Electrochemical method for preparing nickel metal tubular nano array

A nano-array, electrochemical technology, applied in nano-technology and other directions, can solve the problem of few nano-tubes, and achieve the effect of easy operation and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0022] a) Preparation of alumina template

[0023] The high-purity (99.999%) aluminum sheet was degreased, dried and annealed in vacuum, and the porous alumina template (AAO) was prepared by the secondary anodic oxidation method. The secondary anodic oxidation process was as follows:

[0024] Prepare the aluminum template—clean the aluminum template—surface polish the aluminum template—the first alumina template—remove the oxide film of the aluminum template for the first time—the second alumina template—remove the aluminum substrate—remove the barrier layer—obtain the alumina template (AAO template), nanopores are generated on the alumina template,

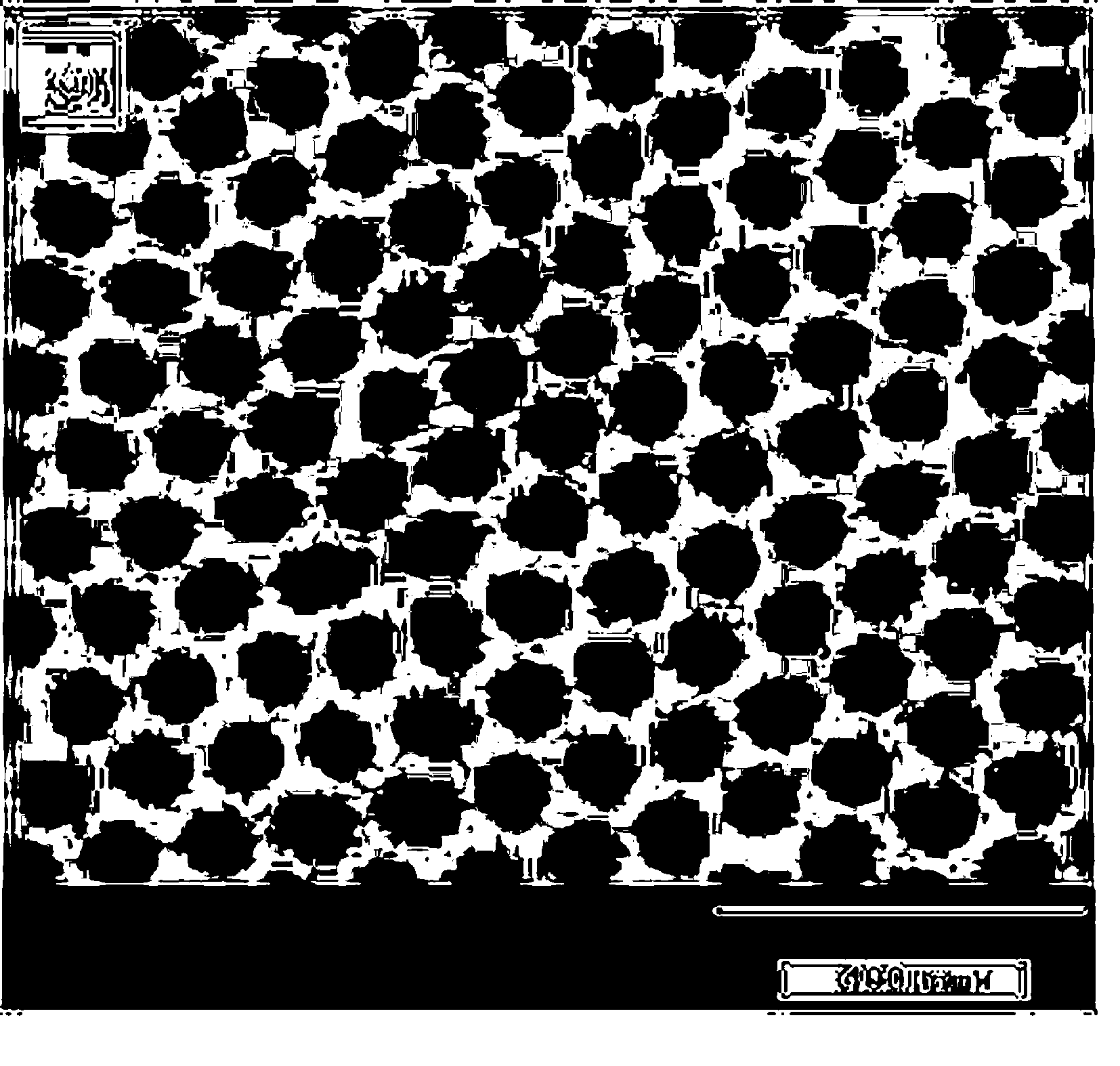

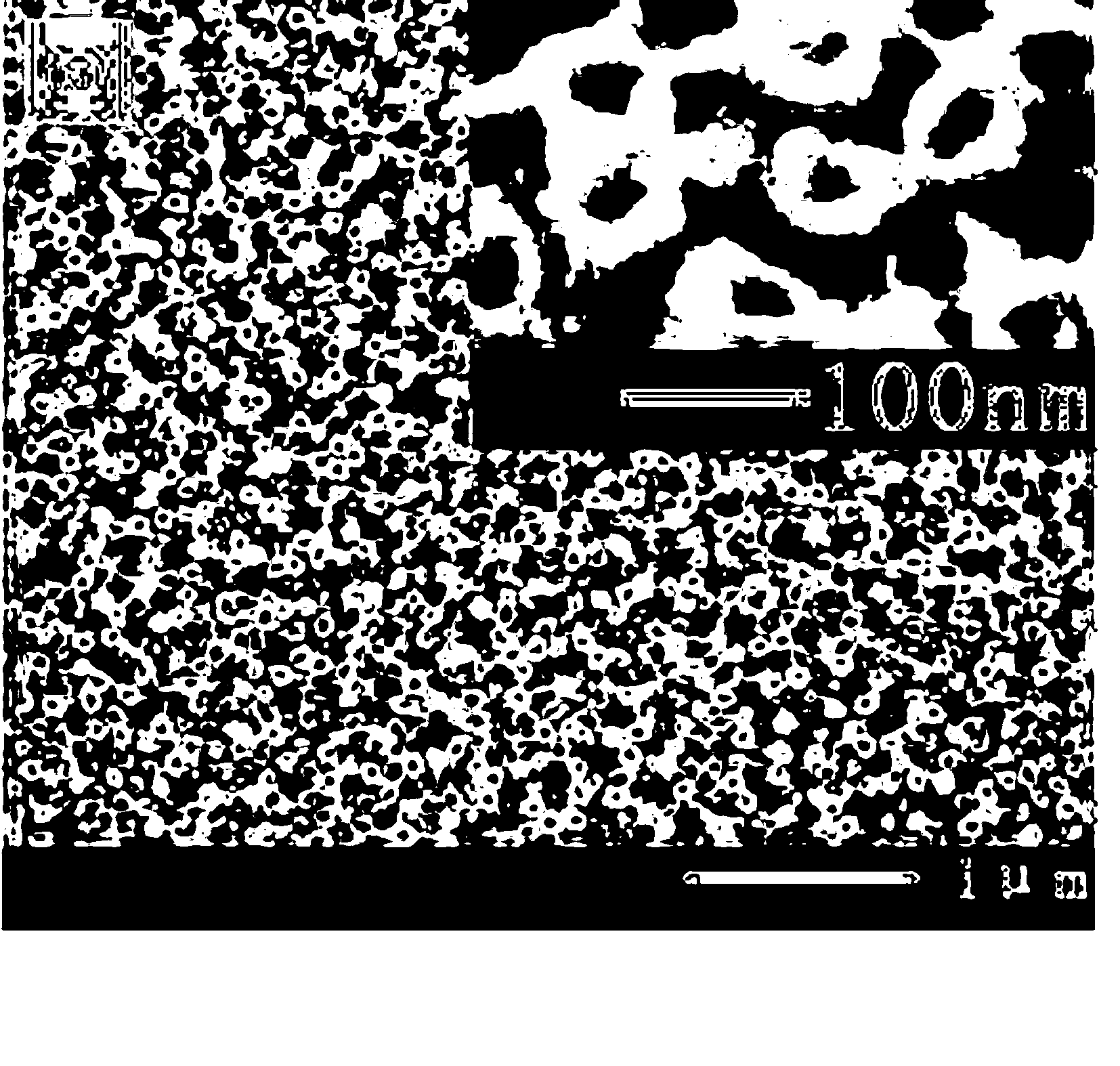

[0025] Such as figure 1 , 2 As shown, the nanopores on the obtained alumina template are regular hexagonal porous structures with a pore diameter of 65-75nm, and the density of nanopores on the alumina tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com