Patents

Literature

55 results about "Electron diffraction pattern" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

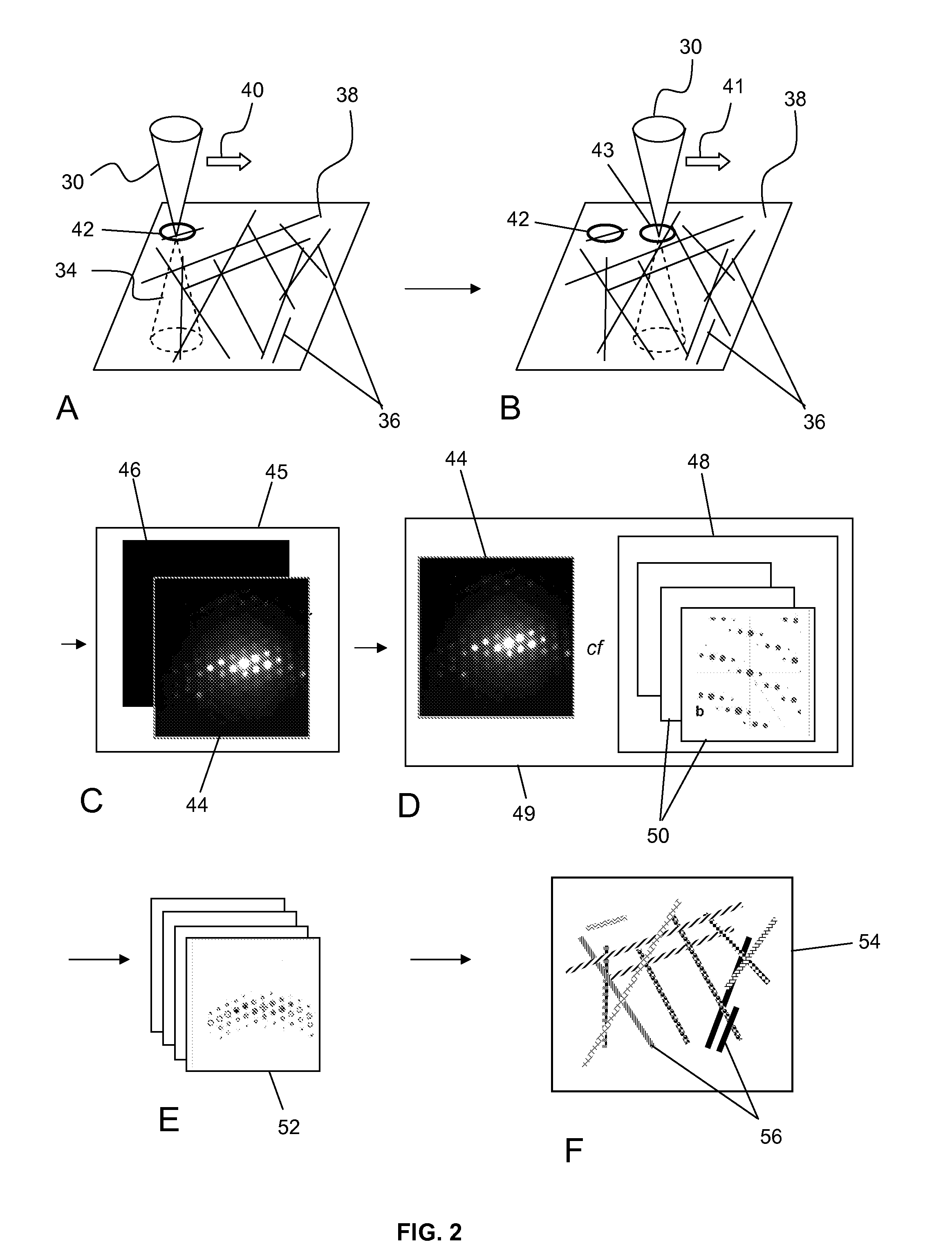

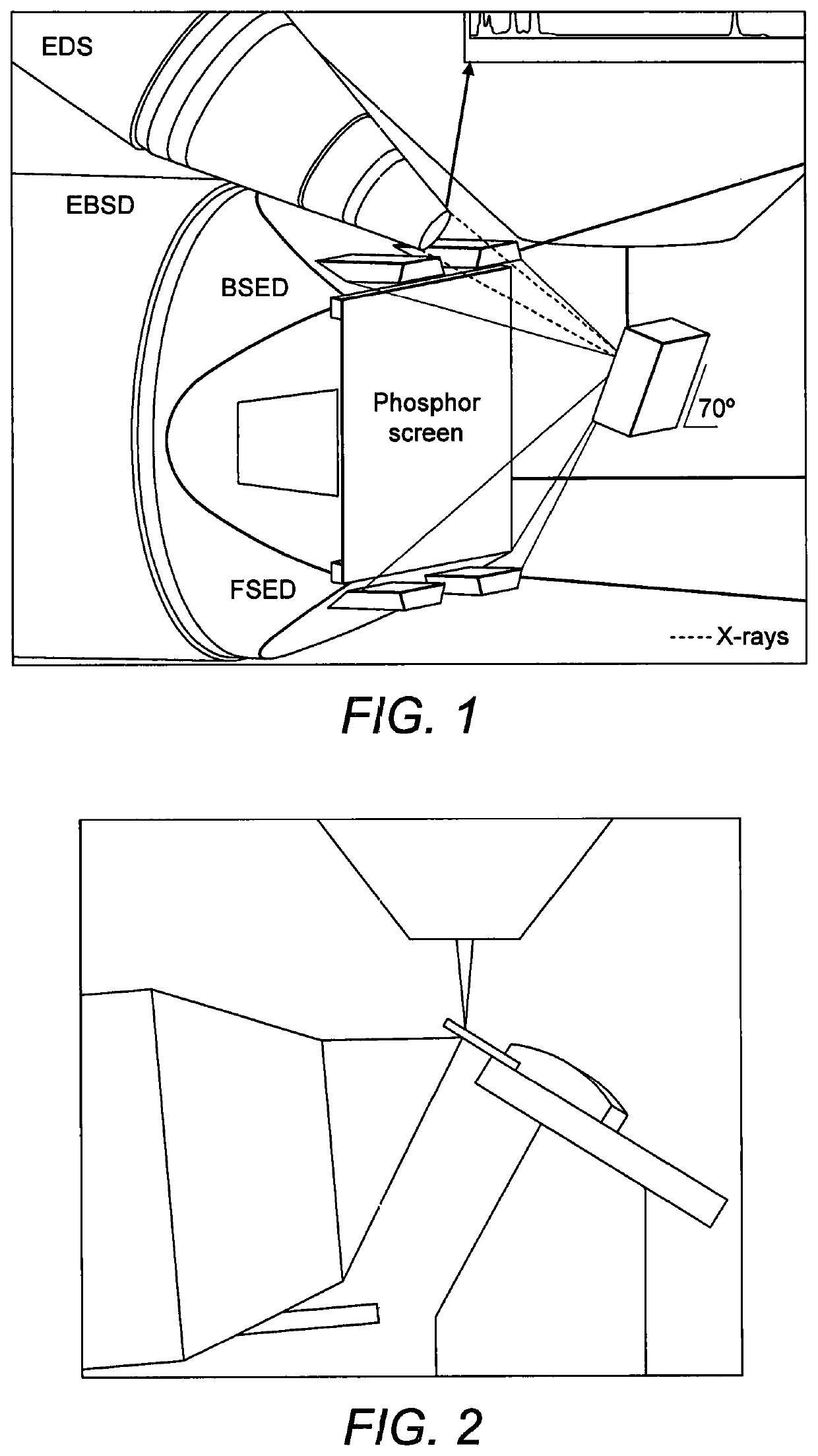

Methods and devices for high throughput crystal structure analysis by electron diffraction

ActiveUS20110220796A1Enhanced identification/fingerprintingGood quality orientation phase mapMaterial analysis using wave/particle radiationElectric discharge tubesCrystal orientationBeam scanning

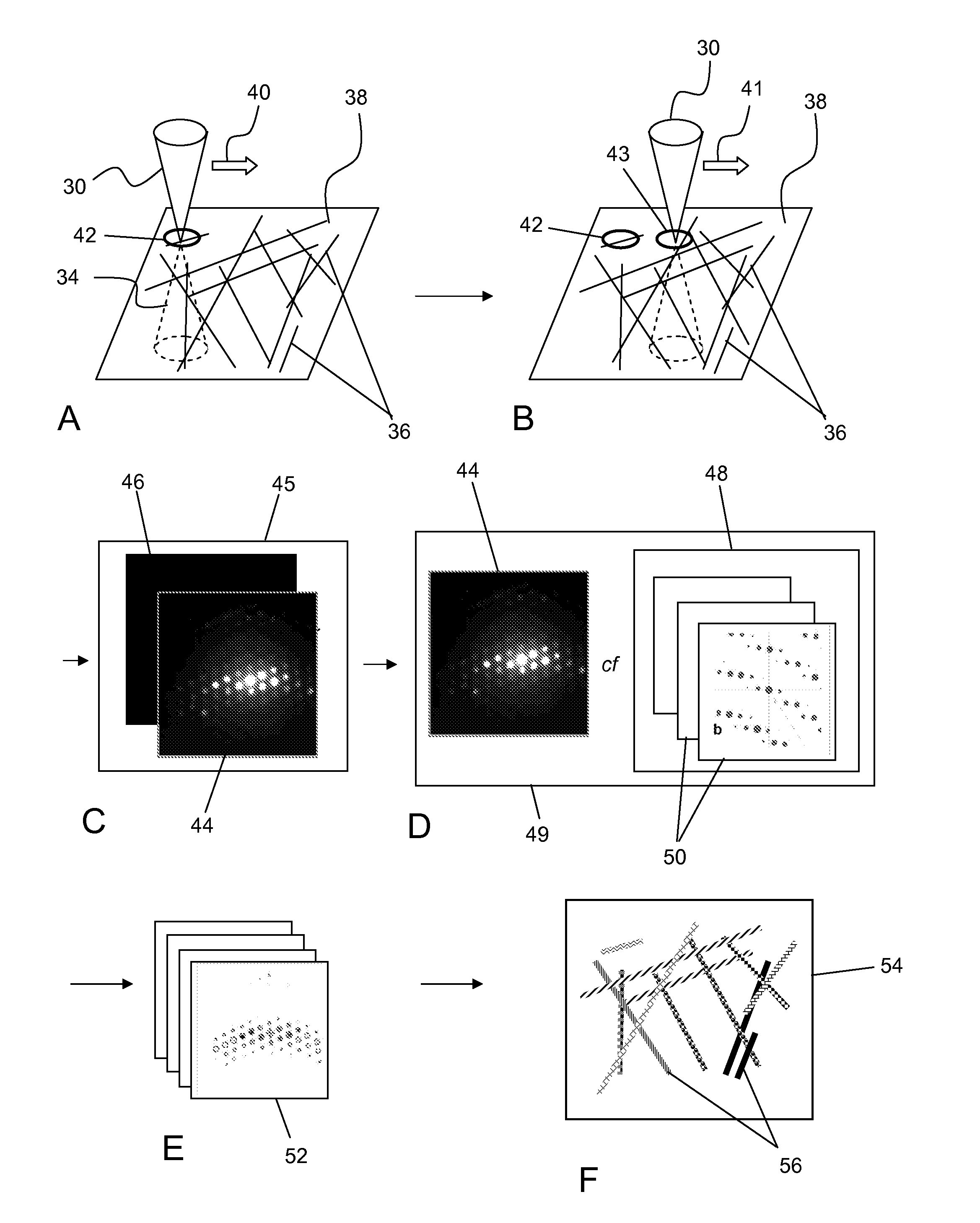

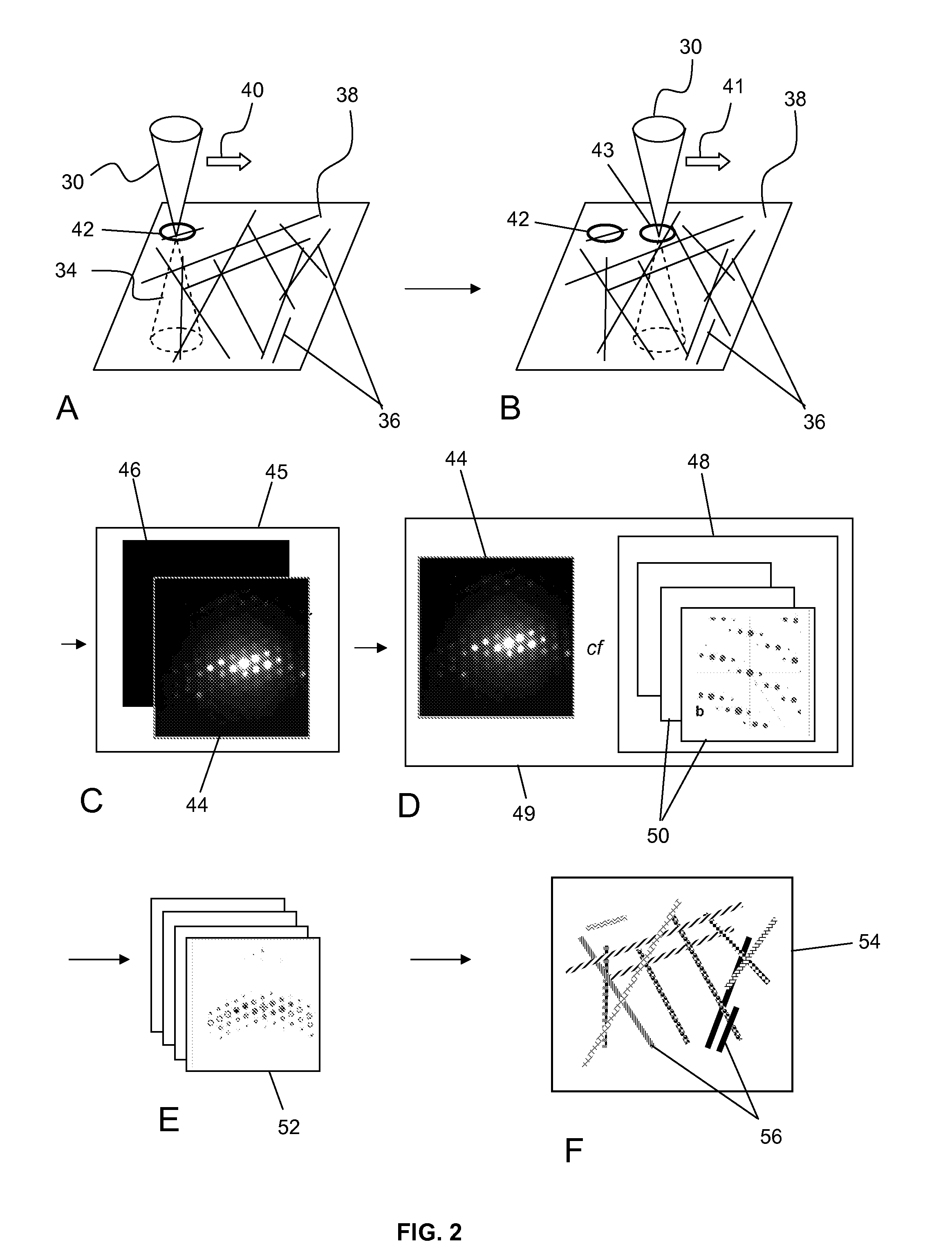

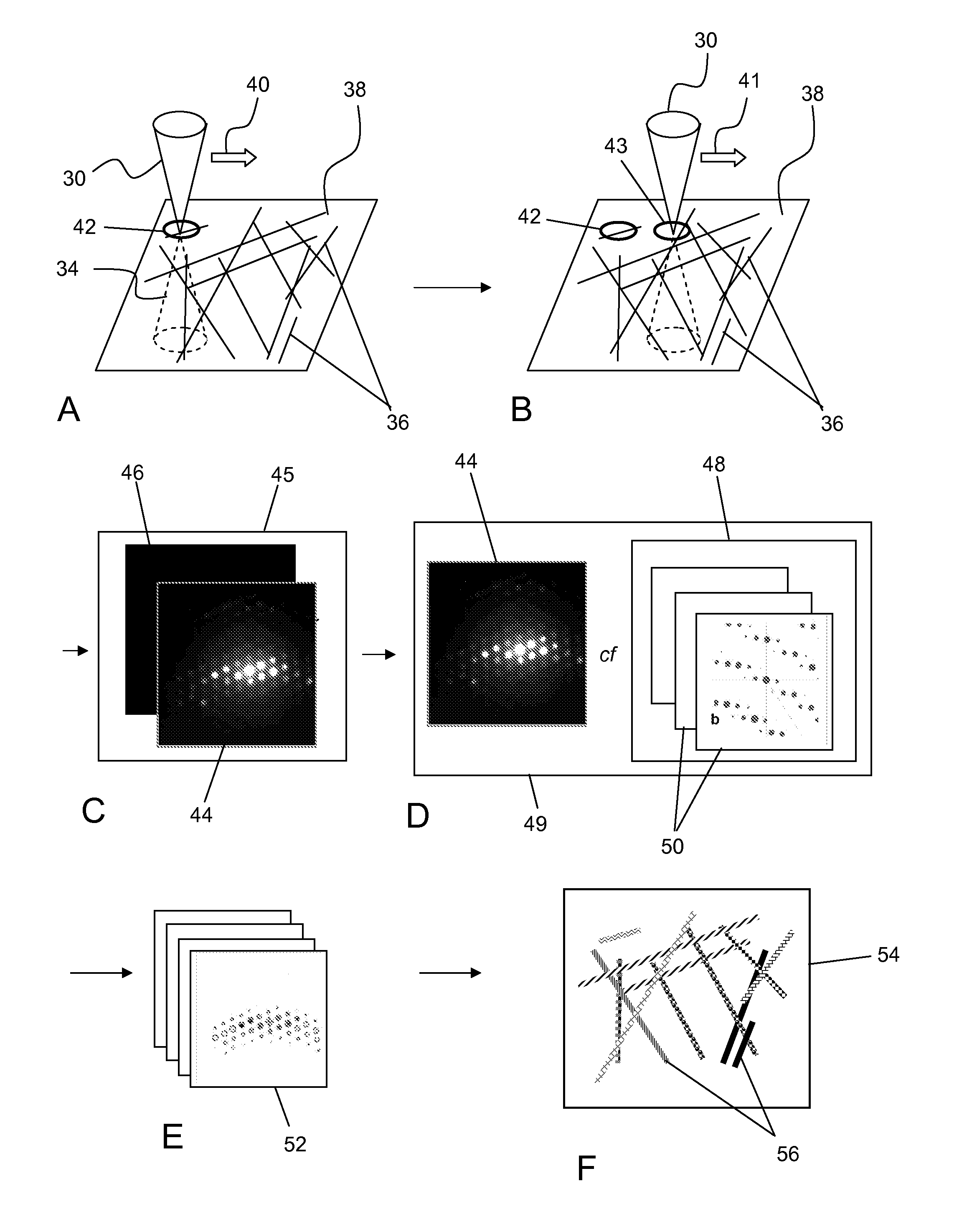

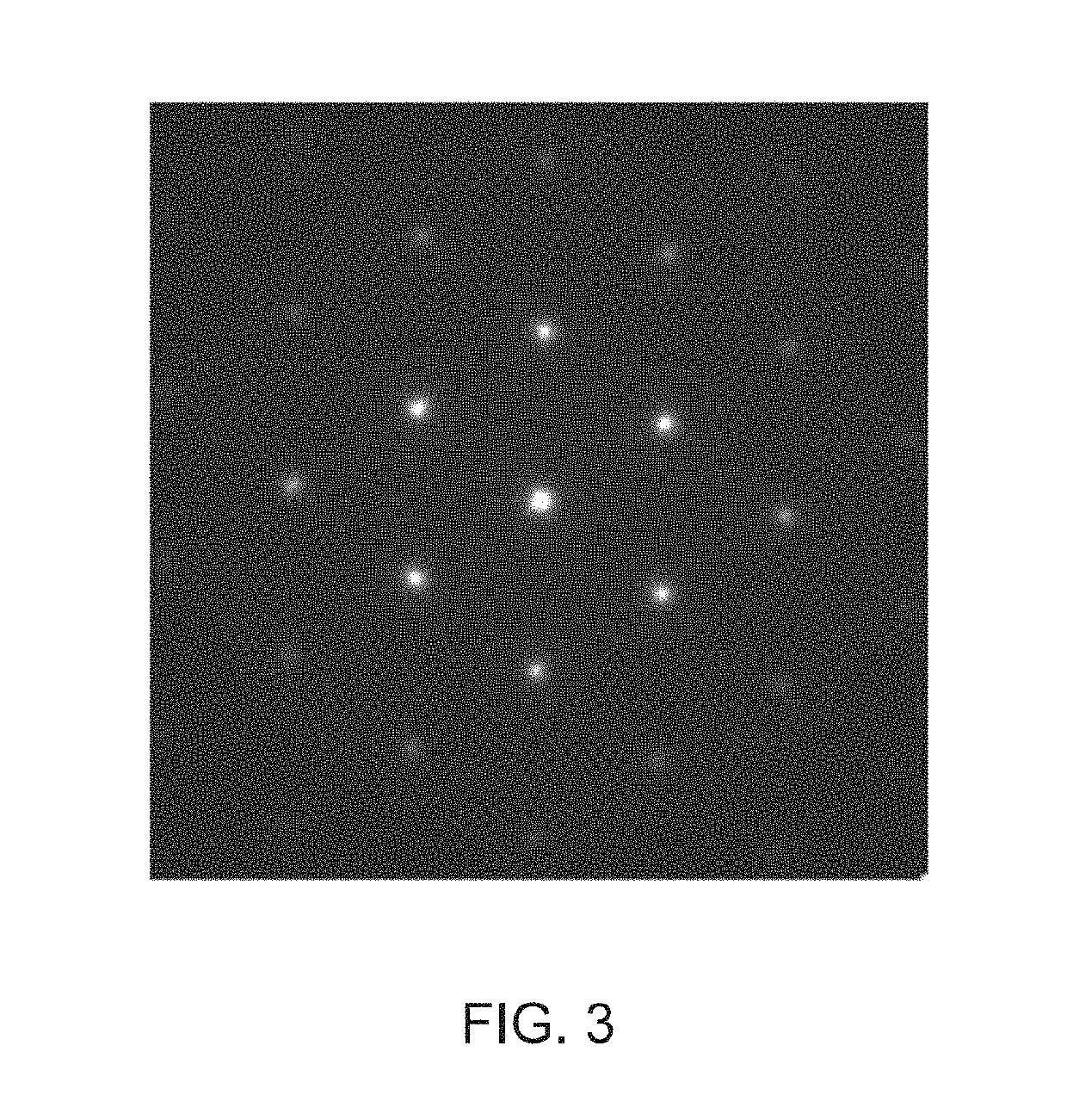

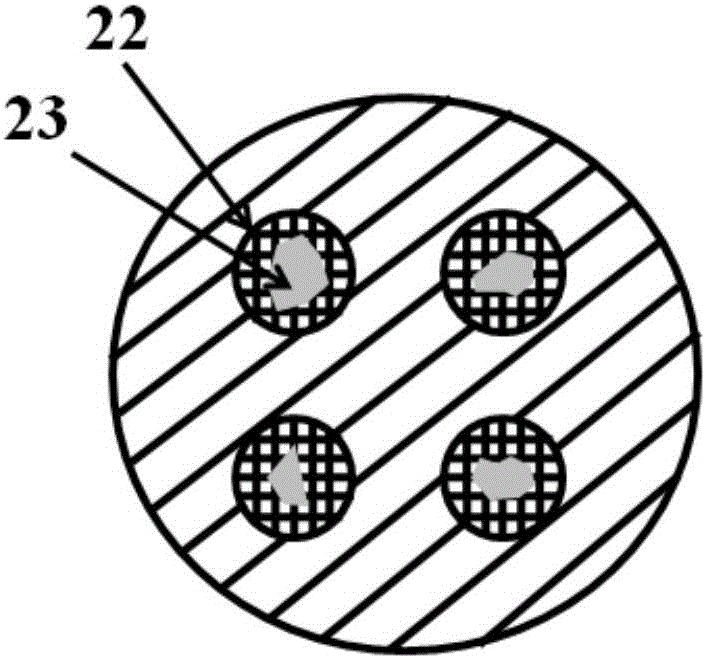

A method and device for electron diffraction tomography of a crystal sample, which employs scanning of the electron beam over a plurality of discrete locations of the sample, in combination with a beam scanning protocol as the beam converges at every discrete location (42, 43) of the sample (38) to obtain a series of electron diffraction patterns, use of template matching to determine crystal orientations and thickness maps to obtain a common intensity scaling factor.

Owner:NANOMEGAS SPRL +2

Methods and devices for high throughput crystal structure analysis by electron diffraction

ActiveUS8253099B2Enhanced identification/fingerprintingBetter quality orientation phase mapsMaterial analysis using wave/particle radiationElectric discharge tubesTemplate matchingStructure analysis

A method and device for electron diffraction tomography of a crystal sample, which employs scanning of the electron beam over a plurality of discrete locations of the sample, in combination with a beam scanning protocol as the beam converges at every discrete location (42, 43) of the sample (38) to obtain a series of electron diffraction patterns, use of template matching to determine crystal orientations and thickness maps to obtain a common intensity scaling factor.

