Novel color steel press plate

A profiled panel, a new type of technology, is applied in the direction of building components, heat preservation, etc., and can solve the problems of poor ventilation of the profiled panel house, high temperature of the house, and ineffective thermal insulation effect of the profiled panel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

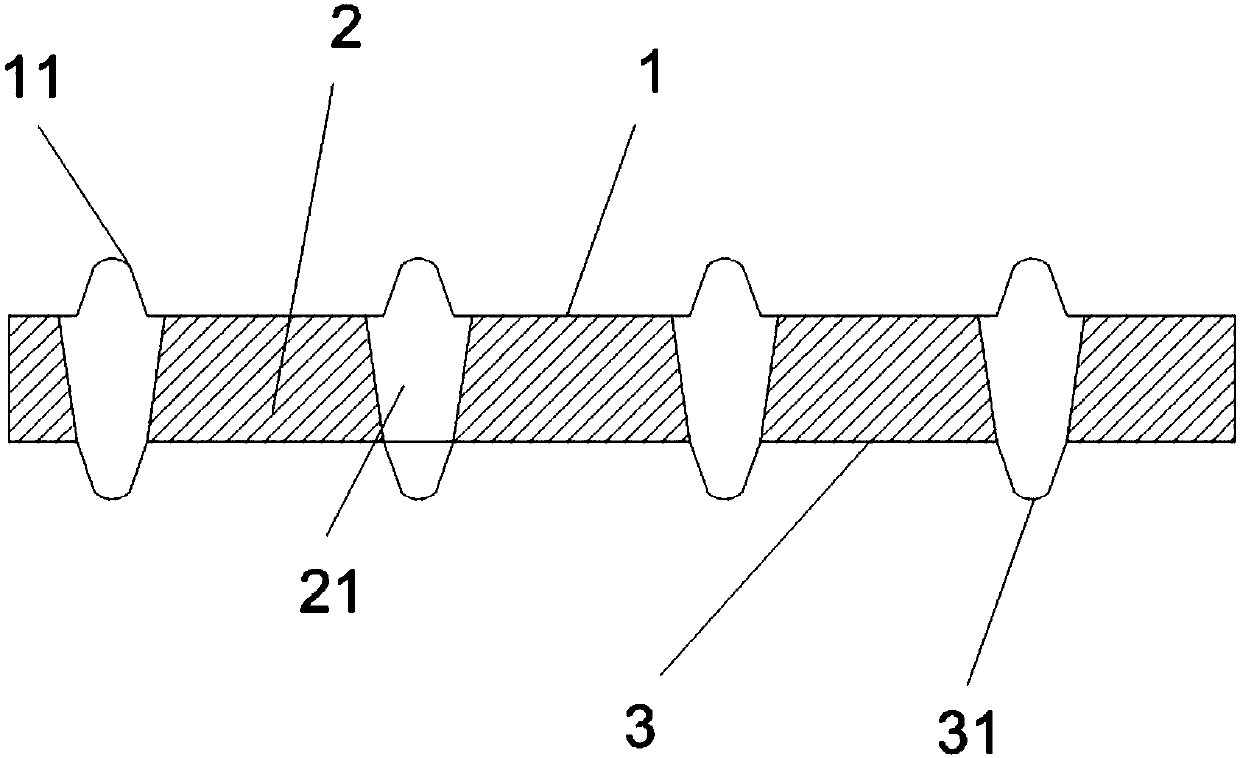

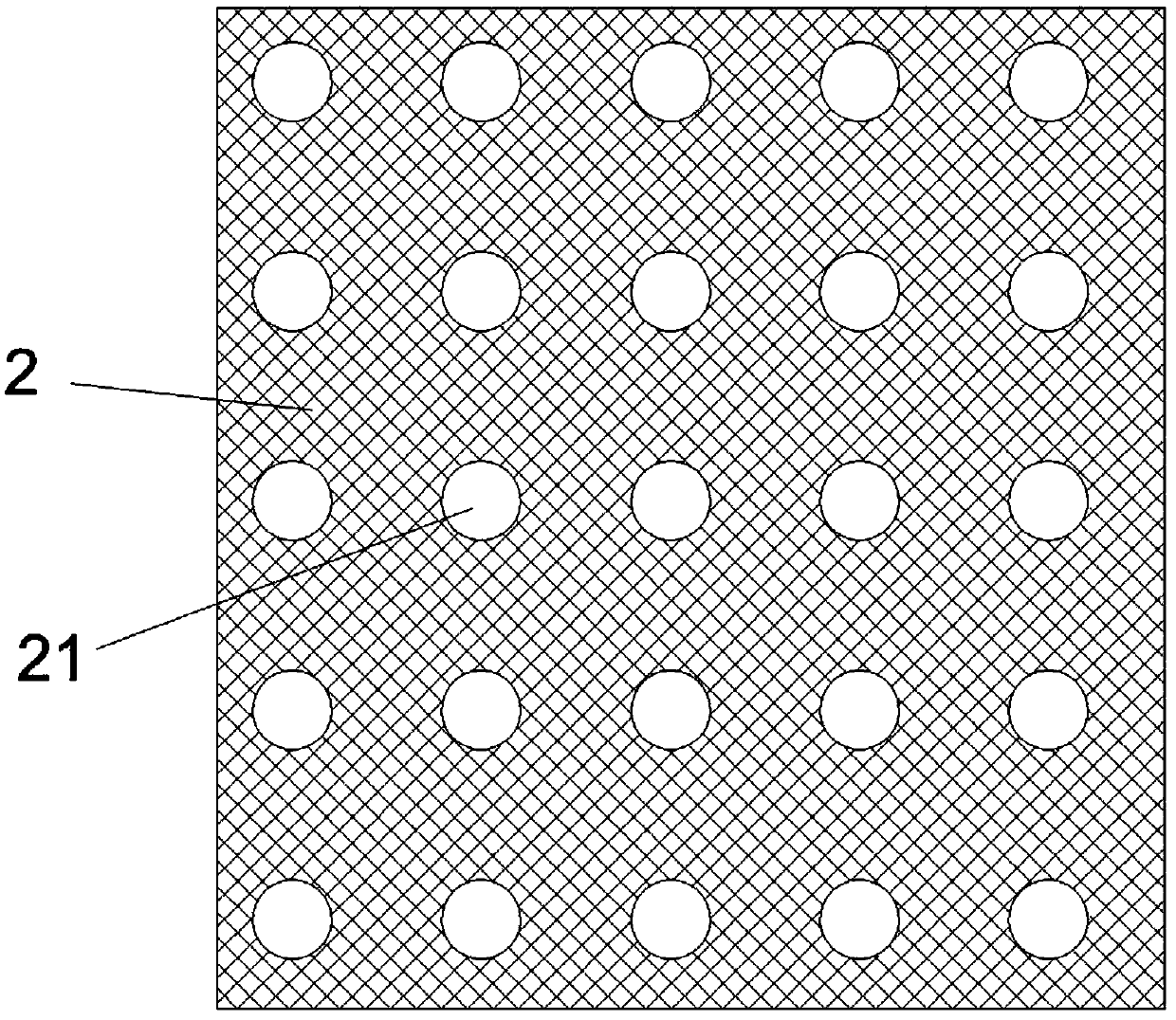

[0023] refer to figure 1 and figure 2 As shown, they are respectively the cross-sectional view and longitudinal section view of this embodiment, the new color steel profiled plate, which includes the internal pressure profiled plate body 3 and the external pressure profiled plate body 1, the internal pressure profiled plate body 3 and the external profiled plate body 3 A filling layer 2 is provided between the profiled plate bodies 1, a second protrusion 31 is provided on the lower surface of the internal profiled plate body 3, and a first protrusion 31 is provided on the upper surface of the external profiled plate body 1. 11, the upper surface and the lower surface of the filling layer 2 are respectively provided with protrusions that cooperate with the protrusions on the internal pressure profile body 3 and the external pressure profile body 1, and the filling layer 2 is provided with a conical hole 21 , the large end diameter hole of the conical hole 21 is connected with...

