In-situ high/low-temperature indentation testing device applied to cone-beam CT imaging

A CT imaging and testing device technology, applied in measurement devices, testing material hardness, instruments, etc., can solve problems such as the inability to unify the microscopic deformation mechanism and mechanical properties of materials, and achieve compact structure, extended temperature range, and novel ideas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

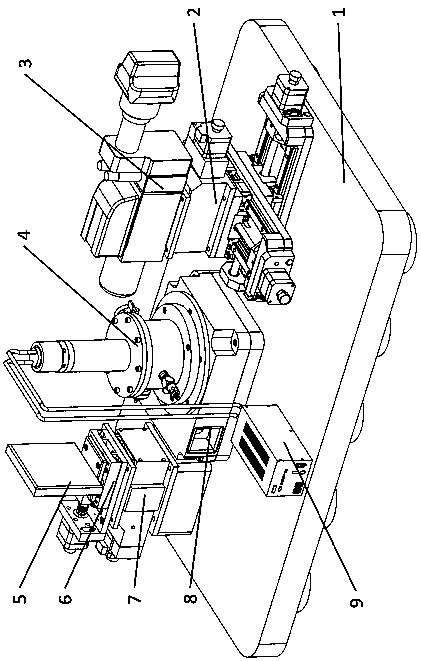

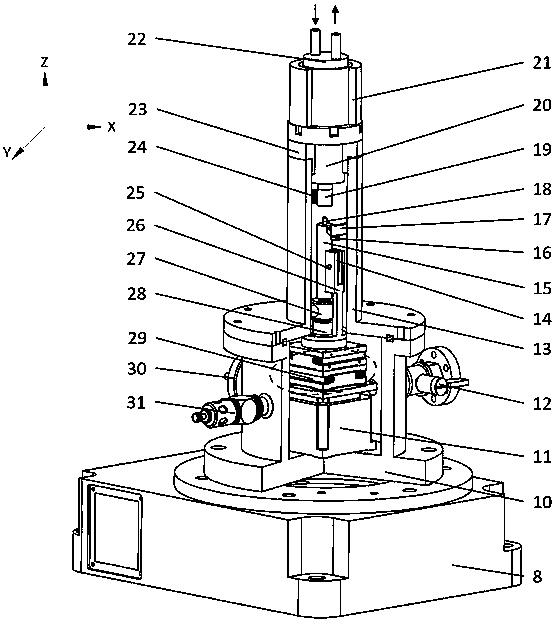

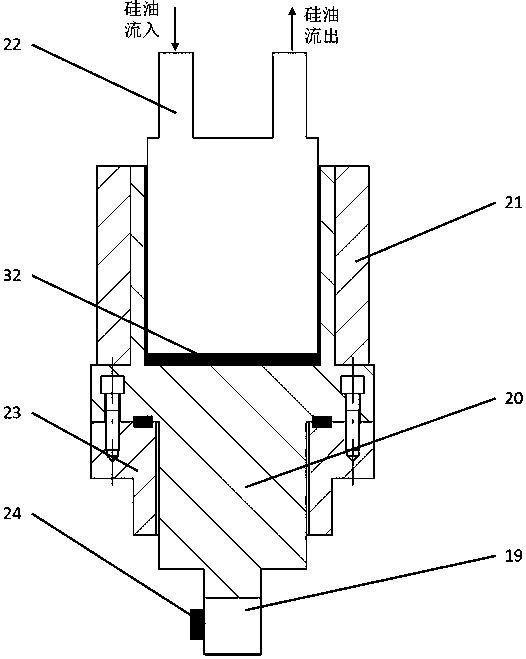

[0027] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

[0028] see Figure 1 to Figure 5 As shown, the in-situ high / low temperature indentation testing device for cone-beam CT imaging of the present invention organically combines CT non-destructive testing technology and indentation testing technology; under the dynamic monitoring of cone-beam CT imaging unit Carry out in-situ nanoindentation tests in high / low temperature environments. The invention can carry out micro-nano indentation test for the change of mechanical properties of materials in high / low temperature environment of -50°C~120°C, and can also perform in-situ observation and three-dimensional imaging of the microscopic deformation and damage process of materials under the action of high stress and strain , which provides a new technical means for studying the physical and mechanical properties of sample m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com