Owner:NANOMEGAS SPRL +2

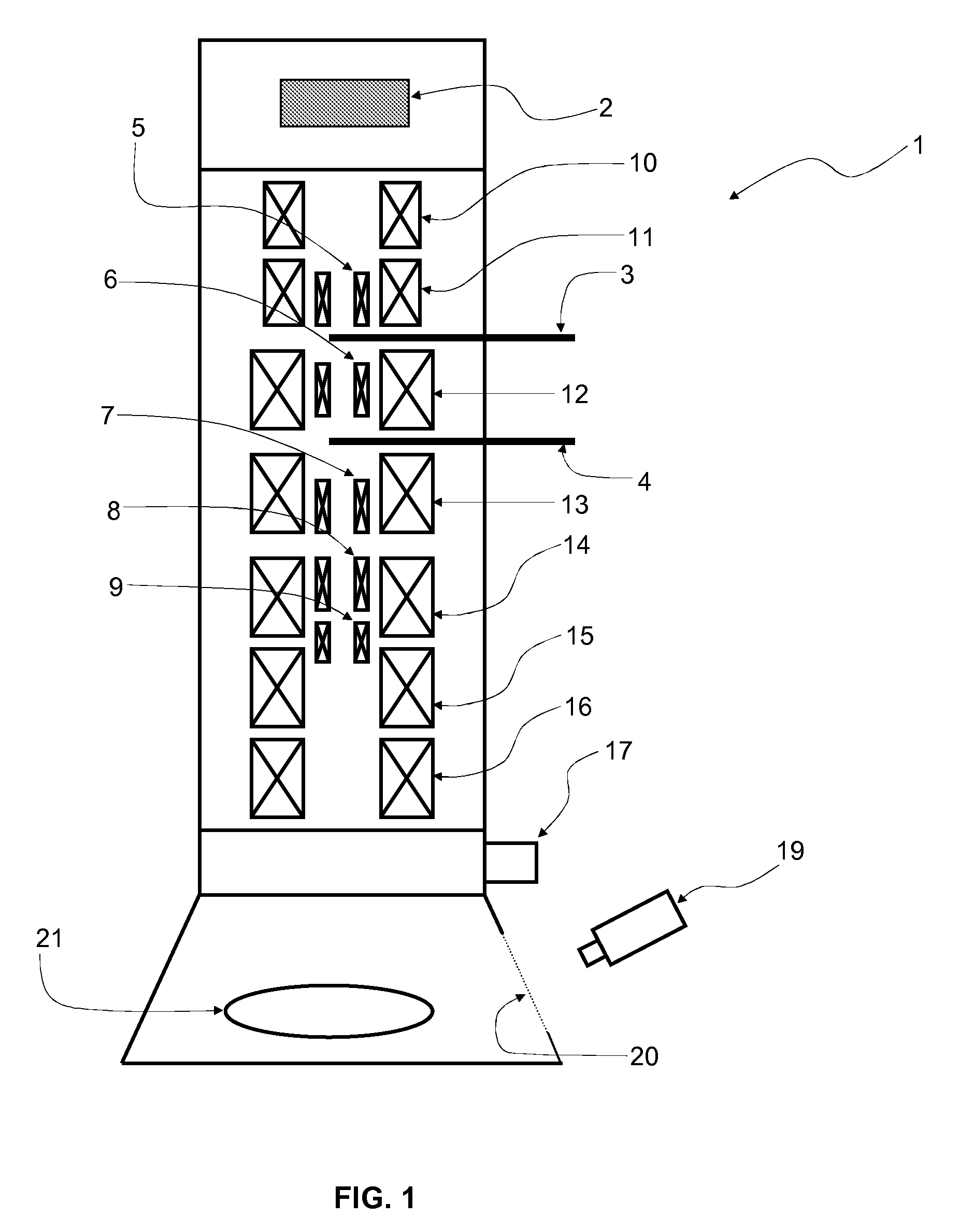

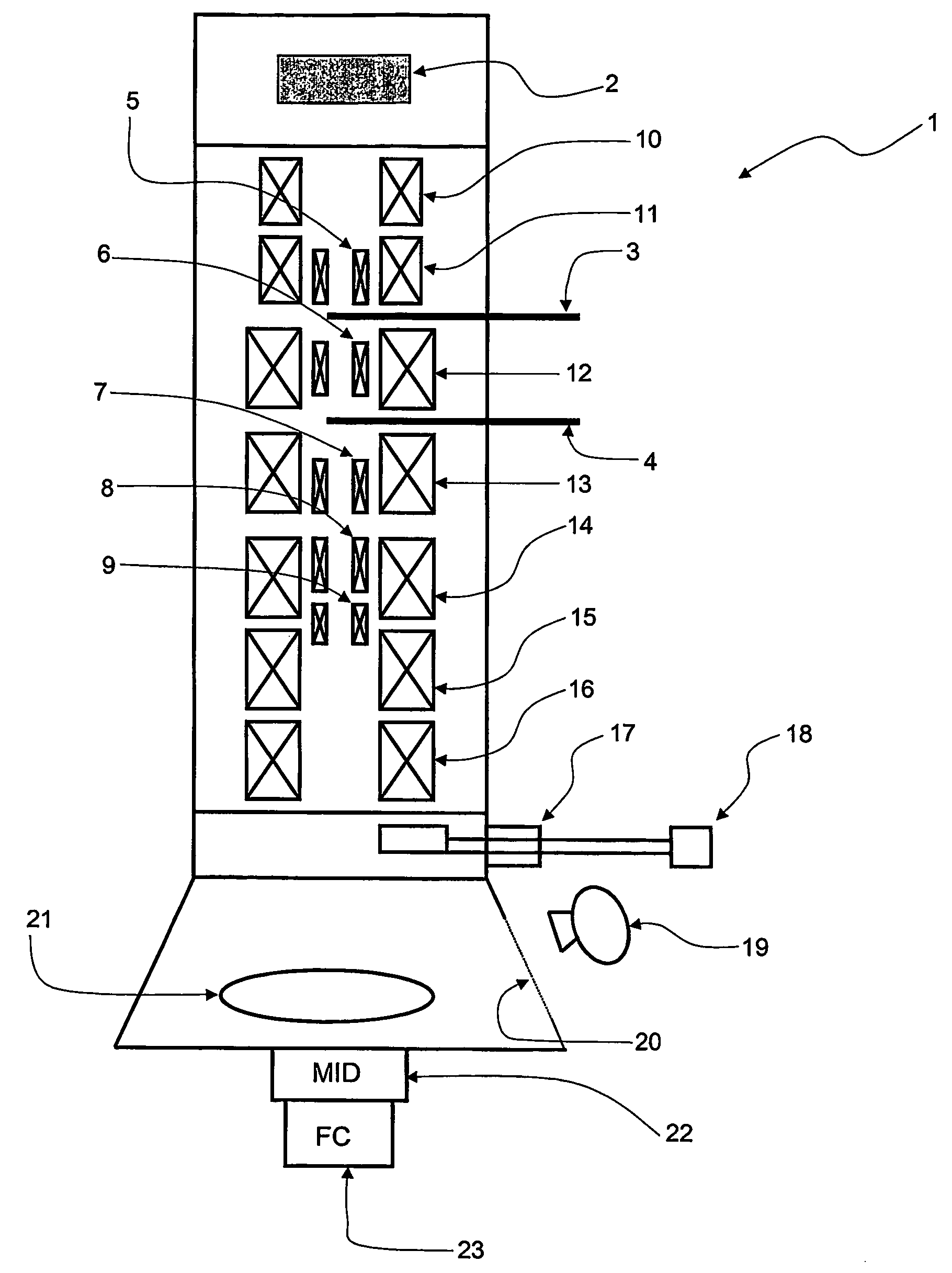

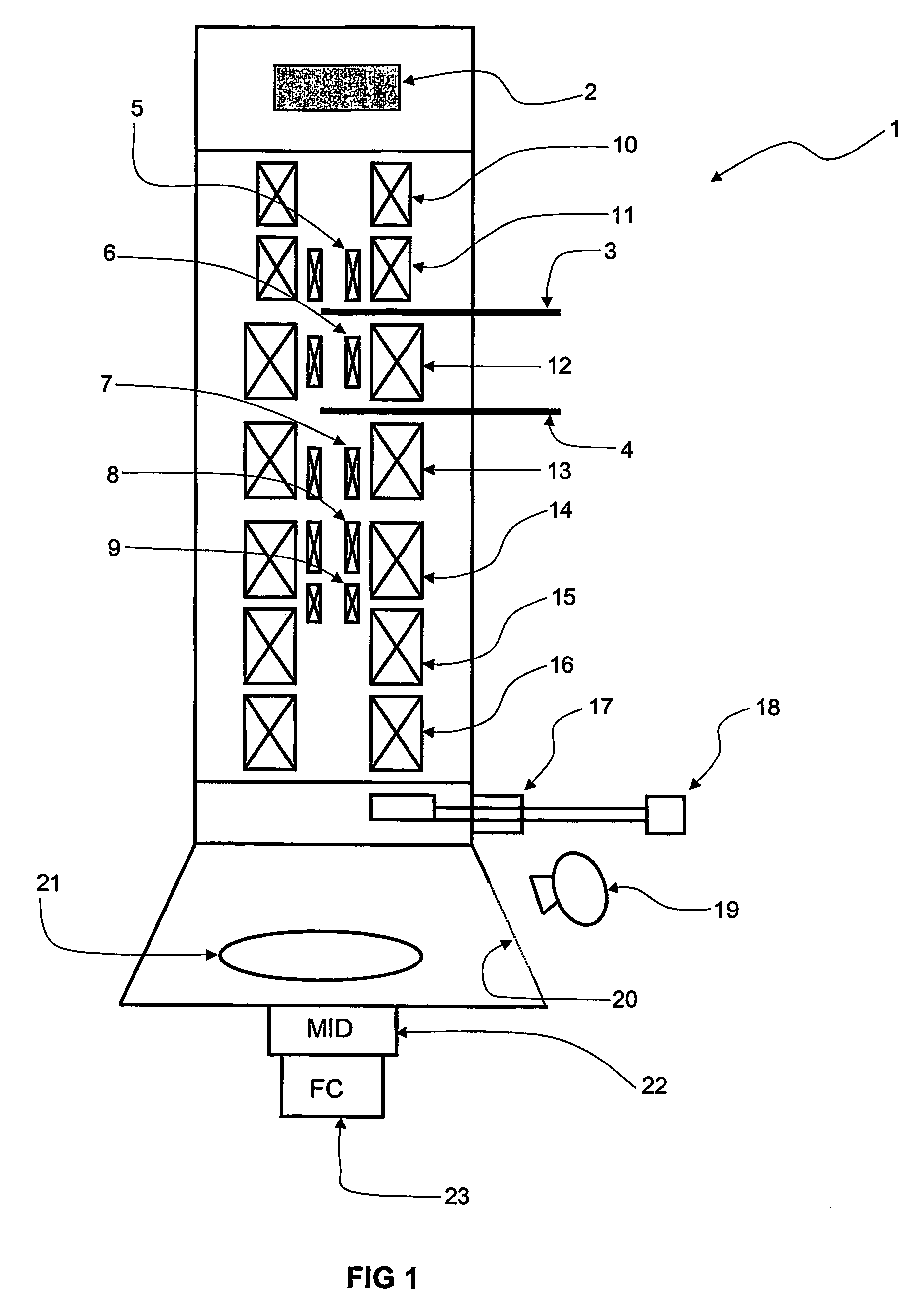

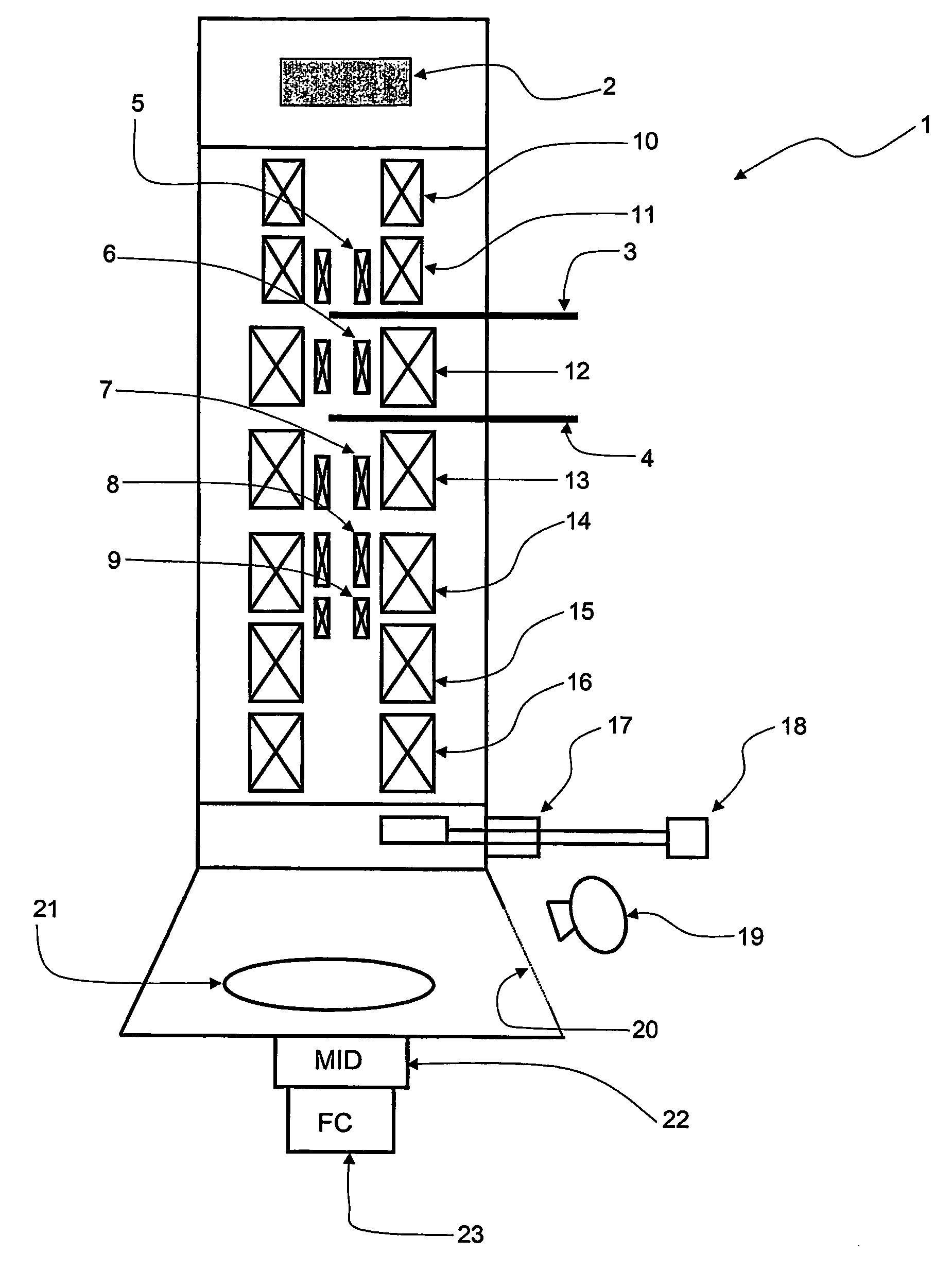

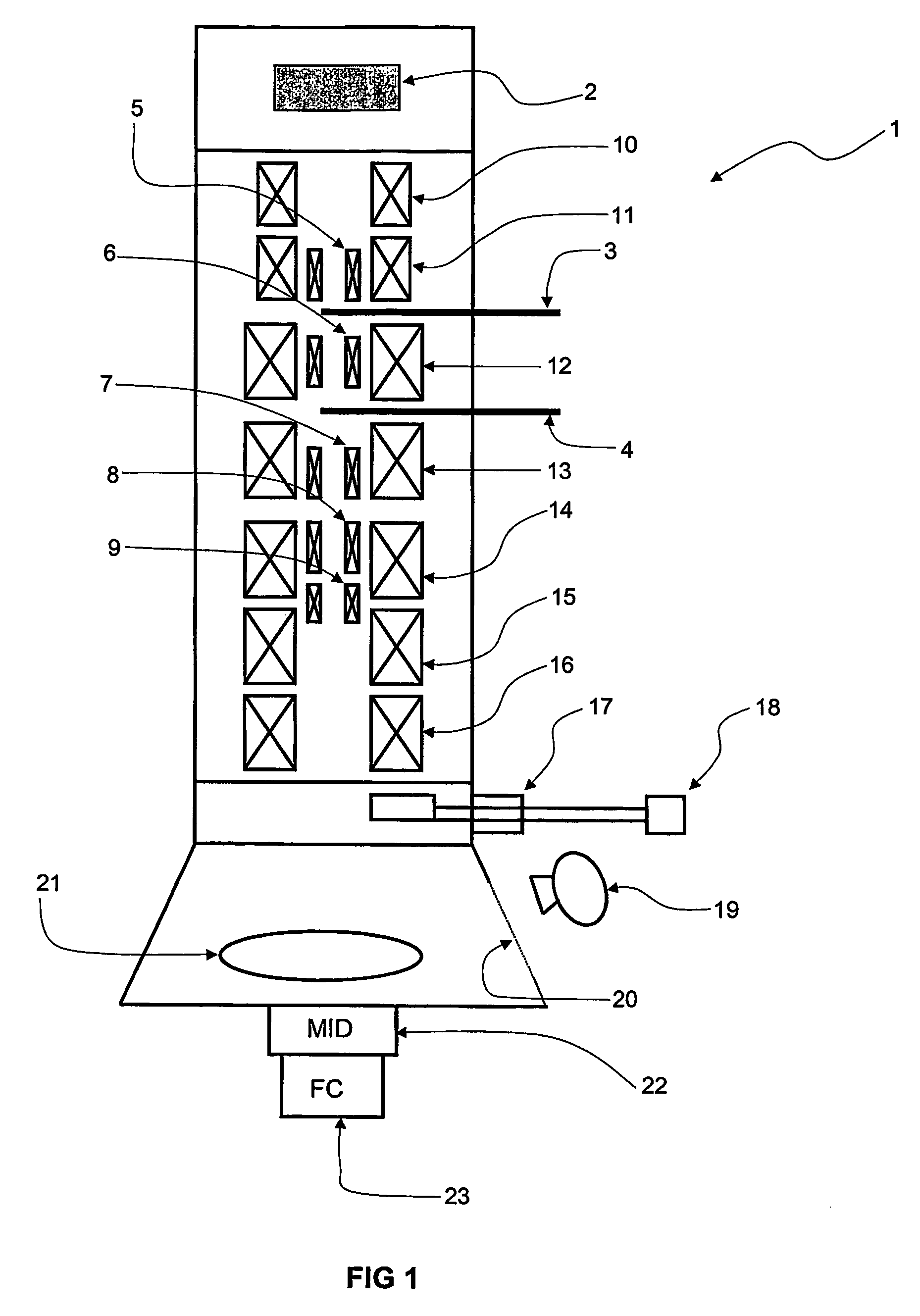

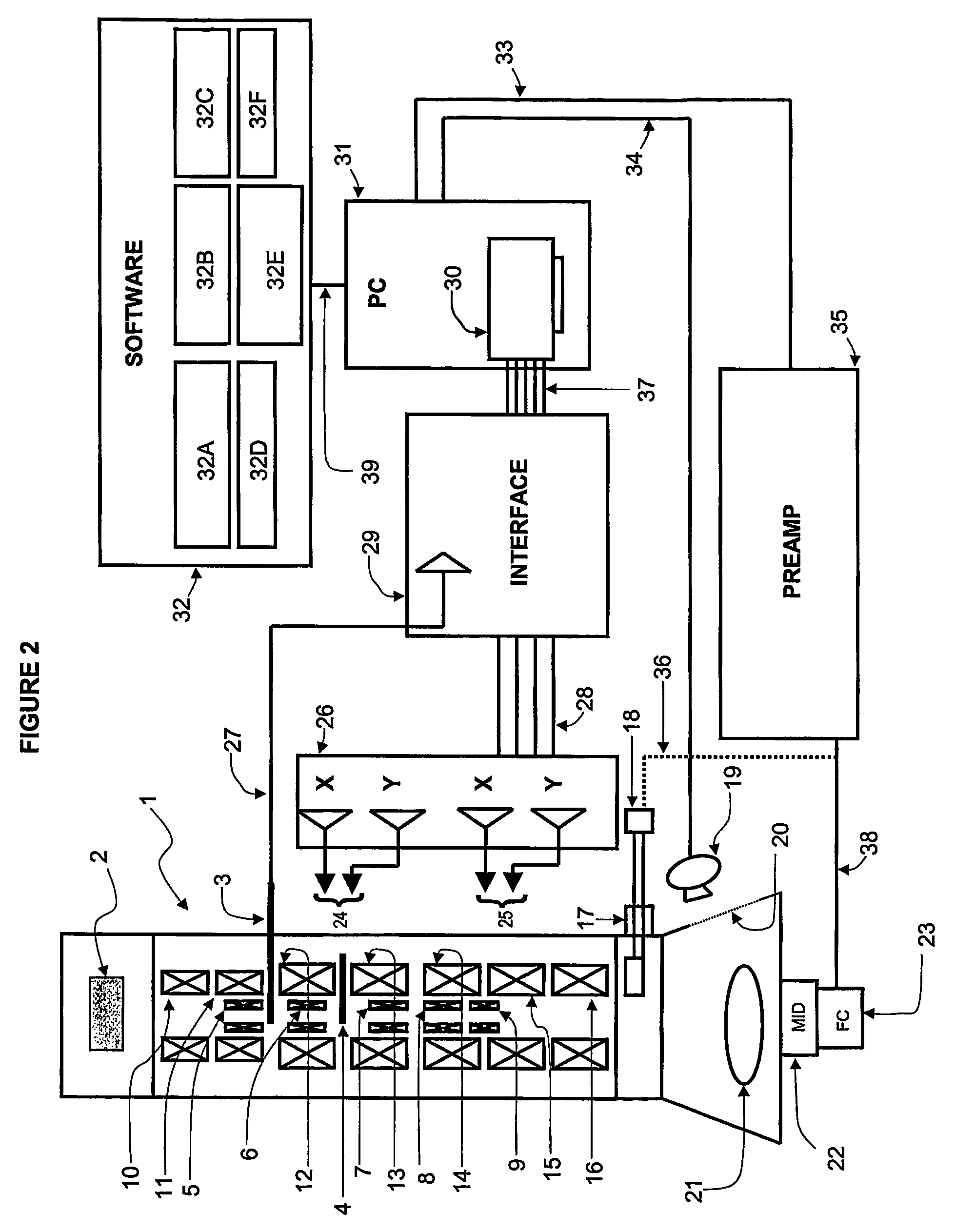

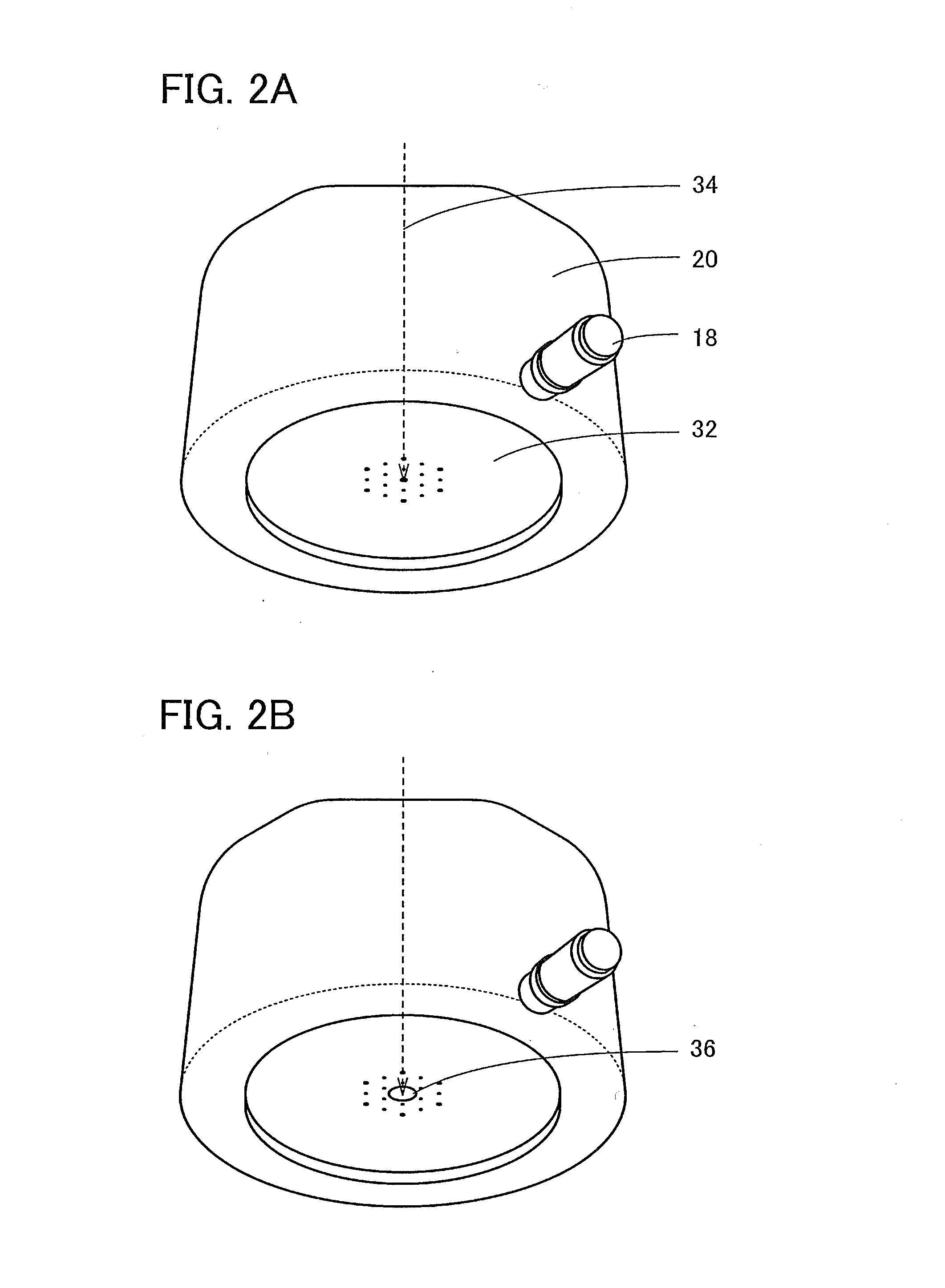

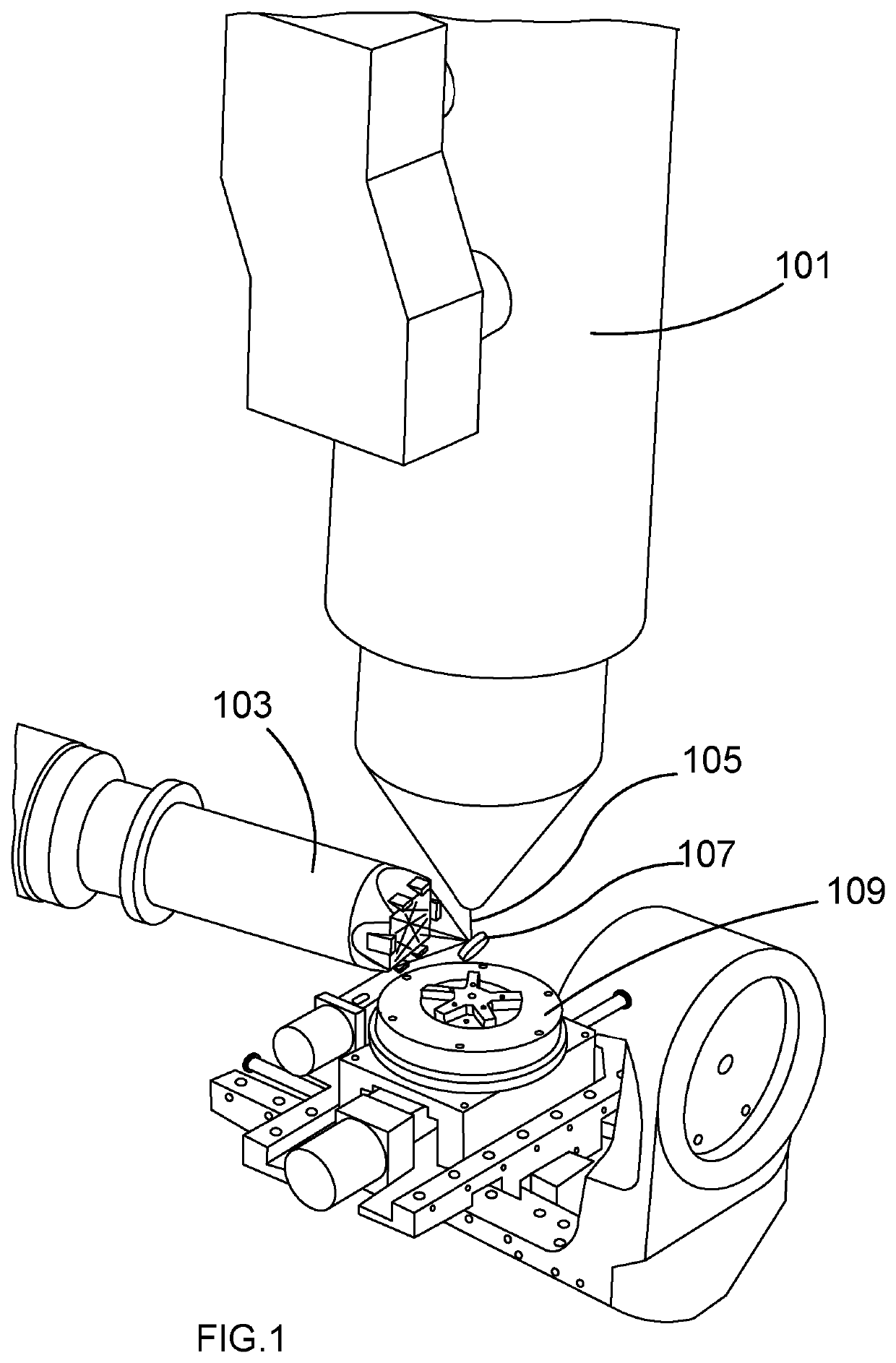

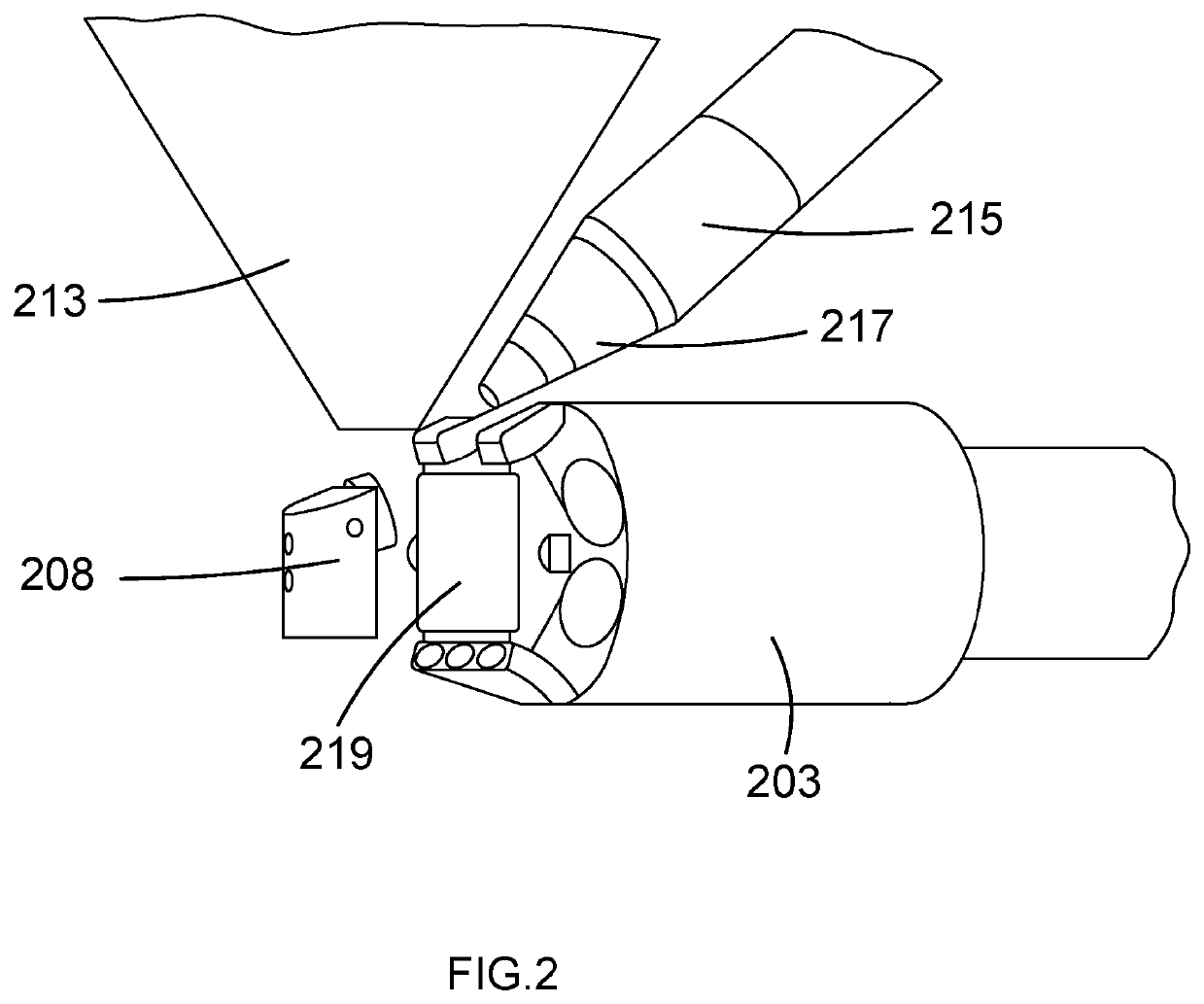

Method for measuring diffraction patterns from a transmission electron microscopy to determine crystal structures and a device therefor

InactiveUS20070023659A1Minimize damageMinimizing damageElectric discharge tubesMaterial analysis using radiation diffractionPrecessionCrystal structure

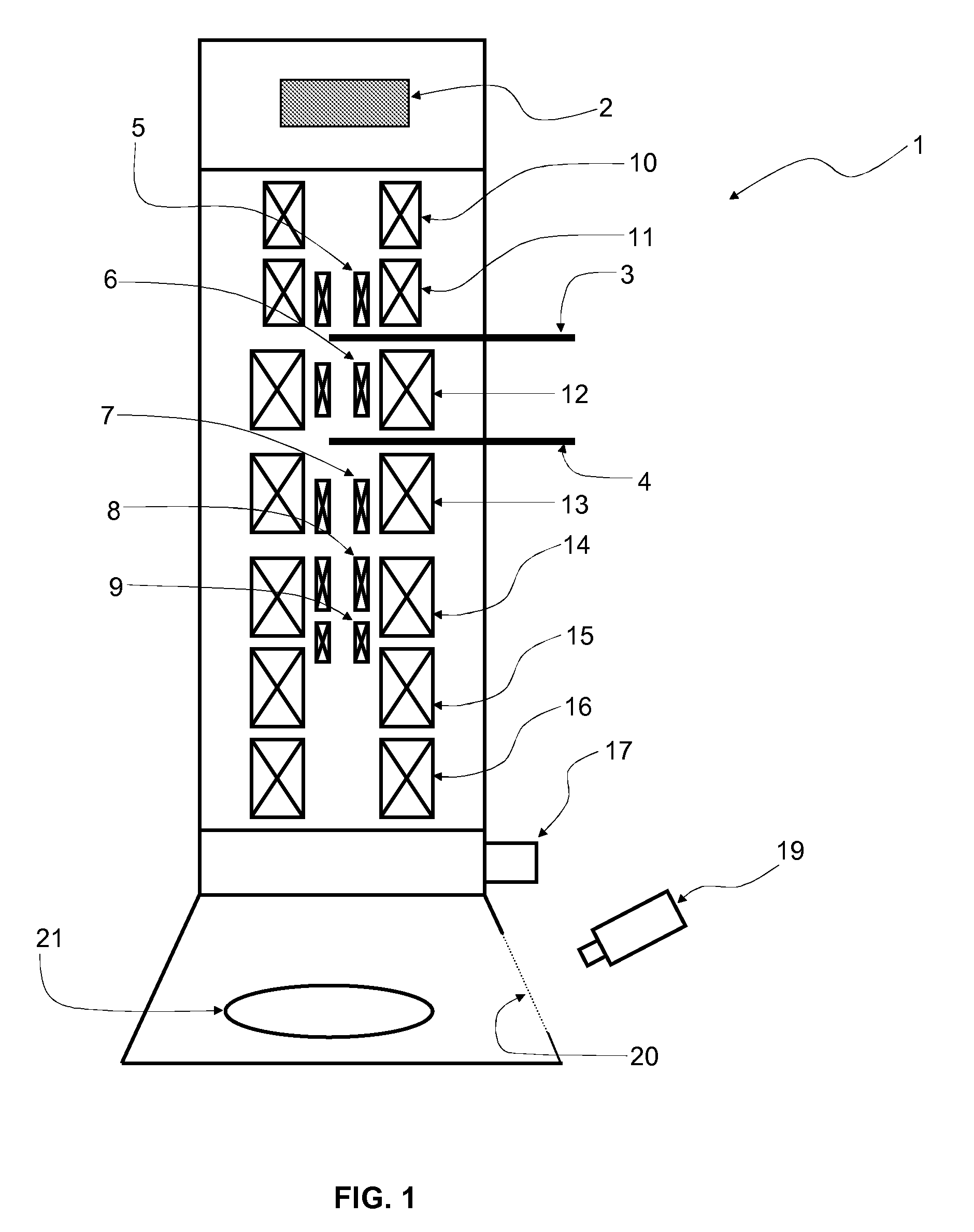

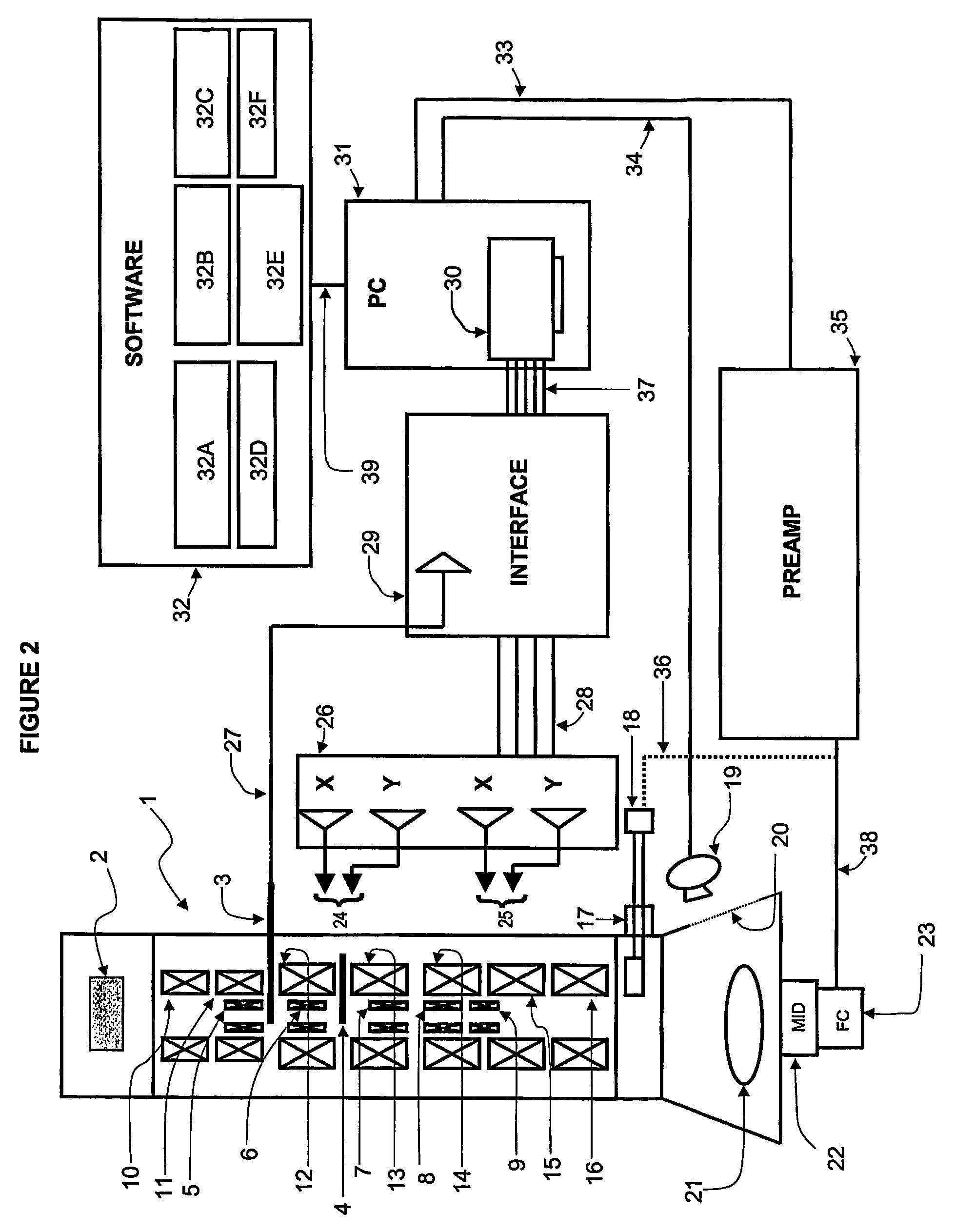

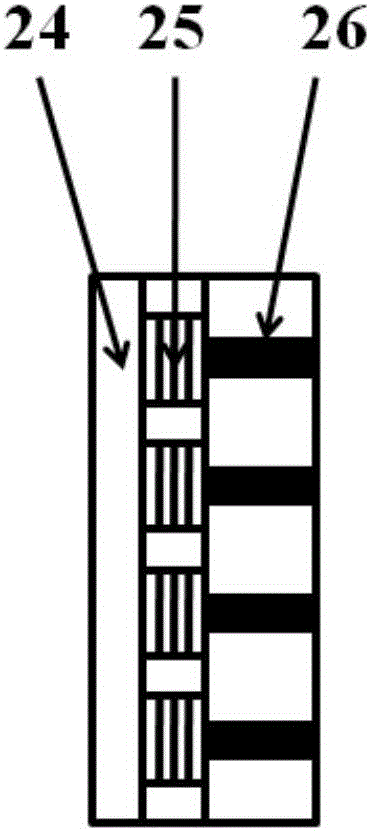

A device and method which enable a transmission electron microscope to measure electron diffraction patterns of a sample very precisely are disclosed. The patterns are suitable for structure determination. The electron beam is precessed by means of deflector coils (6) in the transmission electron microscope before the sample (4), in combination with a similar precession of the electron diffraction pattern by means of deflector coils (9) situated after the sample. The electron diffraction pattern is scanned by means of deflector coils (9) situated after the sample.

