Preparation method for as-cast lead or lead alloy EBSD sample

A lead alloy and sample technology, applied in the field of EBSD sample preparation, can solve the problems of incomplete display, unable to display grains, small grain size, etc., and achieve the effect of less passes, real sample structure and high calibration rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

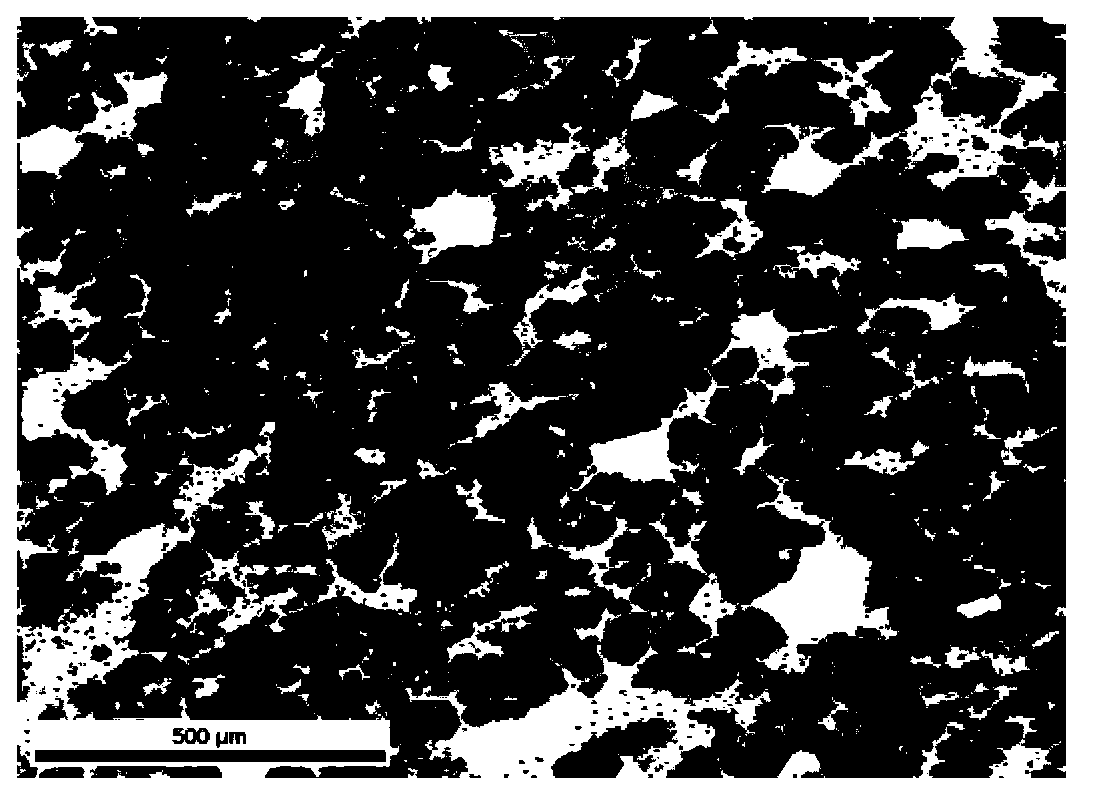

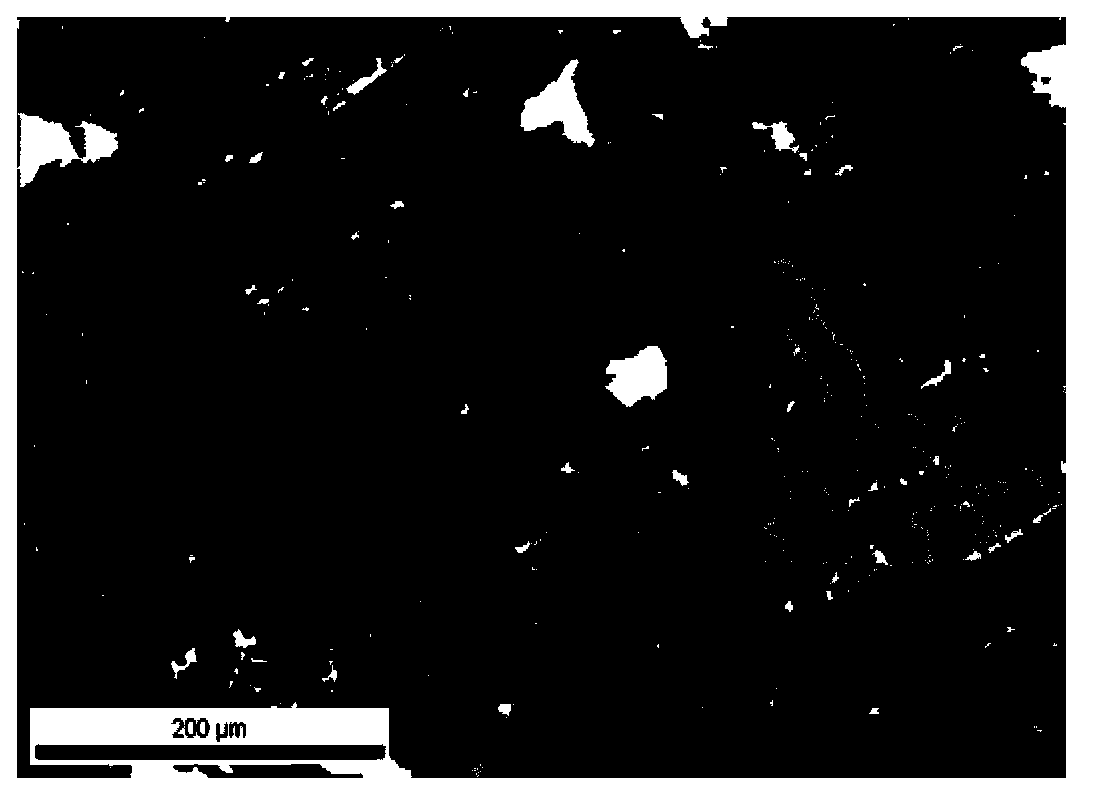

Image

Examples

Embodiment 1

[0032] Cut a sample from the cast pure lead ingot, and the sample is processed as follows:

[0033] a. Manual grinding: use 800# Al 2 o 3 Water sandpaper is used to polish the surface to be tested of the cast pure lead sample until the surface to be tested is smooth;

[0034] b. Chemical polishing 1: Add H dropwise on the surface of the pure lead sample to be tested with a rubber dropper 2 o 2 and CH 3 COOH volume ratio is 0.8:1 chemical polishing solution I, rinse with deionized water while adding dropwise, until no black / gray product is generated on the surface of the sample to be tested;

[0035] c. Chemical polishing 2: drop H on the surface to be tested of the cast lead sample treated in step b with a rubber dropper 2 o 2 and CH 3 Chemical polishing solution II with a volume ratio of COOH of 0.1:0.9, rinse with deionized water for 0.5 min while adding it dropwise, to make the surface of the sample to be tested bright;

[0036] d. Erosion: Add citric acid and ammon...

Embodiment 2

[0038] Cut a sample from the ingot of as-cast Pb-0.6%Ag alloy (in this as-cast lead-silver alloy sample, the content of Ag is 0.6% by weight, and the balance is Pb), and the sample is processed as follows:

