Method for nano-crystallization of Zr-based amorphous alloy induced by nanoindentation combined with fatigue load

An amorphous alloy, fatigue load technology, applied in material analysis using radiation diffraction, using stable tension/pressure testing material strength, measuring devices, etc., can solve the limitations of increasing the crystallization of amorphous alloys, complex processes, Adapt to the problem of small surface, to achieve the effect of improving the efficiency of nano-crystallization, speeding up the experimental process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

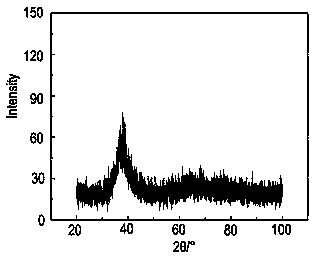

[0029] A plate-shaped dog-bone-shaped specimen containing double V defects is prepared by slow-moving wire-cutting of a large amorphous alloy rod-shaped raw material, see figure 1 As shown, the two sides of the test piece are designed as regular hexagons, the gauge length of the test piece is 3.5mm, the width is 1.2mm, the thickness is 0.6mm, the longitudinal depth of the V-shaped defect is 0.5mm, and the V-shaped angle is 40° , the transverse distance of the tip of the double V defect is 1mm, and the supporting fixture is also processed into a hexagonal groove and a hexagonal wedge-shaped surface consistent with the size of the test piece. The surface of the test piece is first polished with sandpaper of different meshes, and then mechanically polished on a polishing machine to obtain a sufficiently smooth and bright surface. The polishing liquid used is a diamond polishing liquid with a concentration of 10% and a particle size of 0.1 μm. The polishing speed is 100rad / min, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com