Owner:SERGEEVICH AVILOV ANATOLY +1

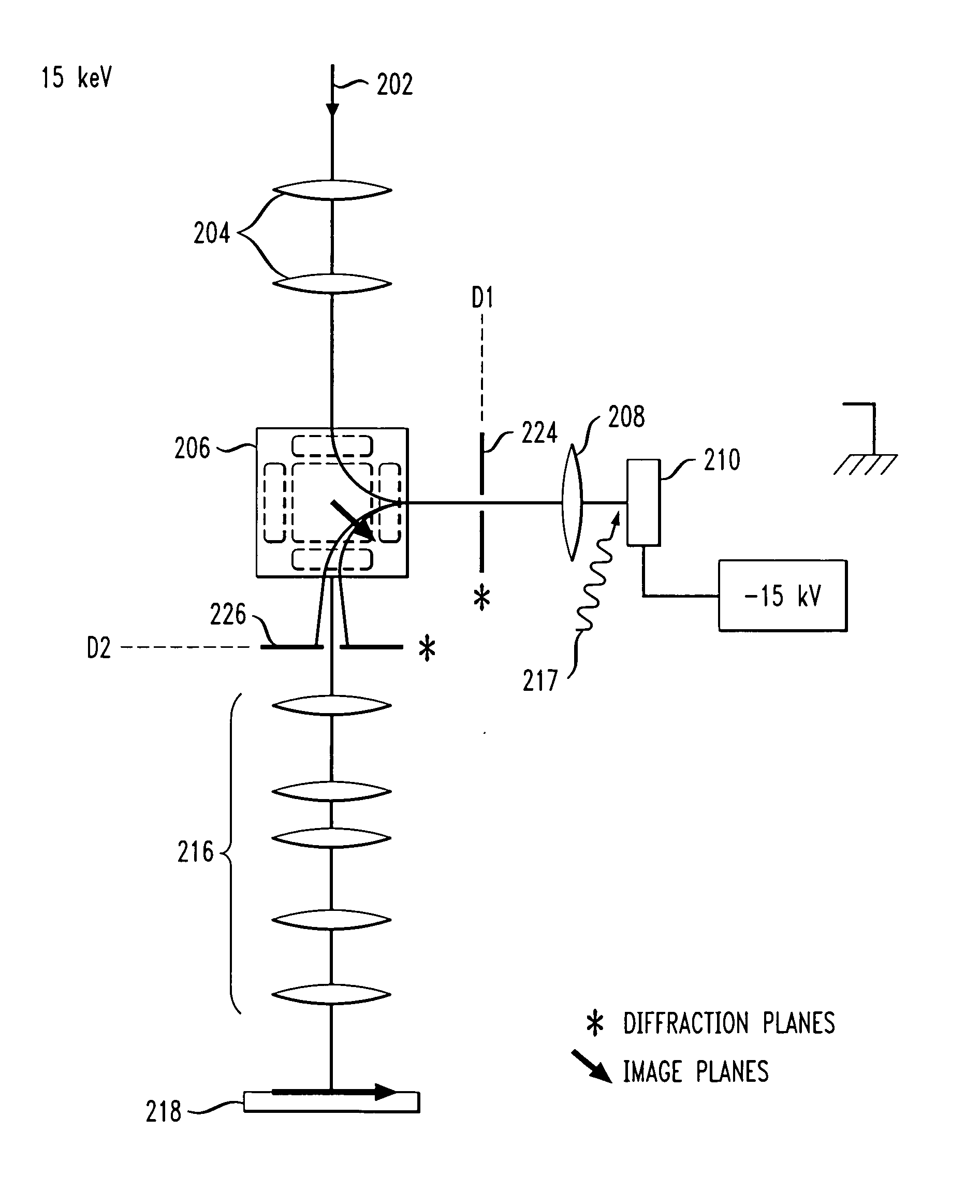

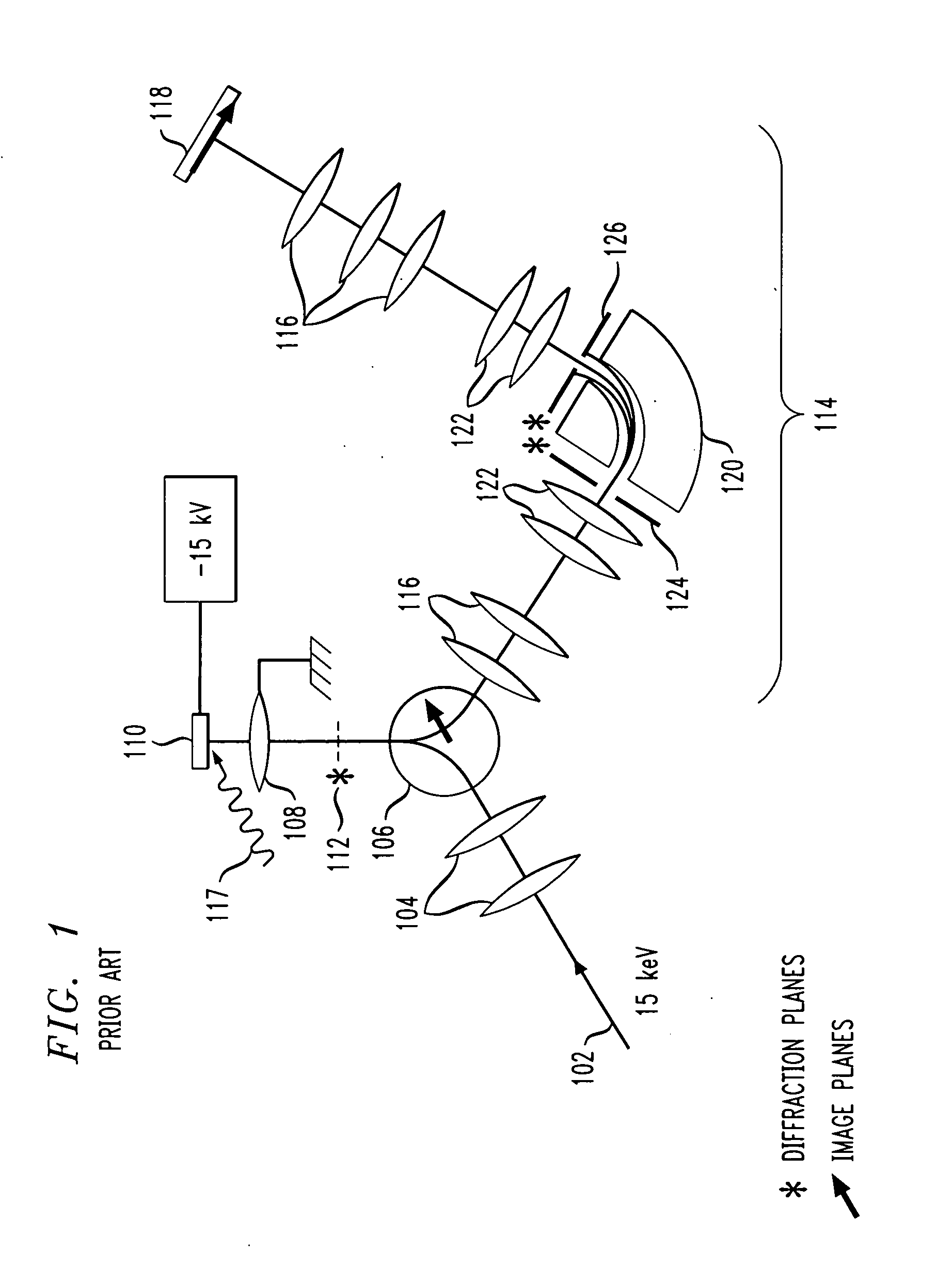

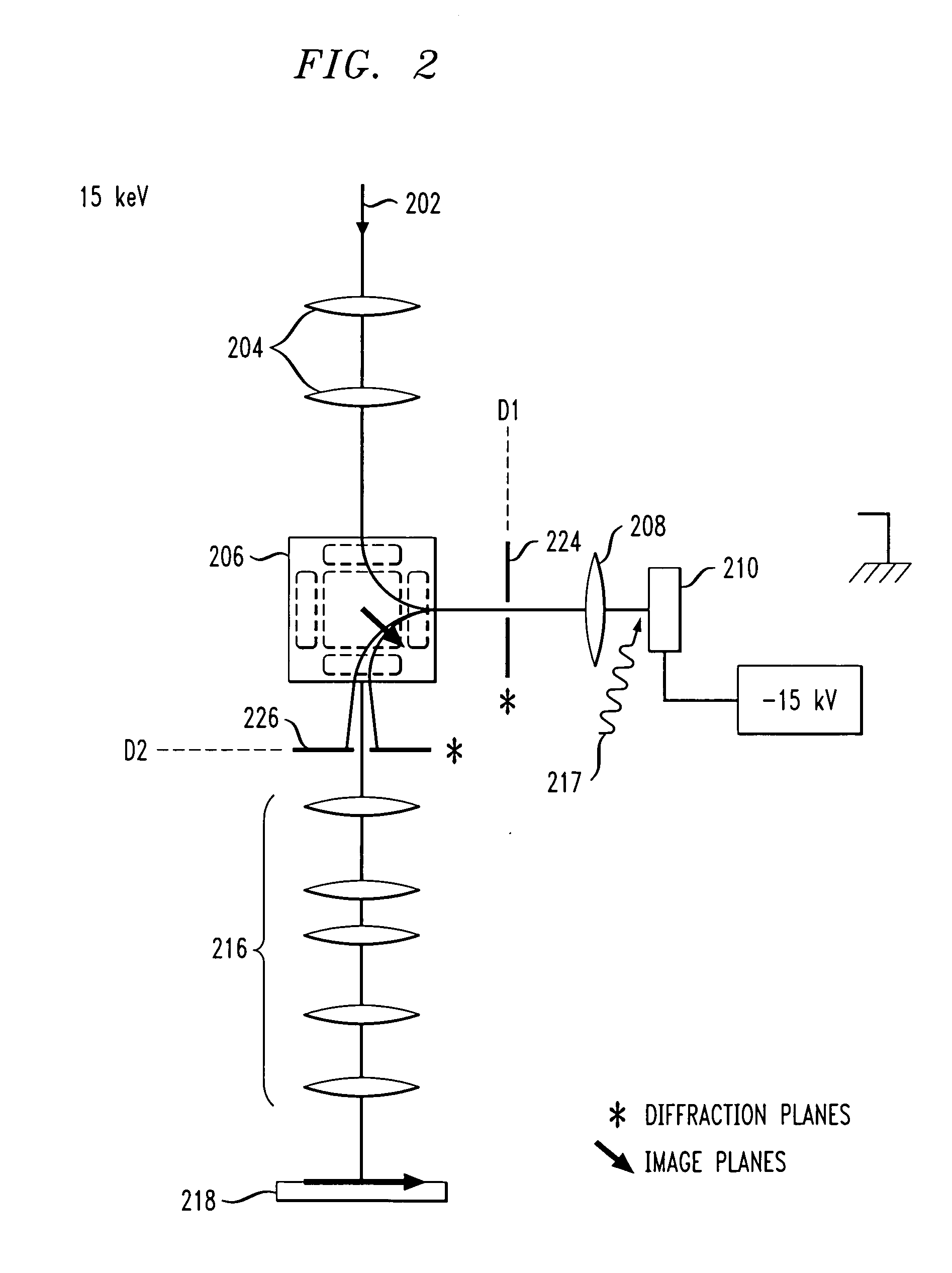

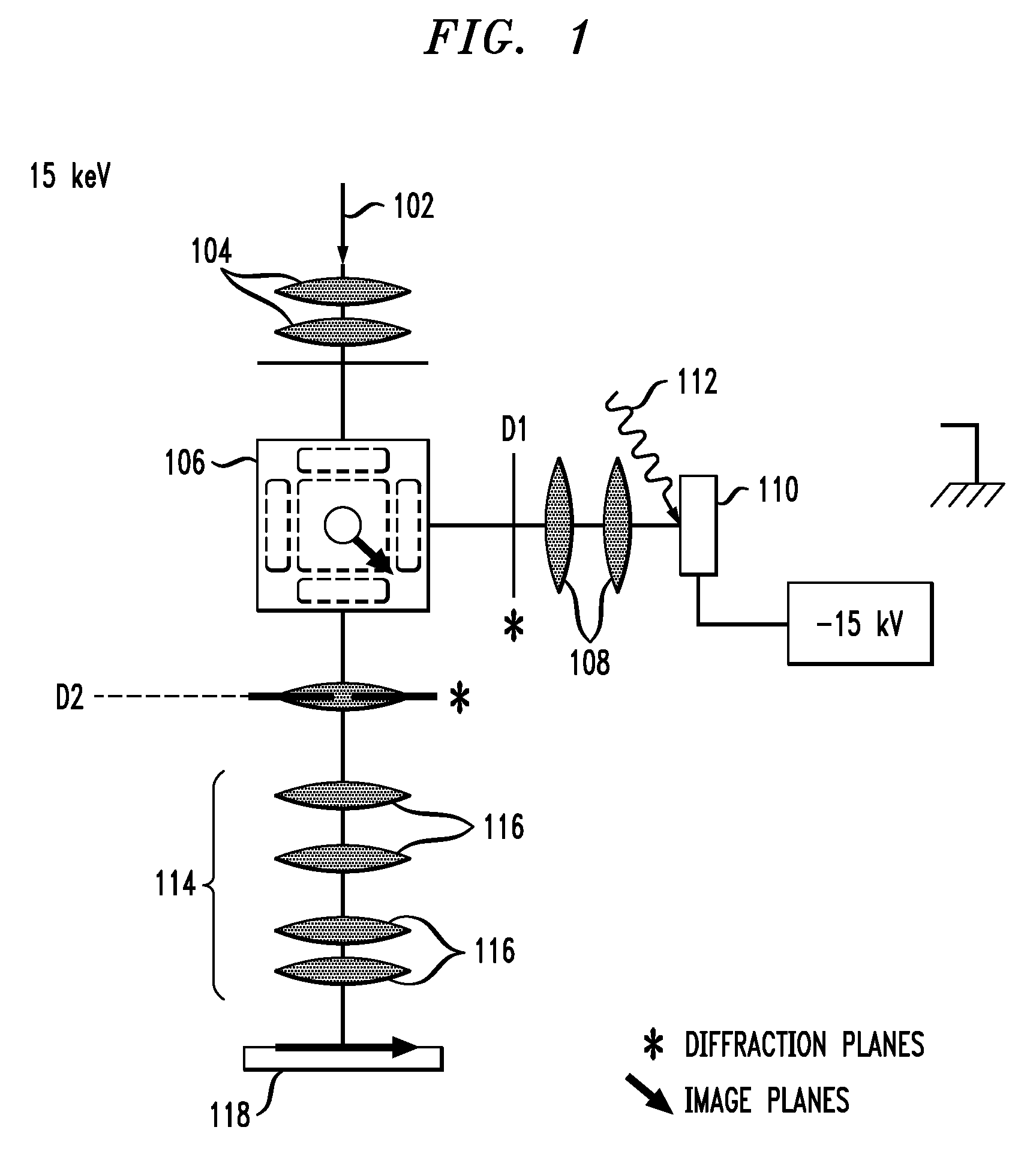

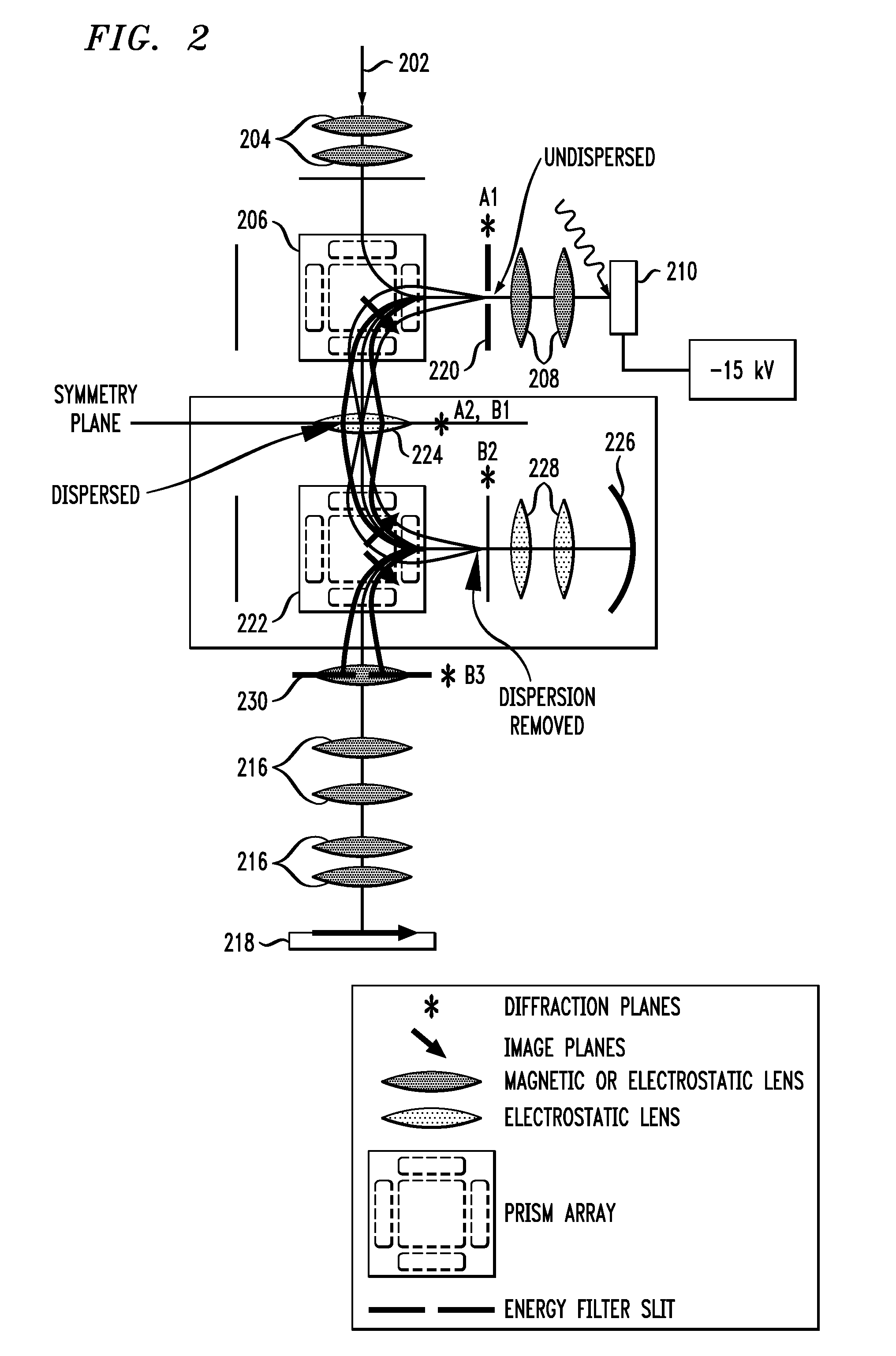

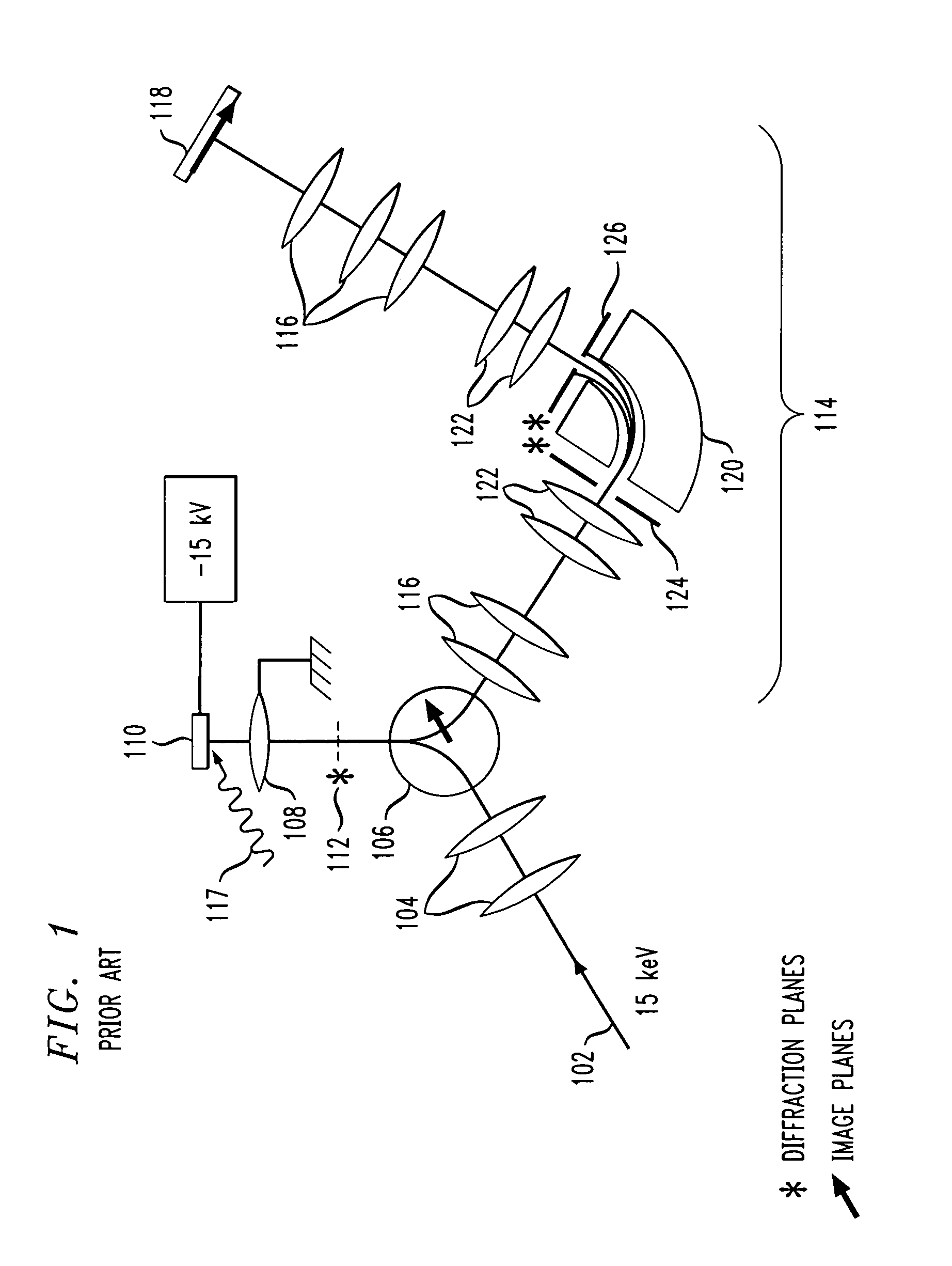

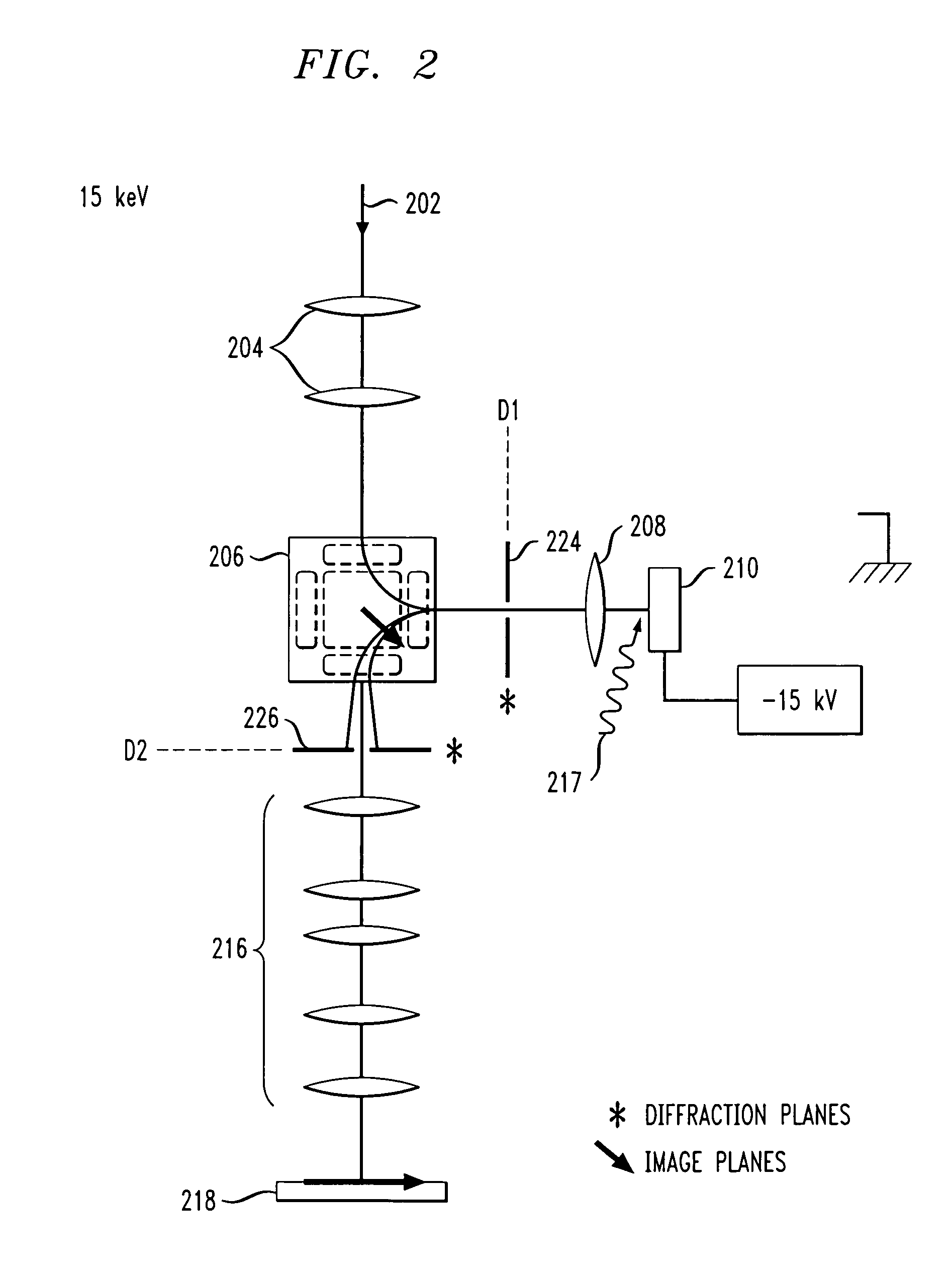

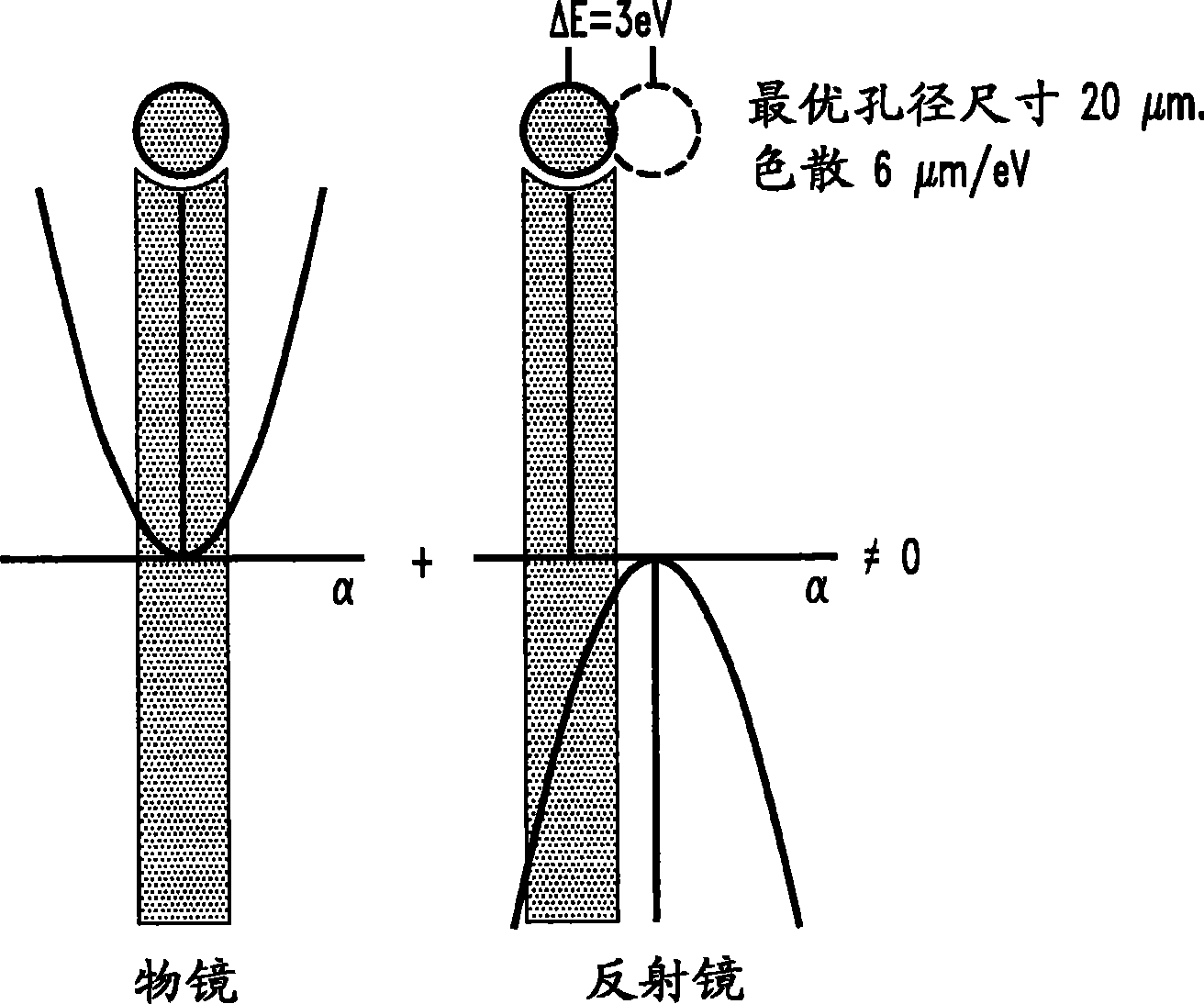

Aberration-correcting cathode lens microscopy instrument

ActiveUS20070200070A1Stability-of-path spectrometersMaterial analysis using wave/particle radiationExit planeElectron diffraction pattern

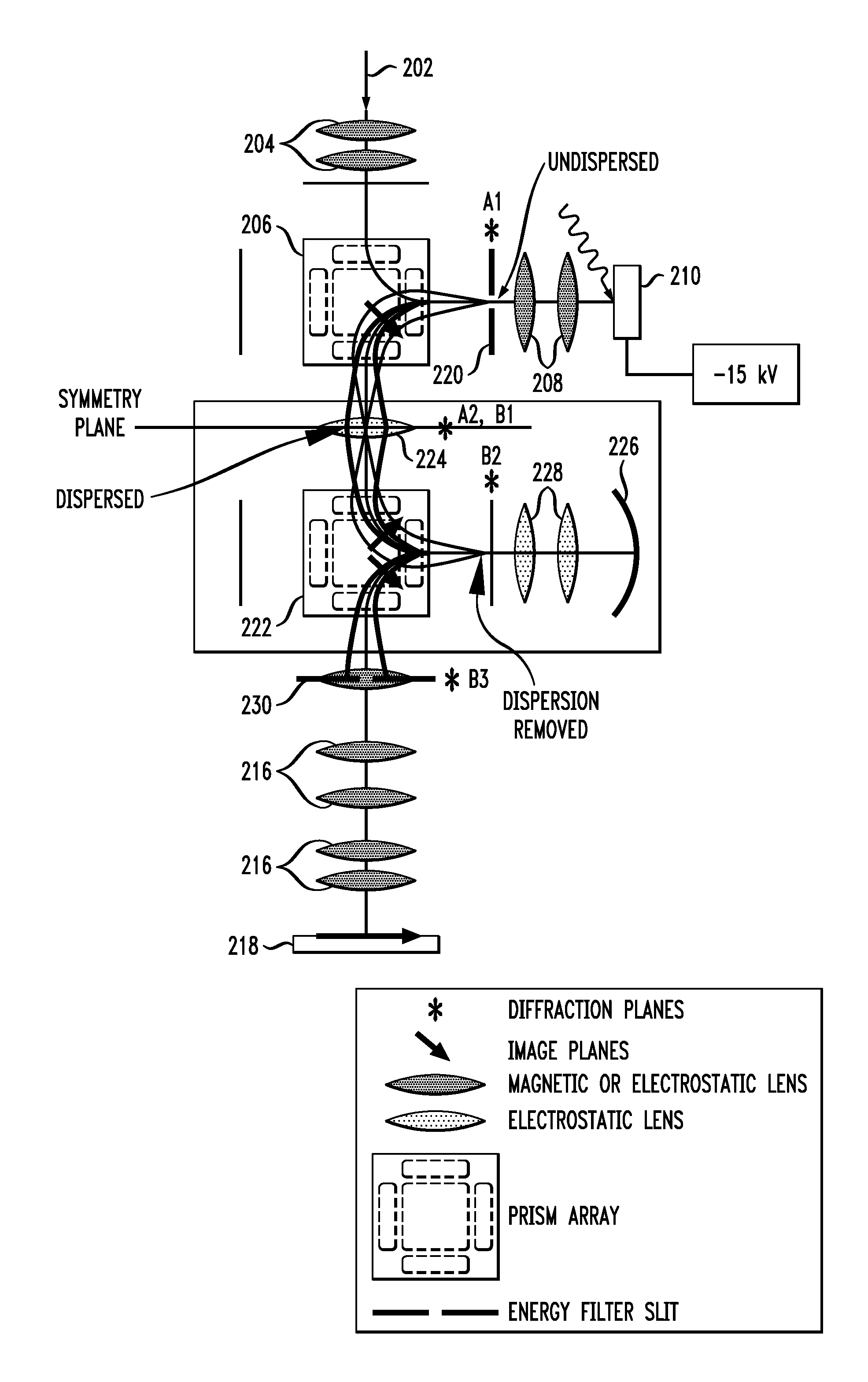

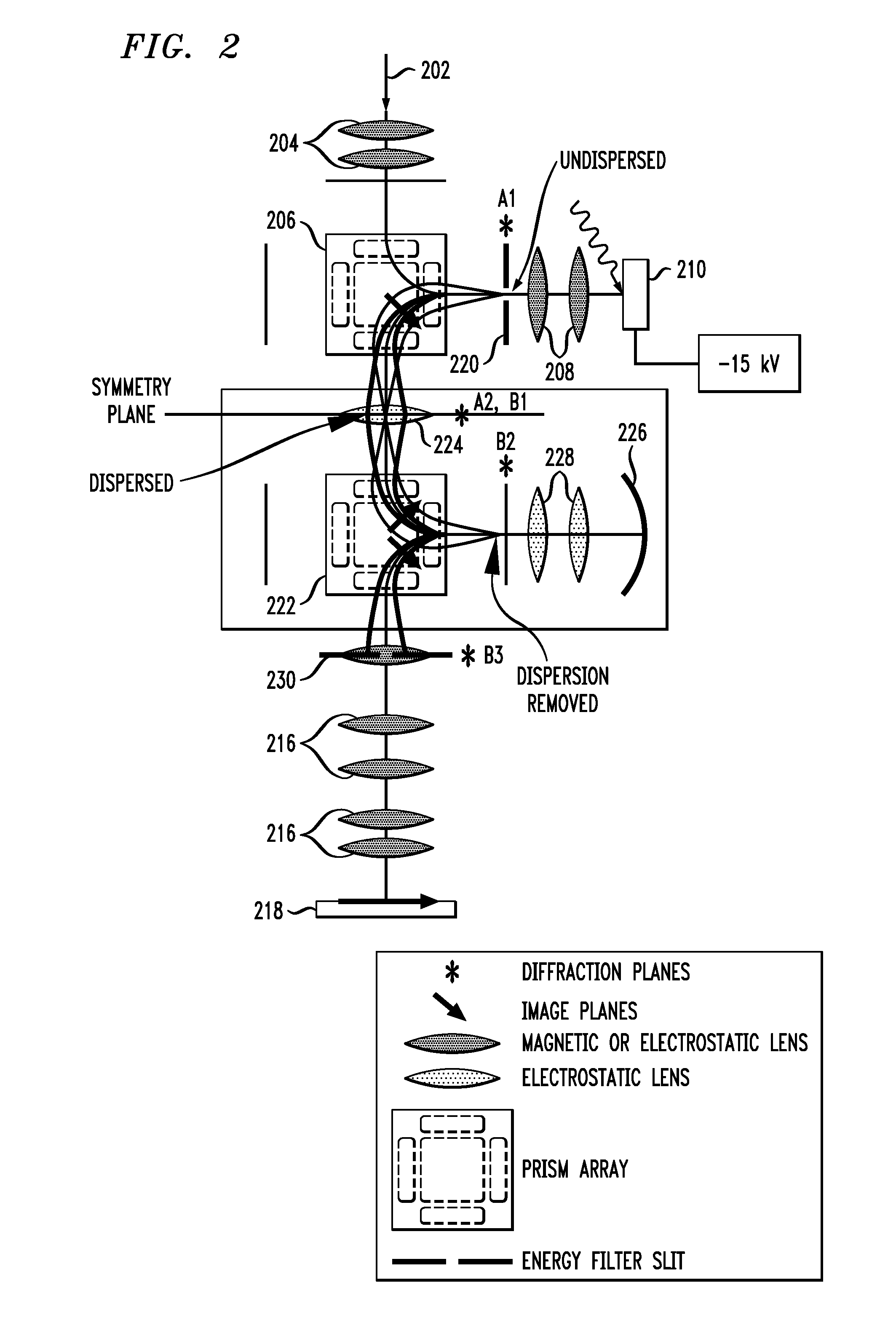

An aberration-correcting microscopy instrument is provided. The instrument has a first magnetic deflector disposed for reception of a first non-dispersed electron diffraction pattern. The first magnetic deflector is also configured for projection of a first energy dispersed electron diffraction pattern in an exit plane of the first magnetic deflector. The instrument also has an electrostatic lens disposed in the exit plane of a first magnetic deflector, as well as a second magnetic deflector substantially identical to the first magnetic deflector. The second magnetic deflector is disposed for reception of the first energy dispersed electron diffraction pattern from the electrostatic lens. The second magnetic deflector is also configured for projection of a second non-dispersed electron diffraction pattern in a first exit plane of the second magnetic deflector. The instrument also has an electron mirror configured for correction of one or more aberrations in the second non-dispersed electron diffraction pattern. The electron mirror is disposed for reflection of the second non-dispersed electron diffraction pattern to the second magnetic deflector for projection of a second energy dispersed electron diffraction pattern in a second exit plane of the second magnetic deflector.