Embodiment 2

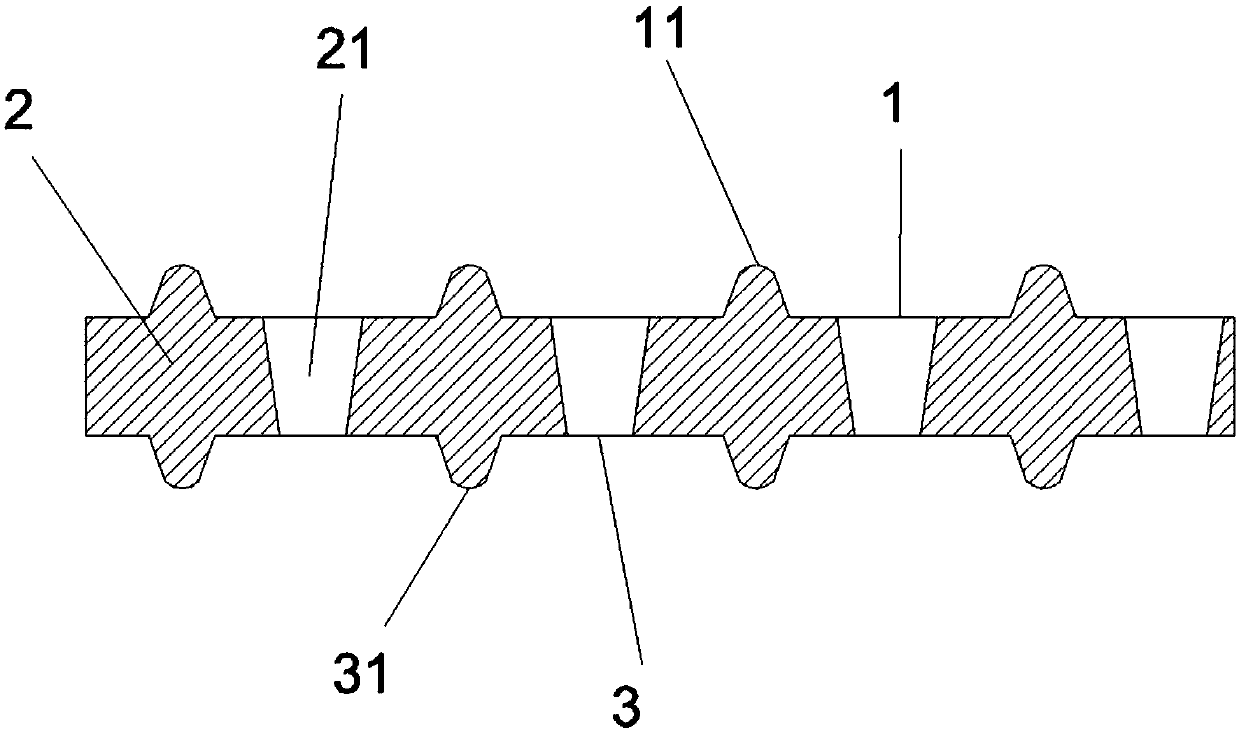

[0029] refer to image 3 As shown, it is a cross-sectional view of this embodiment, a new color steel profiled plate, which includes an internal profiled plate body 3 and an external profiled plate body 1, and the internal profiled plate body 3 and the external profiled plate body 1 A filling layer 2 is arranged between them, a second protrusion 31 is provided on the lower surface of the internal pressure profile body 3, a first protrusion 11 is provided on the upper surface of the external pressure profile body 1, and the The upper surface and the lower surface of the filling layer 2 are respectively provided with protrusions that cooperate with the protrusions on the internal pressure profiled plate body 3 and the external pressure profiled plate body 1, and a conical hole 21 is arranged in the filled layer 2, and the conical hole The big end diameter hole of 21 is connected with external pressure profile plate body 1.

[0030] In addition, the filling layer 2 described in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com