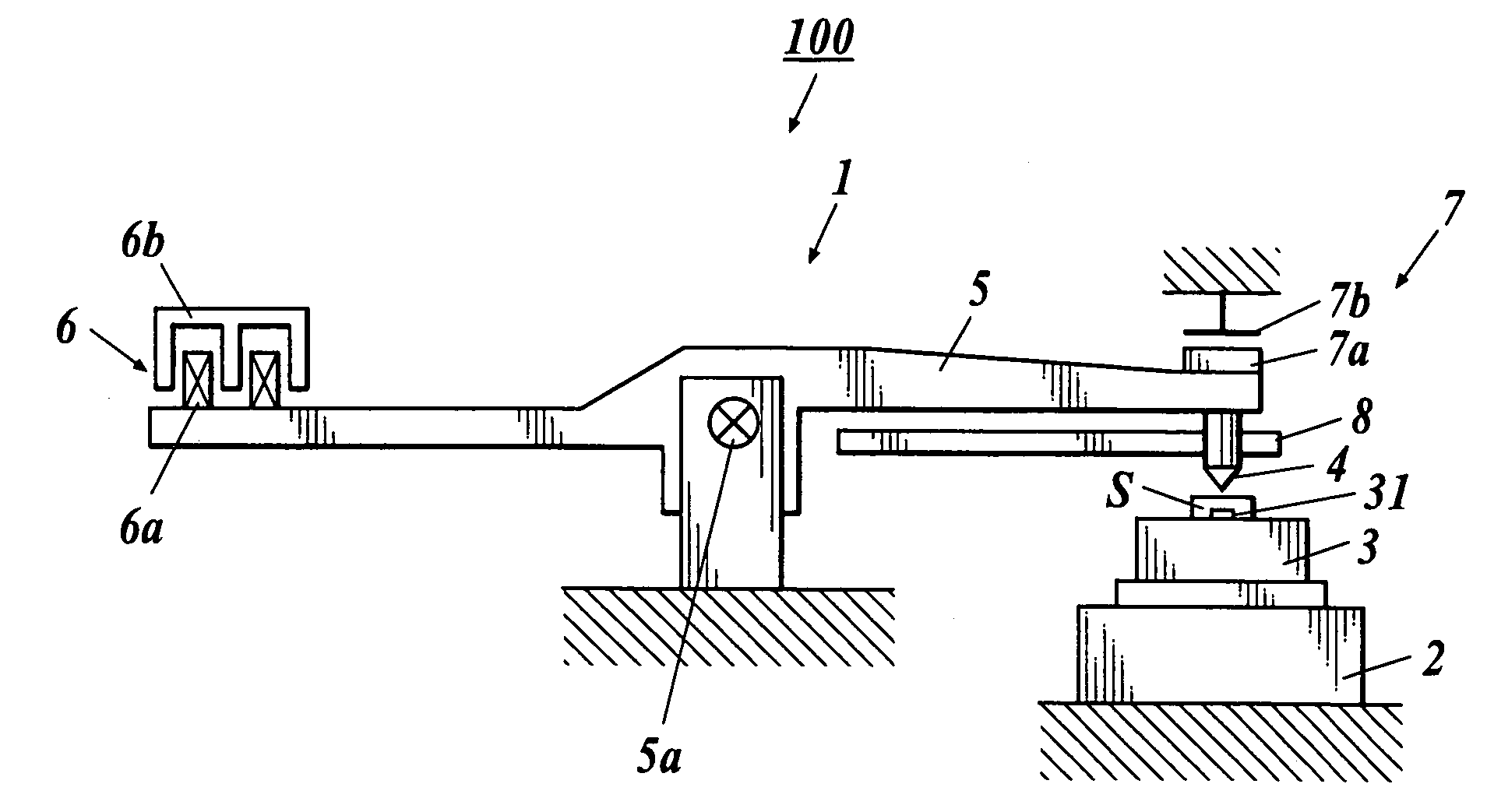

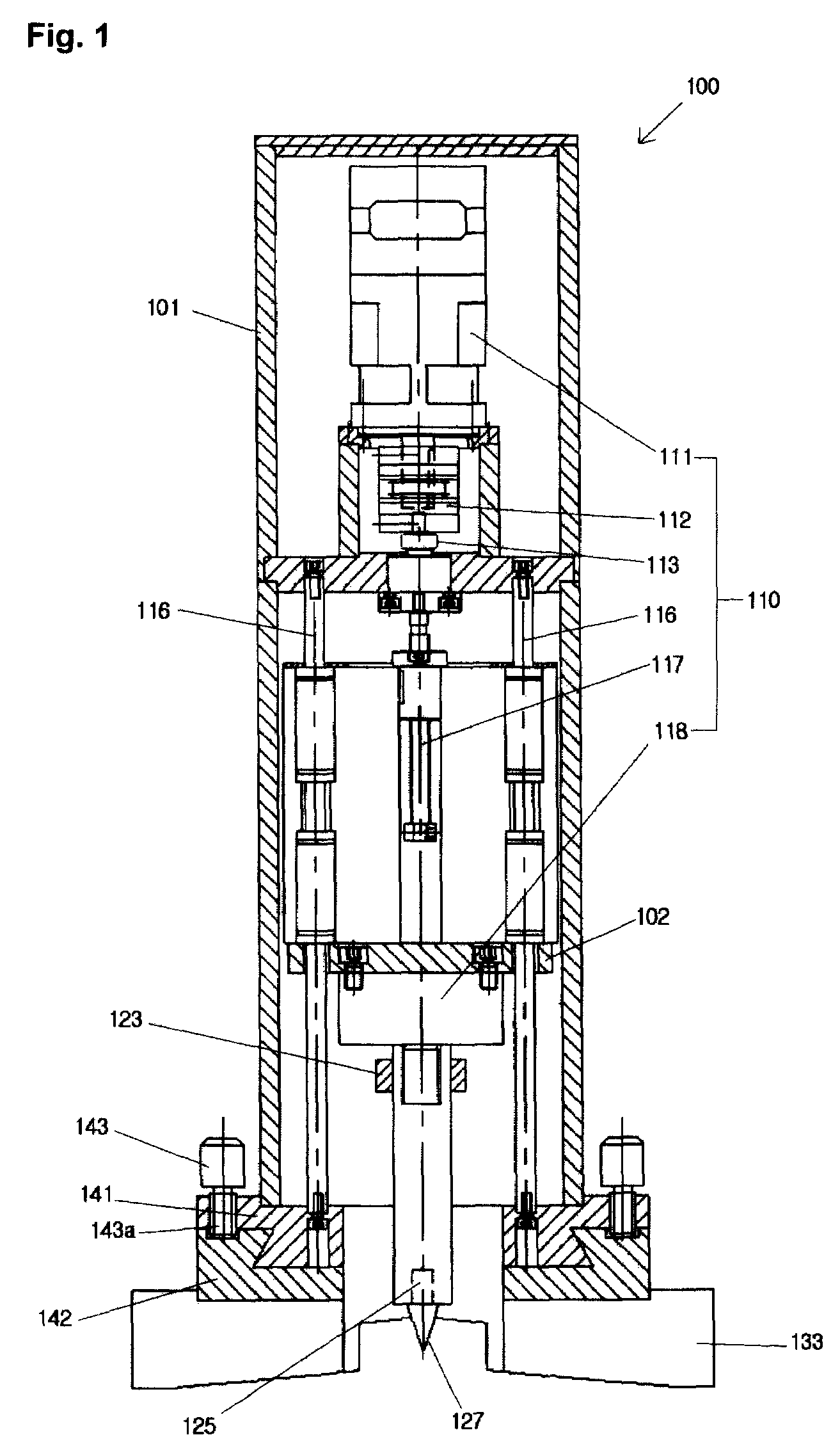

The invention relates to an in-situ nano-indentation tester based on an adjustable stretching-bending preload, and belongs to the field of electromechanical precision scientific instruments. The in-situ nano-indentation tester comprises an in-situ nano-indentation testing module, a stretching preload loading module and a bending preload loading module, wherein the in-situ nano-indentation testing module consists of a precision displacement / force loading unit and a load / displacement signal detection unit; the stretching preload loading module consists of a precision driving unit A, a precision transmission unit A, a load / displacement signal detection and control unit A and a clamping unit A; the bending preload loading module consists of a precision driving unit B, a precision transmission unit B, and a load / displacement signal detection and control unit B. The in-situ nano-indentation tester has the advantages of small size, compact structure and high testing precision; supplied test contents are rich; the deformation / displacement / load rate can be controlled; the in-situ nano-indentation tester can be arranged on carrying platforms of various main-stream electronic microscopic vacuum cavities and is compatible with imaging equipment; the application range is wide.

Owner:JILIN UNIV

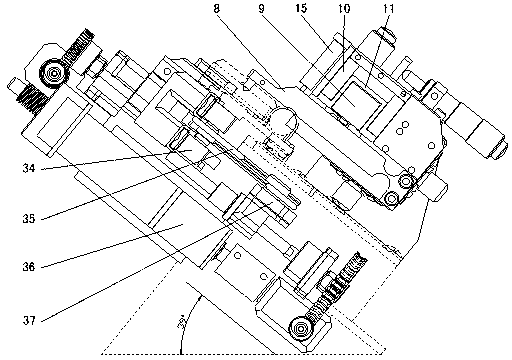

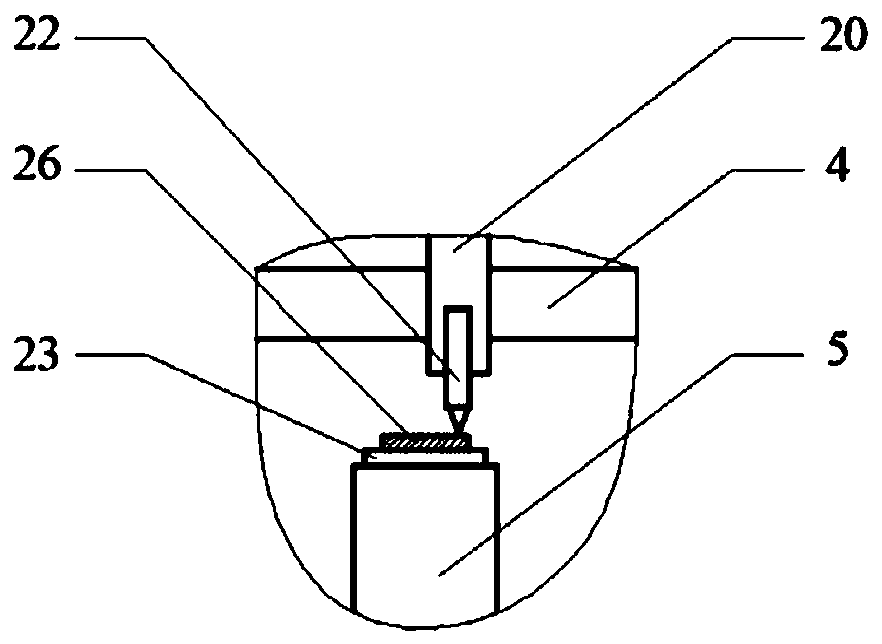

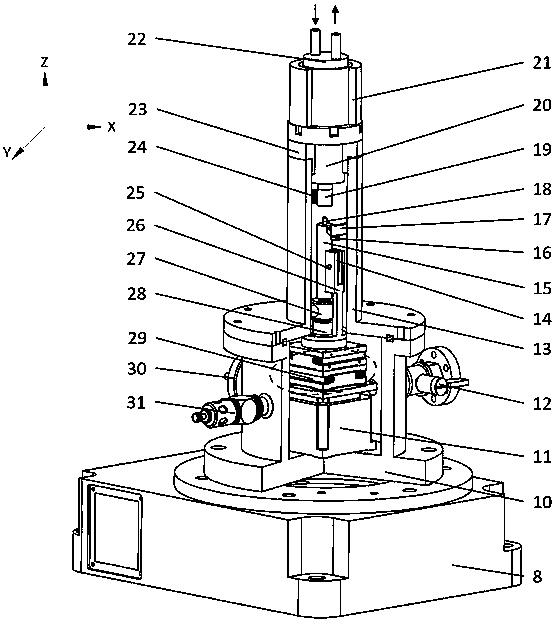

Nano indentation testing device under stretch-four-point bending preload

InactiveCN105973694AGet modulus of elasticityGet Yield StrengthStrength propertiesMicroscopic observationEngineering

The invention discloses a nano indentation testing device under a stretch-four-point bending preload. The nano indentation testing device integrates a pure-stretch test, a pure four-point bending test and a composite load test based on the two single load forms, and meanwhile a nano indentation testing mechanism is integrated on the basis of stretch-four-point bending. A testing platform is composed of a precise stretch preload drive transmission unit and detection and clamping unit, a precise four-point bending preload drive transmission unit and clamping and detection unit and the like. The in-situ nano indentation testing mechanism comprises an X-direction displacement platform, a Y-direction displacement platform, a Z-direction displacement platform, a piezoelectric stack, a flexible hinge, a pressure sensor, a displacement sensor, a diamond indenter clamping bar and the like. The nano indentation testing device is small in size, compact in structure and capable of conducting an experimental test under an optical microscope through real-time microscopic observation, an in-situ bending composite test can be utilized to obtain mechanical property parameters of a material, and in-situ monitoring is conducted on microscopic deformation, damage and the fracture process of the material.

Owner:CHANGCHUN UNIV OF TECH

Method and device for testing continuous thermoregulation high-vacuum low-temperature micro nanoindentation

ActiveCN104697872ARealize contact temperature changeSimple structureInvestigating material hardnessComputer moduleScientific instrument

The invention relates to a method and a device for testing continuous thermoregulation high-vacuum low-temperature micro nanoindentation, belonging to the field of precise scientific instruments. An X-direction precision regulating module is used for regulating the position of a press-in point; a Z-direction precise press-in driving module is used for pressing in precisely, and a displacement signal and force signal precision detection module is used for detecting a displacement signal and a force signal precisely; a variable temperature object support and a cryostat are connected so as to achieve contact thermoregulation of a sample. The device is integrated with a customerized vacuum box so as to achieve micro nanoindentation testing of a sample when the temperature is continuously changed at 77K-500K under the vacuum environment; the problems of precise temperature variation, heat insulation, precise detection and the like in low-temperature micro nanoindentation testing are solved; the blank of the indentation testing technique of a traditional micro nanoindentation in a low-temperature environment when the environment temperature is changed is filled up. According to the device, the structure is simple, the process is convenient, the size is small, the response is rapid, the positioning is accurate, the temperature can be changed and controlled precisely, the displacement load signal can be detected precisely, and the micro precision press-in function can be achieved.