Owner:IBM CORP

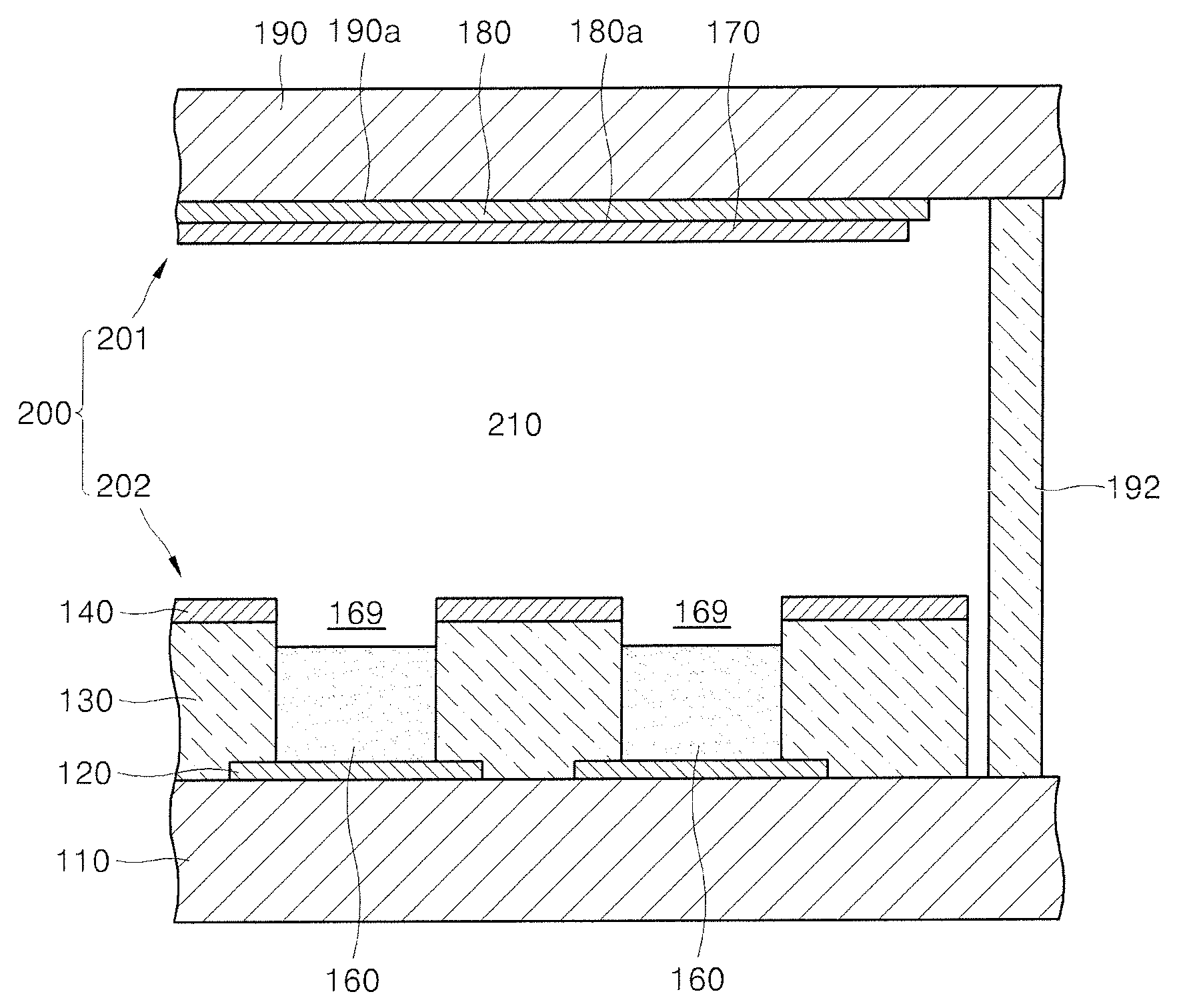

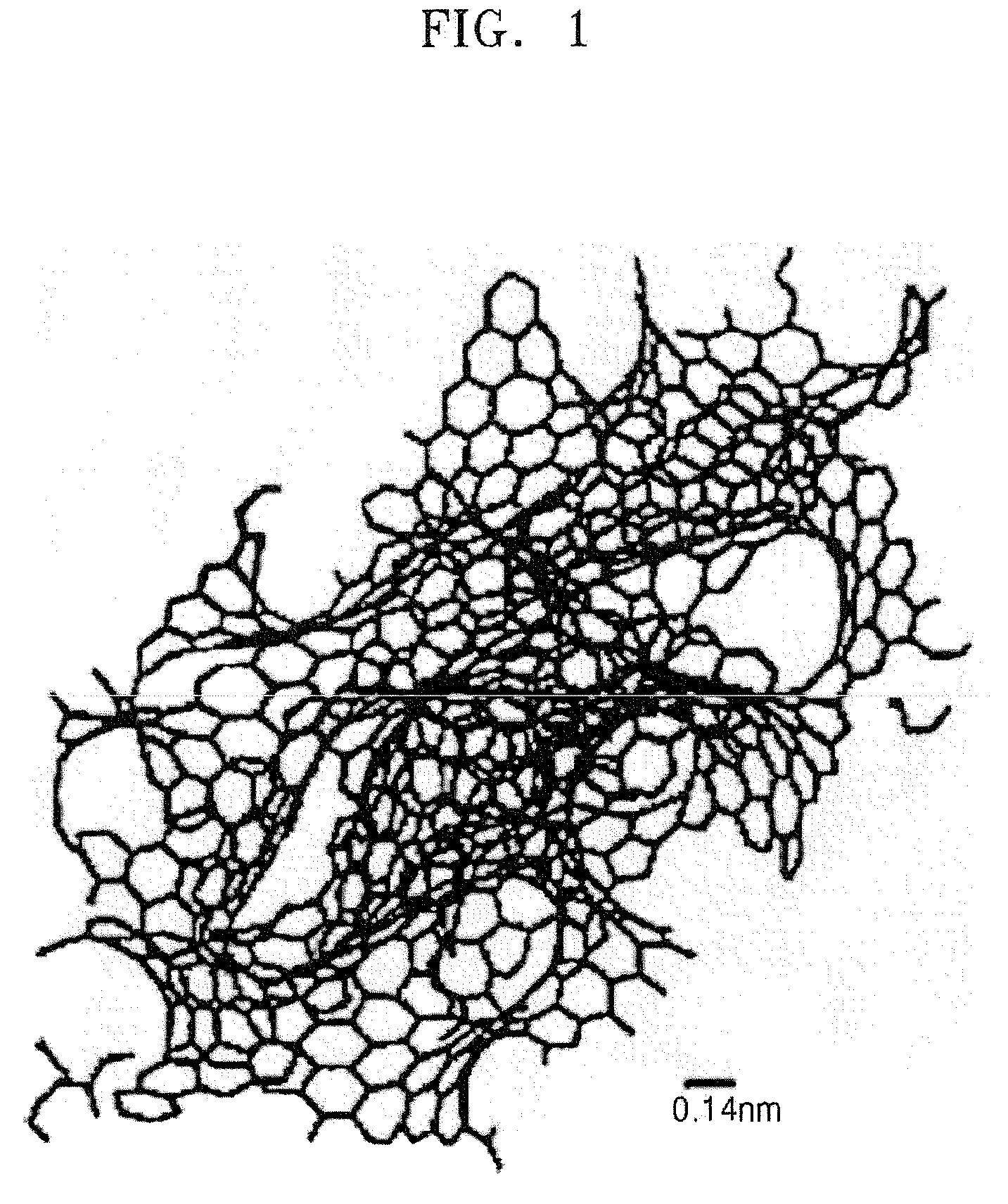

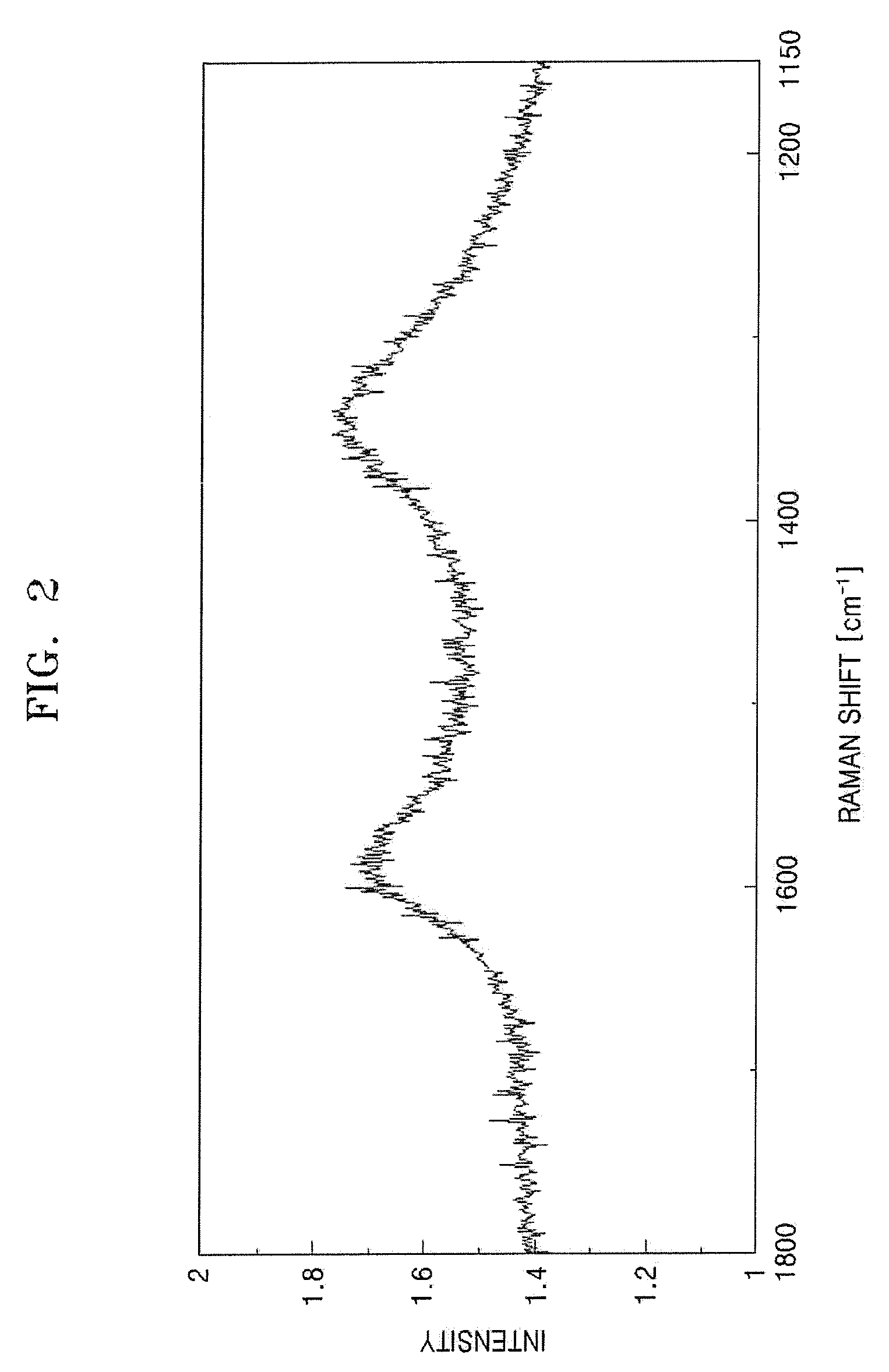

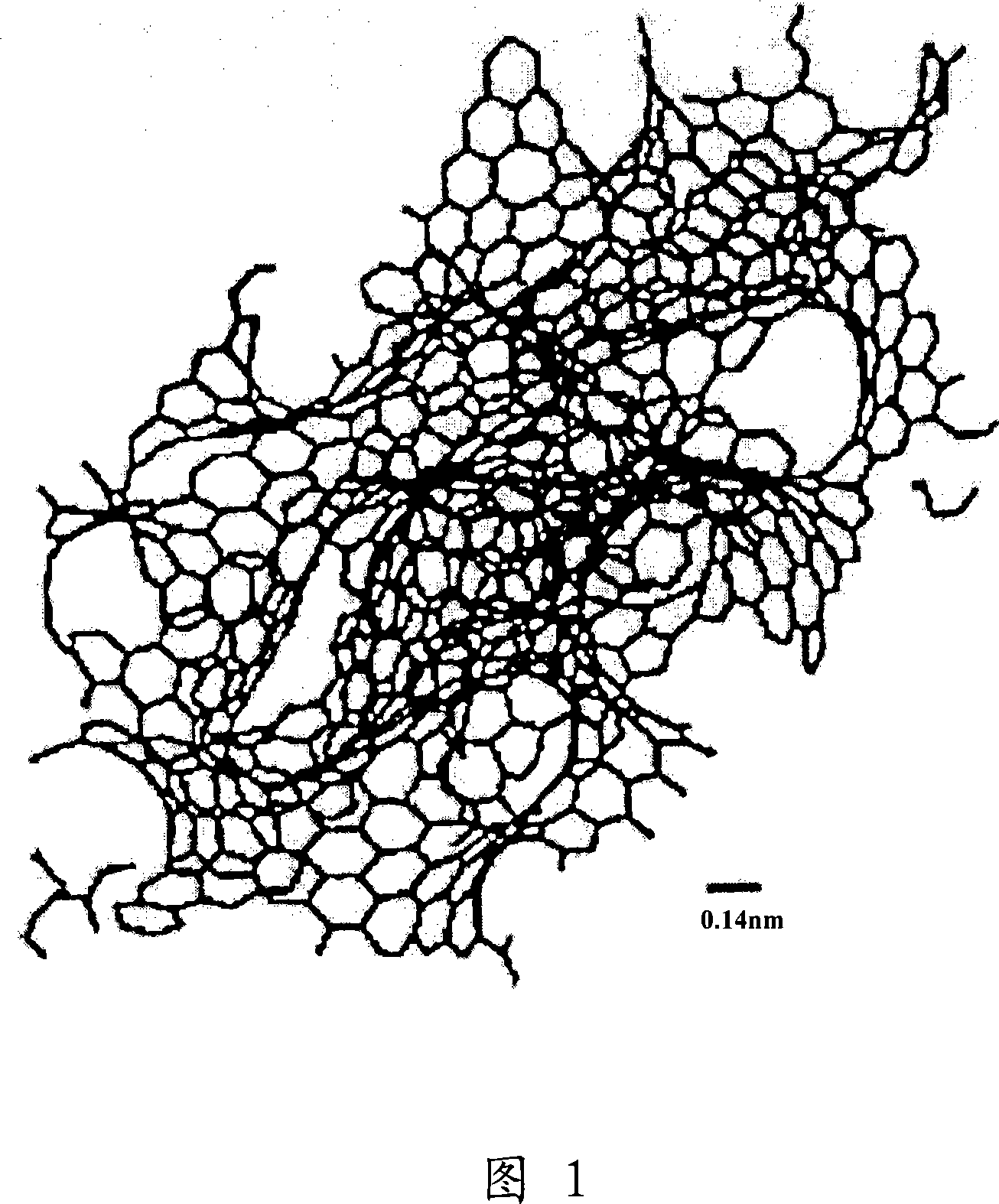

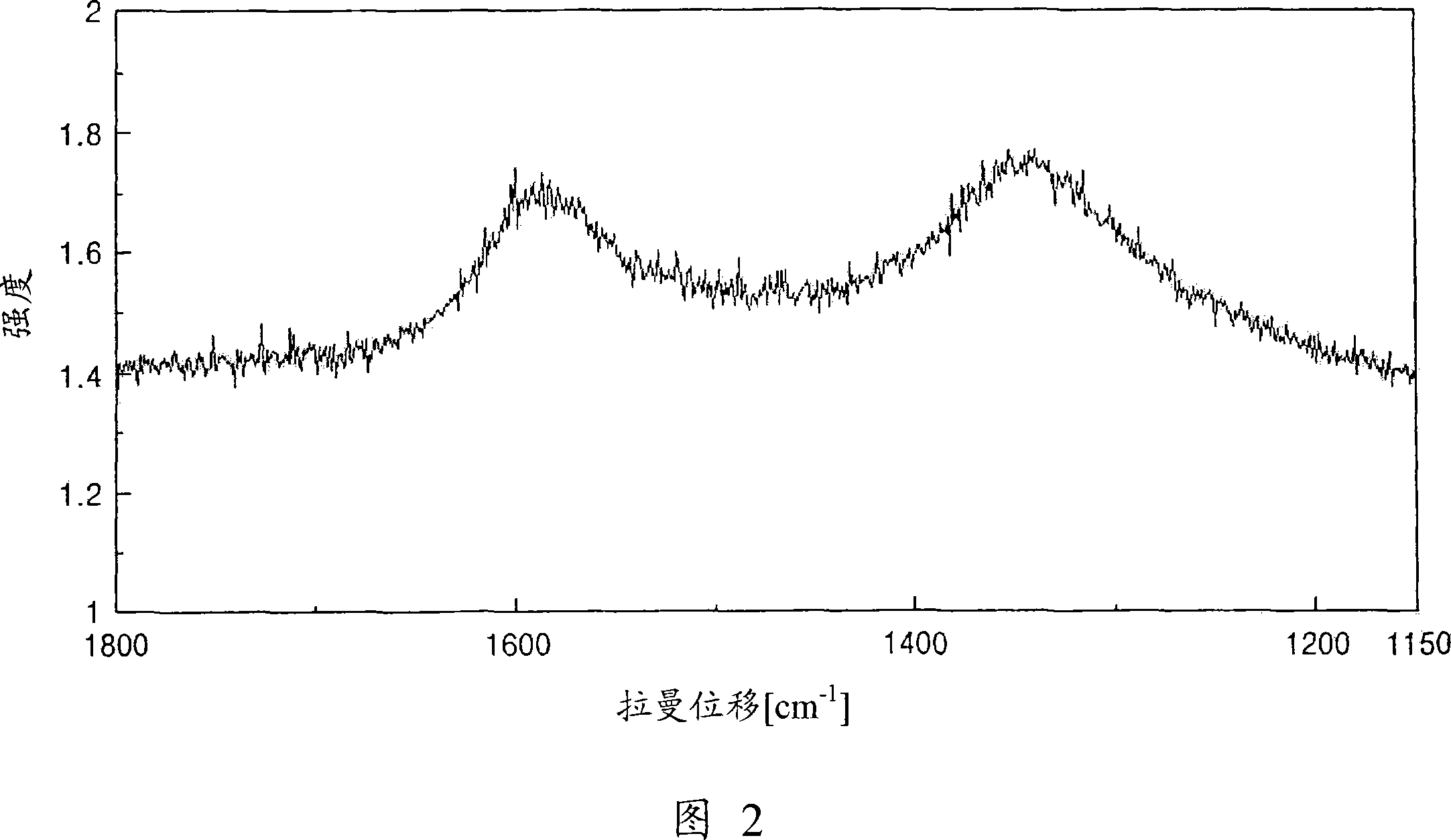

Carbide derived carbon, emitter for cold cathode including the same and electron emission device including the emitter

InactiveUS20080169749A1Improve uniformityLong life-timeDischarge tube luminescnet screensElectric discharge tubesChemical reactionX-ray

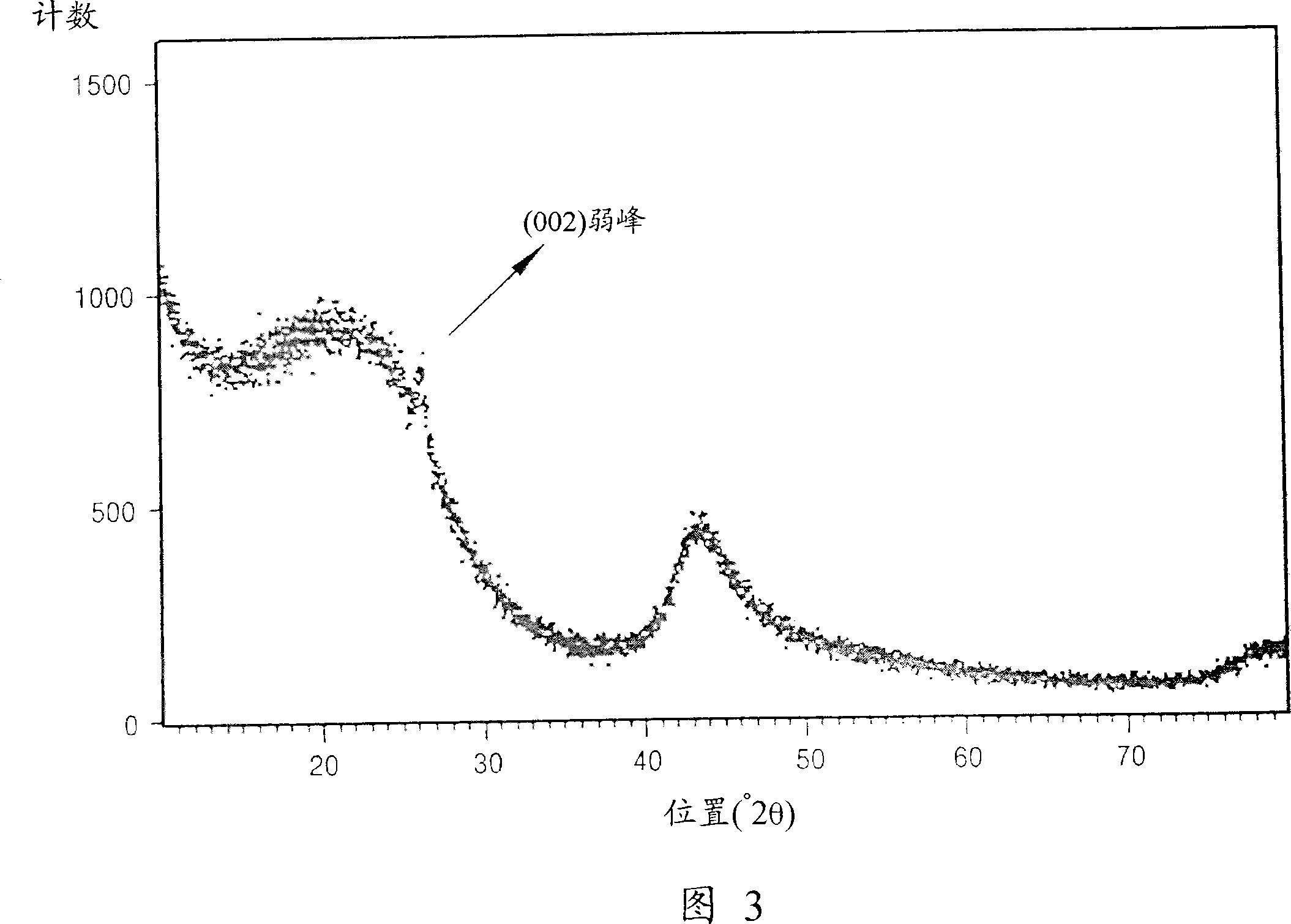

Provided are carbide derived carbon prepared by thermochemically reacting carbide compounds and a halogen element containing gas and extracting all atoms of the carbide compounds except carbon atoms, wherein the intensity ratios of the graphite G band at 1590 cm−1 to the disordered-induced D band at 1350 cm−1 are in the range of 0.3 through 5 when the carbide derived carbon is analyzed using Raman peak analysis, wherein the BET surface area of the carbide derived carbon is 1000 m2 / g or more, wherein a weak peak or wide single peak of the graphite (002) surface is seen at 2θ=25° when the carbide derived carbon is analyzed using X-ray diffractometry, and wherein the electron diffraction pattern of the carbide derived carbon is the halo pattern typical of amorphous carbon when the carbide derived carbon is analyzed using electron microscopy. The emitter has good uniformity and a long lifetime. An emitter can be prepared using a more inexpensive method than that used to manufacture conventional carbon nanotubes.

Owner:LOFFE PHYSICO TECHN INST OF RUSSIAN ACADEMY OF SCI +1

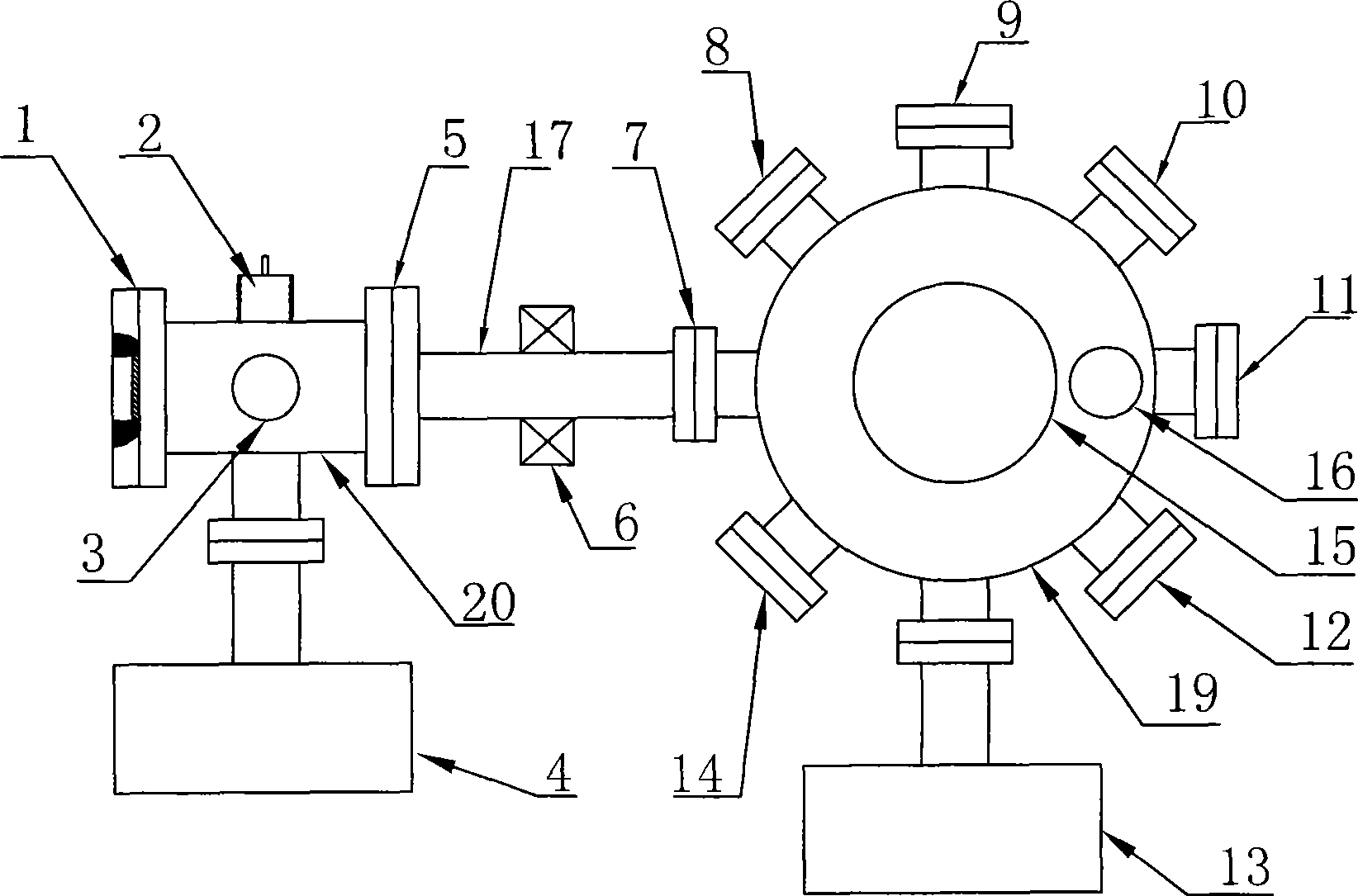

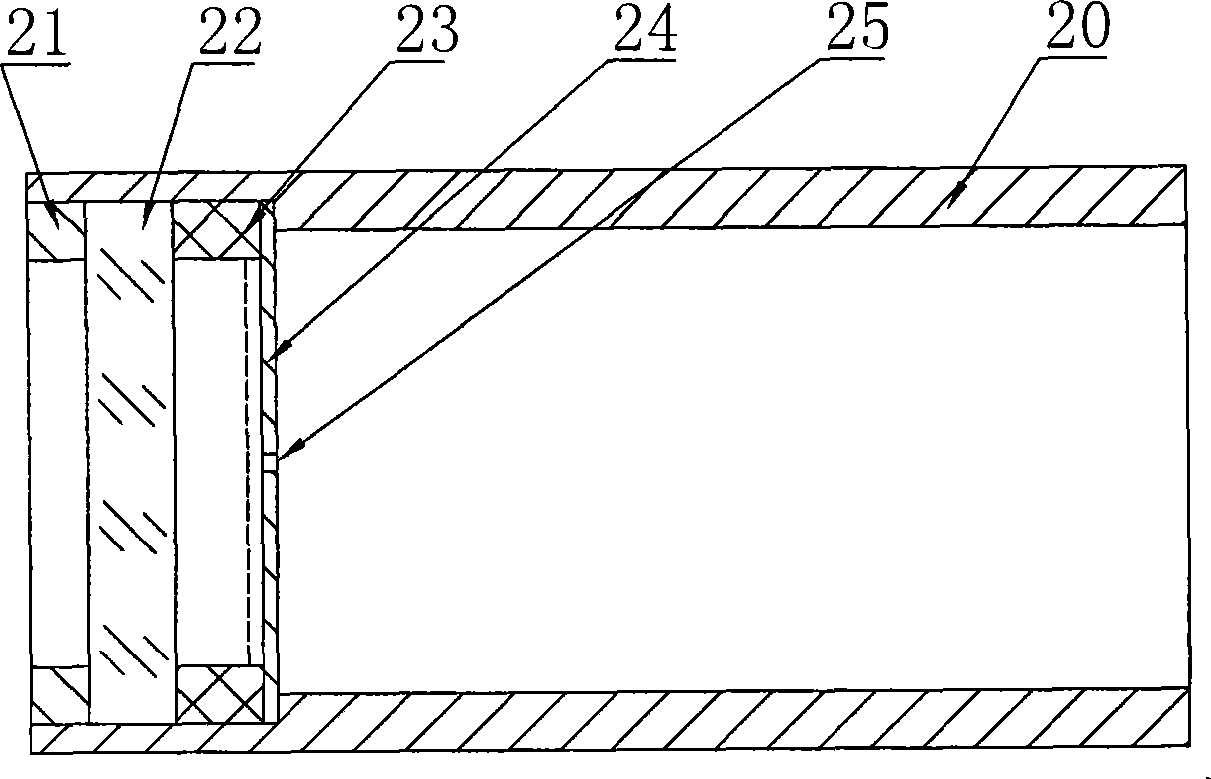

Multi-purpose ultrafast electric diffraction apparatus

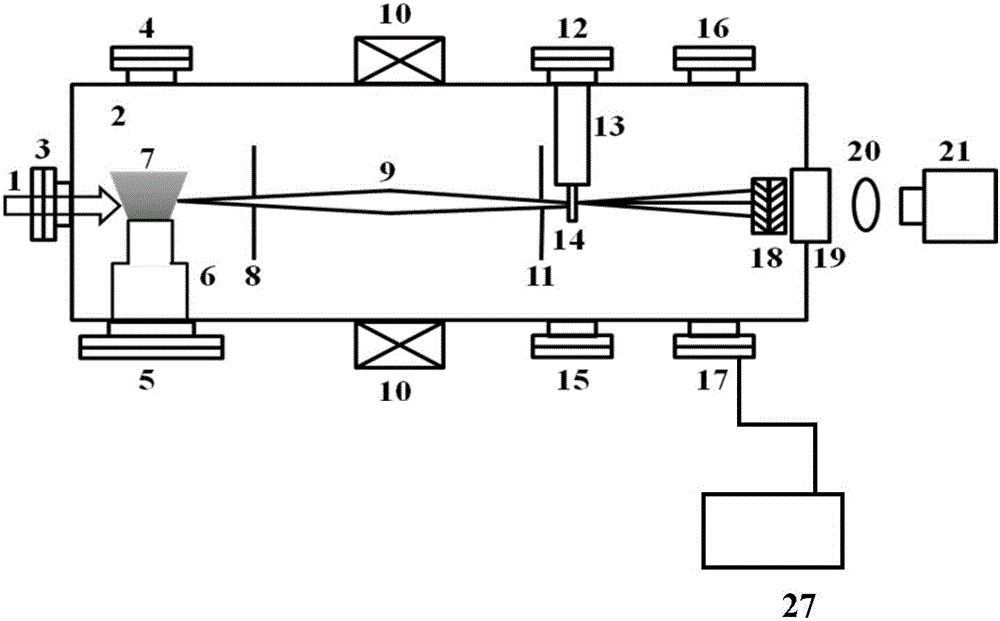

InactiveCN101435785AIncrease vacuumWon't failMaterial analysis using radiation diffractionPhotocathodeLaser source

