A kind of graphene metal composite material prepared by metal salting-out method and preparation method thereof

A metal composite material, metal material technology, applied in the field of composite material preparation, can solve the problems of graphene agglomeration, affecting product performance, etc., achieve the effect of improving sample performance, increasing hardness and melting point, and solving easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

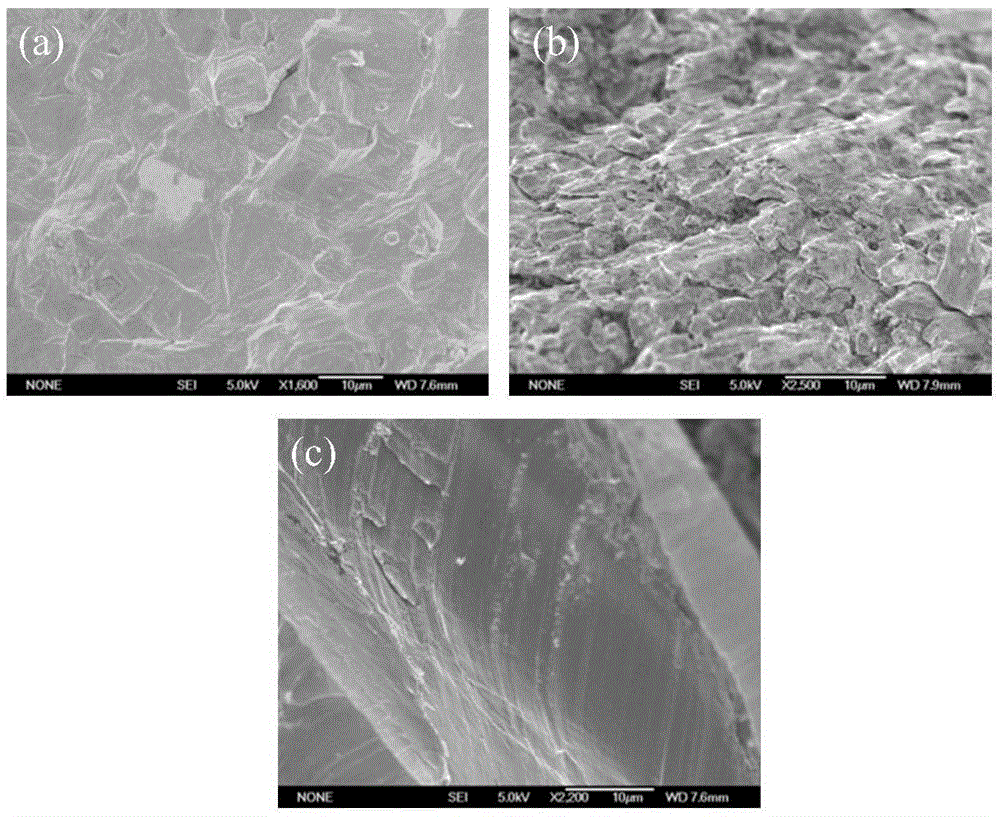

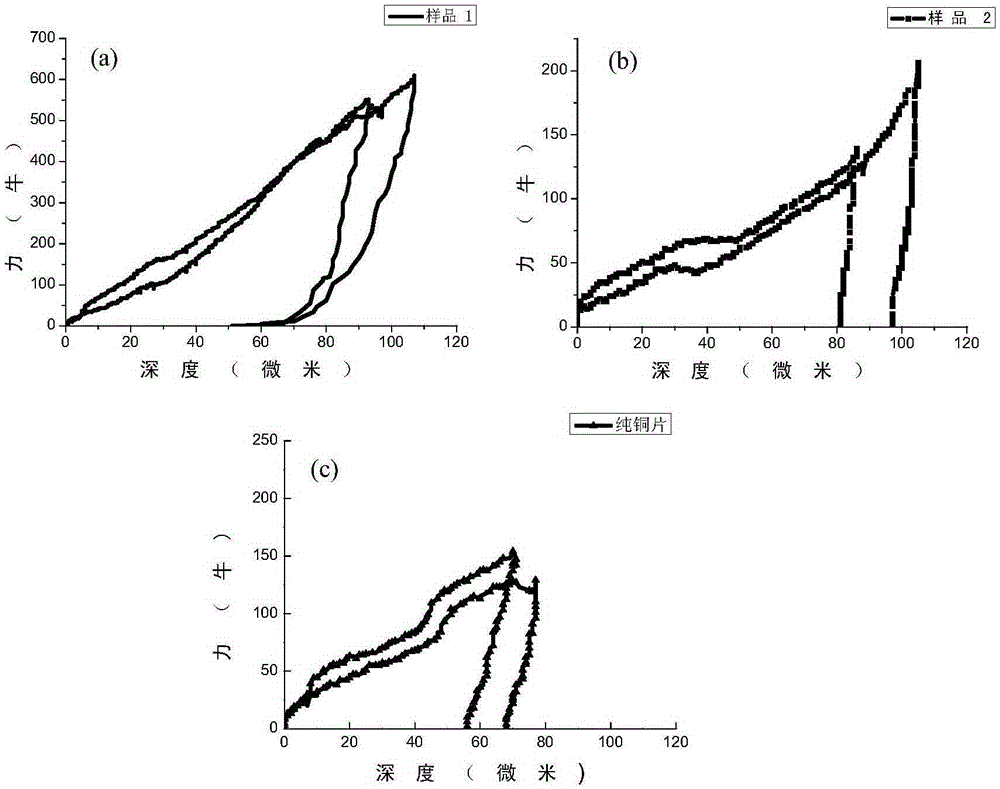

[0026] This example prepares graphene copper-metal composite material according to the following steps:

[0027] a. Add 0.3 g of graphene oxide into 20 mL of distilled water, and ultrasonically disperse for 2 hours to obtain a graphene oxide suspension;

[0028] b. Dissolve 20g of copper acetate (CA) in 30mL of glycerin and stir evenly to obtain a metal salt / glycerin system;

[0029] c. After mixing the graphene suspension with the metal salt / glycerol system, stir at 50°C for 6h, and then stir at 150°C for 3h to obtain a solid-liquid mixture;

[0030] d. Suction filter the solid-liquid mixture obtained in step c, obtain dark purple powder on filter paper, wash 3 times with distilled water, then wash 2 times with absolute ethanol to obtain dark purple powder, and finally dry at 110°C for 1 hour, namely Obtain graphene-copper-metal composite material, denoted as sample 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com