Owner:JILIN UNIV

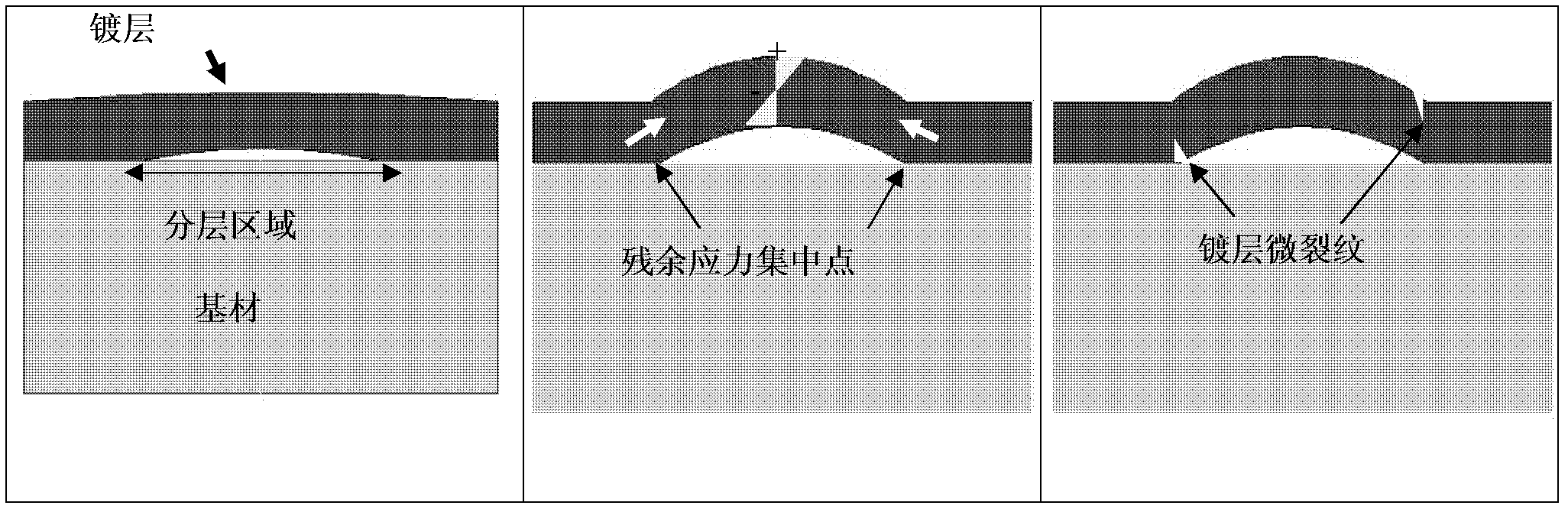

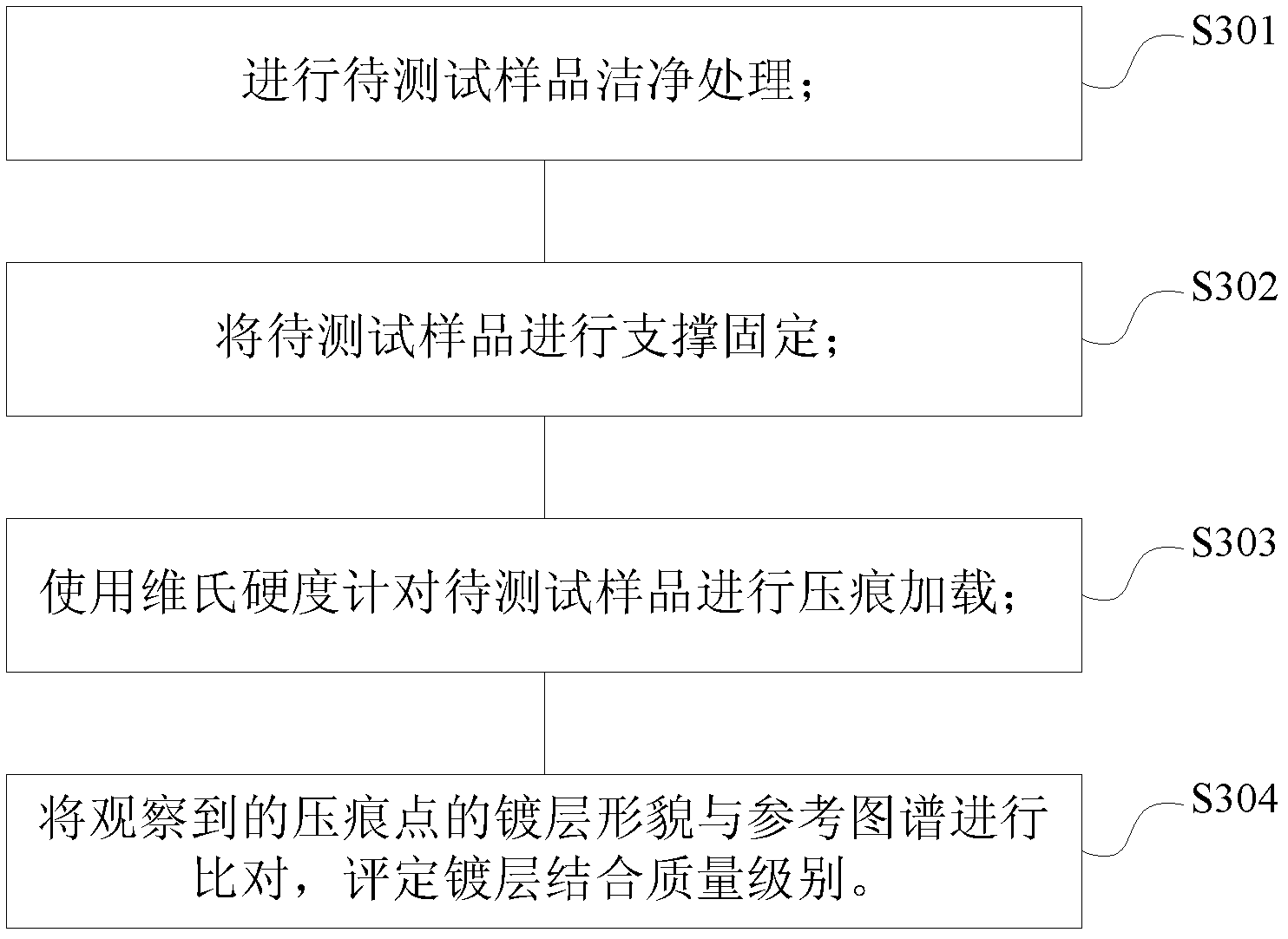

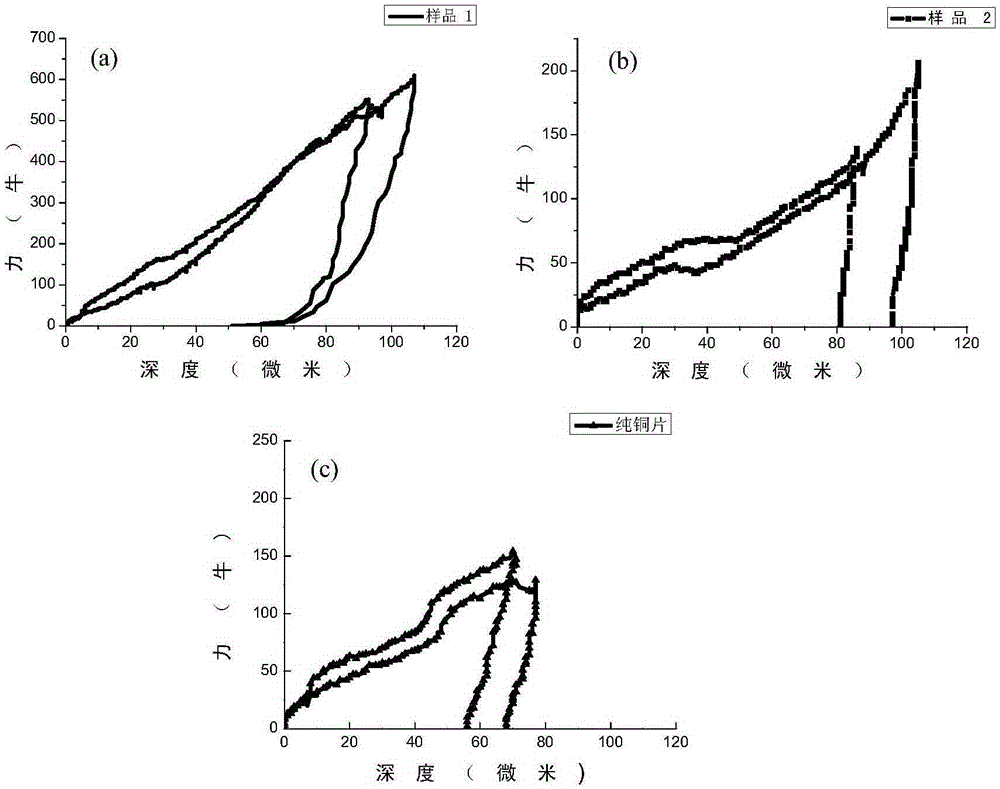

Detection method of plating binding quality of metallic film

InactiveCN102507355AReduce restrictionsDoes not affect appearanceInvestigating material hardnessReference mapRetention time

The invention relates to the metal plating technology, and provides a detection method of plating binding quality of a metallic film. The detection method comprises the steps of: carrying out impress loading on a sample to be tested by using a Vickers hardness tester; comparing appearance of the plating with observed impress points with a reference map, and evaluating the level of the plating binding quality. The technical scheme has low dimensional limit, is suitable for research and judgment of plating binding quality of thin materials and small-size samples, and is also suitable for testing large-size samples; the sample is loaded by using a Vickers pressing head, and the testing is carried out by using the Vickers hardness tester, thus approximate nondestructive test is realized and the integral appearance of the product is not influenced; impress testing is carried out by using the Vickers hardness tester, the load size, loading rate and load retention time can be accurately controlled, the influence of the test conditions is low and the testing has good repeatability; and finally, the scheme can directly use a standard microhardness Vickers hardness tester to test, the operation is simple, convenient and quick, special instruments are not needed, and the method is economical and practical and has good universality.

Owner:ZTE CORP

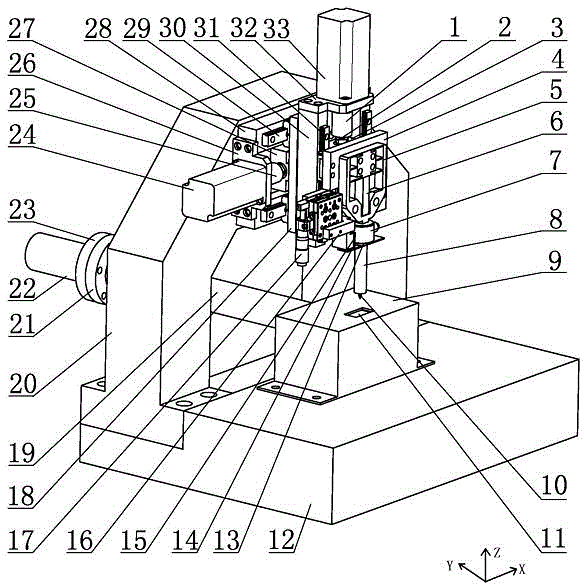

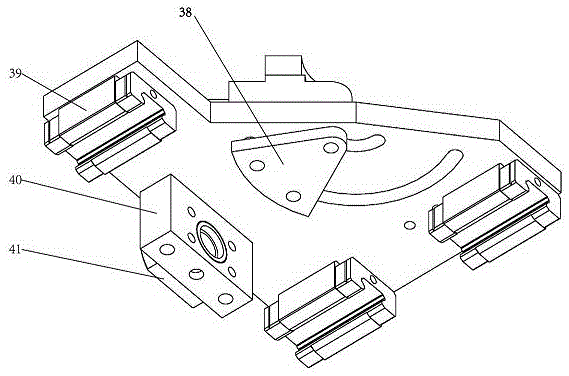

Tension-shear preload based in-situ indentation testing device and method

ActiveCN105067431AFreely change the clamping angleAchieving common loadMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesCombined testCantilevered beam

The invention relates to a tension-shear preload based in-situ indentation testing device and method and belongs to the field of precision and scientific instruments. The device is characterized in that a mechanical drive module comprises a servo motor, two stages of worms and gears, a screw and screw nuts, rotation of the motor can be converted into rectilinear motion at a quasi-static rate, and a tension process is realized; an any-angle tension-shear combined loading module tightly presses a movable device on a base through friction force of bolts, and the load stress inclination of a test piece can be changed through change of the angle of the movable device; a cantilever indentation module realizes loading through a piezoelectric stack which is mounted above a cantilever beam and parallel to the cantilever beam, and the cantilever beam is extruded and forced to bend to realize indentation when the piezoelectric stack is powered and generates actuation. When a tension-shear combined test is performed, the device is placed under a microscope for in-situ observation. The tension-shear preload based in-situ indentation testing device has reliable principle, compact structure and higher practical value, and can perform tension-shear-indentation multi-load mechanics test of materials as well as in-situ observation accurately.