The invention relates to a multipurpose ultrafast electron diffraction device, which comprises a laser source, an electron gun capable of generating ultrafast electron beams, a sample chamber, an electron diffraction image detector and a vacuum pumping system, wherein a cathode and an anode are arranged in the electron gun; the cathode is plated with a metallic film; the center of the anode is provided with an anode keyhole; an insulating ring is arranged between the cathode and the anode; the electron gun and the sample chamber are connected through an electron beam channel; the outer circumference of the electron beam channel is sleeved with a magnetic coil; a joint of the electron beam channel and the sample chamber is provided with an electron beam channel keyhole; the diameter of the electron beam channel keyhole is between phi 1 and phi 2 millimeters; and a vacuum system comprises an electron gun vacuum system connected with the electron gun, as well as a sample chamber vacuum system connected with the sample chamber. The multipurpose ultrafast electron diffraction device provided by the invention solves the problems that the prior ultrafast electron diffraction device can not simultaneously adapt to solid-phase and vapor-phase electron diffraction experiments, can not regulate energy, is serious in the distortion of an electric field near the anode, and is invalid in photocathode.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

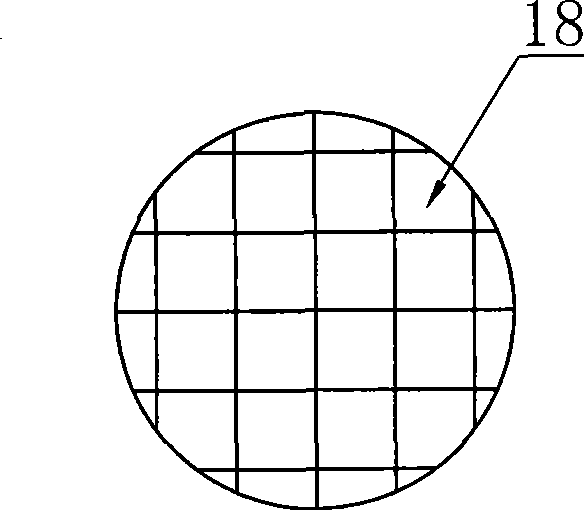

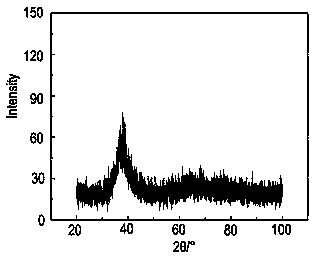

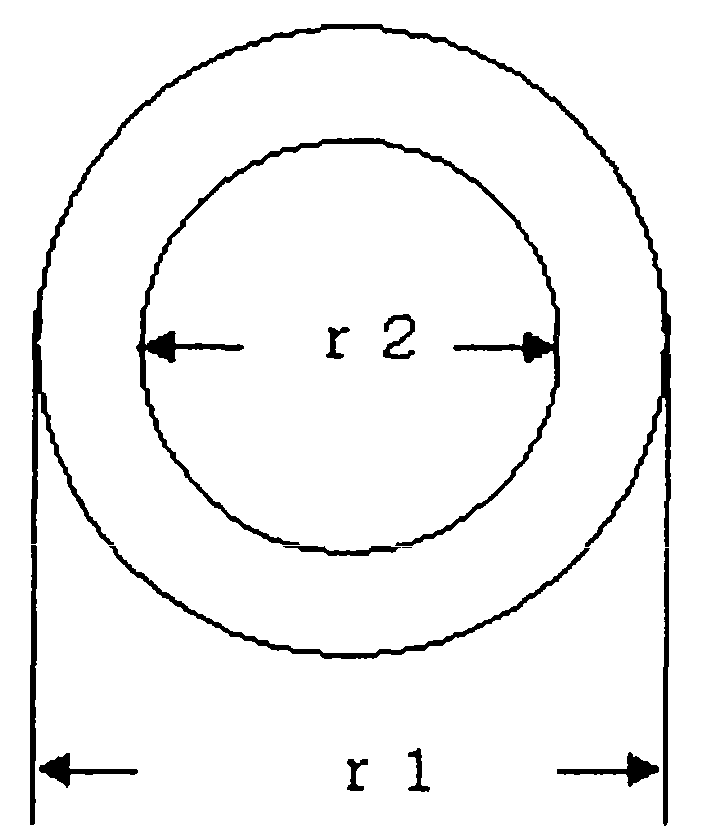

Electrochemical method for preparing nickel metal tubular nano array

The invention provides an electrochemical method for preparing a regularly ordered Ni tubular nano array with an AAO (Anodic Aluminum Oxide) template in an ammonium sulfate system. With the method, a Ni nano tube, of which the external diameter is about 70nm and the inner diameter is about 50nm, can be obtained. The obtained Ni nano tube can be represented by a scanning electron microscope (SEM), a transmission electron microscope (TEM), a selected area electron diffraction (SAED) pattern and an X-ray diffraction (XRD). The Ni nano tube prepared by the method is ordered in height and uniform in size, the appearance of the Ni nano tube is dependent on the structure of the AAO template, and the external diameter of the Ni nano tube is equal to the pore diameter of the template.

Owner:佛山市中国地质大学研究院

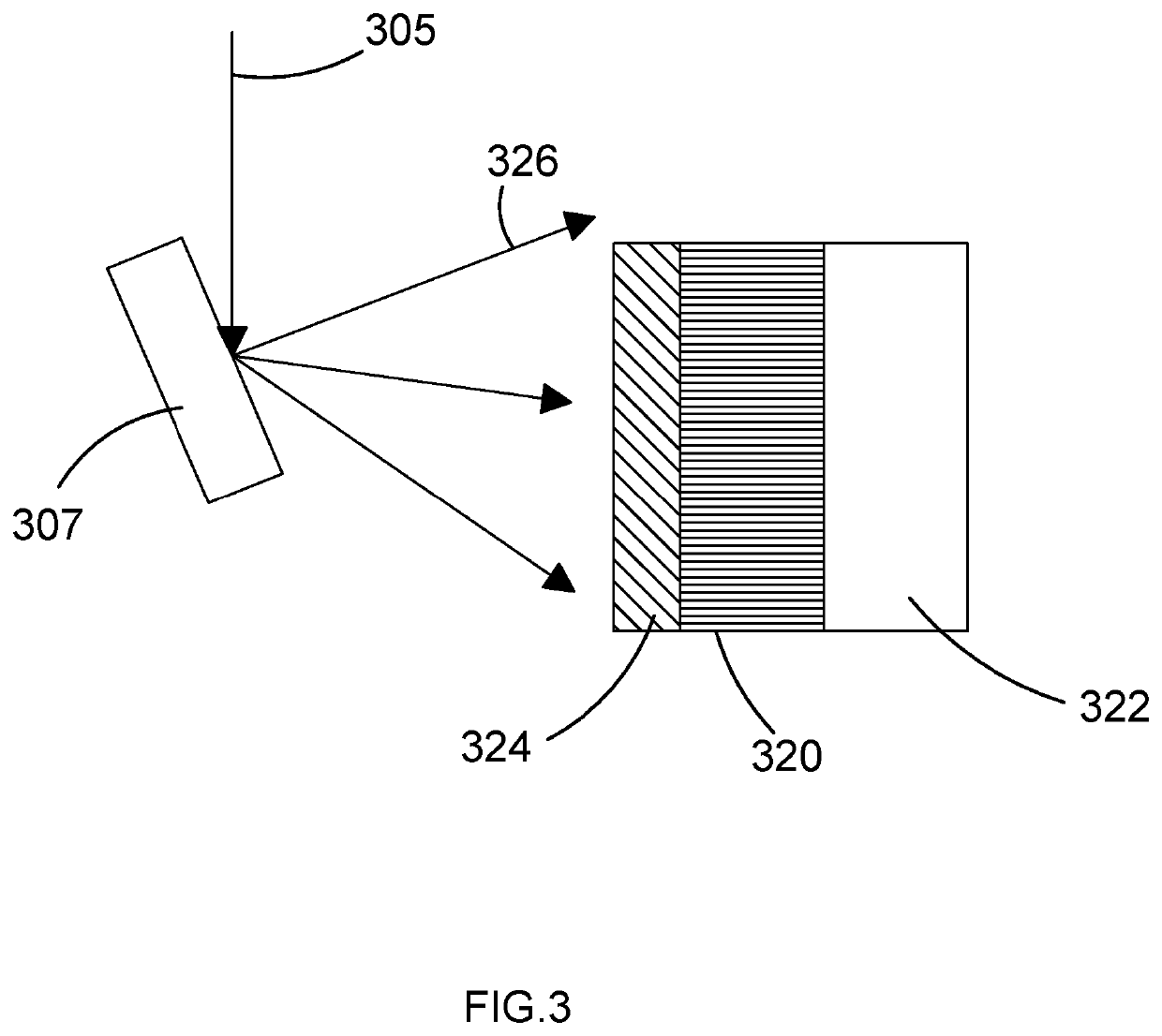

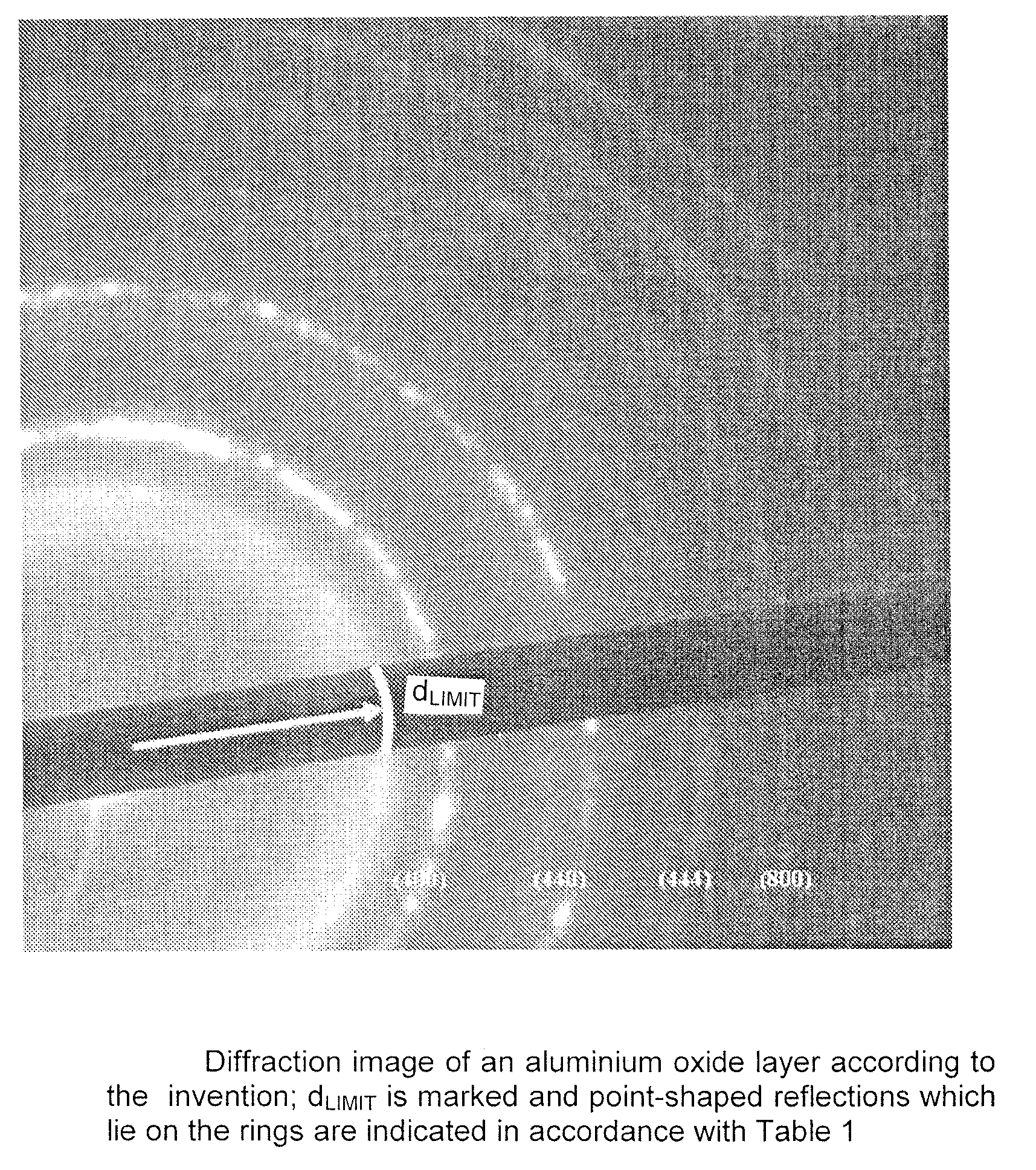

Cutting tool

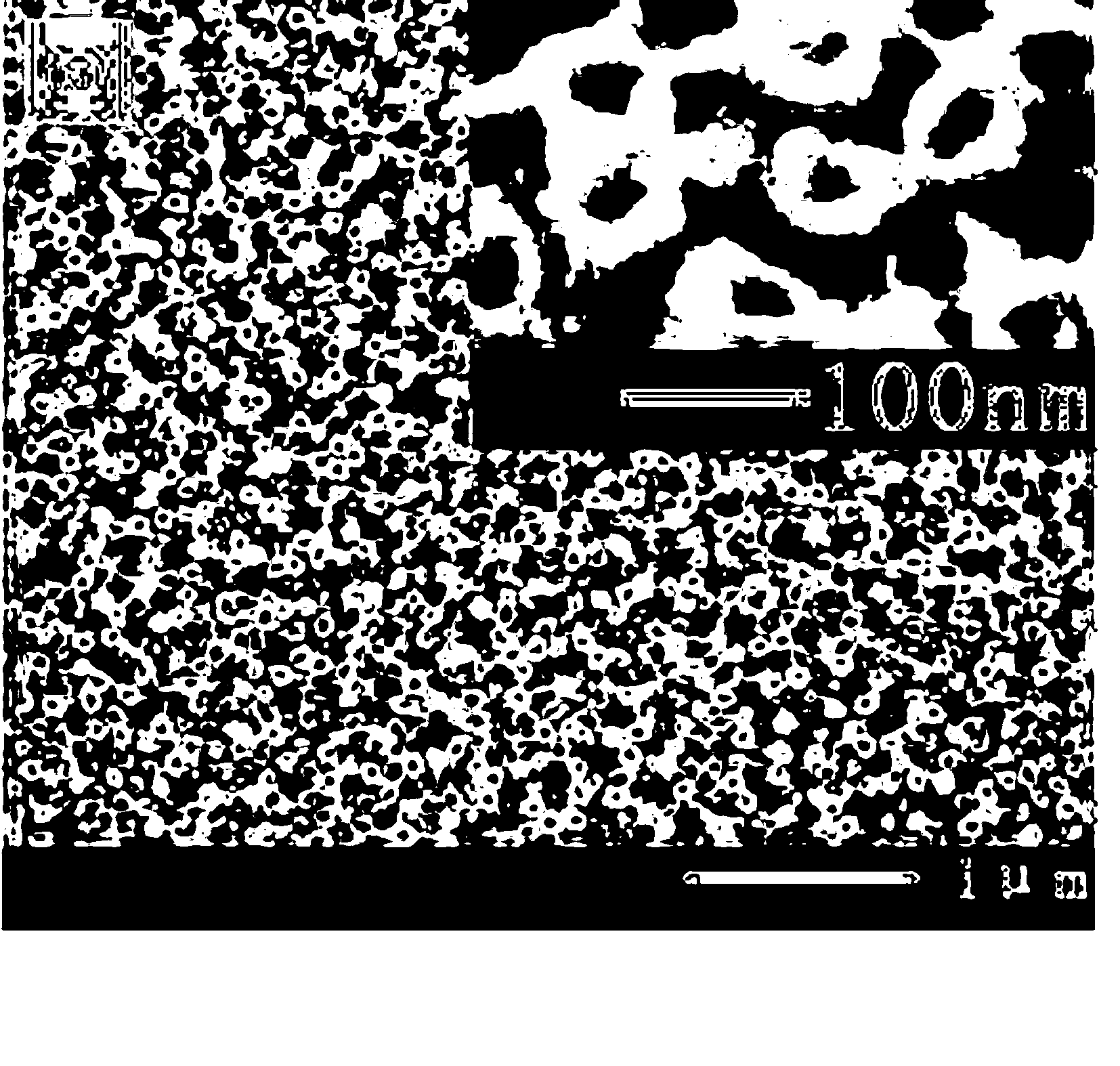

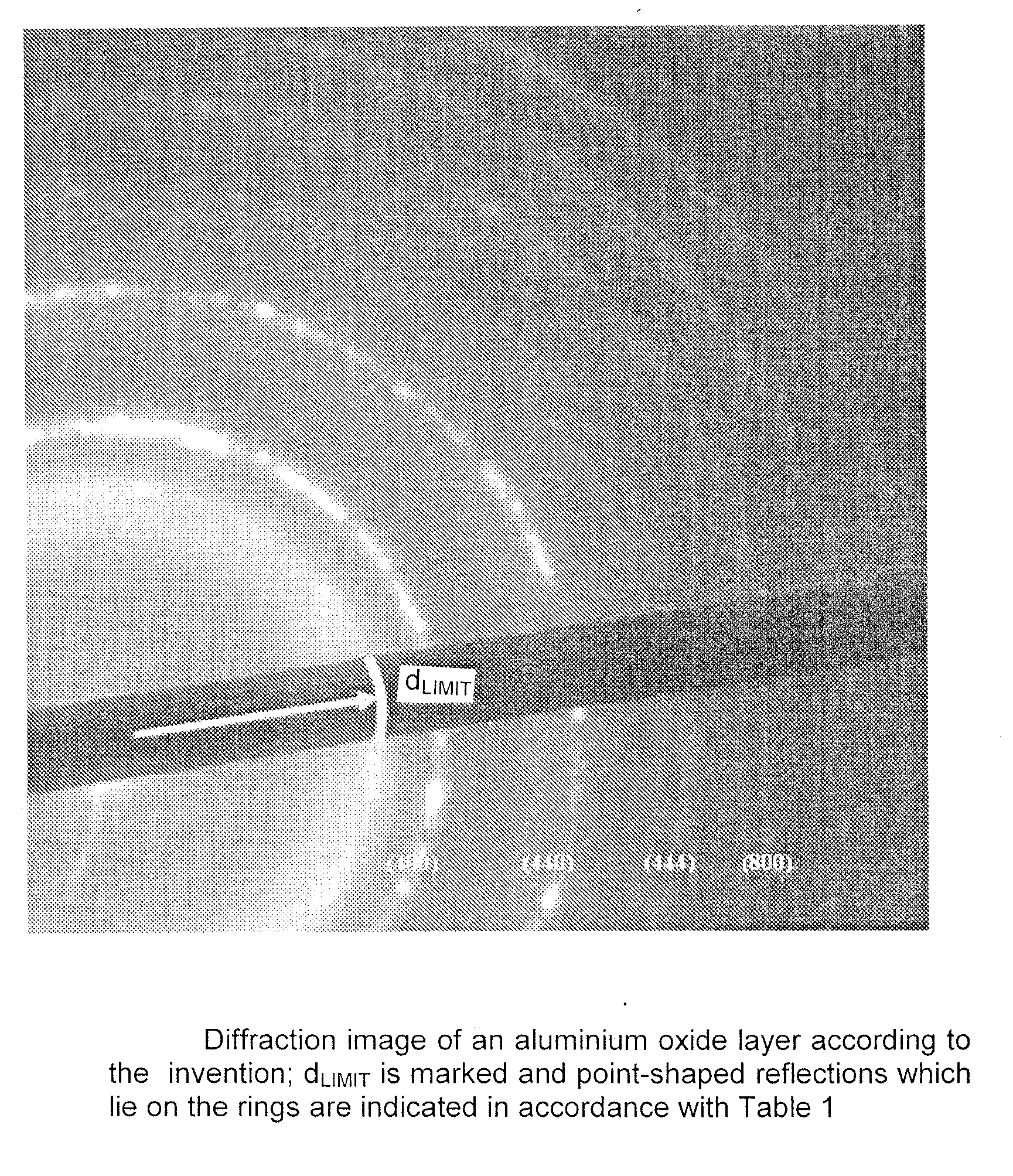

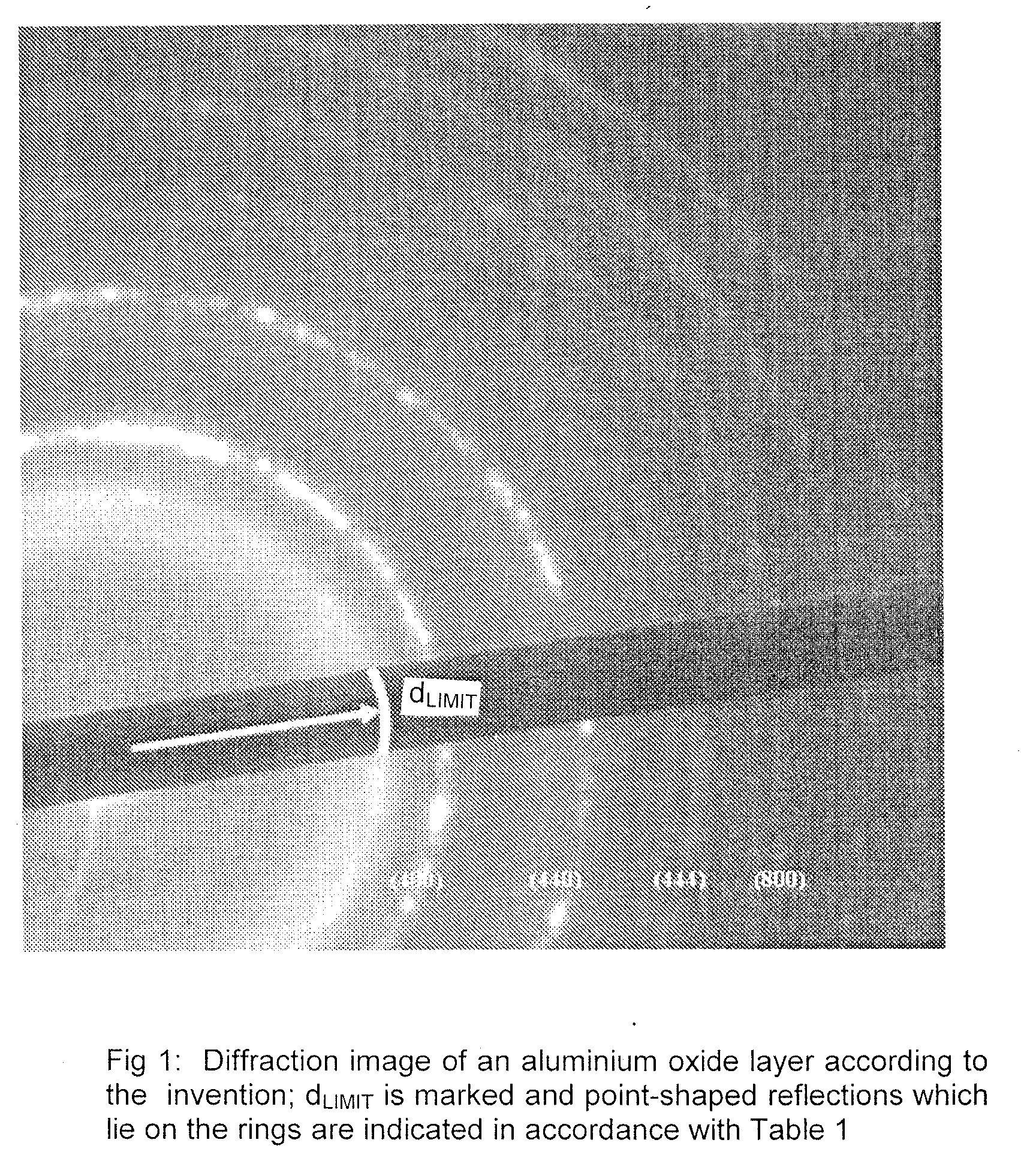

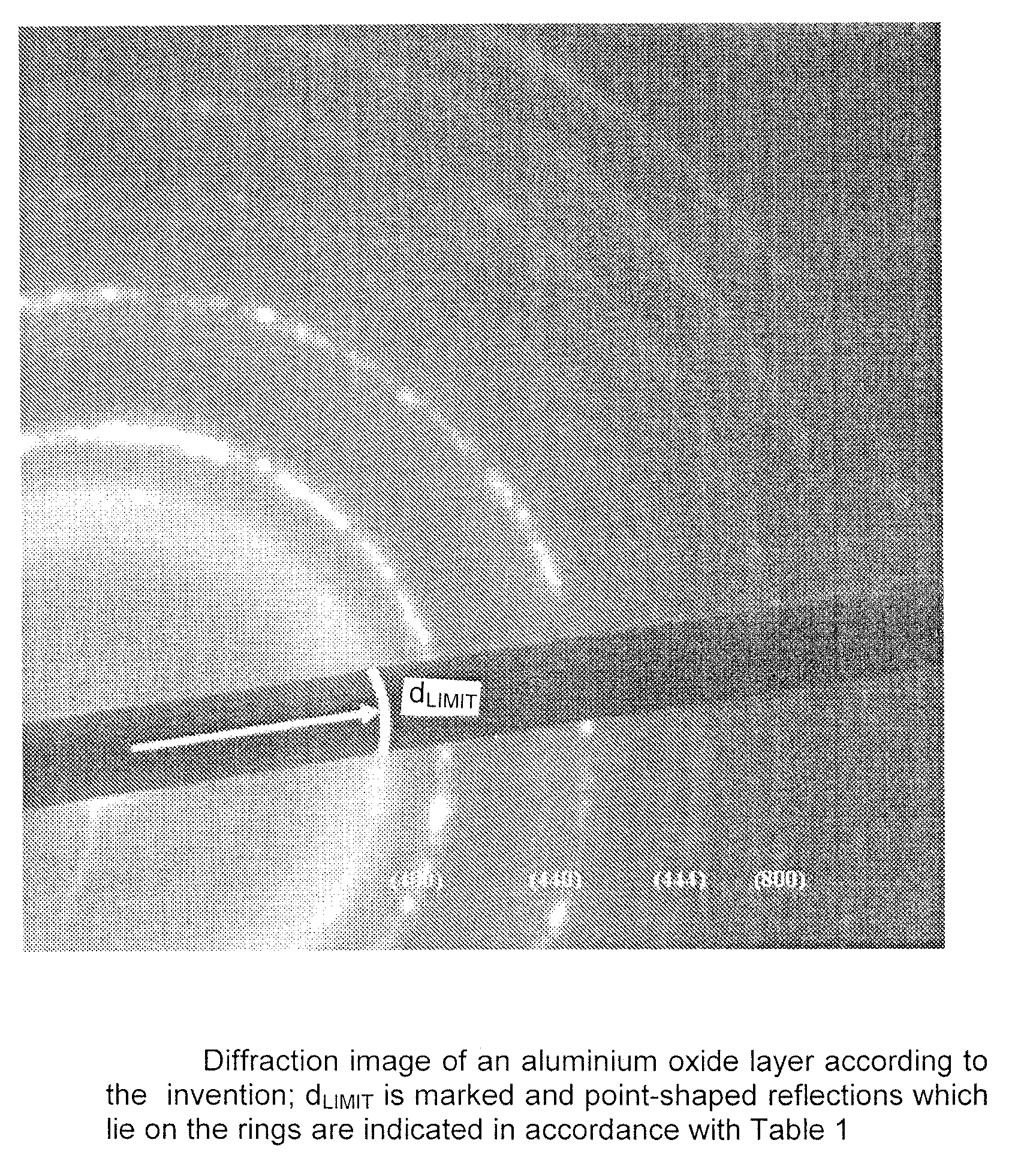

ActiveUS20110311805A1High hardnessImprove wear resistanceTurning machine accessoriesVacuum evaporation coatingDiffuse intensityElectron diffraction pattern

The invention relates to a cutting tool having a substrate base body and a single or multi-layered coating attached thereupon, wherein at least one layer of the coating is a metal oxide layer produced in the PVD process or in the CVD process and the metal oxide layer has a grain structure wherein there is structural disorder within a plurality of the existing grains that are characterized in that in electron diffraction images of the grains, point-shaped reflections occur up to a maximum lattice spacing dGRENZ and for lattice spacing greater than dGRENZ no point-shaped reflections occur, but rather a diffuse intensity distribution typical for amorphous structures.

Owner:WALTER AG

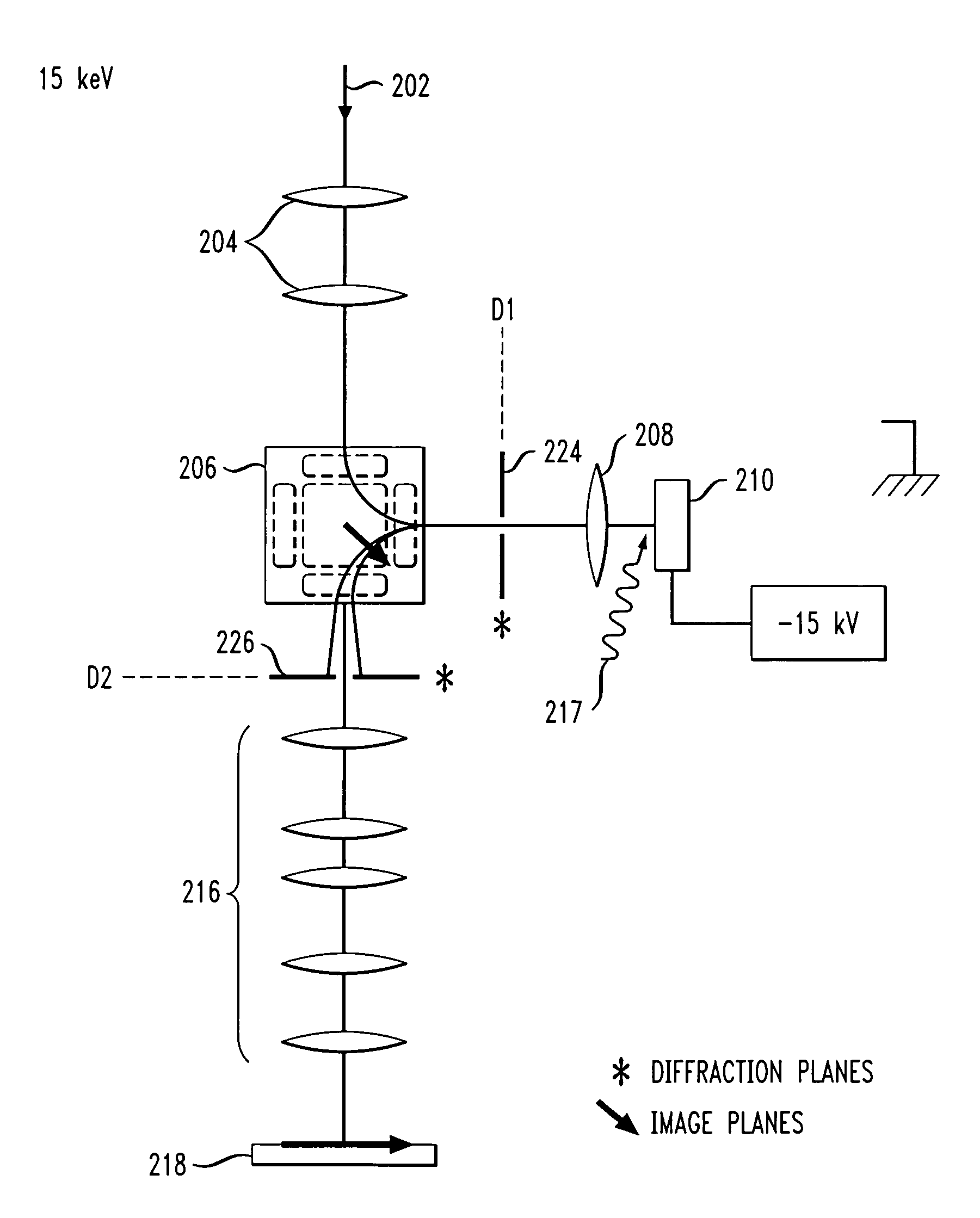

Energy-filtering cathode lens microscopy instrument

InactiveUS20070200062A1Eliminate the problemLow costMaterial analysis using wave/particle radiationPhotoelectric discharge tubesExit planeElectron diffraction pattern

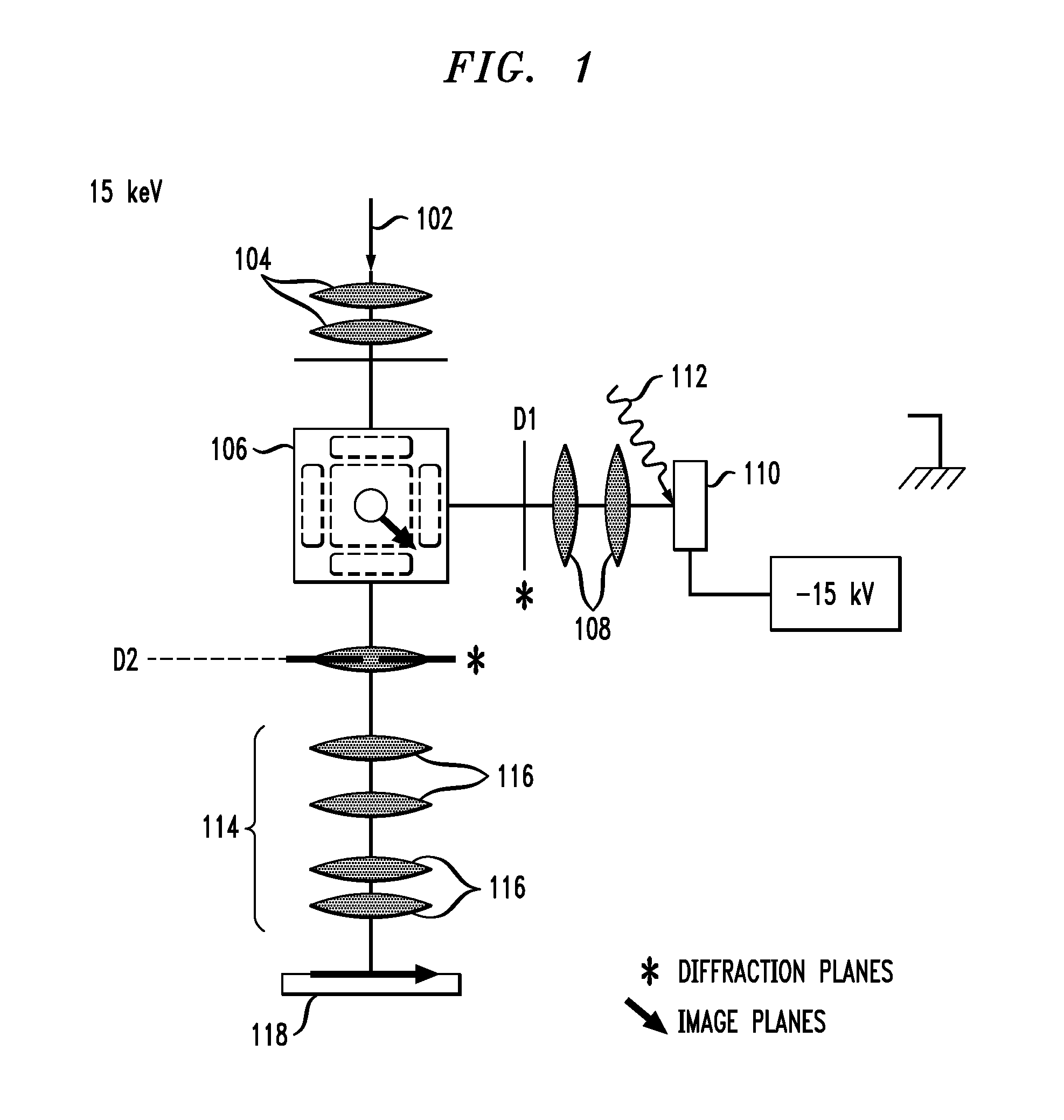

An energy filtering microscopy instrument is provided. An objective lens is disposed for reception of electrons in order to form an electron diffraction pattern in a backfocal plane of the objective lens. An entrance aperture disposed in the backfocal plane of the objective lens for filtering a slice of the electron diffraction pattern. A magnetic deflector has an entrance plane and an exit plane. The entrance aperture is disposed in the entrance plane. The magnetic deflector is disposed to receive the slice of the electron diffraction pattern and project an energy dispersed electron diffraction pattern to the exit plane. An exit aperture is disposed in the exit plane of the magnetic deflector for selection of desired electron energy of the energy dispersed electron diffraction pattern.

