Method for testing nano-indentation of coating property

A test method, nanoindentation technology, applied in the direction of testing material hardness, measuring device, strength characteristics, etc., can solve problems such as adverse thermal barrier coating reliability and service life prediction, drastic temperature changes, thermal barrier coating delamination or Spalling and other problems, to avoid temperature gradient and thermal stress problems, comprehensive quantitative analysis, convenient calculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

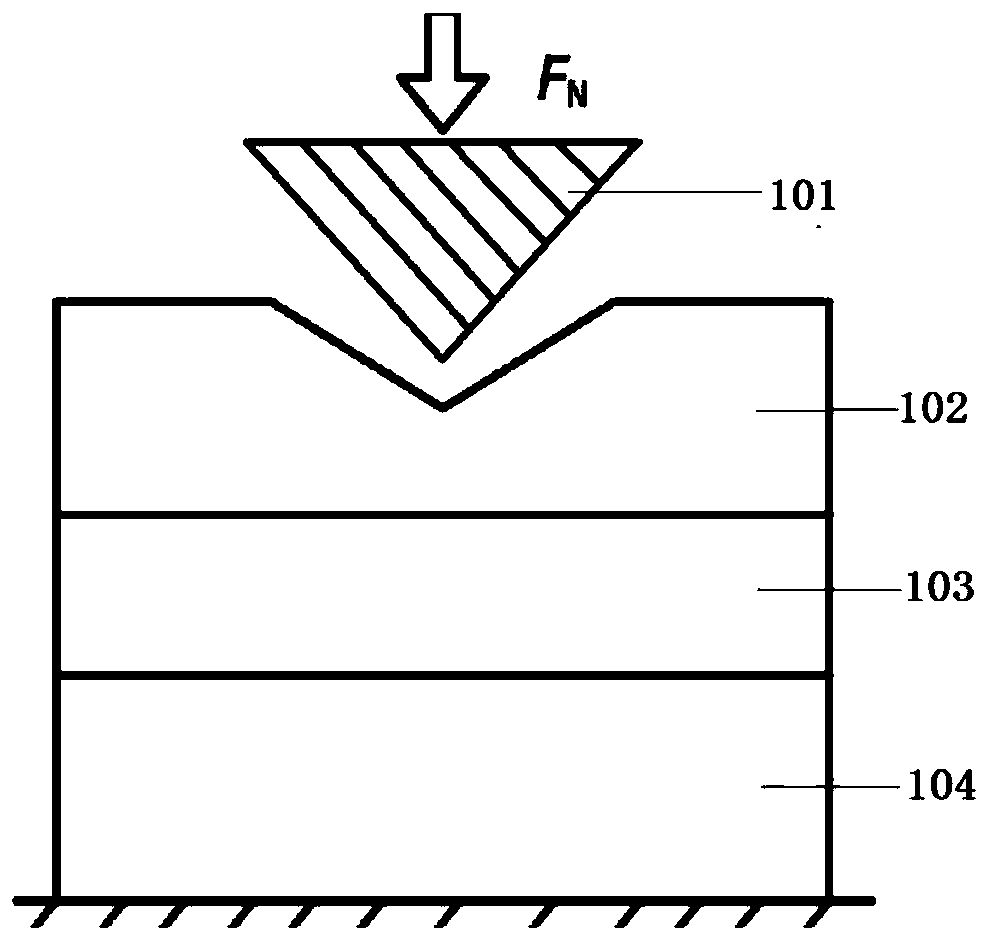

[0089] In this embodiment, two kinds of samples are prepared, namely the sample comprising only the substrate 104, the transition layer 103 and the coating 102, referred to as the AS sample (As Sprayed Sample), and the sample comprising the substrate 104, the transition layer 103, and the thermally oxidized growth layer. The sample with coating 102 is called OS sample (Oxidized Sample) for short.

[0090] Specifically, the substrates of the two samples are made of nickel-based superalloy Inconel 718, which is resistant to high temperature and difficult to oxidize, and the substrate 104 is processed into a cuboid shape, and its nominal size is 24mm×6mm×5mm (length×width×height). . The steps of grinding, polishing, cleaning and descaling are performed on the surface of the substrate 104 . Preferably, acetone is used to soak and remove stains on the surface to be sprayed. Preferably, an ultrasonic cleaner is used to clean and descale the surface of the substrate. Sand blasting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com