Owner:JILIN UNIV

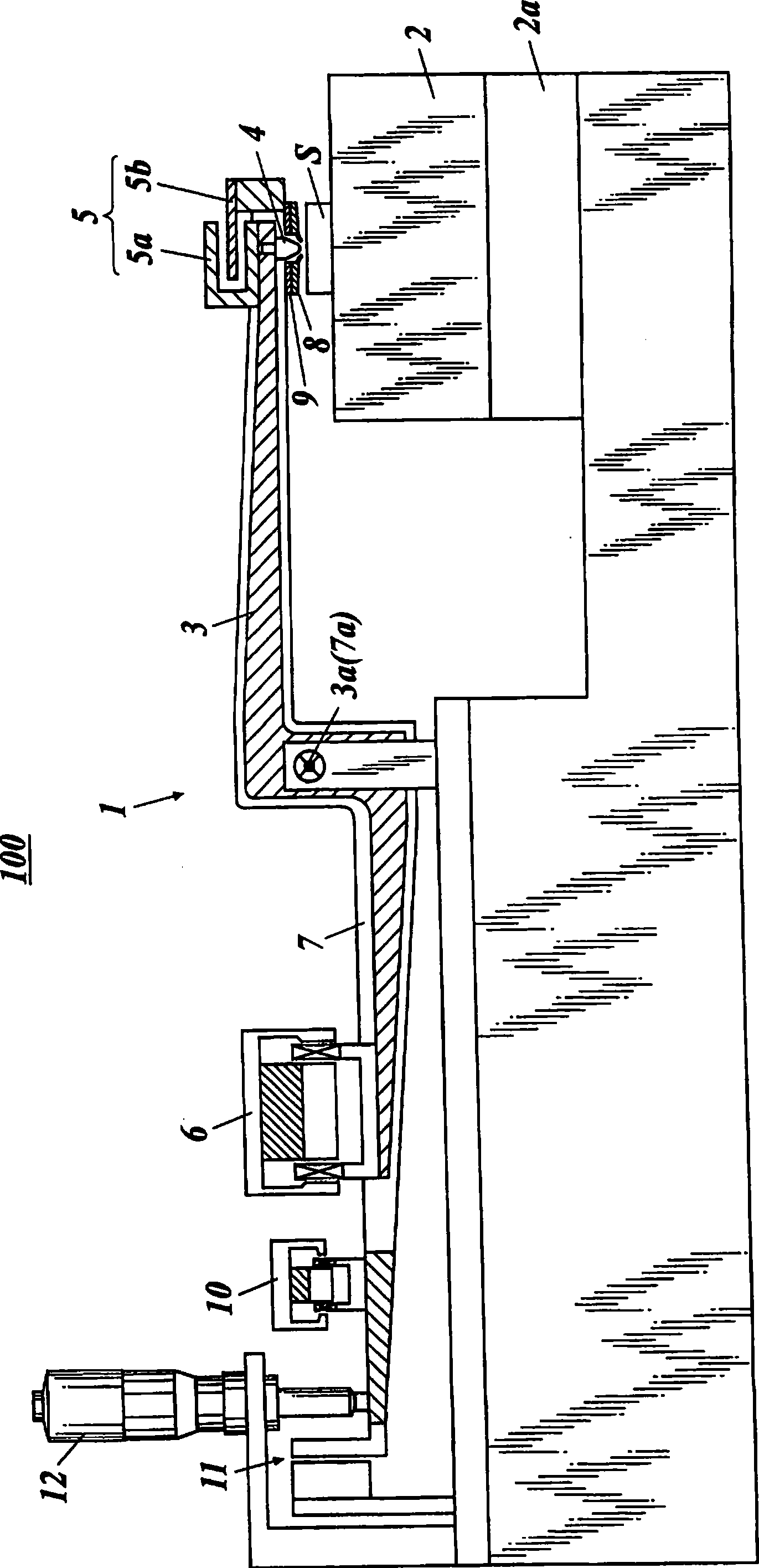

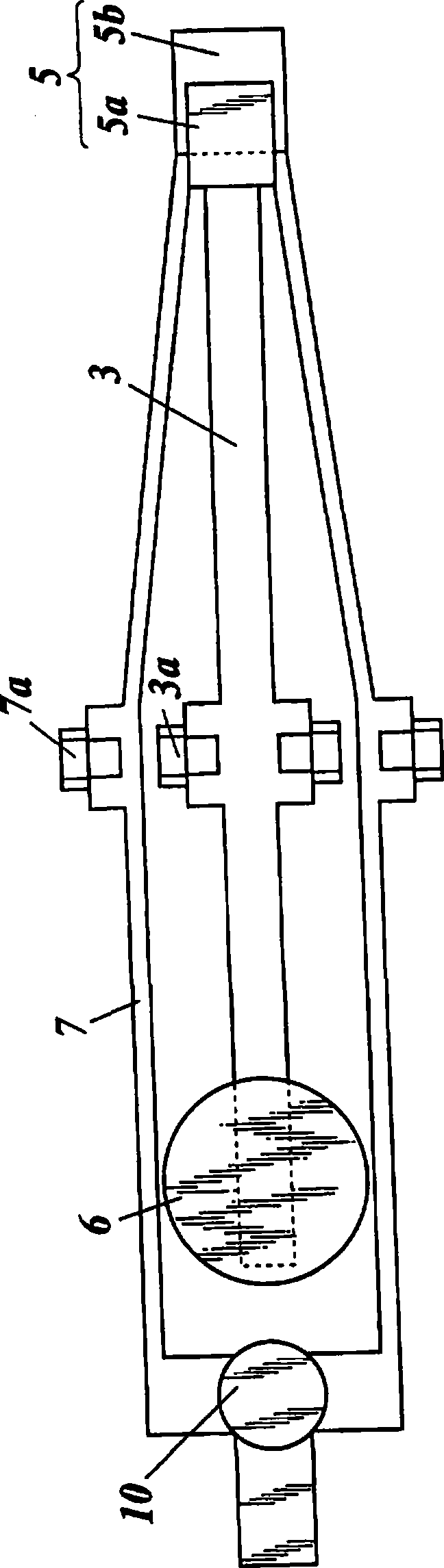

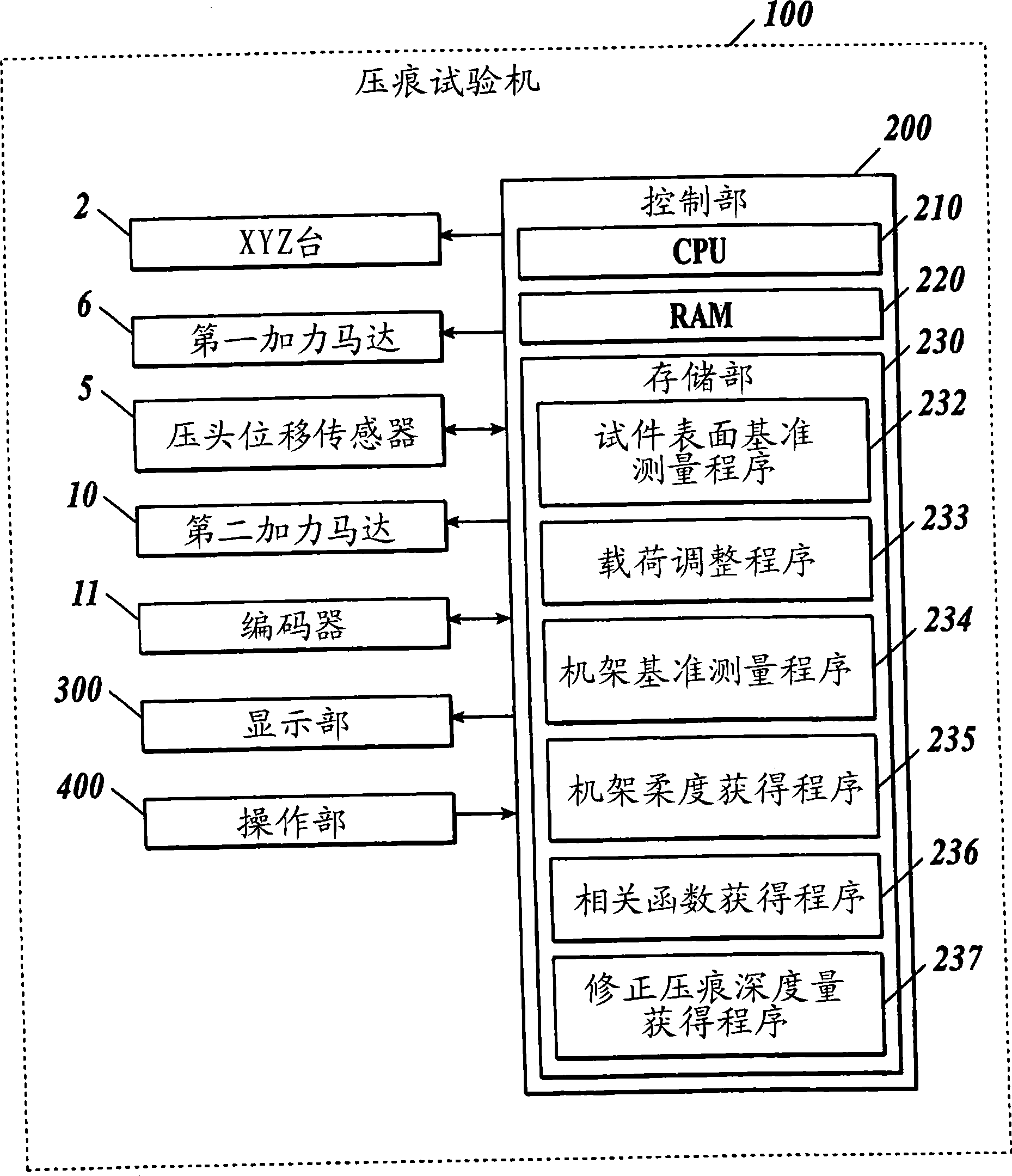

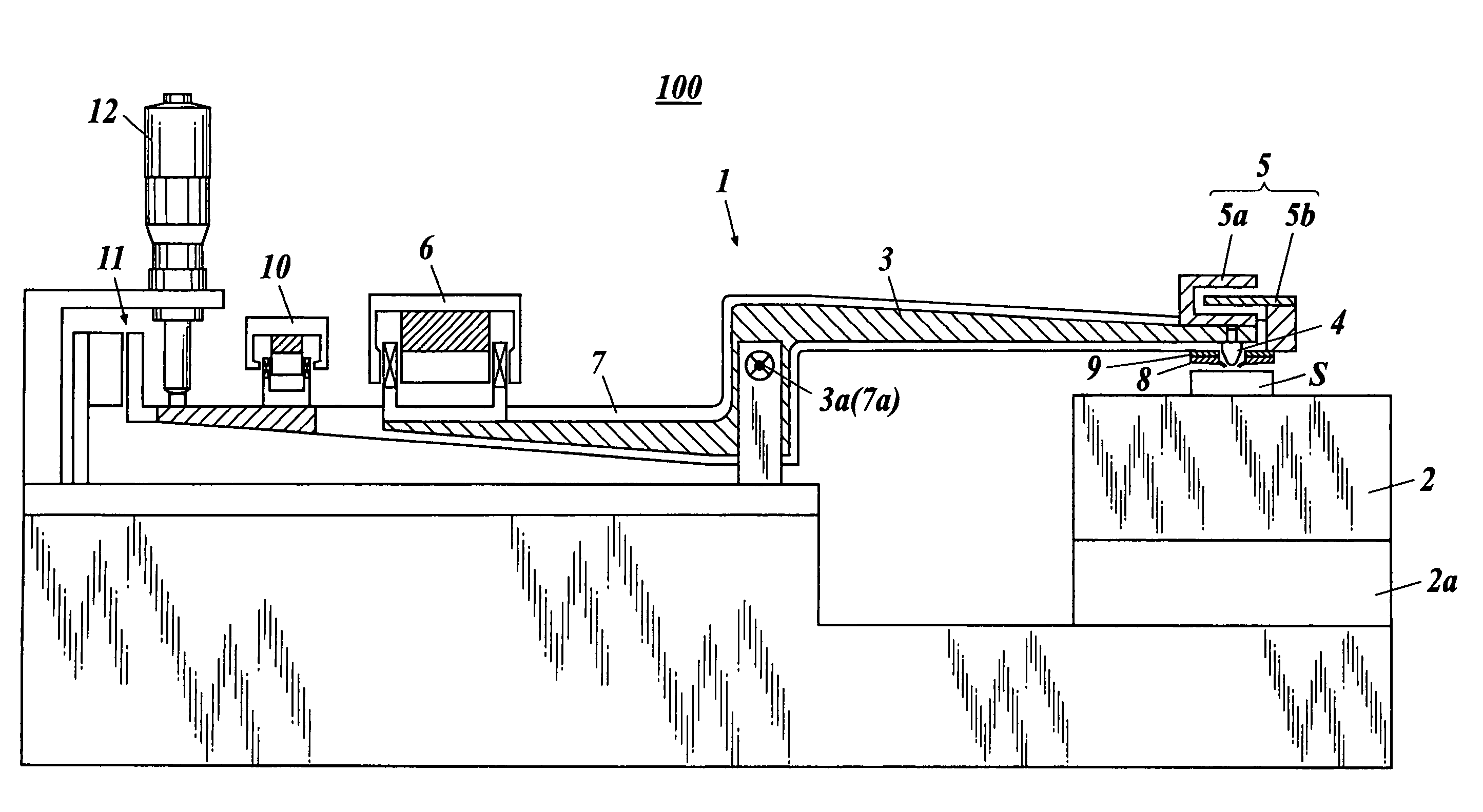

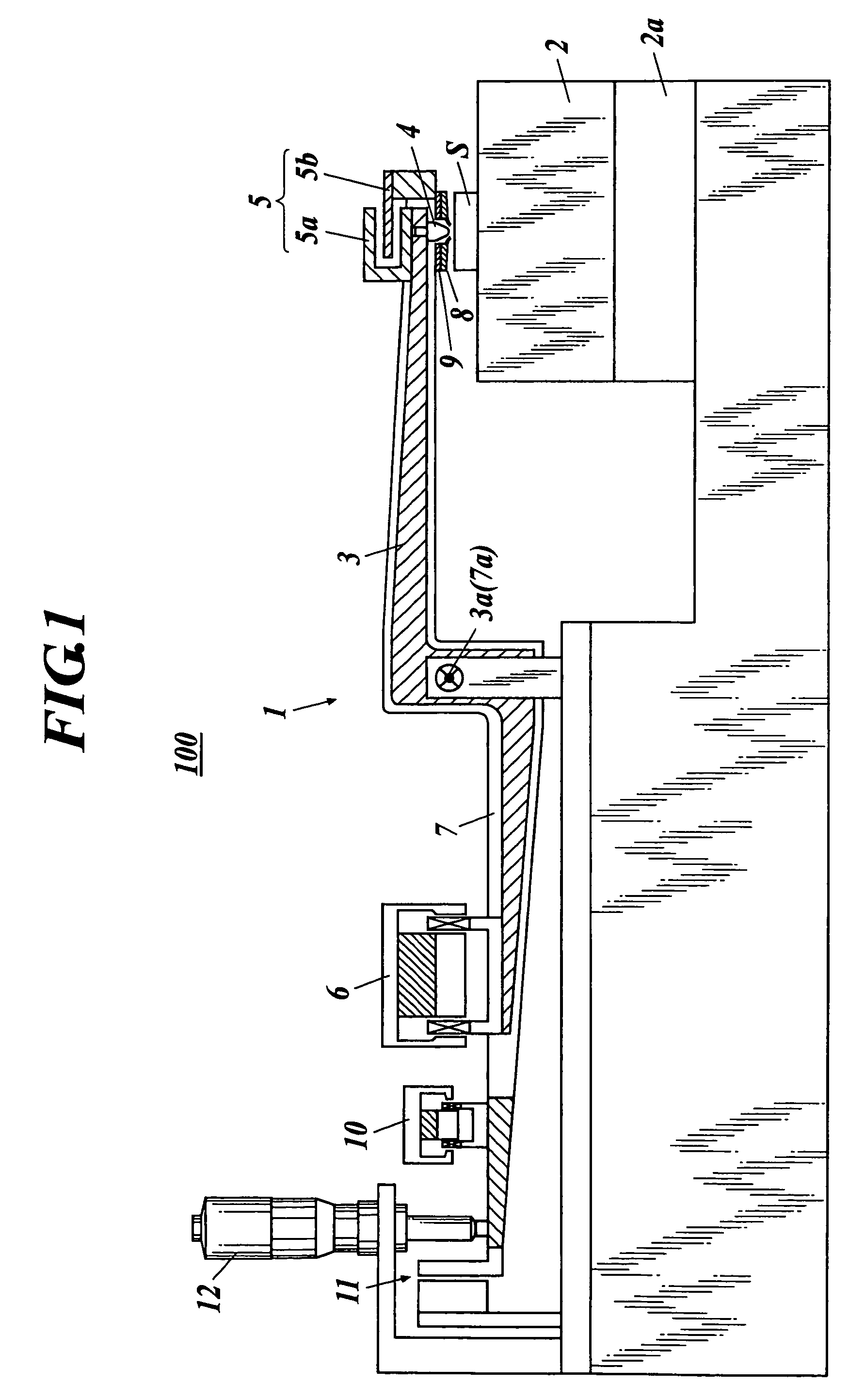

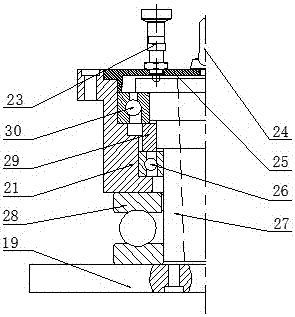

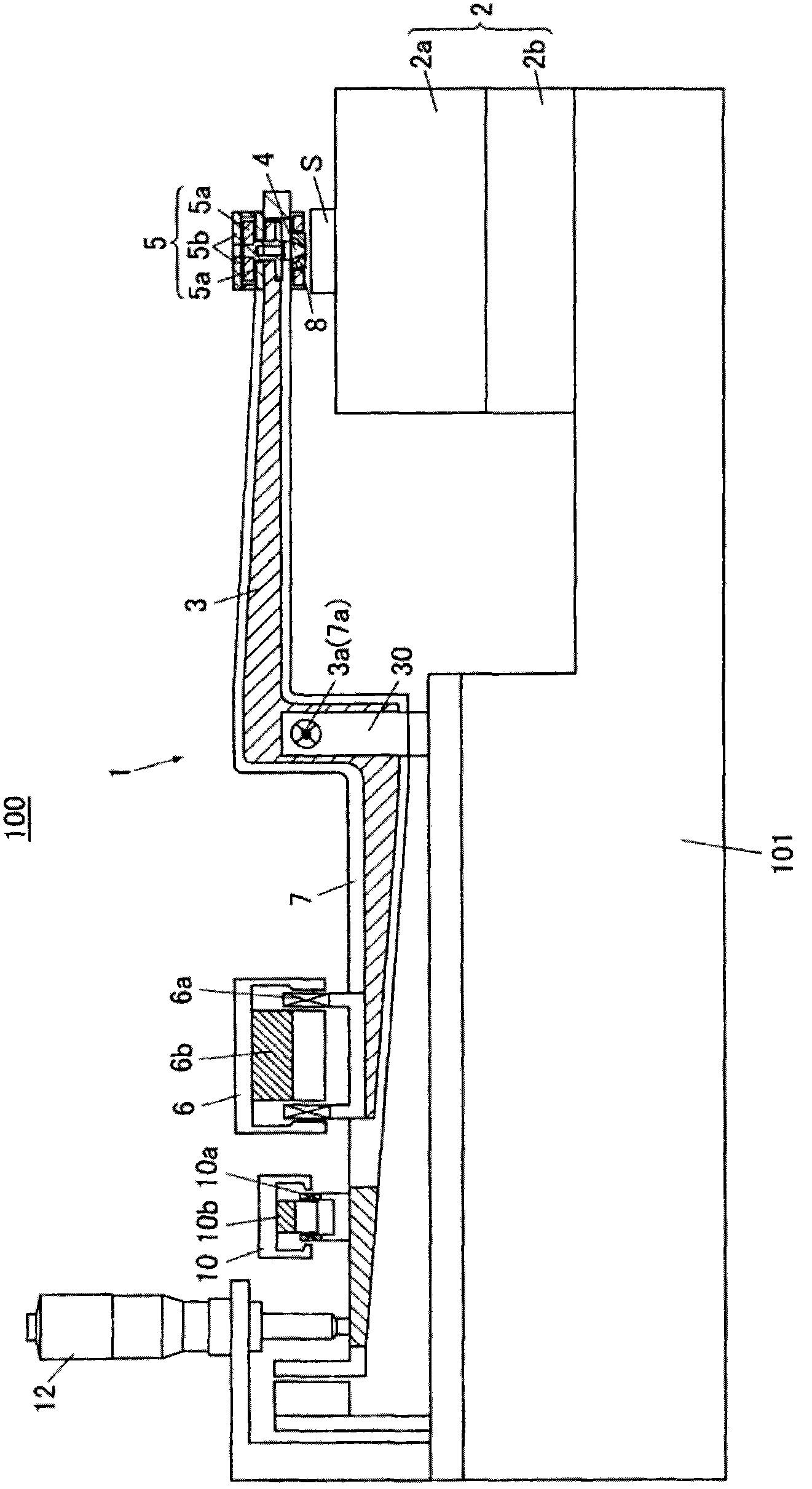

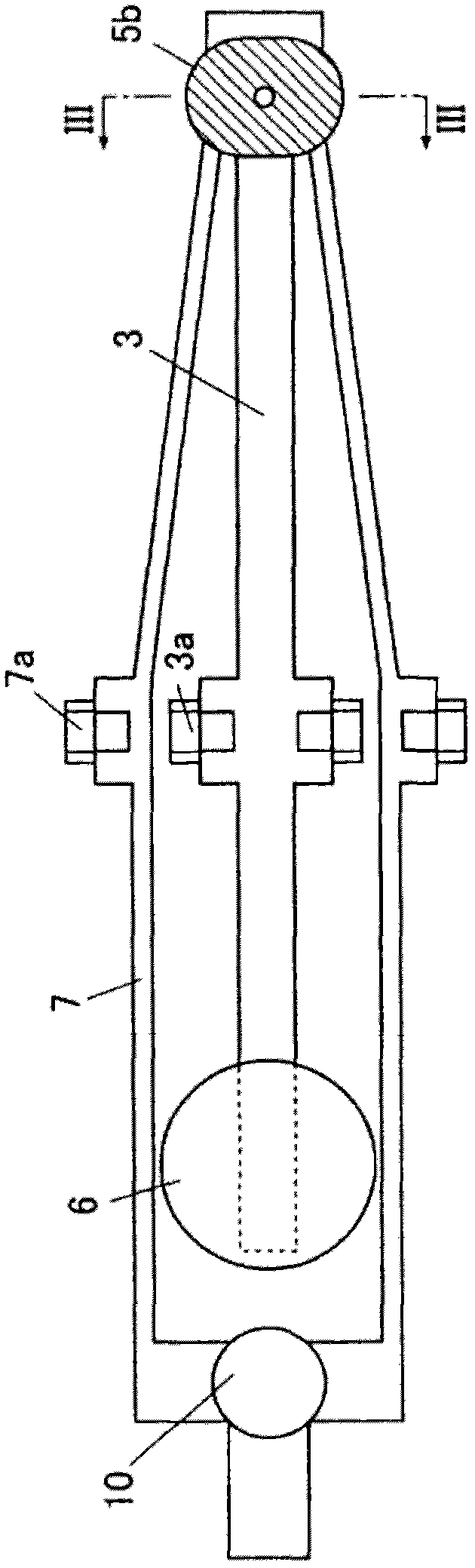