Owner:IBM CORP

Method of preparing a carbonaceous material for an emitter of an electron emission device

Provided are carbide derived carbon materials prepared by thermochemically reacting carbide compounds and a halogen containing gas and extracting all atoms of the carbide compounds except carbon atoms, wherein the intensity ratios of the graphite G band at 1590 cm -1 to the disordered-induced D band at 1350 cm-1 are in the range of 0.3 through 5 when the carbide derived carbon is analyzed using Raman peak analysis, wherein the BET surface area of the carbide derived carbon is 1000 m 2 / g or more, wherein a weak peak or wide single peak of the graphite (002) surface is seen at 2 = 25 DEG when the carbide derived carbon is analyzed using X-ray diffractometry, and wherein the electron diffraction pattern of the carbide derived carbon is the halo pattern typical of amorphous carbon when the carbide derived carbon is analyzed using electron microscopy.

Owner:SAMSUNG SDI CO LTD +1

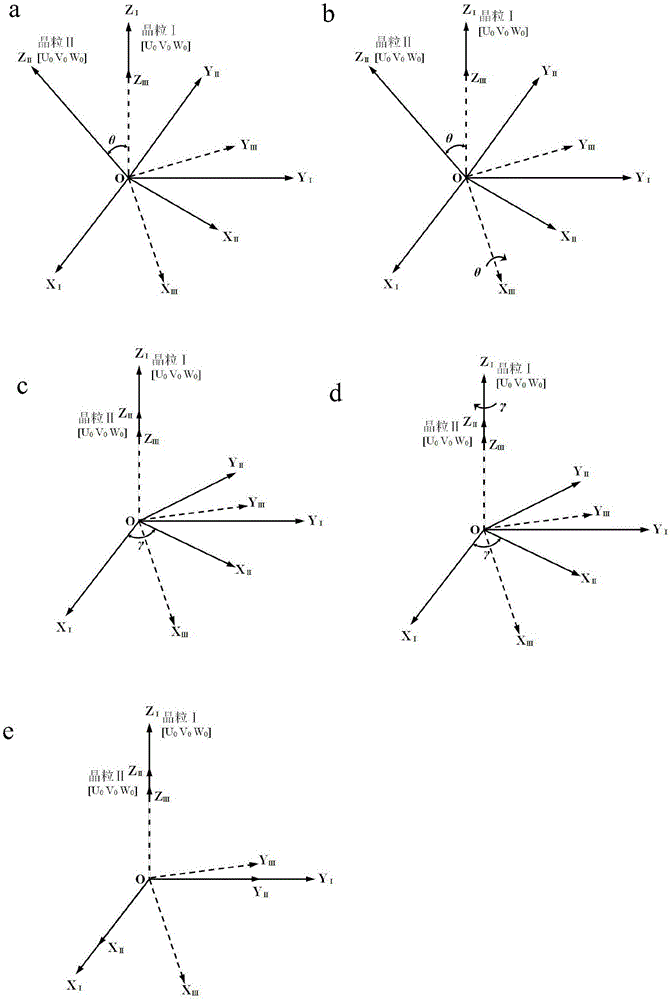

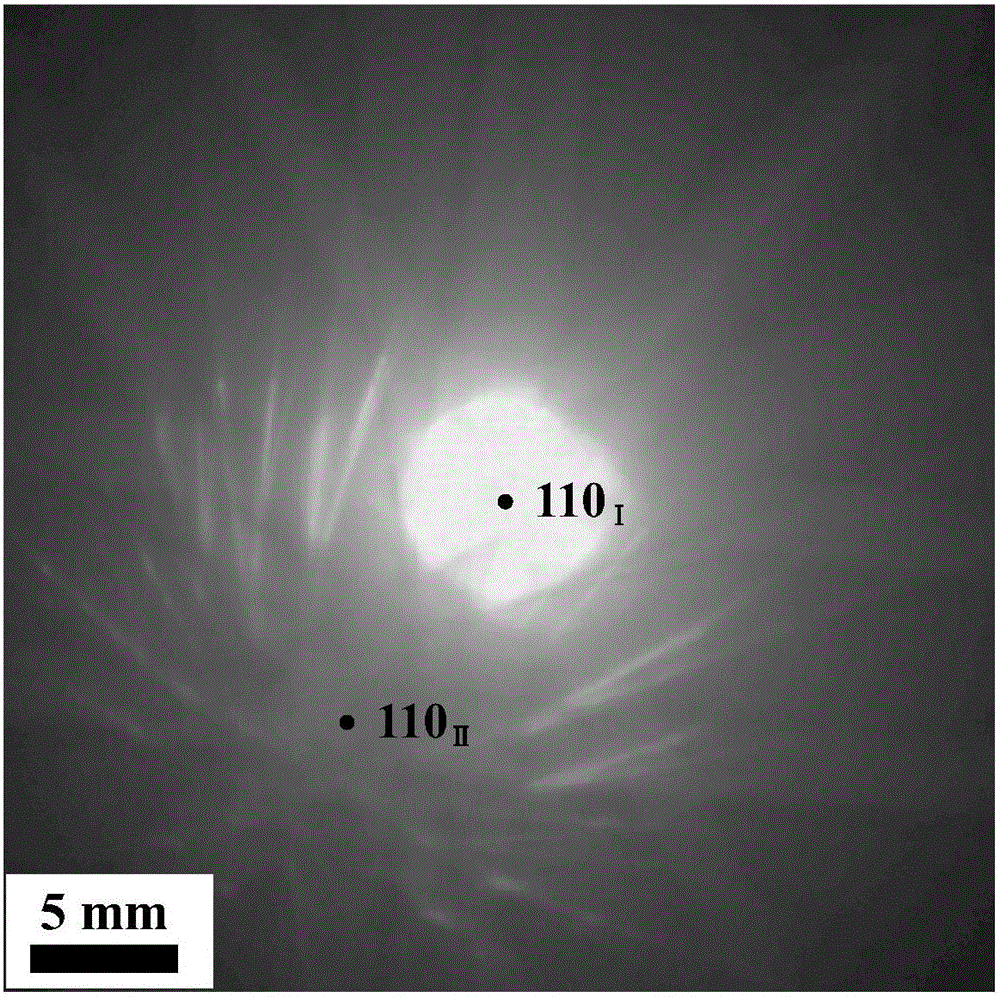

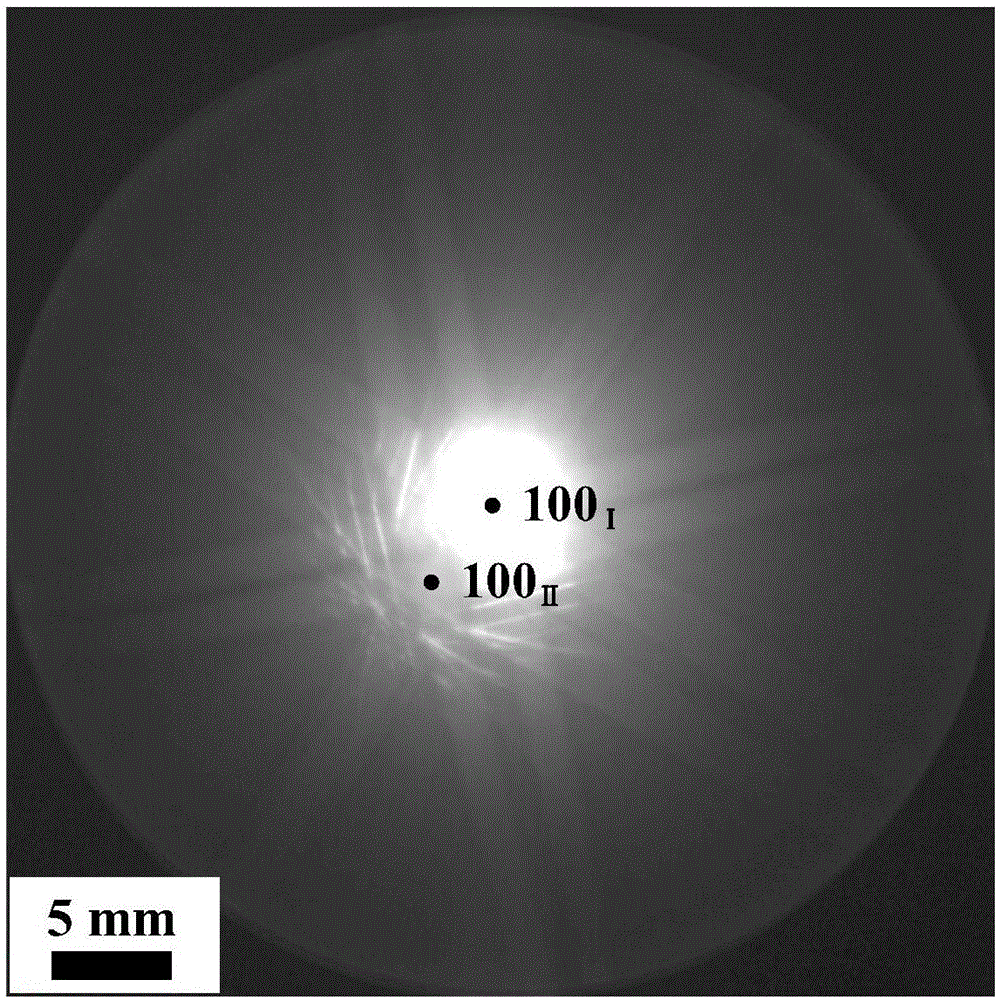

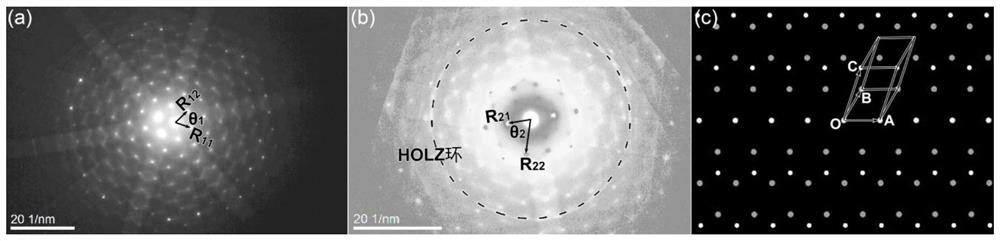

Method for rapidly and accurately measuring low angle grain boundary orientation under transmission electron microscope

ActiveCN106802306AQuick measurementAccurate measurementMaterial analysis using radiation diffractionConventional transmission electron microscopeKikuchi line

The invention discloses a method for rapidly and accurately measuring low angle grain boundary orientation under a transmission electron microscope. The method comprises the following steps: using a transmission electron microscope double bar-tilting rotation tilting sample, enabling a zone axis of a crystalline grain I in a coordinate system I to be at the position of a positive zone axis, and collecting a convergent beam electron diffraction pattern of the crystalline grain I at the moment; keeping a camera constant L of the transmission electron microscope and the parameter of the convergent beam diffraction condition unchanged, and collecting a convergent beam electron diffraction pattern of a crystalline grain II in a coordinate system II; superposing a kikuchi pattern of the collected crystalline grain I and a kikuchi pattern of the collected crystalline grain II by using software; measuring the distance S between a kikuchi pole of the crystalline grain I and a kikuchi pole of the crystalline grain II as well as the rotation angle gama of the kikuchi pole of the crystalline grain II vertical to the pattern surface relatively to the kikuchi pole of the crystalline grain I; calculating the angle theta according to the geometric characteristic of the kikuchi line, theta=arctan(s / L)=s / L; using a formula (6) cos theta=(cosgama+cosgamacostheta+costheta-1) / 2 to calculate the orientation of the crystalline grain I and the crystalline grain II. The method does not need the additional installation of hardware and software, and the common transmission electron microscope is used to measure the orientation.

Owner:YANSHAN UNIV

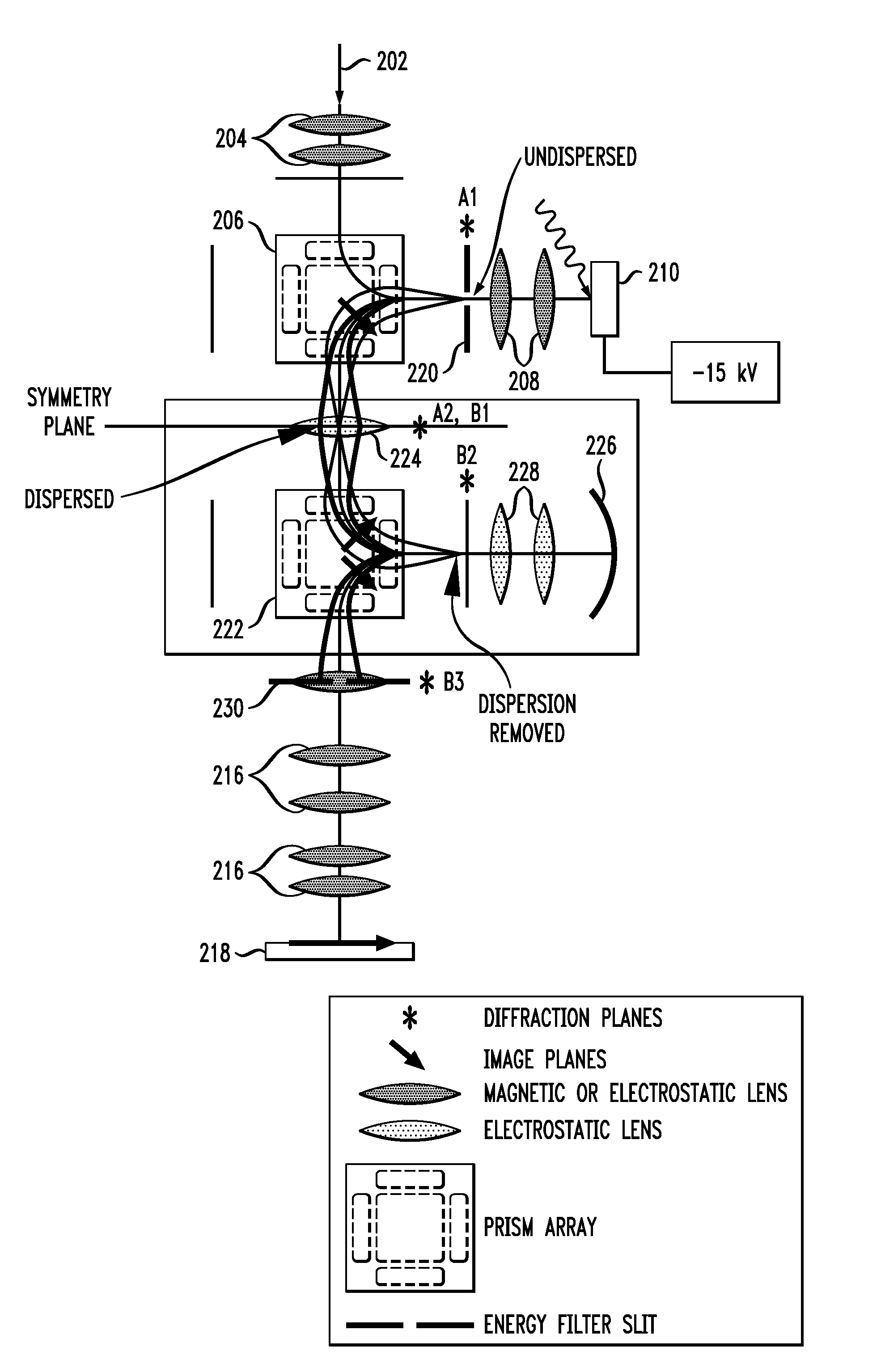

Aberration-correcting cathode lens microscopy instrument

ActiveUS7348566B2Stability-of-path spectrometersMaterial analysis using wave/particle radiationExit planeOptical aberration

Owner:INT BUSINESS MASCH CORP

Energy-filtering cathode lens microscopy instrument

InactiveUS7453062B2Eliminate energyLow costStability-of-path spectrometersMaterial analysis using wave/particle radiationExit planePlane of incidence

An energy filtering microscopy instrument is provided. An objective lens is disposed for reception of electrons in order to form an electron diffraction pattern in a backfocal plane of the objective lens. An entrance aperture disposed in the backfocal plane of the objective lens for filtering a slice of the electron diffraction pattern. A magnetic deflector has an entrance plane and an exit plane. The entrance aperture is disposed in the entrance plane. The magnetic deflector is disposed to receive the slice of the electron diffraction pattern and project an energy dispersed electron diffraction pattern to the exit plane. An exit aperture is disposed in the exit plane of the magnetic deflector for selection of desired electron energy of the energy dispersed electron diffraction pattern.

Owner:IBM CORP

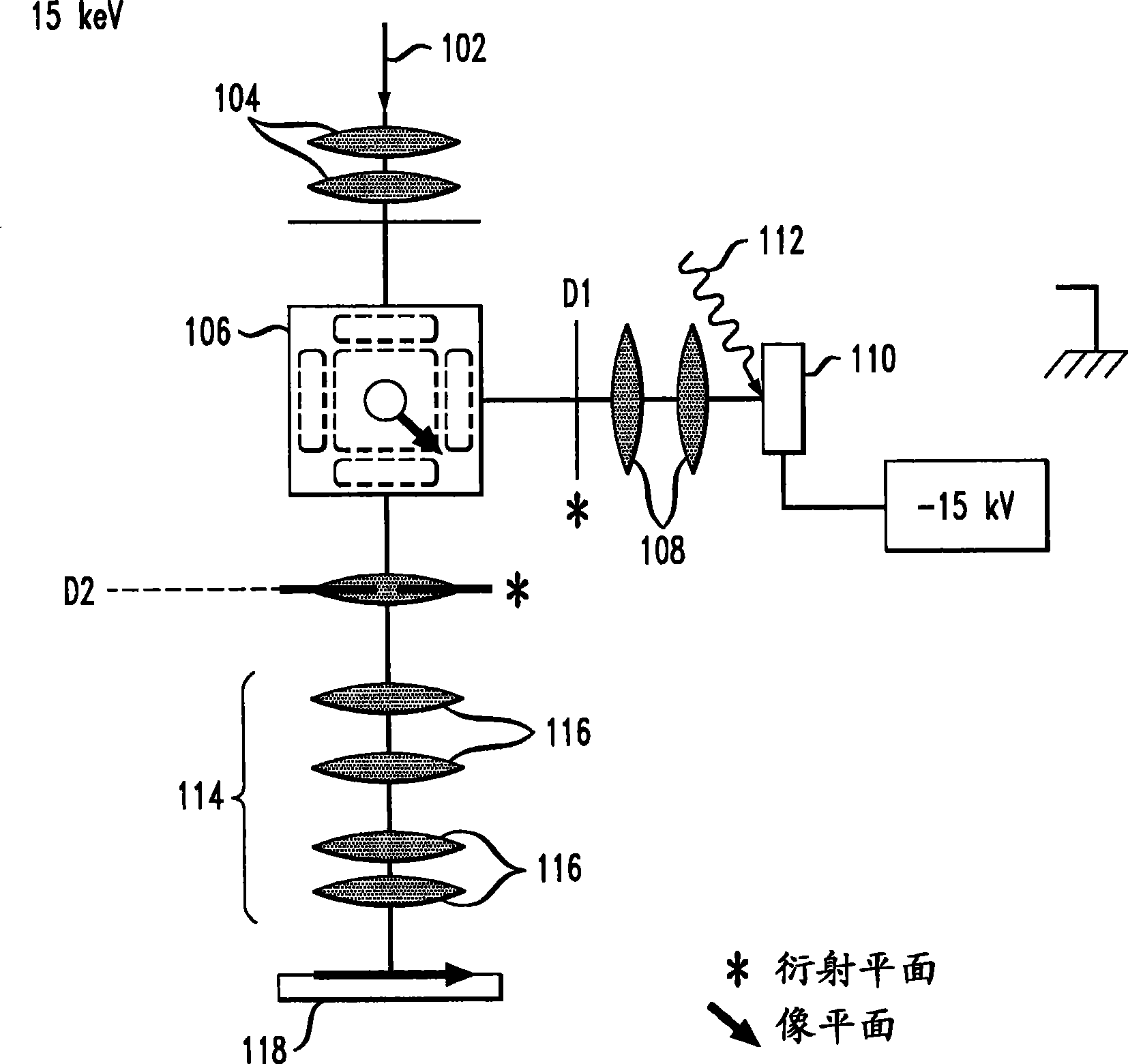

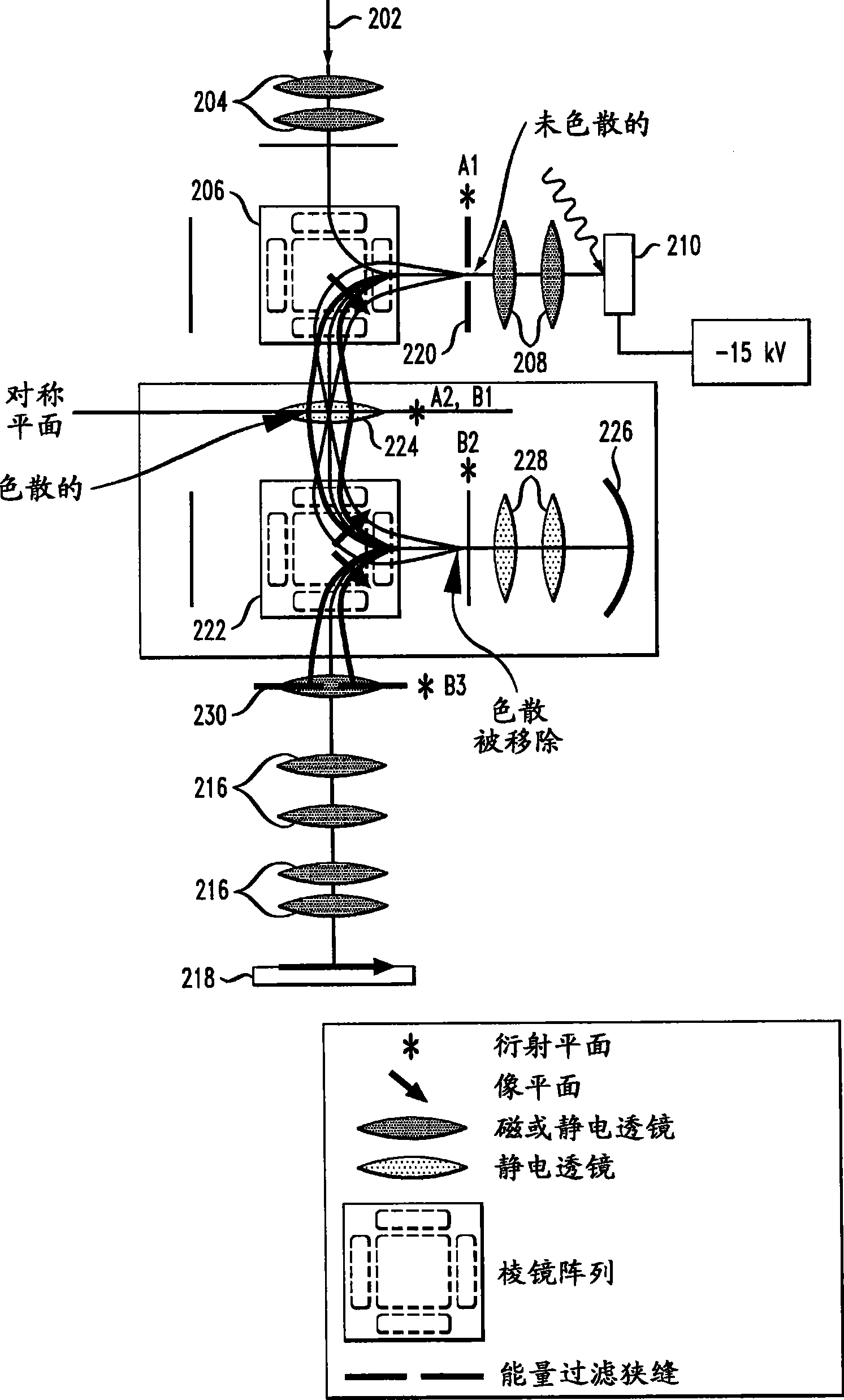

Aberration-correcting cathode lens microscopy instrument

ActiveCN101390186AElectric discharge tubesMaterial analysis using radiation diffractionExit planeOptical aberration

An aberration-correcting microscopy instrument is provided. The instrument has a first magnetic deflector (206) disposed for reception of a first non-dispersed electron diffraction pattern. The first magnetic deflector is also configured for projection of a first energy dispersed electron diffraction pattern in an exit plane (A2) of the first magnetic deflector. The instrument also has an electrostatic lens (224) disposed in the exit plane of a first magnetic deflector, as well as a second magnetic deflector (222) substantially identical to the first magnetic deflector. The second magnetic deflector is disposed for reception of the first energy dispersed electron diffraction pattern from the electrostatic lens. The second magnetic deflector is also configured for projection of a second non-dispersed electron diffraction pattern in a first exit plane (B2) of the second magnetic deflector. The instrument also has an electron mirror configured for correction of one or more aberrations in the second non-dispersed electron diffraction pattern. The electron mirror (226) is disposed for reflection of the second non-dispersed electron diffraction pattern to the second magnetic deflector for projection of a second energy dispersed electron diffraction pattern in a second exit plane (B3) of the second magnetic deflector.

Owner:INT BUSINESS MASCH CORP

Method for nano-crystallization of Zr-based amorphous alloy induced by nanoindentation combined with fatigue load

ActiveCN110118696AImprove nanocrystallization efficiencyShorten traditional fatigue test timeMaterial strength using tensile/compressive forcesMaterial analysis using radiation diffractionIndentation testingNanocrystal

The invention relates to a method for nano-crystallization of a Zr-based amorphous alloy induced by nanoindentation combined with fatigue load, and belongs to the field of amorphous alloy modification. An original test piece with double V-notch is subjected to XRD test, the test piece is subjected to a tensile experiment by using a high-temperature fatigue tester, pre-tensile loadsare applied to both ends of the test piece, meanwhile fatigue loads are applied through piezoelectric stack on one side of the test piece until the test piece is broken,and the XRD pattern of the test piece after breakage shows a steamed break-like diffuse peak and indicates thatthe test piece after fatigue break does not crystallize; a indentation test is carried out on the test piece after the fatigue break, and the indentation with the most serious plastic accumulation is selected from an indentation topography and subjected to FIB cutting to obtain a TEM sample. The crystallization phenomena at differentdistances from the inclined surface of the indentation are observed by an electron diffraction pattern, and the precipitation of nanocrystals in the amorphous alloy is observed by TEM bright / dark field imaging;and the steps are repeated in the test piece after tensile failureto observea TEM dark field image.