[0039] a. Manual grinding: use 800# Al 2 o 3 Water sandpaper is used to polish the surface to be tested of the as-cast Pb-0.6%Ag alloy sample until the surface to be tested is flat;

[0040] b. Chemical polishing 1: Add H dropwise on the surface of the cast Pb-0.6% Ag sample to be tested with a rubber dropper 2 o 2 and CH 3 COOH volume ratio is 1.2:0.8 chemical polishing solution I, rinse with deionized water while adding dropwise, until no black / gray product is generated on the surface of the sample to be tested;

[0041] c. Chemical polishing 2: Add H dropwise on the surface to be tested of the cast Pb-0.6%Ag sample treated in step b with a dropper 2 o 2 and CH 3 Chemical polishing solution II with a volume ratio of COOH of 0.05:0.95, rinse with deionized water fo...

Embodiment 3

[0044] From the as-cast Pb-0.2%Ag-0.08%Ca-0.05%Sr alloy ingot (in this cast lead-silver-calcium-strontium alloy sample, the content of Ag is 0.2% by weight, the content of Ca is 0.08% by weight, and the content of Sr is 0.05% by weight, and the balance is Pb), a sample is cut out, and the sample is processed as follows:

[0045] a. Manual grinding: use 800# Al 2 o 3 Water sandpaper is used to grind the surface to be tested of the cast lead-silver-calcium-strontium alloy sample until the surface to be tested is flat;

[0046] b. Chemical polishing 1: Add H dropwise on the surface of the cast Pb-0.2%Ag-0.08%Ca-0.05%Sr alloy sample to be tested with a rubber dropper 2 o 2 and CH 3 COOH volume ratio is 0.8:1.2 chemical polishing solution I, rinse with deionized water while adding dropwise, until no black / gray product is generated on the surface of the sample to be tested;

[0047] c. Chemical polishing 2: Use a rubber dropper to drop H on the surface to be tested of the cast ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com