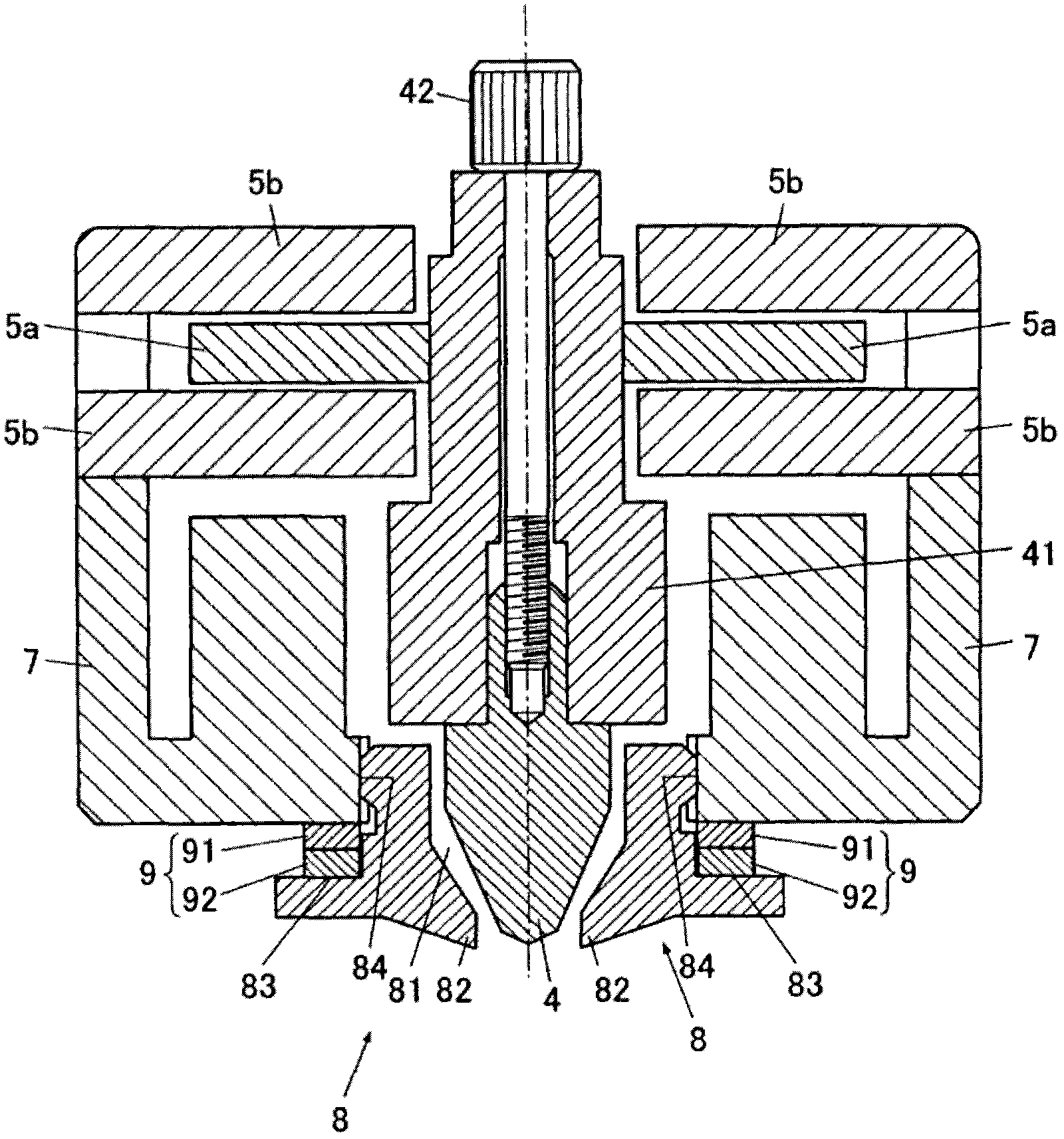

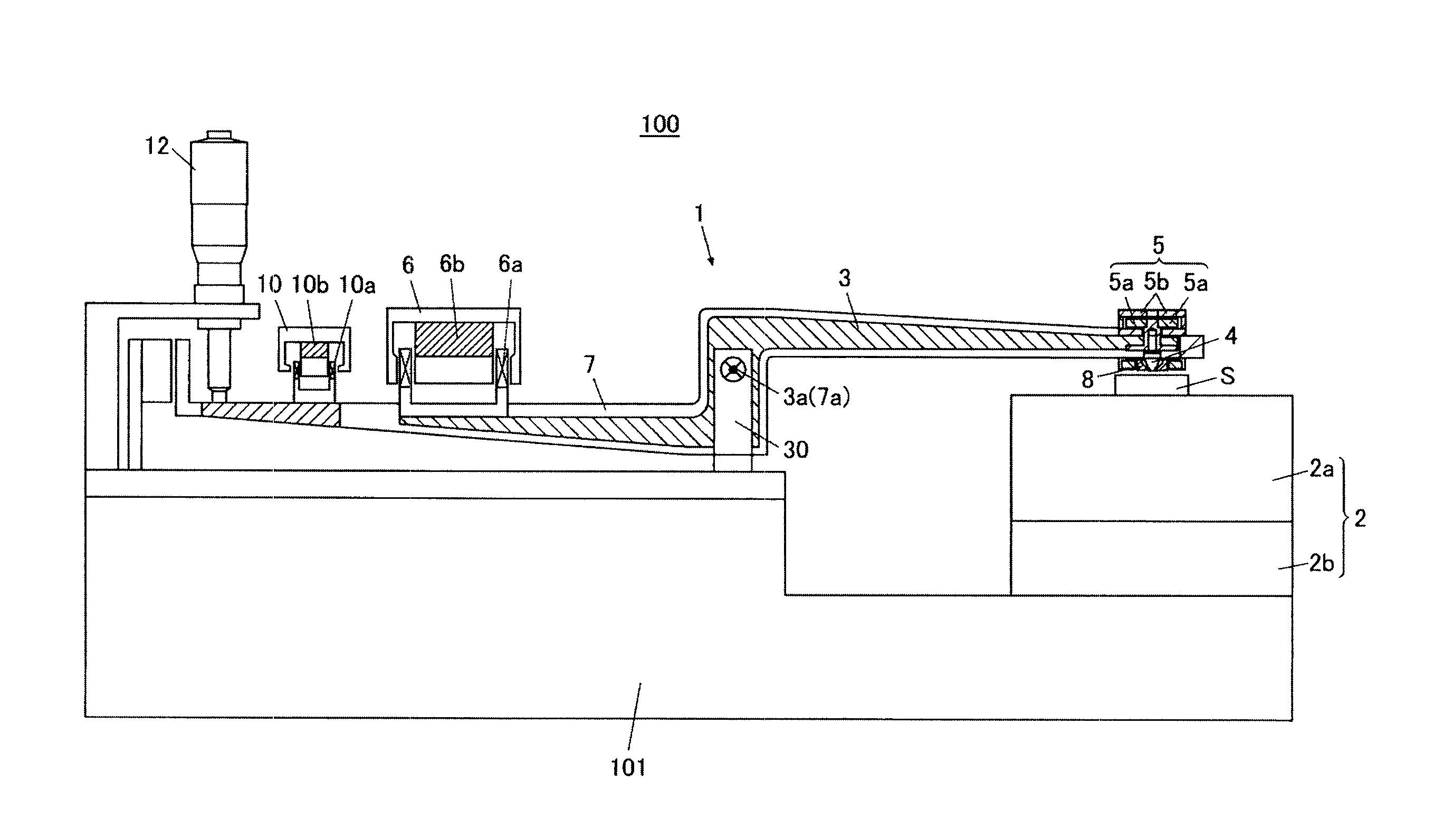

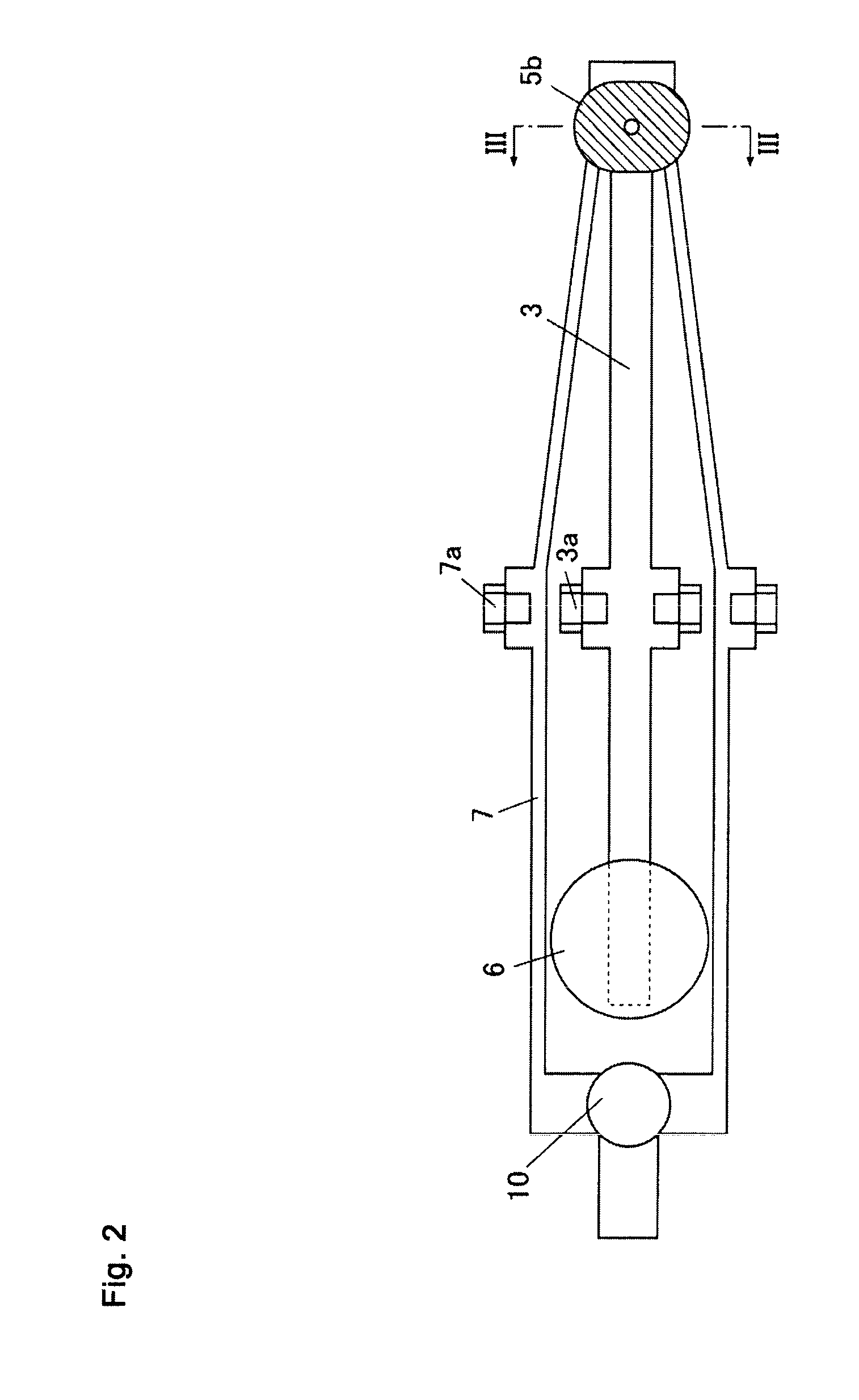

Indentation testing instrument and indentation testing method

ActiveCN101470061AAppropriate flexibilityAccurate measurementInvestigating material hardnessIndentation testingEngineering