Owner:JILIN UNIV

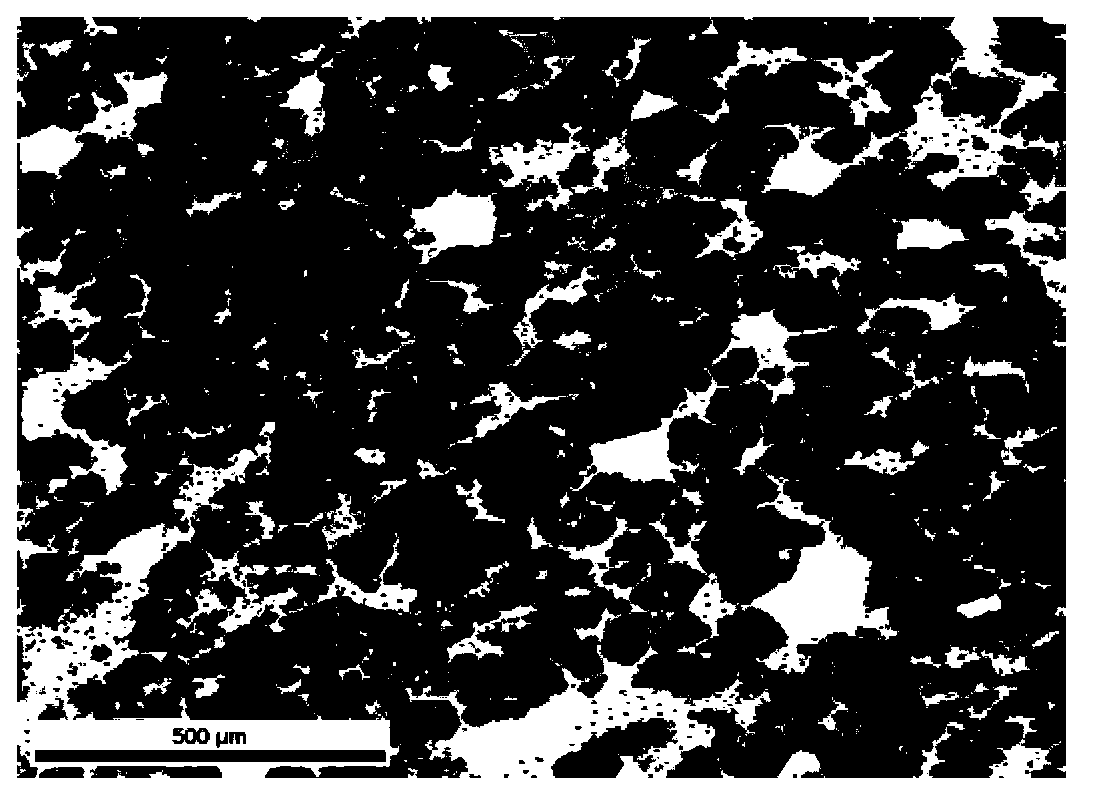

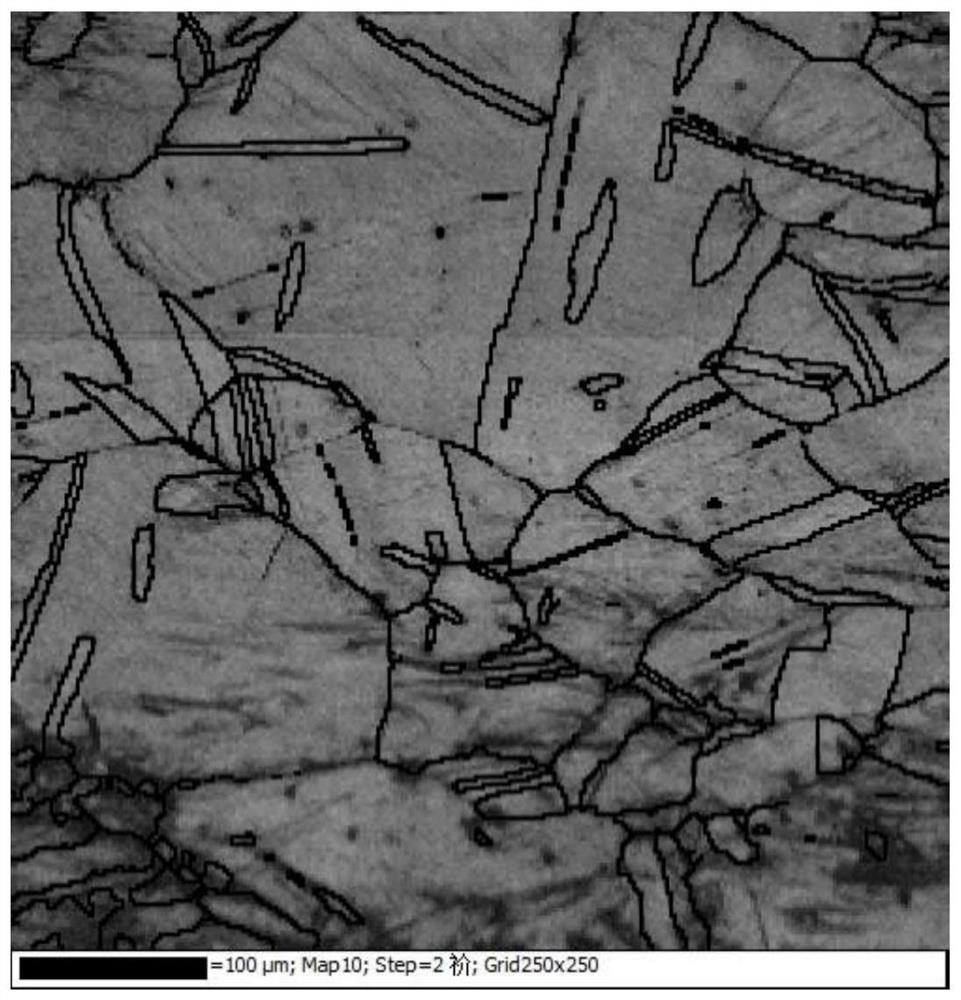

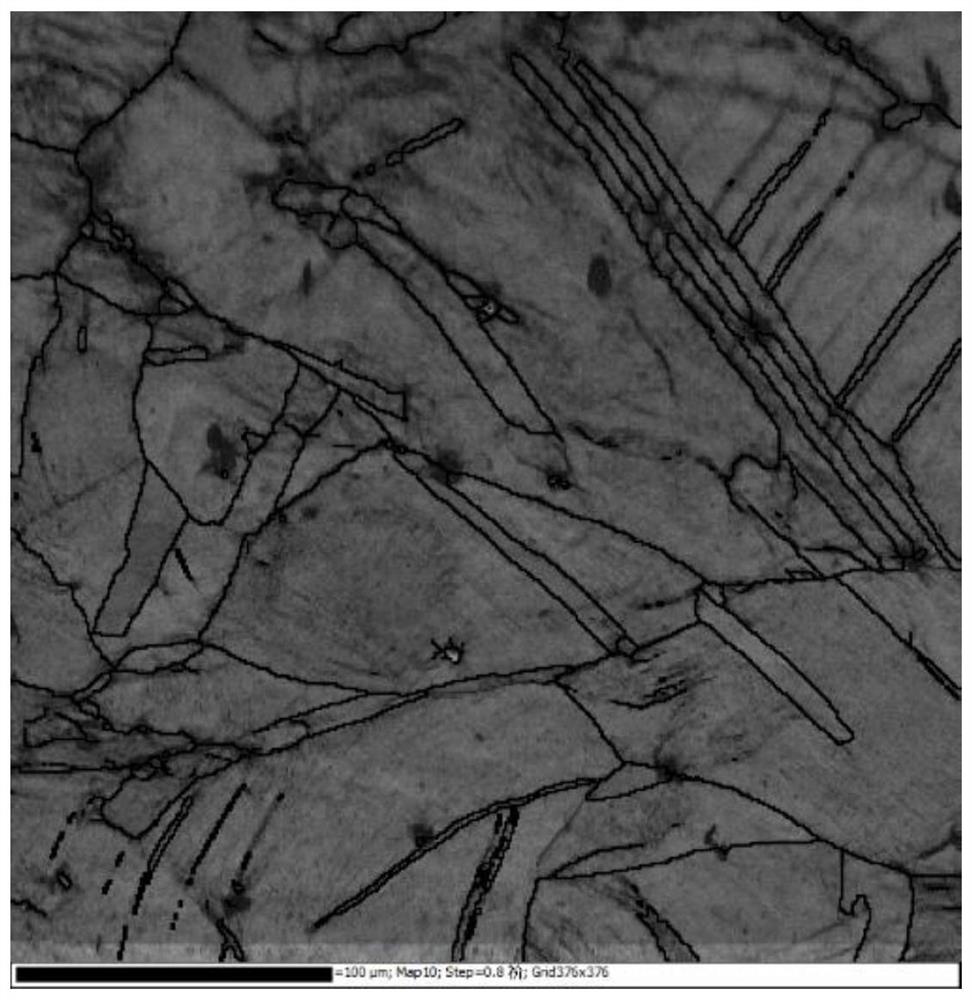

Electrolytic polishing solution of invar alloy and electrolytic polishing method

The invention discloses an electrolytic polishing solution of an invar alloy and an electrolytic polishing method. The electrolytic polishing solution of the invar alloy is characterized in that C3H8O2, HClO4 and C2H5OH are mixed according to the volume ratio of 1 to 2 to 17-22; the invar alloy sample is placed in the electrolytic polishing solution as an anode, and insoluble metal is used as a cathode; and the temperature of the electrolytic polishing solution is 0-10 DEG C, the polishing voltage is 30-40 V, and electrolytic polishing is carried out on an invar alloy sample. According to themethod, the polishing solution is simple to prepare and good in polishing effect, the surface of the sample is flat and smooth, no obvious deformation layer is generated, and the polishing solution can be used multiple times; the stress layer on the surface can be effectively removed, the electrolytic polishing quality is effectively improved, and the high-calibration rate electron diffraction pattern is obtained; the electrolytic polishing method can effectively remove the stress layer on the surface of the sample, the electrolytic polishing quality is effectively improved, and the strong diffraction pattern which is generated by the EBSD test is facilitated, so that the high-calibration rate can be obtained, and the research of microstructure of the crystal boundary characteristic, texture, stress strain and the like of the invar alloy is facilitated.

Owner:HEBEI IRON AND STEEL

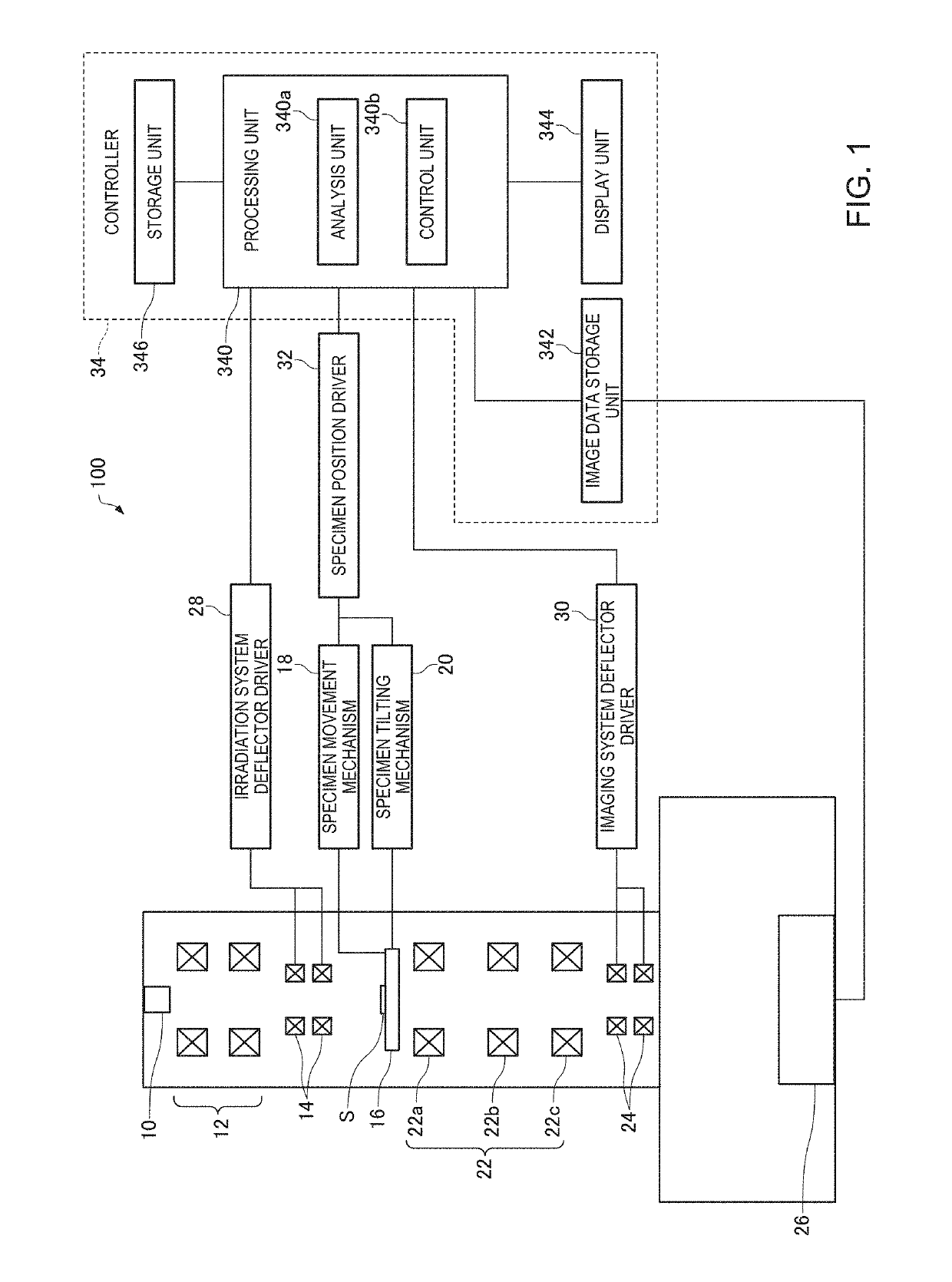

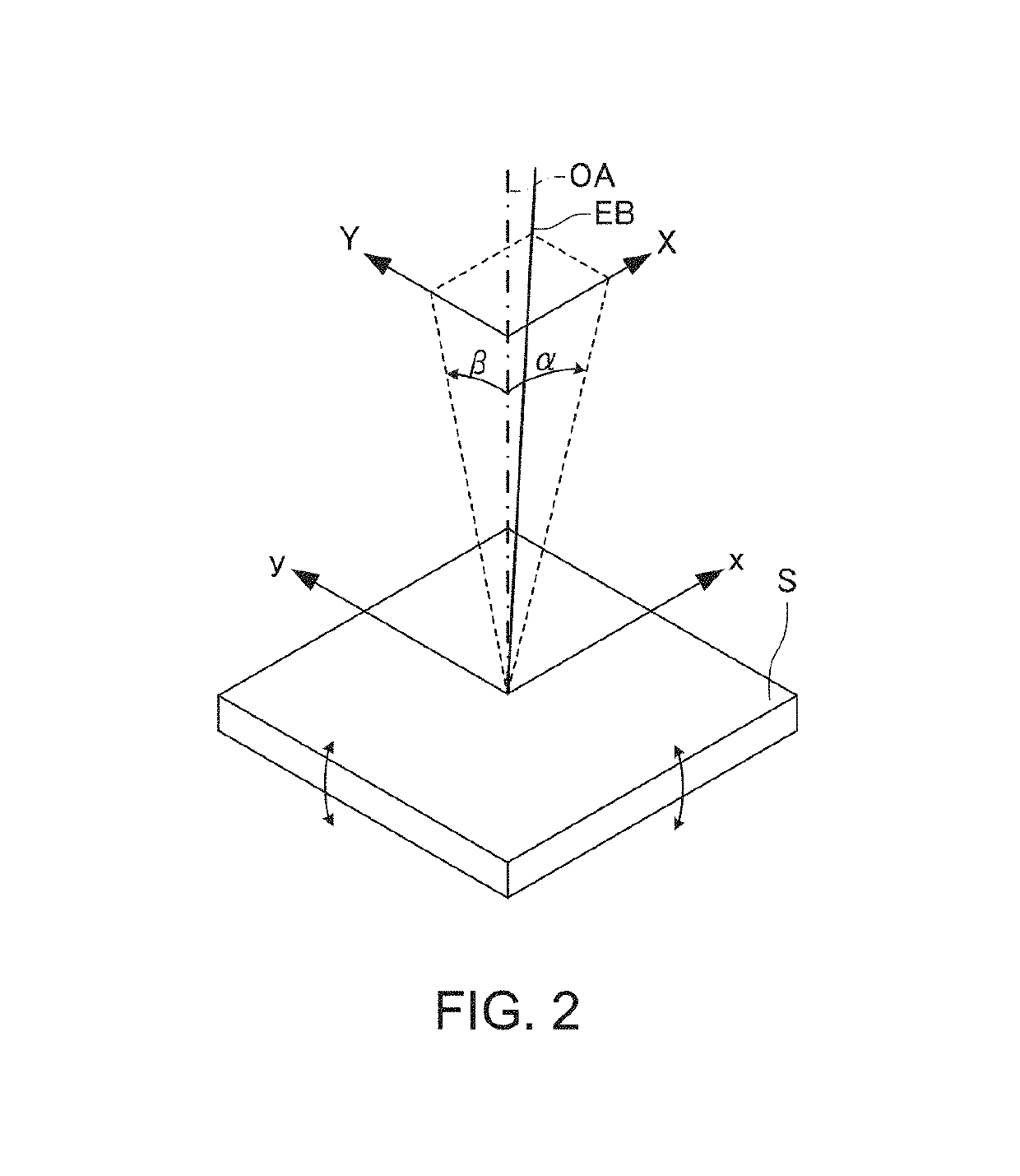

Electron Microscope and Specimen Tilt Angle Adjustment Method

An electron microscope includes: an irradiation lens system that irradiates a specimen with an electron beam; an irradiation system deflector that deflects an electron beam incident on the specimen; a specimen tilting mechanism that tilts the specimen; an imaging lens system that forms an electron diffraction pattern or an electron microscope image by using an electron having passed through the specimen; an imaging device that acquires the electron diffraction pattern or the electron microscope image formed by the imaging lens system; and a controller that controls the irradiation system deflector and the specimen tilting mechanism. The controller performs: a process of acquiring a plurality of electron diffraction patters formed by using electron beams having different incidence angles to the specimen, the different incidence angles having been obtained by deflecting the electron beams incident on the specimen by using the irradiation system deflector; a process of calculating a tilt angle of the specimen based on the plurality of electron diffraction patterns; and a process of controlling the specimen tilting mechanism so that the specimen has the calculated tilt angle.

Owner:JEOL LTD

Preparation method for as-cast lead or lead alloy EBSD sample

ActiveCN103913362AEasy to manufactureOrganization realPreparing sample for investigationKikuchi lineElectron

The invention relates to a preparation method for an as-cast lead or lead alloy EBSD (electron back-scattered diffraction) sample. The method includes: manual polishing: using waterproof abrasive paper to polish a to-be-tested surface of the as-cast lead or lead alloy sample; chemical polishing 1: adding a chemical polishing solution composed of H2O2 and CH3COOH in a volume ratio of 0.8-1.2:0.8-1.2 to the to-be-tested surface dropwise; chemical polishing 2: then adding a chemical polishing solution composed of H2O2 and CH3COOH in a volume ratio of 0.05-0.2:0.8-0.95 to the to-be-tested surface dropwise; erosion: covering the sample surface by an erosion solution composed of citric acid, ammonium molybdate and deionized water in a weight ratio of 10-20:6-12:60-150, then soaking the sample in alcohol for 5-10 seconds, then taking the sample out and blowing it dry, thus obtaining the sample that can display Kikuchi lines through the electron back-scattered diffraction technology. The sample preparation method is simple in operation, and the prepared sample has real texture and a high back-scattered electron diffraction pattern calibration rate.

Owner:GRIMAT ENG INST CO LTD

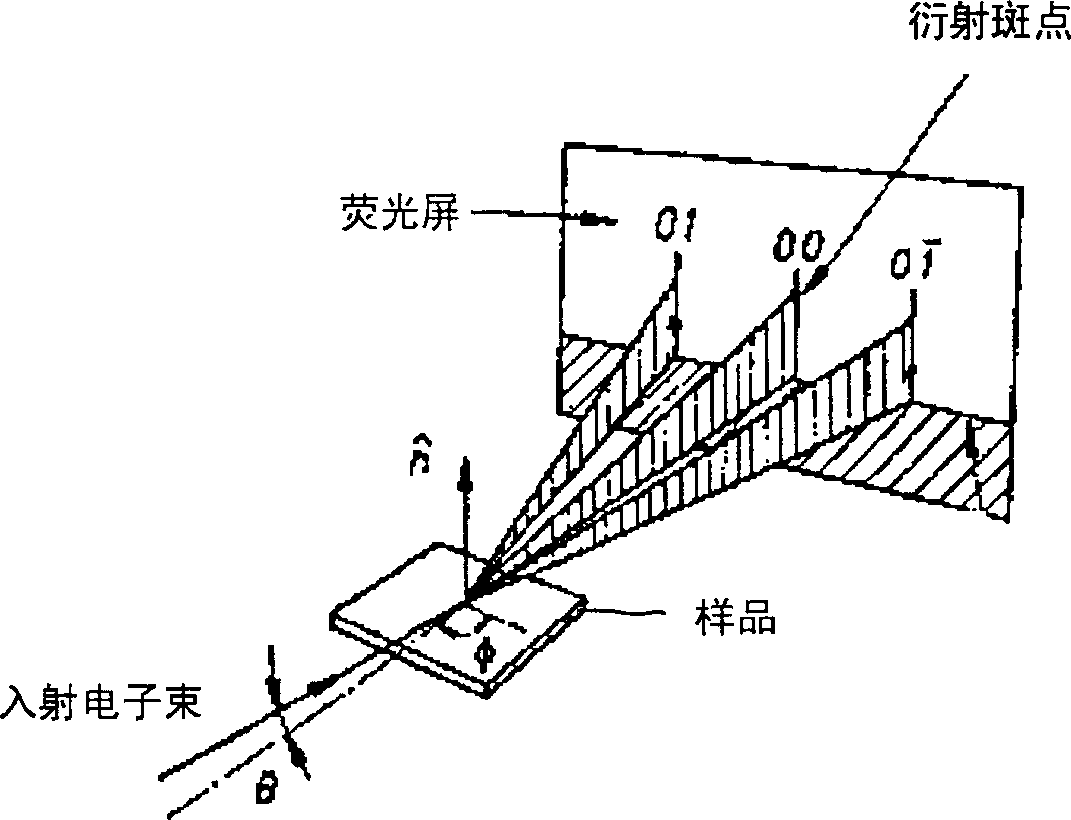

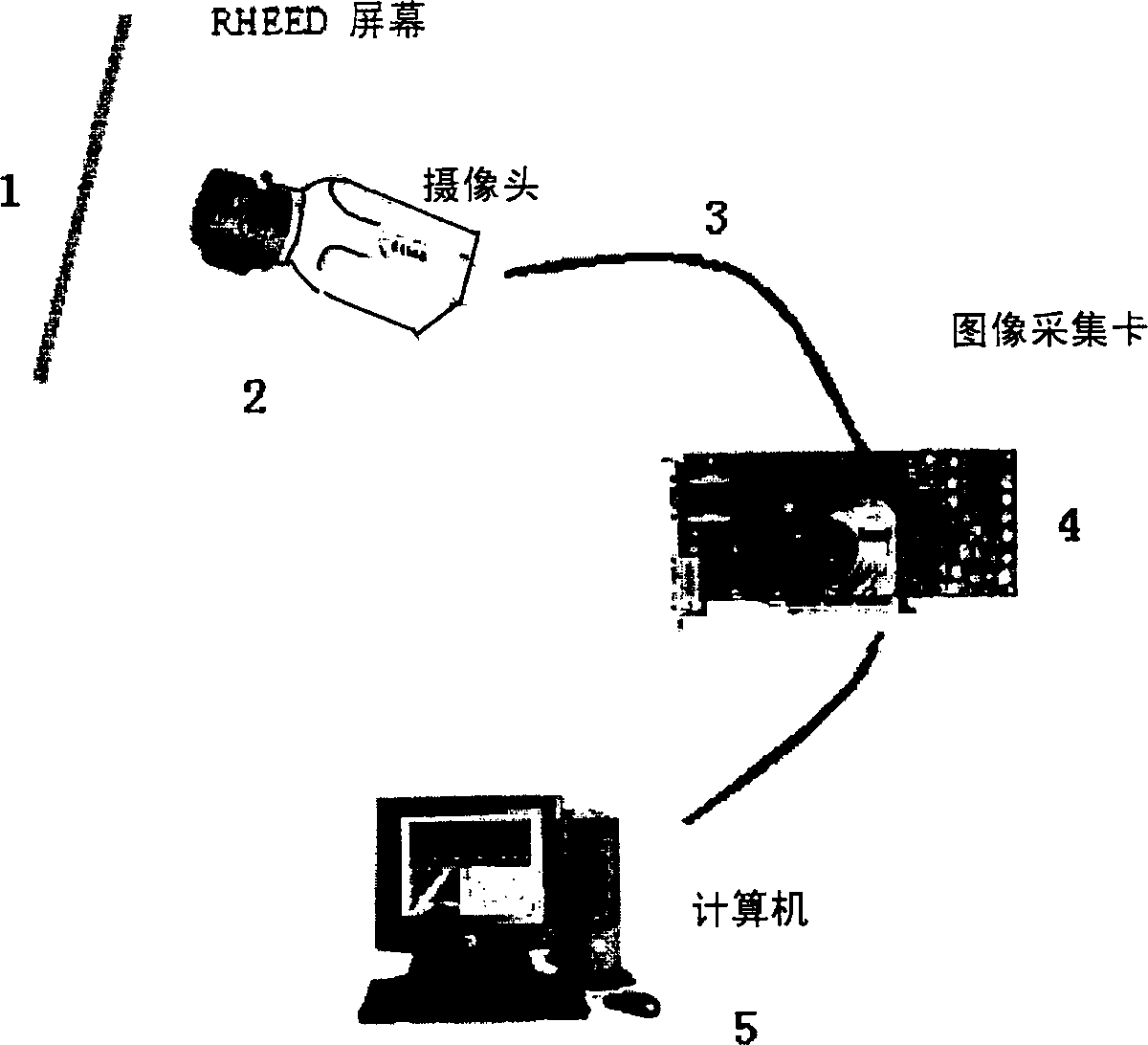

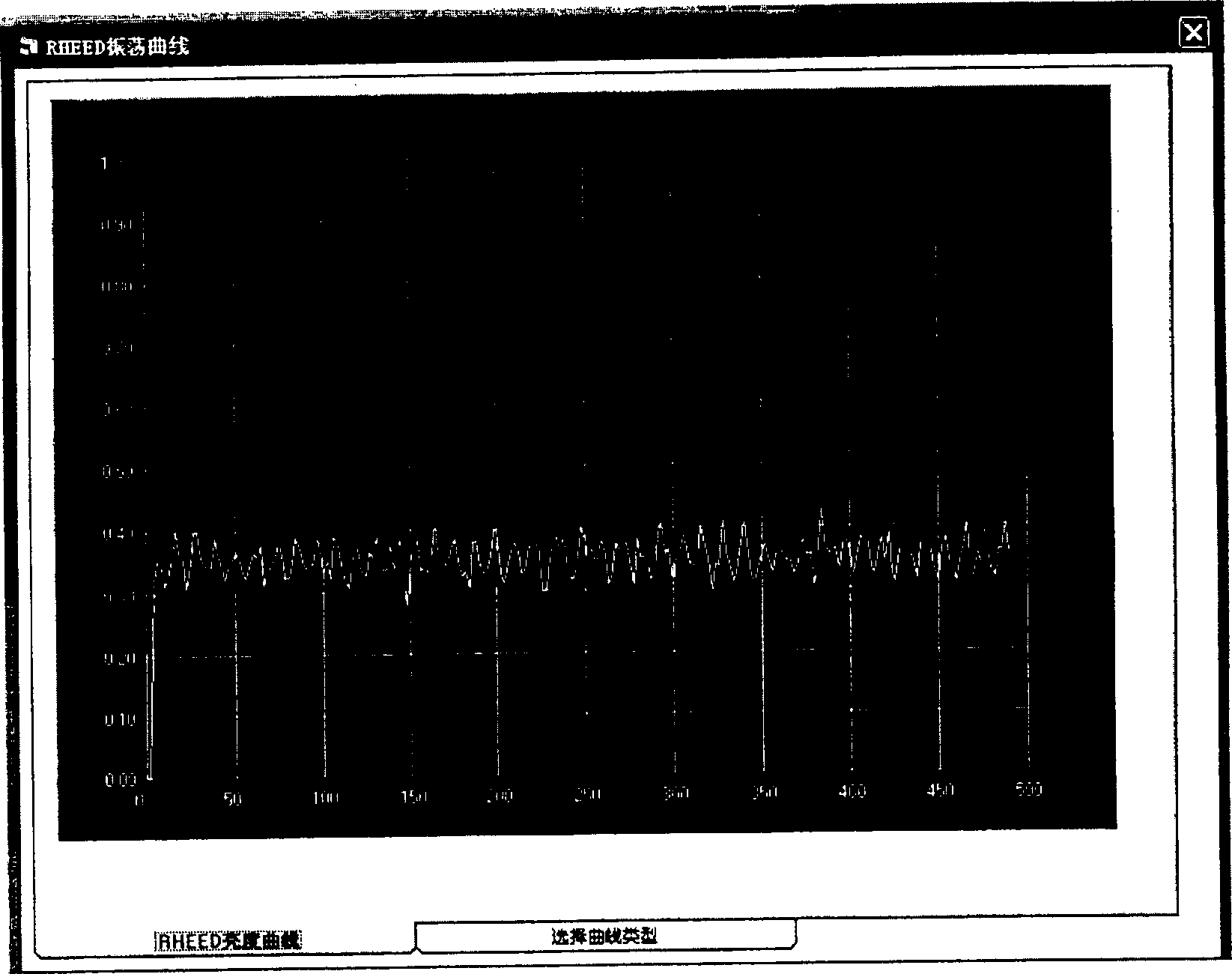

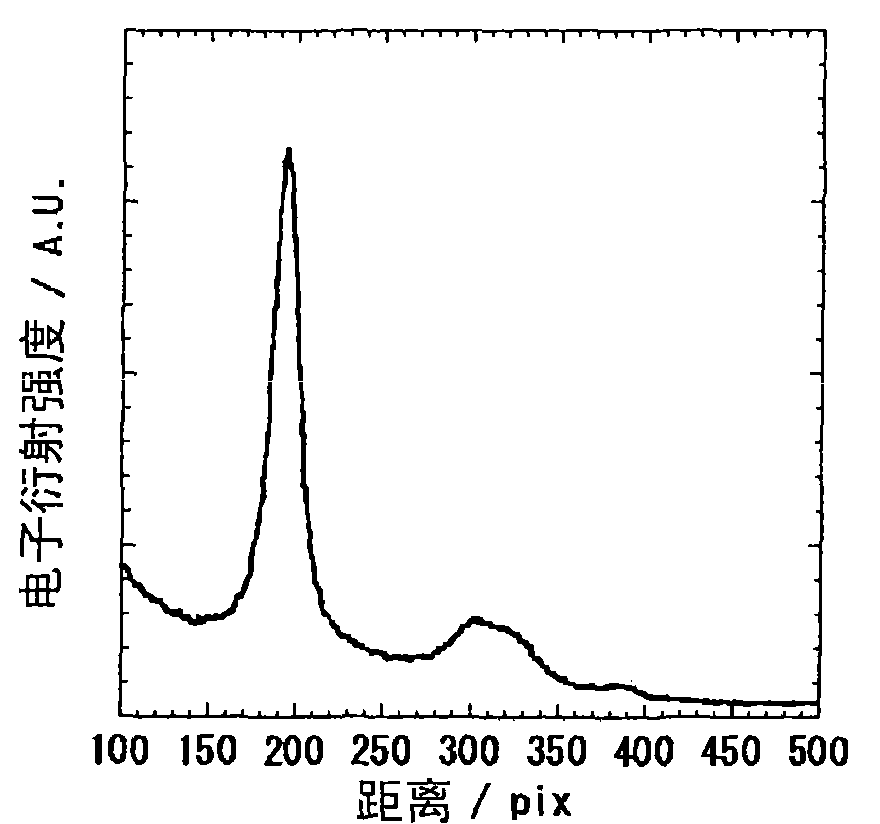

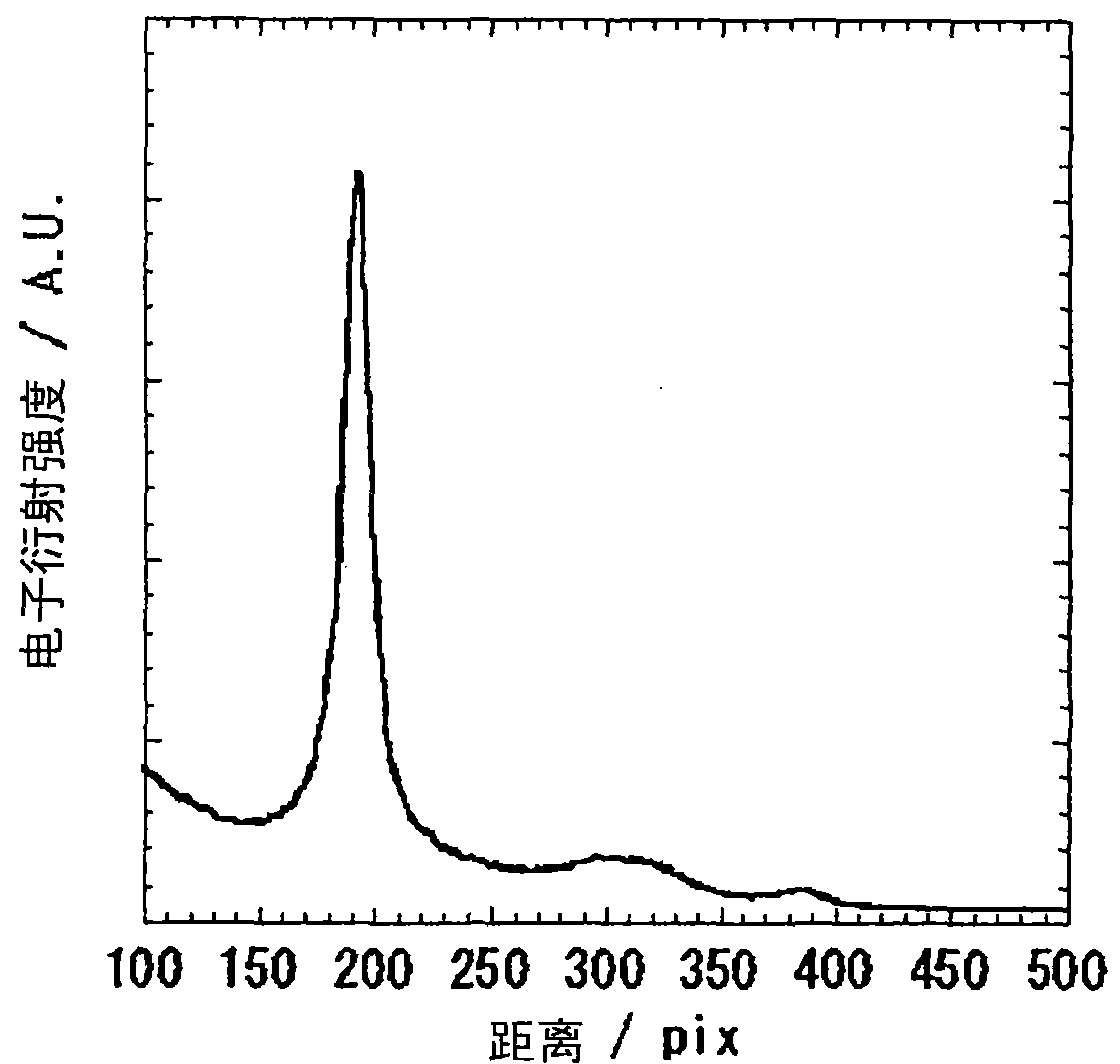

High-energy electron-diffraction diagram processing system and method

InactiveCN1828508AEasy to observeLiquid-phase epitaxial-layer growthSemiconductor/solid-state device manufacturingHigh energyComputer graphics (images)

The system comprises: a HEEP fluorescent screen, a CCD cam behind the screen fixed by a stainless cylinder, an image acquisition card connected with the cam by a video line to convert the obtained analog signal into the digital signal and store in memory, and a computer with data to image the data on screen.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Method for measuring diffraction patterns from a transmission electron microscopy to determine crystal structures and a device therefor

InactiveUS7601956B2Minimizing damageElectric discharge tubesMaterial analysis using radiation diffractionPrecessionCrystal structure

A device and method which enable a transmission electron microscope to measure electron diffraction patterns of a sample very precisely are disclosed. The patterns are suitable for structure determination. The electron beam is precessed by means of deflector coils (6) in the transmission electron microscope before the sample (4), in combination with a similar precession of the electron diffraction pattern by means of deflector coils (9) situated after the sample. The electron diffraction pattern is scanned by means of deflector coils (9) situated after the sample.

Owner:SERGEEVICH AVILOV ANATOLY +1

Polybenzazole fiber and pyridobisimidazole fiber

InactiveCN101506412BImproved post-processing performanceReduce intensitySolid-state devicesMonocomponent synthetic polymer artificial filamentFiberHeat resistance

The present invention provides a polybenzazole fiber and a pyridobisimidazole fiber which can maintain the excellent heat resistance, flame retardance of polybenzazole fiber and pyridobisimidazole fiber and simultaneously increases the afterprocessing property without changing the condition of manufacturing process with a large scale or requiring the long-time heat treatment in high temperature. The polybenzazole fiber is characterized in that when the diffraction peak area which is on the equator-direction profile and comes from the crystallization surface (200) is set to S1, and the diffraction peak area which comes from the crystallization surface (010) and the surface (-210) is set to S2, the existence state of polybenzazole crystal satisfies that S2 / S1 is 0.1-0.8 in the electron-diffraction diagram obtained from the top part (surface-1mu m) of polybenzazole fiber. The pyridobisimidazole fiber is characterized in that when the diffraction peak area which is on the equator-direction profile and comes from the crystallization surface (200) is set to S1, and the diffraction peak area which comes from the crystallization surface (110), (210) and (400) is set to S2, the existence state of pyridobisimidazole crystal satisfies that S2 / S1 is 0.1-1.5.

Owner:TOYOBO CO LTD

Electrolytic polishing solution and electrolytic polishing method for Invar alloy

The invention discloses an electrolytic polishing solution of an invar alloy and an electrolytic polishing method. The electrolytic polishing solution of the invar alloy is characterized in that C3H8O2, HClO4 and C2H5OH are mixed according to the volume ratio of 1 to 2 to 17-22; the invar alloy sample is placed in the electrolytic polishing solution as an anode, and insoluble metal is used as a cathode; and the temperature of the electrolytic polishing solution is 0-10 DEG C, the polishing voltage is 30-40 V, and electrolytic polishing is carried out on an invar alloy sample. According to themethod, the polishing solution is simple to prepare and good in polishing effect, the surface of the sample is flat and smooth, no obvious deformation layer is generated, and the polishing solution can be used multiple times; the stress layer on the surface can be effectively removed, the electrolytic polishing quality is effectively improved, and the high-calibration rate electron diffraction pattern is obtained; the electrolytic polishing method can effectively remove the stress layer on the surface of the sample, the electrolytic polishing quality is effectively improved, and the strong diffraction pattern which is generated by the EBSD test is facilitated, so that the high-calibration rate can be obtained, and the research of microstructure of the crystal boundary characteristic, texture, stress strain and the like of the invar alloy is facilitated.

