Tension-shear preload based in-situ indentation testing device and method

A technology of tensile shearing and testing equipment, which is applied in the direction of testing material strength by applying stable shear force, testing material strength by applying stable tension/pressure, testing material hardness, etc., and can solve problems such as the influence of material mechanical properties , to achieve the effects of simplified indentation module device, compact structure, precise mechanical test and in-situ observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

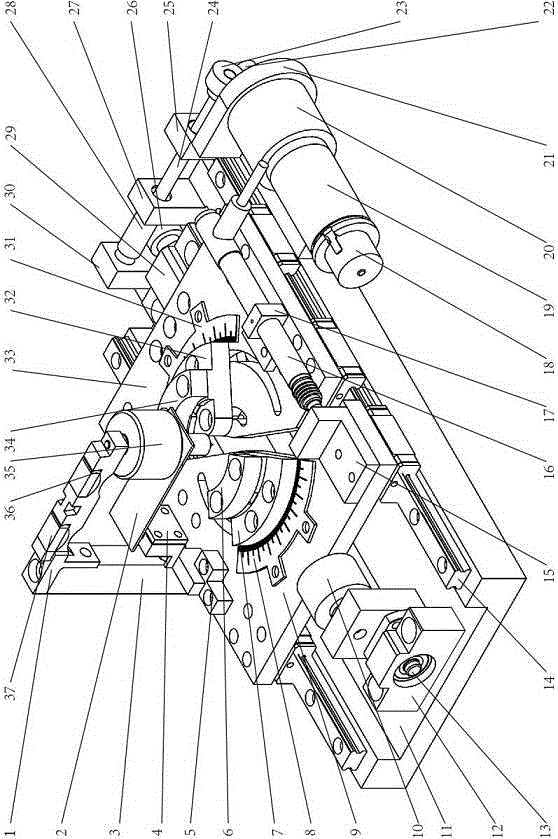

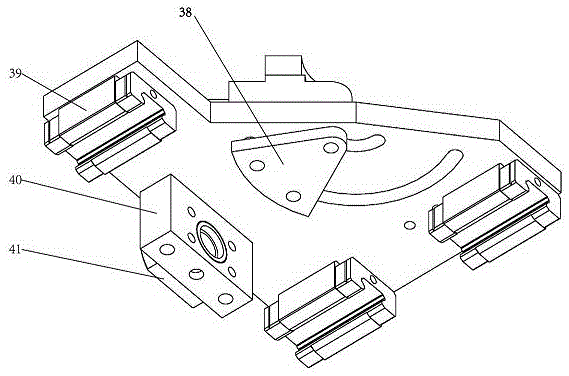

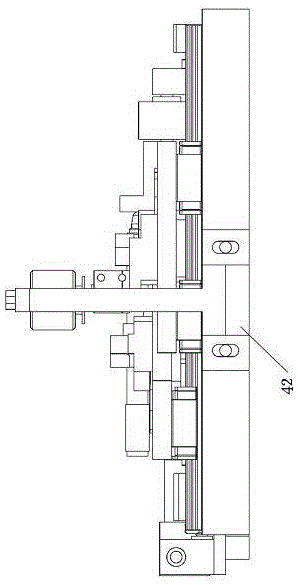

[0042] see Figure 1 to Figure 9 As shown, the tension-shear preload in-situ indentation test device of the present invention consists of four parts: a mechanical transmission module, an arbitrary-angle tension-shear composite loading module, a cantilever indentation module and a measurement module.

[0043] The mechanical transmission module includes a main frame 11, a primary worm gear 23 and a primary worm 22 provide a primary deceleration, a connecting rod 24, a secondary worm gear 26, and a secondary worm 28 provide a secondary deceleration, a secondary worm support frame a27, and a secondary worm The first-stage worm support frame b30, because the second-stage worm gear protrudes too long, the auxiliary support frame 25, the motor support frame 21 to increase its rigidity, the reducer 20 placed to obtain the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com