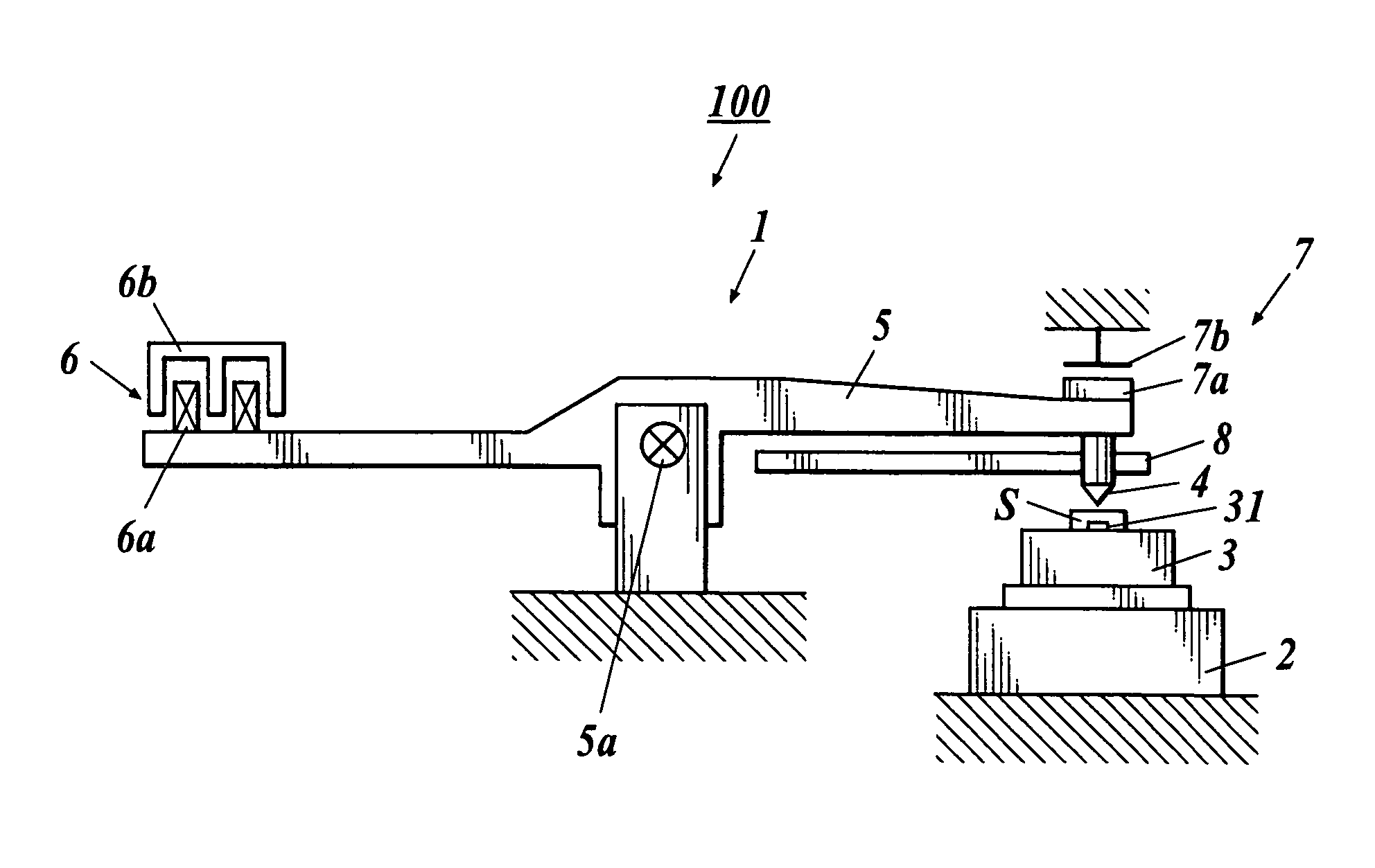

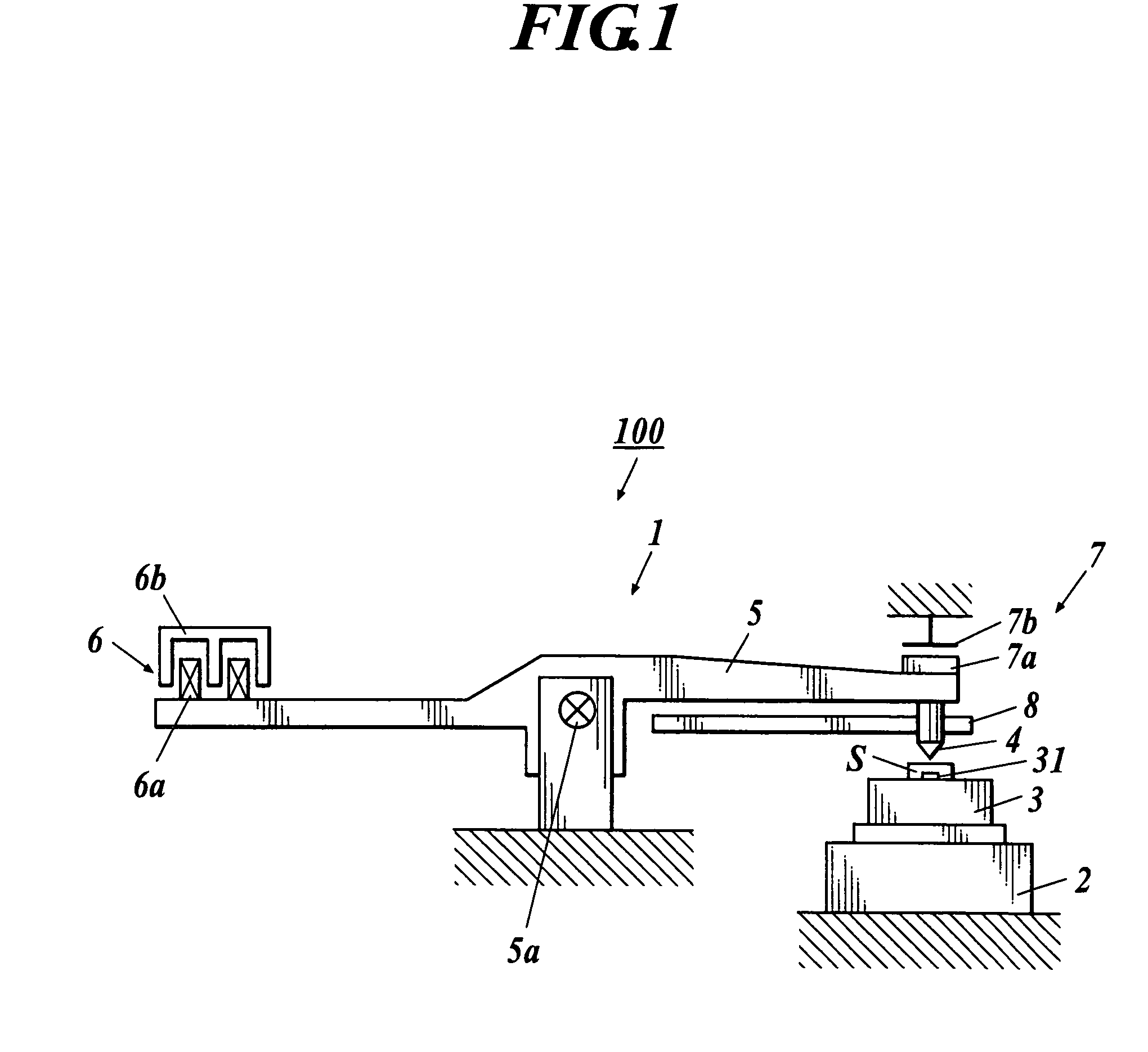

Disclosed an indentation testing instrument including: a loading lever supported pivotally; an indenter provided on the loading lever; an indenter linkage section; a loading lever driving section; a reference lever supported pivotally having a same shaft center as the loading lever; an indenter reference section provided on the reference lever as a positional reference of a tip portion of the indenter; an indenter position detection section; a reference lever driving section; a stopper to stop the reference lever; a specimen surface reference measurement member to turn the loading lever from the state that the indenter reference section touches the specimen surface, and to measure a first indentation depth amount; and a machine frame reference measurement member to turn the loading lever from the state that the reference lever touches the stopper and the indenter reference section is spaced apart from the specimen surface, and to measure a second indentation depth amount.

Owner:MITUTOYO CORP

Method for testing nano-indentation of coating property

InactiveCN110031349ATemperature won't changeGuaranteed accuracyInvestigating material hardnessCoated surfaceIndentation testing

The invention discloses a method for testing a nano-indentation of a coating property. The method comprises the following specific steps of fixing a sample on a sample holder of a nano-indentation test system; regulating the temperature of the sample and a pressure head by using a temperature module, so that the sample and the pressure head are kept at a target temperature; applying and unloadinga load on the coating surface according to the set, and synchronously recording the depth of the indentation to obtain a load-depth curve; and calculating mechanical parameters of the coating based onthe load-depth curve. The temperature module enables the pressure head and the sample to reach the target temperature and maintain the target temperature and then an indentation test is carried out,so that the temperature of the sample, the pressure head and a contact point during the measurement process is ensured to be not changed, the load-depth curve of various temperature conditions can beobtained, and mechanical parameters of the coating at various temperatures can be calculated conveniently. Meanwhile, the problems of temperature gradient and thermal stress formed between the sampleand the pressure head are avoided, and the precision of the load-depth curve is effectively guaranteed.

Owner:CASIC DEFENSE TECH RES & TEST CENT

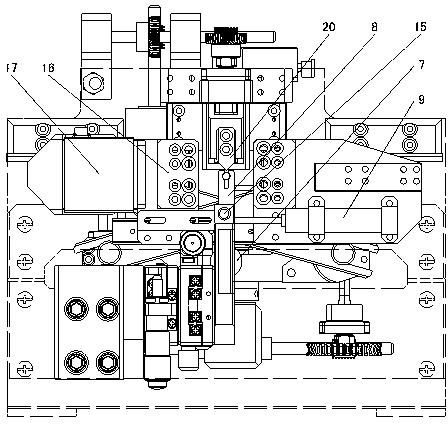

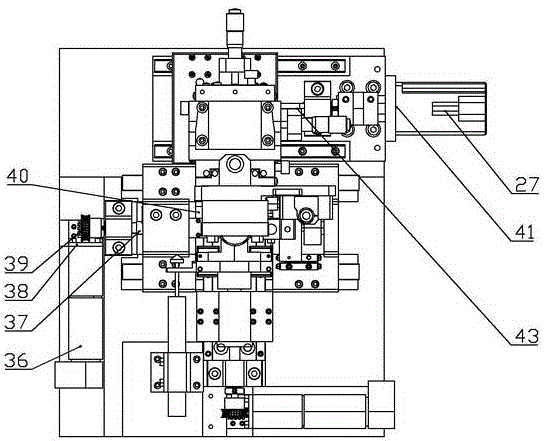

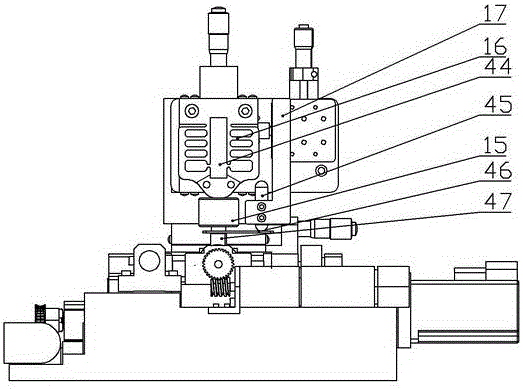

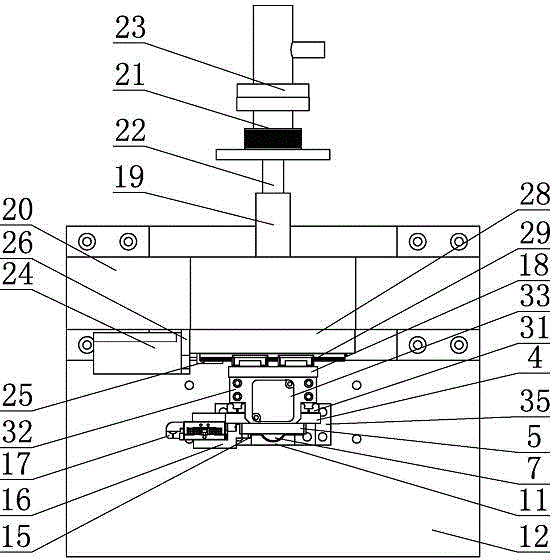

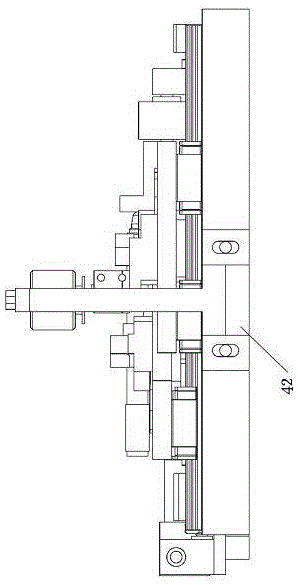

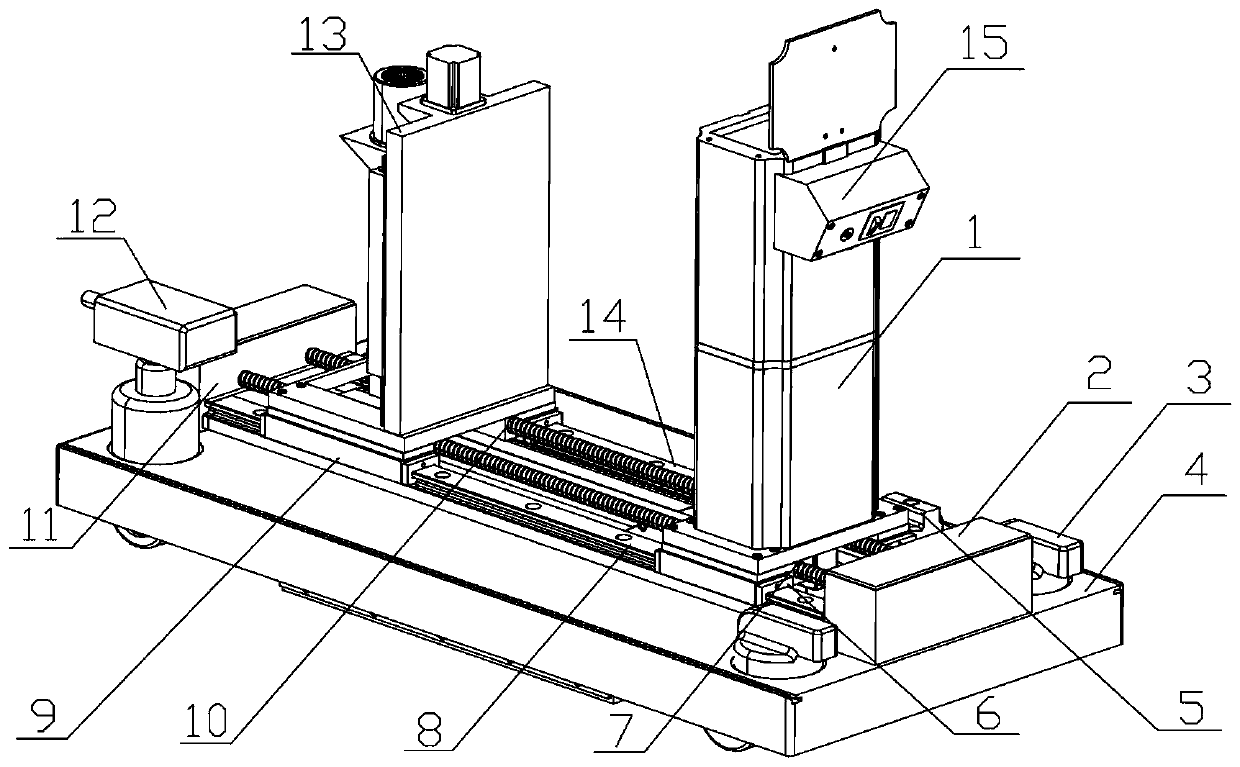

Stretching-bending combined-load in-situ nano-indentation test device and method

ActiveCN105181500AReal-time online observation of crack initiationOnline observation of crack initiationMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesForce linesClosed loop

The invention relates to a stretching-bending combined-load in-situ nano-indentation test device and a method and belongs to the field of precision scientific instruments and material mechanical testers. The overall structure of the test device is in a crossing distribution form and comprises three parts, namely, a stretching loading module, a bending loading module and an indentation loading module, wherein the stretching loading module is arranged in the middle place; the bending loading module and the indentation loading module are respectively distributed on the two sides of the stretching loading module; each of the stretching loading module, the bending loading module and the indentation loading module comprises a driving component, a transmission component, an executing component and a displacement signal and force signal precise detecting component; the loading force lines of the stretching loading module, the bending loading module and the indentation loading module are in the same plane. The synchronous acquisition for the loading / displacement signals can be realized and the closed-loop control on a servo driving system can be realized. The device is smart in structure, is compatible with a mainstream optical microscope and is capable of realizing the multi-load in-situ test for a macroscopic test piece with the feature size above millimeter level.

Owner:JILIN UNIV

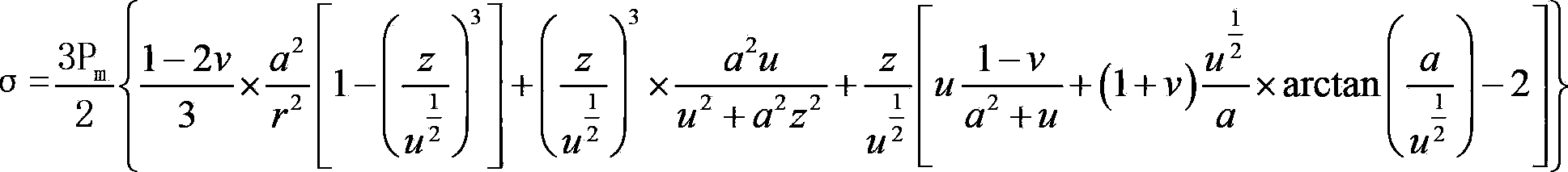

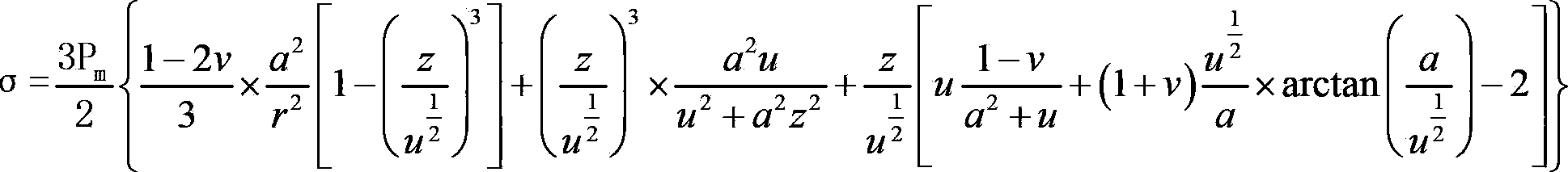

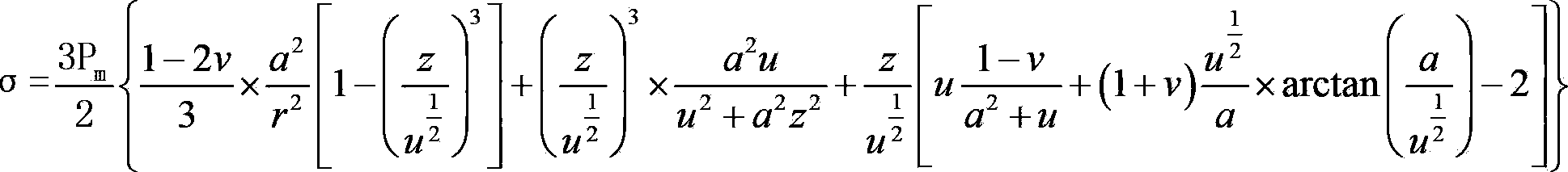

Residual stress testing method

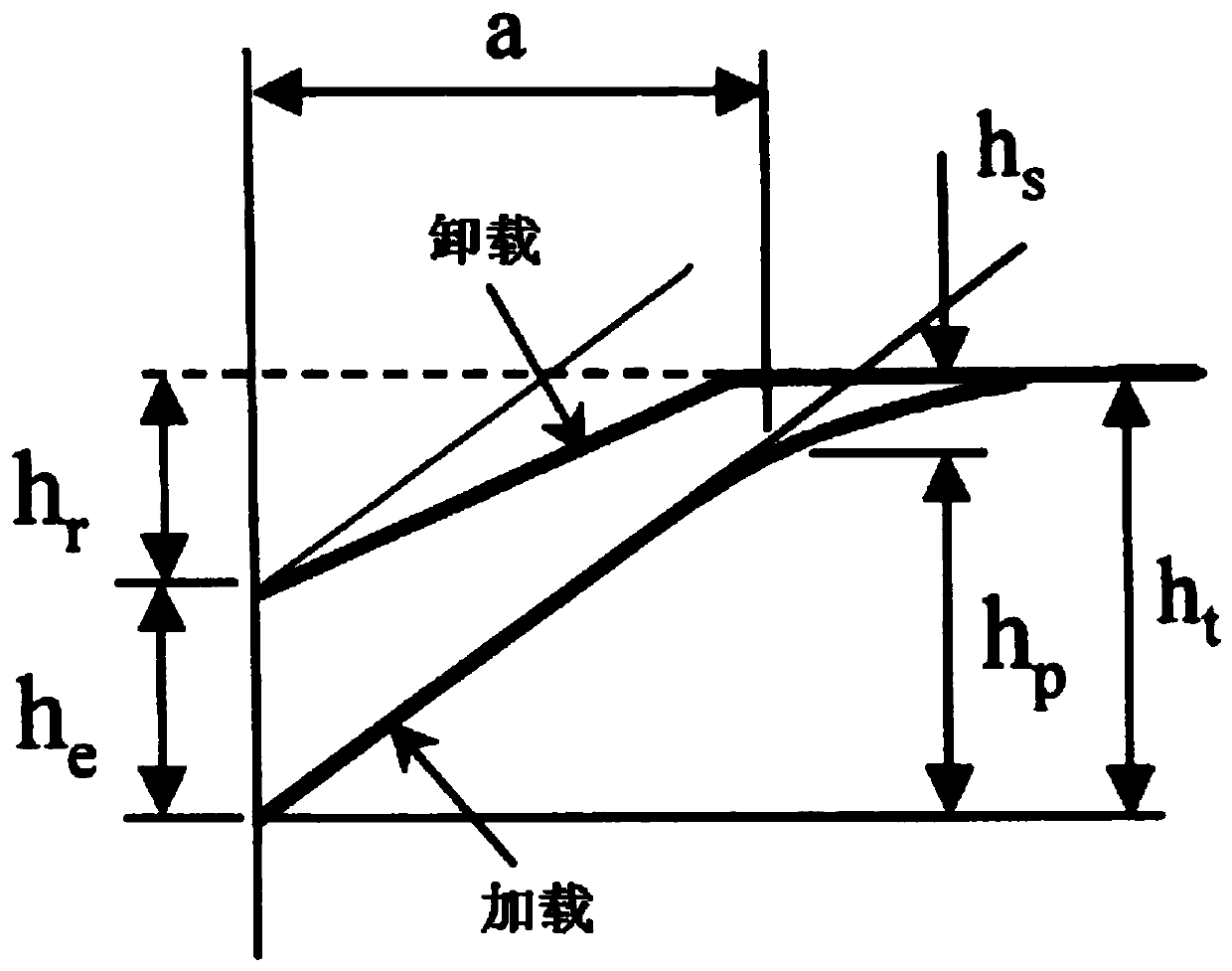

InactiveCN103808575AResidual stress is easyResidual stress calculationInvestigating material hardnessIndentation testingElastic modulus