Owner:HEBEI IRON AND STEEL

Method of performing electron diffraction pattern analysis upon a sample

ActiveUS10663414B2Less likelihoodGood correlationMaterial analysis using wave/particle radiationElectric discharge tubesParticle beamParticle physics

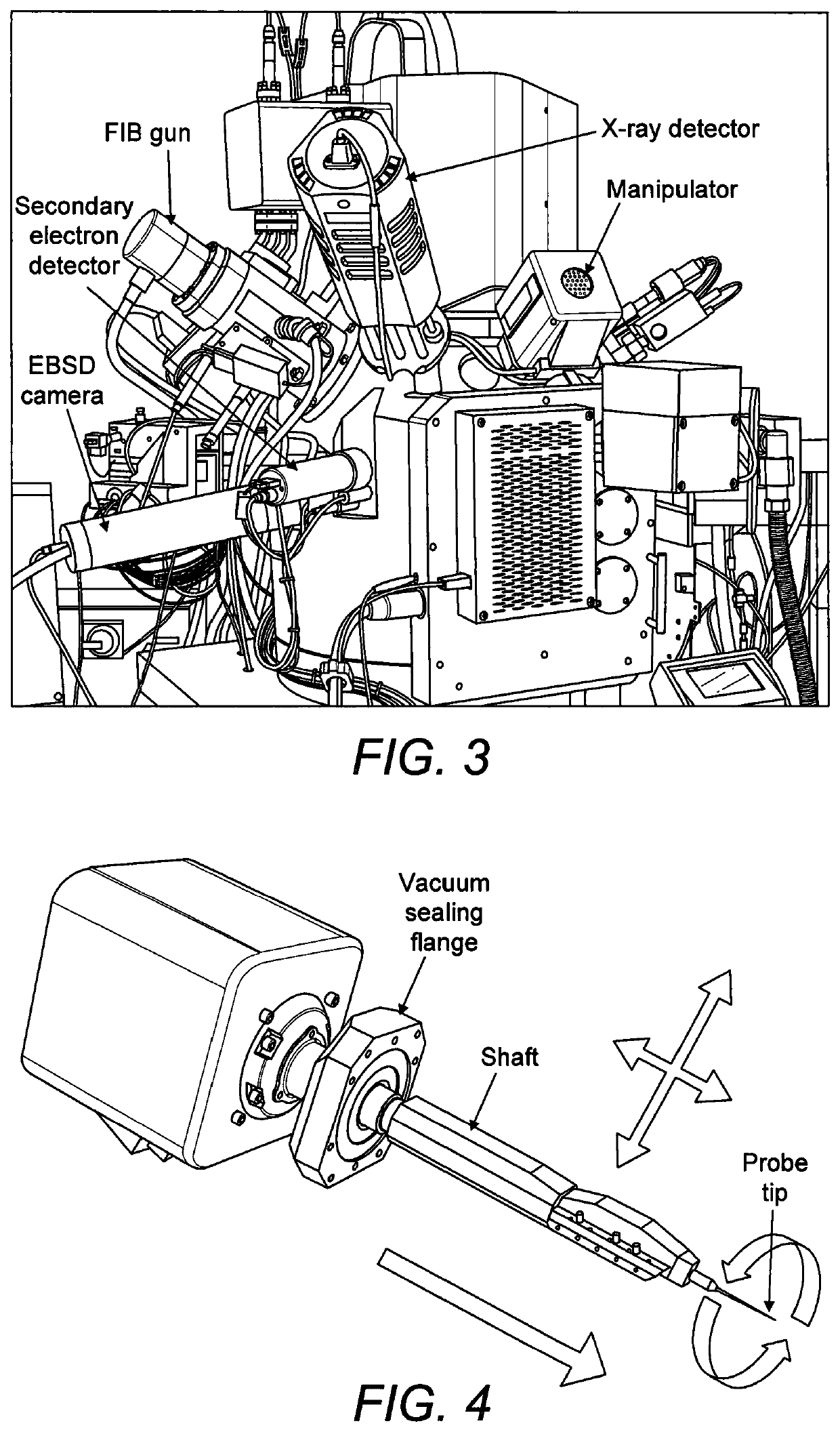

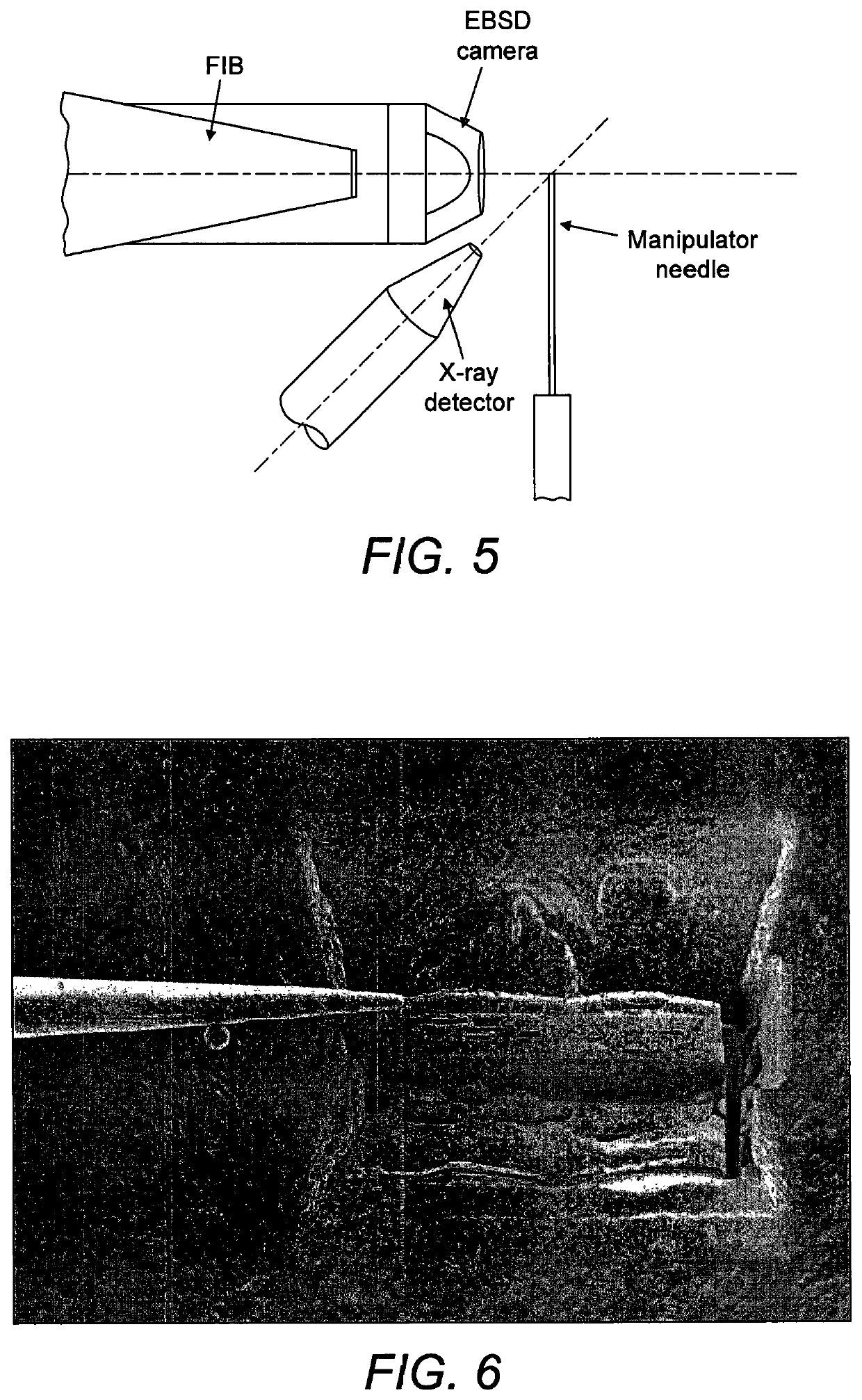

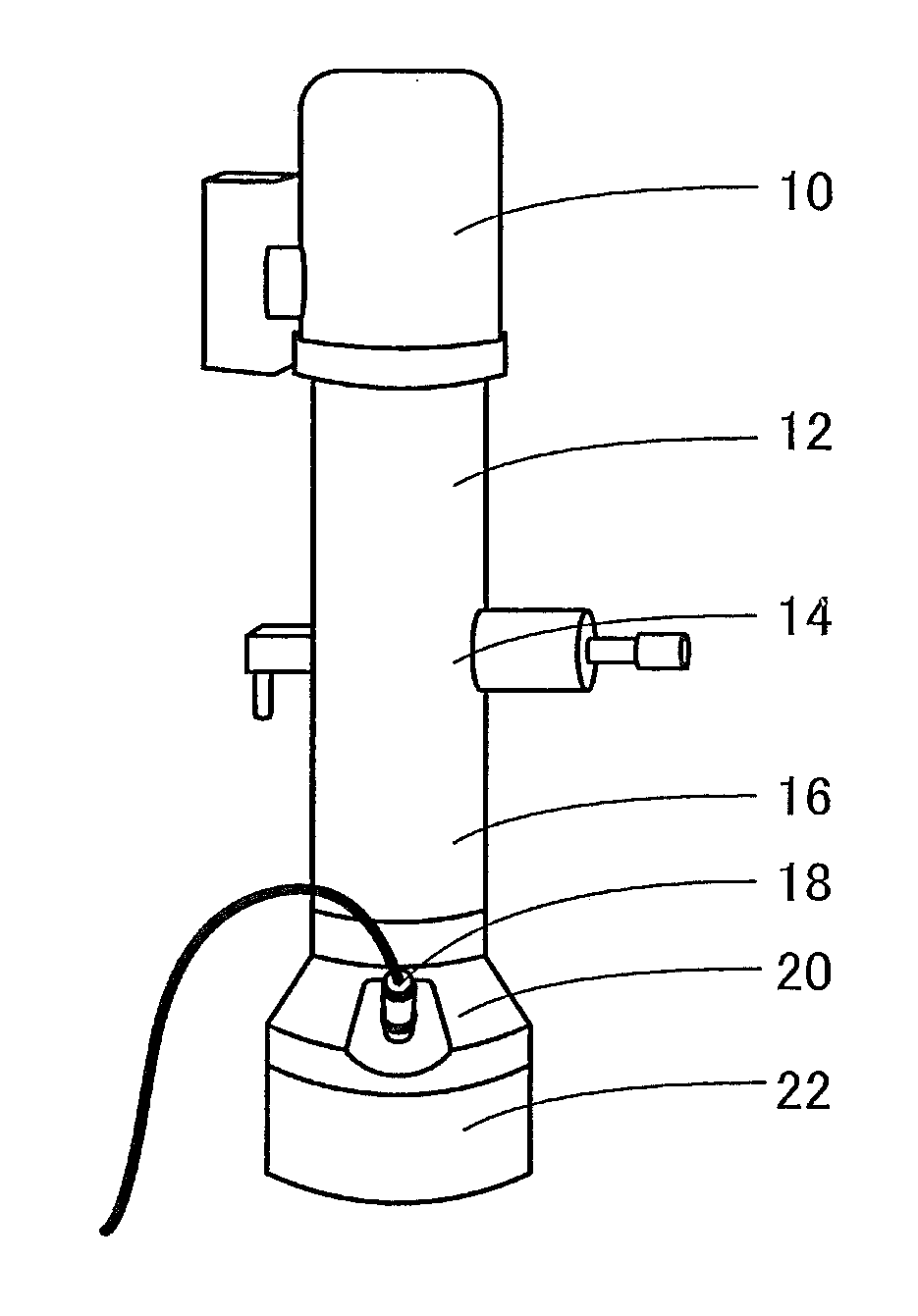

A method is provided for performing electron diffraction pattern analysis upon a sample in a vacuum chamber of a microscope. Firstly a sample is isolated from part of a specimen using a focused particle beam. A manipulator end effector is then attached to the sample so as to effect a predetermined orientation between the end effector and the sample. With the sample detached, the manipulator end effector is rotated about a rotation axis to bring the sample into a predetermined geometry with respect to an electron beam and diffraction pattern imaging apparatus so as to enable an electron diffraction pattern to be obtained from the sample while the sample is still fixed to the manipulator end effector. An electron beam is caused to impinge upon the sample attached to the manipulator end effector so as to obtain an electron diffraction pattern.

Owner:OXFORD INSTR NANOTECH TOOLS

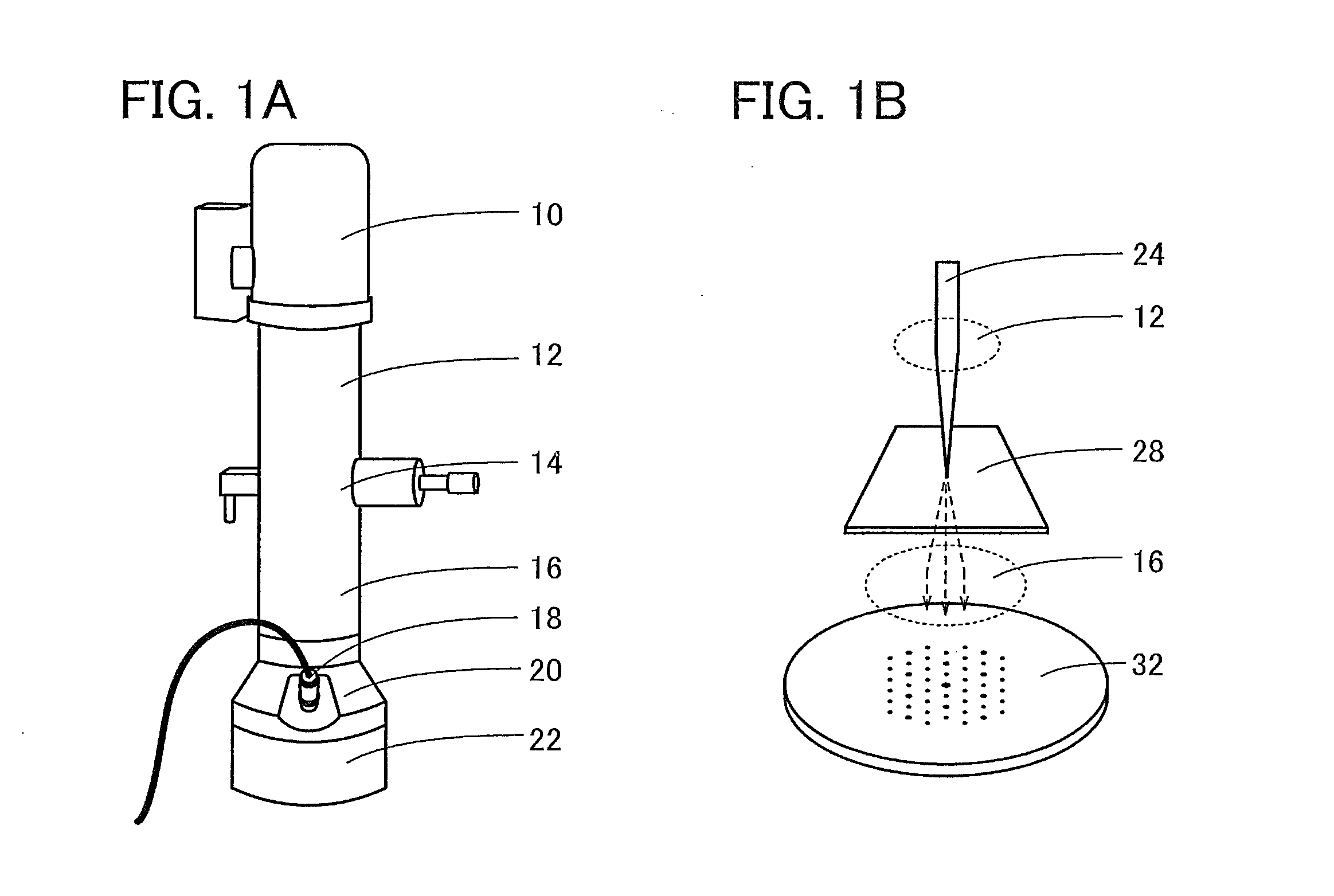

Transmission electron diffraction measurement apparatus and method for measuring transmission electron diffraction pattern

ActiveUS20150008321A1Easy to useElectric discharge tubesMaterial analysis using radiation diffractionElectron diffraction patternElectron

Provided is a transmission electron diffraction measurement apparatus including an electron gun; a first optical system under the electron gun; a sample chamber under the first optical system; a second optical system under the sample chamber; an observation chamber under the second optical system; a region that emits light by receiving energy from an electron in the observation chamber; and a camera facing the region.

Owner:SEMICON ENERGY LAB CO LTD

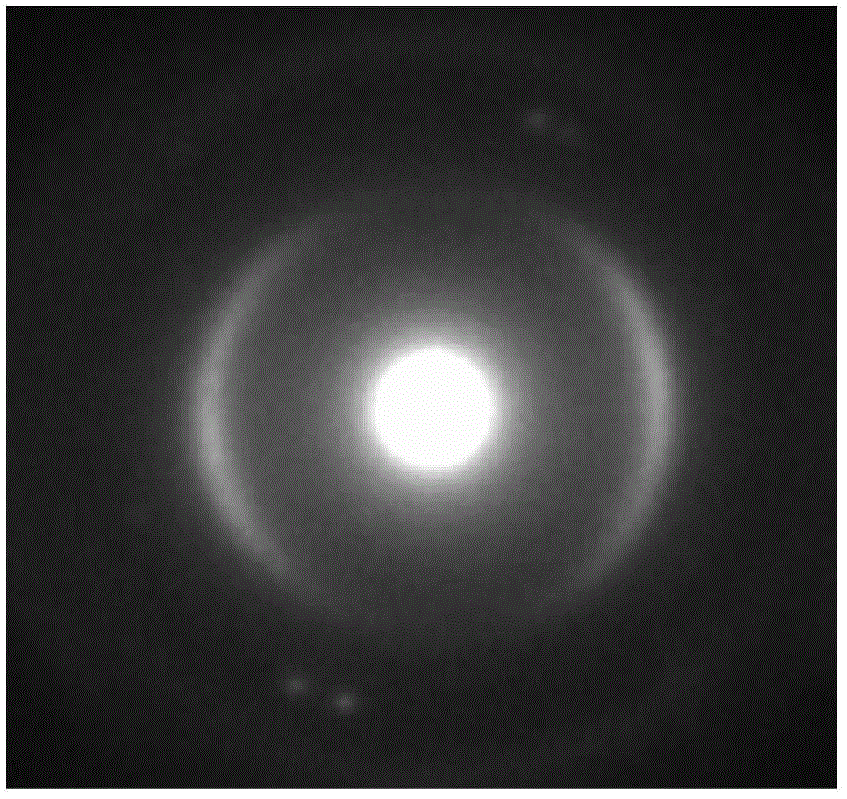

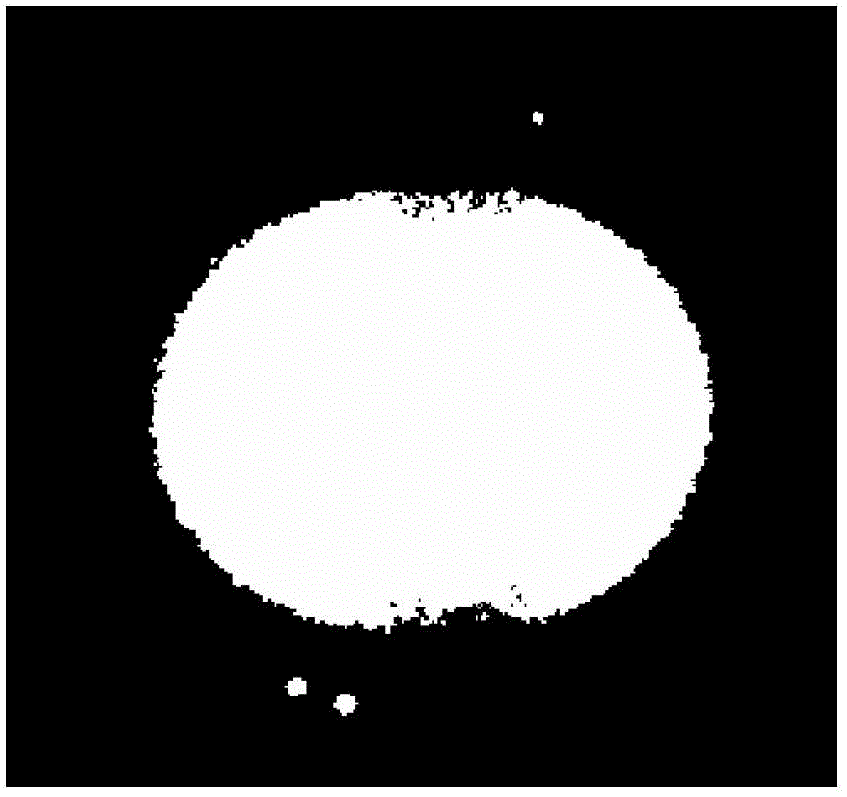

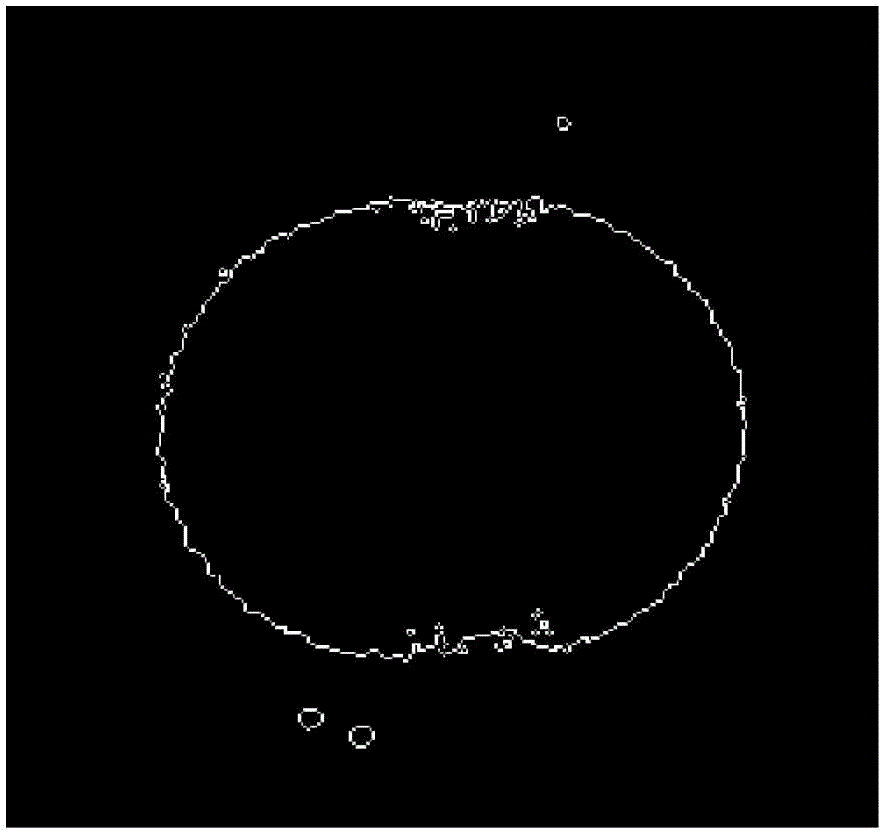

Selected area electron diffraction spectrum and image processing method for determining preferred orientation degree of pyrolytic carbon

InactiveCN103150732AAccurate Intensity-Azimuth CurveImage analysisImaging processingPyrolytic carbon

The invention discloses a selected area electron diffraction pattern and image processing method for determining preferred orientation degree of pyrolytic carbon. The method comprises the following steps that binarization processing is performed on an original pattern, a diffraction ring and an inner area of the diffraction ring, a brightness value of which is greater than or equal to 50, is selected, and marginalized processing is performed; bright area boundaries are determined, a least square method is used for fitting a center of a circle and a radius, and an approximate center of the circle and an approximate radius of the diffraction ring are obtained; according to the approximate center of the circle and the approximate radius, a small radius of a circular area is 0.7 times the approximate radius, and a large radius of the circular area is 1.2 times the approximate radius; an inner area and an outer area of the diffraction ring are deducted, then the binarization processing is performed again, a part, the brightness value of which is greater than or equal to 145, is selected from the circular area, i.e. the diffraction ring; and according to the least square method, the center of the circle and the radius of the diffraction ring are fitted again, pattern sampling points are determined, and a strength-azimuth curve is obtained to determine the preferred orientation degree of the pyrolytic carbon. By using the method, the strength-azimuth curve of a pyrolytic carbon coating can be simply, conveniently and accurately obtained, so as to determine the preferred orientation degree of the pyrolytic carbon.

Owner:HANGZHOU DIANZI UNIV

Improved system for electron diffraction analysis

ActiveUS20200273663A1Minimized angular variationMinimize dynamic rangeElectric discharge tubesOphthalmologyElectron microscope

A method and system for processing a diffraction pattern image obtained in an electron microscope are disclosed. The method comprises, according to a first set of microscope conditions, causing an electron beam to impinge upon a calibration specimen so as to cause resulting electrons to be emitted therefrom and monitoring the resulting electrons using a detector device so as to obtain a calibration image comprising a plurality of pixels having values, the first set of microscope conditions being configured such that the calibration image includes substantially no electron diffraction pattern; obtaining, from the calibration image, a gain variation image comprising a plurality of pixels, each having a value representing relative detector device gain for a corresponding pixel of the calibration image; according to a second set of microscope conditions, causing an electron beam to impinge upon a target specimen so as to cause resulting electrons to be emitted therefrom and monitoring the resulting electrons using the detector device so as to obtain a target image comprising a plurality of pixels having values, the second set of microscope conditions being configured such that the target image includes an electron diffraction pattern; and for each pixel of the target image, removing from the pixel value, in accordance with the value of the corresponding pixel of the gain variation image, the contribution to the pixel value of the relative detector device gain, so as to obtain a gain variation-corrected image.

Owner:OXFORD INSTR NANOTECH TOOLS

Cutting tool

ActiveUS8691378B2High hardnessImprove wear resistanceTurning machine accessoriesVacuum evaporation coatingDiffuse intensityGrain structure

The invention relates to a cutting tool having a substrate base body and a single or multi-layered coating attached thereupon, wherein at least one layer of the coating is a metal oxide layer produced in the PVD process or in the CVD process and the metal oxide layer has a grain structure wherein there is structural disorder within a plurality of the existing grains that are characterized in that in electron diffraction images of the grains, point-shaped reflections occur up to a maximum lattice spacing dGRENZ and for lattice spacing greater than dGRENZ no point-shaped reflections occur, but rather a diffuse intensity distribution typical for amorphous structures.

Owner:WALTER AG

Electronic diffraction device based on laser plasma wake-field acceleration

The invention provides a femtosecond electronic diffraction device based on laser plasma wake-field acceleration, comprising a laser, a gas generator, a micropore, a magnetic lens, a sample rack, a detection system, a vacuum chamber, a vacuum system, a five-dimensional system and the like, wherein the laser is used for generating ultrashort ultra-high laser pulses, the gas generator is used for generating a high-density gas target, the ultrashort ultra-high laser pulses may react with the gas target to generate electron beams, and the electron beams are collimated by the micropore and condensed by the magnetic lens and then act with a sample to generate an electronic diffraction pattern that is collected by the detection system. The device of the invention is up to 10 femtoseconds in time resolution, pumped light and detection electron beams are in good time synchronization in a femtosecond electronic diffraction experiment, there is no need for a photoelectric cathode, a high-pressure electrode or microwave source and other components, and therefore the device is simpler and more compact and is widely applicable to the scientific research of ultrafast dynamic process.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

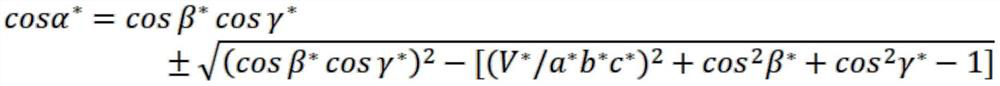

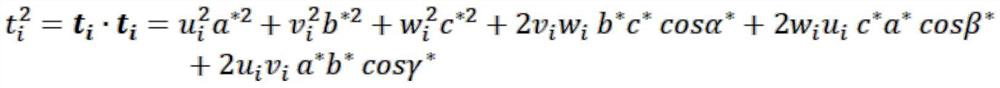

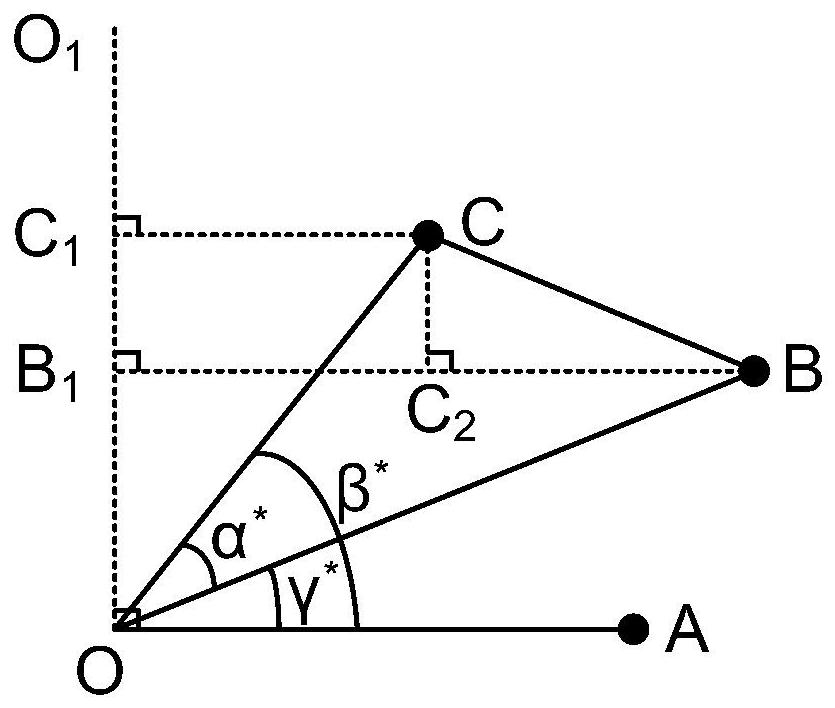

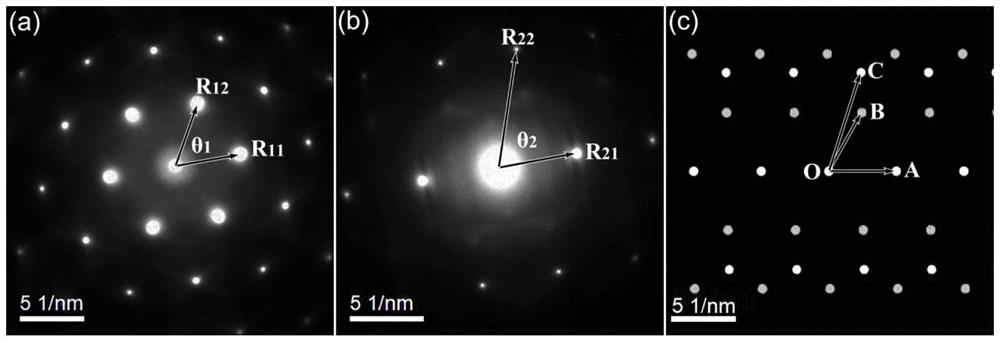

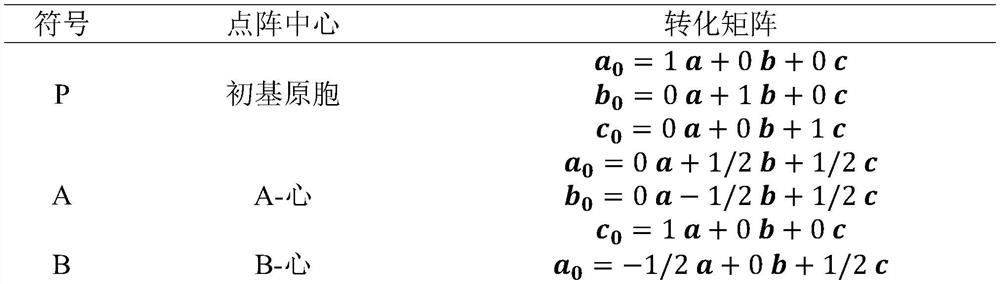

Method for reconstructing crystal Bravais lattice by using electron diffraction pattern

ActiveCN112782202ASymmetrical SimplificationQuick analysisMaterial analysis using wave/particle radiationBravais latticeElectron diffraction pattern

The invention belongs to the technical field of material microstructure analysis and crystal structure characterization, and particularly relates to a method for reconstructing a crystal Bravais lattice by using an electron diffraction pattern. The method can be used for phase recognition of materials and reconstruction of Brafir of known or unknown phases, and is particularly suitable for occasions where three diffraction patterns are difficult to obtain, a belt axis is strictly tilted, and the tilt angle is accurately determined. For example the following occasion, when the crystal grain is small, the crystallinity is poor, and the crystal surface is uneven, the crystal belt shaft is difficult to strictly tilt, and the tilt angle error is large.

Owner:MINZU UNIVERSITY OF CHINA

Method for carrying out object phase identification by utilizing two electron diffraction patterns with axes or high-resolution images

ActiveCN112986293ASymmetrical SimplificationAvoid uncertaintyMaterial analysis using wave/particle radiationCrystal systemElectron microscope

The invention relates to a method for carrying out object phase identification by utilizing two electron diffraction patterns with axes or high-resolution images, and belongs to the technical field of material microstructure analysis and crystal structure characterization. According to the method, a high-symmetry belt axis does not need to be tilted, a strict positive belt axis does not need to be tilted, tilting information of each electron diffraction piece does not need to be recorded, and a transmission electron microscope does not need to be provided with an objective lens with a large pole shoe; according to the method, a reciprocal space reconstruction method and a traditional indexing method are combined, and through double inspection of primary group primitive cells and a reciprocal angle alpha*, the uncertainty of the traditional indexing method can be effectively overcome, and the crystal phase can be accurately identified. In an actual electron microscope experiment, the crystal tilting can be greatly simplified, and the provided analysis method is not influenced by a crystal system and the symmetry, and is suitable for phase identification of all crystal systems.

Owner:MINZU UNIVERSITY OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com