Stretching-bending combined-load in-situ nano-indentation test device and method

A nano-indentation and composite load technology, which is applied in the direction of testing material strength by applying stable bending force, testing material strength by applying stable tension/pressure, and testing material hardness, etc., can solve the lack of deformation damage mechanism and deformation damage mechanism It is difficult to study the law of load action and material performance parameters, and it is impossible to test three-dimensional specimens.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

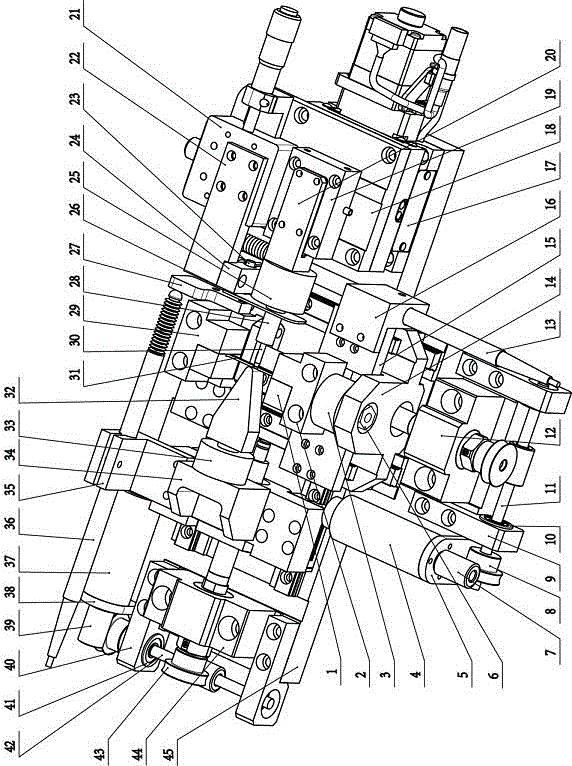

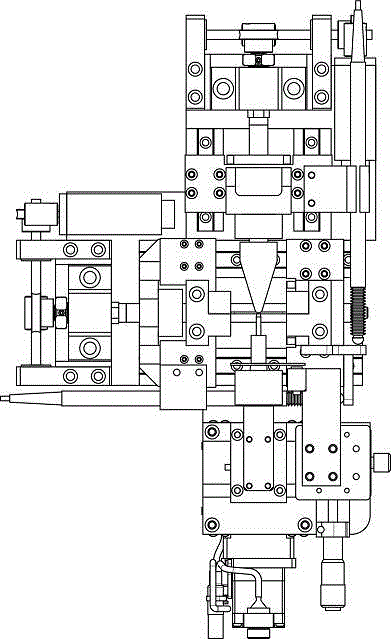

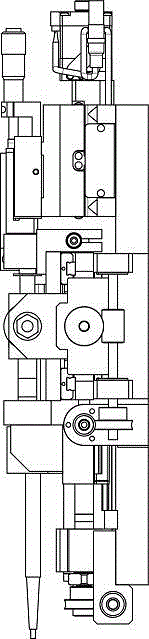

[0044] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

[0045] see Figure 1 to Figure 10 , the in-situ nano-indentation test device under the preloaded condition of tensile-bending composite load of the present invention, in the test process, the material to be tested is subjected to specific stretching, bending, and stretching-bending through a specific loading unit. Prestressing, and then in-situ nano-indentation test is performed on the tested material samples to determine the dynamic changes of basic mechanical performance parameters such as indentation response, hardness and elastic modulus of the material under the corresponding prestressed state and their relationship with preloading. The correlation law between the load and the material performance; the device can also realize the separate loading of the three forms of tension-bending-indentation and the combi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com