The invention provides a residual stress testing method relating to an indentation testing method based on a residual stress strain relationship. The residual stress testing method based on an indentation method is simple in operation method, has certain depth in theoretical analysis, numerical analysis and experiment research and is systemic and comprehensive. The residual stress testing method comprises the following steps: applying a certain load to a to-be-tested point of a test piece by virtue of a pressure head, so as to enable the pressure head to generate plastic deformation on the surface of the test piece; forming a spherical crown-shaped dent, and generating a stress field around the dent; calculating a residual stress sigma according to a formula (described in the specification), wherein r represents for the radius, a represents for the size of a contact surface of the dent, and v represents for the elastic modulus of the test piece.

Owner:徐世铭

Method for correcting mechanical parameters of perpendicularity of flat pressing head to indentation test material

ActiveCN109540663AMaterial strength using tensile/compressive forcesInvestigating material hardnessMicro nanoMeasuring instrument

The invention relates to a method for correcting the mechanical parameters of the perpendicularity of a flat pressing head to an indentation test material, which belongs to the field of material mechanical property testing. The perpendicularity of the flat pressing head relative to the surface of a test piece in an indentation test is measured by an ultra-precision perpendicularity measuring instrument. The flat pressing head applies a press-in load to the test piece to carry out micro-nano indentation testing, so as to acquire a load-depth curve of the material indentation test. The slope atthe top of the curve of an unload part of the load-depth curve is acquired, and the elastoplastic theory and an Olive-Pharr method are used to quantitatively evaluate the influence of the perpendicularity of the flat pressing head on the indentation contact area. The correction calculation method for the mechanical property parameters of the perpendicularity of the flat pressing head to the testedmaterial is acquired. According to the invention, the perpendicularity of the flat pressing head in the indentation test is measured; the mechanical property parameters of the material in the indentation test are corrected and calibrated; and the quantitative evaluation method is provided for quantitatively evaluating the influence of the perpendicularity of the pressing head in the indentation test and correcting an indentation test result.

Owner:JILIN UNIV

Evaluating method of the residual stress determining method using the continuous indentation method

ActiveUS7472603B2Error minimizationAccurate estimateAnalysing solids using sonic/ultrasonic/infrasonic wavesMeasurement arrangements for variablePresent methodStress relieving

Owner:FRONTICS +1

Test management method for indentation tester and indentation tester

ActiveUS8087282B2Ensure reliabilityWeighing apparatus detailsInvestigating material hardnessTester deviceEngineering

Disclosed a test management method for an indentation tester which includes a control section and forms an indentation on a surface of a heated or cooled sample by pressing an indenter to which a load is applied onto the surface of the sample, the test management method including the steps of: measuring a predetermined reference block as the sample under a plurality of temperature environments to obtain a test result; calculating a test error caused by temperature environment based on the test result by the control section; and judging whether or not the test error is within a predetermined range by the control section.

Owner:MITUTOYO CORP

Method for testing interfacial strength between semi-flexible pavement asphalt mixture skeleton and cement mortar

InactiveCN107560951AImprove bindingImprove driving comfortInvestigating material ductilityInvestigating material hardnessRoad surfaceLaboratory test

The invention provides a method for testing interfacial strength between a semi-flexible pavement asphalt mixture skeleton and cement mortar and belongs to the technical field of pavement material strength test. The problem that the interfacial mechanical strength between a semi-flexible pavement asphalt mixture skeleton and cement mortar is difficultly tested by the current test method is solved.The method disclosed by the invention comprises the following steps: manufacturing a semi-flexible pavement test piece through a laboratory test by adopting a nano-indenter test method; performing test sample cutting treatment on the semi-flexible pavement according to test instrument requirements, and selecting a sample with representative material interface characteristic for later use; and finally, performing indentation test on the sample characteristic interface by using a nanoindentor, thereby obtaining the interfacial mechanical strength characteristics of the semi-flexible pavement characterized by mechanical parameters of the material interface, such as hardness, elasticity modulus, creep function, fracture toughness, interface bonding force and the like. The method disclosed bythe invention has the characteristics of being simple, convenient and intuitive and can be promoted to evaluation of service conditions of the built pavement, the test parameters can be docked with anumerical simulation method, and development of the numerical simulation method is promoted.

Owner:NANJING FORESTRY UNIV

Indentation testing instrument and indentation testing method

Owner:MITUTOYO CORP

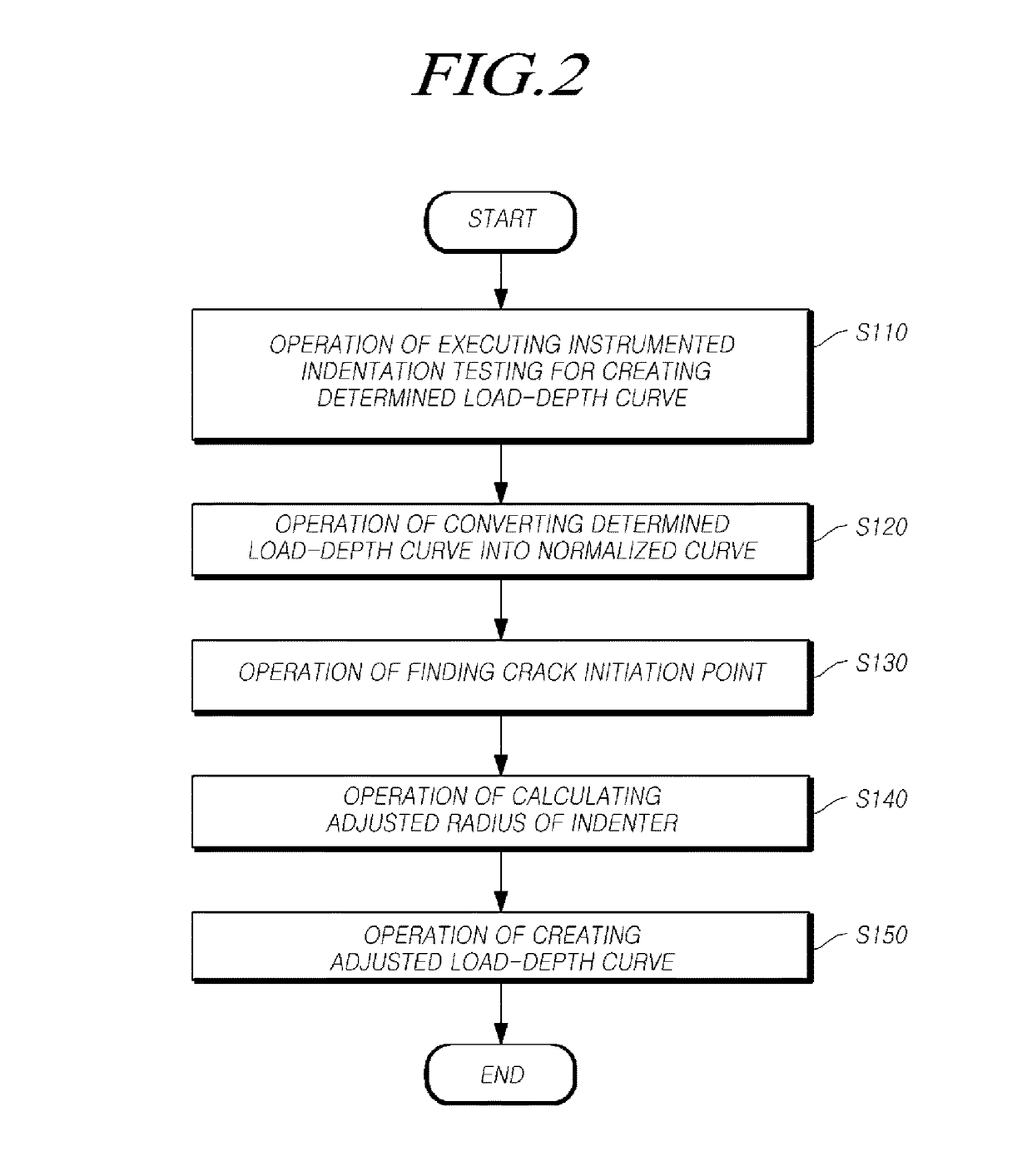

Method for evaluating fracture toughness using instrumented indentation testing

ActiveUS9702798B1Measure directlyMaterial strength using tensile/compressive forcesInvestigating material hardnessIndentation testingComputer science

The present invention relates to a method for measuring a fracture toughness using an instrumented indentation testing, which measures a load and an indentation depth in real time while applying a load to a specimen by an indenter having a flat punch shape.

Owner:FRONTICS

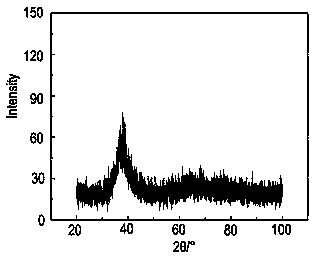

Method for nano-crystallization of Zr-based amorphous alloy induced by nanoindentation combined with fatigue load

ActiveCN110118696AImprove nanocrystallization efficiencyShorten traditional fatigue test timeMaterial strength using tensile/compressive forcesMaterial analysis using radiation diffractionIndentation testingNanocrystal

The invention relates to a method for nano-crystallization of a Zr-based amorphous alloy induced by nanoindentation combined with fatigue load, and belongs to the field of amorphous alloy modification. An original test piece with double V-notch is subjected to XRD test, the test piece is subjected to a tensile experiment by using a high-temperature fatigue tester, pre-tensile loadsare applied to both ends of the test piece, meanwhile fatigue loads are applied through piezoelectric stack on one side of the test piece until the test piece is broken,and the XRD pattern of the test piece after breakage shows a steamed break-like diffuse peak and indicates thatthe test piece after fatigue break does not crystallize; a indentation test is carried out on the test piece after the fatigue break, and the indentation with the most serious plastic accumulation is selected from an indentation topography and subjected to FIB cutting to obtain a TEM sample. The crystallization phenomena at differentdistances from the inclined surface of the indentation are observed by an electron diffraction pattern, and the precipitation of nanocrystals in the amorphous alloy is observed by TEM bright / dark field imaging;and the steps are repeated in the test piece after tensile failureto observea TEM dark field image.

Owner:JILIN UNIV

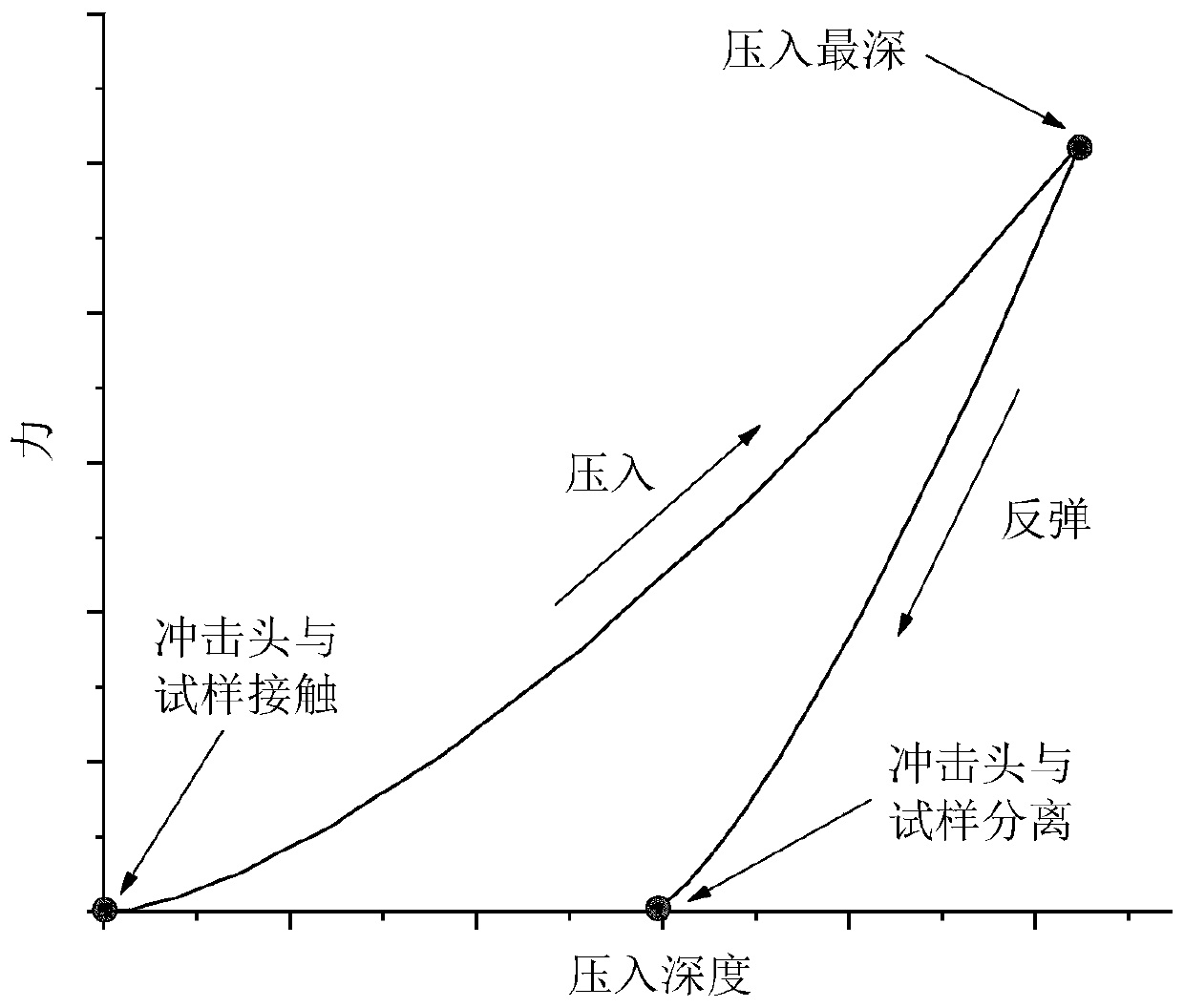

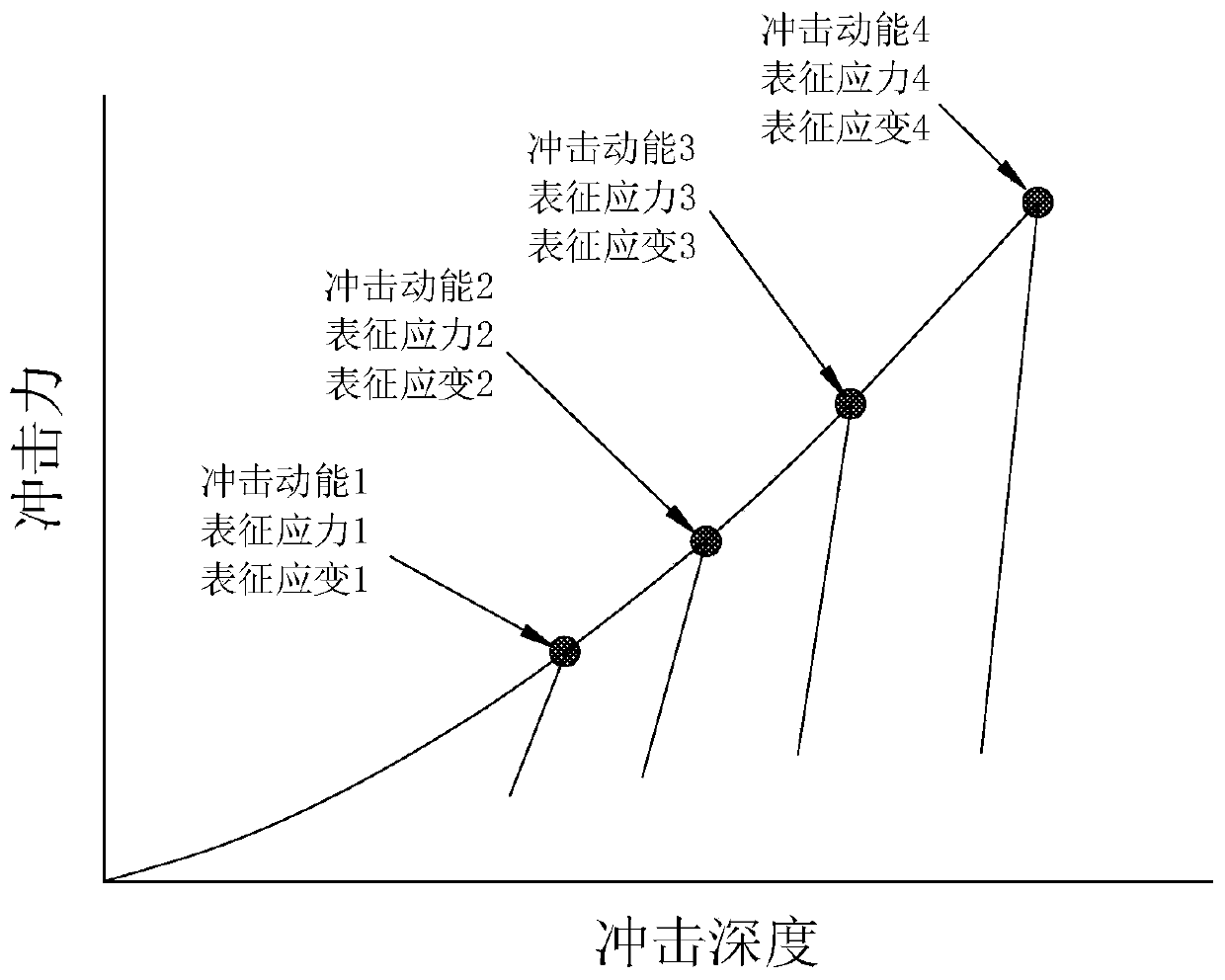

Dynamic load indentation testing method for metal materials

InactiveCN110455658ASimple structureComplex structureMaterial strength using tensile/compressive forcesInvestigating material hardnessStress–strain curveMetallic materials

The invention relates to a dynamic load indentation testing method for metal materials, comprising the following steps: (1) vertically impacting the surface of a metal material to be tested by using an impact pressure head mechanism provided with an acceleration sensor therein, and recording, by the acceleration sensor, an acceleration-time curve; (2) converting the obtained acceleration-time curve into an impact force-indentation depth curve; (3) performing multiple dynamic indentation tests of different impact forces to obtain a series of impact force-indentation depth curves; 4) convertingthe obtained impact force-indentation depth curves into characterization stress and characterization strain, and fitting a true stress-strain curve accordingly; and (5) figuring out the yield strengthand tensile strength of the metal material according to the true stress-strain curve. According to the dynamic load indentation testing method provided by the invention, the yield strength and tensile strength of the metal material are obtained by using the acceleration-time curve obtained by the acceleration sensor through steps one by one, and the detection efficiency of the metal material is greatly improved by the method.

Owner:EAST CHINA UNIV OF SCI & TECH +1

On-line automatic detector for mechanical parameters of materials under complex working conditions

ActiveCN111504826AReduce volumeHigh positioning accuracyInvestigating material hardnessScientific instrumentEngineering

The invention belongs to the technical field of precise scientific instruments, and particularly relates to an online automatic detector for the mechanical parameters of the materials under the complex working conditions. The online automatic detector comprises a shell, and a precise indentation test unit, a base magnetic force moving unit, a material surface polishing unit and a guide rail driving unit which are arranged in the shell. The precision indentation testing unit and the material surface polishing unit are arranged on the guide rail driving unit and are in sliding fit with the guiderail driving unit, and the guide rail driving unit is fixed on the base magnetic moving unit. The online automatic detector for the mechanical parameters of the materials under the complex working conditions is simple in structure, can carry out the indentation test under service conditions, can accurately solve the mechanical parameters, such as material hardness, elastic modulus, yield strength, residual stress, fracture toughness, etc., and can solve the system errors caused by displacement and load detection units in complex environments.

Owner:JILIN UNIV

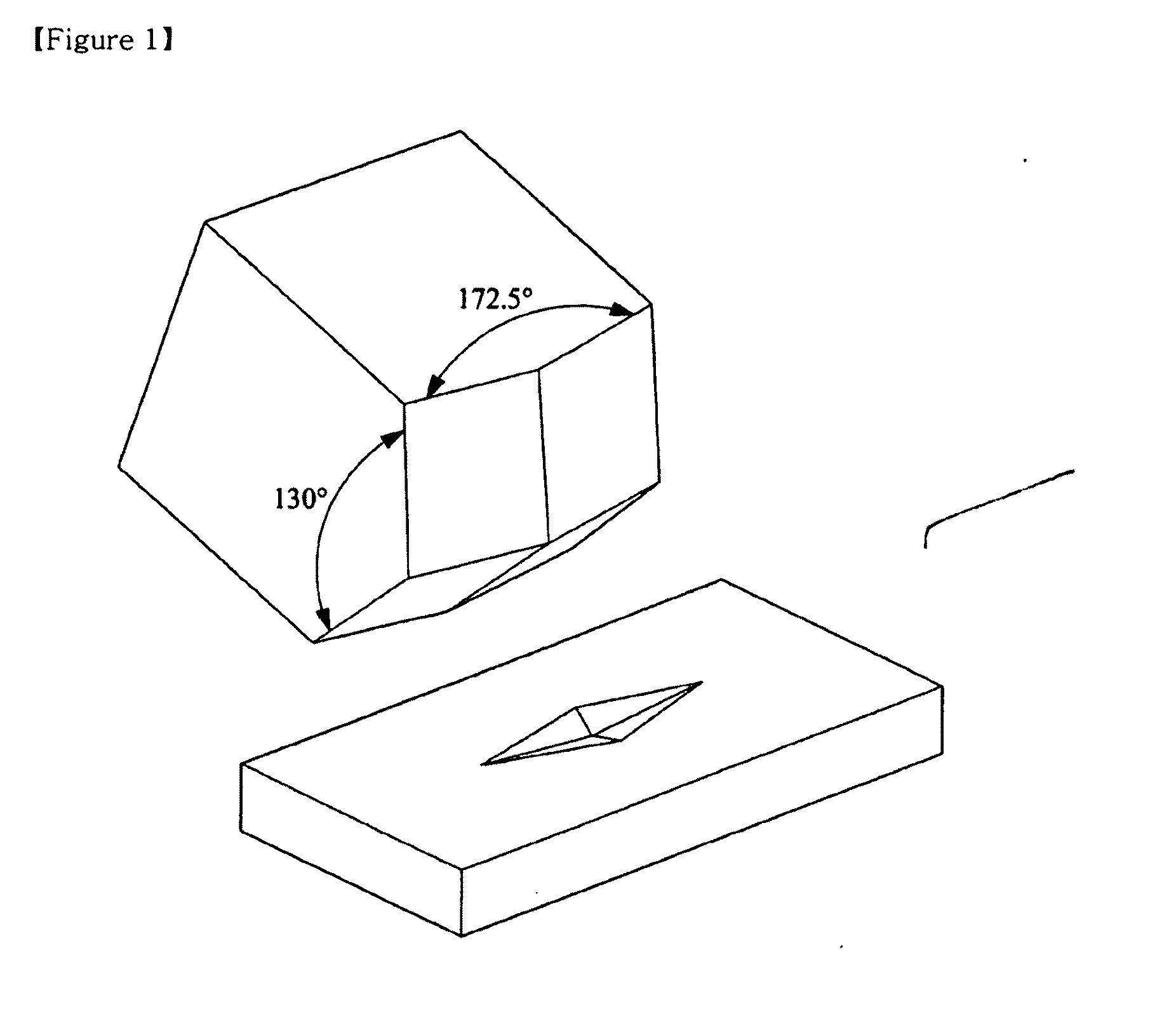

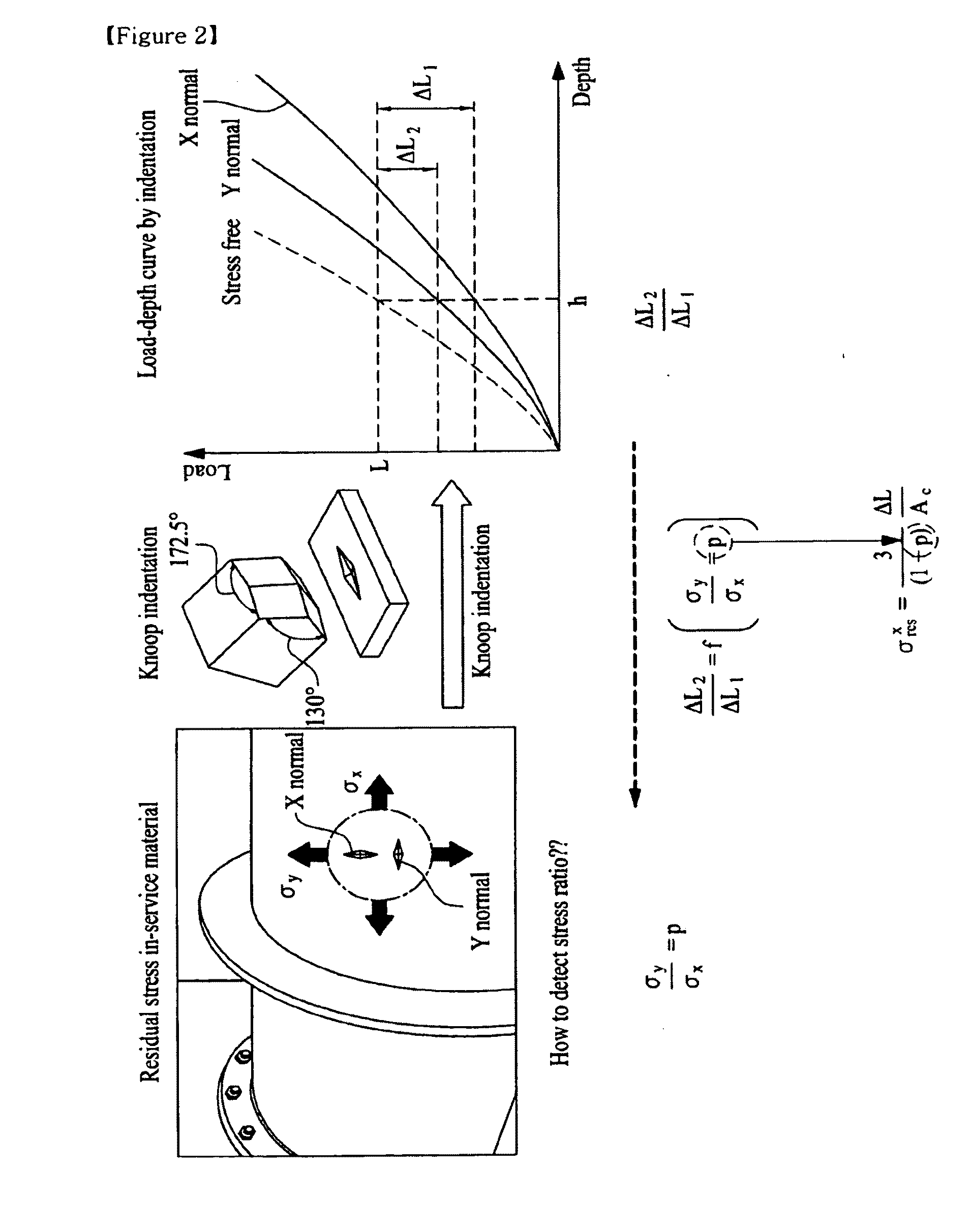

Estimation of non-equibiaxial stress using instrumented indentation technique

ActiveUS20100198530A1Analysing solids using sonic/ultrasonic/infrasonic wavesFlow propertiesDiagonalIndentation testing

Method for evaluating an asymmetric residual stress for a material by the indentation test comprises applying the residual stresses with an uniaxial and an symmetrical biaxial tensions on the material and then performing an instrumented indentation test indenting an asymmetric indenter on the material; and comparing a slope of indentation load-depth curve when the long diagonal direction of the asymmetric indenter is perpendicular to the direction of the largest residual stress with that in stress-free state, and then a slope of indentation load-depth curve when the long diagonal direction of the asymmetric indenter is parallel to the direction of the largest residual stress with that in stress-free state, so as to evaluate the asymmetric residual stress for the material.

Owner:FRONTICS

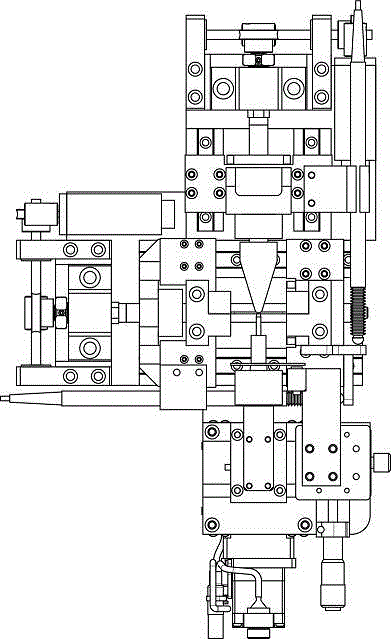

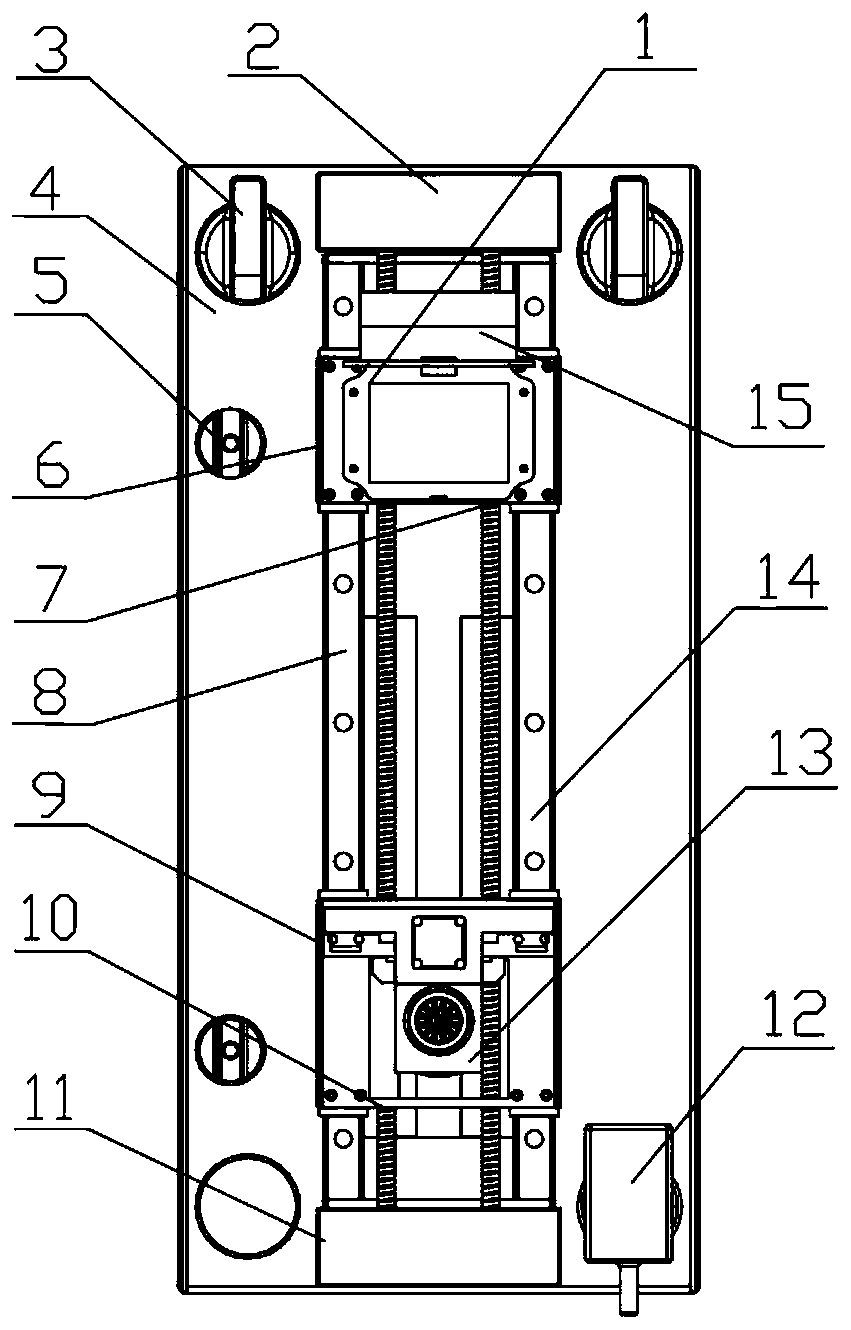

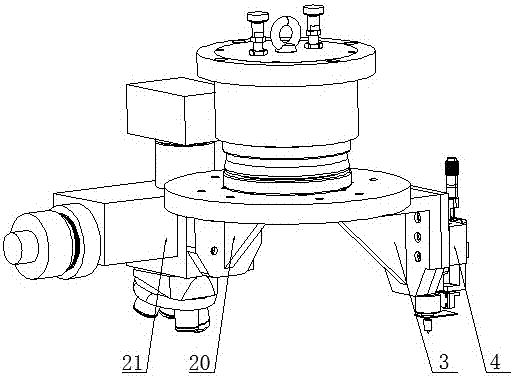

Suspended rotary rapid positioning in-situ indentation/deepened arc indentation testing device

PendingCN107132139AQuick focusSimple structureInvestigating material hardnessMicro nanoElectric machine

The invention relates to a suspended rotary rapid positioning in-situ indentation / deepened arc indentation testing device and belongs to the field of mechanical and electronic integrated precise instruments. The device comprises a suspended rotary rapid positioning module, a deepened arc indentation testing module, a micro-nano indentation module and an in-situ observation module, wherein the micro-nano indentation module and the in-situ observation module are integrated on the suspended rotary rapid positioning module; the deepened arc indentation testing module is composed of an indentation tester and a test piece supporting platform together; and the test piece supporting platform is composed of two parts, namely a shear-type electric lifting table and an electric rotating platform. The device disclosed by the invention has the advantages that the device is novel in structure, has motor-driven rapid feed ability and micro-nano-level piezoelectric micro actuating ability, and can be used for accurately testing the hardness, elasticity modulus, scratching resistance and other mechanical property performances of the test materials. The loading displacement resolution reaches a micro-nano level, and the loading force resolution reaches a micro-Newton level. The effective test means is provided for mechanical behaviors and service behaviors of the materials.

Owner:JILIN UNIV

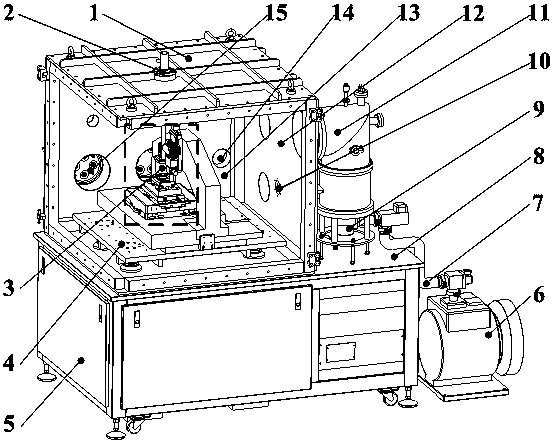

Low-temperature micro-nano indentation test system for large-stroke low-temperature drift under microscopic assembly

ActiveCN108535129AConvenient researchSimple structureInvestigating material hardnessMicro nanoClosed loop

The invention relates to a low-temperature micro-nano indentation test system for large-stroke low-temperature drift under a microscopic assembly, belonging to the technical field of precision instruments. The low-temperature micro-nano indentation test system comprises a vacuum chamber system module, a sliding cryostat assembly and an indentation testing mechanical structure module. Large-strokequasi-static loading is carried out with a hybrid drive mode of a precision displacement drive platform and a voice coil motor in cooperation; a sample and an indenter are simultaneously cooled by a contact refrigeration method; an embedded integrated heating element and temperature measuring element are used to carry out continuous temperature varying closed-loop adjustment and weaken the influence of low temperature drift on test results; the microscopic imaging assembly is used to carry out accurate positioning of indentation locations and in-situ observation of surface topography. The low-temperature micro-nano indentation test system can be used for providing the experimental basis for studying the mechanical properties of materials in low temperature environment and the change rule of mechanical properties of materials with temperature, and has significant application value in research on the mechanical properties of key service materials of aerospace and polar and deep-sea scientific research equipment, superconducting transmission equipment, etc.

Owner:JILIN UNIV

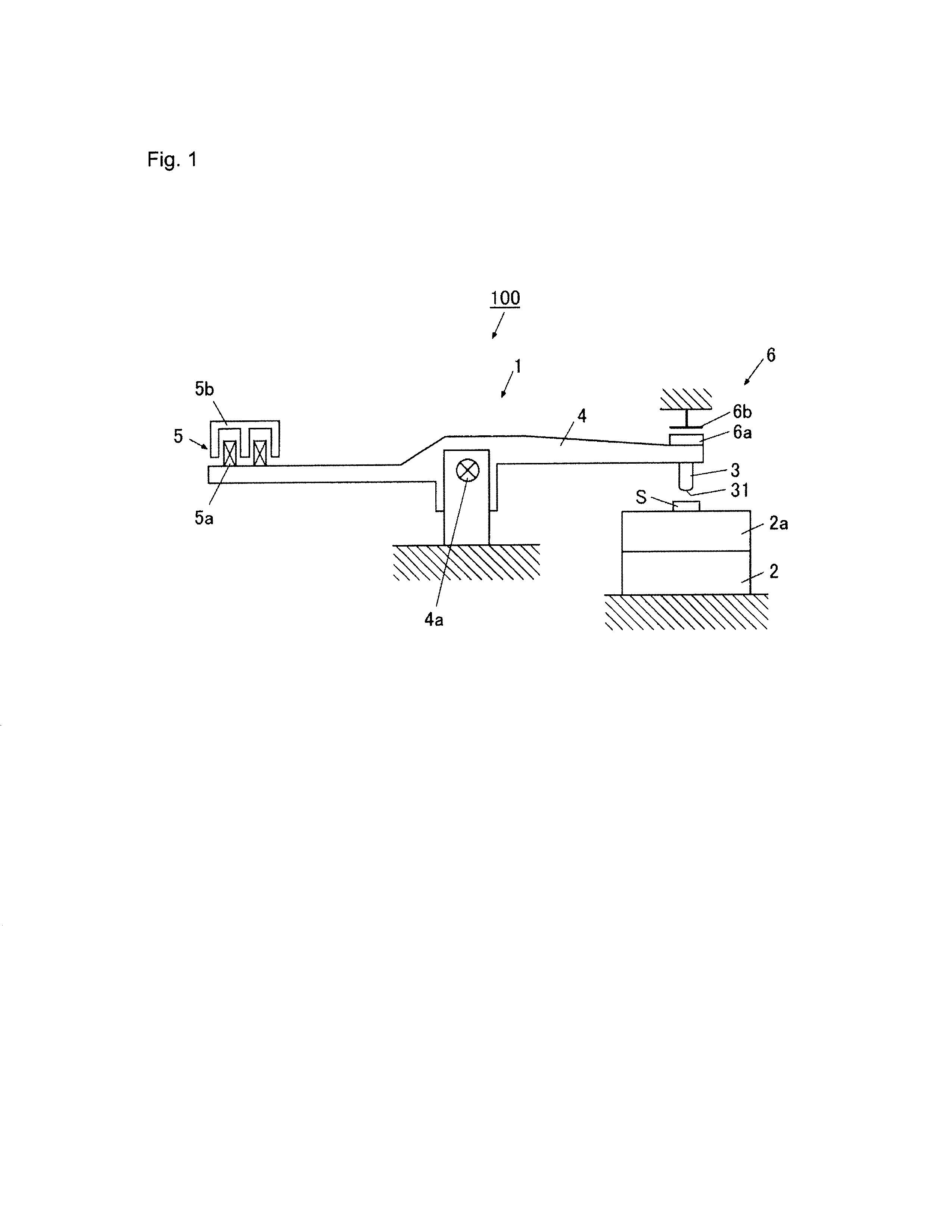

Hardness tester and program

ActiveUS20130174653A1Ensure correct executionProcess stabilityInvestigating material hardnessClassical mechanicsIndentation testing

The present invention provides a hardness tester capable of accurately detecting a point where an indenter contacts a sample in instrumented indentation testing. Prior to beginning measurement, the hardness tester defines an expected range for a value for a displacement, speed, or acceleration of an indenter during a process of approaching a sample. After measurement has begun, the hardness tester measures the value for the displacement, speed, or acceleration of the indenter during the process of approaching the sample. When the measured value is not within the expected range, the hardness tester determines that detection of a zero point has failed.

Owner:MITUTOYO CORP

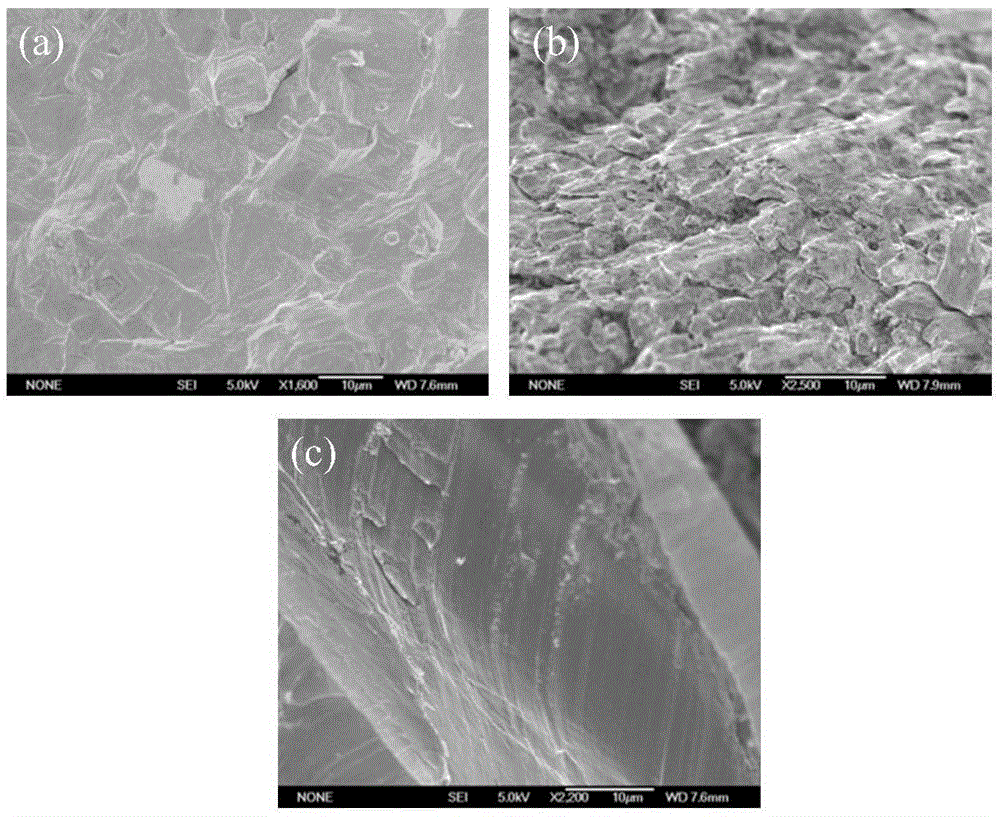

A kind of graphene metal composite material prepared by metal salting-out method and preparation method thereof

The invention discloses a graphene metal composite material prepared through a metal salt precipitation method and a preparation method of the graphene metal composite material prepared through the metal salt precipitation method. The graphene metal composite material is characterized in that metal salt and graphene oxide are used as raw material, through the metal salt precipitation method, the graphene oxide is reduced to be graphene, the meta salt is precipitated to be metal material, and therefore the graphene metal composite material with the metal material as a parent is formed, wherein the flake graphene is inserted into the metal material in an embedded mode. The graphene metal composite material is prepared through the metal salt precipitation method, reaction in-situ is performed on oxygen-containing functional groups on the graphene oxide and metallics obtained through precipitating the metal salt, and a bonding effect is achieved between the metallics and the graphene oxide, so that the flake graphene is not prone to be agglomerated, and the problems that graphene is prone to being agglomerated and poor in dispersity in the parent metal material are solved. Through indentation testing and melting point testing, the hardness of the sample is improved, the melting point of the sample is increased, and performance of the sample is improved.

Owner:UNIV OF SCI & TECH OF CHINA

Indentation testing device and testing method

ActiveCN110132750AAddresses an issue where the zero point of contact cannot be determined directlyShorten the test cycleMaterial strength using tensile/compressive forcesTemperature controlThermal insulation

The invention provides a novel high-flux wide-temperature-range indentation testing device and testing method capable of measuring various mechanical properties (including elasticity modulus, yield strength, tensile strength, creep property and the like) of a material. The device can directly determine a contact zero of a pressure head and a test specimen through a fine tuning way, simultaneouslycan provide a temperature environment of 253DEG below zero to 1000DEG C, and can simultaneously carry out multiple groups of indentation tests under the same temperature environment. The device comprises a base, a sample platform, a force application system, a distance regulation system, a feedback control system, a measurement system, a temperature control system and / or a thermal insulation system. By use of the device, the problem that an existing indentation testing device can not directly determine the contact zero of the pressure head and the test specimen, meanwhile, the problem that anexisting device can not simultaneously carry out multiple groups of indentation tests under the same temperature environment is also solved, the device and the method capable of testing a plurality of same test specimens or the test specimens of different sizes under one working condition are provided, and wide-temperature-range indentation testing is realized through the conversion of a temperature environmental box.

Owner:EAST CHINA UNIV OF SCI & TECH

Indentation tester

ActiveCN103454170AEasy to realize adjustment operationRealize adjustment operationInvestigating material hardnessIndentation testingMechanical engineering

Owner:MITUTOYO CORP

Indentation tester

ActiveUS9046456B2Readily and cheaply adjustingReadily and cheaply madeInvestigating material hardnessIndentation testingEngineering

Owner:MITUTOYO CORP

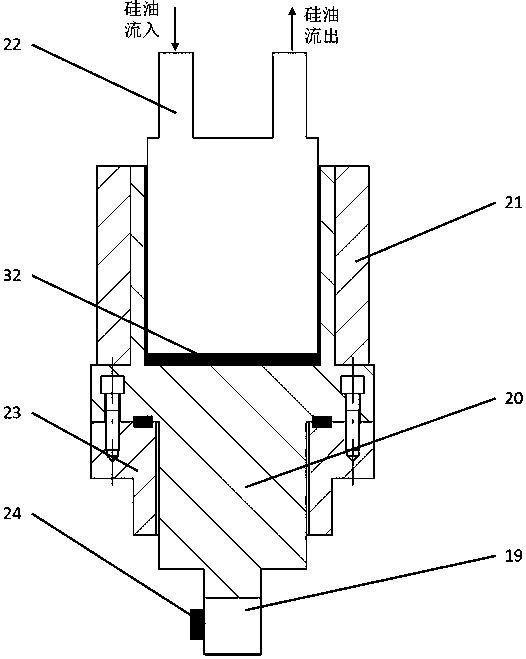

In-situ high/low-temperature indentation testing device applied to cone-beam CT imaging

PendingCN110044752AConstant and stable temperature controlPlay the role of heat conductionInvestigating material hardnessMicro nanoDynamic monitoring

The invention relates to an in-situ high / low-temperature indentation testing device applied to cone-beam CT imaging and belongs to the field of testing of mechanical-electrical integration precision scientific instruments and materials. The in-situ high / low-temperature indentation testing device comprises a cone-beam CT imaging unit, a high / low-temperature indentation testing unit, an electric rotating platform, a vibration isolation platform and a silicone oil temperature control device, wherein the cone-beam CT imaging unit, the electric rotating platform and the silicone oil temperature control device are mounted on the vibration isolation platform; a high / low-temperature indentation testing unit is fixed on the electric rotating platform and comprises a high / low-temperature loading submodule, a precision loading and detecting submodule and a vacuum guaranteeing submodule. The in-situ high / low-temperature indentation testing device is capable of carrying out in-situ micro-nano indentation testing in the high / low-temperature environment with the temperature from 50 DEG C below zero to 120 DEG C under dynamic monitoring of the cone-beam CT imaging unit, carrying out in-situ observation and three-dimensional imaging of micro deformation and damage processes of the materials under the actions of high stress and high strain, and providing an effective technical manner for revealing mechanics behaviors of the materials under thermal coupling loading conditions and constitutive relations of microstructure changes of the materials.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com